DG201A, DG202

Data Sheet June 1999

Quad SPST, CMOS Analog Switches

The DG201A and DG202 quad SPST analog switches are

designed using Intersil’s 44V CMOS process. These

bidirectional switches are latch-proof and feature breakbefore-make switching. Designed to block signals up to

30V

in the OFF state, the DG201A and DG202 offer the

P-P

advantages of low ON resistance (≤175Ω), wide input signal

range (±15V) and provide both TTL and CMOS compatibility.

The DG201A and DG202 are specification and pinout

compatible with the industry standard devices.

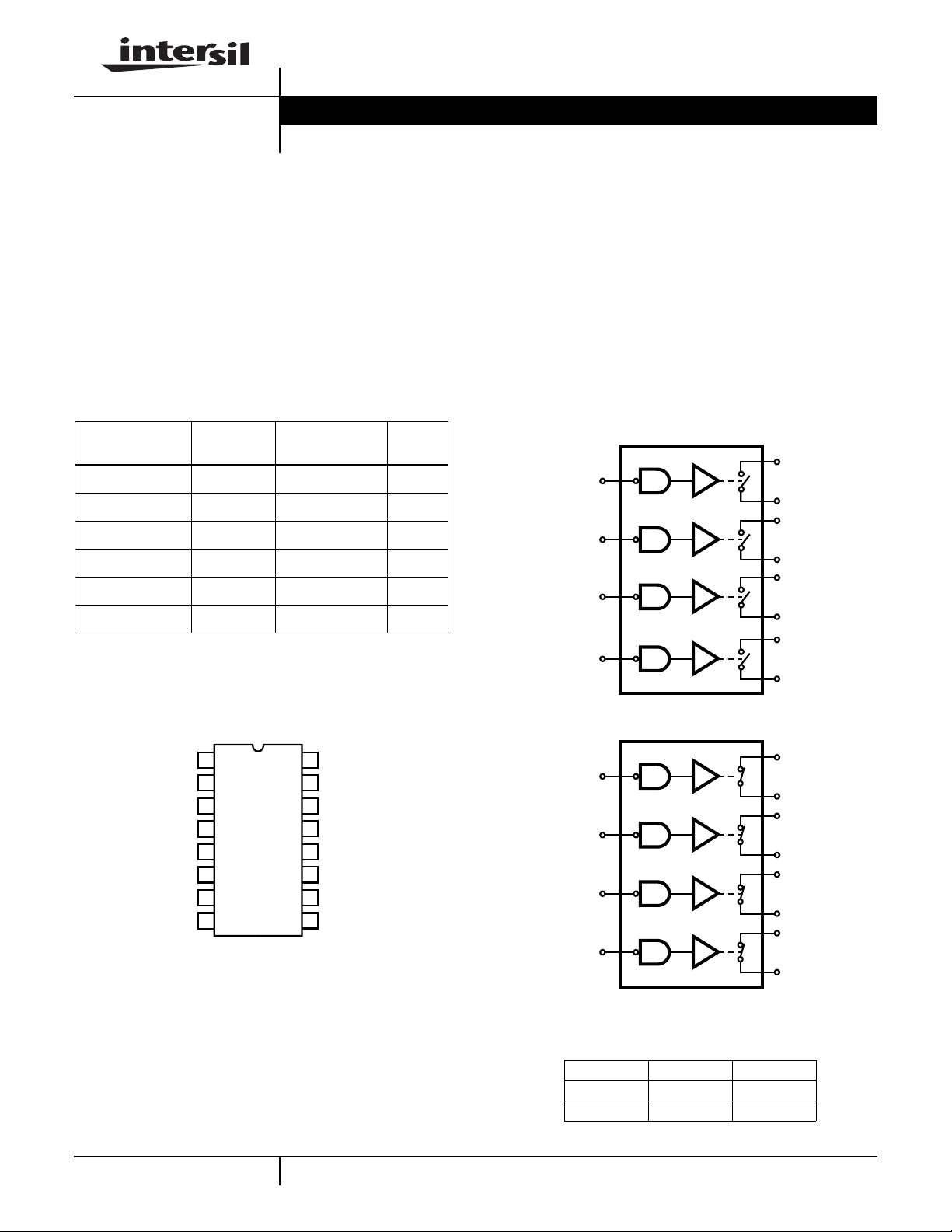

Ordering Information

TEMP.

PART NUMBER

RANGE (oC) PACKAGE

DG201AAK -55 to 125 16 Ld CERDIP F16.3

DG201ABK -25 to 85 16 Ld CERDIP F16.3

DG201ACJ 0 to 70 16 Ld PDIP E16.3

DG201ACY 0 to 70 16 Ld SOIC M16.3

DG202AK -55 to 125 16 Ld CERDIP F16.3

DG202CJ 0 to 70 16 Ld PDIP E16.3

PKG.

NO.

Pinout

DG201A, DG202

(CERDIP, PDIP, SOIC)

TOP VIEW

File Number

3117.2

Features

• Input Signal Range. . . . . . . . . . . . . . . . . . . . . . . . . . ±15V

•Low r

(Max). . . . . . . . . . . . . . . . . . . . . . . . . . 175Ω

DS(ON)

• TTL, CMOS Compatible

• Latch-Up Proof

• True Second Source

• Maximum Supply Ratings. . . . . . . . . . . . . . . . . . . . . . 44V

• Logic Inputs Accept Negative Voltages

Functional Block Diagrams

DG201A

S

IN

1

IN

2

IN

3

IN

4

DG202

1

D

1

S

2

D

2

S

3

D

3

S

4

D

4

IN

D

S

GND

S

D

IN

1

1

2

1

3

1

4

V-

5

6

4

7

4

8

4

16

15

14

13

12

11

10

9

IN

2

D

2

S

2

V+ (SUB-

-

STRATE)

NC

S

3

D

3

IN

3

IN

1

IN

2

IN

3

IN

4

SWITCHES SHOWN FOR LOGIC “1” INPUT

S

1

D

1

S

2

D

2

S

3

D

3

S

4

D

4

TRUTH TABLE

LOGIC DG201A DG202

0 ON OFF

1 OFF ON

Logic “0” ≤0.8V, Logic “1” ≥ 2.4V

4-1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207 | Copyright © Intersil Corporation 1999

DG201A, DG202

Absolute Maximum Ratings Thermal Information

V+ to V- . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44V

V- to Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-25V

VIN to Ground (Note 1) . . . . . . . . . . . . . . . . . . .(V-) -2V to (V+) +2V

VS or VD to V+ (Note 1). . . . . . . . . . . . . . . . . . . . . . . . +2 to (V-) -2V

VS or VD to V- (Note 1) . . . . . . . . . . . . . . . . . . . . . . . -2 to (V+) +2V

Current, any Terminal Except S or D . . . . . . . . . . . . . . . . . . . . 30mA

Continuous Current, S or D . . . . . . . . . . . . . . . . . . . . . . . . . . . 20mA

Peak Current, S or D (Pulsed 1ms, 10% Duty Cycle Max) . . . . . 70mA

Operating Conditions

Temperature Range

“A” Suffix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -55oC to 125oC

“B” Suffix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -25oC to 85oC

“C” Suffix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0oC to 70oC

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operationofthe

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1. Signals on VS, VD, or VIN exceeding V+ or V- will be clamped by internal diodes. Limit forward diode current to maximum current ratings.

2. θJA is measured with the component mounted on an evaluation PC board in free air.

Thermal Resistance (Typical, Note 2) θJA (oC/W) θJC (oC/W)

CERDIP Package. . . . . . . . . . . . . . . . . 75 20

PDIP Package . . . . . . . . . . . . . . . . . . . 100 N/A

SOIC Package . . . . . . . . . . . . . . . . . . . 100 N/A

Maximum Junction Temperature

Ceramic Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175oC

Plastic Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150oC

Maximum Storage Temperature Range. . . . . . . . . . -65oC to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . 300oC

(SOIC - Lead Tips Only)

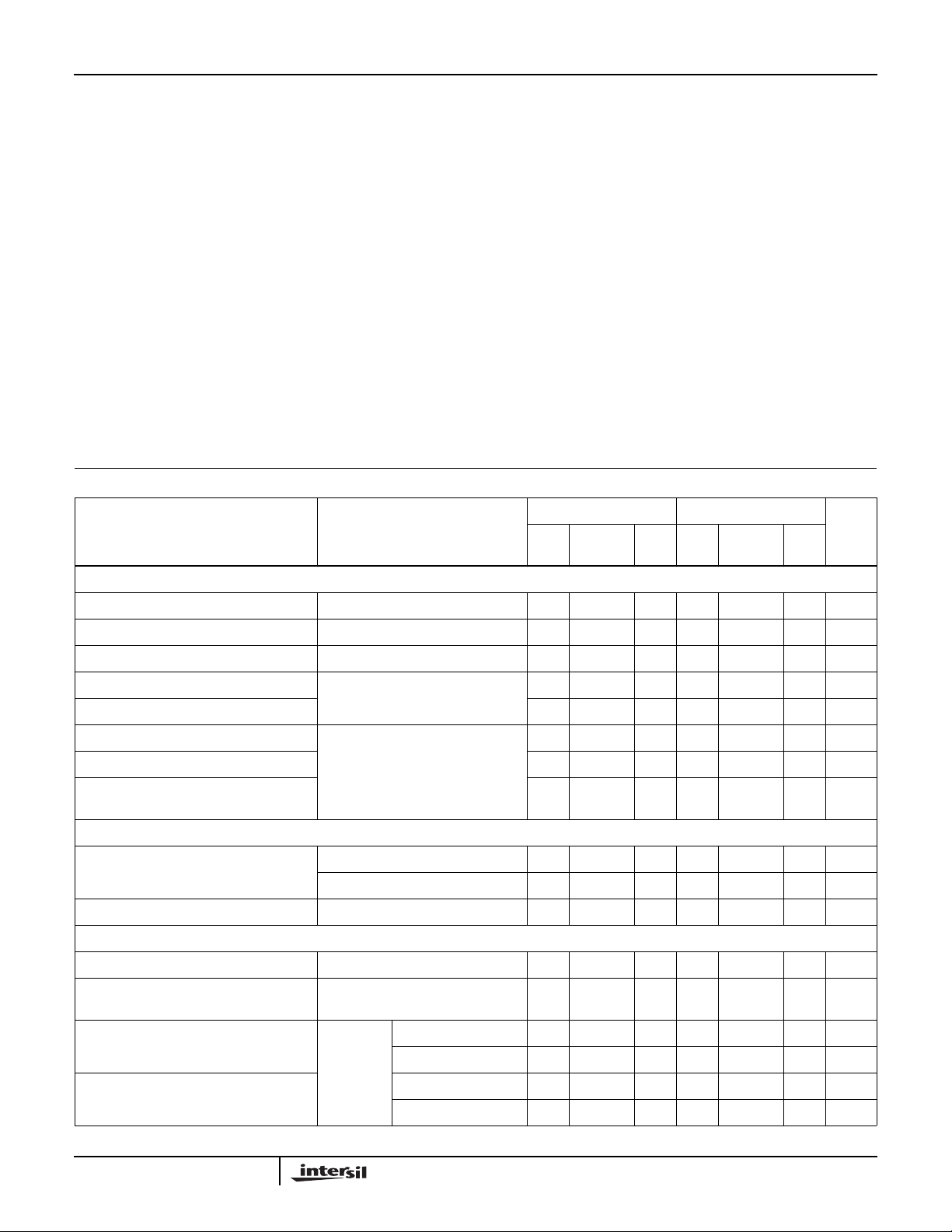

Electrical Specifications V+ = 15V, V- = -15V, GND = 0V, T

PARAMETER TEST CONDITIONS

DYNAMIC CHARACTERISTICS

Turn-ON Time, t

Turn-OFF Time, t

Charge Injection, Q CL = 1nF, RS = 0, VS = 0V - 20 - - 20 - pC

OFF Isolation, OIRR VIN = 5V, RL = 75Ω, VS = 2.0V,

Crosstalk (Channel to Channel), CCRR - -90 - - -90 - dB

Source OFF Capacitance, C

Drain OFF Capacitance, C

Channel ON Capacitance,

C

D(ON)+CS(ON)

DIGITAL INPUT CHARACTERISTICS

Input Current with Voltage High, I

Input Current with Voltage Low, I

ANALOG SWITCH CHARACTERISTICS

Analog Signal Range, V

Drain-Source ON Resistance, r

Source OFF Leakage Current, I

Drain OFF Leakage Current, I

ON

OFF

S(OFF)

D(OFF)

IH

IL

ANALOG

DS(ON)

S(OFF)

D(OFF)

See Figure 1 - 480 600 - 480 - ns

See Figure 1 - 370 450 - 370 - ns

f = 100kHz

f = 140kHz, VIN = 5V, VS = VD = 0V - 5.0 - - 5.0 - pF

VIN = 2.4V -1.0 -0.0004 - -1.0 -0.0004 - µA

VIN = 15V - 0.003 1.0 - 0.003 1.0 µA

VIN = 0V -1.0 -0.0004 - -1.0 -0.0004 - µA

VD = ±10V, VIN = 0.8V (DG201A)

IS = 1mA, VIN = 2.4V (DG202)

VIN = 2.4V

(DG201A)

VIN = 0.8V

(DG202)

VS = 14V, VD = -14V - 0.01 1.0 - 0.01 5.0 nA

VS = -14V, VD = 14V -1.0 -0.02 - -5.0 -0.02 - nA

VS = -14V, VD = 14V - 0.01 1.0 - 0.01 5.0 nA

VS = 14V, VD = -14V -1.0 -0.02 - -5.0 -0.02 - nA

= 25oC

A

“A” SUFFIX “B” AND “C” SUFFIX

(NOTE 3)

TYP MAX MIN

-70--70-dB

- 5.0 - - 5.0 - pF

-16--16-pF

-15 - 15 -15 - 15 V

- 115 175 - 115 200 Ω

(NOTE 3)

TYP MAX

UNITSMIN

4-2

DG201A, DG202

Electrical Specifications V+ = 15V, V- = -15V, GND = 0V, T

PARAMETER TEST CONDITIONS

Drain ON Leakage Current, I

(Note 5)

POWER SUPPLY CHARACTERISTICS

Positive Supply Current, I+ All Channels ON or OFF - 0.9 2 - 0.9 2 mA

Negative Supply Current, I- -1 -0.3 - -1 -0.3 - mA

D(ON)

VIN = 0.8V

(DG201A)

VIN = 2.4V

(DG202)

VD = VS = 14V - 0.1 1.0 - 0.1 5.0 µA

VD = VS = -14V -1.0 -0.15 - -5.0 -0.15 - µA

Electrical Specifications V+ = 15V, V- = -15V, GND = 0V, T

PARAMETER TEST CONDITIONS

DIGITAL INPUT CHARACTERISTICS

Input Current with Voltage High, I

IH

VIN = 2.4V -10 - - µA

VIN = 15V - - 10 µA

= 25oC (Continued)

A

“A” SUFFIX “B” AND “C” SUFFIX

(NOTE 3)

TYP MAX MIN

Over Operating Temperature Range

A

(NOTE 3)

“A” SUFFIX

(NOTE 3)

TYP MAX

TYP MAX

UNITSMIN

UNITSMIN

Input Current with Voltage Low, I

ANALOG SWITCH CHARACTERISTICS

Analog Signal Range, V

Drain-Source ON Resistance, r

Source OFF Leakage Current, I

Drain OFF Leakage Current, I

Drain ON Leakage Current, I

NOTES:

3. Typical values are for design aid only, not guaranteed and not subject to production testing.

4. The algebraic convention whereby the most negative value is a minimum, and the most positive is a maximum, is used in this data sheet.

5. I

is leakage from driver into ON switch.

D(ON)

ANALOG

IL

DS(ON)

S(OFF)

D(OFF)

(Note 5) VIN = 0.8V (DG201A)

D(ON)

VIN = 0V -10 - - µA

-15 - 15 V

VD = ±10V, VIN = 0.8V (DG201A)

IS = 1mA, VIN = 2.4V (DG202)

VIN = 2.4V (DG201A)

VIN = 0.8V (DG202)

VIN = 2.4V (DG202)

VS = 14V, VD = -14V - - 100 nA

VS = -14V, VD = 14V -100 - - nA

VS = -14V, VD = 14V - - 100 nA

VS = 14V, VD = -14V -100 - - nA

VD = VS = 14V - - 200 µA

VD = VS = -14V -200 - - µA

- - 250 Ω

4-3

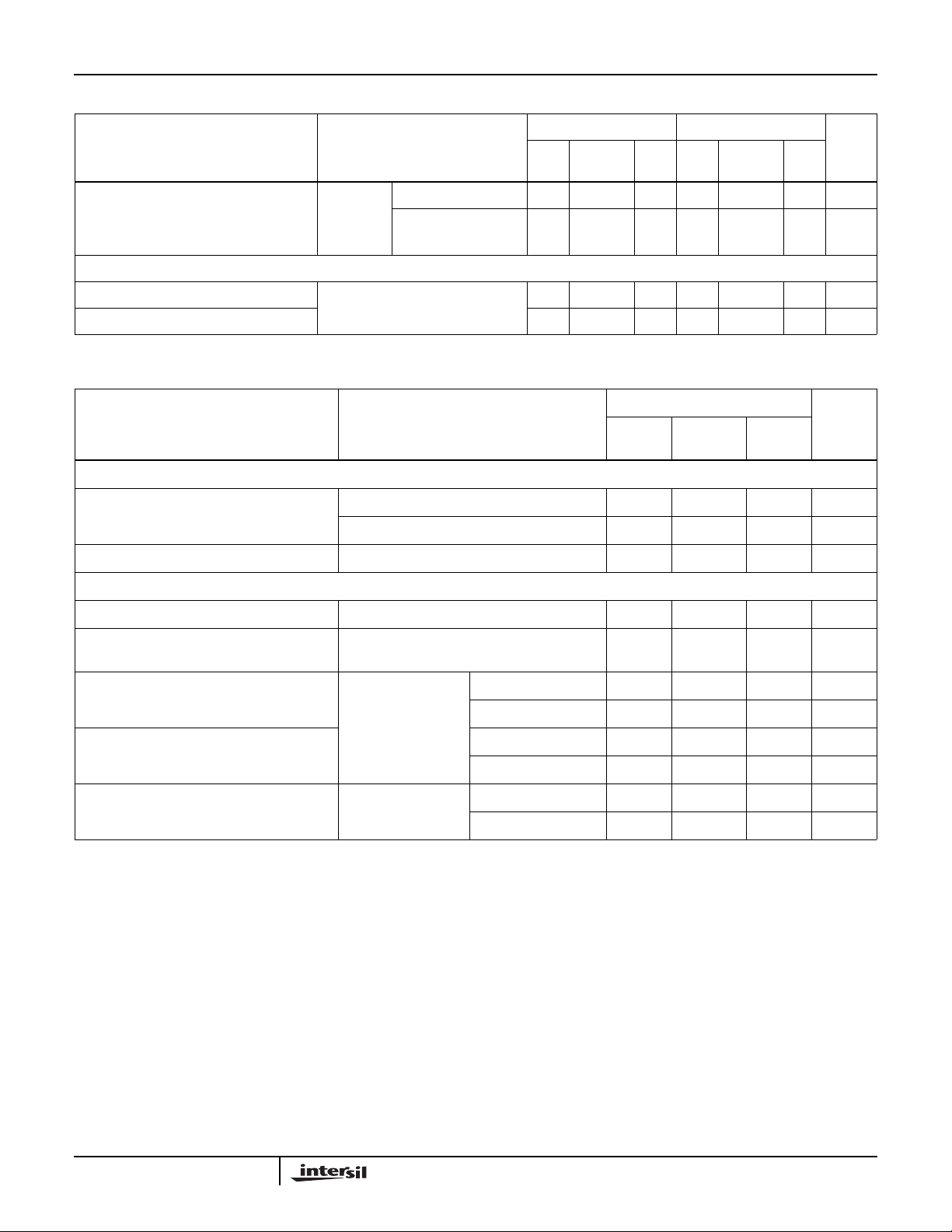

Test Circuits and Waveforms

LOGIC†

tr < 20ns

t

f

SWITCH

SWITCH

OUTPUT

INPUT

< 20ns

INPUT

3V

V

S

†Logic shown for DG201A, invert for DG202.

LOGIC “0” = SWITCH ON

50%

90%

t

ON

t

OFF

DG201A, DG202

VO = V

SWITCH

INPUT

90%

LOGIC

INPUT

V

= 2V

S

S

RL + r

S

1

IN

1

R

L

DS(ON)

GND

15V

-15V

V+

D

1

(REPEAT TEST FOR

IN

V-

R

L

1kΩ

, IN3 AND IN4)

2

SWITCH

OUTPUT

C

L

35pF

V

O

FIGURE 1. tON AND t

R

S

S

X

V

S

D

X

IN

X

OFF

CL = 1nF

NOTES:

6. ∆VO = Measured voltage error due to charge injection.

7. The error in coulombs is Q = CL x ∆VO.

FIGURE 2. CHARGE INJECTION TEST CIRCUIT AND MEASUREMENT POINTS

+15V

C

SIGNAL

GENERATOR

V+

V

S

SWITCHING TEST CIRCUIT AND MEASUREMENT POINTS

V

O

SWITCH

OUTPUT

IN

X

ON

SIGNAL

GENERATOR

C

3

OFF

+15V

V

S1

V+

∆V

O

ON

V

D1

50Ω

V

S

ANALYZER

CHAN A

CHAN B

C = 0.001µF||0.1µF

Chip Capacitors

FIGURE 3. OFF ISOLATION TEST CIRCUIT

V

S

IN

X

V

D

GND

R

L

V-

C

-15V

OIRR 20Log

=

V

--------

V

V

IN

ANALYZER

CHAN A

CHAN B

S

C = 0.001µF||0.1µF

Chip Capacitors

D

0V,

2.4V

R

L

IN

V

1

D2

GND

IN

2

V

S2

V-

C

-15V

CCRR 20 Log

=

0V, 2.4V

NC

V

S

1

-----------

V

2

D

FIGURE 4. CHANNEL TOCHANNEL CROSSTALK TEST

CIRCUIT

4-4

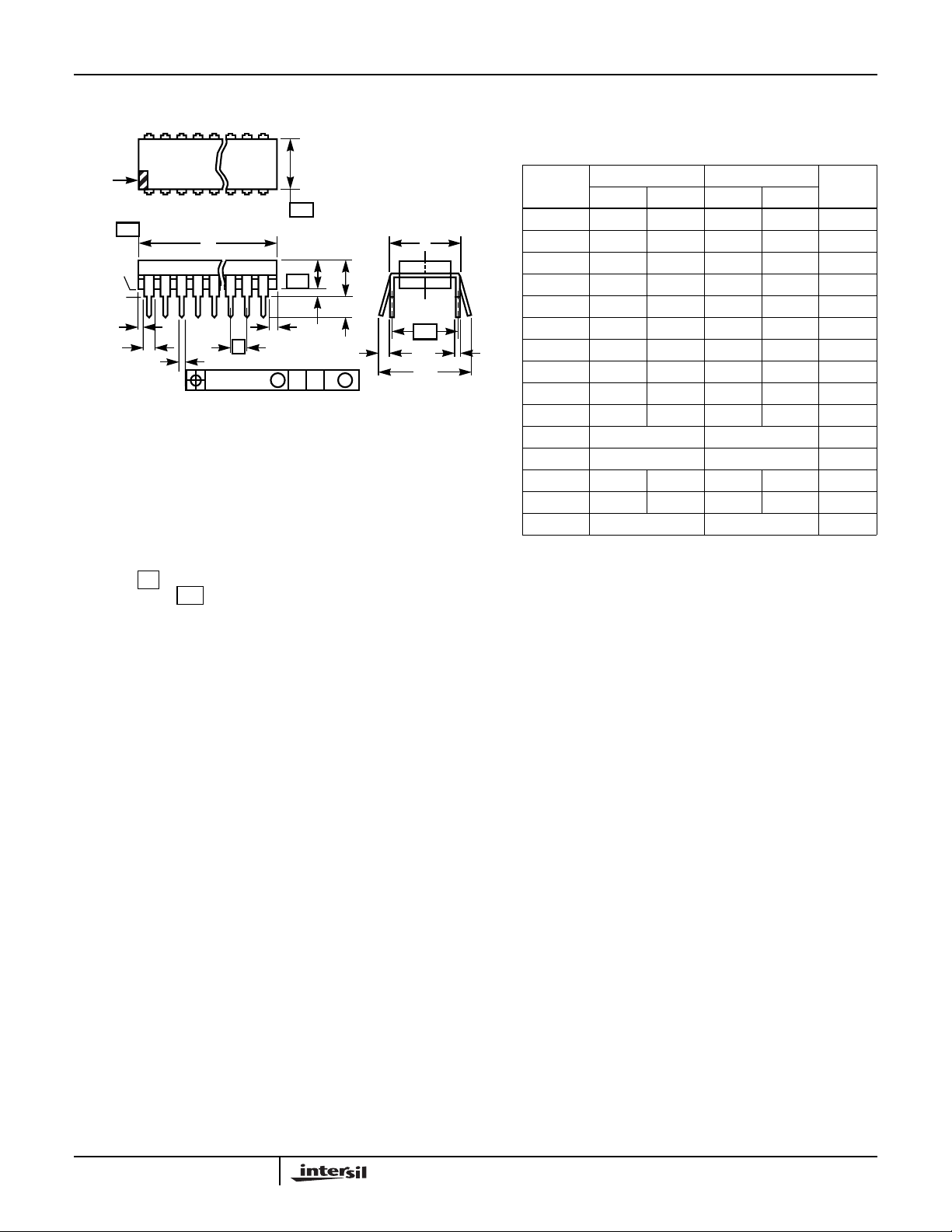

Dual-In-Line Plastic Packages (PDIP)

DG201A, DG202

N

D1

-C-

E1

-B-

A1

A2

E

A

L

e

C

C

L

e

A

C

e

B

INDEX

AREA

BASE

PLANE

SEATING

PLANE

D1

B1

1 2 3 N/2

-AD

e

B

0.010 (0.25) C AM BS

NOTES:

1. Controlling Dimensions:INCH. Incase ofconflict betweenEnglish and

Metric dimensions, the inch dimensions control.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Symbols are defined in the “MO Series SymbolList”inSection 2.2 of

Publication No. 95.

4. Dimensions A, A1andL are measuredwiththe package seatedinJEDEC seating plane gauge GS-3.

5. D, D1, and E1 dimensions do notincludemoldflash or protrusions.

Mold flash or protrusions shall not exceed 0.010 inch (0.25mm).

6. E and aremeasuredwith theleadsconstrained to beperpendic-

e

A

ular to datum .

-C-

7. eBand eCare measuredat the leadtips with theleads unconstrained.

eC must be zero or greater.

8. B1 maximum dimensionsdo not include dambarprotrusions. Dambar

protrusions shall not exceed 0.010 inch (0.25mm).

9. N is the maximum number of terminal positions.

10. Corner leads (1, N, N/2 and N/2 + 1)forE8.3,E16.3, E18.3, E28.3,

E42.6 will have a B1 dimension of 0.030 - 0.045 inch (0.76 - 1.14mm).

E16.3 (JEDEC MS-001-BB ISSUE D)

16 LEAD DUAL-IN-LINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.210 - 5.33 4

A1 0.015 - 0.39 - 4

A2 0.115 0.195 2.93 4.95 -

B 0.014 0.022 0.356 0.558 B1 0.045 0.070 1.15 1.77 8, 10

C 0.008 0.014 0.204 0.355 -

D 0.735 0.775 18.66 19.68 5

D1 0.005 - 0.13 - 5

E 0.300 0.325 7.62 8.25 6

E1 0.240 0.280 6.10 7.11 5

e 0.100 BSC 2.54 BSC e

A

e

B

0.300 BSC 7.62 BSC 6

- 0.430 - 10.92 7

L 0.115 0.150 2.93 3.81 4

N16 169

NOTESMIN MAX MIN MAX

Rev. 0 12/93

4-5

DG201A, DG202

Ceramic Dual-In-Line Frit Seal Packages (CERDIP)

LEAD FINISH

c1

-A-

-B-

bbb C A - B

S

BASE

PLANE

SEATING

PLANE

S1

b2

ccc C A - BMD

D

A

A

b

e

S

S

NOTES:

1. Index area: A notch or a pin one identification mark shall be located adjacent to pin one and shall be located within the shaded

area shown. The manufacturer’s identification shall not be used

as a pin one identification mark.

2. The maximum limits of lead dimensions b and c or M shall be

measured at the centroid of the finished lead surfaces, when

solder dip or tin plate lead finish is applied.

3. Dimensions b1 and c1 apply to lead base metal only. Dimension

M applies to lead plating and finish thickness.

4. Corner leads (1, N, N/2, andN/2+1)may be configured with a

partial lead paddle. For this configuration dimension b3 replaces

dimension b2.

5. This dimension allows for off-center lid, meniscus, and glass

overrun.

6. Dimension Q shall be measured from the seating plane to the

base plane.

7. Measure dimension S1 at all four corners.

8. N is the maximum number of terminal positions.

9. Dimensioning and tolerancing per ANSI Y14.5M - 1982.

10. Controlling dimension: INCH.

-DBASE

E

D

S

S

Q

A

-CL

METAL

b1

M

(b)

SECTION A-A

α

(c)

M

eA

eA/2

aaa C A - B

M

c

D

S S

F16.3 MIL-STD-1835 GDIP1-T16 (D-2, CONFIGURATION A)

16 LEAD CERAMIC DUAL-IN-LINE FRIT SEAL PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.200 - 5.08 -

b 0.014 0.026 0.36 0.66 2

b1 0.014 0.023 0.36 0.58 3

b2 0.045 0.065 1.14 1.65 b3 0.023 0.045 0.58 1.14 4

c 0.008 0.018 0.20 0.46 2

c1 0.008 0.015 0.20 0.38 3

D - 0.840 - 21.34 5

E 0.220 0.310 5.59 7.87 5

e 0.100 BSC 2.54 BSC eA 0.300 BSC 7.62 BSC -

eA/2 0.150 BSC 3.81 BSC -

L 0.125 0.200 3.18 5.08 -

Q 0.015 0.060 0.38 1.52 6

S1 0.005 - 0.13 - 7

o

α

90

105

o

90

o

105

aaa - 0.015 - 0.38 bbb - 0.030 - 0.76 -

ccc - 0.010 - 0.25 -

M - 0.0015 - 0.038 2, 3

N16 168

NOTESMIN MAX MIN MAX

o

Rev. 0 4/94

-

4-6

Small Outline Plastic Packages (SOIC)

DG201A, DG202

N

INDEX

AREA

123

-A-

E

-B-

SEATING PLANE

D

A

-C-

0.25(0.010) BM M

H

L

h x 45

o

α

e

B

0.25(0.010) C AM BS

M

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm (0.006

inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead

flash and protrusions shall not exceed 0.25mm (0.010 inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater above

the seating plane, shall not exceed a maximum value of 0.61mm (0.024

inch)

10. Controlling dimension: MILLIMETER. Converted inch dimensions are

not necessarily exact.

A1

C

0.10(0.004)

M16.3 (JEDEC MS-013-AA ISSUE C)

16 LEAD WIDE BODY SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0926 0.1043 2.35 2.65 -

A1 0.0040 0.0118 0.10 0.30 -

B 0.013 0.0200 0.33 0.51 9

C 0.0091 0.0125 0.23 0.32 D 0.3977 0.4133 10.10 10.50 3

E 0.2914 0.2992 7.40 7.60 4

e 0.050 BSC 1.27 BSC H 0.394 0.419 10.00 10.65 -

h 0.010 0.029 0.25 0.75 5

L 0.016 0.050 0.40 1.27 6

N16 167

o

α

0

o

8

o

0

o

8

Rev. 0 12/93

NOTESMIN MAX MIN MAX

-

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (407) 724-7000

FAX: (407) 724-7240

4-7

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

Loading...

Loading...