Datasheet 5962-0620705Q3A, 5962-0620706Q3A, 5962-0620707Q2A, 5962-0620708Q2A Datasheet (intersil)

®

http://www.BDTIC.com/Intersil

5962-0620705Q3A, 5962-0620706Q3A,

5962-0620707Q2A, 5962-0620708Q2A

Data Sheet May 31, 2006

±15kV ESD Protected, +5.0V 1Microamp,

250kbps, RS-232 Transmitters/Receivers

The Intersil 5962-062070xQxA devices are 5.0V powered

RS-232 transmitters/receivers which meet ElA/TIA-232 and

V.28/V.24 specifications. Additionally, they provide ±15kV

ESD protection (IEC61000-4-2 Air Gap and MIL-STD 883

Human Body Model) on transmitter outputs and receiver

inputs (RS-232 pins). Targeted applications include

ruggedized portable products and remotely deployed

devices exposed to extreme temperature and humidity

where the low operational and even lower standby, power

consumption is critical. Efficient on-chip charge pumps,

coupled with manual and automatic power-down functions

(except for the 5962-0620707Q2A), reduce the standby

supply current to a 1µA trickle. Small footprint packaging and

the use of small, low value capacitors ensure board space

savings as well. Data rates greater than 250kbps are

guaranteed at worst case load conditions. This family is fully

compatible with 5.0V-only systems.

Specifications for QML devices are controlled by the

Defense Supply Center in Columbus (DSCC). The SMD

numbers listed here must be used when ordering.

Detailed Electrical Specifications for these devices are

contained in SMD 5962-06207. A “hot-link” is provided

on our website for downloading.

FN6298.0

Features

• Meets EIA/TIA-232 and V.28/V.24 Specifications at 5V

• Electrically Screened to DSCC SMD#5962-06207

• QML Qualified per MIL-PRF-38535 Requirements

• SMD Compliance

• Military Temperature Range

• Latch-up Free

• Hermetic Package

• ESD Protection for RS-232 I/O Pins to ±15kV (IEC61000)

• Guaranteed Mouse Driveability (ICL3243E)

• Requires Single +5.0V ±10% Power Supply

• Receiver Hysteresis for Improved Noise Immunity

• Low Power Automatic Power-down Modes

(Except for ICL3232E) . . . . . . . . . . . . . . . . . . . . . . . . .1µA

• Guaranteed Minimum 250kbps Data Rate

• Manual and Automatic Power-down Features

• Multiple Drivers/Receivers

• On-Chip Voltage Converters Require Only Four External

Capacitors

• Regulated Dual Charge Pumps

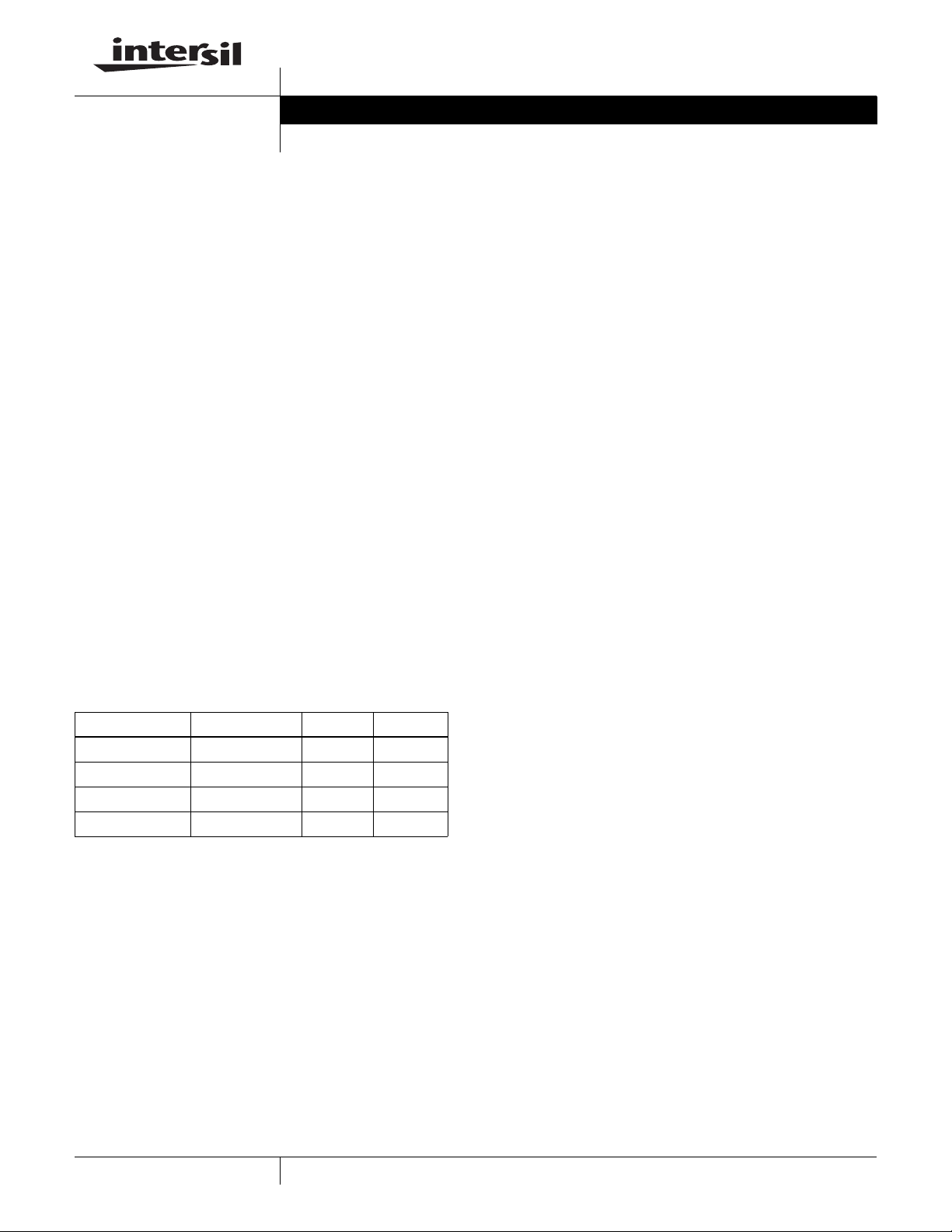

Ordering Information

DESC P/N CONFIGURATION TEMP (°C) PACKAGE

5962-0620705Q3A ICL3243E 3D/5R -55 to +125 28 Ld CLCC

5962-0620706Q3A ICL3238E 5D/3R -55 to +125 28 Ld CLCC

5962-0620707Q2A ICL3232E 2D/2R -55 to +125 20 Ld CLCC

5962-0620708Q2A ICL3221E 1D/1R -55 to +125 20 Ld CLCC

Applications

• Any Military or High-Rel System Requiring RS-232

Communication Ports

- Battery Powered, Hand-Held, and Portable Equipment

- Ruggedized Handheld GPS, Laptop Computers,

Notebooks, Palmtops

- Industrial Control/Shop Floor Communications

- Field Deployed Sensors/Devices Exposed to Extreme

Temperature/Humidity

- Ruggedized Cellular/Mobile Phones

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright Intersil Americas Inc. 2006. All Rights Reserved

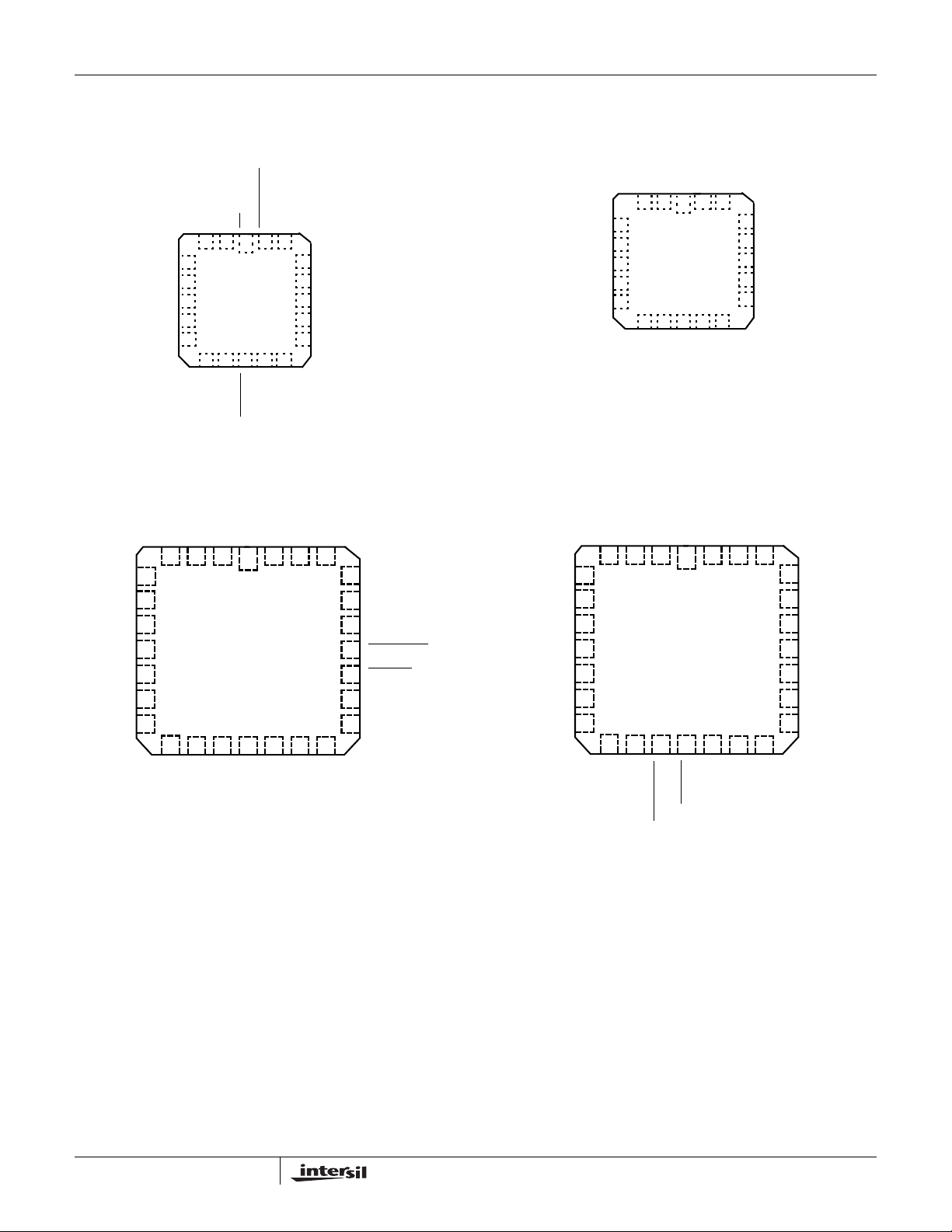

Pinouts

http://www.BDTIC.com/Intersil

5962-0620705Q3A, 5962-0620706Q3A, 5962-0620707Q2A, 5962-0620708Q2A

C1-

C2+

C2-

NC

4

5

6

V-

7

8

ICL3221E (CLCC)

TOP VIEW

EN

C1+

V+

3

9101112

IN

R1

FORCEOFF

220119

13

IN

OUT

T1

R1

INVALID

VCC

18

17

16

15

14

NC

NC

GND

T1OUT

NC

FORCEON

C1-

C2+

C2-

NC

4

5

6

V-

7

8

ICL3232E (CLCC)

TOP VIEW

C1+

V+

VCC

R2

GND

13

IN

NC

OUT

T2

NC

3

220119

9101112

IN

OUT

R2

T2

NC

18

T1

17

OUT

R1

16

IN

R1

15

OUT

14

T1

IN

T

T

T

R

2 IN

R

3 IN

R

4 IN

R

5 IN

1 OUT

2 OUT

3 OUT

5

6

7

8

9

10

11

ICL3243E (CLCC)

1 IN

R

V-

3 2 14

14 15 16 17 1812 13

3 INT2 INT1 IN

T

TOP VIEW

C2+

C2-

5 OUT

R

+

1

V+

C

28 27 26

4 OUTR3 OUTR2 OUT

R

VCC

25

24

23

22

21

20

19

GND

C1-

FORCEON

FORCEOFF

INVALID

R

2OUTB

R

1 OUT

T1 OUT

T2 OUT

T3 OUT

R1 IN

R2 IN

T4 OUT

R3 IN

ICL3238E (CLCC)

TOP VIEW

V-

5

6

7

8

9

10

11

T5 OUT

GND

C2-

3 2 14

14 15 16 17 1812 13

FORCEON

FORCEOFF

C1+

C2+

28 27 26

INVALID

R1OUTB

V+

T5 IN

VCC

25

24

23

22

21

20

19

R3 OUT

C1-

T1 IN

T2 IN

T3 IN

R1 OUT

R2 OUT

T4 IN

2

FN6298.0

May 31, 2006

5962-0620705Q3A, 5962-0620706Q3A, 5962-0620707Q2A, 5962-0620708Q2A

http://www.BDTIC.com/Intersil

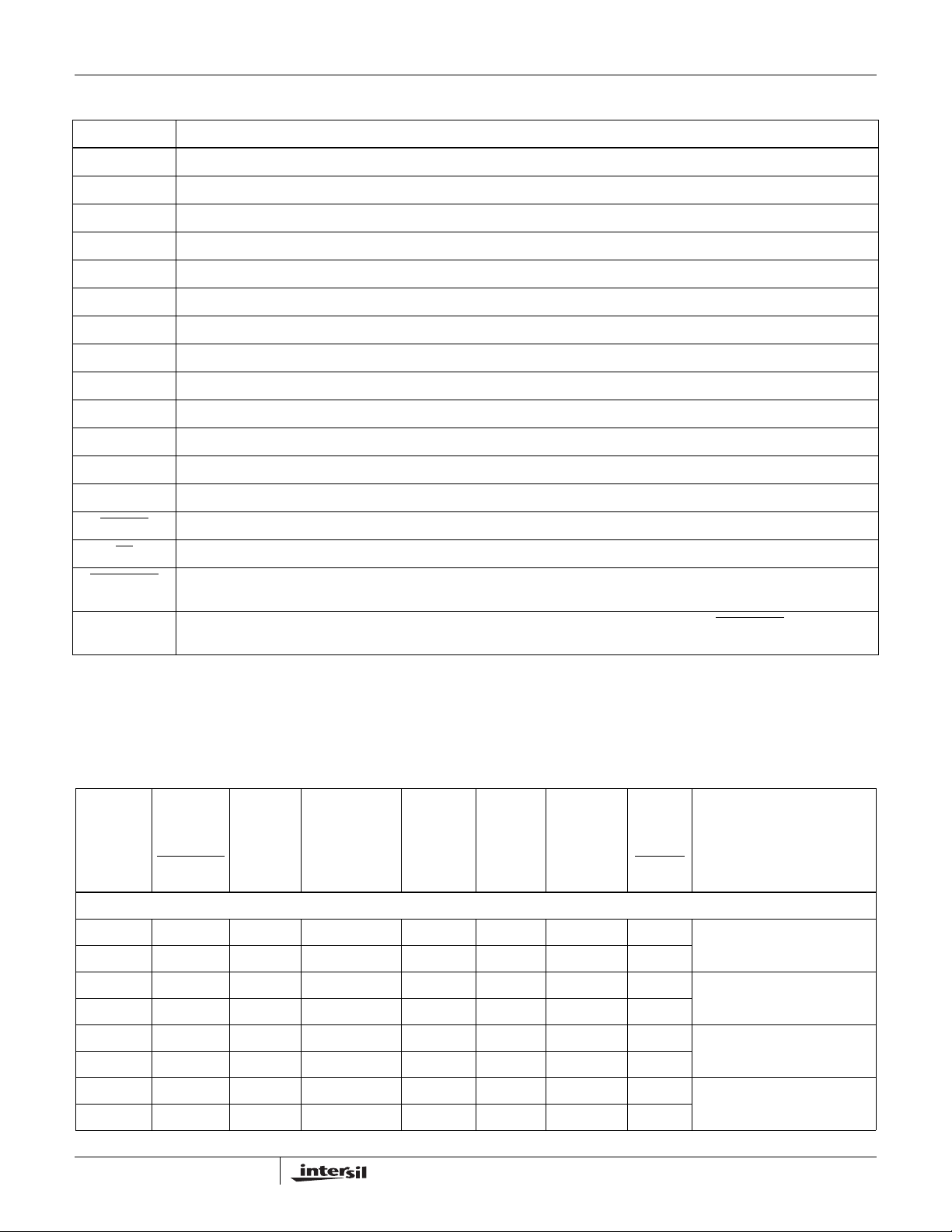

Pin Descriptions

PIN FUNCTION

V

CC

V+ Internally generated positive transmitter supply.

V- Internally generated negative transmitter supply.

GND Ground connection.

C1+ External capacitor (voltage doubler) is connected to this lead.

C1- External capacitor (voltage doubler) is connected to this lead.

C2+ External capacitor (voltage inverter) is connected to this lead.

C2- External capacitor (voltage inverter) is connected to this lead.

T

IN

T

OUT

R

IN

R

OUT

R

OUTB

INVALID

EN

FORCEOFF

System power supply input (4.5V to 5.5V).

TTL/CMOS compatible transmitter Inputs. (Note 1)

±15kV ESD Protected, RS-232 level (nominally ±5.5V) transmitter outputs.

±15kV ESD Protected, RS-232 compatible receiver inputs.

TTL/CMOS level receiver outputs.

TTL/CMOS level, noninverting, always enabled receiver outputs.

Active low output that indicates if no valid RS-232 levels are present on any receiver input.

Active low receiver enable control.

Active low control to shut down transmitters and on-chip power supply. This overrides any automatic circuitry and FORCEON

(See Tables 1 & 2, Note 1).

FORCEON Active high input to override automatic power-down circuitry thereby keeping transmitters active. (FORCEOFF

Note 1).

NOTE:

1. The ICL3238E input pins incorporate positive feedback resistors. Once the input is driven to a valid logic level, the feedback resistor maintains

that logic level until V

RCVR OR

XMTR

EDGE

WITHIN 30

SEC?

ICL3238E

No H H Active Active Active No L Normal Operation (Enhanced

No H H Active Active Active Yes H

Yes H L Active Active Active No L Normal Operation (Enhanced

Yes H L Active Active Active Yes H

No H L High-Z Active Active No L Power-down Due to Enhanced

No H L High-Z Active Active Yes H

FORCEOFF

INPUT

is removed. Unused transmitter inputs may be left unconnected by the user.

CC

TABLE 1. POWER-DOWN LOGIC TRUTH TABLE

RS-232

LEVEL

PRESENT

FORCEON

INPUT

TRANSMITTER

OUTPUTS

RECEIVER

OUTPUTS

R

OUTB

OUTPUT

AT

RECEIVER

INPUT?

INVALID

OUTPUT MODE OF OPERATION

Auto Power-down Disabled)

Auto Power-down Enabled)

Auto Power-down Logic

must be high,

X L X High-Z High-Z Active No L Manual Power-down

X L X High-Z High-Z Active Yes H

3

FN6298.0

May 31, 2006

5962-0620705Q3A, 5962-0620706Q3A, 5962-0620707Q2A, 5962-0620708Q2A

http://www.BDTIC.com/Intersil

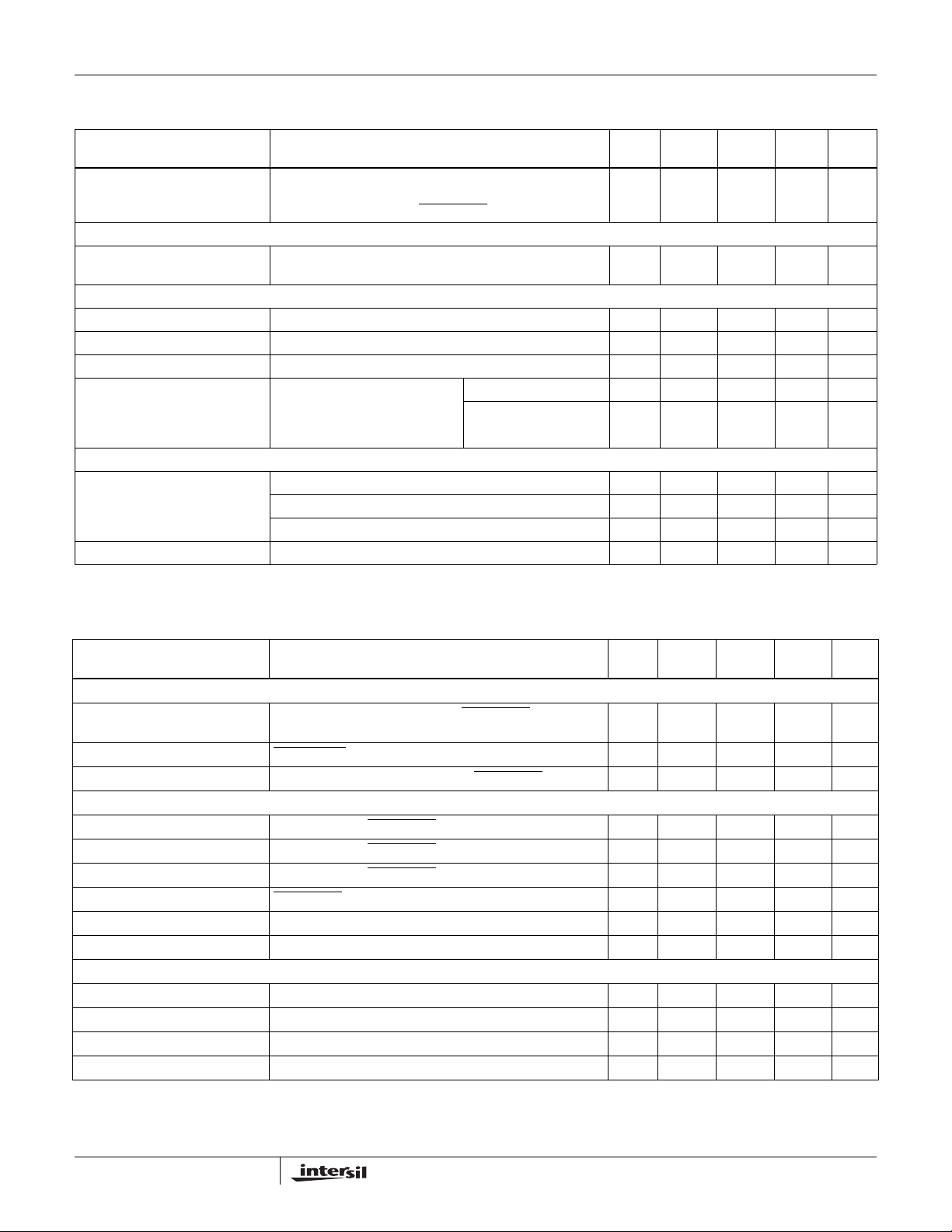

TABLE 1. POWER-DOWN LOGIC TRUTH TABLE (Continued)

RS-232

RCVR OR

XMTR

EDGE

WITHIN 30

SEC?

INVALID DRIVING FORCEON AND FORCEOFF (EMULATES AUTOMATIC POWER-DOWN)

X Note 2 Note 2 Active Active Active Yes H Normal Operation

X Note 2 Note 2 High-Z High-Z Active No L Forced Auto Power-down

NOTE:

2. Input is connected to INVALID

RS-232

SIGNAL

PRESENT

AT

RECEIVER

INPUT?

ICL3221E

No H H L Active Active N.A. L Normal Operation

No H H H Active High-Z N.A. L

Yes H L L Active Active N.A. H Normal Operation

Yes H L H Active High-Z N.A. H

No H L L High-Z Active N.A. L Power-down Due to Auto Power-down

No H L H High-Z High-Z N.A. L

Yes L X L High-Z Active N.A. H Manual Power-down

Yes L X H High-Z High-Z N.A. H Manual Power-down w/Rcvr. Disabled

No L X L High-Z Active N.A. L Manual Power-down

No L X H High-Z High-Z N.A. L Manual Power-down w/Rcvr. Disabled

ICL3243E

No H H N.A. Active Active Active L Normal Operation

Yes H L N.A. Active Active Active H Normal Operation

No H L N.A. High-Z Active Active L Power-down Due to Auto Power-down

Yes L X N.A. High-Z High-Z Active H Manual Power-down

No L X N.A. High-Z High-Z Active L Manual Power-down

NOTE:

3. Applies only to the ICL3243E.

FORCEOFF

INPUT

FORCEOFF

INPUT

FORCEON

INPUT

Output.

TABLE 2. POWER-DOWN AND ENABLE LOGIC TRUTH TABLE

FORCEON

INPUTENINPUT

TRANSMITTER

OUTPUTS

TRANSMITTER

OUTPUTS

RECEIVER

OUTPUTS

RECEIVER

OUTPUTS

R

OUTB

OUTPUT

LEVEL

PRESENT

RECEIVER

INPUT?

(NOTE 3)

R

OUTB

OUTPUTS

AT

INVALID

OUTPUT MODE OF OPERATION

INVALID

OUTPUT MODE OF OPERATION

(Auto Power-down Disabled)

(Auto Power-down Enabled)

Logic

(Auto Power-down Disabled)

(Auto Power-down Enabled)

Logic

4

FN6298.0

May 31, 2006

5962-0620705Q3A, 5962-0620706Q3A, 5962-0620707Q2A, 5962-0620708Q2A

http://www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

VCC to Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to 6V

V+ to Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to 7V

V- to Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +0.3V to -7V

V+ to V- . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14V

Input Voltages

, FORCEOFF, FORCEON, EN . . . . . . . . . . . . . . . -0.3V to 6V

T

IN

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±25V

R

IN

Output Voltages

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±13.2V

T

OUT

, INVALID. . . . . . . . . . . . . . . . . . . . . . . . -0.3V to VCC +0.3V

R

OUT

Short Circuit Duration

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Continuous

T

OUT

ESD Rating (Receiver Input and Transmitter Output Pins) . . .±15kV

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

Thermal Resistance (Typical)

20 Ld CLCC Package . . . . . . . . . . . . . . . . . . . . . . . 90

28 Ld CLCC Package . . . . . . . . . . . . . . . . . . . . . . . 70

Maximum Junction Temperature (Ceramic Package) . . . . 150°C

Maximum Storage Temperature Range . . . . . . . . . .-65°C to 150°C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . 300°C

θ

JA

(°C/W)

Operating Conditions

Temperature Range

ICL32XXE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-55°C to 125°C

Electrical Specifications ICL3221E, ICL3232E, ICL3243E Test Conditions: V

Unless Otherwise Specified. Typicals are at T

PARAMETER TEST CONDITIONS

DC CHARACTERISTICS

Supply Current, Automatic

Power-down

Supply Current, Power-down FORCEOFF

Supply Current, Power-up All Outputs Unloaded, FORCEON = FORCEOFF

LOGIC AND TRANSMITTER INPUTS AND RECEIVER OUTPUTS

Input Logic Threshold Low T

Input Logic Threshold High T

Input Leakage Current T

Output Leakage Current

(Except ICL3232E)

Output Voltage Low I

Output Voltage High I

AUTOMATIC POWER-DOWN (ICL3221E, ICL3243E Only, FORCEON = GND, FORCEOFF = V

Receiver Input Thresholds to

Enable Transmitters

Receiver Input Thresholds to

Disable Transmitters

INVALID

INVALID

RECEIVER INPUTS

Input Voltage Range Full -25 - 25 V

Input Threshold Low Full 0.6 1.2 - V

Input Threshold High Full - 1.5 2.4 V

Input Resistance Full 3 5 7 kΩ

TRANSMITTER OUTPUTS

Output Voltage Swing All Transmitter Outputs Loaded with 3kW to Ground Full ±5.0 ±5.4 - V

Output Resistance V

Output Short-Circuit Current Full - ±35 ±60 mA

Output Voltage Low I

Output Voltage High I

Open, FORCEON = GND, FORCEOFF =V

All R

IN

(ICL3221E, ICL3243E Only)

= GND (Except ICL3232E) Full - 1 10 µA

, FORCEON, FORCEOFF, EN Full - - 0.8 V

IN

, FORCEON, FORCEOFF, EN Full 2.2 - - V

IN

, FORCEON, FORCEOFF, EN Full - ±0.01 ±10 µA

IN

FORCEOFF

OUT

OUT

Powers Up Full -2.7 - 2.7 V

Powers Down Full -0.3 - 0.3 V

OUT

OUT

CC

=GND or EN=V

= 1.6mA Full - - 0.4 V

= -1.0mA Full V

= 1.6mA Full - - 0.4 V

= -1.0mA Full VCC-0.9 - - V

= V+ = V- = 0V, Transmitter Output = ±2V Full 300 10M - Ω

CC

= 25°C, VCC = 5.0V

A

= 4.5V to 5.5V, C1 = 0.01mF, C2 - C4 = 0.1mF;

CC

TEMP

(°C) MIN TYP MAX UNITS

CC

=V

CC

Full - 1 10 µA

Full - 0.3 1.8 mA

Full - ±0.05 ±10 µA

CC

-0.9 V

CC

)

-0.3 - V

CC

5

FN6298.0

May 31, 2006

5962-0620705Q3A, 5962-0620706Q3A, 5962-0620707Q2A, 5962-0620708Q2A

http://www.BDTIC.com/Intersil

Electrical Specifications ICL3221E, ICL3232E, ICL3243E Test Conditions: V

Unless Otherwise Specified. Typicals are at T

= 25°C, VCC = 5.0V (Continued)

A

= 4.5V to 5.5V, C1 = 0.01mF, C2 - C4 = 0.1mF;

CC

TEMP

PARAMETER TEST CONDITIONS

Output Leakage Current V

=±12V, VCC= 0V or 4.5V to 5.5V

OUT

(ICL3232E,V

Automatic Power-down or FORCEOFF

= 0V only)

CC

=GND

(°C) MIN TYP MAX UNITS

Full - - ±25 µA

MOUSE DRIVEABILITY (ICL3243 Only)

Transmitter Output Voltage T1

GND, T1

=T2IN=GND, T3IN=VCC, T3

IN

OUT

and T2

Loaded with 2.5mA Each

OUT

Loaded with 3kW to

OUT

Full ±5 - - V

TIMING CHARACTERISTICS

Maximum Data Rate R

Transmitter Skew t

Receiver Skew t

Transition Region Slew Rate V

=3kW, CL= 1000pF, One Transmitter Switching Full 250 500 - kbps

L

- t

PHL

PLH

- t

PHL

PLH

=5.0V,

CC

= 3kW to 7kW,

R

L

Measured From 3V to -3V or -3V

= 200pF to 2500pF Full 4 8.0 50 V/µs

C

L

= 200pF to 1000pF Full 6 - 50 V/µs

C

L

Full - 200 1000 ns

Full - 100 1000 ns

to 3V

ESD PERFORMANCE

RS-232 Pins (T

, RIN) Human Body Model (MIL-STD 883 Method 3015) 25 - ±15 - kV

OUT

IEC61000-4-2 Contact Discharge 25 - ±8 - kV

IEC61000-4-2 Air Gap Discharge 25 - ±15 - kV

All Other Pins Human Body Model (MIL-STD 883 Method 3015) 25 - ±2 - kV

Electrical Specifications ICL3238E Test Conditions: V

Typicals are at T

= 25°C, VCC = 5.0V

A

= 4.5V to 5.5V, C1 = 0.01mF, C2 - C4 = 0.1mF, Unless Otherwise Specified.

CC

TEMP

PARAMETER TEST CONDITIONS

(°C) MIN TYP MAX UNITS

DC CHARACTERISTICS

Supply Current, Automatic

Power-down

Supply Current, Power-down FORCEOFF

Supply Current, Power-up All Outputs Unloaded, FORCEON = FORCEOFF

All R

Open, FORCEON = GND, FORCEOFF = V

IN

= GND Full -110µA

CC

= V

CC

Full -110µA

Full -0.31.8mA

LOGIC AND TRANSMITTER INPUTS AND RECEIVER OUTPUTS

Input Logic Threshold Low T

Input Logic Threshold High T

Input Leakage Current T

Output Leakage Current FORCEOFF

Output Voltage Low I

Output Voltage High I

, FORCEON, FORCEOFF Wake up Threshold Full --0.8V

IN

, FORCEON, FORCEOFF Wake up Threshold Full 2.4 - - V

IN

, FORCEON, FORCEOFF, VIN = 0V or VCC (Note 4) Full - ±0.01 ±10 µA

IN

= GND Full - ±0.05 ±10 µA

= 1.0mA Full --0.4V

OUT

= -1.0mA Full V

OUT

CC

-0.9 V

-0.3 - V

CC

RECEIVER INPUTS

Input Voltage Range Full -25 - 25 V

Input Threshold Low Full 0.8 1.5 - V

Input Threshold High Full -1.82.4V

Input Resistance Full 357kΩ

6

FN6298.0

May 31, 2006

5962-0620705Q3A, 5962-0620706Q3A, 5962-0620707Q2A, 5962-0620708Q2A

http://www.BDTIC.com/Intersil

Electrical Specifications ICL3238E Test Conditions: V

Typicals are at T

PARAMETER TEST CONDITIONS

ENHANCED AUTOMATIC POWER-DOWN (FORCEON = GND, FORCEOFF = VCC)

Receiver Input Thresholds to

INVALID

Receiver Input Thresholds to

INVALID

INVALID

INVALID

TRANSMITTER OUTPUTS

Output Voltage Swing All Transmitter Outputs Loaded with 3kΩ to Ground Full ±5.0 ±5.4 - V

Output Short-Circuit Current Full - ±35 ±60 mA

Output Leakage Current V

TIMING CHARACTERISTICS

Maximum Data Rate R

Transmitter Skew t

Receiver Skew t

Transition Region Slew Rate V

ESD PERFORMANCE

RS-232 Pins (T

All Other Pins Human Body Model (MIL-STD 883 Method 3015) 25 - ±2.5 - kV

NOTE:

High

Low

Output Voltage Low I

Output Voltage High I

, RIN) IEC61000-4-2 Air Gap Discharge 25 - ±15 - kV

OUT

4. These inputs utilize a positive feedback resistor. The input current is negligible when the input is at either supply rail.

Powered Up Full -2.7 - 2.7 V

Powered Down Full -0.3 - 0.3 V

= 1.0mA Full - - 0.4 V

OUT

= -1.0mA Full VCC-0.9 - - V

OUT

= ±12V, VCC = 0V or 4.5V to 5.5V,

OUT

Automatic Power-down or FORCEOFF

= 3kΩ, CL = 1000pF, One Transmitter Switching Full 250 500 - kbps

L

- t

PHL

PLH

- t

PHL

PLH

= 5.0V,

CC

= 3kΩ to 7kΩ,

R

L

Measured From 3V to -3V or -3V

to 3V

IEC61000-4-2 Contact Discharge 25 - ±8-kV

Human Body Model (MIL-STD 883 Method 3015) 25 - ±15 - kV

= 25°C, VCC = 5.0V (Continued) (Continued)

A

= 4.5V to 5.5V, C1 = 0.01mF, C2 - C4 = 0.1mF, Unless Otherwise Specified.

CC

TEMP

(°C) MIN TYP MAX UNITS

Full - - ±25 µA

= GND

Full - 200 1000 ns

Full - 100 1000 ns

= 150pF to 1000pF Full 61550V/µs

C

L

= 150pF to 2500pF Full 41250V/µs

C

L

Die Characteristics

INTERFACE MATERIALS:

Glassivation:

Type: PSG (Phosphorous Silicon Glass)

Thickness: 13.0kÅ ± 1.0kÅ

Top Metallization:

Type: AlSiCu

Thickness: 10.0kÅ ± 1kÅ

ASSEMBLY RELATED INFORMATION:

Substrate Potential:

GND

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implic atio n or other wise u nde r any p a tent or patent rights of Intersil or its subs idi aries.

For information regarding Intersil Corporation and its products, see www.intersil.com

7

ADDITIONAL INFORMATION:

Worst Case Current Density:

5

<2.0 x 10

A/cm

2

Transistor Count:

ICL3221E: 286

ICL3232E: 296

ICL3243E: 464

ICL3238E: 1235

Process:

Si Gate CMOS

FN6298.0

May 31, 2006

5962-0620705Q3A, 5962-0620706Q3A, 5962-0620707Q2A, 5962-0620708Q2A

http://www.BDTIC.com/Intersil

Ceramic Leadless Chip Carrier Packages (CLCC)

j x 45

E1

o

B

h x 45

-E-

E2

e1

o

A

-F-

0.010 E HS S

L

D

D3

0.007 E FM S HS

B1

L2

D1

-H-

D2

B2

J28.A MIL-STD-1835 CQCC1-N28 (C-4)

28 PAD CERAMIC LEADLESS CHIP CARRIER PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.060 0.100 1.52 2.54 6, 7

A1 0.050 0.088 1.27 2.23 -

B-----

B1 0.022 0.028 0.56 0.71 2, 4

E

E3

0.010 E FSS

A1

PLANE 2

PLANE 1

e

L3

B3

L1

B2 0.072 REF 1.83 REF B3 0.006 0.022 0.15 0.56 -

D 0.442 0.460 11.23 11.68 D1 0.300 BSC 7.62 BSC D2 0.150 BSC 3.81 BSC D3 - 0.460 - 11.68 2

E 0.442 0.460 11.23 11.68 E1 0.300 BSC 7.62 BSC E2 0.150 BSC 3.81 BSC E3 - 0.460 - 11.68 2

e 0.050 BSC 1.27 BSC -

e1 0.015 - 0.38 - 2

h 0.040 REF 1.02 REF 5

j 0.020 REF 0.51 REF 5

L 0.045 0.055 1.14 1.40 -

L1 0.045 0.055 1.14 1.40 L2 0.075 0.095 1.90 2.41 -

L3 0.003 0.015 0.08 0.038 ND 7 7 3

NE 7 7 3

N28 283

NOTES:

1. Metallized castellations shall be connected to plane 1 terminals

and extend toward plane 2 across at least two layers of ceramic

or completely across all of the ceramic layers to make electrical

connection with the optional plane 2 terminals.

2. Unless otherwise specified, a minimum clearance of 0.015 inch

(0.38mm) shall be maintained between all metallized features

(e.g., lid, castellations, terminals, thermal pads, etc.)

3. Symbol “N” is the maximum number of terminals. Symbols “ND”

and “NE” are the number of terminals along the sides of length

“D” and “E”, respectively.

4. The required plane 1 terminals and optional plane 2 terminals (if

used) shall be electrically connected.

5. The corner shape (square, notch, radius, etc.) may vary at the

manufacturer’s option, from that shown on the drawing.

6. Chip carriers shall be constructed of a minimum of two ceramic

layers.

7. Dimension “A” controls the overall package thickness. The maximum “A” dimension is package height before being solder dipped.

8. Dimensioning and tolerancing per ANSI Y14.5M-1982.

9. Controlling dimension: INCH.

NOTESMIN MAX MIN MAX

Rev. 0 5/18/94

8

FN6298.0

May 31, 2006

5962-0620705Q3A, 5962-0620706Q3A, 5962-0620707Q2A, 5962-0620708Q2A

http://www.BDTIC.com/Intersil

Ceramic Leadless Chip Carrier Packages (CLCC)

j x 45

E1

o

B

h x 45

-E-

E2

e1

o

A

-F-

0.010 E HS S

L

D

D3

0.007 E FM S HS

B1

L2

D1

-H-

D2

B2

J20.A MIL-STD-1835 CQCC1-N20 (C-2)

20 PAD CERAMIC LEADLESS CHIP CARRIER PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.060 0.100 1.52 2.54 6, 7

A1 0.050 0.088 1.27 2.23 -

B-----

B1 0.022 0.028 0.56 0.71 2, 4

E

E3

0.010 E FSS

A1

PLANE 2

PLANE 1

e

L3

B3

L1

B2 0.072 REF 1.83 REF B3 0.006 0.022 0.15 0.56 -

D 0.342 0.358 8.69 9.09 D1 0.200 BSC 5.08 BSC D2 0.100 BSC 2.54 BSC D3 -0.358-9.092

E 0.342 0.358 8.69 9.09 E1 0.200 BSC 5.08 BSC E2 0.100 BSC 2.54 BSC E3 -0.358-9.09 2

e 0.050 BSC 1.27 BSC -

e1 0.015 - 0.38 - 2

h 0.040 REF 1.02 REF 5

j 0.020 REF 0.51 REF 5

L 0.045 0.055 1.14 1.40 -

L1 0.045 0.055 1.14 1.40 L2 0.075 0.095 1.91 2.41 -

L3 0.003 0.015 0.08 0.38 ND 5 5 3

NE 5 5 3

N20 203

NOTES:

1. Metallized castellations shall be connected to plane 1 terminals

and extend toward plane 2 across at least two layers of ceramic

or completely across all of the ceramic layers to make electrical

connection with the optional plane 2 terminals.

2. Unless otherwise specified, a minimum clearance of 0.015 inch

(0.38mm) shall be maintained between all metallized features

(e.g., lid, castellations, terminals, thermal pads, etc.)

3. Symbol “N” is the maximum number of terminals. Symbols “ND”

and “NE” are the number of terminals along the sides of length

“D” and “E”, respectively.

4. The required plane 1 terminals and optional plane 2 terminals (if

used) shall be electrically connected.

5. The corner shape (square, notch, radius, etc.) may vary at the

manufacturer’s option, from that shown on the drawing.

6. Chip carriers shall be constructed of a minimum of two ceramic

layers.

7. Dimension “A” controls the overall package thickness. The maximum “A” dimension is package height before being solder dipped.

8. Dimensioning and tolerancing per ANSI Y14.5M-1982.

9. Controlling dimension: INCH.

NOTESMIN MAX MIN MAX

Rev. 0 5/18/94

9

FN6298.0

May 31, 2006

Loading...

Loading...