S

N

G

I

®

D

E

D

N

E

M

M

O

C

E

R

T

O

N

O

P

E

L

B

I

S

S

T

S

B

U

S

9

L

S

I

R

O

F

T

U

T

I

6

3

5

7

E

N

P

E

Data Sheet

W

R

S

E

D

T

C

U

D

O

July 13, 2006

EL7536

FN7396.8

Monolithic 1A Step-Down Regulator

The EL7536 is a synchronous, integrated FET 1A step-down

regulator with internal compensation. It operates with an

input voltage range from 2.5V to 5.5V , which accommodates

supplies of 3.3V, 5V, or a Li-Ion battery source. The output

can be externally set from 0.8V to V

with a resistive

IN

divider.

The EL7536 features PWM mode control. The operating

frequency is typically 1.4MHz. Additional features include a

100ms Power-On-Reset output, <1µA shut-down current,

short-circuit protection, and over-temperature protection.

The EL7536 is available in the 10 Ld MSOP package,

making the entire converter occupy less than 0.15in

2

of PCB

area with components on one side only. Both packages are

specified for operation over the full -40°C to +85°C

temperature range.

Ordering Information

PART NUMBER

(BRAND)

EL7536IY BDAAA - 10 Ld MSOP MDP0043

EL7536IY-T7 BDAAA 7” 10 Ld MSOP MDP0043

EL7536IY-T13 BDAAA 13” 10 Ld MSOP MDP0043

EL7536IYZ

(Note)

EL7536IYZ-T7

(Note)

EL7536IYZ-T13

(Note)

NOTE: Intersil Pb-free plus anneal products employ special Pb-free

material sets; molding compounds/die attach materials and 100%

matte tin plate termination finish, which are RoHS compliant and

compatible with both SnPb and Pb-free soldering operations. Intersil

Pb-free products are MSL classified at Pb-free peak reflow

temperatures that meet or exceed the Pb-free requirements of

IPC/JEDEC J STD-020.

PART

MARKING

BFAAA - 10 Ld MSOP

BFAAA 7” 10 Ld MSOP

BFAAA 13” 10 Ld MSOP

TAPE &

REEL PACKAGE

(Pb-free)

(Pb-free)

(Pb-free)

PKG.

DWG. #

MDP0043

MDP0043

MDP0043

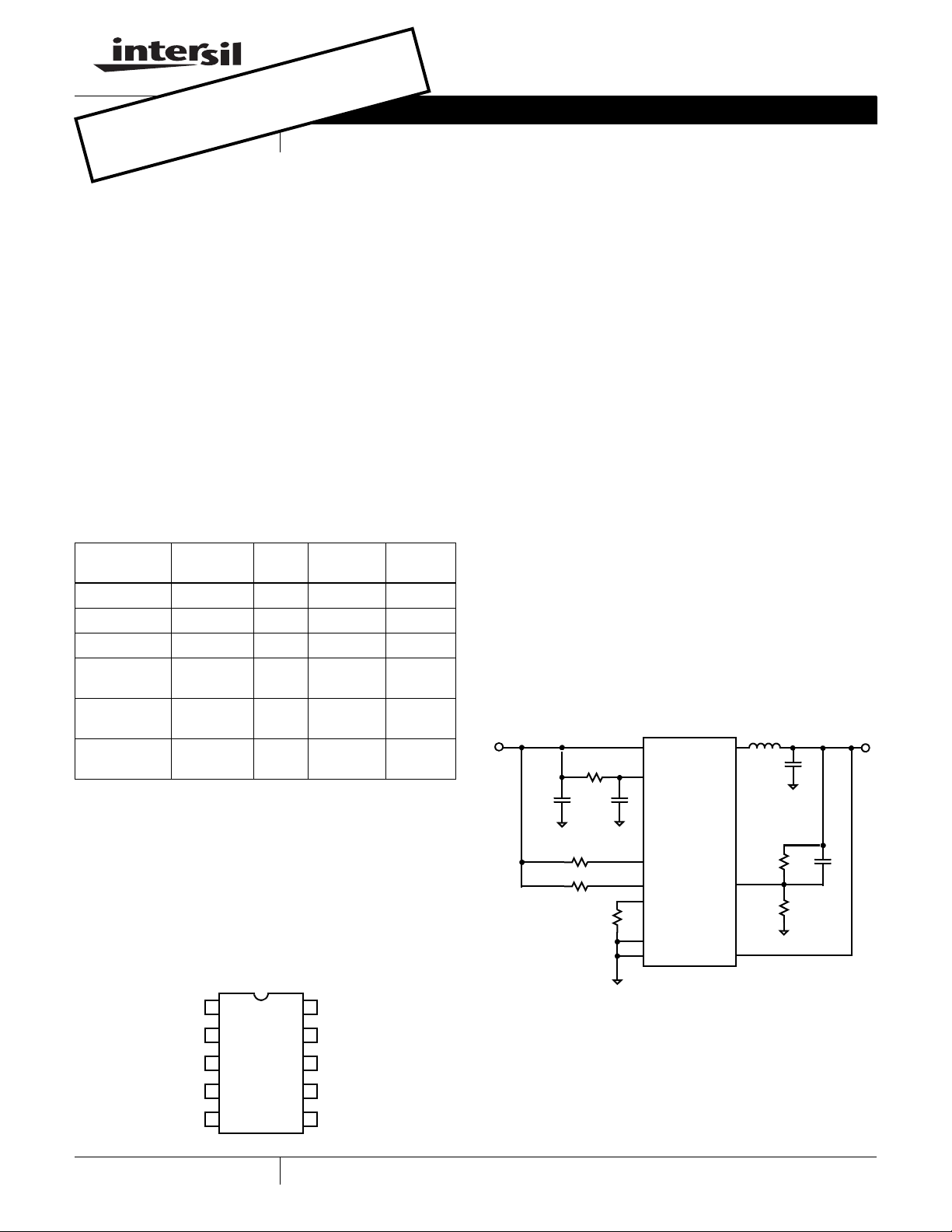

Pinout

EL7536 (10 LD MSOP)

TOP VIEW

Features

• Less than 0.15in2 (0.97cm2) footprint for the complete 1A

converter

• Components on one side of PCB

• Max height 1.1mm MSOP10

• 100ms Power-On-Reset output (POR)

• Internally-compensated voltage mode controller

• Up to 94% efficiency

• <1µA shut-down current

• Overcurrent and over-temperature protection

• Pb-free plus anneal available (RoHS compliant)

Applications

• PDA and pocket PC computers

• Bar code readers

• Cellular phones

• Portable test equipment

• Li-Ion battery powered devices

• Small form factor (SFP) modules

Typical Application Diagram

EL7536

TOP VIEW

V

S

C

10µF

(2.5V to 5.5V)

R3 100Ω

2

100kΩ

R

5

R4 100kΩ

100kΩ

C

0.1µF

R

L

VIN

VDD

3

EL7536

POR

EN

RSI

6

PGND

SGND

LX

FB

VO

1

1.8µH

10µF

R1*

124kΩ

R

100kΩ

C

1

*

2

(1.8V @ 1A)

C

470pF

4

V

O

SGND FB

1

PGND VO

2

LX POR

3

4

VIN EN

5 6

VDD RSI

1

10

9

8

7

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

All other trademarks mentioned are the property of their respective owners.

* V

= 0.8V * (1 + R1 / R2)

O

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright © Intersil Americas Inc. 2003-2006. All Rights Reserved.

EL7536

Absolute Maximum Ratings (T

V

, VDD, POR to SGND. . . . . . . . . . . . . . . . . . . . . . -0.3V to +6.5V

IN

LX to PGND. . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to (V

RSI, EN, V

, FB to SGND. . . . . . . . . . . . . . . -0.3V to (VIN + +0.3V)

O

= 25°C)

A

+ +0.3V)

IN

Operating Ambient Temperature . . . . . . . . . . . . . . . .-40°C to +85°C

Storage Temperature. . . . . . . . . . . . . . . . . . . . . . . .-65°C to +150°C

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+125°C

PGND to SGND. . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +0.3V

Peak Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2A

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

IMPORTANT NOTE: All parameters having Min/Max specifications are guaranteed. Typ values are for information purposes only . Unless otherwise noted, all tests are

at the specified temperature and are pulsed tests, therefore: T

Electrical Specifications V

DD

= V

IN

= TC = T

J

A

= VEN = 3.3V, C1 = C2 = 10µF, L = 1.8µH, VO = 1.8V, unless otherwise specified.

PARAMETER DESCRIPTION CONDITIONS MIN TYP MAX UNIT

DC CHARACTERISTICS

V

FB

I

FB

V

, V

IN

DD

V

IN,OFF

V

IN,ON

I

DD

R

DS(ON)-PMOS

R

DS(ON)-NMOS

I

LMAX

T

OT,OFF

T

OT,ON

I

, I

EN

RSI

V

, V

EN1

RSI1

V

, V

EN2

RSI2

V

POR

V

OLPOR

Feedback Input Voltage 790 800 810 mV

Feedback Input Current 250 nA

Input Voltage 2.5 5.5 V

Minimum Voltage for Shutdown VIN falling 2 2.2 V

Maximum Voltage for Startup VIN rising 2.2 2.4 V

Supply Current PWM, VIN = VDD = 5V 400 500 µA

EN = 0, V

= VDD = 5V 0.1 1 µA

IN

PMOS FET Resistance VDD = 5V, wafer test only 70 100 mΩ

NMOS FET Resistance VDD = 5V, wafer test only 45 75 mΩ

Current Limit 1.5 A

Over-temperature Threshold T rising 145 °C

Over-temperature Hysteresis T falling 130 °C

EN, RSI Current VEN, V

= 0V and 3.3V -1 1 V

RSI

EN, RSI Rising Threshold VDD = 3.3V 2.4 V

EN, RSI Falling Threshold VDD = 3.3V 0.8 V

Minimum VFB for POR, WRT Targeted

V

Value

FB

POR Voltage Drop I

rising 95 %

V

FB

falling 86 %

V

FB

= 5mA 35 70 mV

SINK

AC CHARACTERISTICS

F

t

RSI

t

SS

t

POR

PWM

PWM Switching Frequency 1.4 1.5 1.75 MHz

Minimum RSI Pulse Width Guaranteed by design 25 50 ns

Soft-start Time 650 µs

Power On Reset Delay Time 80 100 120 ms

2

FN7396.8

July 13, 2006

EL7536

Pin Descriptions

PIN NUMBER PIN NAME PIN FUNCTION

1 SGND Negative supply for the controller stage

2 PGND Negative supply for the power stage

3 LX Inductor drive pin; high current digital output with average voltage equal to the regulator output voltage

4 VIN Positive supply for the power stage

5 VDD Power supply for the controller stage

6 RSI Resets POR timer

7 EN Enable

8 POR Power on reset open drain output

9 VO Output voltage sense

10 FB Voltage feedback input; connected to an external resistor divider between V

output

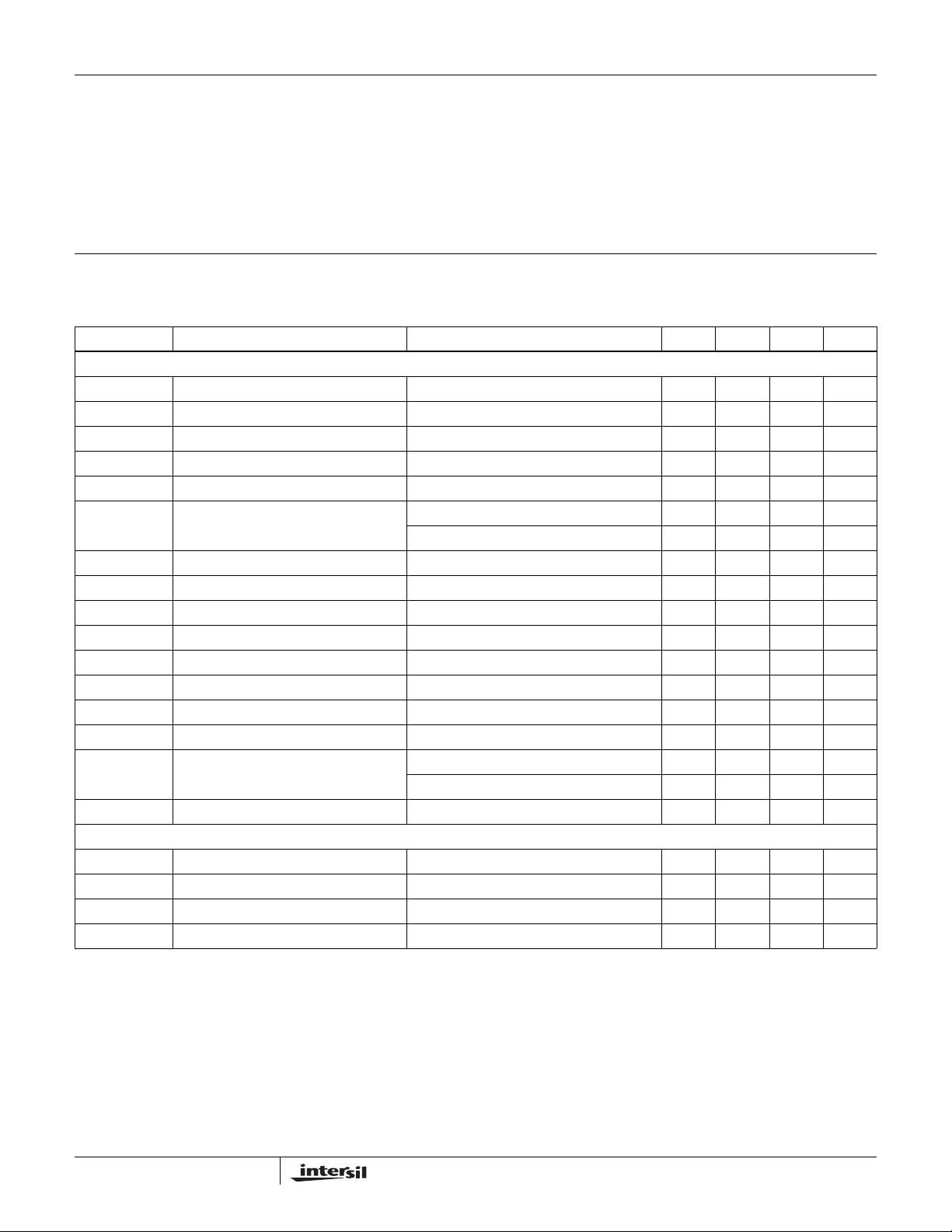

Block Diagram

and SGND for variable

O

EN

2.5V-

3.5V

10µF

+

–

124K

100K

V

DD

V

O

FB

EN

BANDGAP

REFERENCE

SGND

RSI

5M

CLOCK

1.4MHz

SOFT-

START

10pF

-

+

PWM

COMPEN-

SATION

RAMP

GENERATOR

UNDERVOLTAGE

LOCKOUT

POR

+

-

PWM

COMPARATOR

TEMPERATURE

SENSE

CONTROL

LOGIC

+

-

CURRENT

LIMIT

P-DRIVER

N-DRIVER

V

LX

PGND

POR

IN

1.8µ

1.8V

1A

10µF

100K

PG

3

FN7396.8

July 13, 2006

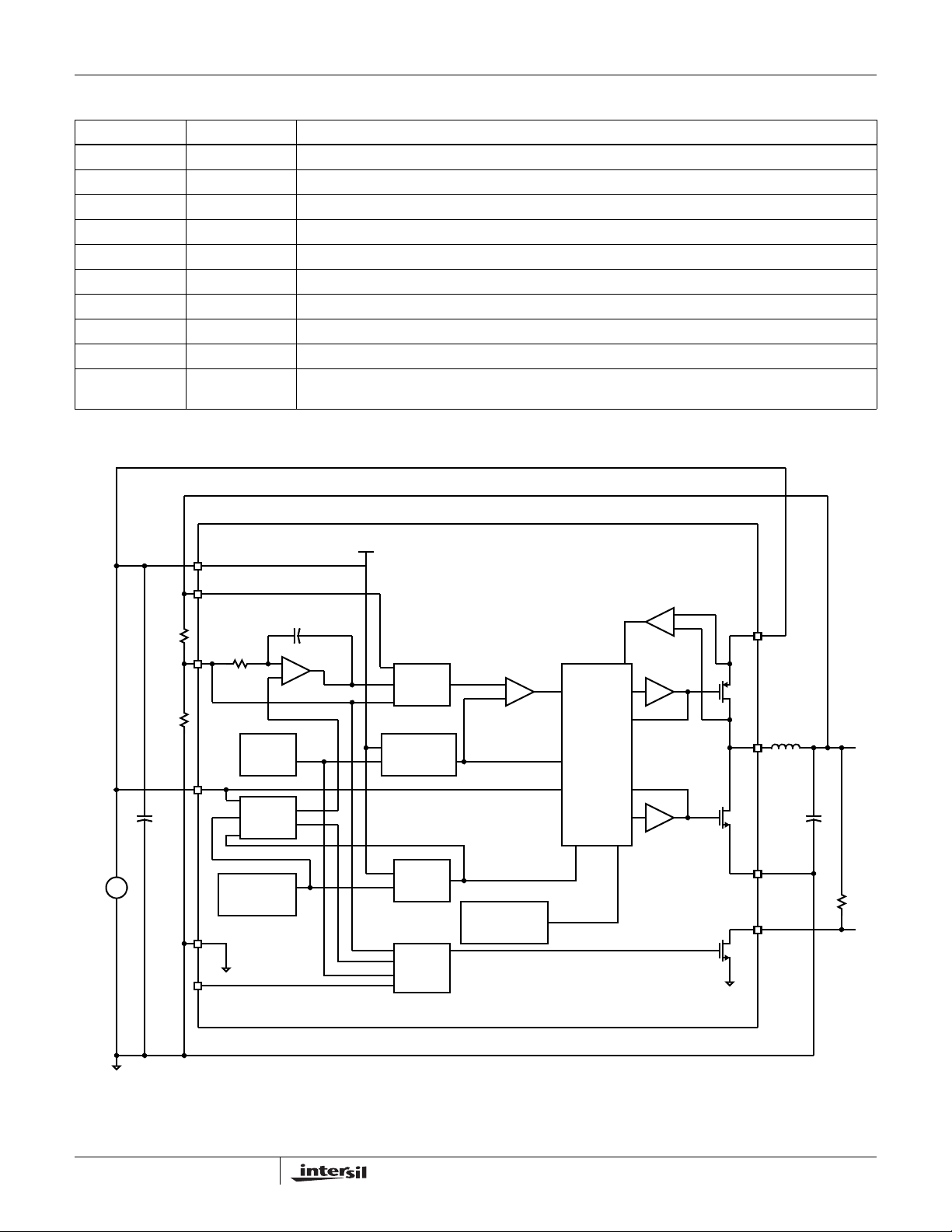

Performance Curves and Waveforms

All waveforms are taken at V

noted.

= 3.3V , VO = 1.8V , IO = 1A with component values shown on page 1 at room ambient temperature, unless otherwise

IN

EL7536

VIN=5V

100

VO=3.3V

95

90

85

80

75

EFFICIENCY (%)

70

65

60

VO=1.2V

0 200 400 600 800 1000

(mA)

I

O

FIGURE 1. EFFICIENCY FIGURE 2. EFFICIENCY

1.44

VIN=5V IO=1A

1.42

1.4

(MHz)

1.38

S

F

1.36

VIN=3.3V IO=0A

VIN=3.3V IO=1A

VIN=5V IO=0A

VIN=3.3V

100

95

90

85

VO=2.5VVO=1.8V

EFFICIENCY (%)

0.1%

0.0%

-0.1%

-0.2%

CHANGES

O

V

-0.3%

80

75

70

65

60

VO=1V

0 200 400 600 800 1000

VO=1.8V

(mA)

I

O

VIN=5V

VO=2.5V

VO=1.2V

VIN=3.3V

1.34

1.32

-50 0 50 100 150

T

(°C)

A

FIGURE 3. F

0.1%

0.0%

-0.1%

-0.2%

-0.3%

CHANGES

-0.4%

O

V

-0.5%

-0.6%

-0.7%

-50 0 50 100 150

vs JUNCTION TEMPERATURE

S

VIN=3.3V IO=0A

VIN=3.3V IO=1A

VIN=5V IO=1A

T

(°C)

J

VIN=5V IO=0A

FIGURE 5. LOAD/LINE REGULATIONS vs JUNCTION

TEMPERATURE

-0.4%

-0.5%

0 0.2 0.4 0.6 0.8 1

(A)

I

O

FIGURE 4. LOAD REGULATIONS

12

10

8

6

(mA)

IN

I

4

2

0

2.5 3

3.5

44.55

V

(V)

IN

FIGURE 6. NO LOAD INPUT CURRENT

4

FN7396.8

July 13, 2006

EL7536

Performance Curves and Waveforms (Continued)

All waveforms are taken at V

noted.

= 3.3V , VO = 1.8V , IO = 1A with component values shown on page 1 at room ambient temperature, unless otherwise

IN

0.5ms/d

FIGURE 7. START-UP 1

V

IN

(1V/d)

I

IN

(0.5A/d)

V

O

(1V/d)

V

IN

(2V/d)

V

O

(2V/d)

RSI

(2V/d)

POR

(2V/d)

V

IN

(2V/d)

V

O

(2V/d)

POR

(2V/d)

50ms/d

FIGURE 8. START-UP 2

0.75A

I

O

ΔV

O

0.25A

20mV/d

50ms/d

0.2ms/d

FIGURE 9. POR FUNCTION FIGURE 10. TRANSIENT RESPONSE

ΔV

ΔV

IN

i

L

V

LX

O

1µs/d

100mV/d

0.5A/d

2V/d

10mV/d

FIGURE 11. STEADY-STATE

5

FN7396.8

July 13, 2006

EL7536

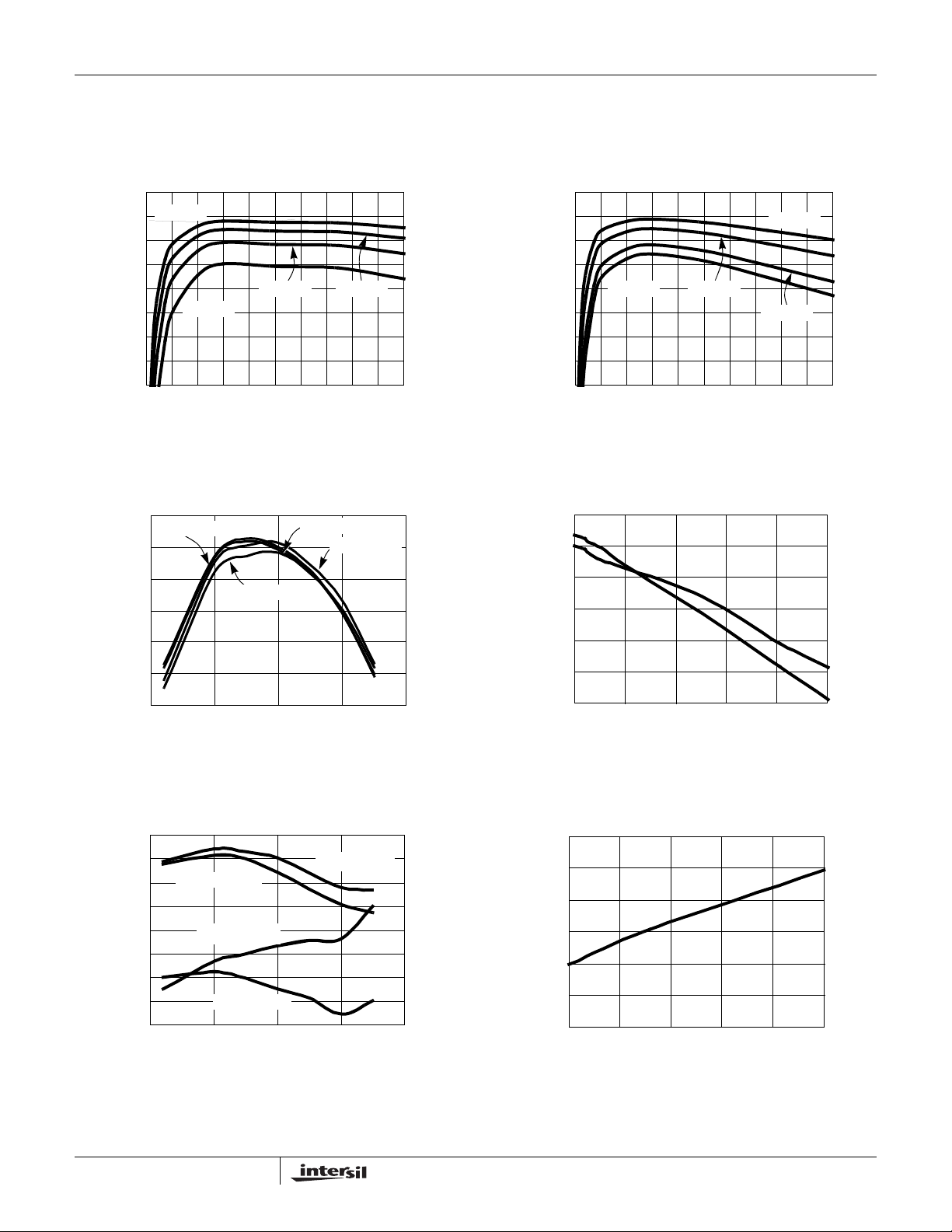

Performance Curves and Waveforms (Continued)

All waveforms are taken at V

noted.

= 3.3V , VO = 1.8V , IO = 1A with component values shown on page 1 at room ambient temperature, unless otherwise

IN

JEDEC JESD51-3 LOW EFFECTIVE THERMAL

CONDUCTIVITY TEST BOARD

0.6

0.5

0.4

0.3

0.2

0.1

0

ALLOWABLE POWER DISSIPATION (W)

0 255075100 150

M

θ

S

J

O

A

P

=

1

2

0

0

6

°

C

/

W

85

AMBIENT TEMPERATURE (°C)

125

FIGURE 12. PACKAGE POWER DISSIPA TION vs AMBIENT

TEMPERATURE

JEDEC JESD51-7 HIGH EFFECTIVE THERMAL

CONDUCTIVITY TEST BOARD

1.00

0.90

0.80

0.70

0.60

0.50

0.40

0.30

0.20

0.10

0

ALLOWABLE POWER DISSIPATION (W)

0 255075100 150

M

θ

S

J

O

A

P

=

1

1

1

0

5

°

C

/

W

85

AMBIENT TEMPERATURE (°C)

125

FIGURE 13. PACKAGE POWER DISSIPA TION vs AMBIENT

TEMPERATURE

6

FN7396.8

July 13, 2006

V

EL7536

Applications Information

Product Description

The EL7536 is a synchronous, integrated FET 1A step-down

regulator which operates from an input of 2.5V to 6V. The

output voltage is user-adjustable with a pair of external

resistors.

The internally-compensated controller makes it possible to

use only two ceramic capacitors and one inductor to form a

complete, very small footprint 1A DC:DC converter.

Start-Up and Shut-Down

When the EN pin is tied to VIN, and VIN reaches

approximately 2.4V, the regulator begins to switch. The

output voltage is gradually increased to ensure proper softstart operation.

When the EN pin is connected to a logic low, the EL7536 is

in the shut-down mode. All the control circuitry and both

MOSFETs are off, and V

total input current is less than 1µA.

When the EN reaches logic HI, the regulator repeats the

start-up procedure, including the soft-start function.

PWM Operation

In the PWM mode, the P channel MOSFET and N channel

MOSFET always operate complementary. When the

PMOSFET is on and the NMOSFET off, the inductor current

increases linearly. The input energy is transferred to the

output and also stored in the inductor. When the P channel

MOSFET is off and the N channel MOSFET on, the inductor

current decreases linearly, and energy is transferred from

the inductor to the output. Hence, the average current

through the inductor is the output current. Since the inductor

and the output capacitor act as a low pass filter, the duty

cycle ratio is approximately equal to V

The output LC filter has a second order effect. To maintain

the stability of the converter, the overall controller must be

compensated. This is done with the fixed internally

compensated error amplifier and the PWM compensator.

Because the compensations are fixed, the value s of input

and output capacitors are 10µF to 22µF ceramic. The

inductor is nominally 1.8µH, but 1.5µA to 2.2µH can be used.

100% Duty Ratio Operation

EL7536 utilizes CMOS power FET's as the internal

synchronous power switches. The upper switch is a PMOS

and lower switch a NMOS. This not only saves a boot

capacitor, it also allows 100% turn-on of the upper PFET

switch, achieving V

V

is,

O

OVINRLRDSON1

close to VIN. The maximum achievable

O

+()IO×–=

falls to zero. In this mode, the

OUT

divided by VIN.

O

Where RL is the DC resistance on the inductor and R

DSON1

the PFET on-resistance, nominal 70mΩ at room temperature

with tempco of 0.2mΩ/°C.

As the input voltage drops gradually close or even below the

preset V

, the converter gets into 100% duty ratio. At this

O

condition, the upper PFET needs some minimum turn-off

time if it is turned off. This off-time is related to input/output

conditions. This makes the duty ratio appears randomly and

increases the output ripple somewhat until the 100% duty

ratio is reached. Larger output capacitor could reduce the

random-looking ripple. Users need to verify if this condition

has adverse effect on overall circuit if close to 100% duty

ratio is expected.

RSI/POR Function

When powering up, the open-collector Power-On-Reset

output holds low for about 100ms after V

reaches the

O

preset voltage. When the active-HI reset signal RSI is

issued, POR goes to low immediately and holds for the

same period of time after RSI comes back to LOW. The

output voltage is unaffected. (Please refer to the timing

diagram). When the function is not used, connect RSI to

ground and leave open the pull-up resister R

at POR pin.

4

The POR output also serves as a 100ms delayed Power

Good signal when the pull-up resister R

is installed. The

4

RSI pin needs to be directly (or indirectly through a resister

R

) connected to Ground for this to function properly.

6

V

O

RSI

100ms

POR

FIGURE 14. RSI & POR TIMING DIAGRAM

MIN

25ns

100ms

Output Voltage Selection

Users can set the output voltage of the converter with a

resister divider, which can be chosen based on the following

formula:

R

⎛⎞

2

0.8 1

V

O

-------

+

×=

⎜⎟

R

⎝⎠

1

Component Selection

Because of the fixed internal compensation, the component

choice is relatively narrow. We recommend 10µF to 22µF

multi-layer ceramic capacitors with X5R or X7R rating for

both the input and output capacitors, and 1.5µH to 2.2µH

inductance for the inductor.

7

FN7396.8

July 13, 2006

At extreme conditions (VIN < 3V, IO > 0.7A, and junction

temperature higher than 75°C), input cap C

is

1

recommended to be 22µF. Otherwise, if any of the above 3

conditions is not true, C

can remain as low as 10µF.

1

The RMS current present at the input capacitor is decided by

the following formula:

This is about half of the output current IO for all the VO. This

input capacitor must be able to handle this current.

The inductor peak-to-peak ripple current is given as:

• L is the inductance

•f

the switching frequency (nominally 1.4MHz)

S

The inductor must be able to handle I

for the RMS load

O

current, and to assure that the inductor is reliable, it must

handle the 1.5A surge current that can occur during a

current limit condition.

In addition to decoupling capacitors and inductor value, it is

important to properly size the phase-lead capacitor C

4

(Refer to the Typical Application Diagram). The phase-lead

capacitor creates additional phase margin in the control loop

by generating a zero and a pole in the transfer function. As a

general rule of thumb, C

should be sized to start the phase-

4

lead at a frequency of ~2.5kHz. The zero will always appear

at lower frequency than the pole and follow the equation

below:

Over a normal range of R

(~10-100k), C4 will range from

2

~470-4700pF. The pole frequency cannot be set once the

zero frequency is chosen as it is dictated by the ratio of R

and R

, which is solely determined by the desired output set

2

point. The equation below shows the pole frequency

relationship:

Current Limit and Short-Circuit Protection

8

1

FN7396.8

July 13, 2006

Mini SO Package Family (MSOP)

M

C

SEATING

PLANE

0.10 C

N LEADS

0.25 C A B

E1E

B

L1

D

N

1

e

b

A

(N/2)+1

PIN #1

I.D.

(N/2)

H

M

0.08 C A B

A

EL7536

MDP0043

MINI SO PACKAGE FAMILY

SYMBOL MSOP8 MSOP10 TOLERANCE NOTES

A1.101.10 Max. A1 0.10 0.10 ±0.05 A2 0.86 0.86 ±0.09 -

b 0.33 0.23 +0.07/-0.08 -

c0.180.18 ±0.05 D 3.00 3.00 ±0.10 1, 3

E4.904.90 ±0.15 -

E1 3.00 3.00 ±0.10 2, 3

e0.650.50 Basic -

L0.550.55 ±0.15 -

L1 0.95 0.95 Basic -

N 8 10 Reference -

Rev. C 6/99

NOTES:

1. Plastic or metal protrusions of 0.15mm maximum per side are not

included.

2. Plastic interlead protrusions of 0.25mm maximum per side are

not included.

3. Dimensions “D” and “E1” are measured at Datum Plane “H”.

4. Dimensioning and tolerancing per ASME Y14.5M-1994.

c

SEE DETAIL "X"

A2

GAUGE

A1

L

DETAIL X

PLANE

3° ±3°

0.25

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implicat ion or oth erwise u nde r any p a tent or p at ent r ights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

9

FN7396.8

July 13, 2006

Loading...

Loading...