ACR Smart

InterPuls S.p.A.

Via F. Maritano, 11 - 42020 - Albinea (RE) – ITALY

Tel. +39 0522 347511

Fax +39 0522 348516

sales@interpuls.com

Instruction Manual, Operation and Maintenance

original instructions

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

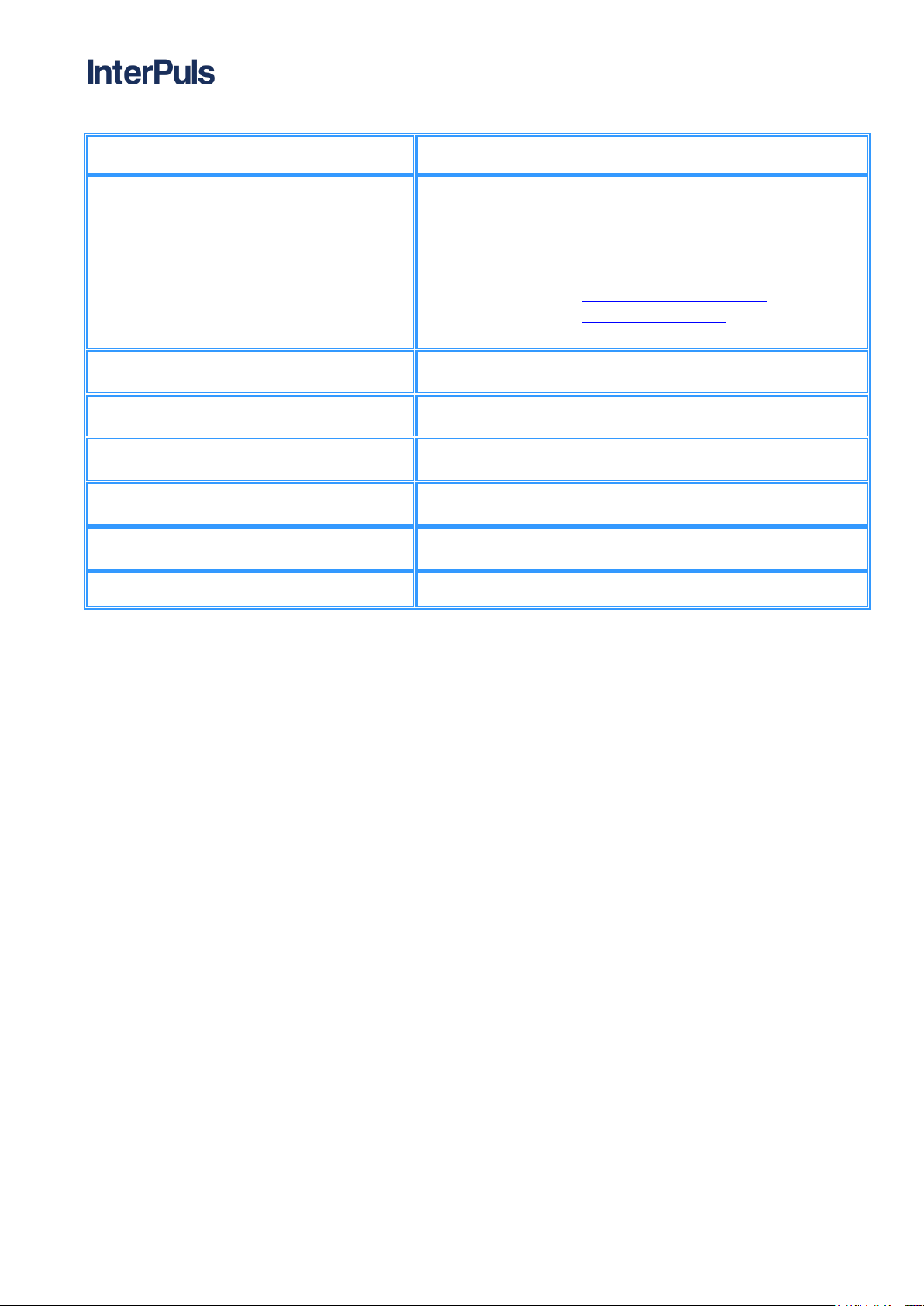

MANUFACTURER

InterPuls S.p.A

ADDRESS

Via: F. Maritano, 11

Postal code 42020 - Albinea (RE) - ITALY

Tel.: +39 0522 347511

Telefax: +39 0522 348516

Website: www.milkrite-interpuls.com

E-mail: sales@interpuls.com

TYPE OF DOCUMENT

Instruction, Use and Maintenance Manual

DOCUMENT CODE

5630006_EN

EDITION

04.17

PRODUCT

Automatic Cluster Removal

MODEL

ACR Smart

YEAR OF MANUFACTURE

2017

InterPuls is a registered trade mark of InterPuls SpA.

The information contained in this document is not binding and can be modified without notice. References in

this document to manufacturer trademarks are for identification only. Certain company and product names

used throughout the document are trademarks of their respective owners.

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 2

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

5630006_04.17_EN

Summary

ACR Smart ......................................................................................................................................................... 1

1 GENERAL INFORMATION .................................................................................................................... 5

General information and safety warnings ...................................................................................... 5 1.1

Important warnings .................................................................................................................... 5 1.1.1

Symbol used in this manual ....................................................................................................... 5 1.1.2

Rules and regulations for the user ............................................................................................. 5 1.1.3

Limitation of liability .................................................................................................................... 5 1.1.4

Prior using the product ................................................................................................................... 5 1.2

Requirements and regulations for personnel ............................................................................. 5 1.2.1

Disposal ......................................................................................................................................... 6 1.3

General regulation ..................................................................................................................... 6 1.3.1

Fire prevention ............................................................................................................................... 6 1.4

Fire prevention ........................................................................................................................... 6 1.4.1

Safety regulations ...................................................................................................................... 6 1.4.2

Characteristic of extinguishers................................................................................................... 6 1.4.3

Normative references applied ........................................................................................................ 6 1.5

Marking .......................................................................................................................................... 6 1.6

Dataplates affixed to the machine ............................................................................................. 6 1.6.1

2 DESCRIPTION OF THE DEVICE ........................................................................................................... 7

General features ............................................................................................................................ 7 2.1

Technical characteristics ............................................................................................................... 7 2.2

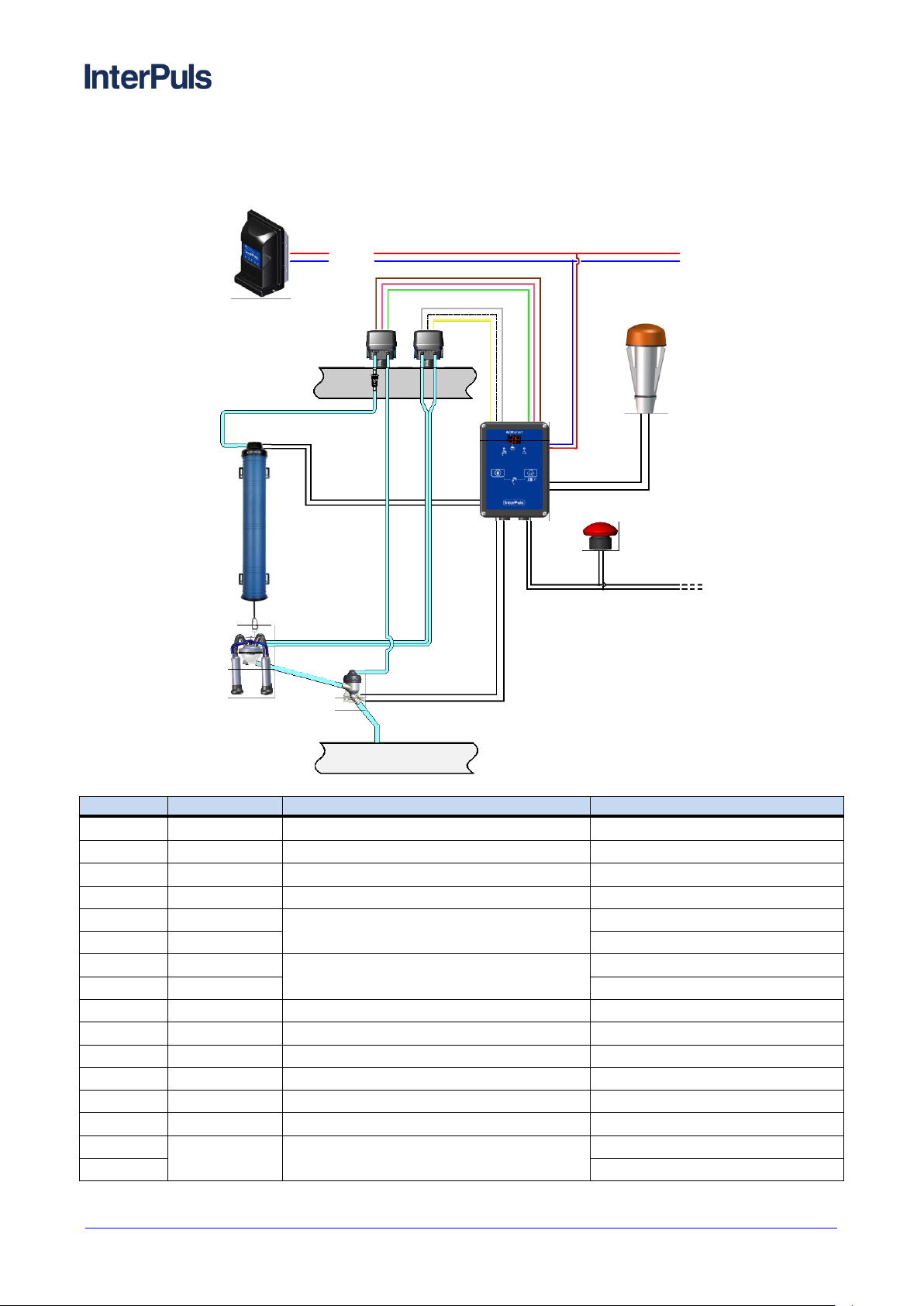

WIRING DIAGRAM ........................................................................................................................ 8

2.3

General connection diagram ...................................................................................................... 8 2.3.1

Connection diagram for sheep and goat ................................................................................... 9 2.3.2

PCB connection ......................................................................................................................... 9 2.3.3

3 DESCRIPTION OF THE DEVICE ......................................................................................................... 10

Display during operation .............................................................................................................. 11 3.1

4 DESCRIPTION OF THE FUNCTIONS ................................................................................................. 12

Detachment stage (stand-by) ...................................................................................................... 12 4.1

Wash ............................................................................................................................................ 12 4.2

Milking .......................................................................................................................................... 13 4.3

Milking with automatic unit removal ......................................................................................... 13 4.3.1

Manual milking ......................................................................................................................... 14 4.3.2

Indication of milk presence ...................................................................................................... 15 4.3.3

Maximum milking time ............................................................................................................. 15 4.3.4

Detachment operation ................................................................................................................. 15 4.4

Stimulation ................................................................................................................................... 16 4.5

Alarm ............................................................................................................................................ 18 4.6

Quick-Lift ...................................................................................................................................... 18 4.7

Swing-Over .................................................................................................................................. 18 4.8

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 3

5630006_04.17_EN

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

5 PROGRAMMING MODE ...................................................................................................................... 19

Accessing the programming mode .............................................................................................. 19 5.1

Programming mode ..................................................................................................................... 19 5.2

Programming parameter table ..................................................................................................... 20 5.3

Parameter reading ....................................................................................................................... 21 5.4

6 GENERAL RECOMMENDATIONS ...................................................................................................... 23

Positioning ................................................................................................................................... 23 6.1

Sensitivity ..................................................................................................................................... 23 6.2

Configurations .............................................................................................................................. 23 6.3

Troubleshooting ........................................................................................................................... 24 6.4

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 4

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

5630006_04.17_EN

1 GENERAL INFORMATION

General information and safety warnings 1.1

Important warnings 1.1.1

To safeguard the operator and prevent any damage to the equipment, before carrying out any kind of

operation it is important to have read and fully understood the instruction manual.

Symbol used in this manual 1.1.2

The following symbols are used in this manual to highlight indications and warnings which are of particular

importance:

WARNING:

This symbol indicates health and safety regulations designed to protect operators and/or any

exposed persons.

CAUTION:

This symbol indicates that there is a risk of causing damage to the equipment and/or its

components.

NOTE:

This symbol is used to highlight useful information.

Rules and regulations for the user 1.1.3

WARNING

Any failure to observe the warnings provided in this manual may lead to equipment

malfunctions or damage to the system.

Limitation of liability 1.1.4

InterPuls S.p.A. declines all liability for damage to persons, animals and/or things caused by incorrect use of

the equipment.

Prior using the product 1.2

Requirements and regulations for personnel 1.2.1

ATTENZIONE

Prima di utilizzare il dispositivo, l’operatore è tenuto a leggere attentamente il manuale.

Il dispositivo deve essere utilizzato da persona maggiorenne, istruita, fisicamente e

psichicamente idonea e che abbia ricevuto indicazioni adeguate in merito al funzionamento

dello stesso.

Nel corso del montaggio e dell’attivazione del dispositivo, occorre seguire le istruzioni del

manuale, le norme e i regolamenti concernenti la sicurezza sul luogo di lavoro e la

salvaguardia della salute.

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 5

5630006_04.17_EN

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

Disposal 1.3

General regulation 1.3.1

The appliances must be disposed of only and exclusively by specially authorized waste disposal companies

in accordance with all relative legislation and prescriptions.

The packaging must be consigned to the relative authorized companies to be recycled.

Fire prevention 1.4

Fire prevention 1.4.1

NOTE

The machine is not equipped with fire extinguishers.

The operator must make sure that the place in which the appliance is installed is equipped

with an adequate number of suitable fire extinguishers. The extinguishers must be positioned

where they are clearly visible and protected from damage and improper use.

Safety regulations 1.4.2

WARNING

It is strictly prohibited to extinguish fires involving electrical equipment with water!

Characteristic of extinguishers 1.4.3

Use powder, foam or halogen extinguishers which must be positioned next to the device.

Operating personnel must receive adequate instruction on how to use the extinguishers.

Normative references applied 1.5

Europe:

Directive no. 2004/108/EC Electromagnetic Compatibility (EMC)

USA:

FCC Federal Communications Commission

Canada:

IC Industry Canada

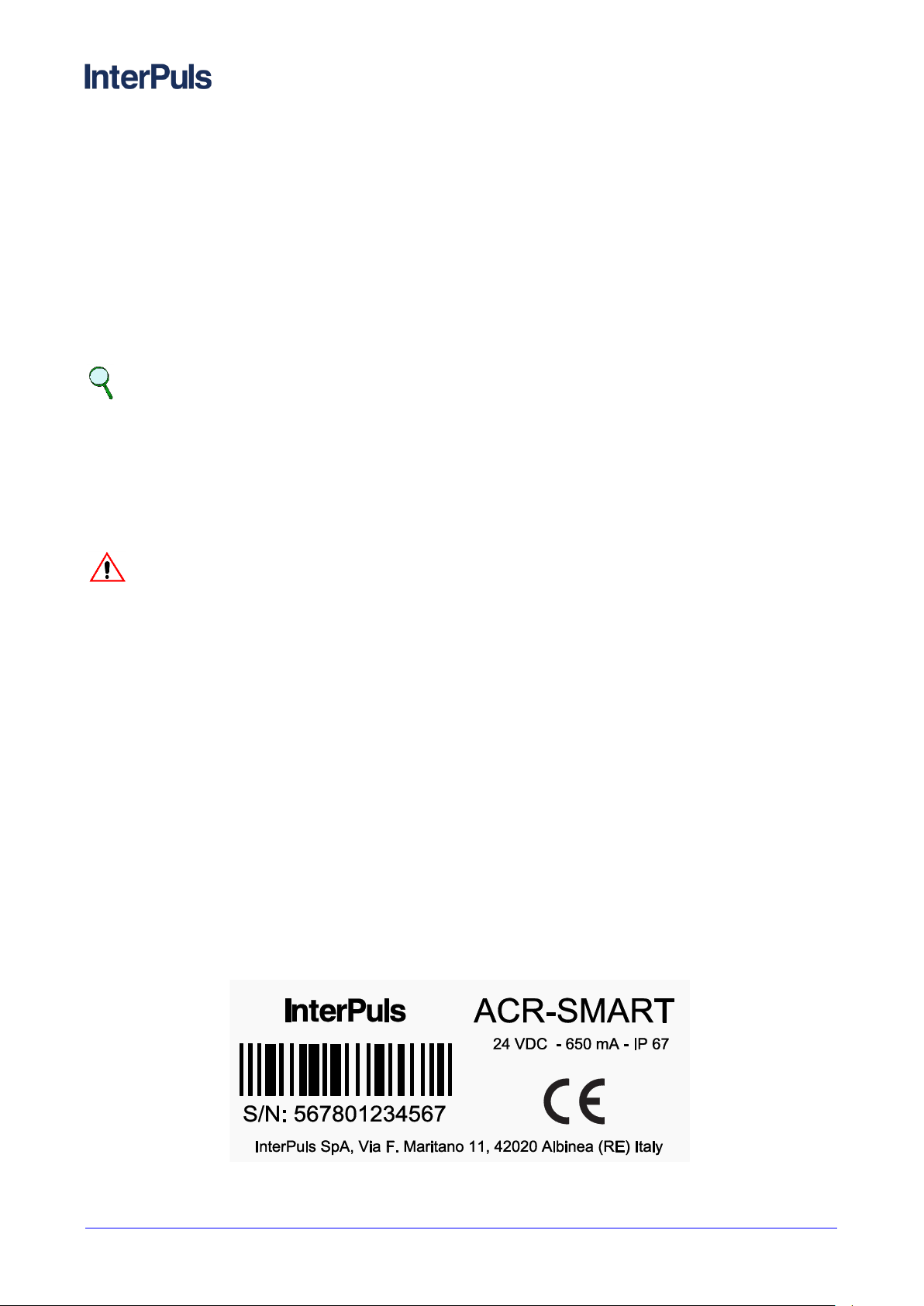

Marking 1.6

Dataplates affixed to the machine 1.6.1

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 6

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

5630006_04.17_EN

General technical characteristics

Dimensions

130x180x38 mm (5,12x7,08x1,49 in)

Weight

0.45 kg (0,99 lb)

Power supply

24 VDC

Power consumption of the panel only

100 mA

Power consumption of the system

ACR Smart + CV + LE: 600 mA

Protection rating (cables installed properly)

IP 67

Operating vacuum

between 36 and 60kPa (10,63 and 17,71 “Hg)

typically 50kPa (14,76 “Hg)

Operating temperatures (environment)

-5ºC ÷ +40ºC (23ºF ÷ 104ºF)

Transport/storage temperatures

-20ºC ÷ +50ºC (-4ºF ÷ 122ºF)

2 DESCRIPTION OF THE DEVICE

General features 2.1

The ACR-Smart panel is designed to control all the milking, detachment and washing functions of the unit.

The ACR-Smart is able to control the milking frequency and the pulsation ratio in a wide range of values in

order to meet the needs of all systems (both in the high line and low line) and of all types of animals (cattle sheep - goats).

The ACR-Smart is able to perform a stimulation that can be forced, automatic (dependent on the flow of milk)

or manual (activated directly by the milker at any time).

The panel is compatible with swing-over systems in which the unit is detached by moving the arm. In fact,

with the ACR-Smart you can control the pneumatic cylinder responsible for moving the unit from the right

hand row to the left hand row and vice versa.

It is suitable for milk transport systems thanks to the alarm indicating the end of the milking process and the

possibility to restart the panel from the last active stage.

The ACR-Smart can be connected to remote start-up devices (AutoStart) and remote stop devices (Quick Lift

Line).

Technical characteristics 2.2

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 7

5630006_04.17_EN

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

Terminal

Colour

Electrical connection

1

Red

24VDC (+)

2 Blue

24VDC (-)

3

Blue

Flashing light 24VDC(+)

4 Black

Flashing light 24VDC (-)

5

Remote start-up key (AutoStart)

6 7

“Quick-Lift” key

8 9

Grey

“Rear” LE pulsation

Brown

10

White

LE “Common”

Black

11

Yellow

“Front” LE pulsation

Blue

12

Green

CV (to valve)

Blue

13

Pink

CV “Common”

Black

14

Brown

CV (to cylinder)

Brown

15

HFS sensor

16

END OF MILKING

SESSION FLASHING

LIGHT

TO THE NEXT PANEL

LE

IUP

DVC AS

MILK LINE

VACUUM

LINE

ACR

SMART

HFS EVO

24VDC+

24VDC -

QUICK-LIFT

KEY

CV

WIRING DIAGRAM 2.3

General connection diagram 2.3.1

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 8

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

5630006_04.17_EN

END OF MILKING

SESSION FLASHING

LIGHT

TO THE NEXT PANEL

LE

IUP

DVC AS

MILK LINE

VACUUM

LINE

ACR

SMART

HFS

24VDC+

24VDC -

QUICK-LIFT KEY

CV

HFS

(S/O Valve)

Quick Lift Line

DVC

(with Autostart)

LAMPADA

(end of milking)

- 24 VDC

+ 24 VDC

BLUE

RED

-24VDC

BLACK

BLUE

+24VDC

Brown

Pink

Green

Yellow

White

Grey

C

Common

Front

Common

Rear

CV

(Control Valve)

LE30

(Pulsator)

Brown

Black

Blue

Blue

Black

Brown

Connection diagram for sheep and goat 2.3.2

PCB connection 2.3.3

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 9

5630006_04.17_EN

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

A

E

B

D

C

3 DESCRIPTION OF THE DEVICE

A) Display

B) LEDs (green LED, red LED)

C) Stop key

D) Milking process start button with automatic detachment, continuous pressure for 3”, stimulation start

E) Combination of keys for accessing the washing or programming mode

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 10

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

5630006_04.17_EN

Display

Indication

Meaning

Code St

Stimulation in progress

Code CL

Panel in washing mode

Left digit: the first segment at the top indicates

the initial delay count

Right digit: milking time

Initial delay without continuous flow

Left digit: when all the horizontal segments

are lit-up, it means that there is continuous

flow during the initial delay

Right digit: milking time

Initial delay with continuous flow

Left digit: when the central segment lights up

it means that there is continuous milk flow

Right digit: milking time

Milking with continuous flow

Right digit: milking time

Left digit: only the bottom segment lit-up

indicates the final delay count

- Milking without continuous flow (final

delay count)

- Detachment operations

The central point flashing indicates manual

milking

- Manual milking

Code dt

Detachment

Code AL (flashing)

Milking without continuous flow alarm

Display during operation 3.1

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 11

5630006_04.17_EN

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

Key

Function

Start automatic milking

Removal or release of the milking unit

+

Start washing

+ x 5”

Access programming mode

QUICK-LIFT operation

Removal or release of the milking unit

AUTO-START operation

Start automatic milking via remote control (cylinder with AS or remote

button)

4 DESCRIPTION OF THE FUNCTIONS

Upon start-up the panel display indicates the software version installed. Depending on the configured

parameters, the panel may then restart during:

washing

detachment (default)

last active stage

Detachment stage (stand-by) 4.1

The display features the code dt (Detachment) with the green LED switched on. During this stage the panel

waits for the commands from the operator.

The S/O valve therefore stays closed, while the unit may switch from the release position to the removal

position or vice versa via the key or via the Quick Lift control

Wash 4.2

The wash function may be operated

manually, when the system is in the detachment position, by pressing the two + keys

instantaneously

automatically if pre-set as a start-up function on the programming menu (parameter I.P. set on L.p.).

The display features the code CL and the green LED starts flashing. The unit is released and the count

relating to the shut-off closure delay starts (parameter c.S.). When it has elapsed, the valve is opened and

the washing stage starts.

You can set a different frequency during the washing cycle (parameter U.F.).

Press the key to stop the washing cycle and retract the unit.

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 12

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

5630006_04.17_EN

The upper line indicates the initial delay count

The central line switched off indicates the

absence of milk

The upper line indicates the initial delay count

The central line indicates the presence of milk

CAUTION

At the end of washing phase it’s recommended to power off the ACRSmart panels to avoid

that the coils of control valves stay powered for long time and being damaged. Upon start-up,

the panel may restart in washing phase or detachment phase according to the parameter I.p.

WARNING

Do not press the key and do not press the quick-lift switch during the washing cycle:

the unit would be removed from the washing plate.

Milking 4.3

Milking with automatic unit removal 4.3.1

To start the milking process with automatic detachment press the key during the detachment stage

or operate the Auto-Start contact.

NOTE

Terminals 11-12 may be used to connect a REMOTE KEY or an AUTO-START device to start

the milking process without having to press the key on the panel

When the automatic milking process starts:

the cylinder releases the unit.

after the vacuum/pulsation delay (parameter P.d.), the pulsator is activated and the valve (shut-off)

of the flow sensor is opened.

The display then starts counting the milking time. The upper horizontal segment indicates the initial delay

count (parameter I.d.). At the same time, the two vertical segments indicate the opening of the pulsator

channels, flashing alternately.

When the milk presence signal constantly exceeds the value defined by the position of the jumpers, the

panel detects a continuous flow and the horizontal segment of the left hand display lights up.

When the initial delay has elapsed (parameter I.d.), the upper horizontal segment switches off.

When there is no longer any milk flow, the central segment switches off and the final delay count starts

(parameter F.d.). The detachment operations start when the delay has elapsed.

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 13

5630006_04.17_EN

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

The upper line switched off indicates the end

of the initial delay

The central line indicates the presence of milk

The sole lower line indicates the absence of

milk and therefore the final delay count

In each milking stage, the two vertical lines

flash following the frequency of the pulsator

During all milking stages, press the key to switch from automatic milking to manual milking and vice

versa.

Throughout milking, the right hand display indicates the duration of the milking process in minutes. The lit-up

dot indicates that milking has exceeded 10 minutes.

>> 15 minutes

Press the key (or activate the quick-lift button) to immediately stop the milking operations and start

the detachment operations.

Manual milking 4.3.2

To start milking with manual unit removal, press the key after the system has been started in

automatic milking mode:

The dot flashing in the left hand digit of the display indicates Manual Milking.

Manual milking LED

The panel stays in the manual milking mode as long as:

the button is pressed to switch to the automatic milking mode

or the button is pressed to start the detachment operations

Press the key to switch from the manual milking mode to the automatic milking mode and vice versa,

at any time.

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 14

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

5630006_04.17_EN

Indication of milk presence 4.3.3

During milking, the left hand display indicates the current milking stage and the presence/absence of milk.

The central horizontal segment indicates if milk is going through the sensor at that time. If the milk presence

signal lasts for a period equal to the continuous flow time (parameter c.F.), the panel detects that there is an

actual continuous flow.

Maximum milking time 4.3.4

WARNING

You can envisage a maximum milking time, which can be set or disabled in the programming

menu (parameter E.t.)

If this limit is reached, the unit detachment operations start automatically and, in the event of

no flow during the milking process, the anomaly is signalled via an alarm

Detachment operation 4.4

When the initial delay has elapsed, if the panel does not detect a continuous flow of milk, the final delay

count starts (parameter F.d.).

If the continuous flow of milk is resumed, the delay is reset. The unit removal operations start when the final

delay has elapsed.

The removal procedure can also be started manually by pressing the key

The pulsator stops

the S/O Valve closes the vacuum passage

the detachment delay time count starts (parameter d.d.), in order to wait for a certain amount of air

to leak through the collection unit hole, lowering the vacuum level under the nipples before removing

the unit

when the delay has elapsed, the cylinder gently removes the unit

if the suction function has been activated (parameter S.L.) , when the suction delay time has elapsed

(parameter S.d.) the residue milk in the collection unit and in the milk pipe is aspirated through the

flow meter

if the automatic unit release function has been activated, when the automatic release delay has

elapsed (parameter A.r.) the unit is released automatically to start a new milking session.

During the detachment stage the green LED flashes and the display features:

- the milking time in the right hand digit

- the sole lower segment in the left hand digit

Absence of continuous flow

and indication of milking time

After the detachment operation the green LED stays fixed on and the display features .

At the end of the milking operations, the pair of terminals 3-4 is powered at 24VDC; the pair of terminals can

be connected to a flashing light for indicating the end of milking.

Press the key to switch off the flashing light and switch to the actual detachment condition (standby); press the key to start a new milking session.

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 15

5630006_04.17_EN

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

Stimulation 4.5

During the stimulation stage, the display features the code St and the LEDs start flashing.

On the programming menu you can define the type of stimulation (parameter t.S.) which may be:

Forced (F.S.)

Automatic (A.S.)

OFF (oF) – can only be activated manually

FORCED STIMULATION

During programming you can set a forced stimulation cycle at the beginning of each milking process.

For a certain period of time (“stimulation time”, which can be set via parameter S.t.) the frequency

and pulsation ratio are gradually modified in order to reach the set values (stimulation frequency

S.F., stimulation ratio S.r.)

AUTOMATIC STIMULATION

Stimulation starts if the function is enabled and if during milking the s/o valve does not detect a

“Continuous Flow” for a certain period of time (called “neutral time”, which can be set via parameter

n.t.).

Therefore the frequency and pulsation ratio vary gradually until reaching the values set for

stimulation (stimulation frequency S.F., stimulation ratio S.r.)

Stimulation stops when the flow meter starts detecting a “Continuous Flow” again or when the

stimulation time elapses (parameter S.t.)

MANUAL STIMULATION

Press and hold the key for 3” during the milking cycle (with any value set for parameter t.S.)

to start the manual stimulation process: the frequency and pulsation ratio vary gradually until

reaching the values set for stimulation (stimulation frequency S.F., stimulation ratio S.r.). Stimulation

stops when the stimulation time has elapsed (parameter S.t.) and the frequency and pulsation ratio

gradually go back to the values set for milking.

NOTE

By setting stimulation ratio (parameter S.r.) on value 0, upon start of the stimulation, the

liners stay completely closed and the pulsation stops until the end of stimulation time (S.t.).

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 16

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

5630006_04.17_EN

Litres/minute

Initial

Delay

Final

Delay

Final

Delay

Final

Delay

Detachment

Operations

Time

Start of milking session

When the Pulsation delay

has elapsed, the pulsator is

activated

The Initial delay count

starts

When the Initital Delay has

elapsed, the sensor starts

monitoring a Continuous

Flow of milk

If a Continuous Flow of

milk is detected, the

milking process continues

normally

If a Continuous Flow of milk

is not detected, the Final

Delay count starts

If a Continuous Flow of milk

is detected before the Final

Delay has elapsed, the

milking process continues

normally

If a Continuous Flow of milk

is not detected, before the

Final Delay has elapsed, the

Detachment Operations

start and the operator is

warned by the warning LED

and display flashing. Now,

press the STOP button to

delete the milking alarm

As soon as there is no

Continuous Flow of milk, the

Final Delay count starts

As soon as a Continuous

Flow signal is detected

again, the milking process

continues normally

If a Continuous Flow is not

detected, the Detachment

Operations start

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 17

5630006_04.17_EN

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

Alarm 4.6

If a continuous flow is not detected during the milking process, when the initial delay has elapsed and during

the subsequent final delay time count, code AL and the red LED start flashing on the display.

The unit removal procedures start automatically, after which code AL still appears alternately with code dt on

the display, and the red LED keeps flashing.

Press the key to reset the alarm and switch to the detachment mode (stand-by).

Quick-Lift 4.7

The quick-lift button corresponds to pressing the key on the panel

If terminals 7-8 on all the panels are connected to an external switch, by pressing this key you can lift or

release all the units at the same time. This way, at the beginning of the milking process, you can release all

the units at the same time.

Swing-Over 4.8

By activating the Swing-Over mode (Type of System dt = S.O. parameter) the ACR-Smart panel can

manage systems in which the unit is detached via a pneumatic piston that moves the Swing-Over arm from

one side to the other.

By connecting this piston to the CV output, normally dedicated to the DVC, and setting the ACR-Smart Type

of System parameter, at the end of the milking process the panel will automatically move the arm in order to

start milking again on the other side.

Therefore, via the button or via the remote Quick-Lift switch, you can move arms from one side of

the milking parlour to the other.

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 18

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

5630006_04.17_EN

5 PROGRAMMING MODE

Accessing the programming mode 5.1

To access the Programming menu, press the + key for 10” while the system is in

detachment mode.

The display features the first parameter identified by its code and the LEDs start flashing alternately.

Programming mode 5.2

In the programming menu you can edit the values associated to the parameters in order to optimise the

milking, stimulation, detachment and washing operations.

The display features the code of the selected parameter.

Press the or keys to scroll the available parameters, each identified by its code.

Press the + keys to access the parameter and modify it. The current value of the selected

parameter is displayed.

Press the or keys to scroll the parameter values.

Press the + keys to confirm the value assigned to the parameter and go back to the previous

menu. If the parameter has been modified, the display flashes.

To exit the programming mode press and hold the + keys for 5”; the panel is then

automatically restarted and the version of the software currently installed in displayed.

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 19

5630006_04.17_EN

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

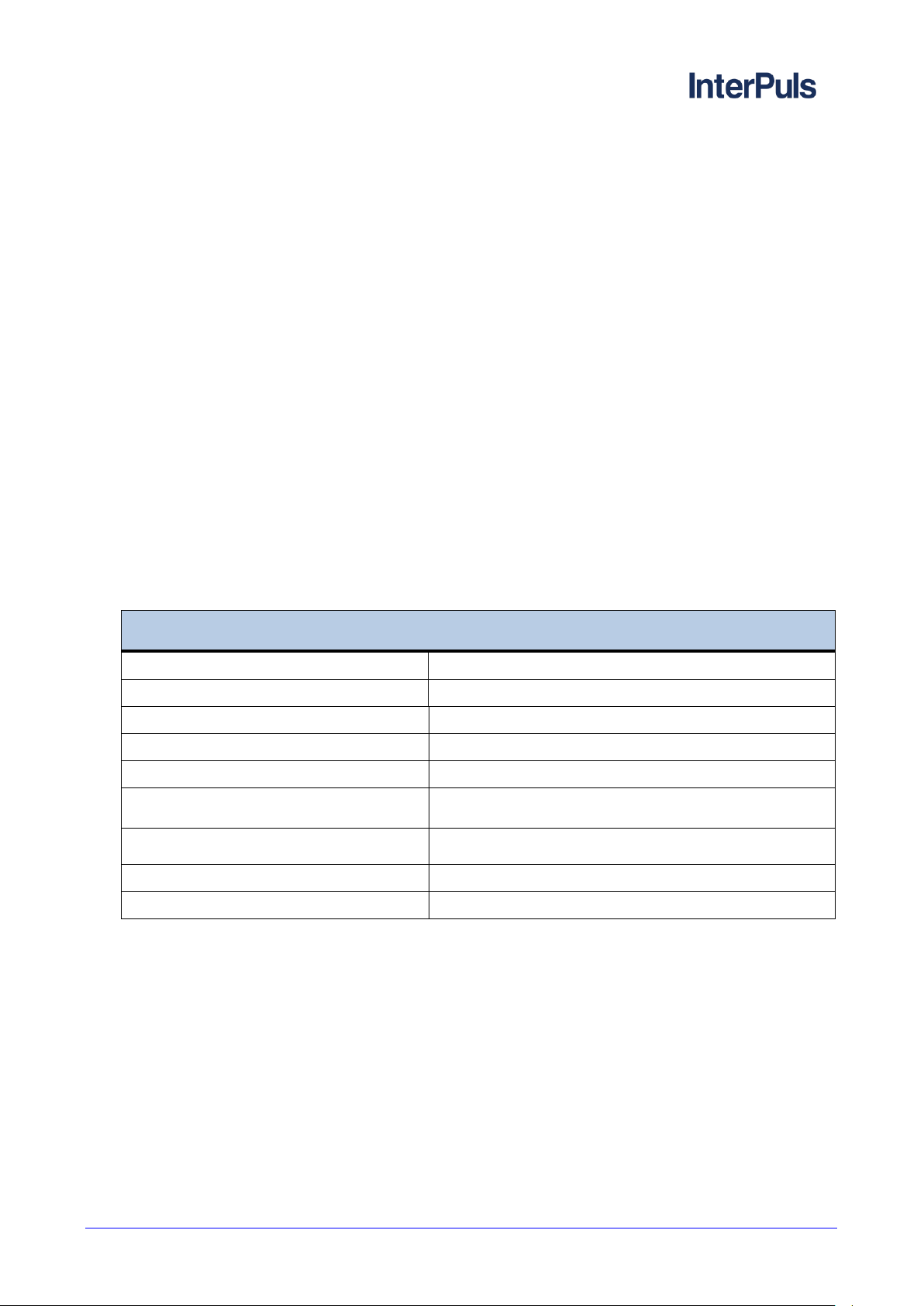

Parameter

name

Code

Description

Range

Unit of

measure

Default

SHUT-OFF

SOLENOID VALVE

ES

Select the type of solenoid valve used for

shut-off, NO - normally open (vac channel)

or NC - normally closed (atm channel)

N.O. – N.C.

//

N.O.

CYLIDER

SOLENOID VALVE

EC

Select the type of solenoid valve used for

DVC, NO - normally open (vac channel) or NC

- normally closed (atm channel)

N.O. – N.C.

//

N.O.

INITIAL DELAY

Id

Time at the beginning of the milking process

in which milk presence is not checked

0÷19

(corresponds to

0÷190)

Seconds (10x)

8 (= 80

seconds)

FINAL DELAY

Fd

If the panel does not detect a continuous

flow of milk throughout the entire delay, it

starts the detachment operations

0÷30

Seconds

9

DETACHMENT

DELAY

dd

At the end of the milking process, it is the

delay between the closure of the s/o valve

and the unit removal

0÷9

Seconds

3

AUTOMATIC

RELEASE DELAY

Ar

When the delay has elapsed, after

detachment, the unit is released

of - 5 - 15 - 30 -

45 - 60

Seconds

of

CONTINUOUS

FLOW TIME

cF

If the sensor detects the presence of milk for

a period equal to the continuous flow time,

then there is an actual flow of milk

0÷4.0

Seconds

1

PULSATION

FREQUENCY

Fr

Pulsation frequency during the milking

process

50÷180

LP

Ppm

60

REAR PULSATION

RATIO

Pr

Pulsation ratio of the hindquarters during

the milking process

10:90 ÷ 90:10

Pulsation ratio

60 (= 60:40)

FRONT

PULSATION

RATIO

PF

Pulsation ratio of the forequarters during

the milking process

10:90 ÷ 90:10

Pulsation ratio

60 (= 60:40)

START-UP STAGE

Ip

Select in which stage the panel must start

- dt: start in detachment mode

- CL: start in washing mode

- LP: start from the last active stage

dt - CL - LP

//

CL

FINAL SUCTION

DELAY

Sd

Delay between the end of the milking

session and the opening of the s/o valve for

suction

0÷9

Seconds

3

FINAL SUCTION

DELAY

SL

During opening of the s/o valve to drain the

pipe completely at the end of the milking

session

0f ÷ 9

Seconds

of

STIMULATION

FREQUENCY

SF

Pulsation frequency during the stimulation

stage

3÷25

(corresponding

to 30÷250)

Ppm

12 (=

120ppm)

STIMULATION

TIME

St

Duration of stimulation

10÷90

Seconds

20

STIMULATION

RATIO

Sr

Pulsation ratio during stimulation

0:100 ÷ 100:0

Pulsation ratio

30 (= 30:70)

NEUTRAL TIME

nt

When this time has elapsed, if there has not

been a continuous flow of milk, automatic

stimulation starts if it has been set

0÷24

(corresponding

to 0÷240)

Seconds (10x)

2 (=20

seconds)

Programming parameter table 5.3

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 20

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

5630006_04.17_EN

TYPE OF

STIMULATION

tS

Selection of type of stimulation

- FS: forced stimulation

- AS: automatic stimulation

- oF: stimulation that can only be

activated manually

FS - AS - oF

//

AS

PULSATION

DELAY

Pd

Delay between the beginning of the milking

process and the pulsation starting

0÷9

Seconds

0

FREQUENCY IN

WASHING MODE

UF

Pulsation frequency during the washing

cycle

0÷15

(corresponding

to 0÷150)

ppm

2 (= 20ppm)

MAXIMUM

MILKING

TIME

Et

The detachment operations always start

when this time has elapsed

10 - 15 - 20

Minutes

20

SHUT OFF

CLOSURE DELAY

cS

Before starting the washing cycle, the s/o

valve stays closed throughout the delay

period, in order for the system to create

vacuum

Of ÷ 90

Seconds

of

TYPE OF SYSTEM

dt

Definition of the type of system in which the

panel is used:

CY: Standard system

SO: Swing-Over

CY - S0

//

CY

Parameter reading 5.4

Shut-Off Solenoid Valve – E.S. and Cylinder Solenoid Valve– E.C.:

- With CV30 inversa set:

o E.S. = N.C. (atm channel)

o E.C. = N.O. (vac channel)

- With CV30 set:

o E.S. = N.C.

o E.C. = N.C.

- With CV20 set:

o E.S. = N.O.

o E.C. = N.O.

Start-up stage – IP :

- dt upon start-up the panel retracts the unit and goes into detachment mode (stand-by)

- CL upon start-up the panel releases the unit and goes into washing mode

- LP upon start-up the panel starts from the last active stage (if it is switched off during the milking

cycle it will restart in detachment mode)

Initial delay – Id :

- 10 second steps

- The parameter values must be multiplied by 10 (the dot lit-up indicates the x10 multiplication)

>> 120 seconds

Pulsation frequency in milking mode – Fr :

- LP indicates that the panel is not controlling pulsation and that it is only powering the pulsator

- The dot lit-up indicates that the value must be added to 100

>> 115ppm

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 21

5630006_04.17_EN

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

Pulsation frequency in stimulation mode – SF :

- The dot lit-up indicates that the value must be multiplied by 10

>> 150ppm

Neutral time – nt :

- The dot lit-up indicates that the value must be multiplied by 10

>> 80 seconds

Stimulation time – tS :

- FS forced stimulation

- AS automatic stimulation

- Of no stimulation

NOTE

It is always possible to activate manual stimulation with any value set in parameter tS.

Type of system – dt :

- CY system with cylinder-operated detachment

- SO system with detachment via movement of the Swing-Over arm (the CV channel controls a

piston that moves the arm from right to left and vice versa)

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 22

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

5630006_04.17_EN

Milk Flow

OHM

Volt

ACR Jumpers

> 500 gr/min

700

6.10 +/- 0.07

JUMPER 1 CLOSED

JUMPER 2 CLOSED

300 gr/min

1270

6.20 +/- 0.07

JUMPER 1 OPEN

JUMPER 2 CLOSED

100 gr/min

2000

6.32 +/- 0.07

JUMPER 1 CLOSED

JUMPER 2 OPEN

< 100 gr/min

2660

6.42 +/- 0.07

JUMPER 1 OPEN

JUMPER 2 OPEN

Type of system

Recommended settings

High Line

Decrease the Continuous Flow c.F. parameter = 0.3 seconds

Low Line

Decrease the Final Delay F.d. parameter = 6 seconds

Goats or sheep

Decrease the Continuous Flow c.F. parameter = 0.2 seconds

Decrease the Final Delay F.d. parameter = 8 seconds

If the system continues to detach too soon, open both jumpers

JUMPER 2 - OPEN

JUMPER 1 - CLOSED

6 GENERAL RECOMMENDATIONS

Positioning 6.1

Make sure that the HFS sensor is in a vertical position.

Sensitivity 6.2

The ACR panel is designed to detect milk flows below the 100 gr/min limit (preferably with the HFS sensor).

It is possible (but NOT recommended) to increase or decrease this threshold via the jumpers on the board.

Configurations 6.3

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 23

5630006_04.17_EN

ACR Smart - Instruction Manual, Operation and Maintenance

original instructions

Problem

Causa

Solution

The unit is detached too soon

Incorrect setting of Final Delay

and/or Continuous Flow

parameters

Increase the F.d. (Final Delay)

parameter and/or decrease the

c.F. (Continuous Flow)

parameter

The unit is detached too late

Incorrect setting of Final Delay

and/or Continuous Flow

parameters

Decrease the F.d. (Final Delay)

parameter and/or increase the

c.F. (Continuous Flow)

parameter

The shut-off valve stays closed

during milking and during washing

Incorrect setting of Shut-Off

Solenoid parameter

Check that the parameter E.S. is

set on N.O. if is used a VAC

channel (eg. CV20) or on N.C. if

is used an ATM channel (eg.

CV30)

Troubleshooting 6.4

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 24

Loading...

Loading...