®

EL5225

Data Sheet March 11, 2004

10-Channel TFT-LCD Reference Voltage

Generator

The EL5225 is designed to produce the reference voltages

required in TFT-LCD applications. Each output is

programmed to the required voltage with 10 bits of

resolution. Reference pins determine the high and low

voltages of the output range, which are capable of swinging

to either supply rail. Programming of each output is

performed using the 3-wire, SPI compatible interface.

A number of the EL5225 can be stacked for applications

requiring more than 10 outputs. The reference inputs can be

tied to the rails, enabling each part to output the full voltage

range, or alternatively, they can be connected to external

resistors to split the output range and enable finer

resolutions of the outputs.

The EL5225 has 10 outputs, and is available in the 24-pin

TSSOP package. They are specified for operation over the

full -40°C to +85°C temperature range.

Ordering Information

PART

NUMBER

(See Note)

EL5225IRZ 24-Pin TSSOP - MDP0044

EL5225IRZ-T7 24-Pin TSSOP 7” MDP0044

EL5225IRZ-T13 24-Pin TSSOP 13” MDP0044

NOTE: Intersil Pb-free products employ special Pb-free material

sets; molding compounds/die attach materials and 100% matte tin

plate termination finish, which are RoHS compliant and compatible

with both SnPb and Pb-free soldering operations. Intersil Pb-free

products are MSL classified at Pb-free peak reflow temperatures that

meet or exceed the Pb-free requirements of IPC/JEDEC J STD-020C.

PACKAGE

(Pb-Free)

TAPE &

REEL PKG. DWG. #

Features

• 10-channel reference outputs

• Accuracy of ±1%

• Supply voltage of 5V to 16.5V

• Digital supply 3.3V to 5V

• Low supply current of 9mA

• Rail-to-rail capability

• Pb-free available (RoHS compliant)

Applications

• TFT-LCD drive circuits

• Reference voltage generators

Pinout

EL5225

(24-PIN TSSOP)

TOP VIEW

1

ENA OUTA

2

SDI

3

SCLK

4

SDO

VS+

VSD

REFH

REFL

5

6

7

8

9

EXT_OSC

24

23

22

21

20

19

18

17

16

FN7356.0

OUTB

OUTC

GND

OUTD

OUTE

OUTF

OUTG

GND

10

VS+

11

GND

12

CAP

1

Copyright © Intersil Americas Inc. 2002-2004. All Rights Reserved. Elantec is a registered trademark of Elantec Semiconductor, Inc.

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

15

14

13

OUTH

OUTI

OUTJ

EL5225

Absolute Maximum Ratings (T

Supply Voltage between V

Supply Voltage between V

Maximum Continuous Output Current . . . . . . . . . . . . . . . . . . . 30mA

& GND. . . . . . . . 4.5V (min) to 18V (max)

S

& GND . . 3V (min) to VS and 7V (max)

SD

= 25°C)

A

Maximum Die Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . +125°C

Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . .-65°C to +150°C

Ambient Operating Temperature . . . . . . . . . . . . . . . . -40°C to +85°C

Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Curves

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

IMPORTANT NOTE: All parameters having Min/Max specifications are guaranteed. Typ values are for information purposes only. Unless otherwise noted, all tests are

at the specified temperature and are pulsed tests, therefore: T

Electrical Specifications V

= 15V, V

S

otherwise specified.

SD

= TC = T

J

= 5V, V

REFH

A

= 13V, V

= 2V, RL = 1.5kΩ and CL = 200pF to 0V, TA = 25°C, unless

REFL

PARAMETER DESCRIPTION CONDITIONS MIN TYP MAX UNIT

SUPPLY

I

S

I

SD

Supply Current No load 9 11.5 mA

Digital Supply Current 0.17 0.35 mA

ANALOG

V

OL

V

OH

I

SC

PSRR Power Supply Rejection Ratio V

t

D

V

AC

∆V

MIS

V

DROOP

R

INH

REG Load Regulation I

Output Swing Low Sinking 5mA (V

Output Swing High Sourcing 5mA (V

REFH

REFH

= 15V, V

= 15V, V

= 0) 50 150 mV

REFL

= 0) 14.85 14.95 V

REFL

Short Circuit Current RL = 10Ω 100 140 mA

+ is moved from 14V to 16V 45 65 dB

S

Program to Out Delay 4ms

Accuracy referred to the ideal value Code = 512 20 mV

Channel to Channel Mismatch Code = 512 2 mV

Droop Voltage 12mV/ms

Input Resistance @ V

REFH

, V

REFL

32 kΩ

= 5mA step 0.5 1.5 mV/mA

OUT

CAP Band Gap Bypass with 0.1µF 1 1.3 1.6 V

DIGITAL

V

IH

F

CLK

V

IL

t

S

t

H

t

LC

t

CE

t

DCO

R

SDIN

T

PULSE

Logic 1 Input Voltage VSD = 5V 4 V

= 3.3V 2 V

V

SD

Clock Frequency 5MHz

Logic 0 Input Voltage VSD = 3.3V/5V 1 V

Setup Time 20 ns

Hold Time 20 ns

Load to Clock Time 20 ns

Clock to Load Line 20 ns

Clock to Out Delay Time Negative edge of SCLK 10 ns

S

Input Resistance 1GΩ

DIN

Minimum Pulse Width for EXT_OSC

5µs

Signal

Duty Cycle Duty Cycle for EXT_OSC Signal 50 %

INL Integral Nonlinearity Error 1.3 LSB

DNL Differential Nonlinearity Error 0.5 LSB

F_OSC Internal Refresh Oscillator Frequency OSC_Select = 0 21 kHz

2

FN7356.0

March 11, 2004

EL5225

Pin Descriptions

PIN NUMBER PIN NAME PIN TYPE PIN FUNCTION

1ENA

2 SDI Logic Input Serial data input

3 SCLK Logic Input Serial data clock

4 SDO Logic Output Serial data output

5 EXT_OSC Logic Input/Output External oscillator input or internal oscillator output

6, 10 VS+ Analog Power Positive supply voltage for analog circuits

NC Not connected

7 VSD Digital Power Positive power supply for digital circuits (3.3V - 5V)

8 REFH Analog Reference Input High reference voltage

9 REFL Analog Reference Input Low reference voltage

11 GND Ground Ground

12 CAP Analog Bypass Pin Decoupling capacitor for internal reference generator, 0.1µF

13 OUTJ Analog Output Channel J programmable output voltage

14 OUTI Analog Output Channel I programmable output voltage

Logic Input Chip select, low enables data input to logic

15 OUTH Analog Output Channel H programmable output voltage

17 OUTG Analog Output Channel G programmable output voltage

18 OUTF Analog Output Channel F programmable output voltage

19 OUTE Analog Output Channel E programmable output voltage

20 OUTD Analog Output Channel D programmable output voltage

22 OUTC Analog Output Channel C programmable output voltage

23 OUTB Analog Output Channel B programmable output voltage

24 OUTA Analog Output Channel A programmable output voltage

OUTL Analog Output Channel L programmable output voltage

OUTK Analog Output Channel K programmable output voltage

16, 21 GND Power Ground

3

FN7356.0

March 11, 2004

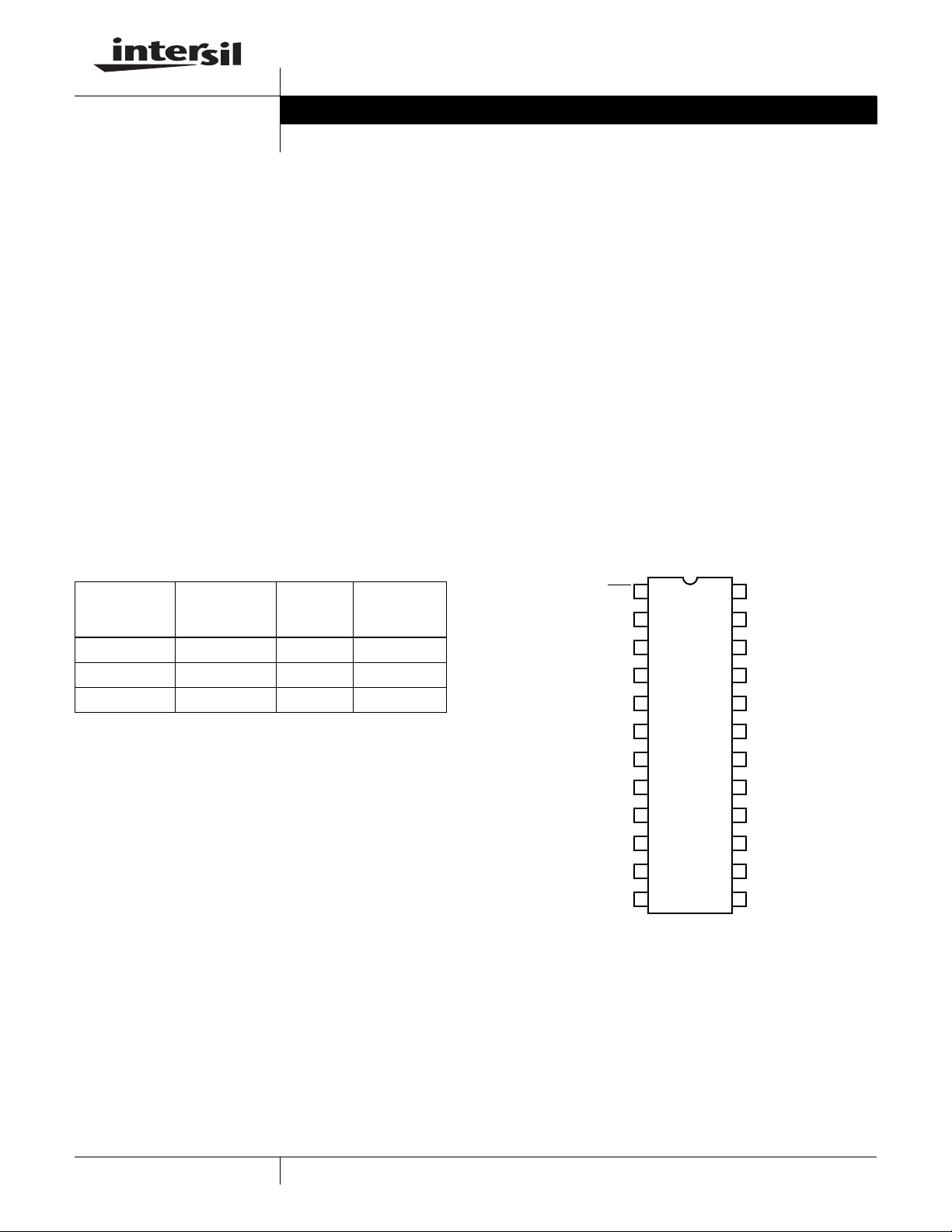

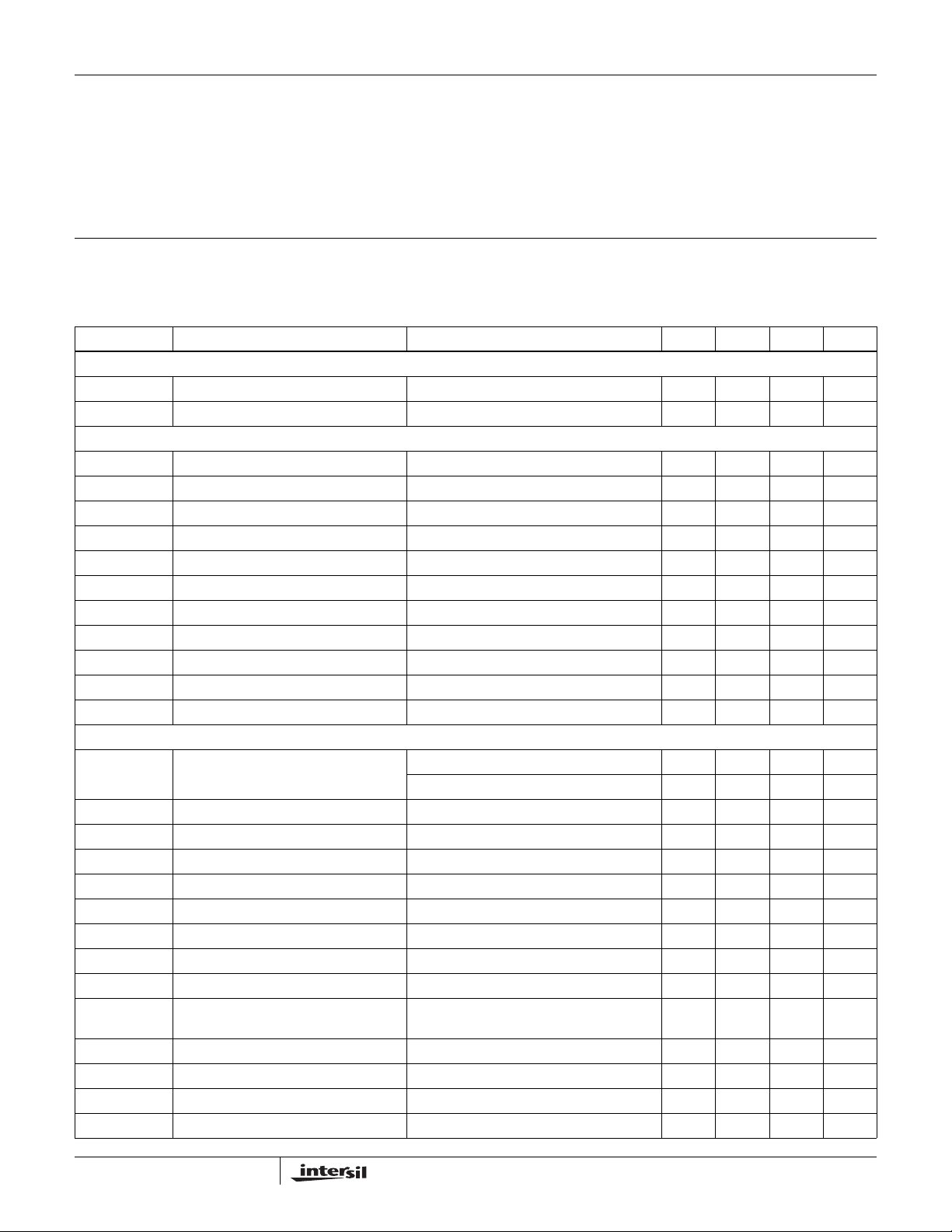

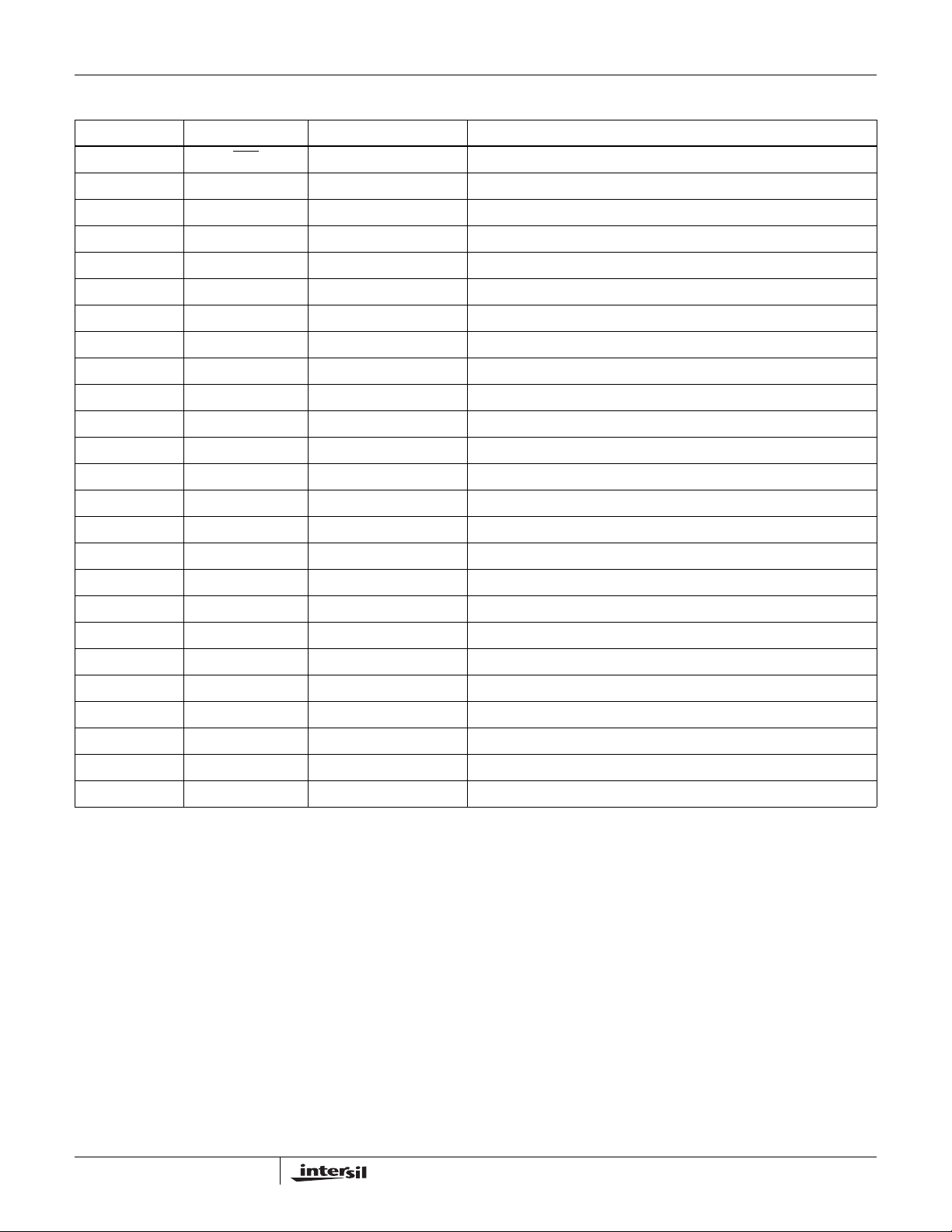

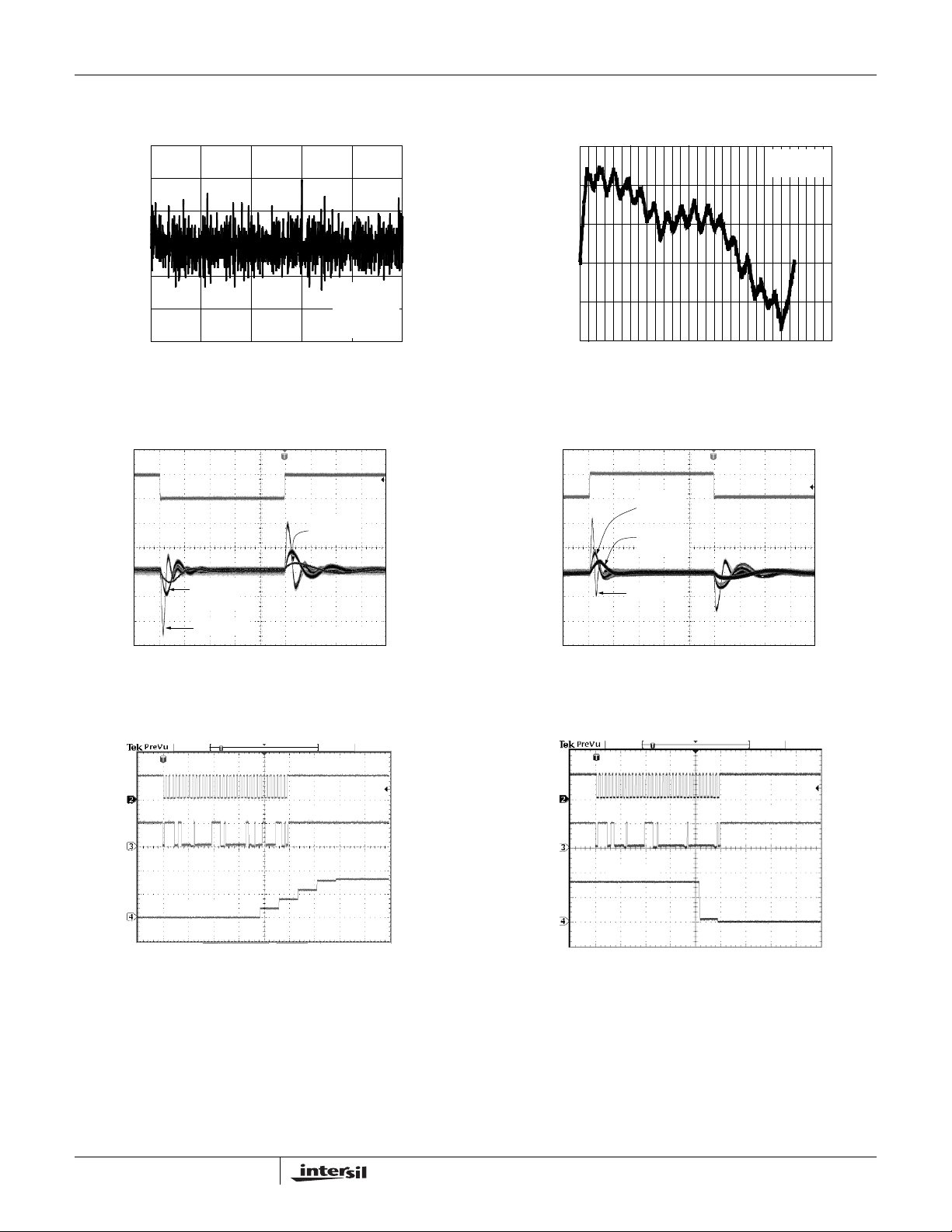

Typical Performance Curves

EL5225

0.3

0.2

0.1

0

-0.1

-0.2

DIFFERENTIAL NONLINEARITY (LSB)

-0.3

10 210 410 610 810 1010

INPUT CODE

VS=15V

=5V

V

SD

V

REFH

V

REFL

=13V

=2V

1.5

1

0.5

0

INL (LSB)

-0.5

-1

0 200 400 600 800 1200

CODE

REFH=13V

REF

=2V

L

1000

FIGURE 1. DIFFERENTIAL NONLINEARITY vs CODE FIGURE 2. INTEGRAL NONLINEARITY ERROR

0mA

5mA

5V

CL=1nF

=20Ω

R

S

CL=4.7nF

=20Ω

R

S

5mA/DIV

200mV/DIV

5mA

0mA

CL=1nF

R

=20Ω

S

CL=4.7nF

R

=20Ω

S

CL=180pF

200mV/DIV

CL=180pF

M=400ns/DIV

VS=V

REFH

=15V

M=400ns/DIV

VS=V

REFH

=15V

FIGURE 3. TRANSIENT LOAD REGULATION (SOURCING) FIGURE 4. TRANSIENT LOAD REGULATION (SINKING)

5V

0V

5V

0V

10V

5V

0V

OUTPUT

M=400µs/DIV

SCLK

SDA

FIGURE 5. LARGE SIGNAL RESPONSE (RISING FROM 0V

TO 8V)

5V

0V

5V

0V

10V

5V

0V

OUTPUT

M=400µs/DIV

FIGURE 6. LARGE SIGNAL RESPONSE (FALLING FROM 8V

TO 0V)

SCLK

SDA

4

FN7356.0

March 11, 2004

Typical Performance Curves (Continued)

EL5225

5V

0V

5V

0V

200mV

OUTPUT

0V

M=400µs/DIV

SCLK

SDA

FIGURE 7. SMALL SIGNAL RESPONSE (RISING FROM 0V

TO 200mV)

JEDEC JESD51-7 HIGH EFFECTIVE THERMAL

CONDUCTIVITY TEST BOARD

1.4

1.176W

1.2

1

0.8

0.6

0.4

POWER DISSIPATION (W)

0.2

0

0 25 50 75 100 125

AMBIENT TEMPERATURE (°C)

T

S

S

θ

O

J

A

P

=

2

8

4

5

°

C

/

W

85

5V

0V

5V

0V

200mV

0V

OUTPUT

M=400µs/DIV

SCLK

SDA

FIGURE 8. SMALL SIGNAL RESPONSE (FALLING FROM

200mV TO 0V)

JEDEC JESD51-3 LOW EFFECTIVE THERMAL

CONDUCTIVITY TEST BOARD

0.9

781mW

0.8

0.7

0.6

0.5

0.4

0.3

0.2

POWER DISSIPATION (W)

0.1

0

0 25 50 75 100 125

T

S

θ

S

J

O

A

P

=

1

2

2

4

8

°

C

/

W

85

AMBIENT TEMPERATURE (°C)

FIGURE 9. POWER DISSIPATION vs AMBIENT

TEMPERATURE

General Description

The EL5225 provides a versatile method of providing the

reference voltages that are used in setting the transfer

characteristics of LCD display panels. The V/T

(Voltage/Transmission) curve of the LCD panel requires that

a correction is applied to make it linear; however, if the panel

is to be used in more than one application, the final curve

may differ for different applications. By using the EL5225,

the V/T curve can be changed to optimize its characteristics

according to the required application of the display product.

Each of the eight reference voltage outputs can be set with a

10-bit resolution. These outputs can be driven to within

50mV of the power rails of the EL5225. As all of the output

buffers are identical, it is also possible to use the EL5225 for

applications other than LCDs where multiple voltage

references are required that can be set to 10 bit accuracy.

5

FIGURE 10. POWER DISSIPATION vs AMBIENT

TEMPERATURE

Digital Interface

The EL5225 uses a simple 3-wire SPI compliant digital

interface to program the outputs. The EL5225 can support

the clock rate up to 5MHz.

Serial Interface

The EL5225 is programmed through a three-wire serial

interface. The start and stop conditions are defined by the

ENA

signal. While the ENA is low, the data on the SDI (serial

data input) pin is shifted into the 16-bit shift register on the

positive edge of the SCLK (serial clock) signal. The MSB (bit

15) is loaded first and the LSB (bit 0) is loaded last (see

Table 1). After the full 16-bit data has been loaded, the ENA

is pulled high and the addressed output channel is updated.

The SCLK is disabled internally when the ENA

SCLK must be low before the ENA

is pulled low.

is high. The

FN7356.0

March 11, 2004

EL5225

To facilitate the system designs that use multiple EL5225

chips, a buffered serial output of the shift register (SDO pin)

is available. Data appears on the SDO pin at the 16th falling

SCLK edge after being applied to the SDI pin.

To control the multiple EL5225 chips from a single three-wire

serial port, just connect the ENA

pins and the SCLK pins

together, connect the SDO pin to the SDI pin on the next

chip. While the ENA

is held low, the 16m-bit data is loaded to

the SDI input of the first chip. The first 16-bit data will go to

the last chip and the last 16-bit data will go to the first chip.

While the ENA

is held high, all addressed outputs will be

updated simultaneously.

The Serial Timing Diagram and parameters table show the

timing requirements for three-wire signals.

The serial data has a minimum length of 16 bits, the MSB

(most significant bit) is the first bit in the signal. The bits are

allocated to the following functions (also refer to the Control

Bits Logic Table)

• Bit 15 is always set to a zero

• Bit 14 controls the source of the clock, see the next

section for details

• Bits 13 through 10 select the channel to be written to,

these are binary coded with channel A = 0, and channel

H= 7

• The 10-bit data is on bits 9 through 0. Some examples of

data words are shown in the table of Serial Programming

Examples

TABLE 1. CONTROL BITS LOGIC TABLE

BIT NAME DESCRIPTION

B15 Test Always 0

B14 Oscillator 0 = Internal, 1 = External

B13 A3 Channel Address

B12 A2 Channel Address

B11 A1 Channel Address

B10 A0 Channel Address

B9 D9 Data

B8 D8 Data

B7 D7 Data

B6 D6 Data

B5 D5 Data

B4 D4 Data

B3 D3 Data

B2 D2 Data

B1 D1 Data

B0 D0 Data

Serial Timing Diagram

ENA

t

HE

SCLK

SDI

t

SD

t

SE

t

HD

B15 B14 B13 B12-B2 B1 B0

MSB LSB

Load MSB first, LSB last

Tt

r

t

w

t

f

t

HE

t

SE

t

6

FN7356.0

March 11, 2004

EL5225

TABLE 2. SERIAL TIMING PARAMETERS

PARAMETER RECOMMENDED OPERATING RANGE DESCRIPTION

T ≥200ns Clock Period

t

r/tf

t

HE

t

SE

t

HD

t

SD

t

W

TABLE 3. SERIAL PROGRAMMING EXAMPLES

CONTROL CHANNEL ADDRESS DATA

0 0 00000000000000Internal Oscillator, Channel A, Value = 0

0 0 00001111111111Internal Oscillator, Channel A, Value = 1023

0 0 00001000000000Internal Oscillator, Channel A, Value = 512

0 0 00111000000001‘tInternal Oscillator, Channel C, Value = 513

0 0 01110000011111Internal Oscillator, Channel H, Value = 31

0 1 01110000011111External Oscillator, Channel H, Value = 31

0.05 * T Clock Rise/Fall Time

≥10ns ENA Hold Time

≥10ns ENA Setup Time

≥10ns Data Hold Time

≥10ns Data Setup Time

0.50 * T Clock Pulse Width

CONDITIONC1 C0 A3 A2 A1 A0 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Analog Section

TRANSFER FUNCTION

The transfer function is:

data

V

OUT IDEAL )(

V

=

where data is the decimal value of the 10-bit data binary

input code.

The output voltages from the EL5225 will be derived from

the reference voltages present at the V

pins. The impedance between those two pins is about 32kΩ.

Care should be taken that the system design holds these two

reference voltages within the limits of the power rails of the

EL5225. GND < V

In some LCD applications that require more than 10

channels, the system can be designed such that one

EL5225 will provide the Gamma correction voltages that are

more positive than the V

can provide the Gamma correction voltage more negative

than the V

potential. The Application Drawing shows a

COM

system connected in this way.

------------ -

REFL

1024

≤ VS and GND ≤ V

REFH

COM

V

REFH

- V

REFL

REFL

and V

REFL

≤ V

REFH

REFH

.

()×+

potential. The second EL5225

CLOCK OSCILLATOR

The EL5225 requires an internal clock or external clock to

refresh its outputs. The outputs are refreshed at the falling OSC

clock edges. The output refreshed switches open at the rising

edges of the OSC clock. The driving load shouldn’t be changed

at the rising edges of the OSC clock. Otherwise, it will generate

a voltage error at the outputs. This clock may be input or output

via the clock pin labeled OSC. The internal clock is provided by

an internal oscillator running at approximately 21kHz and can

be output to the OSC pin. In a 2 chip system, if the driving loads

are stable, one chip may be programmed to use the internal

oscillator; then the OSC pin will output the clock from the

internal oscillator. The second chip may have the OSC pin

connected to this clock source.

For transient load application, the external clock Mode

should be used to ensure all functions are synchronized

together. The positive edge of the external clock to the OSC

pin should be timed to avoid the transient load effect. The

Application Drawing shows the LCD H rate signal used, here

the positive clock edge is timed to avoid the transient load of

the column driver circuits.

After power on, the chip will start with the internal oscillator

mode. At this time, the OSC pin will be in a high impedance

condition to prevent contention. By setting B14 to high, the

chip is on external clock mode. Setting B14 to low, the chip is

on internal clock mode.

7

FN7356.0

March 11, 2004

Block Diagram

EIGHT

CHANNEL

MEMORY

EL5225

REFERENCE HIGH

OUTA

OUTB

OUTH

VOLTAGE

SOURCES

OUTI

OUTJ

REFERENCE LOW

CLK

SDI

LOAD

FILTER

CONTROL IF

CHANNEL OUTPUTS

Each of the channel outputs has a rail-to-rail buffer. This

enables all channels to have the capability to drive to within

50mV of the power rails, (see Electrical Characteristics for

details).

When driving large capacitive loads, a series resistor should

be placed in series with the output. (Usually between 5Ω and

50Ω).

Each of the channels is updated on a continuous cycle, the

time for the new data to appear at a specific output will

depend on the exact timing relationship of the incoming data

to this cycle.

The best-case scenario is when the data has just been

captured and then passed on to the output stage

immediately; this can be as short as 48µs. In the worst-case

scenario, this will be 480µs when the data has just missed

the cycle.

When a large change in output voltage is required, the

change will occur in 2V steps, thus the requisite number of

timing cycles will be added to the overall update time. This

means that a large change of 16V can take between 3.8ms

REFERENCE DECOUPLE

SDO

EXT_OSC

and 4.2ms depending on the absolute timing relative to the

update cycle.

Output Stage and the Use of External Oscillator

Simplified output sample and hold amp stage for one

channel.

CH

S

1.3V

V

+

-

+

IN

-

The output voltage is generated from the DAC, which is V

at the above circuit. The refreshed switches are controlled

by the internal or external oscillator signal. When the OSC

clock signal is low, the switch S

output V

= VIN and at the same time the sample and

OUT

hold cap CH is being charged. When the OSC clock signal is

high, the refreshed switch S

output voltage is maintained by CH. This refreshed process

1

FIGURE 11.

and S2 are opened and the

1

+

1.3V

-

S

2

OSC

and S2 are closed. The

1

V

OUT

IN

8

FN7356.0

March 11, 2004

will repeat every 10-clock cycles for each channel. The time

takes to update the output depends on the timing at the V

IN

and the state of the switches. It can take 1 to 10 clock cycles

to update each output.

EL5225

V

OUT1

For the sample and hold capacitor CH to maintain the

correct output voltage, the driving load shouldn’t be changed

at the rising edge of the OSC signal. Since at the rising edge

of the OSC clock, the refreshed switches are being opened,

if the load changes at that time, it will generate an error

output voltage. For a fixed load condition, the internal

oscillator can be used.

For the transient load condition, the external OSC mode

should be used to avoid the conflict between the rising edge

of the OSC signal and the changing load. So a timing delay

circuit will be needed to delay the OSC signal and avoid the

rising edge of the OSC signal and changing the load at the

same time.

I

OUT

V

OUT

OSC

M=400µs/DIV

OSC

V

OUT2

M=400µs/DIV

FIGURE 13. CHANNEL-TO-CHANNEL REFRESH

Ch1 - Output1

Ch3 - Output2

Ch2 - EXT_OSC

At the falling edge of the OSC, output 1 is refreshing and one

clock cycle later, output2 is being refreshed. The spike you

see here is the response of the output amplifier when the

refreshed switches are closed. When driving a big capacitor

load, there will be ringing at the spikes because the phase

margin of the amplifier is decreased.

The speed of the external OSC signal shouldn’t be greater

than 70kHz because for the worst condition, it will take at

least 4µs to charge the sample and hold Capacitor CH. The

pulse width has to be at least 4µs long. From our lab test, the

duty cycle of the OSC signal must be greater than 30%.

FIGURE 12. TRANSIENT LOAD RESPONSE

Channel 3 - sinking and sourcing 5mA current

Channel 2 - EXT_OSC signal

Channel 1 - V

OUT

Here, the OSC signal is synchronized to the load signal. The

rising edge of the OSC signal is then delayed by some

amount of time and gives enough time for CH to be charged

to a new voltage before the switches are opened.

POWER DISSIPATION

With the 30mA maximum continues output drive capability

for each channel, it is possible to exceed the 125°C absolute

maximum junction temperature. Therefore, it is important to

calculate the maximum junction temperature for the

application to determine if load conditions need to be

modified for the part to remain in the safe operation.

The maximum power dissipation allowed in a package is

determined according to:

P

DMAX

JMAX

---------------------------------------------

=

AMAX

Θ

JA

T

- T

where:

•T

•T

• θ

•P

= Maximum junction temperature

JMAX

= Maximum ambient temperature

AMAX

= Thermal resistance of the package

JA

= Maximum power dissipation in the package

DMAX

9

FN7356.0

March 11, 2004

EL5225

The maximum power dissipation actually produced by the IC

is the total quiescent supply current times the total power

supply voltage and plus the power in the IC due to the loads.

P

DMAXVSIS

Σ VS( - V

OUT

i ) I

LOAD

i×[]+×=

when sourcing, and:

P

DMAXVSIS

Σ V

OUT

iI

LOAD

i×()+×=

when sinking.

Where:

• i = 1 to total 10

•V

= Supply voltage

S

= Quiescent current

•I

S

•V

•I

By setting the two P

can solve for the R

i = Output voltage of the i channel

OUT

i = Load current of the i channel

LOAD

equations equal to each other, we

DMAX

s to avoid the device overheat. The

LOAD

package power dissipation curves provide a convenient way

to see if the device will overheat.

POWER SUPPLY BYPASSING AND PRINTED CIRCUIT

BOARD LAYOUT

Good printed circuit board layout is necessary for optimum

performance. A low impedance and clean analog ground

plane should be used for the EL5225. The traces from the

two ground pins to the ground plane must be very short.

Lead length should be as short as possible and all power

supply pins must be well bypassed. A 0.1µF ceramic

capacitor must be place very close to the V

V

, and CAP pins. A 4.7µF local bypass tantalum

REFL

capacitor should be placed to the V

, V

S

REFH

, V

S

, and V

REFH

,

REFL

pins.

APPLICATION USING THE EL5225

In the first application drawing, the schematic shows the

interconnect of a pair of EL5225 chips connected to give

10 gamma corrected voltages above the V

10 gamma corrected voltages below the V

voltage, and

COM

voltage.

COM

10

FN7356.0

March 11, 2004

Application Drawing

MICROCONTROLLER

LCD

TIMING

CONTROLLER

HORIZONTAL

RATE

HIGH REFERENCE

VO LTAGE

+10V

+12V

+5V

0.1µF

EL5225

0.1µF

0.1µF

0.1µF

REFH

VS

VSD

SDI

SCK

ENA

SDO

OSC

CAP

REFL

OUTA

OUTB

OUTC

OUTD

OUTE

OUTF

OUTI

COLUMN

(SOURCE)

DRIVER

LCD PANEL

+5.5V

LOW REFERENCE

VO LTAGE

+1V

+12V

+5V

0.1µF

GND

EL5225

MIDDLE REFERENCE VOLTAGE

REFH

OSC

VS

0.1µF

VSD

SDI

SCK

ENA

CAP

0.1µF

REFL

0.1µF

GND

EL5225

OUTJ

OUTA

OUTB

OUTC

OUTD

OUTE

OUTF

OUTI

OUTJ

11

FN7356.0

March 11, 2004

TSSOP Package Outline Drawing

EL5225

NOTE: The package drawing shown here may not be the latest version. To check the latest revision, please refer to the Intersil

website at <http://www.intersil.com/design/packages/index.asp>

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

12

FN7356.0

March 11, 2004

Loading...

Loading...