Page 1

www.BDTIC.com/Intersil

®

EL1511

Data Sheet April 10, 2007

Medium Power Differential Line Driver

The EL1511 is a dual operational amplifier designed for

customer premise line driving in DMT ADSL solutions. This

device features a high drive capability of 360mA while

consuming only 7.5mA of supply current per amplifier and

operating from a single 5V to 15V supply. This driver

achieves a typical distortion of less than -85dBc, at 150kHz

into a 25Ω load. The EL1511 is available in the th ermallyenhanced 16 Ld SOIC (0.150") and a 16 Ld QFN (4x4mm)

packages. The EL1511 is specified for operation over the full

-40°C to +85°C temperature range. Electrical characteristics

are given for typical 15V supply operation.

The EL1511 has two control pins, C

the selection of full I

power , 3/ 4-IS, 1/2-IS, and power-down

S

modes.

The EL1511 is ideal for ADSL, SDSL, and HDSL2 line

driving applications for single power supply, high voltage

swing, and low power.

The EL1511 maintains excellent distortion and load driving

capabilities even in the lowest power settings.

and C1, which allow

0

FN7016.2

Features

• Drives up to 360mA from a +15V supply

•24V

differential output drive into 25Ω and 26V

P-P

P-P

differential output drive into 100Ω

• -85dBc typical driver output distortion at full output at

150kHz

• Low quiescent current of 3.5mA per amplifier at 1/2-I

current mode

• Disable down to 1.5mA

• Pb-free plus anneal available (RoHS compliant)

Applications

• ADSL CSA line driving

• ADSL full rate CPE line driving

• G.SHDSL, HDSL2 line driver

• Video distribution amplifier

• Video twisted-pair line driver

S

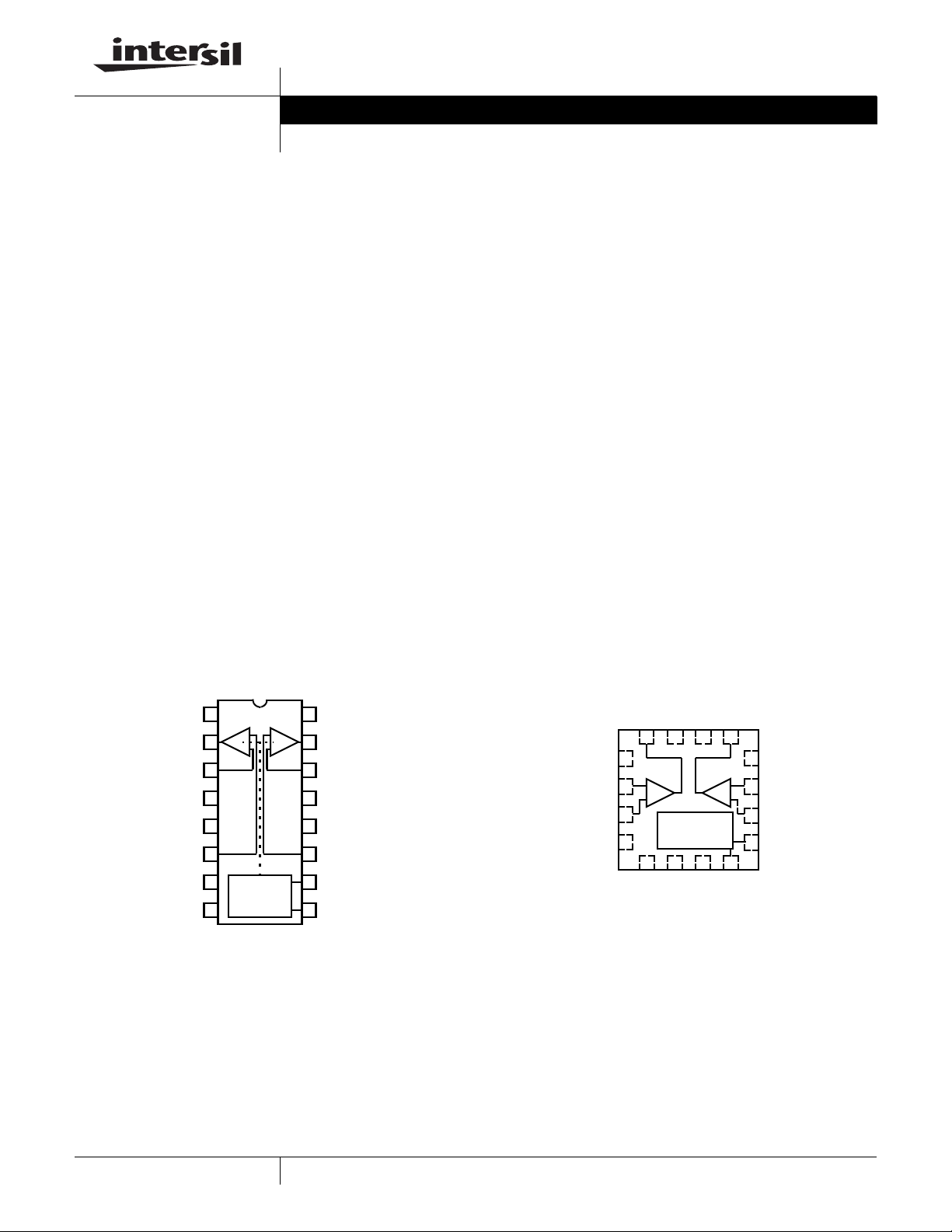

Pinouts

EL1511

[16 LD SO (0.150”)]

TOP VIEW

NC

1

VOUTA

VIN-A

GND*

GND*

VIN+A

GND

VS-

NOTE: * These GND pins are heat spreaders

+

2

-

3

4

5

6

POWER

7

CONTROL

LOGIC

8 9

16

+

15

14

13

12

11

10

VS+

VOUTB

VIN-B

GND*

GND*

VIN+B

C1

C0

NC

INA-

INA+

GND

(16 LD QFN)

TOP VIEW

OUTA

16

1

AMP AAMP

-

2

+

3

4

5

NC

EL1511

NC

VS+

15

14

B

POWER

CONTROL

LOGIC

7

6

NC

VS-

OUTB

13

NC

12

INB-

-

11

+

INB+

10

C1

9

8

C0

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright Intersil Americas Inc. 2003, 2005, 2007. All Rights Reserved

All other trademarks mentioned are the property of their respective owners.

Page 2

www.BDTIC.com/Intersil

EL1511

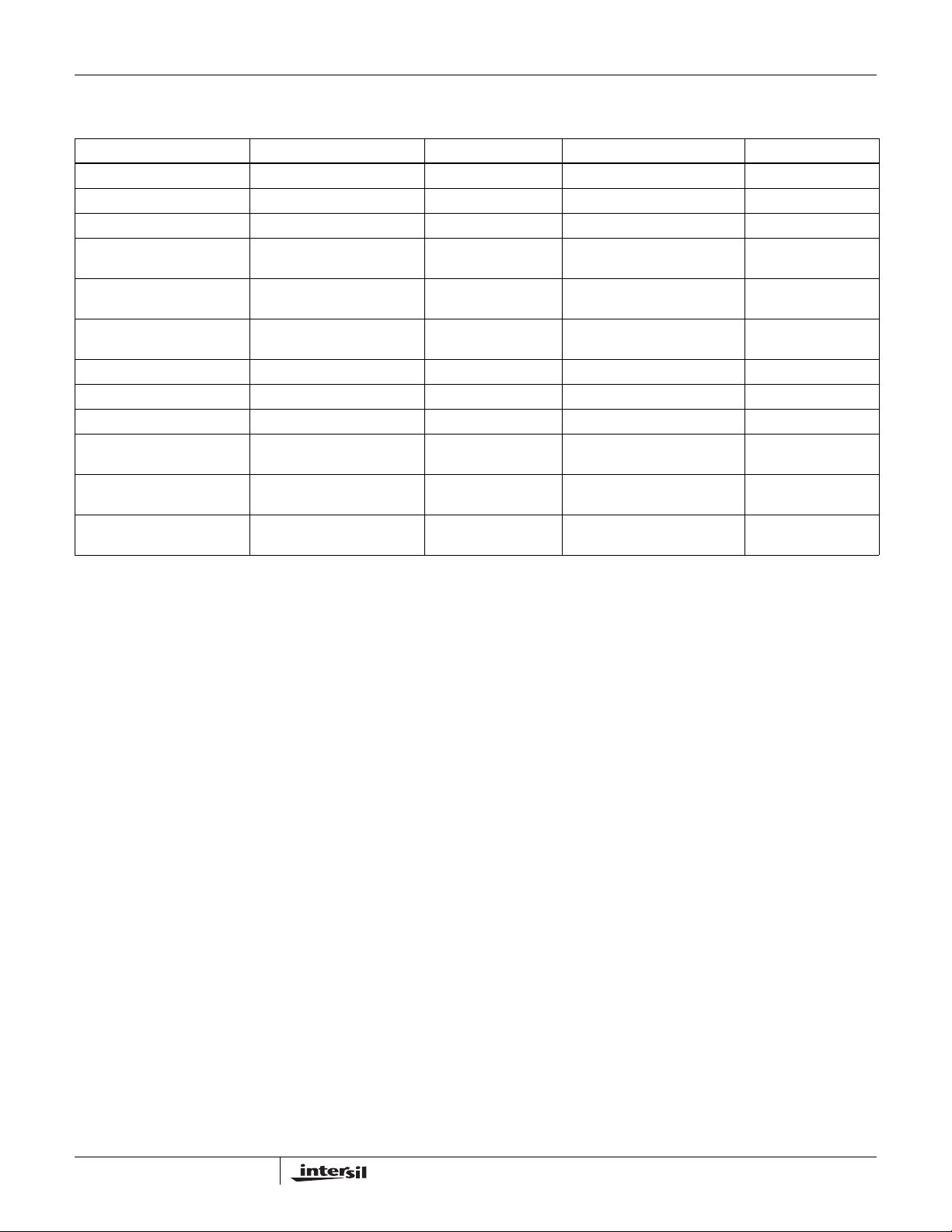

Ordering Information

PART NUMBER PART MARKING TAPE & REEL PACKAGE PKG. DWG. #

EL1511CS EL1511CS - 16 Ld SO (0.150”) MDP0027

EL1511CS-T7 EL1511CS 7” 16 Ld SO (0.150”) MDP0027

EL1511CS-T13 EL1511CS 13” 16 Ld SO (0.150”) MDP0027

EL1511CSZ

(See Note)

EL1511CSZ-T7

(See Note)

EL1511CSZ-T13

(See Note)

EL1511CL 1511CL - 16 Ld QFN MDP0046

EL1511CL-T7 1511CL 7” 16 Ld QFN MDP0046

EL1511CL-T13 1511CL 13” 16 Ld QFN MDP0046

EL1511CLZ

(See Note)

EL1511CLZ-T7

(See Note)

EL1511CLZ-T13

(See Note)

NOTE: Intersil Pb-free plus anneal products employ special Pb-free material sets; molding compounds/die attach materials and 100% matte tin plate

termination finish, which are RoHS compliant and compatible with both SnPb and Pb-free soldering operations. Intersil Pb-free products are MSL

classified at Pb-free peak reflow temperatures that meet or exceed the Pb-free requirements of IPC/JEDEC J STD-020.

EL1511CSZ - 16 Ld SO (0.150”)

(Pb-Free)

EL1511CSZ 7” 16 Ld SO (0.150”)

(Pb-Free)

EL1511CSZ 13” 16 Ld SO (0.150”)

(Pb-Free)

1511CLZ - 16 Ld QFN

(Pb-Free)

1511CLZ 7” 16 Ld QFN

(Pb-Free)

1511CLZ 13” 16 Ld QFN

(Pb-Free)

MDP0027

MDP0027

MDP0027

MDP0046

MDP0046

MDP0046

2

FN7016.2

April 10, 2007

Page 3

www.BDTIC.com/Intersil

EL1511

Absolute Maximum Ratings (T

V

+ to VS- Supply Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . 16.5V

S

V

+ Voltage to Ground . . . . . . . . . . . . . . . . . . . . . . -0.3V to +16.5V

S

- Voltage to Ground. . . . . . . . . . . . . . . . . . . . . . . . -16.5V to 0.3V

V

S

Input C

V

IN

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

IMPORTANT NOTE: All parameters having Min/Max specifications are guaranteed. Typical values are for information purposes only. Unless otherwise noted, all tests

are at the specified temperature and are pulsed tests, therefore: TJ = TC = T

to Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7V

0/C1

+ Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VS- to VS+

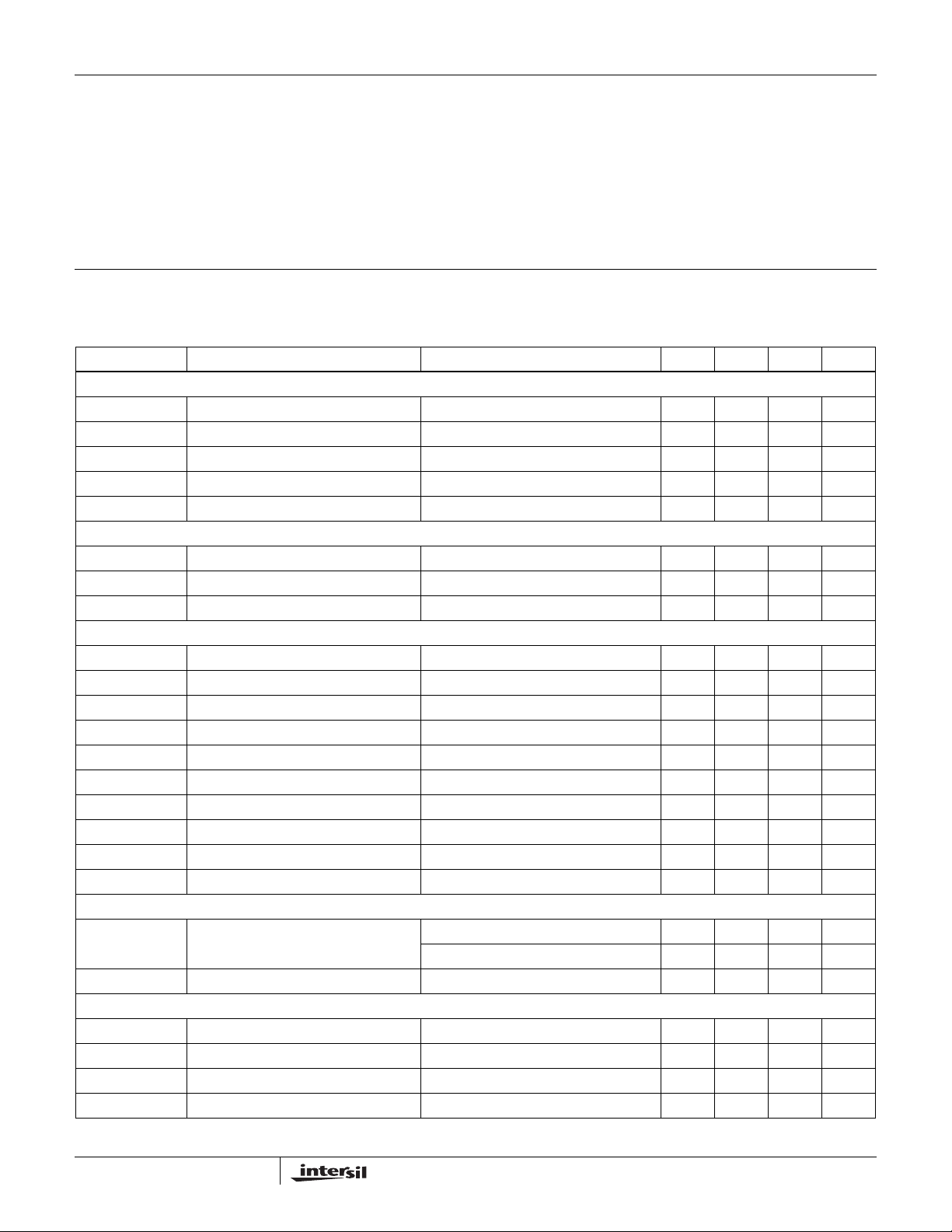

Electrical Specifications V

= +25°C)

A

Current into any Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8mA

Continuous Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . 75mA

Operating Temperature Range . . . . . . . . . . . . . . . . .-40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . . . . . . .-60°C to +150°C

Operating Junction Temperature . . . . . . . . . . . . . . .-40°C to +150°C

Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Curves

A

= ±7.5V, RF = 1.5kΩ, RL = 100Ω to mid supply, TA = +25°C unless otherwise specified.

S

PARAMETER DESCRIPTION CONDITIONS MIN TYP MAX UNIT

AC PERFORMANCE

BW -3dB Bandwidth A

HD Total Harmonic Distortion f = 150kHz, V

= +4 70 MHz

V

O

= 16V

, RL = 25Ω -85 dBc

P-P

dG Differential Gain AV = +2, RL = 37.5Ω 0.15 %

dθ Differential Phase A

SR Slewrate V

= +2, RL = 37.5Ω 0.1 °

V

from -3V to +3V 500 V/µs

OUT

DC PERFORMANCE

V

ΔV

R

OS

OS

OL

Offset Voltage -20 20 mV

VOS Mismatch -10 10 mV

Transimpedance V

from -4.5V to +4.5V 0.7 1.4 2.5 MΩ

OUT

INPUT CHARACTERISTICS

+ Non-Inverting Input Bias Current -5 5 µA

I

B

- Inverting Input Bias Current -30 30 µA

I

B

ΔIB-I

e

N

i

N

V

IH

V

IL

I

IH1

I

IH0

I

IL

- Mismatch -30 30 µA

B

Input Noise Voltage 2.8 nV/√Hz

-Input Noise Current 19 pA/√Hz

Input High Voltage C0 and C1 inputs 2.3 V

Input Low Voltage C0 and C1 inputs 1.5 V

Input High Current for C

Input High Current for C

1

0

Input Low Current for C1or C

0

C1 = 5V 0.2 8 µA

C0 = 5V 0.1 4 µA

C1 = 0V, C0 = 0V -1 1 µA

OUTPUT CHARACTERISTICS

V

I

OUT

OUT

Loaded Output Swing (single ended) VS = ±7.5, RL = 100Ω to GND ±6.3 ±6.5 V

= ±7.5, RL = 25Ω to GND ±5.7 ±6.0 V

V

S

Output Current RL = 0Ω 450 mA

SUPPLY

V

S

+ (Full Power) Positive Supply Current per Amplifier All outputs at 0V, C0 = C1 = 0V 7 9.25 mA

I

S

- (Full Power) Negative Supply Current per Amplifier All outputs at 0V, C0 = C1 = 0V -6.4 -8.75 mA

I

S

+ (3/4 Power) Positive Supply Current per Amplifier All outputs at 0V, C0 = 5V, C1 = 0V 5.3 7.25 mA

I

S

Supply Voltage Single supply 5 15 V

3

FN7016.2

April 10, 2007

Page 4

www.BDTIC.com/Intersil

V

EL1511

Electrical Specifications V

= ±7.5V, RF = 1.5kΩ, RL = 100Ω to mid supply, TA = +25°C unless otherwise specified. (Continued)

S

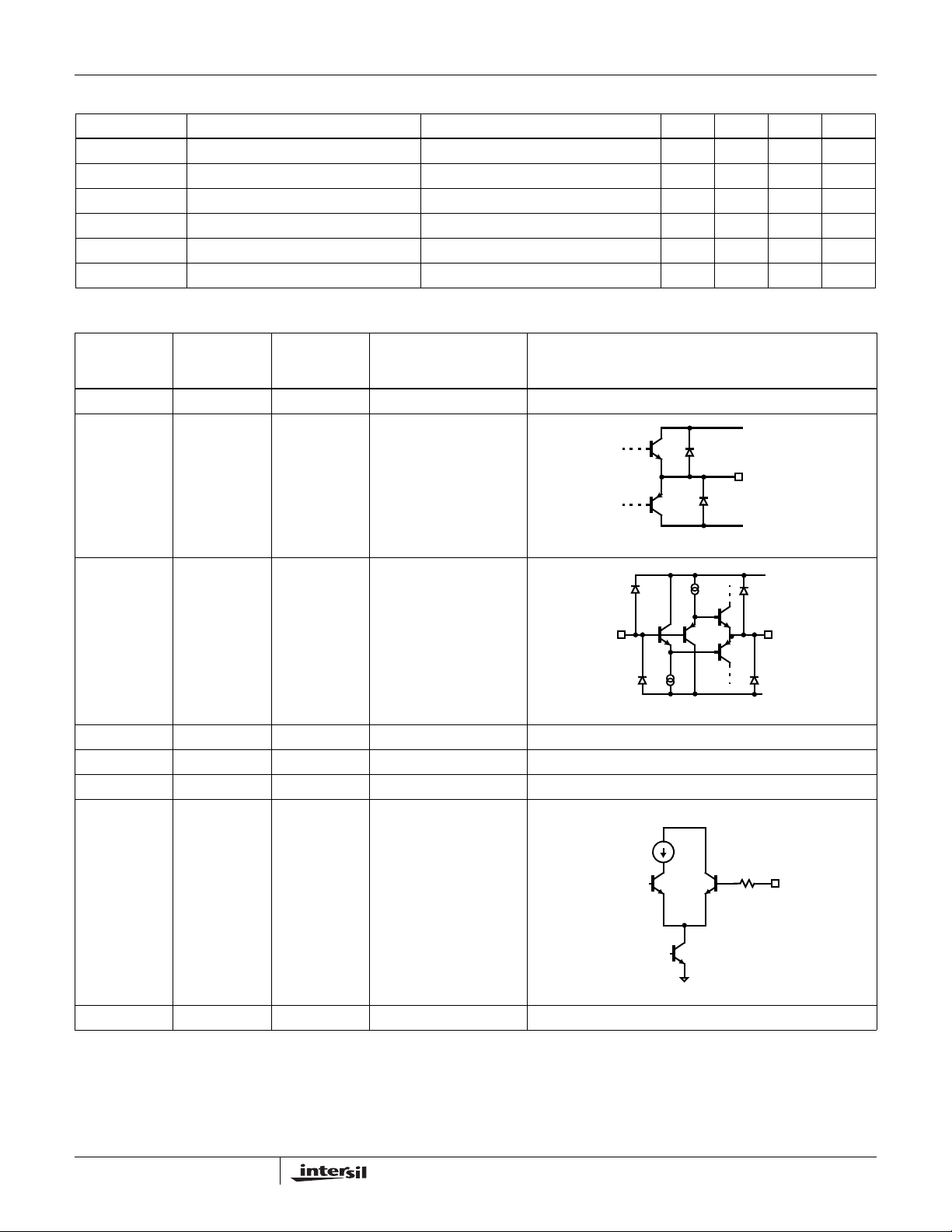

PARAMETER DESCRIPTION CONDITIONS MIN TYP MAX UNIT

IS- (3/4 Power) Negative Supply Current per Amplifier All outputs at 0V, C0 = 5V, C1 = 0V -4.7 -6.75 mA

+ (1/2 Power) Positive Supply Current per Amplifier All outputs at 0V, C0 = 0V, C1 = 5V 3.3 5.75 mA

I

S

- (1/2 Power) Negative Supply Current per Amplifier All outputs at 0V, C0 = 0V, C1 = 5V -2.7 -5.2 mA

I

S

+ (Power Down) Positive Supply Current per Amplifier All outputs at 0V, C0 = C1 = 5V 0.6 1.025 mA

I

S

- (Power Down) Negative Supply Current per Amplifier All outputs at 0V, C0 = C1 = 5V 0 -0.525 mA

I

S

I

GND

GND Supply Current per Amplifier All outputs at 0V 0.6 1 mA

Pin Descriptions

EL1511CS

16 Ld SO

(0.150”)

1 1, 5, 6, 12, 15 NC Not Connected

2, 15 13, 16 OUT Output

3, 14 2, 11 VIN- Inverting Input

EL1511CL

16 Ld QFN PIN NAME PIN FUNCTION EQUIVALENT CIRCUIT

S

OUT

V

S

CIRCUIT 1

+

-

+

V

S

4, 5, 7, 12, 13 4 GND Ground Pins

6, 11 3, 10 VIN+ Non-inverting Input Reference Circuit 2

8 7 VS- Negative Supply

9 8 C0 Power Control

10 9 C1 Power Control Reference Circuit 3

I

BIAS

1.8V Q3Q1

CIRCUIT 2

VS+

+

–

Q2

CIRCUIT 3

500Ω C

IN-IN+

-

V

S

0

4

FN7016.2

April 10, 2007

Page 5

www.BDTIC.com/Intersil

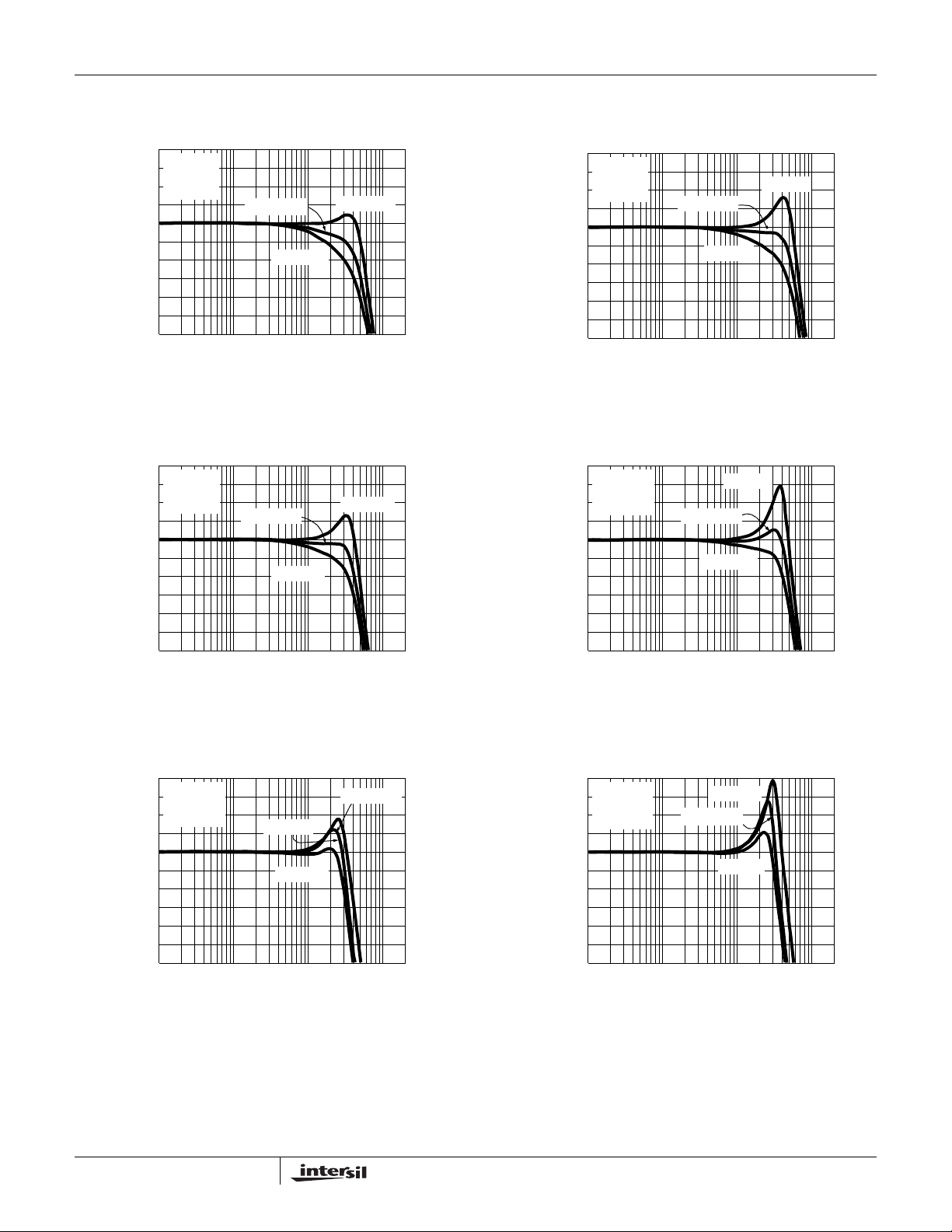

Typical Performance Curves

EL1511

28

VS=±6V

A

=10

V

24

=100Ω

R

L

RF=1.5kΩ

20

16

GAIN (dB)

12

8

100K

1M 100M10M

RF=2kΩ

FREQUENCY (Hz)

RF=1kΩ

FIGURE 1. DIFFERENTIAL FREQUENCY RESPONSE

(FULL POWER MODE)

28

VS=±6V

=10

A

V

24

R

=100Ω

L

20

16

GAIN (dB)

RF=1.5kΩ

RF=2kΩ

RF=1kΩ

22

VS=±6V

=5

A

V

18

=100Ω

R

L

14

10

GAIN (dB)

6

2

100K 1M 10M

RF=1.5kΩ

FREQUENCY (Hz)

RF=2kΩ

RF=1kΩ

100M

FIGURE 2. DIFFERENTIAL FREQUENCY RESPONSE

(FULL POWER MODE)

22

VS=±6V

=5

A

V

18

=100Ω

R

L

14

10

GAIN (dB)

RF=1kΩ

RF=1.5kΩ

RF=2kΩ

12

8

100K 1M

FREQUENCY (Hz)

100M10M

FIGURE 3. DIFFERENTIAL FREQUENCY RESPONSE

(3/4 POWER MODE)

28

VS=±6V

A

=10

V

24

=100Ω

R

L

20

16

GAIN (dB)

12

8

100K 1M

RF=1kΩ

RF=2kΩ

10M

FREQUENCY (Hz)

RF=1.5kΩ

100M

FIGURE 5. DIFFERENTIAL FREQUENCY RESPONSE

(1/2 POWER MODE)

6

2

100K 1M 10M

FREQUENCY (Hz)

100M

FIGURE 4. DIFFERENTIAL FREQUENCY RESPONSE

(3/4 POWER MODE)

22

VS=±6V

A

=5

V

18

=100Ω

R

L

14

10

GAIN (dB)

6

2

100K 1M 10M

FREQUENCY (Hz)

RF=1kΩ

RF=1.5kΩ

RF=2kΩ

100M

FIGURE 6. DIFFERENTIAL FREQUENCY RESPONSE

(1/2 POWER MODE)

5

FN7016.2

April 10, 2007

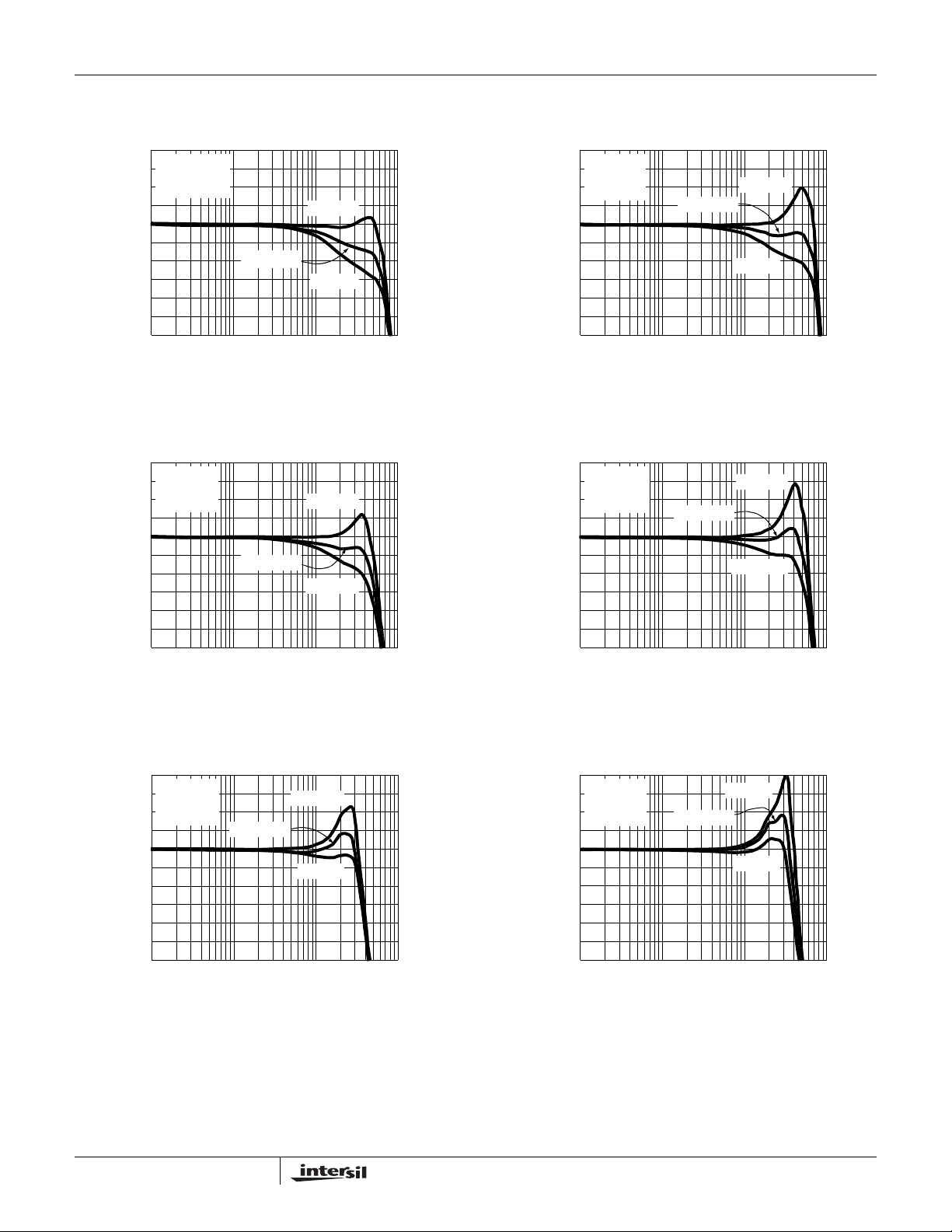

Page 6

www.BDTIC.com/Intersil

Typical Performance Curves (Continued)

EL1511

28

VS=±7.5V

=10

A

V

24

R

=100Ω

L

RF=1kΩ

20

16

GAIN (dB)

12

8

100K 1M 10M 100M

RF=1.5kΩ

RF=2kΩ

FREQUENCY (Hz)

FIGURE 7. DIFFERENTIAL FREQUENCY RESPONSE

(FULL POWER MODE)

28

VS=±7.5V

A

=10

V

24

=100Ω

R

L

20

16

GAIN (dB)

12

RF=1.5kΩ

RF=1kΩ

RF=2kΩ

22

VS=±7.5V

=5

A

V

18

R

=100Ω

L

14

10

GAIN (dB)

6

2

100K 1M 10M 100M

RF=1.5kΩ

FREQUENCY (Hz)

RF=1kΩ

RF=2kΩ

FIGURE 8. DIFFERENTIAL FREQUENCY RESPONSE

(FULL POWER MODE)

22

VS=±7.5V

=5

A

V

18

R

=100Ω

L

14

10

GAIN (dB)

6

RF=1.5kΩ

RF=1kΩ

RF=2kΩ

8

100K 1M 10M 100M

FREQUENCY (Hz)

FIGURE 9. DIFFERENTIAL FREQUENCY RESPONSE

(3/4 POWER MODE)

28

VS=±7.5V

A

=10

V

24

=100Ω

R

L

20

16

GAIN (dB)

12

8

100K 1M 10M 100M

RF=1.5kΩ

FREQUENCY (Hz)

RF=1kΩ

RF=2kΩ

FIGURE 11. DIFFERENTIAL FREQUENCY RESPONSE

(1/2 POWER MODE)

2

100K 1M 10M 100M

FREQUENCY (Hz)

FIGURE 10. DIFFERENTIAL FREQUENCY RESPONSE

(3/4 POWER MODE)

22

VS=±7.5V

=5

A

V

18

=100Ω

R

L

14

10

GAIN (dB)

6

2

100K 1M 10M 100M

RF=1.5kΩ

FREQUENCY (Hz)

RF=1kΩ

RF=2kΩ

FIGURE 12. DIFFERENTIAL FREQUENCY RESPONSE

(1/2 POWER MODE)

6

FN7016.2

April 10, 2007

Page 7

www.BDTIC.com/Intersil

Typical Performance Curves (Continued)

EL1511

30

26

22

18

14

10

6

GAIN (dB)

VS=±6V

2

=1.5kΩ

R

F

-2

A

=5

V

=100Ω

R

-6

L

-10

100K

1M 100M

FREQUENCY (Hz)

CL=22pF

CL=10pF

CL=0pF

10M

FIGURE 13. DIFFERENTIAL FREQUENCY RESPONSE vs C

(FULL POWER MODE)

30

26

22

18

14

10

6

GAIN (dB)

VS=±6V

2

=1.5kΩ

R

F

-2

A

=5

V

=100Ω

R

-6

L

-10

100K 1M

CL=10pF

CL=0pF

FREQUENCY (Hz)

CL=22pF

100M10M

30

22

CL=10pF

14

6

GAIN (dB)

VS=±7.5V

=1.5kΩ

R

F

-2

A

=5

V

=100Ω

R

L

-10

100k 1M 10M 100M

FREQUENCY (Hz)

L

FIGURE 14. DIFFERENTIAL FREQUENCY RESPONSE vs C

(FULL POWER MODE)

30

22

14

6

GAIN (dB)

VS=±7.5V

=1.5kΩ

R

F

-2

A

=5

V

=100Ω

R

L

-10

100K 1M 10M 100M

CL=10pF

FREQUENCY (Hz)

CL=22pF

CL=0pF

L

CL=22pF

CL=0pF

FIGURE 15. DIFFERENTIAL FREQUENCY RESPONSE vs C

(3/4 POWER MODE)

30

26

22

18

14

10

6

GAIN (dB)

VS=±6V

2

R

=1.5kΩ

F

-2

A

V

=100Ω

R

-6

L

-10

100K 1M

=5

CL=22pF

CL=10pF

CL=0pF

100M10M

FREQUENCY (Hz)

FIGURE 17. DIFFERENTIAL FREQUENCY RESPONSE vs C

(1/2 POWER MODE)

L

L

FIGURE 16. DIFFERENTIAL FREQUENCY RESPONSE vs C

(3/4 POWER MODE)

30

22

14

6

GAIN (dB)

VS=±7.5V

=1.5kΩ

R

F

-2

A

=5

V

=100Ω

R

L

-10

100K 1M 10M 100M

CL=10pF

FREQUENCY (Hz)

CL=22pF

CL=0pF

FIGURE 18. DIFFERENTIAL FREQUENCY RESPONSE vs C

(1/2 POWER MODE)

L

L

7

FN7016.2

April 10, 2007

Page 8

www.BDTIC.com/Intersil

Typical Performance Curves (Continued)

EL1511

70

AV=5

R

=1.5kΩ

F

60

=100Ω

R

L

50

40

30

BANDWIDTH (MHz)

20

2.5 4.5 7.5

FULL POWER

(V)

±V

S

3/4 POWER

1/2 POWER

6.53.5 5.5

THD (dB)

-45

VS=±2.5V

-50

A

=5

V

=2kΩ

R

F

-55

=100Ω

R

L

f=150kHz

-60

-65

-70

-75

-80

-85

2.5 4.5 5.5

1/2 POWER

V

OP-P

FULL POWER

3/4 POWER

623.5534

(V)

FIGURE 19. DIFFERENTIAL BANDWIDTH vs SUPPLY VOLTAGE FIGURE 20. DIFFERENTIAL TOTAL HARMONIC DISTORTION

vs DIFFERENTIAL OUTPUT VOLTAGE

16

12

1/2 POWER

8

4

PEAKING (dB)

0

-4

2.5 4.5 7.56.53.5 5.5

3/4 POWER

FULL POWER

±V

AV=5

R

=1.5kΩ

F

=100Ω

R

L

(V)

S

-45

-50

-55

-60

-65

-70

THD (dB)

-75

-80

-85

-90

VS=±6V

=5

A

V

R

=1.5kΩ

F

=100Ω

R

L

f=150kHz

FULL POWER

3/4 POWER

1/2 POWER

41218202814610 16

(V)

V

OP-P

FIGURE 21. DIFFERENTIAL PEAKING vs SUPPLY VOLTAGE FIGURE 22. DIFFERENTIAL TOTAL HARMONIC DISTORTION

vs DIFFERENTIAL OUTPUT VOLTAGE

-10

-20

-30

-40

-50

-60

-70

-80

ISOLATION (dB)

-90

-100

-110

10k 100k 1M

B → A

A → B

100M10M

FREQUENCY (Hz)

-30

VS=±7.5V

=5

A

V

-40

=1.5kΩ

R

F

R

=100Ω

L

-50

f=150kHz

-60

THD (dB)

-70

-80

-90

3/4 POWER

61422

2 101826

FULL POWER

1/2 POWER

(V)

V

OP-P

FIGURE 23. CHANNEL ISOLATION vs FREQUENCY FIGURE 24. DIFFERENTIAL TOTAL HARMONIC DISTORTION

vs DIFFERENTIAL OUTPUT VOLTAGE

8

FN7016.2

April 10, 2007

Page 9

www.BDTIC.com/Intersil

Typical Performance Curves (Continued)

EL1511

-45

VS=±2.5V

-50

=5

A

V

=2kΩ

R

F

-55

R

=100Ω

L

-60

f=1MHz

-65

-70

HD (dB)

-75

-80

-85

-90

12.5

V

OP-P

HD3

HD2

641.5 5325.53.5 4.5

(V)

FIGURE 25. DIFFERENTIAL HARMONIC DISTORTION vs

DIFFERENTIAL OUTPUT VOLTAGE

(FULL POWER MODE)

-45

VS=±2.5V

-50

A

=5

V

=2kΩ

R

F

-55

=100Ω

R

L

-60

f=1MHz

V

OP-P

HD3

HD2

61.5 424.52.5 535.5

(V)

-65

-70

HD (dB)

-75

-80

-85

-90

13.5

-45

VS=±6V

-50

=5

A

V

=1.5kΩ

R

F

-55

R

=100Ω

L

f=1MHz

-60

V

OP-P

HD3

HD2

(V)

-65

HD (dB)

-70

-75

-80

-85

210 2041261481618

FIGURE 26. DIFFERENTIAL HARMONIC DISTORTION vs

DIFFERENTIAL OUTPUT VOLTAGE

(FULL POWER MODE)

-45

VS=±6V

-50

A

=5

V

=1.5kΩ

R

F

-55

=100Ω

R

L

f=1MHz

-60

-65

HD (dB)

-70

-75

-80

-85

210 2041261481618

V

OP-P

HD3

HD2

(V)

FIGURE 27. DIFFERENTIAL HARMONIC DISTORTION vs

DIFFERENTIAL OUTPUT VOLTAGE

(3/4 POWER MODE)

-50

VS=±2.5V

=5

A

-55

V

R

=2kΩ

F

=100Ω

R

L

-60

f=1MHz

-65

-70

HD (dB)

-75

-80

-85

13.561.5 424.52.5 535.5

V

HD3

HD2

OP-P

(V)

FIGURE 29. DIFFERENTIAL HARMONIC DISTORTION vs

DIFFERENTIAL OUTPUT VOLTAGE

(1/2 POWER MODE)

9

FIGURE 28. DIFFERENTIAL HARMONIC DISTORTION vs

DIFFERENTIAL OUTPUT VOLTAGE

(3/4 POWER MODE)

-45

VS=±6V

-50

=5

A

V

=1.5kΩ

R

F

-55

R

=100Ω

L

f=1MHz

-60

V

OP-P

HD3

HD2

2010 16618814412

(V)

-65

HD (dB)

-70

-75

-80

-85

2

FIGURE 30. DIFFERENTIAL HARMONIC DISTORTION vs

DIFFERENTIAL OUTPUT VOLTAGE

(1/2 POWER MODE)

FN7016.2

April 10, 2007

Page 10

www.BDTIC.com/Intersil

Typical Performance Curves (Continued)

EL1511

-30

VS=±7.5V

=5

A

V

-40

R

=1.5kΩ

F

=100Ω

R

L

-50

f=1MHz

-60

HD (dB)

-70

-80

-90

226

V

OP-P

HD3

HD2

14610

(V)

2218

FIGURE 31. DIFFERENTIAL HARMONIC DISTORTION vs

DIFFERENTIAL OUTPUT VOLTAGE

(FULL POWER MODE)

-30

VS=±7.5V

A

=5

V

-40

=1.5kΩ

R

F

=100Ω

R

L

-50

f=1MHz

-60

HD (dB)

-70

-80

-90

226

V

OP-P

HD3

HD2

14610

(V)

2218

-45

VS=±2.5V

=5

A

-50

V

=2kΩ

R

F

R

=100Ω

L

-55

f=1MHz

-60

-65

THD (dB)

-70

3/4 POWER

-75

-80

1634.525.52.5 41.5 3.5 5

1/2 POWER

FULL POWER

V

OP-P

(V)

FIGURE 32. DIFFERENTIAL TOTAL HARMONIC DISTORTION

vs DIFFERENTIAL OUTPUT VOLTAGE

-45

VS=±6V

-50

=5

A

V

=1.5kΩ

R

F

-55

R

=100Ω

L

f=1MHz

-60

-65

1/2 POWER

THD (dB)

-70

-75

-80

-85

22010 16618814412

FULL POWER

3/4 POWER

V

OP-P

(V)

FIGURE 33. DIFFERENTIAL HARMONIC DISTORTION vs

DIFFERENTIAL OUTPUT VOLTAGE

(3/4 POWER MODE)

-30

VS=±7.5V

=5

A

V

-40

R

=1.5kΩ

F

=100Ω

R

L

-50

f=1MHz

-60

HD (dB)

-70

-80

-90

226

V

OP-P

HD3

HD2

14610

(V)

2218

FIGURE 35. DIFFERENTIAL HARMONIC DISTORTION vs

DIFFERENTIAL OUTPUT VOLTAGE

(1/2 POWER MODE)

10

FIGURE 34. DIFFERENTIAL TOTAL HARMONIC DISTORTION

vs DIFFERENTIAL OUTPUT VOLTAGE

-30

VS=±7.5V

A

=5

V

-40

=1.5kΩ

R

F

=100Ω

R

L

-50

f=1MHz

-60

THD (dB)

-70

-80

-90

1/2 POWER

FULL POWER

3/4 POWER

2218

V

OP-P

14610

(V)

226

FIGURE 36. DIFFERENTIAL TOTAL HARMONIC DISTORTION

vs DIFFERENTIAL OUTPUT VOLTAGE

FN7016.2

April 10, 2007

Page 11

www.BDTIC.com/Intersil

Typical Performance Curves (Continued)

0.14

VS=±6V

A

=2

V

=1.5kΩ

R

F

0.1

1/2 POWER

3/4 POWER

FULL POWER

0

1.5 2 2.5

133.5

NUMBER OF 150Ω LOADS

FIGURE 37. DIFFERENTIAL GAIN FIGURE 38. DISABLE TIME

VS=±6V

A

=2

V

=1.5kΩ

R

F

1/2 POWER

0.1

FULL POWER

133.5

NUMBER OF 150Ω LOADS

3/4 POWER

dG (%)

dP (°)

0.12

0.08

0.06

0.04

0.02

0.15

0.14

0.13

0.12

0.11

0.09

0.08

0.07

EL1511

CH 2

V

OUT

C0, C

1

CH 1=2V/DIV

CH 1

4

CH 1=2V/DIV

CH 2=2V/DIV

V

CH 2

CH 1

41.5 2 2.5

OUT

C0, C

1

400ns/DIV

40ns/DIV

CH 2=2V/DIV

FIGURE 39. DIFFERENTIAL PHASE FIGURE 40. ENABLE TIME

16

IS+ (FULL POWER) IS- (FULL POWER)

14

IS+ (3/4 POWER)

12

10

(mA)

S

8

I

6

4

2

2 3.5 5 7.52.5 4 6374.5 5.5 6.5

IS- (3/4 POWER)

IS+ (1/2 POWER) IS+ (1/2 POWER)

(V)

±V

S

10

8

6

4

2

0

-2

-4

-6

INPUT BIAS CURRENT (µA)

-8

-10

-50 100 150-25 0 50 12525 75

IB-

IB+

DIE TEMPERATURE (°C)

FIGURE 41. SUPPLY CURRENT vs SUPPLY VOLTAGE FIGURE 42. INPUT BIAS CURRENT vs TEMPERATURE

11

FN7016.2

April 10, 2007

Page 12

www.BDTIC.com/Intersil

Typical Performance Curves (Continued)

EL1511

16

14

12

10

8

6

4

SUPPLY CURRENT (mA)

2

0

-50 100 150-25 0 50 12525 75

DIE TEMPERATURE (°C)

FULL POWER

3/4 POWER

1/2 POWER

DISABLED

7

6

5

4

3

2

1

0

-1

OFFSET VOLTAGE (mV)

-2

-3

-50 100 150-25 0 50 12525 75

DIE TEMPERATURE (°C)

FIGURE 43. POSITIVE SUPPLY CURRENT vs TEMPERATURE FIGURE 44. OFFSET VOLTAGE vs TEMPERATURE

5.2

RL=100Ω

5.15

5.1

50.5

5

4.95

4.9

OUTPUT VOLTAGE (±V)

4.85

4.8

-50 100 150-25 0 50 12525 75

DIE TEMPERATURE (°C)

3

2.5

2

1.5

1

0.5

TRANSIMPEDANCE (MΩ)

0

-50 100 150-25 0 50 12525 75

DIE TEMPERATURE (°C)

FIGURE 45. OUTPUT VOLTAGE vs TEMPERATURE FIGURE 46. TRANSIMPEDANCE vs TEMPERATURE

520

510

500

490

480

470

SLEW RATE (V/µs)

460

450

440

-50 100 150-25 0 50 12525 75

DIE TEMPERATURE (°C)

30

20

10

0

-10

-20

-30

PSRR (dB)

-40

-50

-60

-70

10K

PSRR-

100K 10M1M

FREQUENCY (Hz)

PSRR+

100M

FIGURE 47. SLEW RATE vs TEMPERATURE FIGURE 48. POWER SUPPLY REJECTION vs FREQUENCY

12

FN7016.2

April 10, 2007

Page 13

www.BDTIC.com/Intersil

Typical Performance Curves (Continued)

D

EL1511

100

IB-

10

e

N

CURRENT NOISE (pA/Hz)

VOLTAGE NOISE (nV/√Hz),

IB+

1

10 10M

FREQUENCY (Hz)

100M100K 1M10K100 1K

100

VS=±6V

A

=1

V

=1.5kΩ

R

10

F

1

0.1

0.01

OUTPUT IMPEDANCE (Ω)

0.001

10K 100K 1M 100M

FREQUENCY (Hz)

10M

FIGURE 49. VOLTAGE AND CURRENT NOISE vs FREQUENCY FIGURE 50. OUTPUT IMPEDANCE vs FREQUENCY (ALL

POWER LEVELS)

USING EL1511CS/EL1511CL DEMOBOARD,

2”X2” (4-LAYER) DEMOBOARD WITH

HEATSINK VIA INTERNAL GROUND PLANE

POWER DISSIPATION (W)

3.5

2.5

1.5

0.5

4

3

2

1

0

37°C/W

47°C/W

AMBIENT TEMPERATURE (°C)

Q

F

N1

6

S

O

1

6

(

0

.

1

5

0

”

)

100-40 -20 0 20 40 60

80

10M

1M

100k

10k

MAGNITUDE (Ω)

1k

100

100 10K

GAIN

FREQUENCY (Hz)

PHASE

50

0

-50

-100

-150

PHASE (°)

-200

-250

-300

100M1M1K 100K 10M

FIGURE 51. TRANSIMPEDANCE (ROL) vs FREQUENCY FIGURE 52. PACKAGE POWER DISSIPATION AND THERMAL

RESISTANCE

JEDEC JESD51-7 HIGH EFFECTIVE THERMAL

CONDUCTIVITY (4-LAYER) TEST BOARD, QFN EXPOSE

DIEPAD SOLDERED TO PCB PER JESD51-5

4

3.5

3.125W

3

Q

F

N1

4

6

0

°

C/

W

85

1500 25 50 75 100 125

POWER DISSIPATION (W)

2.5

2

1.5

1

0.5

0

AMBIENT TEMPERATURE (°C)

FIGURE 53. PACKAGE POWER DISSIPATION vs AMBIENT

TEMPERATURE

13

FN7016.2

April 10, 2007

Page 14

www.BDTIC.com/Intersil

EL1511

Applications Information

Product Description

The EL1511 is a dual operational amplifier designed for

customer premise driver functions in DMT ADSL solutions

and is built using Elantec's proprietary complimentary bipolar

process. Due to the current feedback architecture, the

EL1511 closed-loop 3dB bandwidth is dependent on the

value of the feedback resistor. First the desired bandwidth is

selected by choosing the feedback resistor, R

gain is set by picking the gain resistor, R

beginning of the Typical Performance Curves section show

the effect of varying both R

and RG.

F

Power Supply Bypassing and Printed Circuit

Board Layout

As with any high frequency device, good printed circuit

board layout is necessary for optimum performance. Ground

plane construction is highly recommended. Lead lengths

should be as short as possible, below ¼. The power supply

pins must be well bypassed to reduce the risk of oscillation.

A 1.0µF tantalum capacitor in parallel with a 0.01µF ceramic

capacitor is adequate for each supply pin.

For good AC performance, parasitic capacitances should be

kept to a minimum, especially at the inverting input (see

Capacitance at the Inverting Input section). This implies

keeping the ground plane away from this pin. Carbon resistors

are acceptable, while use of wire-wound resistors should not

be used because of their parasitic inductance. Similarly,

capacitors should be low induct a nce fo r be st perfor mance .

Use of sockets, particularly for the SO (0.150") package,

should be avoided. Sockets add parasitic inductance and

capacitance which will result in peaking and overshoot.

, and then the

F

. The curves at the

G

Power Dissipation

The EL1511 amplifier combines both high speed and large

output current drive capability at a moderate supply current

in very small packages. It is possible to exceed the

maximum junction temperature allowed under certain supply

voltage, temperature, and loading conditions. To ensure that

the EL1511 remains within its absolute maximum ratings, the

following discussion will help to avoid exceeding the

maximum junction temperature.

The maximum power dissipation allowed in a package is

determined by its thermal resistance and the amount of

temperature rise according to:

T

–

JMAXTAMAX

P

DMAX

The maximum power dissipation actually produced by an IC

is the total quiescent supply current times the total power

supply voltage plus the power in the IC due to the load, or:

P

DMAX

where I

quiescent supply current flowing in the output driver transistor

should be subtracted from the first term because, under

loading and due to the class AB nature of the output stage,

the output driver current is now included in the second term.)

In general, an amplifier's AC performance degrades at

higher operating temperature and lower supply current.

Unlike some amplifiers, the EL1511 maintains almost

constant supply current over temperature so that AC

performance is not degraded as much over the entire

operating temperature range.

---------------------------------------------

=

S

θ

JA

V

OUT

2VSVSV

–()

OUT

--------------- -

×+×=

R

L

is the supply current. (To be more accurate, the

Capacitance at the Inverting Input

Due to the topology of the current feedback amplifier, stray

capacitance at the inverting input will affect the AC and

transient performance of the EL1511 when operating in the

non-inverting configuration.

In the inverting gain mode, added capacitance at the inverti ng

input has little effect since this point is at a virtual ground and

stray capacitance is therefore not “seen” by the amplifier.

Feedback Resistor Values

The EL1511 has been designed and specified with RF =

1.5kΩ for A

relatively flat frequency response with <1.5dB peaking out to

60MHz. As is the case with all current feedback amplifiers,

wider bandwidth, at the expense of slight peaking, can be

obtained by reducing the value of the feedback resistor.

Inversely, larger values of feedback resistor will cause rolloff

to occur at a lower frequency. By reducing R

bandwidth can be extended to 70MHz with 3.0dB of peaking.

See the curves in the Typical Performance Curves section

which show 3dB bandwidth and peaking vs frequency for

various feedback resistors.

= +5. This value of feedback resistor yields

V

to 1kΩ,

F

14

Estimating Line Driver Power Dissipation in ADSL

CPE Application

The below figure shows a typical ADSL CPE line driver

implementation. The average line power requirement for the

ADSL CPE application is 13dBM (20mW) into a 100W line.

The average line voltage is 1.41V

to average ratio (crest factor) of 5.3 implies peak voltage of

7.5V into the line. Using a differential drive configuration and

transformer coupling with standard back termination, a

transformer ratio of 1:2 is selected. With 1:2 transformer

ratio, the impedance across the driver side of the

transformer is 25Ω, the average voltage is 0.705V

the average current is 28.2mA. The power dissipated in the

EL1511 is a combination of the quiescent power and the

output stage power when driving the line:

DP

quiescentPoutput-stage

DVSIQVS( 2V

+=

OUT-RMS

In the ½ power mode, the EL1511 consumes typically 6.6mA

quiescent current and still able to maintain very low

distortion. The distortion results are shown in typical

. The ADSL DMT peak

RMS

) I

××–+×=

OUT-RMS

and

RMA

FN7016.2

April 10, 2007

Page 15

www.BDTIC.com/Intersil

performance section of the data sheet. When driving a load,

a large portion (about 50%) of the quiescent current

becomes output load current:

PD 12 6.6mA( 50%) 12V( 2 0.705) 28.2mA××–+××=

where:

PD = 338mW

Assuming a maximum ambient temperature of 85°C and

keeping the junction temperature less than 150°C, the

maximum thermal resistance from junction to ambient

required is:

150 85–

----------------------

Θ

JA

338mW

192° C/W==

With proper layout, the EL1511CS package can achieve

47°C/W, well below the thermal resistance required by the

application.

EL1511

TOP (16 Ld QFN)

From

AFE

TX+

T

V

S

+

-

VS-

R

F

464

1.5k

G

V

S

+

-

V

S

R

F

1.5k

2R

-

X

R

+

+

-

12.5

R

12.5

T

TXFR

1:2

100

T

PCB Layout Considerations for Thermal Packages

The EL1511 die is packaged in two different thermal efficient

packages, the 16 Ld SO and 16 Ld QFN packages. The 16

Ld SO package has the same dimensions as standard 0.15"

wide narrow body 16 Ld SO package with a special fused

lead frame that extends out through the center ground pins.

Both packages can use PCB surface metal vias areas and

internal ground planes, to spread heat away from the

package. The larger the PCB area the lower the junction

temperature of the device will be. In XDSL applications,

multiple layer circuit boards with internal ground plane are

generally used. 13 mil vias are recommended to connect the

metal area under the device with the internal ground plane.

Examples of the PCB layouts are shown in the figures below

that result in thermal resistance θ

package and 47°C/W for the SO package. The thermal

resistance is obtained with the EL1511CL and CS demo

boards. The demo board is a 4-layer board built with 2oz.

copper and has a dimension of 4in

follow the thermal layout guideline to achieve these results.

of 37°C/W for the QFN

JA

2.

Note, the user must

INTERNAL GROUND PLANE (16 Ld QFN)

TOP (16 Ld SO)

INTERNAL GROUND PLANE (16 Ld SO)

A separate Application Note for the QFN package and layout

recommendations is also available.

15

FN7016.2

April 10, 2007

Page 16

www.BDTIC.com/Intersil

EL1511

QFN (Quad Flat No-Lead) Package Family

A

1

2

3

2X

0.075 C

L

(E2)

C

SEATING

PLANE

0.08 C

N LEADS

& EXPOSED PAD

A

C

N

(N-2)

(N-1)

PIN #1

I.D. MARK

TOP VIEW

0.10 BAMC

b

N LEADS

(N/2)

BOTTOM VIEW

e

SIDE VIEW

(c)

A1

DETAIL X

D

(N/2)

(N-2)

(N-1)

N

(D2)

0.10

SEE DETAIL "X"

2

(L)

N LEADS

0.075

PIN #1 I.D.

1

2

3

NE

7

C

2X

B

E

C

3

5

MDP0046

QFN (QUAD FLAT NO-LEAD) PACKAGE FAMILY

(COMPLIANT TO JEDEC MO-220)

MILLIMETERS

SYMBOL

A 0.90 0.90 0.90 0.90 ±0.10 -

A1 0.02 0.02 0.02 0.02 +0.03/-0.02 -

b 0.25 0.25 0.23 0.22 ±0.02 c 0.20 0.20 0.20 0.20 Reference D 7.00 5.00 8.00 5.00 Basic -

D2 5.10 3.80 5.80 3.60/2.48 Reference 8

E 7.00 7.00 8.00 6.00 Basic -

E2 5.10 5.80 5.80 4.60/3.40 Reference 8

e 0.50 0.50 0.80 0.50 Basic L 0.55 0.40 0.53 0.50 ±0.05 -

N 44 38 32 32 Reference 4

ND 11 7 8 7 Reference 6

NE 11 12 8 9 Reference 5

MILLIMETERS

SYMBOL

A 0.90 0.90 0.90 0.90 0.90 ±0.10 -

A1 0.02 0.02 0.02 0.02 0.02 +0.03/

b 0.25 0.25 0.30 0.25 0.33 ±0.02 -

c 0.20 0.20 0.20 0.20 0.20 Reference -

D 4.00 4.00 5.00 4.00 4.00 Basic D2 2.65 2.80 3.70 2.70 2.40 Reference -

E 5.00 5.00 5.00 4.00 4.00 Basic -

E2 3.65 3.80 3.70 2.70 2.40 Reference -

e 0.50 0.50 0.65 0.50 0.65 Basic -

L 0.40 0.40 0.40 0.40 0.60 ±0.05 -

N 28 24 20 20 16 Reference 4

ND 6 5 5 5 4 Reference 6

NE 8 7 5 5 4 Reference 5

NOTES:

1. Dimensioning and tolerancing per ASME Y14.5M-1994.

2. Tiebar view shown is a non-functional feature.

3. Bottom-side pin #1 I.D. is a diepad chamfer as shown.

4. N is the total number of terminals on the device.

5. NE is the number of terminals on the “E” side of the package

(or Y-direction).

6. ND is the number of terminals on the “D” side of the package

(or X-direction). ND = (N/2)-NE.

7. Inward end of terminal may be square or circular in shape with radius

(b/2) as shown.

8. If two values are listed, multiple exposed pad options are available.

Refer to device-specific datasheet.

TOLERANCE NOTESQFN44 QFN38 QFN32

TOLER-

ANCE NOTESQFN28 QFN24 QFN20 QFN16

-0.02

Rev 11 2/07

-

16

FN7016.2

April 10, 2007

Page 17

www.BDTIC.com/Intersil

Small Outline Package Family (SO)

A

D

NN

(N/2)+1

EL1511

h X 45°

PIN #1

E

C

SEATING

PLANE

0.004 C

E1

B

0.010 BM CA

I.D. MARK

1

e

0.010 BM CA

(N/2)

c

SEE DETAIL “X”

L1

H

A2

GAUGE

PLANE

A1

b

DETAIL X

L

4° ±4°

MDP0027

SMALL OUTLINE PACKAGE FAMILY (SO)

INCHES

SO16

SYMBOL

A 0.068 0.068 0.068 0.104 0.104 0.104 0.104 MAX -

A1 0.006 0.006 0.006 0.007 0.007 0.007 0.007 ±0.003 A2 0.057 0.057 0.057 0.092 0.092 0.092 0.092 ±0.002 -

b 0.017 0.017 0.017 0.017 0.017 0.017 0.017 ±0.003 -

c 0.009 0.009 0.009 0.011 0.011 0.011 0.011 ±0.001 D 0.193 0.341 0.390 0.406 0.504 0.606 0.704 ±0.004 1, 3

E 0.236 0.236 0.236 0.406 0.406 0.406 0.406 ±0.008 -

E1 0.154 0.154 0.154 0.295 0.295 0.295 0.295 ±0.004 2, 3

e 0.050 0.050 0.050 0.050 0.050 0.050 0.050 Basic L 0.025 0.025 0.025 0.030 0.030 0.030 0.030 ±0.009 -

L1 0.041 0.041 0.041 0.056 0.056 0.056 0.056 Basic -

h 0.013 0.013 0.013 0.020 0.020 0.020 0.020 Reference -

N 8 14 16 16 20 24 28 Reference -

NOTES:

1. Plastic or metal protrusions of 0.006” maximum per side are not included.

2. Plastic interlead protrusions of 0.010” maximum per side are not included.

3. Dimensions “D” and “E1” are measured at Datum Plane “H”.

4. Dimensioning and tolerancing per ASME Y14.5M-1994

(0.150”)

SO16 (0.300”)

(SOL-16)

SO20

(SOL-20)

SO24

(SOL-24)

SO28

(SOL-28)

TOLERANCE NOTESSO-8 SO-14

A

0.010

Rev. M 2/07

17

FN7016.2

April 10, 2007

Page 18

www.BDTIC.com/Intersil

EL1511

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implic atio n or other wise u nde r any p a tent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

18

FN7016.2

April 10, 2007

Loading...

Loading...