InterQuip EASIKIT EK450-26 User Manual

.

EK450

.

INSTRUCTION

MANUAL

EK450 INSTRUCTION MANUAL

EK450

The manufacturer does not accept responsibility for any loss, damage to other equipment, injury to personnel or any other circumstance resulting from the use of

our equipment. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means electronic, mechanical, photocopying, recording or otherwise - unless the permission of the publisher has been given beforehand. © All specifications are subject

to change without notice

2

EK450 INSTRUCTION MANUAL

CONTENTS

INTRODUCTION ...................................................................................... 4

1 SAFETY INSTRUCTIONS ................................................................... 5

2 ENVIRONMENTAL PROTECTION .......................................................... 5

3 CONFORMITY .......................................................................................... 5

4 TOOLS / PPE / PARTS & PACKAGING LIST ........................................... 6

4.1 Tools and Equipment Required .................................................... 6

4.2 Recommended PPE ..................................................................... 6

4.3 Packing List .................................................................................. 6

5 LIFTING AND SUPPORTING ............................................................... 7 - 8

5.1 Manual Handling .......................................................................... 7

5.2 Mechanical Handling .................................................................... 7

5.3 Supporting in temporary Installations ........................................ 8

5.4 Helpful Hints ................................................................................. 8

6 ASSEMBLY ....................................................................................... 8 – 37

6.1 Assembly Procedure .................................................................. 8

6.2 Assembly Instructions ........................................................ 9 – 11

6.3 Return Rollers .......................................................................... 11

6.4 Fitting Belt - Clip Joint ...................................................... 12 – 13

6.5 Fitting Belt – Vulcanized Joint .......................................... 13 – 15

6.6 Fitting Motor & Gearbox ........................................................... 15

6.7 Fitting EASIKIT® Support Stands ..................................... 16 – 22

6.8 Electrical Installation ................................................................ 23

6.9 Emergency Stop Grab Wires.................................................... 24

6.10 Belt Tensioning and Tracking ........................................... 25 – 27

6.11 Hoppers ................................................................................... 28

6.12 Bottom Covers ................................................................. 28 – 29

6.13 Side Guides ..................................................................... 29 – 30

6.14 Belt Scrapers ................................................................... 31 – 34

6.15 Auto Grease Units .................................................................... 35

7 EASIKIT® ROUTINE MAINTENANCE ............................................. 36 – 42

8 EASIKIT® EK450 PARTS LIST ................................................................ 43

9 EASIKIT® EK450 EXPLODED DIAGRAMS ..................................... 44 – 46

10 WARRANTY ............................................................................................ 47

3

EK450 INSTRUCTION MANUAL

INTRODUCTION

This product is designed to provide years of reliable service throughout its working life.

The unique design of the EASIKIT

and hands-on experience in the conveyor industry. In depth experience, attention to detail, a

commitment to quality and excellent service are the foundations that have built a first-rate

reputation and provided complete customer satisfaction.

Please take time to read this Instruction Manual; it will guide you step by step through

installation to ensure you get the maximum performance from your conveyor.

This manual covers installation, parts required, maintenance, CE conformity and warranty

®

Conveyor System is the result of 30 years of research

conditions.

We, the designers and distributors want you to achieve a high level of satisfaction with your

EASIKIT

to contact us.

®

Conveyor System. If you have any comments or questions, please do not hesitate

InterQuip USA LLC

4 Duke Place

Norwalk, CT 06854

(203) 322-2600

info@interquip.net

4

EK450 INSTRUCTION MANUAL

1. SAFETY INSTRUCTIONS

To use this equipment properly, you must observe the safety regulations, the assembly instructions and the

operating instructions to be found in this manual. All persons who use and service the equipment have to be

acquainted with this manual and must be informed about any potential hazards. Children and frail people

must not use the equipment. Children should be supervised at all times if they are in the area in which the

equipment is being used.

It is also imperative that you observe the accident prevention regulations in force in your area. The same

applies for general rules of occupational health and safety.

The manufacturer shall not be liable for any changes made to the equipment or for any damage resulting

from such changes.

Caution:

1.1. Read all instructions. Failure to follow instructions listed below may result in electric shock, fire

and/or serious injury. Always isolate from electrical supply before carrying out maintenance,

including changing the belt.

1.2. Do not attempt to assemble the conveyor in high winds

1.3. Prior to assembling your conveyor check components against parts list to ensure that there are no

shortages, the assembly should not commence unless all items are present.

2. ENVIRONMENTAL PROTECTION

Recycle unwanted materials instead of disposing them as waste. All parts and packaging should be sorted,

taken to the local recycling center and disposed of in an environmentally safe way.

3. CONFORMITY

EASIKIT® conforms to relevant safety standards in the country in the EU where the product is manufactured.

The machinery, taking into account the state of art, complies with, or is designed and constructed so far as it

is possible to comply with, the relevant health and safety regulations.

5

EK450 INSTRUCTION MANUAL

4. TOOLS / PPE / PARTS & PACKING LIST

4.1 TOOLS AND EQUIPMENT REQUIRED

• Phillips screwdriver

• Adjustable spanner

• Podium steps

• Tape measure

• Large set square

• Offset wrench or socket wrench

• 19mm spanners and sockets

• SDS Electric hammer drill

• Temporary support frames/trestles

4.2 RECOMMENDED PPE

• Hard Hat

• Gloves

• Goggles

• Safety footwear

4.3 PARTS & PACKING LIST

• Supplied separately

6

EK450 INSTRUCTION MANUAL

5. LIFTING & SUPPORT

EASIKIT® EK450 Sections

Length

Width

Height

Weight

Head Unit without Motor

37.75”

23”

12.25”

117 lbs.

Tail / Base Tension Unit

47”

22”

12.25”

159 lbs.

3.3’ (1.0m) Section

41.25”

20”

12.25”

77 lbs.

6.6’ (2.0m) Section

80.75”

20”

12.25”

143 lbs.

Small Steel Hopper

31.5”

24.75”

12.25”

40 lbs.

WARNING!

5.1 MANUAL HANDLING

• Individual sections should be handled by at least 2 people

• Sections & components over 50kgs will require mechanical handling

OBSERVE CORRECT LIFTING PROCEDURES AT ALL TIMES.

MIND YOUR BACK - THESE SECTIONS ARE HEAVY!

FAMILIARIZE YOURSELF WITH THE WEIGHT OF EACH SECTION

5.2 MECHANICAL HANDLING

• Conveyors up to 16’ (5.0m) long should be lifted into place with nylon straps to poles inserted

through the holes on the head and base tension units. Conveyors over 16’ (5.0m) long should

be lifted with at least six (6) nylon straps.

WARNING!

ENSURE THAT YOUR CONVEYOR IS CORRECTLY AND SAFELY

LIFTED AT ALL TIMES. ENSURE THAT NOBODY IS UNDERNEATH

THE CONVEYOR WHEN IT IS BEING LIFTED.

7

EK450 INSTRUCTION MANUAL

5.3 SUPPORTING IN TEMPORARY INSTALLATIONS

• Recommended support method for a temporary installation is scaffolding/temporary support

trestles which should be erected by a qualified person whilst the conveyor is being assembled.

ENSURE THAT THE CONVEYOR IS SUPPORTED SATISFACTORILY AT

REGULAR INTERVALS DURING ASSEMBLY – (max 13’) AS IT WILL BE TOO

HEAVY TO MANUALLY LIFT ONTO SUPPORTS WHEN COMPLETE

5.4 HELPFUL HINTS

The more supports there are used during assembly of your conveyor the easier it will be to

•

assemble.

Once your conveyor is fully assembled and operational you will find it beneficial to ensure that

•

there is a minimum gap of 100mm between any part of the conveyor and the floor as this will

help prevent material jamming on the returning belt.

6.1 ASSEMBLY PROCEDURE

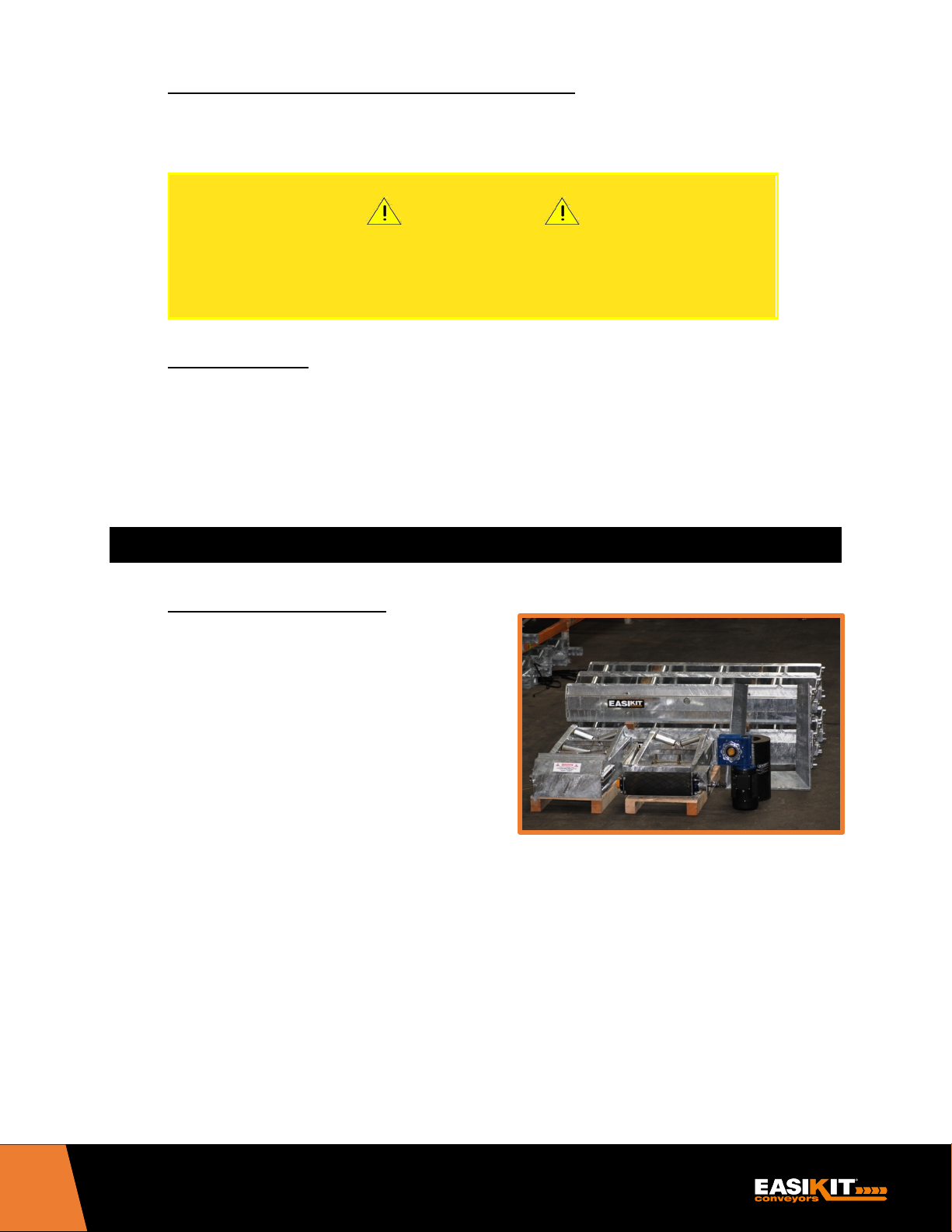

Your conveyor has been delivered to you on

pallets (unless supplied ready assembled).

After opening the pallet, you will have all the parts

required to complete your conveyor assembly.

Before you start...........read through instructions carefully and check that all the items listed on your

Parts & Packing list have been supplied. If any items are missing, contact your supplier immediately

prior to assembly.

You will need assistance.........you will find that assistance of at least two other people, and

appropriate mechanical handling equipment, will speed the job and make assembly easier and safer.

WARNING!

6. ASSEMBLY

8

EK450 INSTRUCTION MANUAL

Selecting your site……...choose an area that is firm, level, and capable of supporting the weight of

the conveyor and product to be conveyed on the belt. In addition, the base should be suitable to

facilitate secure anchoring of the conveyor feet.

You will require unrestricted access to all edges of the conveyor.

CONVEYOR STANDS MUST BE ANCHORED SECURELY AT THE FEET TO A

STABLE BASE. BUILDING ANCHORS ARE NOT SUPPLIED AS PART OF THE KIT

AND SHOULD BE PURCHASED SEPARATELY.

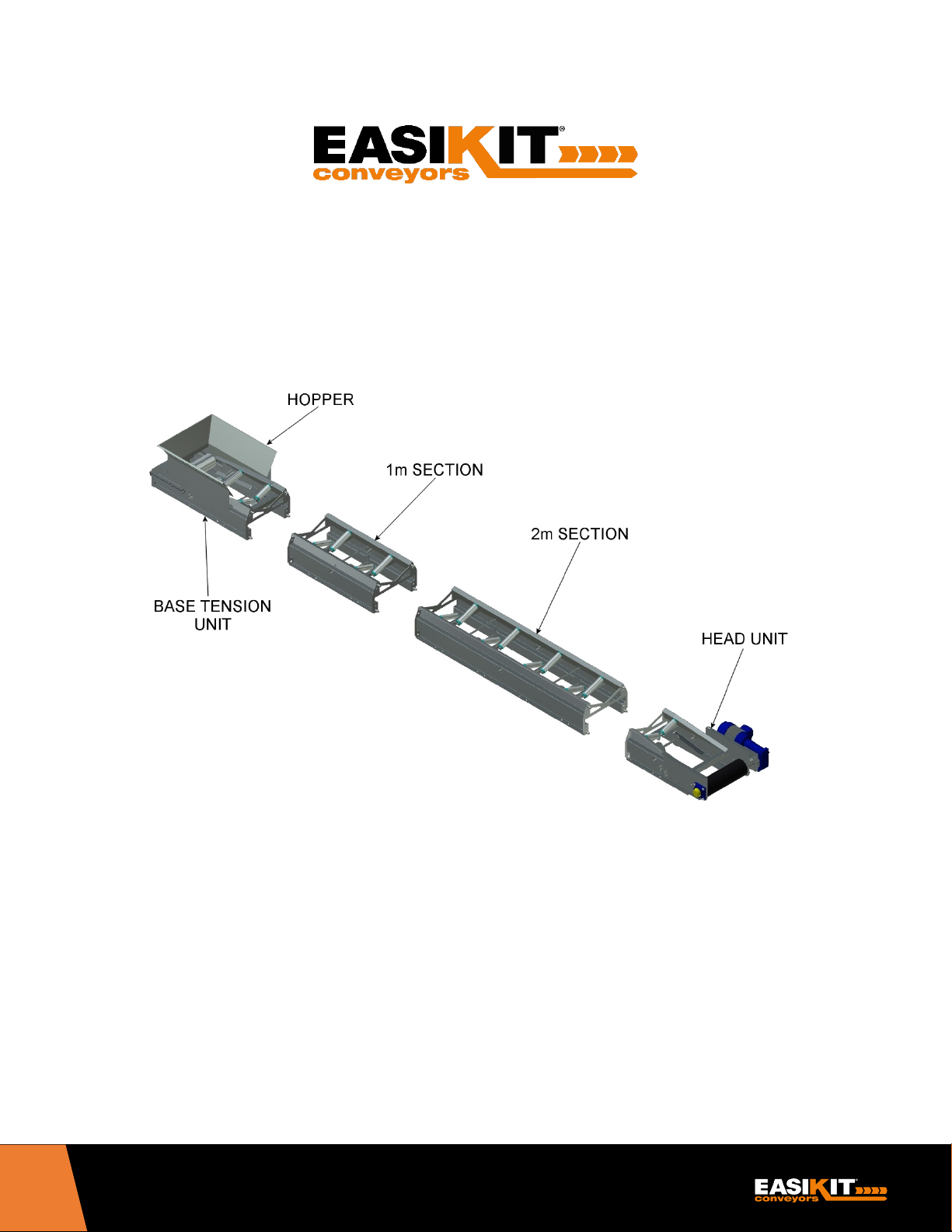

6.2 ASSEMBLY INSTRUCTIONS

ENSURE THAT THE CONVEYOR IS CORRECTLY SUPPORTED THROUGHOUT

THE ENTIRE ASSEMBLY PROCEDURE.

The instructions provided below are given as the recommended method of assembly using

scaffolding/temporary supports. However, in some circumstances and with your own experience,

you may prefer to assemble the conveyor directly onto support stands. If this is your choice of

installation, please familiarize yourself with the section on fitting support stands (Section 6.7) prior to

attempting to assemble the conveyor. You will require mechanical means of handling the conveyor

if you intend to assemble the conveyor directly onto support stands (see Section 5 – Lifting &

Supporting).

Position Base Tension Unit (without hopper attached) onto a flat surface or on temporary

1.

supports in approximate area of where the conveyor will be finally positioned

Offer up intermediate sections (1.0m or 2.0m sections) in line with Base Tension Unit as

2.

required lining up connecting lugs with holes in opposite section. (If your conveyor includes a

1.0m section in its modular length, this should be installed first nearest to the Base Tension

Unit.)

WARNING!

WARNING!

9

EK450 INSTRUCTION MANUAL

Push the sections together simply inserting connecting lugs into adjacent holes.

3.

Insert the joining bolts and tighten nuts with two 19mm spanners or sockets.

4.

Continue adding intermediate sections as described in 2, 3 and 4 above, until the desired length of your

5.

conveyor is achieved.

10

Couple Head Unit to the last intermediate section as described in 2, 3 and 4 above.

6.

Note: Do not fit the hopper at this stage.

Note: You will find it more advantageous to fit the belt next, prior to fitting the motor and gearbox.

EK450 INSTRUCTION MANUAL

6.3 RETURN ROLLERS

DISC RETURN ROLLERS

EASIKIT® EK450 Conveyors are supplied with Disc Return Rollers as standard and can be used with

plain or cleated belt. These are fitted in bushings in pre-drilled holes in the sections.

Disc Return Roller Bushing View of underside of conveyor showing Disc Return Rollers

STANDARD RETURN ROLLERS

These are supplied when a chevron belt is required and are fitted in pre-drilled holes in the conveyor

side framework.

11

EK450 INSTRUCTION MANUAL

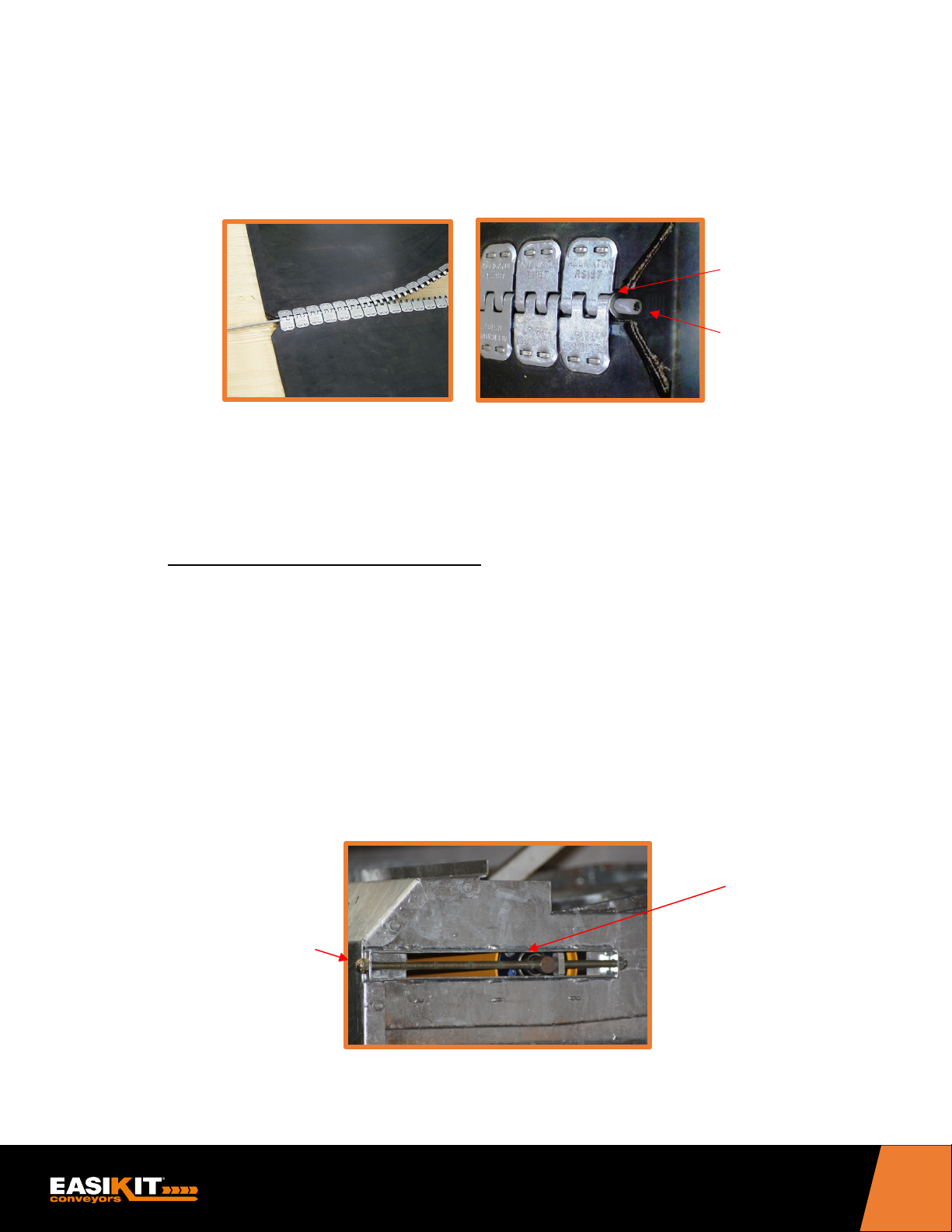

6.4 FITTING BELT – CLIP JOINT

(B)

(A)

nuts

Top Cover

1. Ensure that the drum on Base Tension Unit is as far forward (towards motor end) as

possible, unwind the Adjusting Nuts (A) repeating on the opposite side. This will slide the tail

drum (B) along the conveyor. Continue until drum is as far forward as possible to provide

the minimum belt length position.

Adjusting

2. Ensure that the belt is the correct way up. Your belt is constructed with several layers of

rubber and fabric ply. It is important that the thickest ply is facing upwards as this is the

wearing surface.

Tail drum

3. Feed one end of the belt into the conveyor frame over the return rollers at one end of the

conveyor, ensuring that the belt is the correct way up with the wear surface facing

downwards and running on the return rollers.

4. Pull belt over the top of the return rollers down towards the opposite end of the conveyor.

BELT

RETURN ROLLERS

12

EK450 INSTRUCTION MANUAL

5. Pull belt around the head and tail drums and onto the top of the conveyor over the top

(B)

(A)

nuts

rollers to meet the opposite end of the belt.

6. Interlock belt fasteners and insert hinge pin. Clamp the washers either end, to prevent

hinge pin movement. Ensure that the ends of the hinge pin are within the width of the

conveyor belt. This may need to be cut if needed.

Washer

Clamped

End of hinge

pin within the

width of belt

7. Make sure belt is lined up in the centre of head and tail drums. The belt should now be

tensioned following the tensioning procedure as described in Section 6.10.

6.5 FITTING BELT – VULCANIZED JOINT

In normal circumstances it is more advantageous to fit the belt as above and vulcanize the belt joint

when the conveyor is ready assembled. However, if this is not possible, the instructions below are

a guide to fitting a pre-vulcanized endless belt to your conveyor after the sections have been fitted

together.

1. Ensure that the drum on Base Tension Unit is as far forward (towards motor end) as

possible, unwind the Adjusting Nuts (A) repeating on the opposite side. This will slide the tail

drum (B) along the conveyor. Continue until drum is as far forward as possible to provide

the minimum belt length position.

Adjusting

Tail drum

13

EK450 INSTRUCTION MANUAL

2. Remove the tail drum guard on base tension unit. (Code no 345208 on EK450 Base Tension

Unit exploded drawing –see page 44). This can be removed using two open ended

spanners.

3. Remove all return rollers on the underside of your conveyor. Disc Return Rollers will need

the R-Clip removing first.

4. Roll out belt to its full length alongside of the assembled conveyor.

5. Lift one end of the belt up and loop over the tail drum of the base tension unit. This should

be carried out with a minimum of two people.

6. Mechanically lift one side of the conveyor to enable the belt to be fed through under the

conveyor frame and over the temporary support trestles. As the belt is being inserted,

replace the return rollers in turn along the length of the conveyor to support the belt.

7. Loop the other end of the belt over the head unit drum.

Useful Hint:

In some instances where access is tight or difficult, it may be advantageous to

dismantle and remove the head drum from the Head Drive Unit. This can be achieved

by simply removing one drive drum mounting plate (code 345113/4 on EK450 Head

Unit exploded drawing on page 44). The drive shaft grub screws in the bearing will

need to be released on both sides and the drum removed from the head unit. Once

the belt has been positioned in place, the drum can be reassembled into the head unit

in reverse procedure of removal. It is important to ensure that the drum is

repositioned centrally and the grub screws are tightened securely.

8. Ensure that the belt is centrally positioned on the head and tail drums and along the length

of conveyor both top and underside.

9. Replace the tail drum guard in reverse procedure to how it was removed using two open

ended spanners to re-tighten the fixings.

10. The belt should now be tensioned following the tensioning procedure as described in

section 6.12.

14

EK450 INSTRUCTION MANUAL

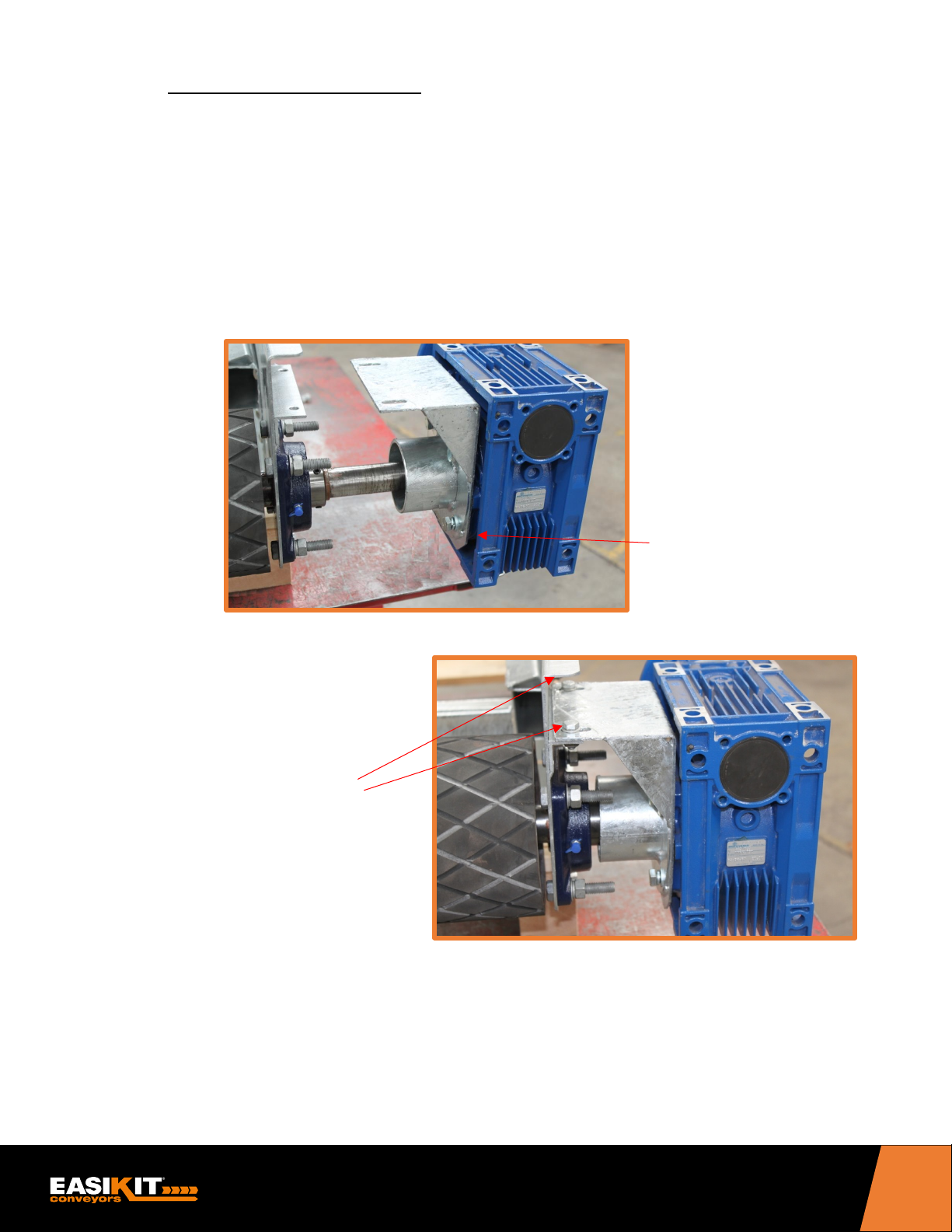

6.6 FITTING MOTOR & GEARBOX

The motor can be fitted to the conveyor at this stage. Alternatively, if your conveyor will be supported

on stands, you may prefer to fit the motor once the conveyor installation is complete. If this is your

choice, refer to Section 6.7 (Fitting EASIKIT® Support Stands) prior to carrying out the instructions

below.

Ensure that the drive shaft is clean and lubricated with a ‘copper slip’ type lubricant prior to

fitting the motor. It is recommended to first loosely position the motor mounting bracket to

the gearbox and then align the motor onto the drive shaft prior to bolting onto the mounting

bracket. (N.B. The motor body should be parallel to the conveyor, do not mount it vertical).

Carefully align fixing holes and secure and tighten evenly.

Loosely position the

motor mounting bracket

to the gearbox

Align the motor

onto the drive

shaft and bolt onto

the mounting

bracket

15

Loading...

Loading...