Intersil Corporation CA3098 Datasheet

Semiconductor

t

l

CA3098

OBSOLETE PRODUCT

le

3098)

ject

gram-

e

itt

erwith

ory,

Input

ision

l

ctor)

hor ()

words

ris

icon-

arator,

windetec-

ow

t bias

nt, 5V

e sup-

supply

nt, low

r, ttl

output,

ary

era-

8V,

itt trig-

nput,

in hys-

is, high

ut cur open

ctor

ut)

NO RECOMMENDED REPLACEMENT

Call Central Applications 1-800-442-7747

or email: centapp@harris.com

Programmable Schmitt Trigger with

Memory, Dual Input Precision Level

Detector

The CA3098 Programmable Schmitt Trigger is a monolithic

silicon integrated circuit designed to control high operating

current loads such as thyristors, lamps, relays, etc. The

CA3098 can be operated with either a single power supply

with maximum operating voltage of 16V, or a dual power

supply with maximum operating voltage of ±8V. It can

directly control currents up to 150mA and operates with

microwatt standby power dissipation when the current to be

controlled is less than 30mA. The CA3098 contains the

following major circuit function features (see Block Diagram):

1. Differentialamplifiers and summer: the circuit uses two

differential amplifiers, one to compare the input voltage

with the “high” reference, and the other to compare the

input with the “low” reference. The resultant output of the

differentialamplifiersactuatesa summer circuit which deliversa trigger that initiates a change in state of a flip-flop.

2. Flip-flop: the flip-flop functions as a bistable “memory”

element that changes state in response to each trigger

command.

3. Driver and output stages: these stages permitthe circuit

to “sink” maximum peak load currents up to 150mA at terminal 3.

4. Programmable operating current: the circuit incorporates

access at terminal 2 to permit programming the desired

quiescent operating current and performance parameters.

Pinout

CA3098

(PDIP)

TOP VIEW

LOW REF.

I

BIAS

OUT

1

2

3

4

V-

1

8

+IN

7

HIGH REF.

6

V+

5

CURRENT

CONTROL

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

January 1999 File Number 896.5

Features

• Programmable Operating Current

• Micropower Standby Dissipation

• Direct Control of Currents Up to. . . . . . . . . . . . . . . 150mA

• Low Input On/Off Current of Less Than 1nA for

Programmable Bias Current of 1µA

• Built-in Hysteresis. . . . . . . . . . . . . . . . . . . . . . 20mV (Max)

Applications

• Control of Relays, Heaters, LEDs, Lamps, Photosensitive

Devices, Thyristors, Solenoids, etc.

• Signal Reconditioning

• Phase and Frequency Modulators

• On/Off Motor Switching

• Schmitt Triggers, Level Detectors

• Time Delays

• Overvoltage, Overcurrent, Ov ertemperature Protection

• Battery-Operated Equipment

• Square and Triangular-Wave Generators

Part Number Information

PART

NUMBER

CA3098E -55 to 125 8 Ld PDIP E8.3

TEMP

RANGE (oC) PACKAGE PKG. NO.

© Harris Corporation 1999

Copyright

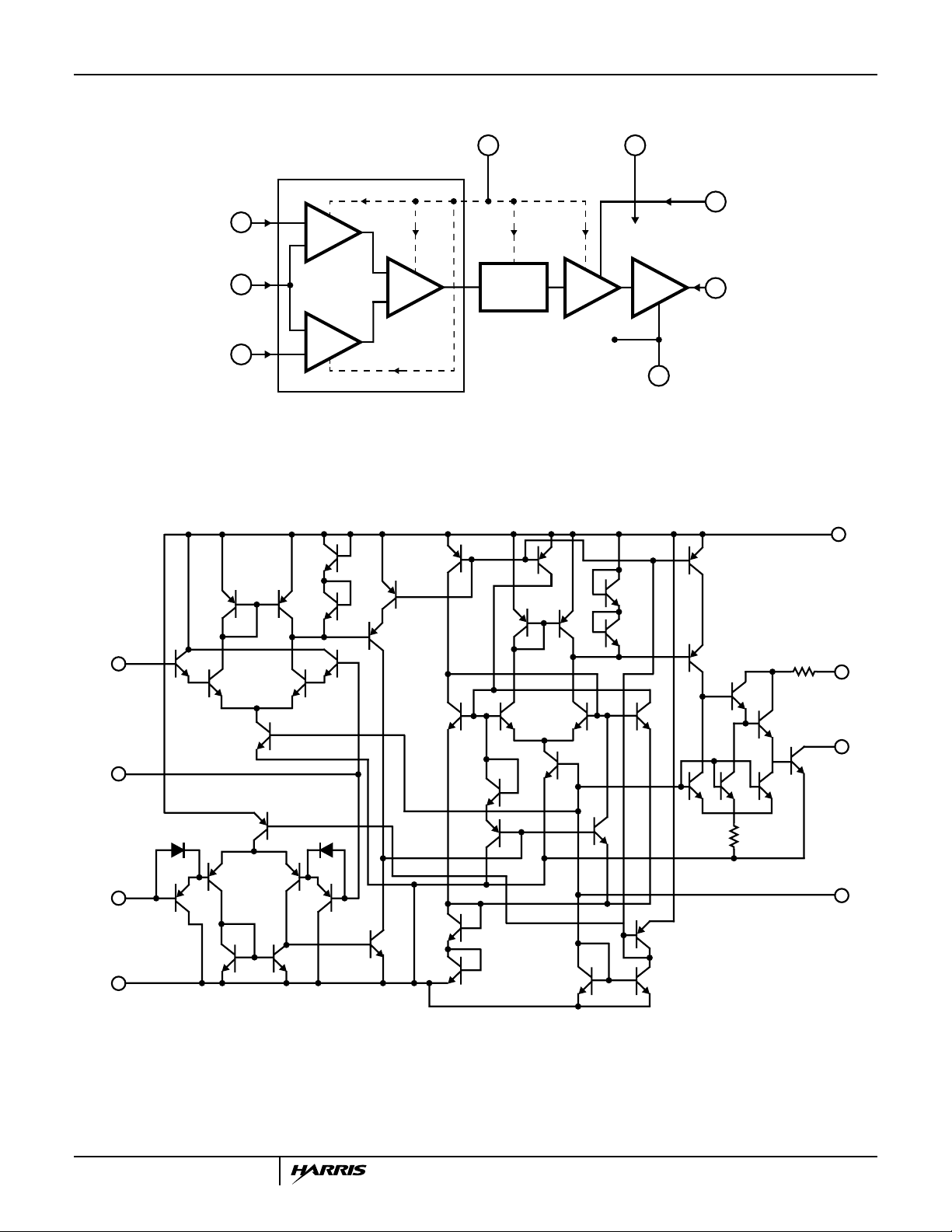

Block Diagram

“HIGH”

REF. (HR)

SIGNAL

INPUT

“LOW”

REF. (LR)

Schematic Diagram

CA3098

PROGRAMMABLE

2

BIAS CURRENT

INPUT (I

7

8

1

DIFF.

AMP

DIFF.

AMP

COMPARATOR

SUMMER

FLIP-FLOP

(MEMORY)

)

BIAS

DRIVER OUTPUT

SUBSTRATE

6

V+

OUTPUT

CURRENT

CONTROL

5

“SINK

OUTPUT”

3

4

V-

“HIGH”

REF. (HR)

7

SIGNAL

INPUT

8

“LOW”

REF. (LR)

1

V-

4

6

OUTPUT

CURRENT

CONTROL

R

14

500Ω

“SINK”

OUTPUT

Q

46

BIAS

V+

5

3

2

)

Q

8

Q

Q

6

Q

Q

7

9

10

Q

Q

1

Q

2

Q

5

Q

16

Q

Q

12

Q

4

Q

3

14

Q

15

Q

Q

17

Q

18

Q

20

Q

24

Q

11

Q

26

Q

34

19

Q

35

22

Q

27

Q

31

Q

32

Q

23

Q

25

Q

28

Q

30

Q

Q

33

Q

Q

36

Q

Q

39

Q

40

Q

41

29

Q

43

37

38

Q

Q

Q

44

R

3

50K

PROGRAMMABLE

BIAS CURRENT

INPUT (I

42

45

2

CA3098

Absolute Maximum Ratings Thermal Information

Supply Voltage Between V+ and V-. . . . . . . . . . . . . . . . . . . . . . .16V

Voltage Between High Reference or Sink Output and V-. . . . . . .16V

Differential Input Voltage Between Terminals 8 and 1 . . . . . . . . .10V

and Terminals 7 and 8

Load Current (Terminal 3) (Duty Cycle ≤25%). . . . . . . . . . . . 150mA

Input Current to Voltage Regulator (Terminal 5) . . . . . . . . . . . 25mA

Programmable Bias Current (Terminal 2) . . . . . . . . . . . . . . . . . 1mA

Output Current Control (Terminal 5) . . . . . . . . . . . . . . . . . . . . 15mA

Operating Conditions

Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . -55oC to 125oC

Voltage Range

+IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V- to V+

HIGH REF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (V- +2.0V) to V+

LOW REF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (V-) to (V+ -2.0V)

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operationofthe

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

Thermal Resistance (Typical, Note 3) θ

PDIP Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125oC/W

JA

Maximum Junction Temperature (Die). . . . . . . . . . . . . . . . . . .175oC

Maximum Junction Temperature (Plastic Package). . . . . . . . .150oC

Maximum Storage Temperature Range. . . . . . . . . . -65oC to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . 300oC

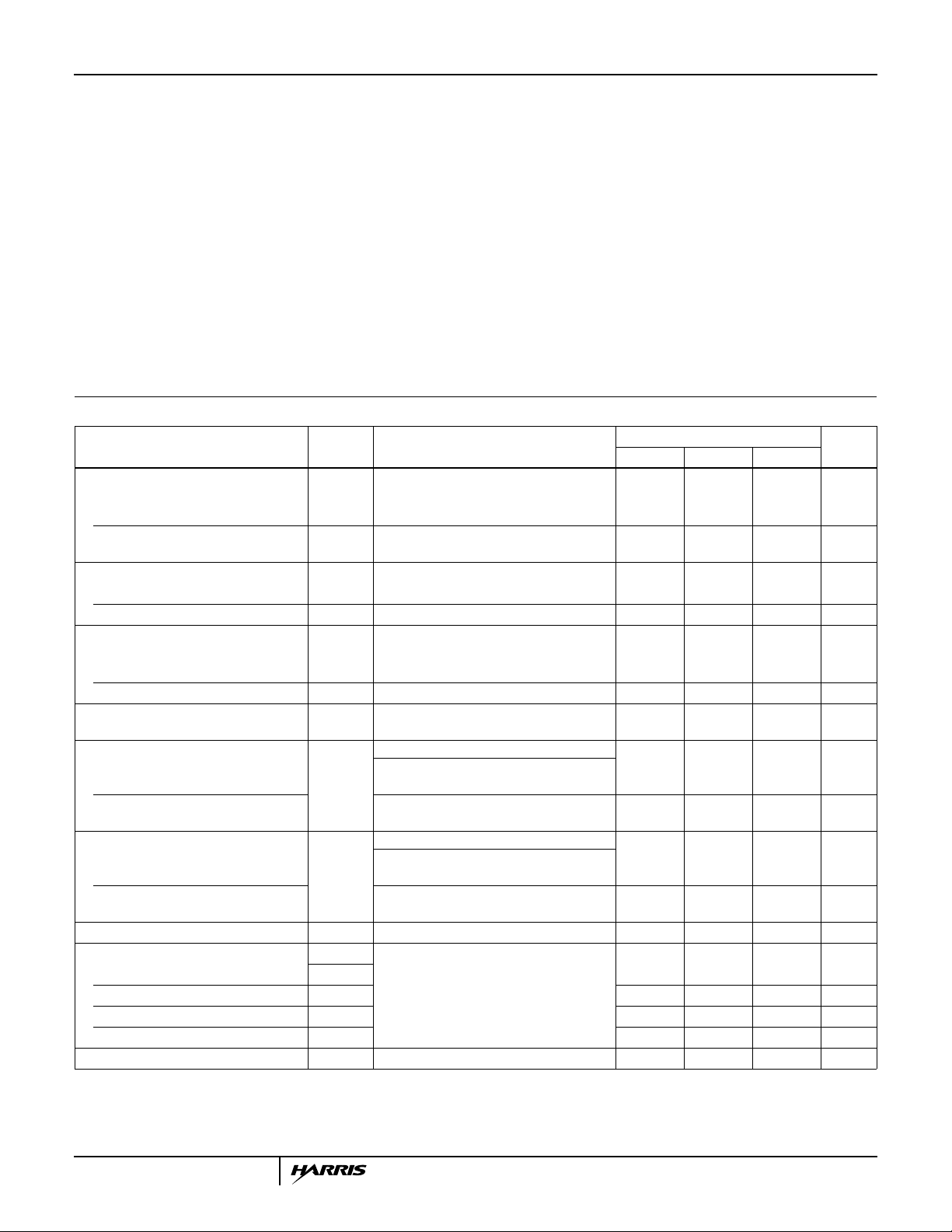

Electrical Specifications T

= 25oC, Unless Otherwise Specified

A

CA3098

PARAMETER SYMBOL TEST CONDITIONS

Input Offset Voltage

“Low” Reference (Figures 2, 5) V

“High Reference (Figures 2, 6) V

IO(LR)VLR

IO(HR)VHR

= GND, VHR = V+ to (V- +2V),

I

= 100µA

BIAS

= GND, VLR = V- to (V+ -2V),

I

= 100µA

BIAS

-15 -3 6 mV

-10 -1 10 mV

Temperature Coefficient

“Low” Reference (Figure 7) -55oC to 125oC - 4.5 - µV/oC

“High” Reference (Figure 8) -55oC to 125oC-±8.2 - µV/oC

Minimum Hysteresis

Voltage (Figure 9) V

IO(HR-

LR)

V

= 0V (Note 1), V+ = 4V, V- = -4V, I

REG

= 1µA

IAS

B-

- 3 20 mV

Temperature Coefficient (Figure 10) -55oC to 125oC - 6.7 - µV/oC

Output Saturation Voltage

(Figures 11, 12)

Total Supply Current I

“ON” (Figures 3, 13, 14) VI = 6V, V

“OFF” (Figures 3, 13, 14) VI = 10V, V

Input Bias Current (Figures 3, 15) I

I

B(PNP)

I

B(NPN)

Output Leakage Current I

Switching Times (Figures 4, 16-27) I

Delay Time t

Fall Time t

Rise Time t

Storage Time t

Output Current (Note 2) I

V

CE(SAT)VI

TOTAL

IB

CE(OFF)

D

F

R

S

O

= 5V, V

I

= 100µA

BIAS

I

= 100µA

BIAS

V+ = 16V, I

VI = 16V, V

V+ = 16V, I

VI = 6V, V

I

= 100µA

BIAS

= 6V (Note 1), V+ = 12V,

REG

> 6V (Note 1), V+ = 16V,

REG

< 10V (Note 1),

REG

= 100µA

BIAS

< 16V (Note 1),

REG

= 100µA

BIAS

> 6V (Note 1), V+ = 16V,

REG

- 0.72 1.2 V

500 710 800 µA

400 560 750 µA

- 42 100 nA

- 28 100 nA

Current from Terminal 3 when Q46 is “OFF” - - 10 µA

= 100µA, V+ = 5V, V

BIAS

(Note 1)

REG

= 2.5V

- 900 - ns

-30-ns

- 2000 - ns

- 6.5 - µs

100 - - mA

NOTES:

1. For definition of V

see Figure 3.

REG

2. Continuous (DC) output current must be limited to ≤40mA. For 100mA output current, the duty cycle must be ≤40%.

3. θJA is measured with the component mounted on an evaluation PC board in free air.

UNITSMIN TYP MAX

3

CA3098

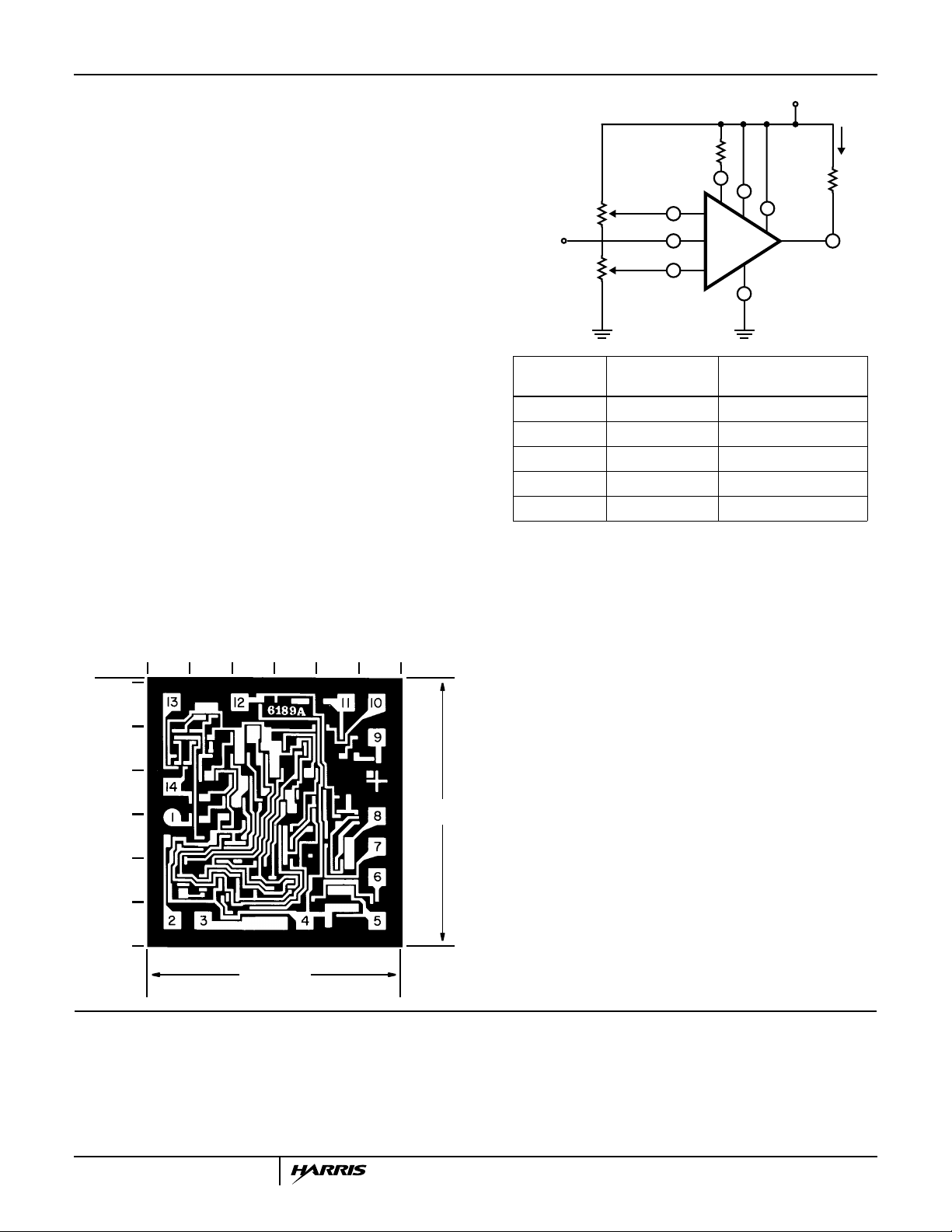

General Description of Circuit Operation

When the signal input voltage of the CA3098 is equal to or

less than the “low” reference voltage (LR), current flowsfrom

an external power supply through a load connected to

Terminal 3 (“sink” output). This condition is maintained until

the signal input voltage rises to or exceeds the “high”

reference voltage (HR), thereby effecting a change in the

state of the flip-flop (memory) such that the output stage

interrupts current flow in the external load. This condition, in

turn, is maintained until such time as the signal again

becomes equal to or less than the “low” reference voltage.

The CA3098 comparator is unique in that it contains circuit

provisions to permit programmability. This feature provides

flexibility to the designer to optimize quiescent power

consumption, input circuit characteristics, hysteresis, and

additionally permits independent control of the comparator,

namely, pulsing, strobing, keying, squelching, etc.

Programmability is accomplished by means of the bias

current (I

An auxiliary means of controlling the magnitude of load

current flowat Terminal3 is provided by “sinking” current into

Terminal 5. Figure 1 highlights the operation of the CA3098

when connected as a simple hysteresis switch (Schmitt

trigger).

) supplied to Terminal 2.

BIAS

120kΩ

R

B

2

“HIGH” REF. = 8V

7

INPUT

SIGNAL

E

IN

“LOW” REF. = 4V

INPUT SIGNAL

SEQUENCE

14≥ EIN > 0 0

28≥ EIN > 4 0

3E

28≥ EIN > 4 12

14≥ EIN > 0 0

FIGURE 1. BASIC HYSTERESIS SWITCH (SCHMITT

TRIGGER) AND RESULTANT OUTPUT STATES

8

1

LEVEL

> 8 12

IN

6

5

CA3098

4

OUTPUT VOLTAGE (V)

(TERMINAL 3)

V+ = 12V

3

DC

I

O

R

L

E

O

Metallization Mask Layout

0 102030 405058

61

60

50

40

30

20

10

0

63 (1.600)

66 (1.676)

Dimensions in parentheses are in millimeters and are derived

from the basic inch dimensions as indicated. Grid graduations

are in mils (10

-3

inch).

The layout represents a chip when it is part of the wafer. When

the wafer is cut into chips, the cleavage angles are 57

o

of 90

with respect to the face of the chip. Therefore, the

o

instead

isolated chip is actually 7mils (0.17mm) larger in both

dimensions.

4

Loading...

Loading...