Page 1

COMPACT

GC

Instruction manual

version 2.01 (January 2005)

Page 2

CompactGC manual

CompactGC Instruction Manual

January 2005 Edition

© 2005 Interscience B.V., The Netherlands. All rights reserved.

Published by Interscience B.V., The Netherlands, P.O. Box 2148, 4800 CC Breda

Tel: +31 76 5411800 Fax: +31 76 5420088

Printing History: First Edition, version 1.04, released July 2003

Second Edition, version 2.01, released January 2005

Disclaimer

Technical Information contained in this publication is for reference purposes only and is subject to change

without notice. Every effort has been made to supply complete and accurate information; however,

Interscience B.V. assumes no responsibility and will not be liable for any errors, omissions, damage, or loss

that might result from any use of this manual or the information contained therein (even if this information is

properly followed and problems st ill aris e).

This publication is not part of the Agreement of Sale between Interscience B.V. and the purchaser of a

CompactGC system. In the event of any conflict between the provisions of this document and those

contained in Interscience B.V. Terms of Delivery, the provisions of the Terms of Delivery shall govern.

Reference to System Configurations and Specifications supersede all previous information and are subject

to change without notice.

Trademarks

CompactGC is a trademark of Interscience B.V. Other brand and product names may be trad emarks or

registered trademarks of their respective companies.

Valco® valves is a registered trademark of Valco Instruments Co. Inc. and Valco International.

EZChrom® is a trademark of Scientific Software, Inc.

ii

Page 3

CompactGC manual

Manufacturer: Interscien ce B.V .

Interscience B.V. is the manufacturer of the instrument described in this manual and, as such, is responsible

for the instrument safety, reliability and performance only if:

• installa tion

• re-calibration

• changes and repairs

have been carried out by authorized personnel and if:

• the local installation complies with local law regulations

• the instrument is used according to the instructions provided and if its operation is only entrusted to

qualified trained personnel. The CompactGC should be handled as described in the pre-installation guide

“Gaschromatografiesystemen”.

Interscience B.V. is not liable for any d amages derived from the non-co mpliance wi th the aforementioned

recommendations.

Interscience B.V.

Postbus 2148

4800 CC BREDA

The Netherlands

tel: 076-5411800

fax: 076-5420088

www.interscience.nl

info@interscience.nl

iii

Page 4

CompactGC manual

Table of contents

1. Safety 2

2. Installation 4

3. Instrument description 7

3.1 Digital gas supply 8

3.2 Valve oven 10

3.3 Column oven 10

3.4 Detectors 11

4. Pre-concentration Module (PM) 16

5. The CompactGC editor program 17

Command buttons 18

Tab pages 19

Pull down menu’s 22

6. Operation 28

6.1 Column installation 28

6.2 Leak check 30

6.3 Quick start up 31

7. Maintenance and troubleshooting 33

®

Appendix 1: EZChrom

/ EZStart® settings 34

Appendix 2: Electrical connenctions 39

Appendix 3: LED status display 41

Index

1

Page 5

CompactGC manual

1. Safety

Safety summary

The following general safety precautions must be observed during all phases of

operation, service, and repair of this instrument. Failure to comply with these

precautions or with specific warnings elsewhere in this manual violates safety standards

of design, man u f a ct u r e , an d in tended use of this equipment. Interscience assumes no

liability for the customer’s failure to comply with these requirements.

Ground the instrument

To minimize shock hazard, the instrument chassis and cabinet must be connected to an

electrical ground, using the provided three-pin AC power cable.

Do not operate in an explosive atmosphere

Do not operate the instrument in the presence of flammable gasses or fumes.

Operation of any electrical instrument in such an environment constitutes a definite

safety hazard. Contact your supplier for purged housings if the CompactGC needs to

be applied in an EX classified zone.

Keep away from live circuits

Analytical column and component replacement and internal adjustments must be

made by qualified maintenance personnel. Do not replace components with the

power cable connected. Under certain conditions, dangerous voltages may exist even

with the power cable removed. To avoid injuries, always disconnect power and

discharge circuits before touching them.

Do not service or adjust alone

Do not attempt internal service or adjustment unless another person, capable of

rendering first aid and resuscitation, is present.

Do not substitute parts (electronics)

Because of the danger of introducing additional hazards, do not install substitute parts

or perform any unauthorized modification of the instrument. Contact Interscience

Services to ensure that safety features are maintained.

Do not over-pressurize the instrument

See ‘installation’ for maximum allowed pressures.

2

Page 6

CompactGC manual

Hot surfaces should be avoided

The CompactGC has heated inlets. Contacting these inlets once they are at operating

temperatures can result in inju ry.

The use of hydrogen

The use of hydrogen for feeding the flame in certain types of detectors requires the

operator’s extreme attention and the compliance with special precautions due to the

hazards involved in the use of this gas. Moreover, the operator shall be present while

analyses are run to immedi ately detect any malfun ctioning. Hydrogen is a dangerous

gas (when mixed with air it may generate an explosive mixture), particularly when, in a

closed area, it reaches a concentration corresponding to its lower level of explosion

(4% in volume). For these reasons, before using hydrogen, the following

recommendations must be observed:

1. Ensure that all hydrogen cylinders are complying with the safety conditions provided

for their proper use and storage: they must be equipped with suitable safety valves,

automatic safety systems and all that is required by current regulations even with

regard to safety in sites with danger of explosion or fire.

2. During the connection of hydrogen lines, ensure that the gas feeding inlet is

perfectly closed.

3. Before using the instrument, ensure that the lines designed for hydrogen are

perfectly leak-tight.

According to the results obtained, it will be possible to inspect each single section of

the pneumatic circuit as pointed out in said paragraph. Should it be necessary to

operate in the inside of the pneumatic compartment or column oven, the check shall

be carried out with all circuits under pressure. This procedure shall be repeated until all

causes of

leakage have been eliminated.

3

Page 7

CompactGC manual

2. Installation

Instrument classification

The instrument classification is according to IEC 10.10:

• internal use

• temperature 18 to 30 °C

• maximum relative humidity between 50 % and 80 %

• transient overload in compliance with installation categories II

• pollution level according to IEC 664 (3.7.3) 2

Space requirements

The CompactGC measures approximately:

Width : 45.0 cm (without 19” mounting handles)

Height : 17.8 cm (4HE; 18.5 cm including sockets)

Depth : 54.0 cm (including handles)

Weight : depending on configuration, approximately 25 kg

The unit can be placed on a bench, or can be mounted in a standard 19” rack. For

installation of the analytical c olumn and for service, the instrument is accessed by

removing the top cover.

Ventilation

Depending on the configuration and operation parameters, sufficient ventilation must

be available for cooling purposes.

Gasses

Connections

All gas connections are 1/16” Swagelok, except for the actuator gas (1/8”).

Pressure

The maximum pressure for all gasses is 500 kPa. For carrier- and detector gas, 300

kPa is recommended. For fastest valve switching, helium is recommended for

actuator gas, but air can also be applied (350 kPa).

In case of the PDD (Pulsed Discharge Detector), the discharge gas is directly

connected to the Helium suppl y via an internal restrictor. A stable 350 kPa He

pressure is needed for this application.

Quality

For carrier gas, He 5.0 (N50) is recommended.

4

Page 8

CompactGC manual

Demand

Carrier gas: 2-50 ml/min for each anal ysis ch annel , depending on settings

TCD: 2 ml/min (reference gas)

FID: 30 ml/min H

; 300 ml/min air

2

PDD: 30 ml/min He

PID 2 ml/min make-up

Power requirements

The CompactGC requires 220/230V single phase voltage, 50 Hz. With all options

installed, the maximum power consumption is 900 VA. In practice, depending on the

configuration, the typical power assertion is much lower.

Digital connections

CompactGC Editor

This 9-pole connection is used for RS-232 communication for parameter

programming and status readout. Maximum (tested) length is 10 m.

EZChrom

® /

EZStart®

This RS-232 connection is used for the digital detector data in case of the

EZChrom

®

/ EZStart ® data system. Maximum (tested) length is 10 m.

Wherever in this manual is spoken about EZChrom

for EZStart

Note that in case of the EZChrom

connections are needed.

®.

®

data system, two RS 232

®

, it is also applicable

Digital output

The GC-ready and GC-Start-out signals are available on this connector. (Startout is used to start the data system in case of analog data signal). The

programmable output bits are also present on this connector. See appendix 2 for

more deta ils.

Digital input

Via this connector, the CompactGC can be started and stopped by remote

control hardware signals. See appendix 2 for more details.

Figure 2.1 is showing the electrical and pneumatic connections.

5

Page 9

CompactGC manual

Carrier gas in

(1/16” Swagelok )

Mains switch

220V power

connec t io n

EZChrom

RS 232 connec t or

(D sub 9 pole)

Figure 2.1: electrical and pneumatic connections

Split out

(1/16” Swag elok)

CGC Editor

RS 232 connector

(D sub 9 pole)

Detector ga s in

1/16” Swag el o k)

Flash

programming

Actuator He-Air

(1/8” Swagelok)

Digital output

(D sub 15 po le)

Detector out

(1/16” Sw agelok)

Digital input

(D sub 15 pole)

6

Page 10

CompactGC manual

3. Instrument description

The CompactGC is a fully digital 19” rack GC, dedicated for fast gas analysis (however

analysis of liquid samples is also possible). The instrument uses reliable well-known

technique like Valco

columns with down sized dimensions, to obtain short analysis times. Typical analysis

times are 10 seconds to 2 minutes. The CompactGC editor, a dedicated program for

method programming, sets all parameters. The CompactGC is an up to 3-channel

instrument, with a choice of four different detectors. The signal of the detectors is

available in digital format, for use with the EZChrom

form for connection to other data systems. The basic setup of the system is shown in

figure 3.1.

®

valves, robust detectors and standard available capillary

®

data systems, as well in analog

detector

electronics

digital

gas

power

supply

control

detectors

Figure 3.1: Basic system

column

oven

valve

oven

7

Page 11

CompactGC manual

The front half of the instrument contains the ‘chromatography hardware’: on the right

side the valve oven for (maximum 3) heated valves, in the middle the isothermal

column oven(s) (maximum 3), on the left side the detector compartment, for up to 3

detectors. A module for cryogenic trapping, in case of trace gas analysis, can be

installed in place of one of the column ovens.

On the back half of the instrument, from right to left side, the power supply, the digital

gas supply, and detector controllers can be seen.

3.1

Digital gas supply

The gas control of the instrument is fully digital, and can be present in two types of

modules:

• Carrier Gas Module (CGM) for carrier gas

• Detector Gas Module (DGM) for detector gasses

CGM

The Carrier Gas Module is a sophisticated carrier gas supply device, which can be

operated in the following modes:

• Constant pressure

• Programmed pressure

• Pressure pulse (pressure surge)

Four different gasses can be used: helium, hydrogen, nitrogen and argon. In case of

change of carrier gas type, recalibration of the splitflow is needed. Contact your

service organization for more information. Hydrogen is not recommended for safety

reasons.

Constant pressure

The most common used operating mode is constant pressure, with digital control of the

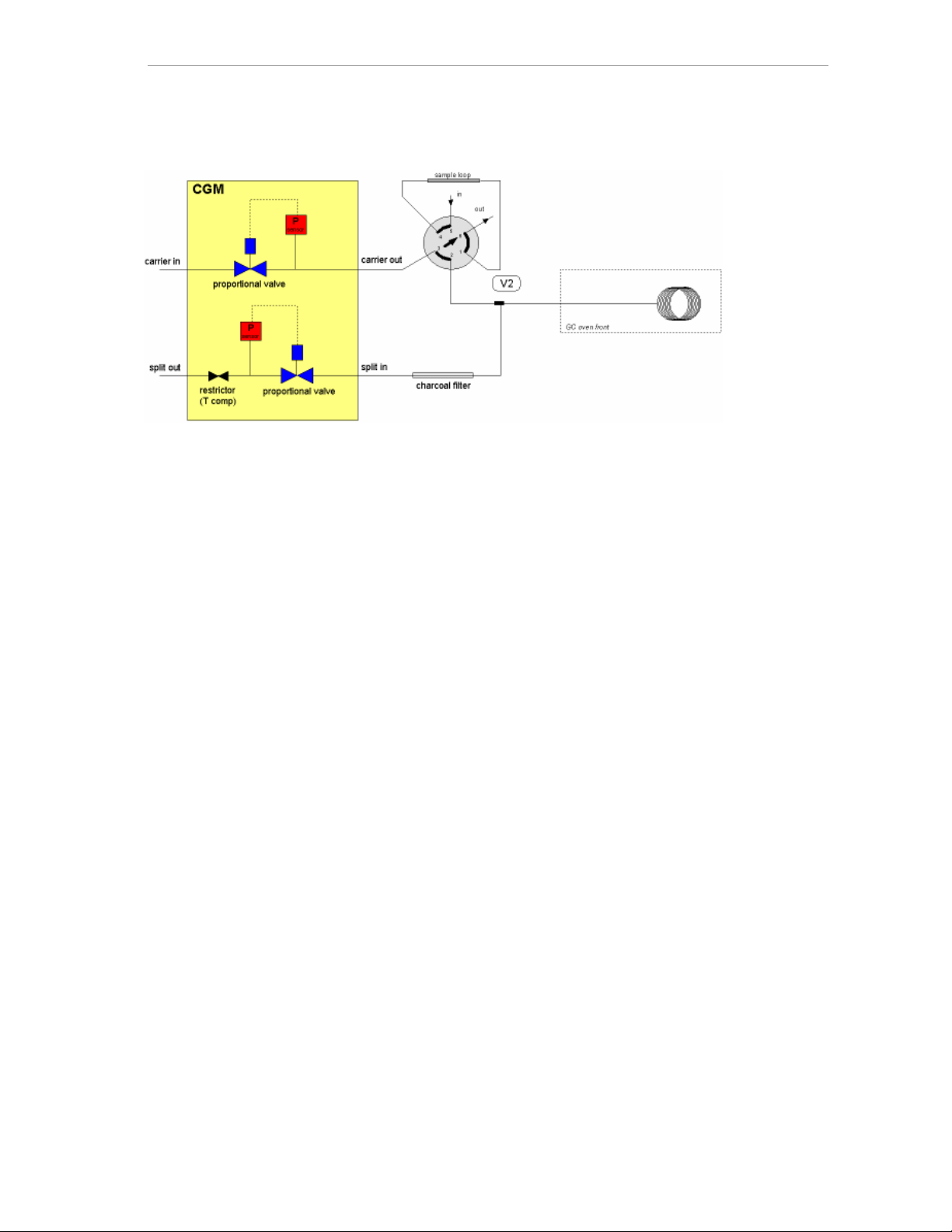

split flow. See figure 3.2.

In this diagram, the constant pressure is obtained by the upper proportional valve and

pressure sensor (P). The lower proportional valve and pressure sensor, in combination

with a temperature compensated restrictor are controlling the split flow.

Normally, the optimum flow for a certain type of column is the starting point of method

development. The needed pressure can be determined by measuring the flow on the

detector outlet, of can be calculated using the available flow calculator (CGC editor).

8

Page 12

CompactGC manual

Figure 3.2: Diagram CGM

Programmed pressure, pressure surge

These modes of carrier gas control are obtained by programming the targeted

parameters using the Run Time Table. See chapter 5 for more details.

If the CompactGC runs out of carrier gas (no inlet supply), the system switches to the

Hibernate mode (all flow and temperature channels are set to value 0) and cools

down.

The GC needs a reboot (mains power switch, or ‘warm reset’ from the CGC editor

menu) to return to normal operation.

DGM

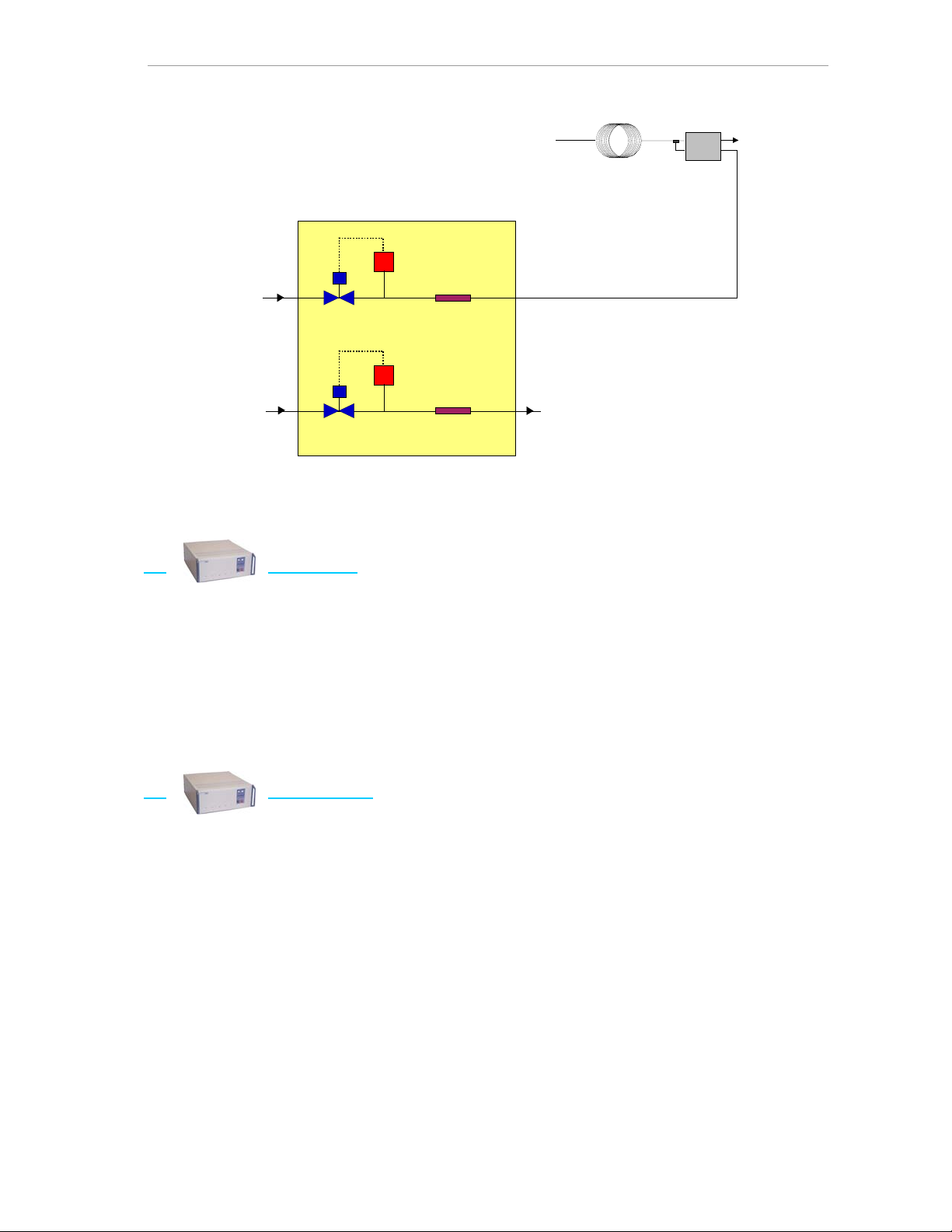

The second type of digital gas supply contains two pressure channels, and is therefore

used to control two detector gasses, f.i. hydrogen and air in case of FID, or two

reference gasses in case of double TCD. In combination with a calibrated, temperature

compensated restrictor in the module, constant detector gas flows are obtained. See

figure 3.3. The flows needed for proper detector operation are entered using the CGC

editor program.

9

Page 13

CompactGC manual

detector gas in

proportional

valve 1

P

Pressure

sensor

Fixed

restrictor

(temperature

compensated)

capillary column 1

PPM

TCD front

TCD

TCD 1 out

P

detector gas in

(second detector)

Figure 3.3: Diagram DGM

3.2 Valve oven

The valve oven is an independent heated temperature compartment that provides:

• housing for maxi mum 3 Valco

®

valves, for several configurations like injection,

backflush, streamselection, etc.

• heated sample inlet

• housing for sample conditioning (filtering, pressure reducing, etc.)

The oven can easily be accessed for maintenan ce, injection-loop changing, etc.

3.3 Column oven

In the CompactGC, up to three column ovens can be installed. In order not to lose

analysis time compared to a temperature programmed run (cooling down phase), the

analysis conditions are normally developed on base of isothermal analysis. Therefore

the applied ovens are isothermal and highly stable. The three ovens have independent

temperature control, so each column operates at its optimum temperature. The

standard supplied oven is used for fused silica columns with an internal diameter of 0.32

mm maximum. For wide-bore columns (0.53 mm id), metal columns are advised. The

most common used columns are 2-15 meter/0.32 mm id fused silica. In the oven,

columns with a winding diameter of 8 cm are installed. These columns can be ordered

in this dimension,

mentioned diameter. See chapter 6.1 for column installation.

Ovens for packed columns are available on request.

but also standard columns are used, after rewinding them to the

10

Page 14

CompactGC manual

3.4 Detectors

Four detectors are available: Thermal Conductivity Detector (TCD), Flame Ionisation

Detector (FID), Pulsed Discharge Detector (PDD) and Photo Ionisation Detector (PID)

(available end 2003). Up to three of these detectors can be configured in the

CompactGC.

TCD

The TCD is a very widely used detect or for analysis of gases, but in principle all

components with different thermal conductivity in relation to the carrier gas can be

detected. The response is concentration dependant: a higher column flow or make-up

flow results in a decreased sensitivity.

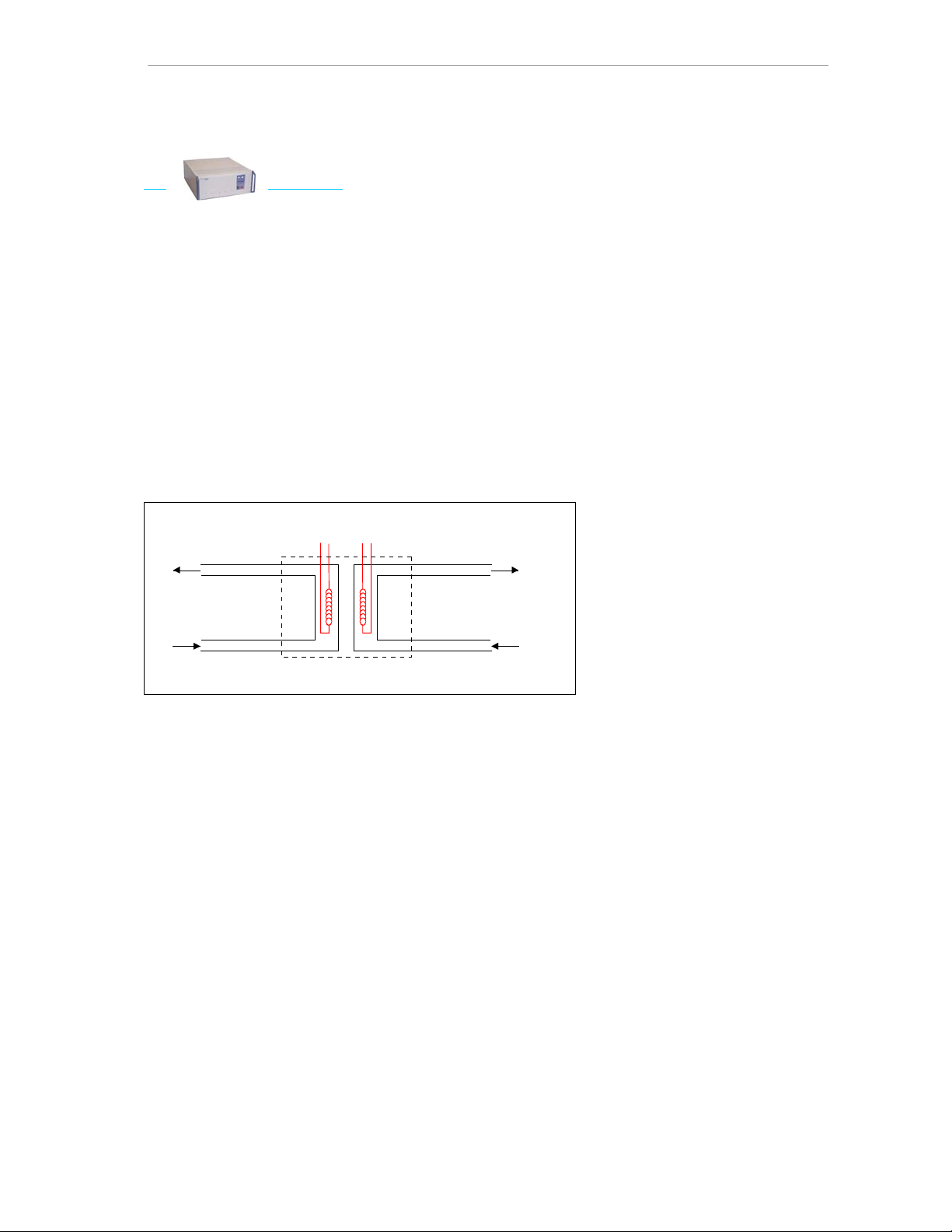

This detector is a dual channel microvolume cell with two filaments on constant mean

temperature. See figure 3.4.

dual filaments

analysis flow

Figure 3.4: TCD detector

reference fl o w

Operation principle

The filaments are continuously losing heat to the wall of the detectorcell by the thermal

conducting carrier gas (see figure 3.5). When a component with a different thermal

conductivity compared to the carrier gas pass es the filament, the electronic circuit in

which both filaments are integrated (Wheatstone bridge) is adjusting the current to

maintain the constant filament temperature. This current change is dependant on the

component concentration, and is convert e d to a chromatographic signal that can be

handled by the data system.

11

Page 15

CompactGC manual

capillary column 1

analysis

reference

Figure 3.5: Principle of the TCD

TCD front

TCD

TCD front out

The reference flow is supplied by a Detector Gas Module (DGM), and this flow is also

used for make-up gas according figure 3.5. This resu lts in a better peak shape,

especially for the higher concentrations, and a less critical column connection.

Consequently at the ‘TCD out’ exit both flows are measured together. If the column

flow needs to be checked, the reference flow can be switched off for a short time

(don’t forget to switch off the filament first). The normal reference flow is 1-2 ml/min.

Since the response of the detector is concentration dependant, a higher reference

flow results in lower sensitivity.

Operation conditions

Cell temperature: 10-20 ºC above column temperature

Filament (bridge) temperature: 20-120 ºC above cell temperature, depending on

required sensitivity

Reference flow: 1-2 ml/min

Polarity: depending on carrier gas

Range: depending on required sensitivity

FID

Operation principle

In gas analysis, the FID is popular for carbon-hydrogen containing compounds, due its

high sensitivity, good stability, and wide linear response. The response is massdependant, so flow rate does not affect the sensitivity.

In the FID (see figure 3.6), the effluent of the column is mixed with hydrogen, this mixture

is burned as it emerges from a metallic jet. This jet acts as one electrode (polarizing

electrode), while a metallic collar surrounding the flame forms the second electrode. A

potential is applied across the pair of electrodes to accelerate the electrons that are

generated during the combustion process of the organic compounds. The resultant

ionization current is sent to an electrometer impedance amplifier, and converted into a

suitable output signal.

12

Page 16

CompactGC manual

ignition coil

detector cell

collector electrode

polarized electrode

base body

electrometer

air

hydrogen

flame jet

column

Figure 3.6: Diagram of the FID

The hydrogen is mixed with the carrier gas at the column outlet, acting also as a makeup gas. For safety reasons, leakage should be avoided here.

The FID detector cell can easily be removed from the detector base body (it is advised

to lower the temperature first). With a special tool, the flame jet too can be removed.

Operation conditions

Temperature: 10-20 ºC above column temperature, minimum 120 ºC, to avoid

condensation of the formed water

Hydrogen flow: 30 ml/min

Air flow: 300 ml/min

During ignition, the hydrogen pressure is raised by 40 % for easy start of the flame. This is

performed automatically when the ignition button is actuated on the related TAB

page. The ignition current is switched off after 6 seconds. Note that the ignition state on

the TAB page will remain to ‘on’ (since the control program is an editor), so when the

flame has to be ignited again (f.i. after the column was changed), first ‘ignite off’ has to

be send to the CompactGC, followed by ‘ignite on’.

13

Page 17

CompactGC manual

PDD

Operation principle

The Pulsed Discharge Detector (see figure 3.7) is a non-radioactive ionization detector

with a universal concentration dependant response. A stable, low power, pulsed DC

discharge in helium acts the ionization source. Eluants from the column, flowing counter

to the flow of helium from the discharge region, are ionized by photons from the helium

discharge above. Resulting electrons are focused towards the collector electrode by a

bias electrode.

Figure 3.7: Diagram of the PDD

The principle mode of ionization is photoionisat ion by radiation arising from the transition

of diatomic helium to the dissociative ground state. This is the well known Hopfield

emission. The photon energy from the diatomic helium continuum is in the range of 13.5

to 17.7 eV.

The PDD is essentially non-destructive (0.01-0.1 % ionization) and highly sensitive. The

response to organic compounds is linear over five orders of magnitude with minimum

detectable quantities (MDQ) in the low picogram range. The response to fixed gasses is

positive (the standing current increases), with MDQ’s in the low ppb range. The

detector response is universal except for neon and helium.

Operation

Since the PDD is highly sensitive, also to air, extreme care should be taken to leakages,

quality of carrier gas, and all possible sources of detector pollution. Although a helium

purifier is used, gas quality should be 5.0 (or N50) or better.

14

Page 18

CompactGC manual

To avoid unnecessary gas couplings, the system is directly connected to the gas supply

(figure 3.8), which means that the reducer pressure of the gas supply controls the

discharge flow. This flow has to be adjusted to 25-30 ml/min (ca. 350 kPa). On the gas

exit (vent) of the detector, the discharge flow as well as the column flow is

simultaneously present, so for measurement of the discharge flow, the column flow

needs to be switched off. The column flow can be calculated by subtracting the

discharge flow from the total flow.

customer gas supply

T-piece

fixed restrictor

PDD

reducer

FPM

capillary column

He cylinder

vent

Figure 3.8: GC system with the PDD

After a leak check of this CompactGC channel, and adjustment of the wanted flows,

the discharge can be started by the ‘pulser’ button on the related TAB page in the

CompactGC editor. The start of the detector is confirmed by a soft high frequenc y

sound, and a baseline raise.

Operation conditions

Temperature: 10-20 ºC above column temperature

Discharge flow: 30 ml/min, to be adjusted by external He gas supply regulator (350

kPa)

Range: 64-256 nA

PID

This detector is not released yet.

15

Page 19

CompactGC manual

4. Pre-concentration Module (PM)

For trace analysis of gases, sample components can be pre-concentrated using a

Peltier cooled micro trap. Contact your local supplier for more information about this

option.

16

Page 20

CompactGC manual

5. The CompactGC editor program

Since the CompactGC it selves has only two push buttons on his front for starting and

stopping the analysis, the CompactGC editor program is used to program all the

different GC parameters like temperatures, flow/pressures, detector setting, etc. The

CompactGC control program is an ed itor, which means that the different parameters

are first only edited on the PC screen; after pushing the SEND button the methodchanges are uploaded to the CompactGC and activated. After programming the

CompactGC conditions, if wanted, the editor can be closed, and the PC can be

disconnected from the PC, since all values are stored in the permanent memory of the

CompactGC, and the programmed sequence is carried out independently of the

CompactGC editor. When the editor program does remain active during the GC run,

all actu al values and status inform ation are displayed to inform the op erator.

When the user starts the CompactGC editor, automatically all configuration and

method information is send from the CompactGC to the PC. The configuration data

(like number of channels, detectors, etc, a lot of different configurations is possible) is

stored in the CompactGC, so the user can see immediately the correct presentation of

the parameters of the connected CompactGC.

Figure 5.1: Main window of the CompactGC editor

17

Page 21

CompactGC manual

COMMAND BUTTONS

GET METHOD

With this button, the CompactGC editor gets the complete method and configuration

information from the CompactGC.

SEND METHOD

The operator pushes this buttons when new entered method-parameters have to be

sent to the CompactGC. Only the changed parameters are sent.

STATUS

Besides the actual values displayed at the channel pages, a status window can be

opened to display all parameters of the different channels together, also during a GC

run. Also status information like run and sequence number, valve positions, etc, is

available here.

Figure 5.2: Actual Status display.

18

Page 22

CompactGC manual

START – STOP run

These buttons have the same function as both push buttons on the CompactGC. (The

instrument can also be started and stopped using the electrical connections on the

rear, see appendix 2).

TAB PAGES

FRONT – MIDDLE – BACK Channel

The three possible analysis channels are named front, middle, and back channel. The

front channel is in the closest position to the operator and the front of the instrument.

Each channel has its own tab-page, which contains all the relevant parameters for one

analysis: settings for carrier gas, temperatures, and detector . The set value and actual

value are both present. When the operator changes a parameter, always the SEND

button has to be used to load the CompactGC with the new information.

AUX

On this page, setting for external devices, if present, are shown.

VALVES

This page is used for test and development purposes. The external events, in most cases

valves, can be controlled directly from here. A mouse-click on the wanted event,

followed by the SEND buttons activates the choice. In the same way, the additional 8

parallel output bits can also be directly controlled.

RUN TIME TABLE (RTT)

This page controls different actions on time base. The time base is set to zero after each

start of the GC run. One of the actions is f.i. the valve command: after each GC start

the injection valve is actuated. The following columns are available:

Entry

The entry number of the table.

Time

The time at which an action takes place, after the run is started.

Lock

In order to edit the table in a user-friendly way, related commands can be linked

in time. F.i. in case of a fixed time between two different lines in the RTT, for one of

these lines a capital ‘A’ is entered in this particular column. For the other line a

small ‘a’ is set. When the time for ‘A’ is changed now, the same absolute shift is

performed on ‘a’.

19

Page 23

CompactGC manual

Sequence

This command is used in combination with the ‘reset sequence counter’

command in the next column of the table, which allows a certain action only to

be executed at a selected run number in a sequence. By resetting the sequence

counter, a loop is created, that is repeated every time. F.i. in a sequence of 10

analyses, only at run number 1 (needs to be entered in this particular column), a

selection valve is actuated for calibration purposes. Another applicat ion is stream

selection.

Command

The following actions can be selected in this column:

T set

The temperature of the available devices can be altered with

this command on time base

FP set

This command allows you to change flow and pressure settings

during the run

Valve

This command is used to activate the external events, mostly

valves. Since up to 8 events can be connected, also the valve

number has to be entered.

Output bit

The output bit command programs the state of the additional

8-bit parallel output. In case of another data than EZChrom

®

,

this command is used to start the data-acquisition. See

appendix 2.

Start chromatogram

In case of digital data connection to EZChrom

starts the data-acquisition. The use is mandatory in this case.

Autozero detector

During the run, the detector output signal is set to zero using this

command. Note that this act io n takes time, and no peaks are

allowed to elute during the autozero process.

Detector gain/range

During the run, the detector input sensitivity can be changed in

order to detect both high and low concentration peaks in the

same sample. This action takes time, so no peaks are allowed

to elute during the switching process.

®

, this command

20

Page 24

CompactGC manual

Load default method

During a run, the different parameters can be reset to their start

(method) values. This is convenient when a lot of parameters

have changed, and the original settings are needed during the

run.

Reset sequence counter

See the explanation of the sequence column.

End of this run

This command stops the present run of the CompactGC. In

case of digital data-collection by EZChrom

®

, the dataacquisition is stopped also. If the number of runs is 2 or more,

immediately the next run is started. Since the CompactGC

starts his next run immediately, and EZChrom

process the acquired data, the EZChrom

®

needs time to

®

runtime should

always be shorter than the CompactGC runtime. The time

EZChrom

®

needs between runs is dependent on the length of

the run, PC processor speed, network connections, etc.

Normally 5-10 seconds are appr opriat e.

Channel

If an action can be applied to more than device (temperature, flow, valves), a

channel number has to be entered.

Channel name

If name of the selected device is shown in this column.

Value

In case of a valve switching command, ‘1’ needs to be entered in this field to

activate the valve, and with value ‘0’ the valve returns to his standby position. In

combination with commands ‘T set’ and ‘FP set’ the new settings are entered

here. Commands like ‘autozero’ and ‘start chromatogram’ do not have a value.

Comment

In order to increase the readability of the RTT, comments can be entered for each

command line

For a better overview of the RTT, the operator can disable the automatic sort (on

retention time) of the table.

On the end of this page, the number of runs is entered. This number will be

executed after the start-button is pressed. A number of 999 is equal to infinite

analysis.

21

Page 25

CompactGC manual

The Run Time Table will automatically sort on retention time. A line can be modified

after it has been scrolled to the editing window. Lines can also be added or deleted.

Like other parameters, the edited RTT will become active after it has been send to the

CompactGC by using the SEND button in the main window .

PULL DOWN MENU’s

File

Besides the functions of the above mentioned command buttons, the CompactGC

method can be printed from here.

View

Status

This line has the same function as the Show Status command button.

Log file

From this line, two types op log files, CompactGC -memo, and CompactGC actual date can be l oaded to view every normal action and fault messages.

Drawing

This is a viewer for BMP and JPG files, and is used to view the schematic diagram

that is supplied with the instrument for convenient editing of the CompactGC (see

figure 5.3).

Figure 5.3: View drawing

22

Page 26

CompactGC manual

Method

T, F and P defaults

Valve and bits default

Run time table

These windows offer the same functionality as the TAB pages.

Detector defaults

Figure 5.4: Detector defaults

In addition to the detector settings on the TAB pages, parameters less frequently

used are available on this page:

T filament (TCD)

This parameter sets the filament temperature of the TCD. A high

value in relation to the TCD block temperature means high

sensitivity.

Input gain (TCD)

Gain factor of the input amplifier. A higher value corresponds to

higher sensitivity (but noise is more amplified too).

Input polarity (TCD)

Polarity of the TCD signal, depends on the type of carrier gas.

Input current (FID, PDD and PID)

Input range of the detector amplifier. A lower value means

higher sensitivity.

23

Page 27

CompactGC manual

Sample rate

The number of samples per second (sps) is entered here. The

correct value depends on the peak width. F.i. for 0.32 mm id

columns, peak widths of 0.5 to 2 seconds are normal. For a

correct analog to digital conversion without losing data

integrity, 15 to 25 points per peak are necessary. This means a

sps value of 25 or 50. In case of analog output, only on this

page the sps parameter can be selected. In combination with

EZChrom

®

, this setting is overruled by the entered value in the

data system, but the choice is limited to the listed values (12.5,

25, 50 and 100 Hz).

High voltage (FID, PDD and PID)

In case of ionization detectors, this parameter switches the

polarization voltage on and off.

FID ignite (FID)

After setting the correct detector gas values for hydrogen and

air, this button activates the ignition coil in the detector housing

for 6 seconds so the flame will turn on. During this time, the

hydrogen pressure is raised for better ignition.

Pulser (PDD)

When using the Pulsed Discharge Detector, this buttons start the

discharge current.

Lamp (PID)

By this button, the lamp in case of PID is turned on.

Detector analog output

When the analog output is used, the output gain and shift

(offset) are enter ed here.

Test chromatogram

After activating this option, during the next run only a

synthesized chromatogram is added to the present detector

signal. This feature is used for test purposes.

Setup

Comport

For RS 232 communication com1 to com12 can be used.

24

Page 28

CompactGC manual

FP calculator

On this page, the column flow can be calculated.

The column flow is related to the carrier gas inlet pressure and gas type, the

column dimensions and the column temperature. Note that P

(column outlet

out

pressure) also influences this flow; in case of FID and PDD, this pressure is

atmospheric, but in case of TCD, this pressure is higher since a restriction tubing is

presence between the column end and the TCD. The pressure can be det ermined

by measuring the column flow on the detector outlet, and entering the right P

out

value in the calculator.

The calculator uses temperature driven viscosity polynominals.

Tmax

This page allows you to protect columns from temperatures above the maximum

allowable temperature. The User Tmax can be set, the System Tmax is a fixed

value. This parameter is protected by a password. After changing parameters, use

the command ‘Send changes to GC’ to save the changes in the CompactGC.

Edit positions.

This option is password protected, and gives the opportunity to

change the position of the different devices (temperature and

flow/pressure) and detector settings on the TAB pages. Position 100,

200, 300 and 400 are referring to the Front, Middle, Back and Aux

channel page. On each page, the following 20 positions are

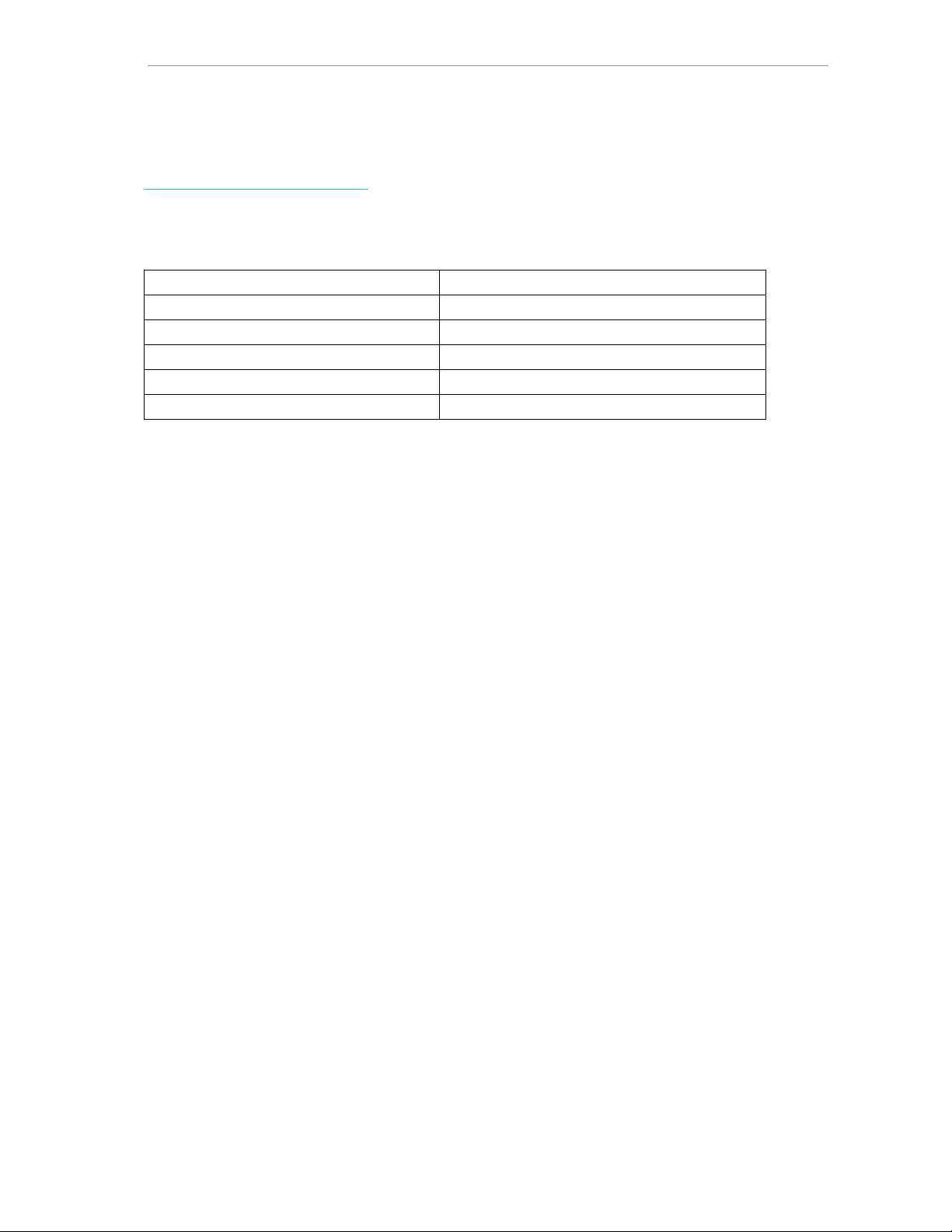

available:

X00 X01

X02 X03

X04 X05

X06 X07

X08 X09

X10 X11

X12 X13

X14 X15

X16 X17

X18 X19

(X = TAB page number)

After changing parameters, use the command ‘Send changes to GC’ to save the

changes in the CompactGC.

Edit T/F device names.

This option is password protected, and gives the opportunity to change the names

of the temperature controls (f.i. for column name display) and flow devices (f.i.

when another carrier gas is used). After changing parameters, use the command

‘Send changes to GC’ to save the changes in the CompactGC.

25

Page 29

CompactGC manual

Edit Flame-Off level.

Figure 5.5: Flame-Off window

For safety reason, the FID signal level is monitored after each run; this level is

displayed in the STATUS page (only in stand-by mode). In case of a Flame-Off

situation, this option avoids spreading of hydrogen in the CompactGC. In the

example the ‘action level’ is set to 1 pA; if the signal level drops below this value,

the system will:

- go in ‘Hibernate mode’. This means that all gas supply channels will close, and

the system will cool down, or

- close the hydrogen channel for that detector only, or

- take no action (so there is NO protection!)

The flame on/off status, according to the ‘FID action level’ is also displayed in the

STATUS window.

IMPORTANT: for safety reasons, these parameters need to be set correctly.

Especially in case of low-bleed columns, there is a small (1-2 pA) signal drop when

the flame goes out, so the ‘FID action level’ needs to be set precisely. It is the

responsibility of the end user to obtain an adequate protection level in using these

parameters.

When a Flame-Off situation occurs, a warning message (pop-up window in the

CGC editor) is displayed, and the operator has 2 minutes time to change the

situation before the selected action is executed. When the FID flame is restored,

the pop-up window automatically disappears.

The flame-off detection is not active during data acquisition, so make sure there is

some spare time between each run (data collection) to detect a possible FlameOff condition. This time is reserved by setting the ‘start chromatogram’ in the Run

Time Table to 1 second or later.

26

Page 30

CompactGC manual

Control

Start / Stop analysis:

Function similar to the buttons displayed on the main menu.

FID Flame-Off disable until (re)arming

This command disables the Flame- Off detection when this is temporar y not

wanted. The detection is armed again by (1) the following command, (2) a new

flame ignition, (3) a CGC restart. The status of the Flame-Off detection

(enabled/disabled) is list ed in the STATUS window.

FID Flame-Off arm

This command enables the Flame-Off detection manually. The status of the FlameOff detection (enabled/disabled) is listed in the STATUS window.

Restart CGC – warm (re)boot

This command allows a remote (soft) restart of the CGC. This menu addition is

primary targeted to rest art the system after a Flame-Off alarm that brings the GC

in protected mode and/or canceling a Hibernate mode.

Note: This warm reset is nearly the same as a mains power on/off, with the

exception that a major protective alarm (f.i. in case of a temperature sensor

failure) cannot (and should not) be resetted.

About

Displays the software version of this editor program

27

Page 31

CompactGC manual

6. Operation

6.1 Column installation

Columns with different external diameter can be installed. See the accessories

catalogue for the available dimensions. Normally 0.32 mm id (0.45 mm od, 0.5 mm

ferrule needed) columns are used, but also 0.25 mm id and 0.53 mm id (metal) can be

applied.

Figure 6.1: Injector (valve) side

Injector (valve) side

• Install the knurled nut and the ferrule (with appropriate internal diameter) without

the column).

• Cut the column end to the correct length, in such a way that no stress is present

on the column after installation.

• Install the column, using the heated aluminum interface path between the

column oven and the valve oven. If the column does not enter the knurled nut on

the valve easily, guide it with tweezers or another tool.

• Tighten the nut by hand.

28

Page 32

CompactGC manual

Detector side (TCD and FID)

• Install the knurled nut and the ferrule (with appropriate internal diameter) without

the column).

• Cut the column end to the correct length, in such a way that no stress is present

on the column after installation.

• Guide the column into the nut.

• Tighten the nut by hand

nut

nut

valve

Figure 6.2: Column installation

Detector side (PDD)

The distance between the column end, and the lower part of the nut is 11.4 cm.

Figure 6.3: Installation of the column with the PPD detector

29

Page 33

CompactGC manual

6.2 Leak check

A leak check is performed by pressurizing the sealed system with carrier gas. Any leaks

are registered by a drop in the pressure reading. The pneumatic diagram, supplied with

the system, is a useful tool.

TCD channel

• turn of the bridge temperature

• turn off the reference gas (send value 0)

• seal the end of the channel by a 1/16” cap on the detector outlet

• set the total flow to zero

• set the inlet pressure to 100 kPa, and after the channel is pressured, set the

pressure to zero

• observe the pressure

FID channel

Extreme care should be taken to a leak-tight gas connection since hydrogen is used as

FID feeding gas. This feeding gas is mixed with the carrier gas at the end of the column

(see figure 6.2; left nut). In case of a leak, hydrogen will enter the column oven.

For a total check of this channel, the FID detector is disconnected, and the flame jet is

replaced by a blind jet.

• turn off the hydrogen and air gas supply (send value 0)

• seal the detector base or the end of the column

• set the total flow to zero

• set the inlet pressure to 100 kPa, and after the channel is pressured, set the

pressure to zero

• observe the pressure

An electronic leakchecker may also be used.

PDD channel

For this channel, except the gas from the digital gas controllers, also discharge gas is

supplied directly via a restrictor (see the PDD, chapter 3.4).

• turn off the pulser

• set the total carrier flow to zero

• set the inlet pressure to 150 kPa, and after the channel is pressurized, set the

pressure to zero

• close the external gas supply to the CompactGC

• wait until a stable pressure readout is obtained (approximately 150 kPa) , and

observe if this value remains stable

30

Page 34

CompactGC manual

6.3 Quick start up

In case of digital data communication (EZChrom®), power-on the CompactGC first,

followed by the data system to establish the digital connection.

The following steps are important in starting up the analysis:

Remember that the CompactGC control program is an editor, and ‘SEND’ is

necessary to activate the entered values

• install the column, and perform a leak check

• set the correct column flow by adjusting the carrier gas pressure (TAB page). This

flow can be measured on the detector outlet, or can be calculated using the FP

calculator (remember that P

depends on the used detector)

out

• set the desired column temperatures depending on the application; in constant

pressure mode, the column flow is dependant on the column temperature, so

adjustment of the pressure can be necessary

• send the detector parameters (see chapter 5)

• enter the correct values for valve switching and d ata c o llection in the run time

table

For data-acquisition with EZChrom

®

the command ‘start chromatogram’ should be

present (at 1 sec). For analog data collection set output bit 7 to 1 at 1 second, and

enter value 0 at 2 seconds.

The end of the run has to be programmed in the RRT (figure 6.4) as well in the data

system. Since the CompactGC starts his run directly after the preceding one, and the

data system needs time to process and save the acquired data, the runtime of the data

system always needs to be shorter than the runtime of the CompactGC (5-10 seconds ,

depending on the speed of the data system and, if present, the network connection).

Enter short valve switching periods for injection (f.i valve on (1) at 1 second; valve off (0)

at 2 seconds).

Enter also the number of analysis on this page.

• in case of analog data-acquisition, enter the correct acquisition rate on the

‘detector defaults’ page (with digital data, the EZChrom

®

setting will be copied)

• Set up the data system method: enter the correct data-acquisition rate for each

channel, and a runtime that is 5-10 seconds shorter than the CompactGC runtime;

in case of EZChrom

start the data system (‘waiting for trigger’ is displayed)

®

, only 12.5, 25, 50 and 100 points per seconds are allowed;

• switch on the detector(s); in case of TCD: activate the Autozero function; the

‘SEND’ command is not needed for this function

• If the CompactGC reports ‘ready’, the run can be started

31

Page 35

CompactGC manual

Figure 6.4: run time table window

In case the CompactGC was switched off, the data system has to be closed and

restarted for re-establishing the digital communication with EZChrom

®

.

32

Page 36

CompactGC manual

7. Maintenance and troubleshooting

Full instrument servicing will normally be performed by an Interscience service engineer

under the instrument warranty, or, when this has expired, possibly under a Service

Contract Program.

Filters

The filters in the split line of the carrier gas normally need no replacement, since their

function is to protect the electronic split regulation by a gradually release of the vented

components.

Ferrules

Ferrules and seals should be replaced when they are too flat or broken to produce a

good seal.

Valves

Depending on the type and use of Valco

on a regular base.

Log file

In case of electronic failure, inspect the log file (CompactGC editor: view log file).

®

valve, the rotor seals need to be replaced

33

Page 37

CompactGC manual

Apendix 1: EZChrom® / EZStart® settings

The datacommunication between EZChrom

®

and the CompactGC is based on the

SS420x protocol. The following parameters need to be entered:

Interface configuration

Tools/interface configuration

When the correct RS-232 connection is present, the information shown at ‘serial

number’ confirms the communication with the CompactGC. When not connected, or

not active, the window below is shown. The connection should be validated before

starting another activity.

34

Page 38

CompactGC manual

Instrument configuration

The interface connection window can be closed, and the configuration window of the

instrument needs to be opened:

Add modules according the CompactGC configuration. Besides one to three

detectors, the event configuration should also be selected.

35

Page 39

CompactGC manual

Detector configuration

Detector 1 corresponds to the front channel of the CompactGC, detector 2 to the

middle channel, and detector 3 to the CompactGC back channel. Appropriate names

can be entered here (FID front, TCD back, etc.).

For TCD, the Y-as Multiplier is set to 0.002500, for FID/PDD/PID 0.00100 has to be entered.

Serial port: corresponding to the used RS-232 port.

Channel: 1 for front channel; 2 for middle channel; 3 for back channel

36

Page 40

CompactGC manual

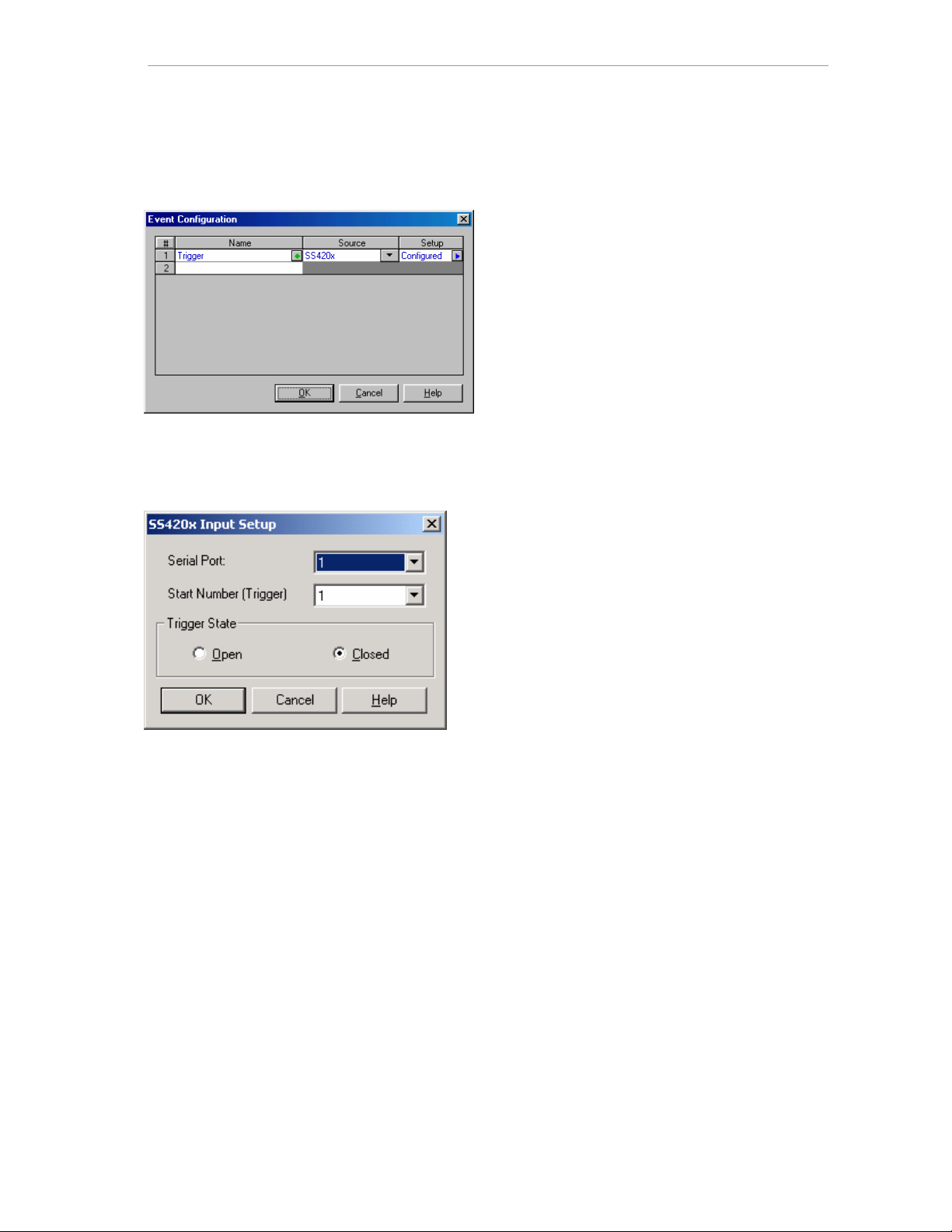

Event configuration

When the blue arrow is selected, ‘triggered state closed’ needs to be entered.

The Trigger should also be set to the used RS-232 port in other to start the EZChrom

data-acquisition by the CompactGC.

Instrument setup

After finishing the configuration, the instrument can be opened.

In EZChrom

®

, open Method/Instrument Setup and configure each channel:

®

37

Page 41

CompactGC manual

Complete the setup by setting the external trigger as shown below.

38

Page 42

CompactGC manual

Apendix 2: Electrical connections

For both RS 232 connections, a 9-pole D-sub standard RS-232 cable is needed.

Digital input

1

915

8

Pin description Input level

1 D-in bit 0 – start CompactGC L=Tue (TTL/OC/relais)

2 D-in bit 1 – stop CompactGC L=Tue (TTL/OC/relais)

3 D-in bit 2 L=Tue (TTL/OC/relais)

4 D-in bit 3 L=Tue (TTL/OC/relais)

5 D-in bit 4 L=Tue (TTL/OC/relais)

6 D-in bit 5 L=Tue (TTL/OC/relais)

7 D-in bit 6 L=Tue (TTL/OC/relais)

8 D-in bit 7 L=Tue (TTL/OC/relais)

9 ground 0 V

10 ground 0 V

11 ground 0 V

12 ground 0 V

13 ground 0 V

14 ground 0 V

15 ground 0 V

Digital output

(internal pull-up; bit 0-5=10K; bit 6-7=1K )

8

15

1

9

39

Page 43

CompactGC manual

Pin Description Output level

1 D-out bit 7 – start out Low active ; open

2 D-out bit 6 – ready Low active ; open

3 D-out bit 5 Low active ; open

4 D-out bit 4 Low active ; open

5 D-out bit 3 Low active ; open

6 D-out bit 2 Low active ; open

7 D-out bit 1 Low active ; open

8 D-out bit 0 Low active ; open

9 Ground 0 V

10 Ground 0 V

11 Ground 0 V

12 Ground 0 V

13 Ground 0 V

14 Ground 0 V

15 Ground 0 V

Analog detector output (optional)

If present, the analog detector is a 9-pole D-sub connector (female on rear

CompactGC). This output provides a high stable, high resolution (20 bits) analog signal.

In order to preserve the quality as good as possible, short cables are advised. Beside

the output signal, two additional connections are important: shield and ground. The

shield is not connected at the CompactGC side, and is necessary to protect the signal

from external influences. This cable needs to be connected at the data system. The

ground connection is necessary to equal the ground level of the CompactGC to the

data system, and is important for safety reasons, and omitting damage to the system.

pin Description

1 0 V - front channel

6 1 V - front channel

2 0 V - middle channel

7 1 V - middle channel

3 0 V - back channel

8 1 V - back channel

Shield (not connected on CompactGC side;

connect on data system side)

5 ground

40

Page 44

CompactGC manual

Apendix 3: LED status display

Green and Red system LED‘s (CompactGC front)

display functionality

GREEN slow blinking (short Off) READY (all active devices)

Green Blinking (1 Hz) NOT READY

RED off NO RUN

RED continuous on RUN (run time table)

RED fast blinking (2.5 Hz) ALARM (check log file.)

41

Page 45

CompactGC manual

x

IInnddeex

About (Pull down menu’s) 27

Analog detector output

Electrical connections 40

Analog output (Pull down menu’s) 24

Atmosphere 2

Autozero (Run time table) 20

Aux (Tab pages) 19

Back channel (Tab pages) 19

Bits default (Pull down menu’s) 23

Channel (Run time table) 21

Channel name (Run time table) 21

Classification, instrument 4

Column installation 28

Column oven 10

Command (Run time table) 20

Command buttons 18

Get method 18

Send method 18

Start - stop run 19

Status 18

Comment (Run time table) 21

Comport (Pull down menu’s) 24, 27

Control (Pull down menu’s) 27

Demand 5

Detector analog output (Pull down

menu’s) 24

Detector configuration 36

Detector defaults (Pull down menu’s) 23

Detectors 11

Digital connections 5

Digital input 5

Electrical connections 39

Digital output 5

Electrical connections 39

Drawing (Pull down menu’s) 22

Edit positions (Pull d own menu’s) 25, 26

Editor program 17

Electrical connections 39

End of this run (Run time table) 21

Entry (Run time table) 19

Event configuration 37

EZChrom® / EZStart® connections 5

EZChrom® / EZStart® settings 34

Ferrules 33

FID 12

High voltage (Pull down menu’s) 24

Ignite (Pull down menu’s) 24

Input current (Pull down menu’s) 23

Leak check 30

File (Pull down menu’s) 22

Filters 33

FP set (Run time table) 20

FPM

Digital gas supply 8

Front channel (Tab pages) 19

Gas supply 8

Gasses 4

Connections 4

Demand 5

Pressure 4

Quality 4

Get Method (Command button) 18

Ground 2

High voltage (Pull down menu’s) 24

Hydrogen, use of 3

Ignite (Pull down menu’s) 24

Input current (Pull down menu’s) 23

Input gain (Pull down menu’s) 23

Input polarity (Pull down menu’s) 23

Installation 4

Instrument configuration 35

Instrument description 7

Instrument setup 37

Interface configuration 34

Lamp (Pull down menu’s) 24

Leak check 30

LED status display 41

Load default method (Run time table) 21

Lock (Run time table) 19

Page 46

CompactGC manual

Log file 33

Log file (Pull down menu’s) 22

Maintenance 33

Method (Pull down menu’s) 23

Middle channel (Tab pages) 19

Operation 28

Output bit (Run time table) 20

Oven

Column 10

Valve 10

PDD 14

High voltage (Pull down menu’s) 24

Input current (Pull down menu’s) 23

Leak check 30

Pulser (Pull down menu’s) 24

PID 15

High voltage (Pull down menu’s) 24

Input current (Pull down menu’s) 23

Lamp (Pull down menu’s) 24

Power requirements 5

Pre-concentration Module 16

Pull down menu’s 22

Pulser (Pull down menu’s) 24

Quick start up 31

Reset sequence counter (Run time

table) 21

RTT (Tab pages) 19

Run time table (Pull down menu’s) 23

Run time table (Tab pages) 19

Safety 2

Sample rate (Pull down menu’s) 24

Send method (Command button) 18

Sequence (Run time table) 20

Setup (Pull down menu’s) 24

Software 17

Space requirements 4

Start chromatogram (Run time table) 20

Start run (Command buttons) 19

STATUS (Command button) 18

Status (Pull down menu’s) 22

Stop run (Command button) 19

T filament (Pull down menu’s) 23

T set (Run time table) 20

T, F and P defaults (Pull down menu’s) 23

Tab pages 19

Aux 19

Front - middle - back channel 19

Run time table 19

Valves 19

TCD 11

Input gain (Pull down menu’s) 23

Input polarity (Pull down menu’s) 23

Leak check 30

T filament (Pull down menu’s) 23

Test chromatogram (Pull down menu’s)

24

Time (Run time table) 19

Tmax (Pull down menu’s) 25

Tools/interface configuration 34

Troubleshooting 33

Value (Run time table) 21

Valve (Run time table) 20

Valve default (Pull down menu’s) 23

Valve oven 10

Valves

Maintenance and troubleshooting 33

Valves (Tab pages) 19

Ventilation 4

View (Pull down menu’s) 22

Loading...

Loading...