®

www.BDTIC.com/Intersil

EL1508

Data Sheet March 26, 2007

Differential DSL Line Driver

The EL1508 is designed for driving full rate ADSL signals in

both CO and CPE applications at very low power dissipation.

The high drive capability of 450mA makes this driver ideal

for both CAP and DMT designs. It contains two wideband,

high-voltage, current mode feedback amplifiers with a

number of power dissipation reduction features.

These drivers achieve an MTPR distortion measurement of

better than 70dB, while consuming typically 6mA of total

supply current. This supply current can be set using a

resistor on the I

also be used to adjust supply current to one of four pre-set

modes (full-I

EL1508 operates on ±5V to ±12V supplies and retains its

bandwidth and linearity over the complete supply range.

The device is supplied in a thermally-enhanced 20 Ld SOIC

(0.300”), a thermally-enhanced 16 Ld SOIC (0.150”), and the

small footprint (4x5mm) 24 Ld QFN packages. The EL1508

is specified for operation over the full -40°C to +85°C

temperature range.

pin. Two other pins (C0 and C1) can

ADJ

, 2/3-IS, 1/3-IS, and full power-down). The

S

FN7014.5

Features

• 450mA output drive capability

•43.6V

nd/3rd

•2

differential output drive into 100Ω

P-P

harmonics of -85dBc/-75dBc

• MTPR of -70dB

• Operates down to 3mA per amplifier supply current

• Power control features

• Pin-compatible with EL1503

• Pb-free plus anneal available (RoHS compliant)

Applications

• ADSL line driver

• HDSL line driver

• Video distribution amplifier

• Video twisted-pair line driver

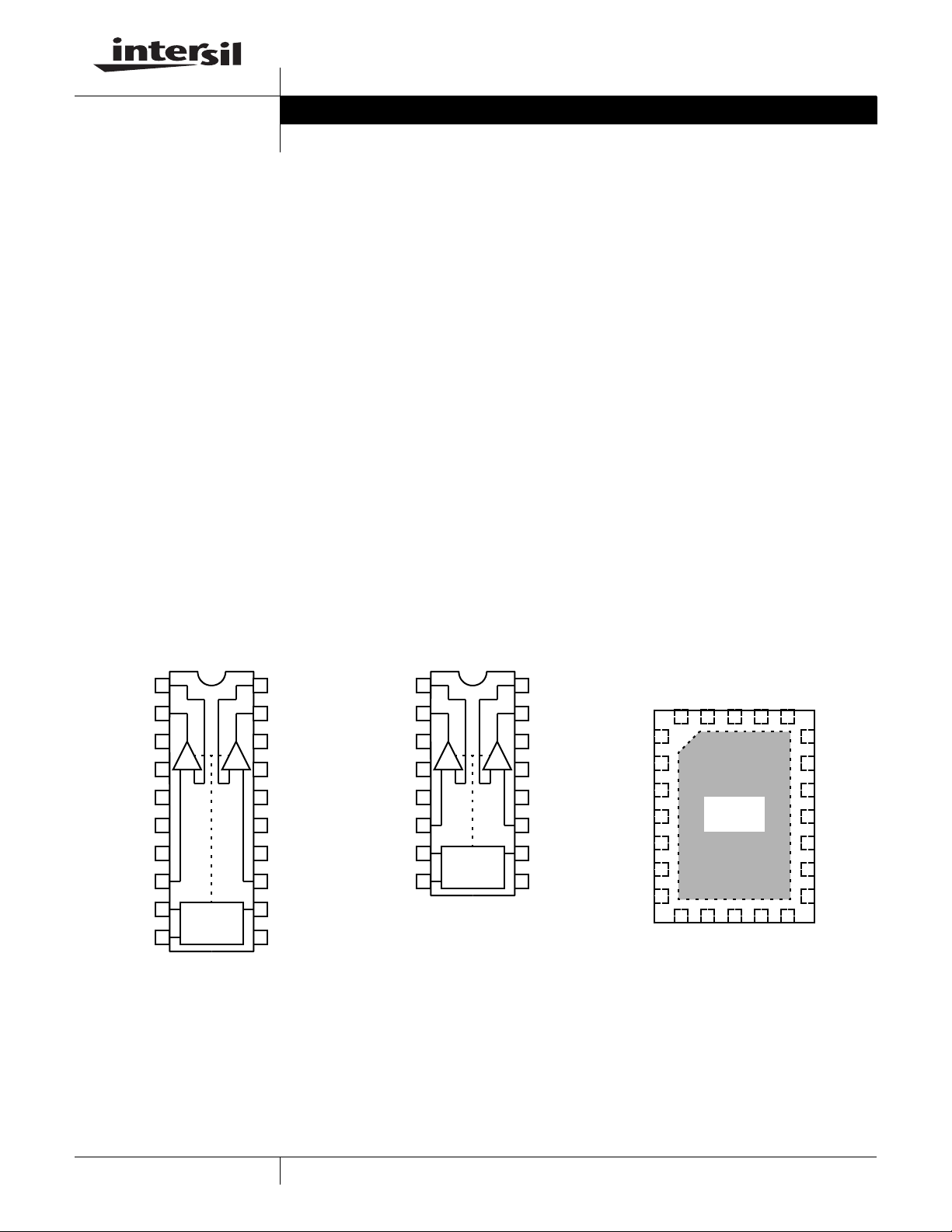

Pinouts

VIN-A

VOUTA

GND*

GND*

GND*

GND*

VIN+A

EL1508

[20 LD SOIC (0.300”)]

TOP VIEW

1

2

3

VS-

C1

C0

4

5

6

7

8

9

10

AB

POWER

CONTROL

LOGIC

EL1508

[16 LD SOIC (0.150”)]

TOP VIEW

VIN-B

20

VOUTB

19

VS+

18

-+ -+

GND*

17

GND*

16

GND*

15

GND*

14

VIN+B

13

IADJ

12

NC

11

*GND PINS ARE HEAT SPREADERS

1

VIN-A

VOUTA

2

VS-

3

GND*

4

GND*

5

VIN+A

6

C1

7

C0

8 9

POWER

CONTROL

LOGIC

VIN-B

16

VOUTB

15

NC

NC

VS-

NC

NC

NC

GND

1

2

3

4

5

6

7

VS+

14

-+ -+

GND*

13

GND*

12

VIN+B

11

IADJ

10

NC

EL1508

(24 LD QFN)

TOP VIEW

VOUTA

VIN-A

24

23

THERMAL

PAD

8

9

C1

VIN+A

NC

22

10

C0

VIN-B

21

11

IADJ

VOUTB

20

19

18

17

16

15

14

13

12

VIN+B

NC

NC

VS+

NC

NC

NC

GND

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright Intersil Americas Inc. 2001-2005, 2007. All Rights Reserved

All other trademarks mentioned are the property of their respective owners.

EL1508

www.BDTIC.com/Intersil

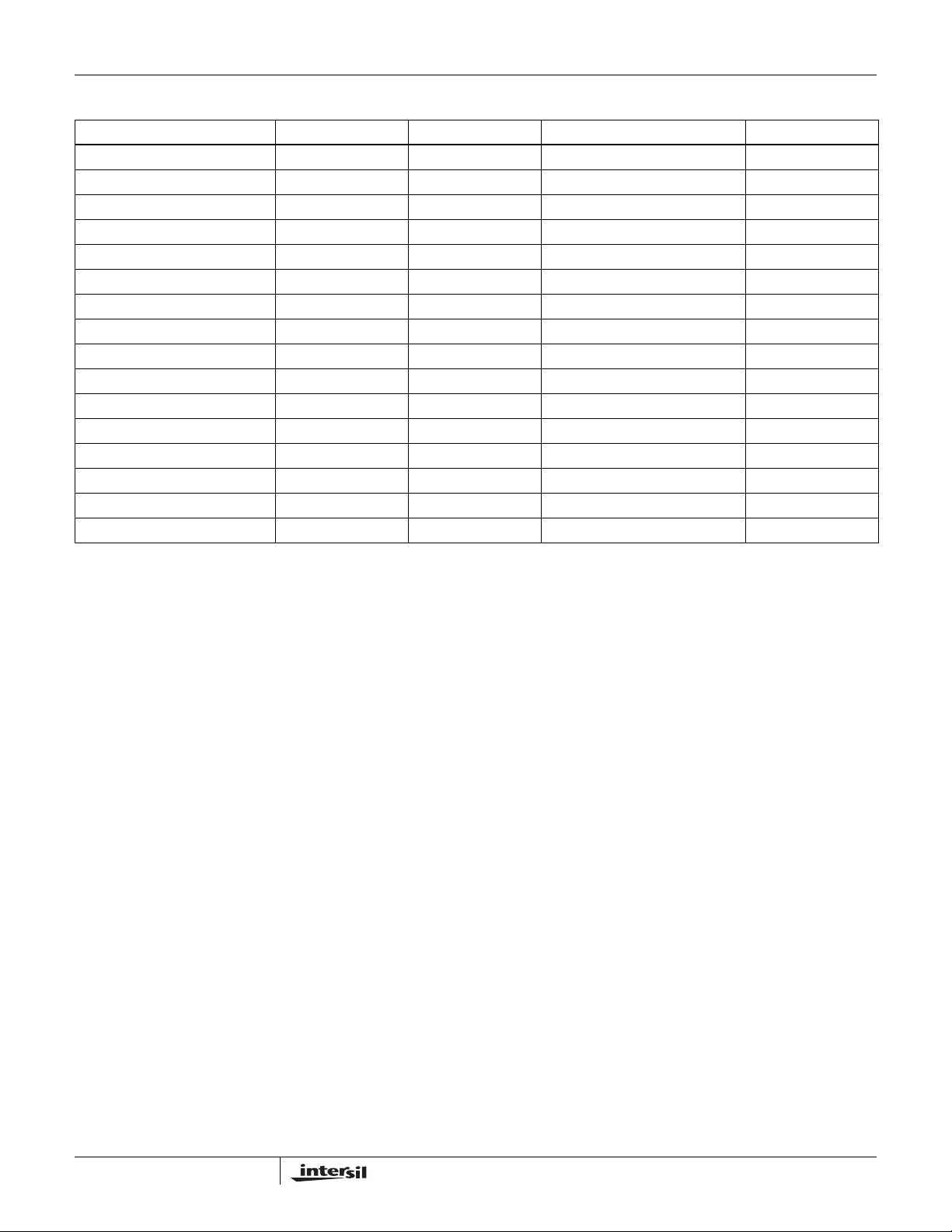

Ordering Information

PART NUMBER PART MARKING TAPE & REEL PACKAGE PKG. DWG. #

EL1508CS EL1508CS - 16 Ld SOIC (0.150”) MDP0027

EL1508CS-T7 EL1508CS 7” 16 Ld SOIC (0.150”) MDP0027

EL1508CS-T13 EL1508CS 13” 16 Ld SOIC (0.150”) MDP0027

EL1508CSZ (See Note) EL1508CSZ - 16 Ld SOIC (0.150”) (Pb-Free) MDP0027

EL1508CSZ-T7 (See Note) EL1508CSZ 7” 16 Ld SOIC (0.150”) (Pb-Free) MDP0027

EL1508CSZ-T13 (See Note) EL1508CSZ 13” 16 Ld SOIC (0.150”) (Pb-Free) MDP0027

EL1508CM EL1508CM - 20 Ld SOIC (0.300”) MDP0027

EL1508CM-T13 EL1508CM 13” 20 Ld SOIC (0.300”) MDP0027

EL1508CMZ (See Note) EL1508CMZ - 20 Ld SOIC (0.300”) (Pb-Free) MDP0027

EL1508CMZ-T13 (See Note) EL1508CMZ 13” 20 Ld SOIC (0.300”) (Pb-Free) MDP0027

EL1508CL 1508CL - 24 Ld QFN MDP0046

EL1508CL-T7 1508CL 7” 24 Ld QFN MDP0046

EL1508CL-T13 1508CL 13” 24 Ld QFN MDP0046

EL1508CLZ (See Note) 1508CLZ - 24 Ld QFN (Pb-Free) MDP0046

EL1508CLZ-T7 (See Note) 1508CLZ 7” 24 Ld QFN (Pb-Free) MDP0046

EL1508CLZ-T13 (See Note) 1508CLZ 13” 24 Ld QFN (Pb-Free) MDP0046

NOTE: Intersil Pb-free plus anneal products employ special Pb-free material sets; molding compounds/die attach materials and 100% matte tin plate

termination finish, which are RoHS compliant and compatible with both SnPb and Pb-free soldering operations. Intersil Pb-free products are MSL

classified at Pb-free peak reflow temperatures that meet or exceed the Pb-free requirements of IPC/JEDEC J STD-020.

2

FN7014.5

March 26, 2007

EL1508

www.BDTIC.com/Intersil

Absolute Maximum Ratings (T

V

+ to VS- Supply Voltage. . . . . . . . . . . . . . . . . . . . . . .-0.3V to 28V

S

+ Voltage to Ground . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to 28V

V

S

V

- Voltage to Ground. . . . . . . . . . . . . . . . . . . . . . . . . . -28V to 0.3V

S

Driver V

C

0

I

ADJ

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied .

IMPORT ANT NOTE: A ll p arameters having Min/Max specificati ons are gua ranteed. Typ values are for information purposes only. Unless otherwise note d, all test s are at

the specified temperature and are pulsed tests, therefore: T

+ Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VS- to VS+

IN

, C1 Voltage to GND . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to 6V

Voltage to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to 4V

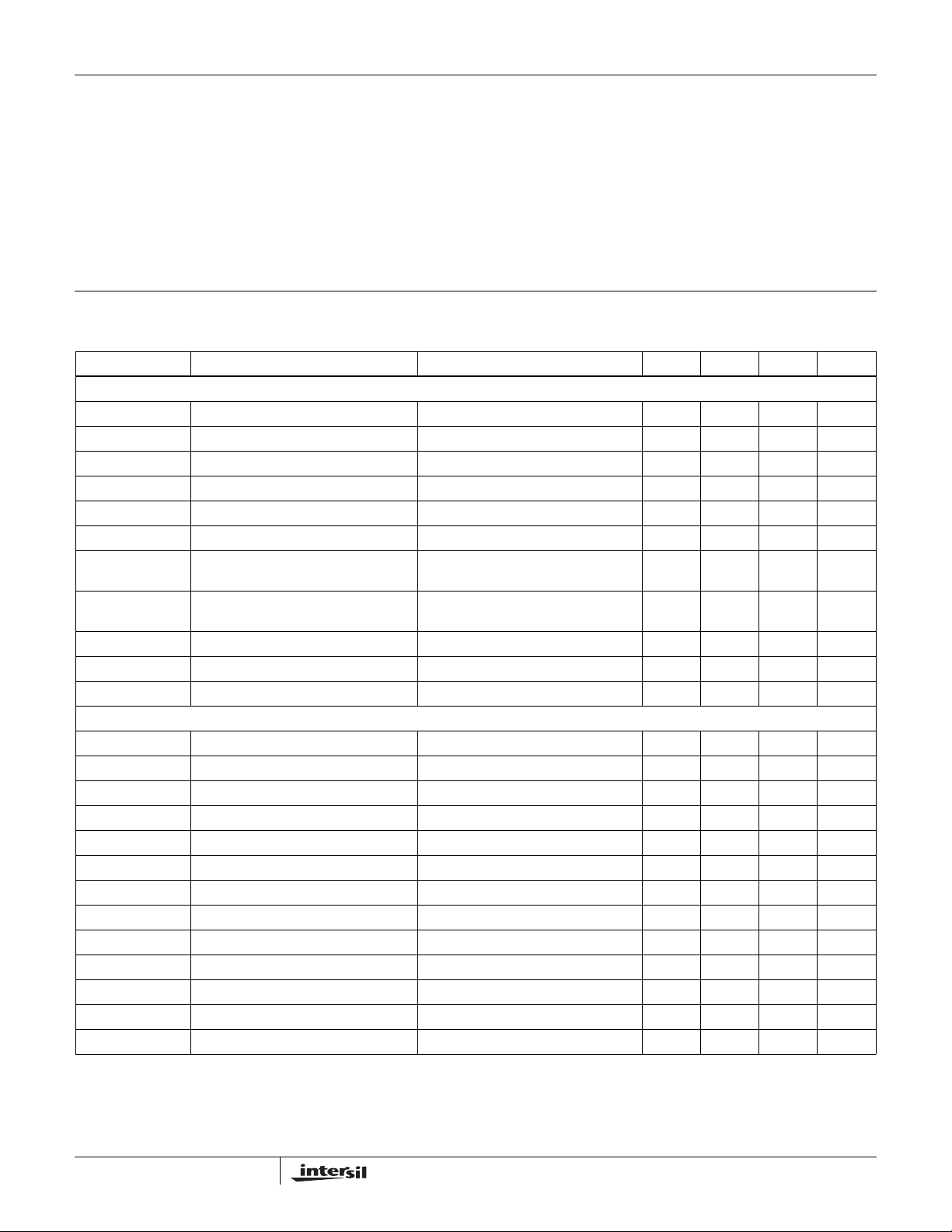

Electrical Specifications V

= 25°C)

A

= TC = T

J

= ±12V, RF = 2.2kΩ, RL= 65Ω, I

S

A

Current into any Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8mA

Output Current from Driver (Static) . . . . . . . . . . . . . . . . . . . . 100mA

Operating Temperature Range . . . . . . . . . . . . . . . . .-40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . . . . . . .-60°C to +150°C

Operating Junction Temperature . . . . . . . . . . . . . . .-40°C to +150°C

Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Curves

= C0 = C1 = 0V, TA = 25°C. Amplifiers tested separately.

ADJL

PARAMETER DESCRIPTION CONDITIONS MIN TYP MAX UNIT

SUPPLY CHARACTERISTICS

+ (Full IS) Positive Supply Current per Amplifier All outputs at 0V, C0 = C1 = 0V 10 14.5 18 mA

I

S

- (Full IS) Negative Supply Current per Amplifier All outputs at 0V, C0 = C1 = 0V -9.5 -13.5 -17.5 mA

I

S

IS+ (2/3 IS) Positive Supply Current per Amplifier All outputs at 0V, C0 = 5V, C1 = 0V 7 10 12.5 mA

- (2/3 IS) Negative Supply Current per Amplifier All outputs at 0V, C0 = 5V, C1 = 0V -6 -9 -12 mA

I

S

+ (1/3 IS) Positive Supply Current per Amplifier All outputs at 0V, C0 = 0V, C1 = 5V 3.75 5.25 7 mA

I

S

- (1/3 IS) Negative Supply Current per Amplifier All outputs at 0V, C0 = 0V, C1 = 5V -2.75 -4.25 -6 mA

I

S

IS+ (6.8k) Positive Supply Current per Amplifier All outputs at 0V, C0 = C1 = 0V,

= 6.8k

R

ADJ

I

- (6.8k) Negative Supply Current per Amplifier All outputs at 0V, C0 = C1 = 0V,

S

+ (Power-down) Positive Supply Current per Amplifier All outputs at 0V, C0 = C1 = 5V 0.75 1.2 2 mA

I

S

- (Power-down) Negative Supply Current per Amplifier All outputs at 0V, C0 = C1 = 5V 0 -0.25 -2 mA

I

S

I

GND

GND Supply Current per Amplifier All outputs at 0V 1 mA

R

= 6.8k

ADJ

33.754.5mA

-3.75 -2.9 -2.25 mA

INPUT CHARACTERISTICS

V

OS

ΔV

OS

+ Non-Inverting Input Bias Current -15 15 µA

I

B

- Inverting Input Bias Current -50 50 µA

I

B

ΔIB-I

R

OL

e

N

i

N

V

IH

V

IL

I

IH1

I

IH0

I

IL

Input Offset Voltage -10 1 10 mV

VOS Mismatch -5 0 5 mV

- Mismatch -25 0 25 µA

B

Transimpedance 1.1 2.9 5 MΩ

Input Noise Voltage 3.5 nV/√Hz

-Input Noise Current 13 pA/√Hz

Input High Voltage C0 and C1 inputs 2.25 V

Input Low Voltage C0 and C1 inputs 0.8 V

Input High Current for C

Input High Current for C

1

0

Input Low Current for C0 or C

1

C1 = 5V 126µA

C0 = 5V 0.5 1 3 µA

C0 = 0V, C1 = 0V -1 1 µA

3

FN7014.5

March 26, 2007

EL1508

www.BDTIC.com/Intersil

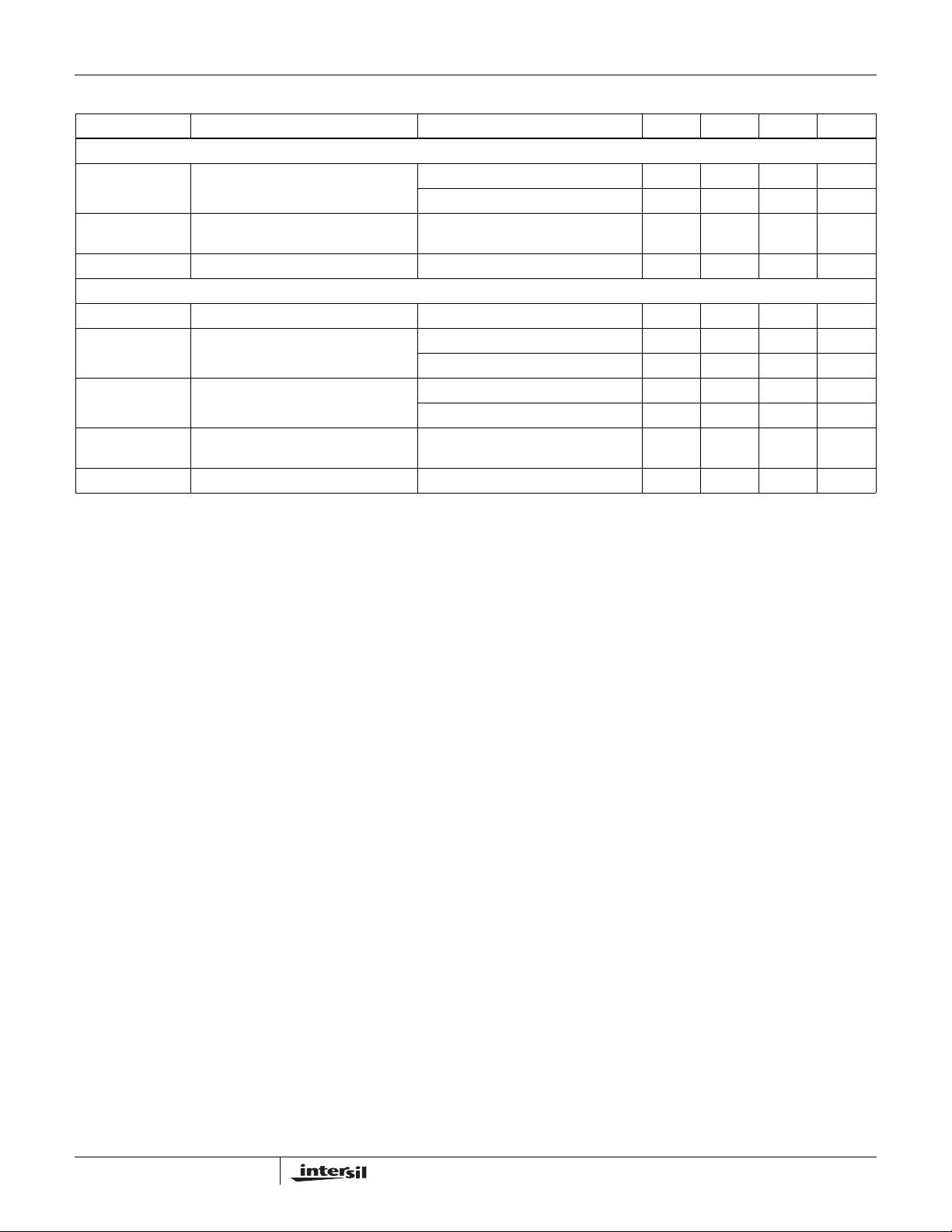

Electrical Specifications V

PARAMETER DESCRIPTION CONDITIONS MIN TYP MAX UNIT

OUTPUT CHARACTERISTICS

V

OUT

I

OL

I

OUT

DYNAMIC PERFORMANCE

BW -3 dB Bandwidth A

HD2 2nd Harmonic Distortion f

HD3 3rd Harmonic Distortion f

MTPR Multi-Tone Power Ratio 26kHz to 1.1MHz, R

SR Slewrate V

Loaded Output Swing RL = 100Ω ±10.6 ±10.8 ±11.5 V

Linear Output Current AV = 5, RL = 10Ω, f = 100kHz,

Output Current V

= ±12V, RF = 2.2kΩ, RL= 65Ω, I

S

R

L

THD = -60dBc

OUT

V

= 1MHz, RL = 100Ω, V

C

fC = 1MHz, RL = 25Ω, V

= 1MHz, RL = 100Ω, V

C

= 1MHz, RL = 25Ω, V

f

C

P

LINE

OUT

= C0 = C1 = 0V, TA = 25°C. Amplifiers tested separately. (Continued)

ADJL

= 25Ω ±9.8 ±10.2 ±10.6 V

450 mA

= 1V, RL = 1Ω 1A

= +5 80 MHz

= 2V

OUT

OUT

OUT

OUT

= 100Ω,

= 20.4dBM

from -8V to +8V measured at ±4V 450 600 800 V/µs

LINE

= 2V

= 2V

= 2V

P-P

P-P

P-P

P-P

-90 dBc

-80 dBc

-90 dBc

-75 dBc

-70 dBc

4

FN7014.5

March 26, 2007

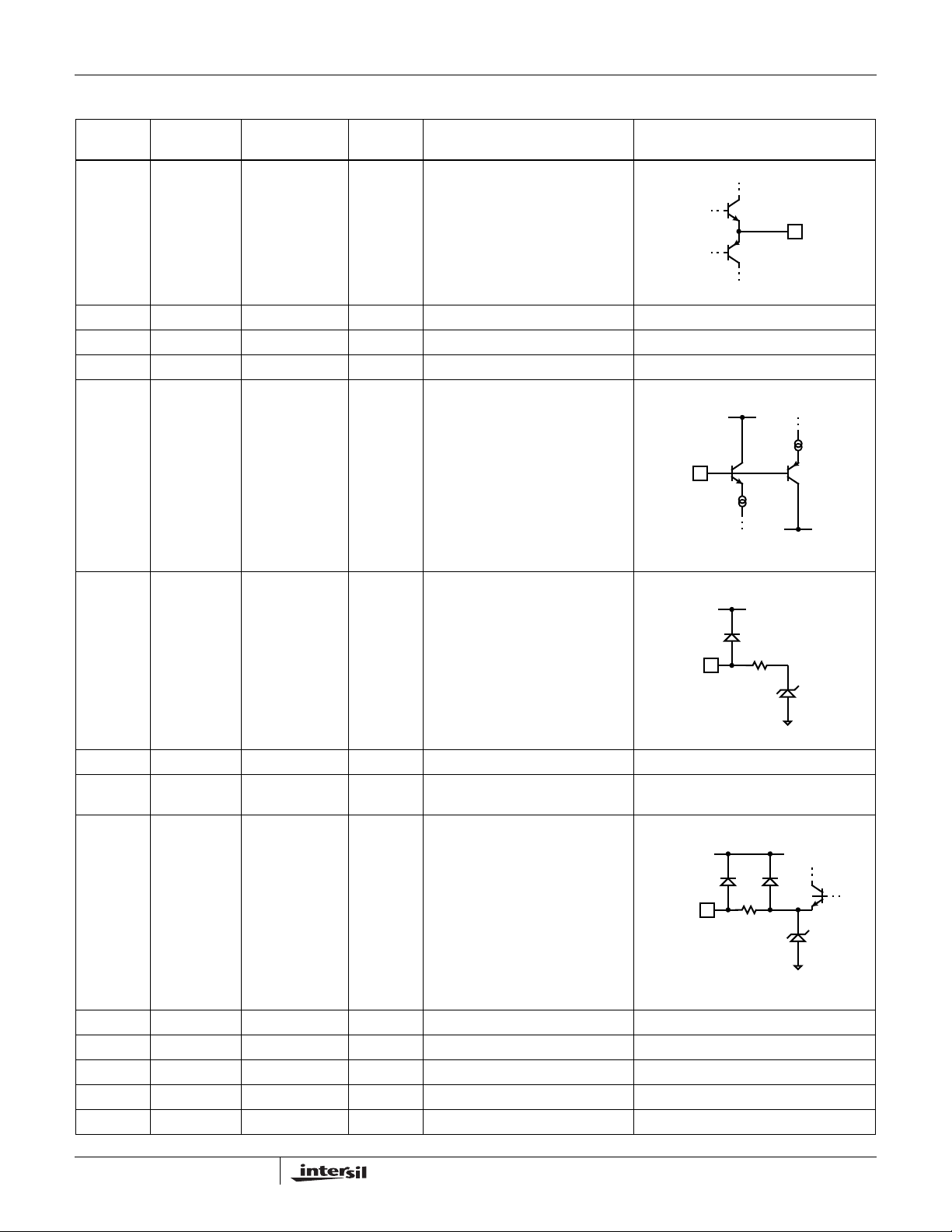

Pin Descriptions

www.BDTIC.com/Intersil

EL1508

16 Ld SOIC

(0.150")

1 1 23 VIN-A Channel A Inverting Input

2 2 24 VOUTA Channel A Output (Reference Circuit 1)

3 3 3 VS- Negative Supply

4, 5 4, 5, 6, 7 7 GND Ground Connection

6 8 8 VIN+A Channel A Non-inverting Input

7 9 9 C1 Current Control Bit 1

20 Ld SOIC

(0.300") 24 Ld QFN PIN NAME FUNCTION CIRCUIT

CIRCUIT 1

VS+

VS-

CIRCUIT 2

VS+

8 10 10 C0 Current Control Bit 2 (Reference Circuit 3)

9 11 1, 2, 4, 5, 6, 14,

15, 16, 18, 19, 22

10 12 11 IADJ Supply Current Control Pin

11 13 12 VIN+B Channel B Non-inverting Input (Reference Circuit 2)

12, 13 14, 15, 16, 17 13 GND Ground Connection

14 18 17 VS+ Positive Supply

15 19 20 VOUTB Channel B Output (Reference Circuit 1)

16 20 21 VIN-B Channel B Inverting Input (Reference Circuit 1)

NC Not Connected

I

ADJ

6.7V

CIRCUIT 3

VS+

GND

CIRCUIT 4

5

FN7014.5

March 26, 2007

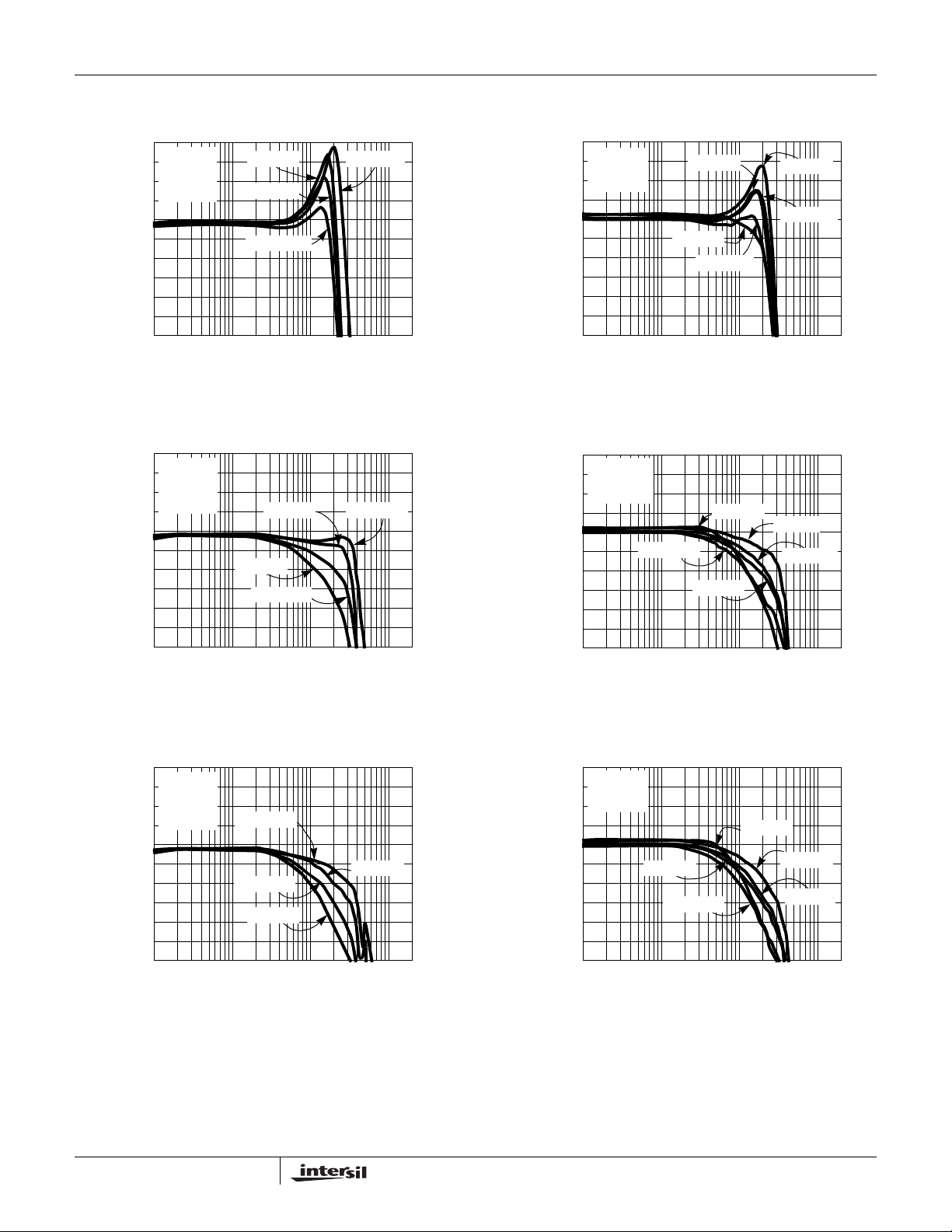

Typical Performance Curves

www.BDTIC.com/Intersil

EL1508

24

AV=10

V

=±12V

S

=100Ω

R

22

L

R

=0Ω

ADJ

20

18

GAIN (dB)

16

14

100K 1M 10M 100M

RF=2kΩ

RF=2.5kΩ

RF=3kΩ

FREQUENCY (Hz)

RF=1.5kΩ

FIGURE 1. DIFFERENTIAL FREQUENCY RESPONSE vs R

(1/3 POWER MODE)

24

AV=10

=±12V

V

S

R

=100Ω

22

L

=0Ω

R

ADJ

20

18

GAIN (dB)

16

RF=3kΩ

RF=2.5kΩ

RF=1.5kΩRF=2kΩ

18

AV=5

V

=±12V

S

=100Ω

R

16

L

14

12

GAIN (dB)

10

8

100K 1M 10M 100M

F

FIGURE 2. DIFFERENTIAL FREQUENCY RESPONSE

(1/3 POWER MODE)

18

AV=5

V

=±12V

S

=100Ω

R

16

L

14

RF=3.5kΩ

12

GAIN (dB)

10

RF=3kΩ

RF=4kΩ

RF=3.5kΩ

FREQUENCY (Hz)

RF=4kΩ

RF=3kΩ

RF=2kΩ

RF=2.5kΩ

RF=2kΩ

RF=2.5kΩ

14

100K 1M 10M 100M

FREQUENCY (Hz)

FIGURE 3. DIFFERENTIAL FREQUENCY RESPONSE vs R

(2/3 POWER MODE)

24

AV=10

V

=±12V

S

=100Ω

R

22

L

R

=0Ω

ADJ

20

18

GAIN (dB)

16

14

100K 1M 10M 100M

RF=1.5kΩ

RF=2kΩ

RF=2.5kΩ

RF=3kΩ

FREQUENCY (Hz)

FIGURE 5. DIFFERENTIAL FREQUENCY RESPONSE vs R

(FULL POWER MODE)

8

100K 1M 10M 100M

FREQUENCY (Hz)

F

FIGURE 4. DIFFERENTIAL FREQUENCY RESPONSE

(2/3 POWER MODE)

18

AV=5

=±12V

V

S

R

=100Ω

16

L

RF=4kΩ

14

12

GAIN (dB)

10

8

100K 1M 10M 100M

F

FIGURE 6. DIFFERENTIAL FREQUENCY RESPONSE

RF=3kΩ

RF=3.5kΩ

FREQUENCY (Hz)

RF=2kΩ

RF=2.5kΩ

(FULL POWER MODE)

6

FN7014.5

March 26, 2007

Typical Performance Curves (Continued)

www.BDTIC.com/Intersil

EL1508

26

VS=±12V

R

=3kΩ

FB

=5

A

V

22

=83Ω

R

L

R

=0Ω

SET

18

14

MAGNITUDE (dB)

10

6

10K 100K 10M 100M

FREQUENCY (Hz)

100pF

68pF

50pF

22pF

0pF

1M

FIGURE 7. EL1508CM SINGLE-ENDED CONFIGURATION

FREQUENCY RESPONSE vs C

L

(1/3 POWER MODE)

26

VS=±12V

=3kΩ

R

FB

A

=5

22

V

=83Ω

R

L

=0Ω

R

SET

18

14

MAGNITUDE (dB)

10

6

10K 100K 10M 100M

FREQUENCY (Hz)

150pF

100pF

62pF

39pF

22pF

5pF

1M

26

VS=±12V

R

=3kΩ

FB

=5

A

22

V

=83Ω

R

L

R

=0Ω

SET

18

14

MAGNITUDE (dB)

10

6

10K 100K 10M 100M

FREQUENCY (Hz)

150pF

100pF

62pF

39pF

22pF

0pF

1M

FIGURE 8. EL1508CM SINGLE-ENDED CONFIGURATION

FREQUENCY RESPONSE vs C

L

(1/3 POWER MODE)

6

5

4

3

2

PEAKING (dB)

1

0

5678910

TOTAL I

(mA)

S

VS=±12V

R

=3kΩ

FB

=10

A

V

=100Ω

R

L

FIGURE 9. EL1508CM SINGLE-ENDED CONFIGURATION

FREQUENCY RESPONSE vs C

6

VS=±12V

=3kΩ

R

FB

5

=10

A

V

R

=100Ω

L

4

3

2

PEAKING (dB)

1

0

0246810

R

(kΩ)

ADJ

FIGURE 11. PEAKING vs R

L

ADJ

7

FIGURE 10. PEAKING vs IS+

7

6

5

4

3

PEAKING (dB)

2

1

0

5 7 9 11 13 15

(mA)

I

SUPPLY

FIGURE 12. PEAKING vs IS+

VS=±7.5V

=3kΩ

R

FB

A

=10

V

=100Ω

R

L

FN7014.5

March 26, 2007

Typical Performance Curves (Continued)

www.BDTIC.com/Intersil

40

30

(Ω)

20

OUT

R

10

0

10K 100K 1M 100M

FREQUENCY (Hz)

FIGURE 13. OUTPUT IMPEDANCE FIGURE 14. CHANNEL SEPARATION

10M

EL1508

0

-20

-40

-60

GAIN (dB)

-80

-100

10K 100K 10M 100M

A to B

B to A

1M

FREQUENCY (Hz)

100

CURRENT NOISE

10

VOLTAGE NOISE

CURRENT NOISE (pA/√Hz)

VOLTAGE NOISE (nV/√Hz),

1

10 1K 100K

100 10K

FREQUENCY (Hz)

1.4

VS=±12V

=3kΩ

R

FB

1.2

=2

A

V

R

=0Ω

SET

1.0

0.8

0.6

0.4

0.2

DIFFERENTIAL GAIN (%), PHASE (°)

0

1.0 2.0 3.0 4.0

NUMBER of 150Ω RESISTOR LOADS

DIFF GAIN

DIFF PHASE

2.5 3.51.5

FIGURE 15. VOLTAGE AND CURRENT NOISE vs FREQUENCY FIGURE 16. DIFFERENTIAL GAIN/PHASE, F

(2/3 POWER MODE)

0.30

VS=±12V

R

=3kΩ

FB

0.25

=2

A

V

=0Ω

R

SET

0.20

0.15

0.10

0.05

DIFFERENTIAL GAIN (%), PHASE (°)

0

1.0 1.5 2.5 3.5 4.0

2.0 3.0

NUMBER of 150Ω RESISTOR LOADS

DIFF GAIN

DIFF PHASE

0.08

VS=±12V

0.07

R

=3kΩ

FB

=2

A

V

0.06

0.05

0.04

0.03

0.02

0.01

DIFFERENTIAL GAIN (%), PHASE (°)

=0Ω

R

SET

0

12345

NUMBER of 150Ω RESISTOR LOADS

DIFF PHASE

=3.58MHz

O

DIFF GAIN

FIGURE 17. DIFFERENTIAL GAIN/PHASE, F

=3.58MHz

O

FIGURE 18. DIFFERENTIAL GAIN/PHASE, FO=3.58MHz

(2/3 POWER MODE)

8

(FULL POWER MODE)

FN7014.5

March 26, 2007

EL1508

www.BDTIC.com/Intersil

Typical Performance Curves - 24 Ld QFN Package

FREQ=1MHz

-10

=±5V

V

S

R

=0

SET

=100Ω

R

L

GAIN=10

-30

-50

-70

HARMONIC DISTORTION (dB)

-90

1357

024689

V

OUTP-P

HD3

(V)

FIGURE 19. HARMONIC DISTORTION TEST

(1/3 POWER MODE)

0

FREQ=1MHz

-10

V

=±5V

S

=0

R

SET

-20

=100Ω

R

L

GAIN=10

-30

-40

-50

HD (dB)

-60

-70

-80

-90

1357

024689

V

OUTp-p

HD2

(V)

HD2

HD3

0

FREQ=1MHz

=±12V

V

S

R

-20

-40

-60

-80

HARMONIC DISTORTION (dB)

-100

=0

SET

=100Ω

R

L

GAIN=10

HD3

HD2

0 5 10 15 20 25

(V)

V

OUTP-P

FIGURE 20. HARMONIC DISTORTION TEST

(1/3 POWER MODE)

0

FREQ=1MHz

=±12V

V

S

R

-20

-40

-60

-80

HARMONIC DISTORTION (dB)

-100

=0

SET

=100Ω

R

L

GAIN=10

0 5 10 15 20 25

V

OUTP-P

HD3

HD2

(V)

FIGURE 21. HARMONIC DISTORTION TEST

(2/3 POWER MODE)

0

FREQ=1MHz

-10

=±5V

V

S

R

-20

-30

-40

-50

-60

-70

-80

HARMONIC DISTORTION (dB)

-90

-100

=0

SET

=100Ω

R

L

GAIN=10

HD2

024689

V

OUTp-p

5731

(V)

FIGURE 23. HARMONIC DISTORTION TEST

(FULL POWER MODE)

HD3

FIGURE 22. HARMONIC DISTORTION TEST

(2/3 POWER MODE)

0

FREQ=1MHz

=±12V

V

S

R

-20

-40

-60

-80

HARMONIC DISTORTION (dB)

-100

=0

SET

=100Ω

R

L

GAIN=10

0 5 10 15 20 25

V

OUTP-P

HD3

HD2

(V)

FIGURE 24. HARMONIC DISTORTION TEST

(FULL POWER MODE)

9

FN7014.5

March 26, 2007

EL1508

www.BDTIC.com/Intersil

Typical Performance Curves - 20 Ld SOIC (0.300") Package

0

FREQ=1MHz

V

=±5V

S

=0

R

SET

-20

=100Ω

R

L

GAIN=10

-40

HD3

HD2

V

OUTP-P

8

(V)

-60

HARMONIC DISTORTION (dB)

-80

01 9234567

FIGURE 25. HARMONIC DISTORTION vs DIFFERENTIAL

OUTPUT VOLTAGE (1/3 POWER MODE)

FREQ=1MHz

-10

V

=±5V

S

=0

R

SET

=100Ω

R

L

GAIN=10

-30

-50

-70

HARMONIC DISTORTION (dB)

-90

01 92 45678

HD2

3

V

OUTP-P

HD3

(V)

FREQ=1MHz

-10

V

=±12V

S

=0

R

SET

=100Ω

R

L

GAIN=10

-30

-50

-70

HARMONIC DISTORTION (dB)

-90

0 5 10 15 20 25

V

OUTP-P

HD 2

HD 3

(V)

FIGURE 26. HARMONIC DISTORTION vs DIFFERENTIAL

OUTPUT VOLTAGE (1/3 POWER MODE)

FREQ=1MHz

-10

=±12V

V

S

=0

R

SET

R

=100Ω

L

GAIN=10

-30

-50

-70

HARMONIC DISTORTION (dB)

-90

0 5 10 15 20 25

V

OUTP-P

HD 2

HD 3

(V)

FIGURE 27. HARMONIC DISTORTION vs DIFFERENTIAL

OUTPUT VOLTAGE (2/3 POWER MODE)

0

FREQ=1MHz

V

=±5V

S

=0

R

-20

SET

=100Ω

R

L

GAIN=10

-40

-60

-80

HARMONIC DISTORTION (dB)

-100

01 8234567

HD2

V

OUTP-P

HD3

(V)

FIGURE 29. HARMONIC DISTORTION vs DIFFERENTIAL

OUTPUT VOLTAGE (FULL POWER MODE)

FIGURE 28. HARMONIC DISTORTION vs DIFFERENTIAL

OUTPUT VOLTAGE (2/3 POWER MODE)

FREQ=1MHz

-10

=±12V

V

S

R

=0

SET

=100Ω

R

L

GAIN=10

-30

-50

-70

HARMONIC DISTORTION (dB)

-90

0 5 10 15 20 25

V

OUTP-P

HD 2

HD 3

(V)

FIGURE 30. HARMONIC DISTORTION vs DIFFERENTIAL

OUTPUT VOLTAGE (FULL POWER MODE)

10

FN7014.5

March 26, 2007

Typical Performance Curves

www.BDTIC.com/Intersil

EL1508

FREQ=1MHz

=±5V

V

S

-10

R

=6.81kΩ

SET

=100Ω

R

L

GAIN=10

-30

-50

HARMONIC DISTORTION (dB)

-70

HD 3

HD 2

013579

2468

V

(V)

OUTP-P

FIGURE 31. EL1508CM HARMONIC DISTORTION vs

DIFFERENTIAL OUTPUT VOLTAGE

(FULL POWER MODE)

0

FREQ=1MHz

V

=±12V

S

=6.81kΩ

R

SET

-20

=100Ω

R

L

GAIN=10

-40

-60

HARMONIC DISTORTION (dB)

-80

0 5 10 15 20 25

V

OUTP-P

HD 2

HD 3

(V)

FREQ=1MHz

-10

V

=±5V

S

=6.81kΩ

R

SET

=100Ω

R

L

GAIN=10

-30

-50

-70

HARMONIC DISTORTION (dB)

-90

1357

024689

V

OUTP-P

HD3

HD2

(V)

FIGURE 32. EL1508CL HARMONIC DISTORTION TEST

(FULL POWER MODE)

0

FREQ=1MHz

V

=±12V

S

=6.81kΩ

R

-20

SET

=100Ω

R

L

GAIN=10

-40

-60

-80

HARMONIC DISTORTION (dB)

-100

0 5 10 15 20 25

(V)

V

OUTP-P

HD3

HD2

FIGURE 33. EL1508CM HARMONIC DISTORTION vs

DIFFERENTIAL OUTPUT VOLTAGE

(FULL POWER MODE)

V

OUT

C0, C

1

40ns/DIV

2V/DIV

FIGURE 35. DISABLE TIME FIGURE 36. ENABLE TIME

11

FIGURE 34. EL1508CL HARMONIC DISTORTION TEST

(FULL POWER MODE)

V

OUT

C0, C

1

2V/DIV

40ns/DIV

March 26, 2007

FN7014.5

Typical Performance Curves (Continued)

www.BDTIC.com/Intersil

EL1508

21.6

21.4

(V)

P-P

21.2

21.0

FREQ=100kHz

=±12V

20.8

OUTPUT VOLTAGE

20.6

70 110

50 90 130 150 170 190

DIFFERENTIAL LOAD RESISTANCE (Ω)

V

S

R

=0

SET

=10

A

V

FIGURE 37. LOAD RESISTANCE vs OUTPUT VOLTAGE

(ALL POWER MODES)

30

25

20

15

10

SUPPLY CURRENT (mA)

5

0

02 681012

L

U

F

3

/

2

3

/

1

4

SUPPLY VOLTAGE (V)

R

E

W

O

P

L

R

E

W

O

P

R

E

W

O

P

+

-

+

-

+

-

25

21

17

+ (mA)

S

I

13

9

5

0246810

(kΩ)

R

ADJ

FIGURE 38. IS+ vs R

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

POWER DISSIPATION (W)

0.5

0

-40 20-20 60 80

θJA = 30°C/W

θJA = 43°C/W

θJA = 53°C/W

θJA = 80°C/W

0100

AMBIENT TEMPERATURE (°C)

(FULL POWER MODE)

ADJ

40

VS=±12V

=10

R

FB

=10

A

V

R

=100Ω

L

FIGURE 39. SUPPLY CURRENT vs SUPPLY VOLTAGE FIGURE 40. POWER DISSIPATION vs AMBIENT

TEMPERATURE for VARIOUS MOUNTED θ

(See Thermal Resistance Curve on page 15)

USING ELANTEC EL1503CS DEMO BOARD, 2”X2”

(4-LAYER). DEMO BOARD WITH HEATSINK VIA

INTERNAL GROUND PLANE

4

3.5

3

θ

J

A

=

4

7

°

C

/

W

100-40 -20 0 20 40 60

80

POWER DISSIPATION (W)

2.5

2

1.5

1

0.5

0

AMBIENT TEMPERATURE (°C)

FIGURE 41. 16 LD SOIC POWER DISSIPATION and THERMAL

RESISTANCE

FIGURE 42. 24 LD QFN POWER DISSIPATION vs AMBIENT

USING JEDEC JESD51-3 HIGH EFFECTIVE THERMAL

CONDUCTIVITY. (4-LAYER) TEST BOARD, QFN

EXPOSED DIEPAD SOLDERED TO PCB PER JESD51-5

4.0

3.5

POWER DISSIPATION (W)

3.0

2.5

2.0

1.5

1.0

0.5

3.378W

0

θ

J

A

=3

7

°

C

/

W

85

AMBIENT TEMPERATURE (°C)

TEMPERATURE

s

JA

1500 255075100125

12

FN7014.5

March 26, 2007

EL1508

www.BDTIC.com/Intersil

Applications Information

The EL1508 consists of two high-power line driver amplifiers

that can be connected for full duplex differential line

transmission. The amplifiers are designed to be used with

signals up to 4MHz and produce low distortion levels. The

EL1508 has been optimized as a line driver for ADSL CO

application. The driver output stage has been sized to

provide full ADSL CO power level of 20dBM onto the

telephone lines. Realizing that the actual peak output

voltages and currents vary with the line transformer turns

ratio, the EL1508 is designed to support 450mA of output

current which exceeds the level required for 1:2 transformer

ratio. A typical ADSL interface circuit is shown in Figure 43

below. Each amplifier has identical positive gain

connections, and optimum common-mode rejection occurs.

Further, DC input errors are duplicated and create commonmode rather than differential line errors.

DRIVER

INPUT+

DRIVER

INPUT-

RECEIVE

OUT +

AMPLIFIERS

RECEIVE

OUT -

FIGURE 43. TYPICAL LINE INTERFACE CONNECTION

2R

G

RECEIVE

+

R

F

R

F

-

+

R

F

R

-

+

+

-

R

R

F

Input Connections

The EL1508 amplifiers are somewhat sensitive to source

impedance. In particular, they do not like being driven by

inductive sources. More than 100nH of source impedance

can cause ringing or even oscillations. This inductance is

equivalent to about 4” of unshielded wiring, or 6” of

unterminated transmission line. Normal high-frequency

construction obviates any such problem.

Power Supplies and Dissipation

Due to the high power drive capability of the EL1508, much

attention needs to be paid to power dissipation. The power

that needs to be dissipated in the EL1508 has two main

contributors. The first is the quiescent current dissipation.

The second is the dissipation of the output stage.

The quiescent power in the EL1508 is not constant with

varying outputs. In reality, 50% of the total quiescent supply

current needed to power each driver is converted in to output

current. Therefore, in the equation below we should subtract

R

OUT

R

OUT

R

IN

R

IN

LINE +

LINE -

Z

LINE

the average output current, I

lowest. We’ll call this term I

, or 1/2 IQ, whichever is the

O

.

X

Therefore, we can determine a quiescent current with the

equation:

P

DquiescentVSIS21X

–()×=

where:

V

is the supply voltage (VS+ to VS-)

S

IS is the operating supply current (IS+ - IS-) / 2

IX is the lesser of IO or 1/2 I

Q

The dissipation in the output stage has two main

contributors. Firstly, we have the average voltage drop

across the output transistor and secondly, the average

output current. For minimal power dissipation, the user

should select the supply voltage and the line transformer

ratio accordingly. The supply voltage should be kept as low

as possible, while the transformer ratio should be selected

so that the peak voltage required from the EL1508 is close to

the maximum available output swing. There is a trade off,

however, with the selection of transformer ratio. As the ratio

is increased, the receive signal available to the receivers is

reduced.

Once the user has selected the transformer ratio, the

dissipation in the output stages can be selected with the

following equation:

V

S

⎛⎞

P

Dtransistors

2I

-------

–

××=

O

V

O

⎝⎠

2

where:

V

is the supply voltage (VS+ to VS-)

S

VO is the average output voltage per channel

is the average output current per channel

I

O

The overall power dissipation (P

P

Dquiescent

and P

Dtransistor

.

) is obtained by adding

DISS

Estimating Line Driver Power Dissipation in ADSL

CO Applications

Figure 44 on the following page shows a typical ADSL CO

line driver implementation. The average line power

requirement for the ADSL CO application is 20dBM

(100mW) into a 100Ω line. The average line voltage is

3.16V

factor) of 5.3 implies peak voltage of 16.7V into the line.

Using a differential drive configuration and transformer

coupling with standard back termination, a transformer ratio

of 1:1 is selected. With 1:1 transformer ratio, the impedance

across the driver side of the transformer is 100Ω, the

average voltage is 3.16V

31.6mA. The power dissipated in the EL1508 is a

. The ADSL DMT peak to average ratio (crest

RMS

and the average current is

RMA

13

FN7014.5

March 26, 2007

EL1508

www.BDTIC.com/Intersil

combination of the quiescent power and the output stage

power when driving the line:

Pd P

quiescentPoutput-stage

dVSIQVS( 2V

In the full power mode and with 6.8k R

+=

) I

OUT-RMS

××–+×=

OUT-RMS

ADJ

registers, the

EL1508 consumes typically 7mA quiescent current and still

able to maintain very low distortion. The distortion results are

shown in typical performance section of the data sheet.

When driving a load, a large portion (about 50%) of the

quiescent current becomes output load current:

Pd 12 7mA( 50%) 12V( 3.16) 31.6mA 2××–+××=

where:

Pd = 598mW

The θ

requirement needs to be calculated. This is done

JA

using the equation:

Θ

=

JA

T

--------------------------------------------

–

JUNCTTAMB

P

DISS

where:

T

T

P

is the maximum die temperature (150°C)

JUNCT

is the maximum ambient temperature (85°C)

AMB

is the dissipation calculated above

DISS

θJA is the junction to ambient thermal resistance for the

package when mounted on the PCB

150 85–

----------------------

Θ

JA

598mW

108° C/W==

PCB Layout Considerations for QFN and SOIC

Packages

The EL1508 die is packaged in three different thermallyefficient packages: a 20 Ld SOIC (0.300”), a 16 Ld SOIC

(0.150”), and a 24 Ld QFN. The 16 Ld SOIC has the same

external dimensions as a standard 0.150” width SOIC

package, but has the center four lead s ( two p er si de )

internally-fused for heat transfer purposes. Both packages

can use PCB surface metal vias areas and internal ground

planes, to spread heat away from the package. The larger

the PCB area the lower the junction temperature of the

device will be. In XDSL applications, multiple layer circuit

boards with internal ground plane are generally used. 13 mil

vias are recommended to connect the metal area under the

device with the internal ground plane. Examples of the PCB

layouts are shown in the figures below that result in thermal

resistance θ

for the SOIC package. The thermal resistance is obtained

with the EL1508CL and CS demo boards. The demo board

is a 4-layer board built with 2oz. copper and has a dimension

2.

of 4in

guideline to achieve these results. In addition to lower

thermal resistance, the QFN package exhibits much lower

2nd harmonic distortion.

A separate Application Note for the QFN package and layout

recommendations is also available.

of 37°C/W for the QFN package and 47°C/W

JA

Note, the user must follow the thermal layout

+

V

R

S

TX+

FROM

AFE

1.5kΩ

T

FIGURE 44. TYPICAL ADSL CO LINE DRIVER

+

VS-

R

F

2R

X

3k

G

-

V

+

-

V

R

F

3k

IMPLEMENTATION

T

10

0.22µF

TXFR 1:1

+

R

S

T

10

-

S

0.22µF

14

100

TOP (24 LD QFN)

INTERNAL GROUND PLANE (24 LD QFN)

FN7014.5

March 26, 2007

EL1508

www.BDTIC.com/Intersil

TOP (16 Ld SO)

55

50

(°C/W)

JA

45

40

35

MOUNTED DEVICE θ

30

02 10684

FIGURE 45. THERMAL RESISTANCE of 20 LD SO (0.300")

EL1508 vs BOARD COPPER AREA

TOP FOIL ONLY-WITH SOLDER MASK

TOP FOIL ONLY-NO SOLDER MASK

AREA OF CIRCUIT BOARD HEAT SINK (in

Note: 2OZ COPPER USED

TOP FOIL-WITH 0.45in2

BOTTOM FOIL WITH MANY

FEEDTHROUGHS

2

)

Power Control Function

The EL1508 contains two forms of power control operation.

Two digital inputs, C

supply current of the EL1508 drive amplifiers. As the supply

current is reduced, the EL1508 will start to exhibit slightly

higher levels of distortion and the frequency response will be

limited. The 4 power modes of the EL1508 are set up as

shown in the following table:

and C1, can be used to control the

0

INTERNAL GROUND PLANE (16 Ld SO)

EL1508CM PCB Layout Considerations

The 20 Ld SOIC (0.300") Power Package is designed so that

heat may be conducted away from the device in an efficient

manner. To disperse this heat, the center four leads on either

side of the package are internally fused to the mounting

platform of the die. Heat flows through the leads into the

circuit board copper, then spreads and convects to air . Thus,

the ground plane on the component side of the board

becomes the heatsink. This has proven to be a very effective

technique, but several aspects of board layout should be

noted. First, the heat should not be shunted to internal

copper layers of the board nor backside foil, since the

feedthroughs and fiberglass of the board are not very

thermally conductive. To obtain the best thermal resistance

of the mounted part, θ

should have as much area as possible and be as thick as

practical. If possible, the solder mask should be cut away

from the EL1508 to improve thermal resistance. Finally,

metal heatsinks can be placed against the board close to the

part to draw heat toward the chassis. The graph below

shows various θ

JA

copper foil areas.

, the topside copper ground plane

JA

s for the 20 Ld SOIC mounted on different

TABLE 1. POWER MODES OF THE EL1508

C

1

00I

0 1 2/3 IS power mode

1 0 1/3 I

1 1 Power-down

C

0

full power mode

S

power mode

S

OPERATION

Another method for controlling the power consumption of the

EL1508 is to connect a resistor from the I

When the I

pin is grounded (the normal state), the supply

ADJ

pin to ground.

ADJ

current per channel is as per the specifications table on page

2. When a resistor is inserted, the supply current is scaled

according to the “R

vs IS” graphs in the Performance

SET

Curves section.

Both methods of power control can be used simultaneously.

In this case, positive and negative supply currents (per amp)

are given by the equations below:

12.4mA

IS+0.9mA

------------------------------------------------------

IS-

1R

------------------------------------------------------

1R

12.4mA

1574Ω÷+()

SET

1574Ω÷+()

SET

( 1/3C0)+×=

2/3C

1/3C

+()×+=

2/3C

1

1

0

Output Loading

While the drive amplifiers can output in excess of 500mA

transiently, the internal metallization is not designed to carry

more than 100mA of steady DC current and there is no

15

FN7014.5

March 26, 2007

EL1508

www.BDTIC.com/Intersil

current-limit mechanism. This allows safely driving rms

sinusoidal currents of 2 x 100mA, or 200mA. This current is

more than that required to drive line impedances to large

output levels, but output short circuits cannot be tolerated.

The series output resistor will usually limit currents to safe

values in the event of line shorts. Driving lines with no series

resistor is a serious hazard.

The amplifiers are sensitive to capacitive loading. More than

25pF will cause peaking of the frequency response. The

same is true of badly terminated lines connected without a

series matching resistor.

Output AC Coupling

When in power-down mode, several volts of differential

voltage may appear across the line driver outputs. If DC

current path exists between the two outputs, large DC

current can flow from the positive supply rail to the negative

supply rail through the outputs. To avoid DC current flow , the

most effective solution is to place DC blocking capacitors in

series at the outputs, as shown by the 0.22µF capacitors in

Figure 44.

Power Supplies

The power supplies should be well bypassed close to the

EL1508. A 2.2µF tantalum capacitor and a 0.1µF ceramic

capacitor for each supply works well. Since the load currents

are differential, they should not travel through the board

copper and set up ground loops that can return to amplifier

inputs. Due to the class AB output stage design, these

currents have heavy harmonic content. If the ground

terminal of the positive and negative bypass capacitors are

connected to each other directly and then returned to circuit

ground, no such ground loops will occur. This scheme is

employed in the layout of the EL1508 demonstration board,

and documentation can be obtained from the factory.

Single Supply Operation

The EL1508 can also be powered from a single supply

voltage. When operating in this mode, the GND pins can still

be connected directly to GND. To calculate power

dissipation, the equations in the previous section should be

used, with V

equal to half the supply rail.

S

Feedback Resistor Value

The bandwidth and peaking of the amplifiers varies with

supply voltage somewhat and with gain settings. The

feedback resistor values can be adjusted to produce an

optimal frequency response. Here is a series of resistor

values that produce an optimal driver frequency response

(1dB peaking) for different supply voltages and gains:

TABLE 2. OPTIMUM DRIVER FEEDBACK RESISTOR FOR

SUPPLY

VOLTAGE

VARIOUS GAINS AND SUPPLY VOLTAGES

DRIVER VOLTAGE GAIN

2.5 5 10

±5V 3.5k 3.25k 3k

±12V 3.5k 3.25k 3k

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implic atio n or other wise u nde r any p a tent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

16

FN7014.5

March 26, 2007

Small Outline Package Family (SO)

www.BDTIC.com/Intersil

A

D

NN

(N/2)+1

EL1508

h X 45°

PIN #1

E

C

SEATING

PLANE

0.004 C

E1

B

0.010 BM CA

I.D. MARK

1

e

0.010 BM CA

(N/2)

c

SEE DETAIL “X”

L1

H

A2

GAUGE

PLANE

A1

b

DETAIL X

L

4° ±4°

MDP0027

SMALL OUTLINE PACKAGE FAMILY (SO)

INCHES

SO16

SYMBOL

A 0.068 0.068 0.068 0.104 0.104 0.104 0.104 MAX -

A1 0.006 0.006 0.006 0.007 0.007 0.007 0.007 ±0.003 A2 0.057 0.057 0.057 0.092 0.092 0.092 0.092 ±0.002 -

b 0.017 0.017 0.017 0.017 0.017 0.017 0.017 ±0.003 c 0.009 0.009 0.009 0.011 0.011 0.011 0.011 ±0.001 -

D 0.193 0.341 0.390 0.406 0.504 0.606 0.704 ±0.004 1, 3

E 0.236 0.236 0.236 0.406 0.406 0.406 0.406 ±0.008 -

E1 0.154 0.154 0.154 0.295 0.295 0.295 0.295 ±0.004 2, 3

e 0.050 0.050 0.050 0.050 0.050 0.050 0.050 Basic L 0.025 0.025 0.025 0.030 0.030 0.030 0.030 ±0.009 -

L1 0.041 0.041 0.041 0.056 0.056 0.056 0.056 Basic -

h 0.013 0.013 0.013 0.020 0.020 0.020 0.020 Reference -

N 8 14 16 16 20 24 28 Reference -

NOTES:

1. Plastic or metal protrusions of 0.006” maximum per side are not included.

2. Plastic interlead protrusions of 0.010” maximum per side are not included.

3. Dimensions “D” and “E1” are measured at Datum Plane “H”.

4. Dimensioning and tolerancing per ASME Y14.5M-1994

(0.150”)

SO16 (0.300”)

(SOL-16)

SO20

(SOL-20)

SO24

(SOL-24)

SO28

(SOL-28)

TOLERANCE NOTESSO-8 SO-14

A

0.010

Rev. M 2/07

17

FN7014.5

March 26, 2007

EL1508

www.BDTIC.com/Intersil

QFN (Quad Flat No-Lead) Package Family

A

1

2

3

2X

0.075 C

L

(E2)

C

SEATING

PLANE

0.08 C

N LEADS

& EXPOSED PAD

A

C

N

(N-2)

(N-1)

PIN #1

I.D. MARK

TOP VIEW

0.10 BAMC

b

N LEADS

(N/2)

BOTTOM VIEW

e

SIDE VIEW

(c)

A1

DETAIL X

D

(N/2)

(N-2)

(N-1)

N

(D2)

0.10

SEE DETAIL "X"

2

(L)

N LEADS

0.075

PIN #1 I.D.

1

2

3

NE

7

C

2X

B

E

C

3

5

MDP0046

QFN (QUAD FLAT NO-LEAD) PACKAGE FAMILY

(COMPLIANT TO JEDEC MO-220)

MILLIMETERS

SYMBOL

A 0.90 0.90 0.90 0.90 ±0.10 -

A1 0.02 0.02 0.02 0.02 +0.03/-0.02 -

b 0.25 0.25 0.23 0.22 ±0.02 c 0.20 0.20 0.20 0.20 Reference -

D 7.00 5.00 8.00 5.00 Basic -

D2 5.10 3.80 5.80 3.60/2.48 Reference 8

E 7.00 7.00 8.00 6.00 Basic -

E2 5.10 5.80 5.80 4.60/3.40 Reference 8

e 0.50 0.50 0.80 0.50 Basic L 0.55 0.40 0.53 0.50 ±0.05 -

N 44 38 32 32 Reference 4

ND 11 7 8 7 Reference 6

NE 11 12 8 9 Reference 5

MILLIMETERS

SYMBOL

A 0.90 0.90 0.90 0.90 0.90 ±0.10 -

A1 0.02 0.02 0.02 0.02 0.02 +0.03/

b 0.25 0.25 0.30 0.25 0.33 ±0.02 c 0.20 0.20 0.20 0.20 0.20 Reference -

D 4.00 4.00 5.00 4.00 4.00 Basic -

D2 2.65 2.80 3.70 2.70 2.40 Reference -

E 5.00 5.00 5.00 4.00 4.00 Basic -

E2 3.65 3.80 3.70 2.70 2.40 Reference -

e 0.50 0.50 0.65 0.50 0.65 Basic L 0.40 0.40 0.40 0.40 0.60 ±0.05 -

N 28 24 20 20 16 Reference 4

ND 6 5 5 5 4 Reference 6

NE 8 7 5 5 4 Reference 5

NOTES:

1. Dimensioning and tolerancing per ASME Y14.5M-1994.

2. Tiebar view shown is a non-functional feature.

3. Bottom-side pin #1 I.D. is a diepad chamfer as shown.

4. N is the total number of terminals on the device.

5. NE is the number of terminals on the “E” side of the package

(or Y-direction).

6. ND is the number of terminals on the “D” side of the package

(or X-direction). ND = (N/2)-NE.

7. Inward end of terminal may be square or circular in shape with radius

(b/2) as shown.

8. If two values are listed, multiple exposed pad options are available.

Refer to device-specific datasheet.

TOLERANCE NOTESQFN44 QFN3 QFN32

TOLER-

ANCE NOTESQFN28 QFN2 QFN20 QFN16

-0.02

Rev 11 2/07

-

18

FN7014.5

March 26, 2007

Loading...

Loading...