To Our Customer:

Thank you for choosing the Interphase Ultrascan PC90 Forward Scanning Sonar.

Throughout the development of this fine product, we have been primarily concerned with

creating a unit that offers the best possible value for your money. Selection of features,

ease of use, superior performance and outstanding reliability were the benchmarks upon

which all important design decisions were made. We are proud of the Ultrascan PC90

Forward Scanning Sonar and your satisfaction is very important to us. We welcome any

comments or suggestions that you might have about this equipment.

It is very important that you complete and return the WARRANTY REGISTRATION

CARD within 15 days of purchase so that your unit may be protected under the warranty.

Thank You Again,

INTERPHASE TECHNOLOGIES, INC.

Interphase Ultrascan PC90™ is a trademark of Interphase Technologies, Inc.

Other brands or products are the trademarks or registered trademarks of their respective holders and

should be treated as such.

©2010 Interphase Technologies, Inc.

Publication # = Ultrascan PC90 1.0 100414

2

Contents

1 Introduction 6

General Information 6

Warranty Information 6

Unpacking and Inspection 7

2 Installing Ultrascan PC90 8

Transducer Installation 8

Thru-Hull Considerations 9

Thru-Hull Transducer Installation 10

Selecting a Location 10

Using a Fairing Block 14

Transom Mount Transducer Installation 13

Selecting a Location 13

Attaching the Bracket 13

Bracket Axel Assembly 15

Beamformer Module Installation 16

Software Installation 17

Connecting to Computer 18

Computer Network Settings 18

Setting Ultrascan PC90 Software’s IP Address 19

3 Quick Start 20

Running Ultrascan PC90 20

Defaults 20

Recordings 20

Beam Width 21

4 Basic Operation 22

Getting Started 22

The Toolbar 22

The Status Bar 23

Operating Modes 23

Playback Mode 23

LIVE Mode 23

3

Setting System Parameters 24

Beamformer IP Address 24

Transducer Mount Corrections 24

Level Adjustment 24

Align Adjustment 25

Keel Offset 25

Displays 26

Setting Color and Units 26

VERT: Vertical Scan Display 28

HORZ: Horizontal Scan Display 28

DOWN: Downlooker Display 28

VSPLIT: Vertical Split-Screen Display 29

Adjusting the Gain and Range 30

Gain Adjustment 30

Range Adjustment 31

Display Smoothing 32

Depth Window 32

Using the Alarm 33

Adjusting the Depth Tracker 34

Surface Masking 34

Threshold 34

Saving Data with Screen Capture 35

5 Advanced Operation 36

Working with NMEA Navigation 36

Logging Depth 36

Recording Live Data 38

Using Ultrascan PC90 Diagnostics 40

6 Interpreting Displays 40

Principles 40

Interpreting the Vertical Display 40

Forward Imaging Capabilities 40

Transducer Sidelobe Effects 41

Interpreting the Horizontal Display 42

Imaging the Bottom 42

Special Situations 43

Forward Imaging Capabilities 43

7 Reference 44

Maintenance 44

Troubleshooting Guide 45

Interference Problems 46

4

Specifications 47

How To Obtain Service 51

9 Advanced Networking Information 48

Warranty 55

5

1 Introduction

NAVIGATION WARNING

Nautical navigation is a critical element in

the safety and success of each open-water

boating experience and should only be

performed by experienced navigators.

While the Ultrascan PC90 product is a

useful navigation aid, it should never be

relied upon as the only means of

navigation. It is prudent to use more than

one proven instrument and more than one

accepted method in support of navigation

decisions.

Award Winning

Technology

For its pioneering work in developing

Phased Array Scanning Sonar,

Interphase Technologies won the

prestigious IMTEC INNOVATION

AWARD.

The Ultrascan PC90 Forward Looking

Scanning Sonar is based

award-winning technology.

on this same

General Information

T

hank you for choosing the Interphase Ultrascan

PC90 Dual-Axis Forward Scanning Sonar. The Ultrascan PC90 has been designed to work with your

on-board PC or PC Network and will display water

depth, bottom conditions, fish and other submerged

objects and debris, all on your computer’s high

resolution color display. If you already have an

Interphase scanning transducer installed on your

vessel, you can order a Ultrascan PC90 without a

transducer (see page 46).

To insure that you receive the maximum benefits

available from the many features of the Interphase

Ultrascan PC90, this manual includes a detailed guide

to the use and interpretation of the system’s modes

and displays. An instructive demonstration mode has

been designed into the Ultrascan PC90 to familiarize

you with the unit’s features. In addition, the Basic

Operation chapter gives you the necessary

information to get your system up and running as

quickly as possible. Please read the Installation

chapter carefully before attempting to install Ultrascan PC90 on your vessel.

Warranty Information

Interphase provides a Limited Warranty on the Ultrascan PC90 Forward Scanning Sonar. Please read

this warranty (reprinted at the back of this manual)

and closely follow its terms and conditions should

your Ultrascan PC90 require repair. It is highly

recommended that you save all packing materials so

that, in the unlikely event that you must return your

Ultrascan PC90 for repair, it can be fully protected.

Should you experience a problem with your Ultrascan

PC90, first refer to the Troubleshooting section (Page

45) of this manual. Most common problems and their

solutions are described here. If problems persist, call

6

Interphase Technical Service at (831) 477-4944, Ext

16. We will be happy to assist you, and if required, we

will give you instructions on how to quickly get your

unit repaired.

The enclosed warranty registration card must be

completed and returned to Interphase within 15 days of

purchase so that your unit may be protected under the

warranty. Failure to return the warranty card may cause

unnecessary delays in processing your unit for warranty

repair.

Unpacking and Inspection

When unpacking your Ultrascan PC90, the following

items should be found in the package. Please notify

your Interphase dealer immediately if any items are

missing.

Standard Equipment

Description Part Number

Beamformer Module D1-0400-001

Ethernet Cable, 10’ length 04-1107-00R

12VDC Power Supply Cable 04-1106-00R

Ultrascan PC90 Software CD 52-1004-001

Operation Manual 25-4018-000

Transducer Options

Description Part Number

Two Transom Transducers

200 kHz Vertical Scan T1-I200-025

200 kHz Horizontal Scan T1-I200-028

Single Thru-Hull Transducer

200 kHz Horizontal/Vertical Scan T1-I200-032

IMPORTANT NOTICE

Please fill out and return the Warranty

Registration Card immediately. This is

our only method of contacting you should

new features and enhancements become

available for your Ultrascan PC90.

During the first year of your warranty,

any software upgrades will be free of

charge, and after the warranty period has

expired, software upgrades will be

available for a nominal charge.

Beamformer Module

Ultrascan PC90

Software CD

6’ DC Power Cable

(2-pin connector)

10’ Ethernet Cable

(RJ-45 Connectors)

7

2 Installing Ultrascan

TYPICAL ULTRASCAN PC90

PC

(or PC Network)

ETHERNET CABLE

30’ Vertical

Scanning

Transducer

Cable

CONFIGURATION

Fuse

Ultrascan Beam-

former Module

ULTRASCAN

INTERPHASE

30’ Horizontal

Transducer

Cable

Transducer (single thru-hull

The diagram at left shows a typical installation of the

Ultrascan PC90 using an on-board desktop or laptop

PC.

In this manual, the Ultrascan installation procedures

have been divided into three major sections;

1) Location and Installation of the Transducer(s)

2) Installation of the Beamformer Module

3) Installation of the Ultrascan PC90 Software

Transducer Installation

The Ultrascan PC90 can be ordered with one of two

10-36

transducer configurations; two transom mount trans-

VDC

ducers or with a single bronze thru-hull transducer or

with no transducer (if you already have an existing

Interphase scanning transducer installed).

The Ultrascan PC90 uses two multi-element phased

transducer arrays. The arrays are “potted” in a

smooth-surfaced tough urethane material that is

acoustically transparent. DO NOT allow any

solvents (i.e. gasoline, acetone) to come in contact

with the transducer(s) as this may dissolve the

plastic housing.

In the single thru-hull configuration all of the transducer elements are enclosed in a single transducer.

For transom-mount applications two transducers are

required, each containing an 8-element array. One of

the multi-element arrays is positioned to scan

vertically from straight ahead to directly below the

boat, while the other array is positioned to scan

forward horizontally from side to side. When the two

thru-hull configuration is chosen, each transducer

contains an 8-element array. One is positioned for

vertical scanning and the other for horizontal

scanning.

8

When selecting the transducer type and hull location

for the transducer(s) keep in mind the primary rule for

transducer operation. This is: the transducer can

function as long as it has an unobstructed forward

view and has smooth flowing non-aerated water

surrounding it.

♦

Do not cut or splice your phased array transducer

cable or removing the 9-pin connector as it will

void the transducer warranty.

♦

On both the thru-hull and transom mount transducers the blunt end is the forward end! See

sketch at right.

♦♦♦♦

If you need a longer length cable than comes

with the transducer (30’), then purchase the

optional extension cables, Interphase Part # 040014-008R for 30’ or 04-1014-007R for 10’

lengths. Total transducer cable lengths over 60’

are not recommended as they will decrease the

effective power and depth range.

♦

Choose a location where there is the least

amount of acoustic noise, air bubbles or

turbulence caused by the boat’s movement. The

transducer should not be located nearby or

especially directly behind the propeller.

♦

Choose a location where the transducer can be

mounted so that it will be level to the water’s

surface and will not be tilted to either side.

Otherwise the transducer will not scan from the

surface ahead to directly beneath the boat.

♦

DO NOT install a bronze transducer housing

directly into an aluminum or steel hull because

electrolytic corrosion will occur. Consult your

boat-yard for more information on how to

properly install transducers into these types of

hulls.

♦

DO NOT allow any solvents i.e. gasoline, acetone to come in contact with the transducer head

unit as this may dissolve the urethane material.

In addition, DO NOT force the cable by pulling

on it. This may cause damage to the internal

transducer wiring.

Scanning Directions.

Vertical Scan mode

shown above and

Horizontal Scan

mode below

Transom Mounted Transducer

Thru-Hull Transducer(s)

Side View

Top View

Forward

Forward

9

Suggested Thru-Hull Transducer Locations

Fin Keel

~ 1/3 L

L = waterline length

Displacement Hull

Planing Hull

Thru-Hull Considerations

Thru-hull transducers are for boats that exceed 40MPH

and /or have inboard motors. Transducer placement

depends on boat size, speed, hull configuration and

sonar application. On displacement hulls, the

transducer is generally located between 1/3 and 1/2 aft

of where the bow meets the water line. This is the

farthest forward the transducer should be mounted. It is

important that the transducer be below turbulent aerated

water created by the bow and does not come out of the

water during normal operation or when the boat is

pitching in a seaway.

Make sure the transducer has a clear view ahead and

that there are no forward hull obstructions that can

cause any turbulence in front of the transducer.

Mount so the transducer(s) bronze stem is within approximately +/- 5 degrees of vertical to insure scanning

in the proper directions. Most vessels will require a

fairing block to compensate for the angle (dead-rise) of

the hull.

Special Thru-Hull Mounting Considerations

On sailboats with a fin keel, the transducer is most

often placed at the leading edge of the keel and

sometimes faired into the keel. As this location may be

where the sling rests when hauling the boat, the

transducer may be placed on either side of the hull with

the foremost face of the transducer even with the

leading edge of the keel. Alternatley, the transducer

may be placed forward of the keel ahead of the lifting

strap location. This should not be ahead of 1/3 aft of

where the bow meets the waterline.

On planing hulls the transducer is typically placed near

the transom. This is to provide smooth flowing water at

the greastest speed. However, most planing hull boats

create transducer aeration when on plane regardless of

transducer location.

It should be noted that thru-hull transducers can effect

boat performance in two important ways. The first

concern is cavitation created by the transducer that

causes reduced engine performance by disrupting water

flow around the propeller. This is smoothed out by the

hull in some boats, but on planing hulls with the

transducer near the transom, the hull is not able to clear

the cavitation. The second concern is uneven drag on

smaller high-speed boats. This may occur when the

10

thru-hull transducer is mounted far off of the

centerline of the boat. At low speeds and on large

boats the effect is negligible. On smaller boats at high

speeds the drag can effect the steering. The effect

increases as the boat’s speed rises. Boats with trim

tabs can usually trim this out, but boats without trim

tabs may feel a pulling sensation toward the

transducer side of the boat.

A less intuative mounting location for the single thruhull transducer on a planing hull is on the centerline

just forward of midship. The goal in this mounting is

to place the transducer so that it is out of the water at

planing speed. As most transducers are aerated at

planing speeds, this removes the transducer from the

water flow preventing cavitation and steering

problems. Most applications for forward scanning

sonar occur when the boat is at low non-planing

speeds including fishing and navigating hazardous

waters. Under these lower speed conditions the

transducer is in the water.

Installing the Thru-hull Transducer

♦

Drill a 1/8” pilot hole from inside the hull to

assure access to tighten the housing nut and

clearance for the transducer cables.

♦

Use a 1-1/16” hole saw and drill the hole from

the outside. Sand or clean the area around the

hole, inside and outside to insure that the sealing

compound will adhere properly to the hull.

♦

Remove the bronze hex nut from the housing

and cable.

♦

Uncoil the transducer cable and thread it through

the hole into the inside of the hull.

♦♦♦♦

Apply a 1/8” thick layer of sealant on the upper

flat surface of the transducer, bronze alignment

pin and fairing block (if used).

♦

From the outside of the hull, push the housing

into the 1” hole. Twist the housing slightly to

squeeze out excess sealant. Carefully confirm

that the transducer is aligned so that the BLUNT

front end is pointed directly toward the front of

the boat.

♦

Install and tighten the bronze hex nut (allow for

swelling in wooden hulls) and remove excess

sealant from the outside to assure smooth water

flow over the transducer.

ULTRASCAN PC90

The single ULTRASCAN PC90 thru-hull

transducer (T1-I200-032) contains two phased arrays, one used to scan vertically and the other horizontally. The transducer has two cables, one connected to each array and each is color coded—green

for the vertical array and blue for the horizontal

array.

Because this transducer scans horizontally,

care must be taken to locate it at a position where it

can see 45 degrees either side of the bow (see sketch

at left with side and overhead views). The horizontal

scan plan is angled downward by 10º to minimize

surface clutter.

It can be mounted in front of a fin keel, or just

off to the side of the leading edge of the keel where

unobstructed forward vertical and horizontal views

are available.

On deep full keel vessels (trawlers, etc) it is

usually not possible to find a suitable location for a

single transducer with the horizontal scan. These

vessels should install the ULTRASCAN PC180 system with two transducers.

ULTRASCAN PC90—90-Degree Vertical and 90-Degree Hori-

zontal Scan

11

Mount Transducer So Bronze Stem is Vertical

Waterline

Keep parallel

to waterline !

Hull

FORWARD

Transducer

BronzeHex

Nut

Waterline

Fairing

Block

Keep parallel

Hull

to waterline !

DANGER: Wood hulls and wood fairing blocks

will expand after the boat is put back into the water,

so it is important that the transducer be only handtightened until the wood fully expands. Otherwise

the wood fairing block may crack.

DANGER: Be sure to check for leaks when the

boat is placed in the water. Allow at least 24 hours

after installation for any leak to appear.

Nearly all vessels have some dead rise angle at the

transducer mounting location. If the thru-hull

transducer were mounted directly to the hull, the

sound beam would be tilted off the vertical at the

same angle as the dead-rise, so most thru-hull

installations will require a fairing block to insure

the transducer is mounted properly.

If you’re installation requires a fairing block, you

may either have one made locally, or purchase a

molded plactic unit from Interphase or your

Interphase distributor. The Interphase part num-

ber for this fairing block is 40-2005-000.

NOTE

The flat top of the transducer must be

parallel to the water line. This will not

necessarily be parallel to the boat’s hull.

Boat’s

Hull

Underwater Sealant

Transducer

12

Transom Mount Considerations

Transom mounted transducers are intended for low

speed boats with external props. Boats with inboard

motors and boats that regularly exceed 35MPH can

not use transom mounted transducers. This is because

with inboard motors the prop is located in front of the

transom transducers and create aeration and excess

turbulence.

I/O motors where the prop is aft of the transom do

not create this situation, but be careful that the

driveshaft of the I/O does not block the forward

horizontal scan. Boats that exceed 40MPH run a risk

of having the transom mounted transduers torn free

of the transom. The transom mounted transducers are

not designed to be used at these speeds.

Transom mounted transducers are mounted on kickup or break-away brackets. This allows the brackets

to kick up at about speeds above 35-40MPH or if

they strike an object. Once kicked up, the transducers

must be manully reset in order to function.

Transom Transducer Kick-Up

Bracket

The transom transducer is attached to the boat with a

heavy-duty stainless steel kick-up bracket to provide

protection against impact. When the transducer

strikes an object, or the water force exceeds the

resistance of the bracket, the transducer automatically

kicks up and becomes non-operational. The bracket

does not automatically reset at lower speeds. The

transducer must be manually returned to its

operational position.

Special Note: The kick-up feature is designed as a

safety consideration to prevent the transducer from

being removed from the boat due to impact or

excessive speed. The kick-up bracket is not designed

for repeated kick-up or to be pulled up manually

during loading and unloading from boat trailers.

Tests have shown that the bracket can kick-up as

many as 30 times before there is a negative effect on

the bracket. Repeated kick-up will cause the

transducer to kick-up at progressively lower speeds.

Excessive kick-ups can cause the transducer bracket

to fail. Brackets that fail due to repeated kick-up are

not covered under the transducer warranty.

If the transducer must be kicked up for installation,

Transom Mount Bracket in Released Position

Note: Will

Not Work at

Speeds Above

35 MPH

Suggested materials required for installation:

♦

capacity of 10mm (3/8”) or larger.

♦

transom hole to route cable and

connector

♦

♦

♦

♦

Variable speed electric drill with a chuck

Hole saw or spade bit 19 mm (7/8”) for

Chamfer bit or 6 mm (1/4”) drill bit

Drill bit No. 28 or 4 mm (9/64”)

Drill bit 3 mm (7/64”)

Marine bedding/sealing compound

13

Twin Outboards

Transom Mount Locations

Cables

Transducers

Cables

Rear

View

Rubber

Grommet

Fasten Spray Shield

with 4 screws & nylok

washers as shown

Spray

Shield

Waterline

Bracket

Axle

18 - 24"

Fasten Spray Shield

with 4 screws & nylok

washers as shown

Spray Shield

Transducer must be

mounted vertically

Mounting

Bracket

Boat Hull

Waterline

Side View

boat service or loading, the nylok nut on the end of

the bracket axle can be loosened. Tighten the nut to

50 inch pounds of torque before operating the boat.

through the spacer.

Note: The Forward Horizontal Transducer must be

able to scan beneath the hull. The deadrise angle of

the hull must be less than 10 degrees in order for the

forward horizontal scan to sweep beneath the hull.

Alternately, the transducer can be mounted at or

below the lowest point on the hull.

The transducer can be installed on either side of an

outboard or inboard/outboard engine, or between twin

outboards. For single engine installations, normally

18” to 24” outboard of the propeller center line is

acceptable and the down stroke side of the propeller is

preferred. Choose a location where water flow is

smoothest. For dual engine installation, just off the

center line is usually acceptable.

Because the transducer rotates back and upwards

when the bracket releases, it must be mounted in a

location where there is sufficient clearance and

headroom to allow the full release.

Attach the Transducer & Spray Shield to the

Bracket

Locate the Stainless Spray Shield inside the

transducer’s stainless mounting ears. Make sure the

spray shield is orientated as shown in sketch below.

Then, assemble the stainless kick-up bracket to the

transducers using the 4 screws, washers and lock nuts

provided. Place the rubber grommet around the

transducer cable and slide it into the slot in the spray

shield. The bracket arms must be mounted outside the

stainless steel mounting ears of the transducer. Do not

fully tighten the lock nuts at this time. Tighten them

after the transducer is mounted and the spray shield is

positioned.

Position the transducer so that it is perpendicular from

side to side and make sure the wider blunt end is

pointed towards the front of the boat.

Mounting the Transducer to the Boat

After you have selected the optimum mounting

location and have assembled the mounting bracket to

the transducer, mount the bracket onto the hull as

shown on the right.

Make sure to position the transducer so that it is level

in the fore and aft direction and so it will look straight

14

down. Check the location of your boat’s waterline

and position the flat top surface of the transducer so

that it is parallel to the waterline as shown below.

Note: If the transducer is not mounted so that its fore

and aft direction is parallel to the surface, then the

forward looking display will be distorted and flat

bottoms will appear to be slanted upwards or

downwards. After mounting the transducer and

actually using the ULTRASCAN on the water, you

may need to readjust the transducer’s mounting for

optimum performance.

Bracket Axle Assembly

On some boats it will be neccessary to remove the

Bracket Axle during installation. See the diagram to

the left and instructions below for details on

assembling the axle.

1. Place one stainless steel washer onto the axle

against the hex end.

2. Place one small stainless steel spacer against

washer.

3. Slide two urethane spacers over the small steel

spacer.

4. With the transducer bracket in place, align the long

stainless steel spacer with the mounting holes of the

mounting bracket and slide the axle in place.through

the spacer.

5. Place one small stainless steel spacer against the

transducer bracket.

6. Slide two urethane spacers over the small steel

spacer.

7. Place one stainless steel washer onto the axel

against the urethane spacer.

8. Place the nylon nut onto the threaded end of the

axel and tighten to 50 inch pounds. If you do not

have a torque wrench, tighten until the nut will not

turn easily. The stainless steel spacers should prevent over-tightening.

Bracket

Axle

Nylon

Nut

5

8

7

6

Kick-up Bracket Replacement Parts

If during installation parts are somehow lost are

damaged, they can be replaced as follows:

Part# 17-0088-008 - Spray Shield Kit - Includes:

Spray Shield, four Mounting Bolts and Nuts, Rubber

Grommet and four Large Mounting Screws.

Part# 17-0089-008 - Transom Transducer Hardware

Kit - Includes: Complete Bracket Axle Assembly and

four Large Mounting Screws.

Part# 17-0056-008 - Kick-Up Bracket Assembly Includes: Complete Bracket Axle Assembly, four

Large Mounting Screws and the Stainless Steel

Mounting Bracket.

4

2

1

3

15

2 Amp Slo-Blow Fuse

Water

Ground

ULTRASCAN

INTERPHASE

Switch or

Breaker

10-36

VDC

GROUND

Ultrascan Beam-

former Module

Transducer (single thru-hull shown)

Beamformer Installation

The red box that came with your Ultrascan PC90

system is called the Beamformer Module. It houses

the transmitters and receivers that communicate with

the transducers. The Beamformer Module must be

connected by an RJ45 Ethernet cable to your shipboard PC or PC network, to the transducers and to a

source of 10 to 36 VDC power.

1) Select a location to mount the Beamformer

Module. Keep in mind that the unit must be

protected from from moisture and extreme

temperatures. Also, you will need to route the

Ethernet cable, the power cord and transducer

cables to the location that you choose.

2) Connect the two-pin plug on the end of the

power supply cable to the power supply jack

located at the front of the Beamformer Module.

Connect the red wire to a switch or breaker con-

nected to your ships positive (+) battery supply.and the black wire to the negative of your

boat’s battery. To prevent accidental damage—

it’s recommended that an inline slow blow 2

Amp fuse also be inserted in the positive lead.

3) Connect one end the Ethernet Cable to the Red

Box and the other to the Ethernet connector on

your PC or to an Ethernet connection on a network switch or router.

4) Connect the two transducer wires to the

matching ports on the back of the Beamformer

Module. They are color coded as follows:

Cable label Port label Color

HORZ HORZ Blue

VERT VERT Green

5) The Ultrascan also includes a ground screw just

to the right of the red data LED. Grounding the

case to a good water ground (engine block,

bonding system, thru-hull, etc) is recommended

as it will help minimize interference from surrounding sources of noise.

16

Software Installation

The Ultrascan PC90 software includes a group of

program files and a demonstration recordings. These

files will all be automatically copied to your computer’s

hard disk during installation.

The total size of the Ultrascan PC90 installation is

about 5 megabytes. We recommend that you make sure

that there is at least 15 megabytes of free space on your

hard drive before you begin the installation. If you plan

to save screen-captured images or record raw sonar

data, you will need additional space. We recommend

beginning with a minimum of 100 megabytes of free

space.

Ultrascan PC90 will run on a computer with Microsoft

Windows XP, Vista or Windows 7. Take the

following steps to install Ultrascan PC90 on your

computer:

1) Exit all programs that are currently running.

2) Insert the Ultrascan PC90 CD Disk into your

computer’s CD drive..

3) Follow the Setup instructions in each dialog box

that is displayed. Click the Next button to accept

the defaults.

The dialog box (shown at right) will prompt you to

accept the default destination folder for the Ultrascan PC90 files or select a different folder.

The dialog box in the lower right will ask whether

you want to create a desktop icon or a Quick

Launch icon. Most users choose to create an

Ultrascan icon on their desktop.

Ultrascan PC90’s Operating Software is

located on a CD which is included with

your system. The latest software is also

available for download at from the

Interphase website at:

www.interphase-tech.com

17

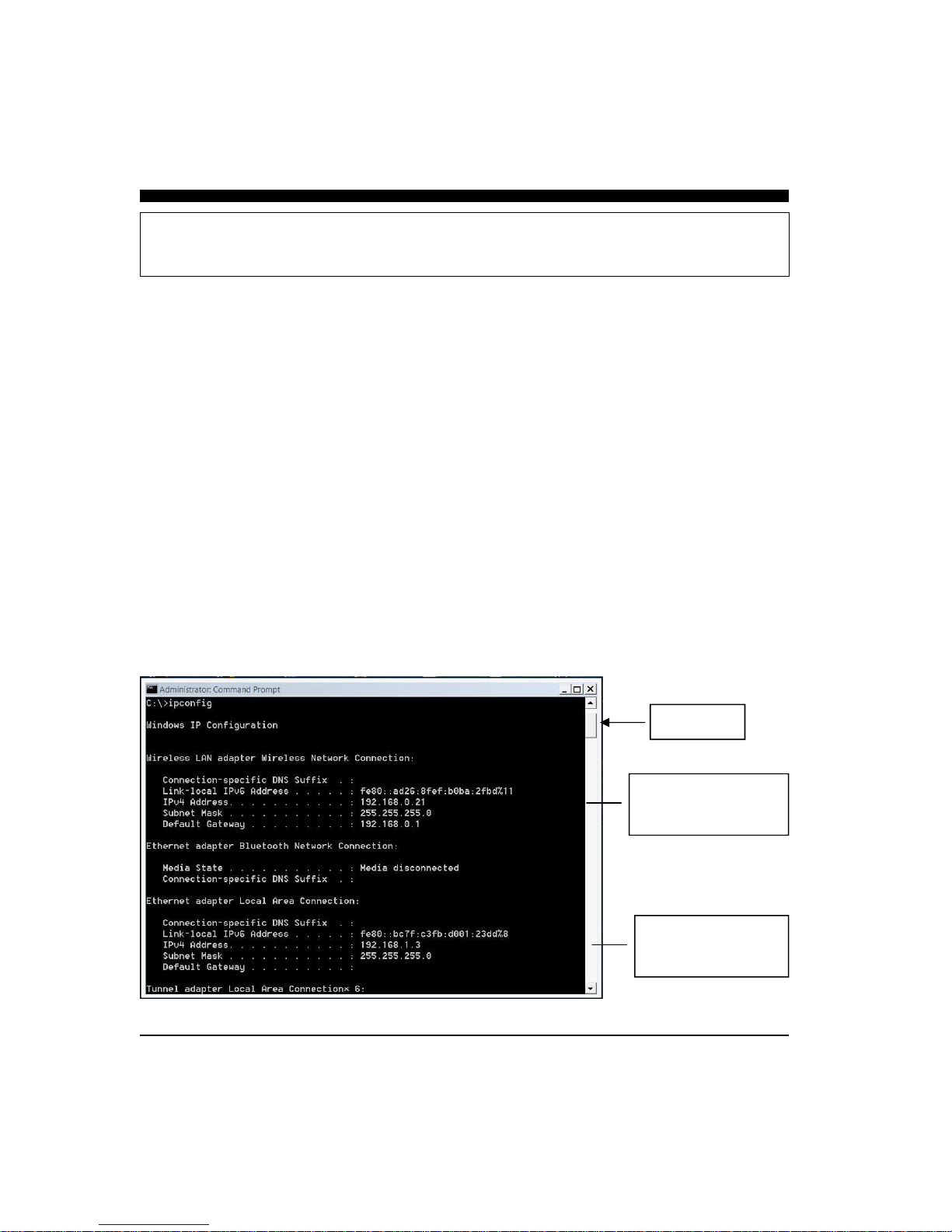

Connecting to a PC

Set Your Computer’s Ethernet Port’s IP

Address to 192.168.1.3

Using the Ethernet cable provided, connect the Ultrascan PC90 to your Computer’s Ethernet port.

The Ethernet port on the Computer should be set to a

static IP address of 192.168.1.3.

To set your computer’s IP address in Windows Vista,

click START —> CONTROL PANEL —> NETWORK AND SHARING CENTER. Then click on

MANAGE NETWORK CONNECTONS

Right click on the Network Connection that needs to

be changed (usually the local area connection) and

then select PROPERTIES as shown at top left.

Select INTERNET PROTOCOL VERSION 4(TCP/

IPv4)

And the click on PROPERTIES as shown at mid left.

A pop-up window like that shown at bottom left will

appear. Choose “Use the following IP address”, and

then enter 192.168.1.3 for the IP address, and

255.255.255.0 for the Subnet mask. Click OK to save

your settings and exit the Local Area Connection

Properties.

18

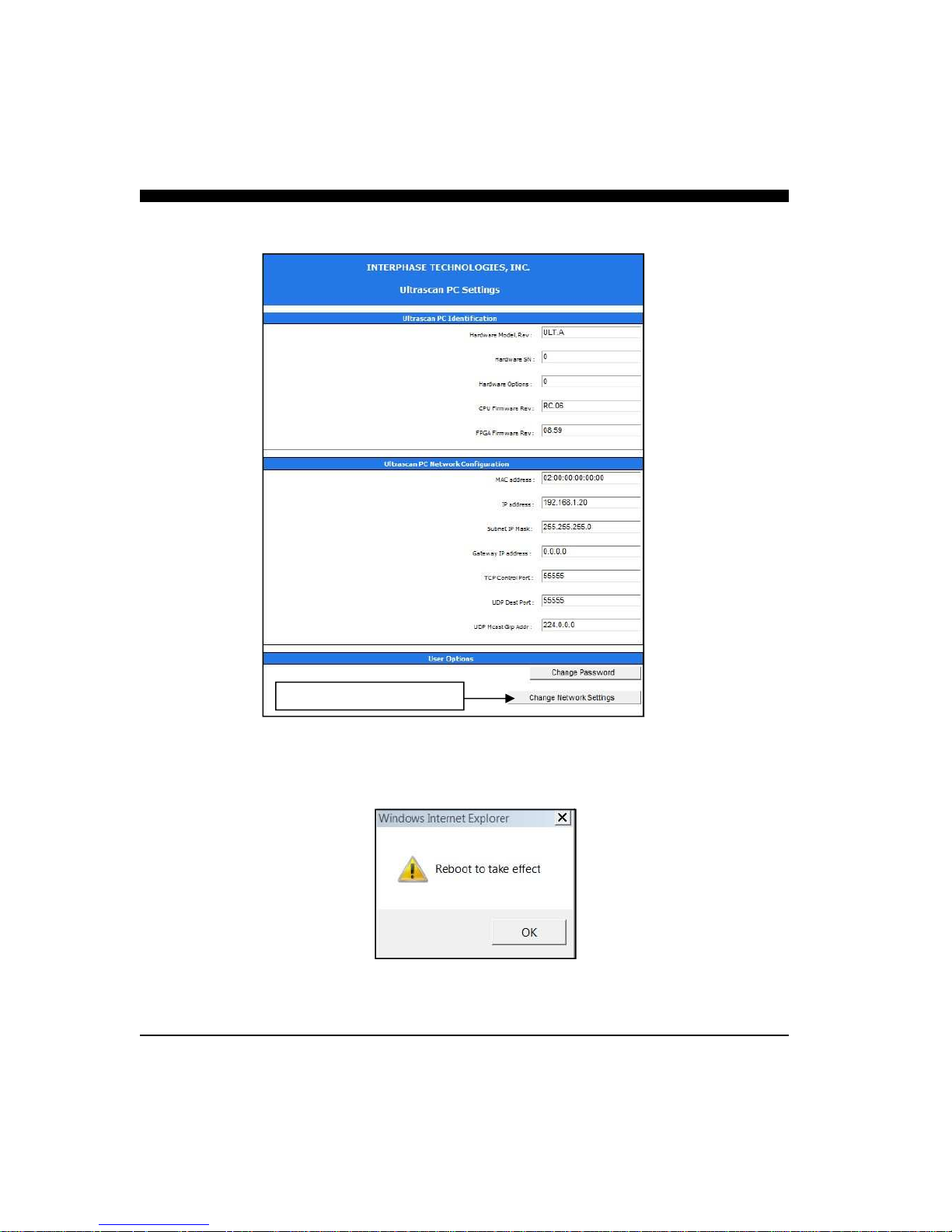

Connect to Ultrascan Beamformer

After setting your PC’s IP address, turn on power to the

Ultrascan PC90. After a few seconds the green power

light will glow.

Wait 30 seconds, then open the Ultrascan PC90 computer

software.

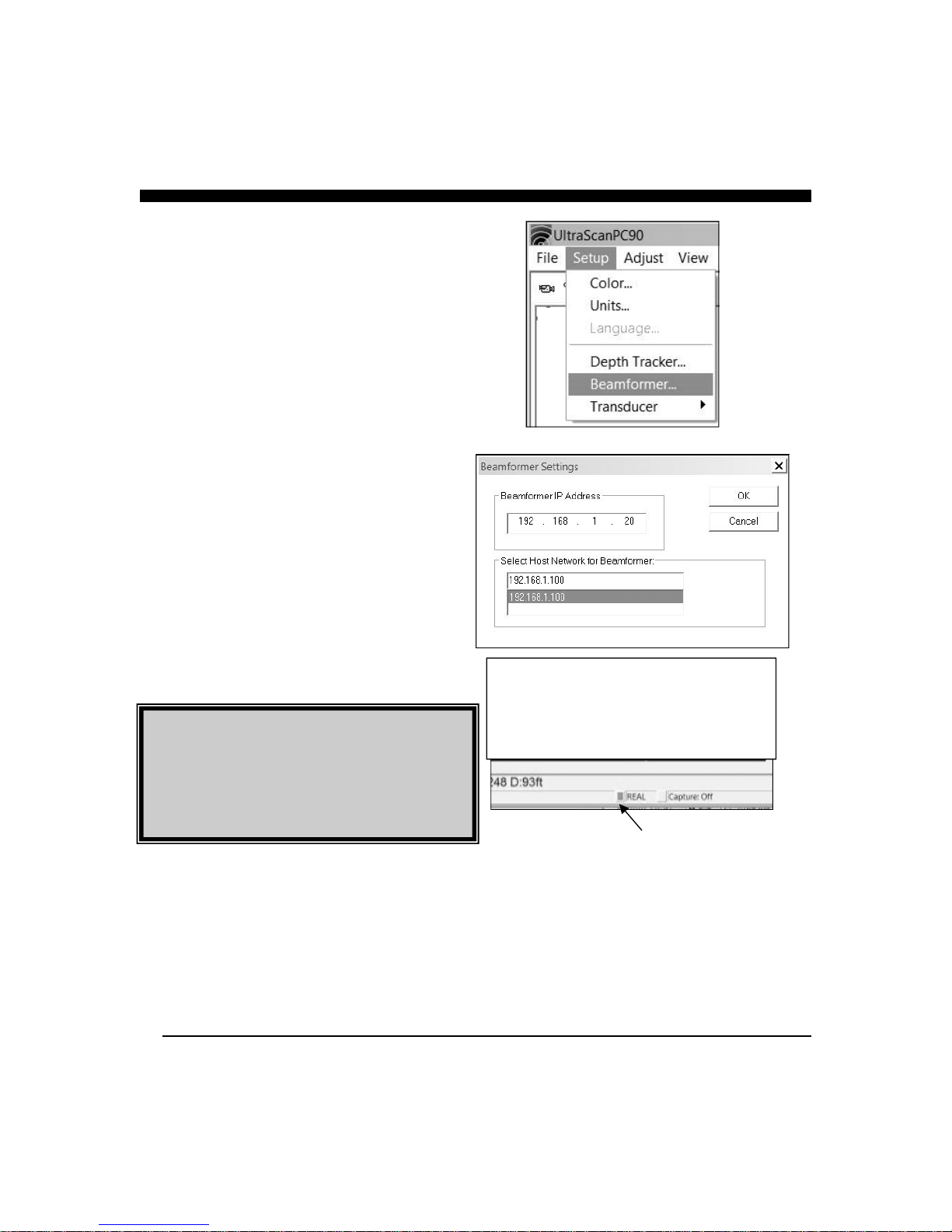

From Ultrascan PC90’s menu, choose SETUP—

>BEAMFORMER, as shown at right. The Beamformer

Settings pop-up window should appear as shown at right.

Enter Beamformer IP Address of 192.168.1.20, and in the

lower section of the window, highlight your computer’s

IP port address which you previously set to 192.168.1.3

Press OK to close the beamformer settings window.

The Orange light on the Ultrascan Beamformer Module

should light when a proper connection between the Beamformer and PC is made.

The Ultrascan PC90 should now be communicating with

your PC. You should see a red/green blinking indicator

on the bottom toolbar of the Ultrascan PC90. Also, the

word “PLAYBACK” will be replaced with the word

“LIVE”, as in the picture at lower right.

Ultrascan PC90’s Beamformer Module is shipped

with the default IP address of 192.168.1.20.

If needed, the IP address can be changed by using

the Ultrascan Web Server. For more information,

see page 50

PING LIGHT—BLINKS

RED/GREEN

WHEN

COMMUNICATING

WITH BEAMFORMER

19

3 Quick Start

Parameter Menu Default Type

Auto-Screen Capture File Off Hard

Running Ultrascan PC90

To start the Ultrascan PC90 system, turn on the

switch or breaker that provides power to the beamformer module.. Then run Ultrascan PC90 by

clicking on the Ultrascan PC90 icon on your computer’s desktop.

If all components have been installed and all cables

are connected, and the Beamformer Module is on,

Ultrascan PC90 will immediately begin to collect and

display data. Take the following steps to adjust Ultrascan PC90 for basic operation:

1) Set defaults as described below. Be sure that

Auto Gain and Auto Range are off.

2) Select a display (see p.26).

3) Select a range setting that is slightly greater than

your current water depth (see p.30).

4) Adjust the gain by first turning it down until little

imagery is visible on the display. Increase the

gain until you begin to see noise, then decrease

the setting by one (see p.30).

Color Setup Normal Soft

Units Setup Feet Soft

Surface Masking Setup Off Hard

Depth Threshold Setup Normal Hard

Auto Gain Adjust Off Hard

Gain Adjust 10 Soft

Auto Range Adjust Off Hard

Range Adjust 25 Feet Soft

Alarm Adjust Off Hard

Defaults

The default settings for many of the Ultrascan PC90

features are shown in the table at left. Hard defaults

are always reset when you exit the program. Soft

defaults are recommended settings for general

operation.

If you are running Ultrascan PC90 for the first time, it

will start with the default settings as shown at left.

Change the settings by selecting the appropriate

command from the specified menu.

Demo Recordings

Ultrascan PC90 installation software includes several

actual recordings which can be played back and used

to demo many of the Ultrascan’s features.

20

Running in PLAYBACK mode will allow you to

practice and to get a feeling for the Ultrascan PC90’s

many features before actually using the system in real

situations on the water. Note: when you play back the

recording, you will not be able to change the range.

However, you will be able to use most of the other

features.

12 Degree

Cone Angle

1000

750

210

158

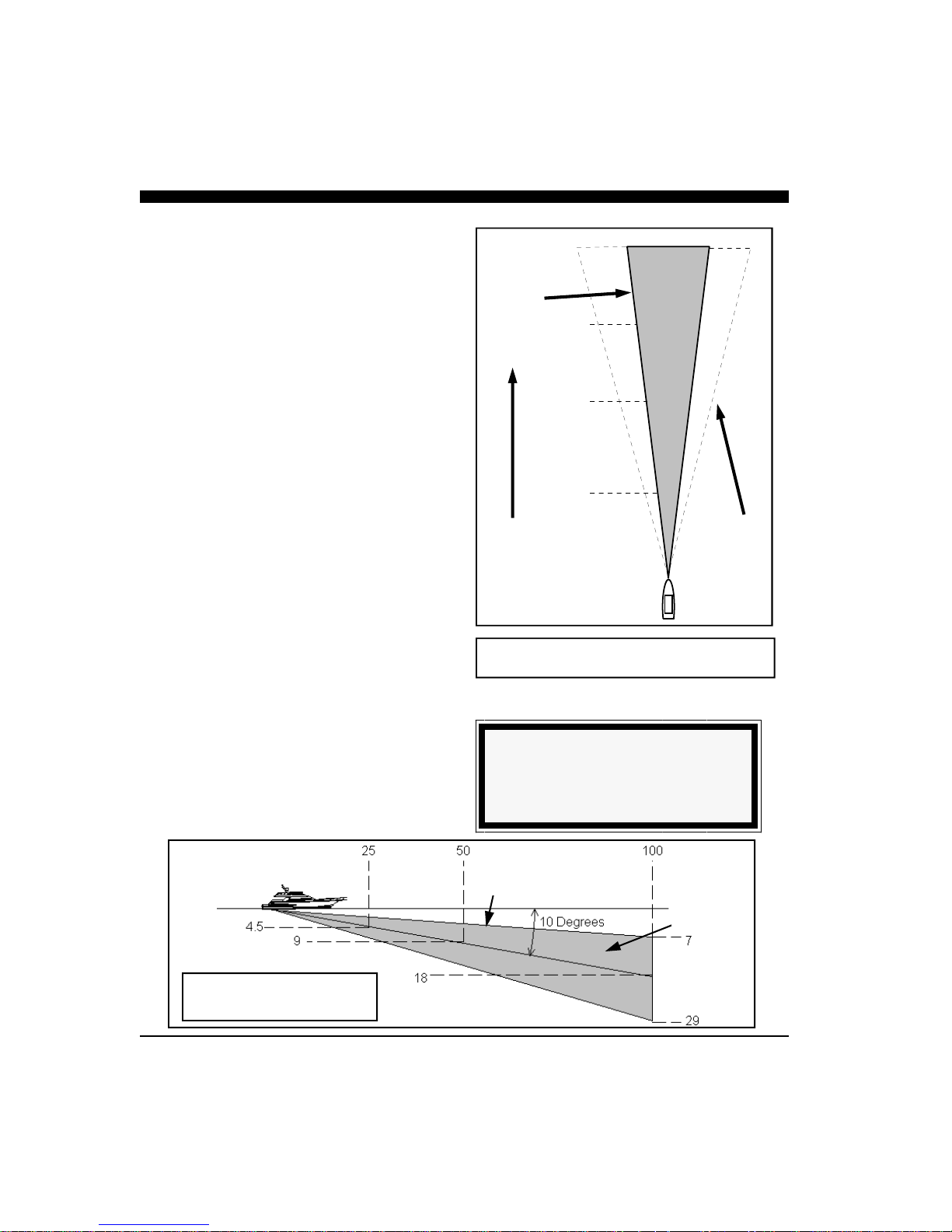

Beam Width

The Ultrascan PC90’s Beam Width is approximately

12 degrees in both the vertical and horizontal scan

modes. The diagrams at right and below show the

approximate width of the vertical and horizontal

scanning beams at different distances from the boat.

The Ultrascan PC90 will generally image features

within the shaded areas.

The Ultrascan PC90 horizontal scan is oriented

approximately ten degrees down from horizontal (see

the diagram below). Thus, the depth to the center of

the beam is approximately 18 percent of the distance

from the boat.

500

250

Distance

Forward or

Below Boat

105

53

Ultrascan can

typically see

targets within

this area.

Width of 12 Degree Acoustic Beam

TIP

The width of the 12-degree main beam is

approximately 1/5 of the distance from the boat

Distance Forward

Depth

Width of Acoustic Beam

Horizontal Scan

21

12º Beam

Width

Ultrascan

PC90 can see

targets within

this area.

4 Basic Operation

Toolbar

Screen Capture Alarm Reset

About Ultrascan

Vessel Position

Units

Water Depth

Range

Latitude

Cursor Position

Bearing

Depth

Longitude

Getting Started

This chapter will help you to learn the modes of

operation and the basic features of the Ultrascan

PC90 system. For more experienced users, this

chapter can be used as a reference. Read Chapter 3

Quick Start to learn how to start the Ultrascan PC90

software.

Ultrascan PC90 is a Windows application with a

standard Windows menu structure. The Ultrascan

PC90 screen includes a data display window as well

as the Toolbar and the Status Bar.

The Toolbar and Status Bar can be toggled on or off

via the View Menu.

The Toolbar

The Toolbar enables quick access to features which

are used often including:

• Screen Capture, which saves the current screen

to the hard disk (see p.35),

• About Ultrascan PC90, which displays the

software version number, and

• Alarm Reset, which turns off the depth alarm

after it has been triggered (see p.31).

The Toolbar also includes three digital data displays

including, from left to right across the screen:

• Depth beneath the transducer calculated by Ultrascan PC90 with the current units,

• Vessel Position information if it is available (e.g.

38º 58.95N 121º 58.49W; refer to the discussion

of NMEA navigation input in Chapter 5

Advanced Operation), and

• Cursor Position. Depending on which display is

active, the cursor position will include range (R),

bearing (B, negative to port, positive to

starboard) and/or depth (D). When the cursor is

outside of a data display area, the position box

displays the current range and gain settings (e.g.

Rnge=25ft; Gain=20).

22

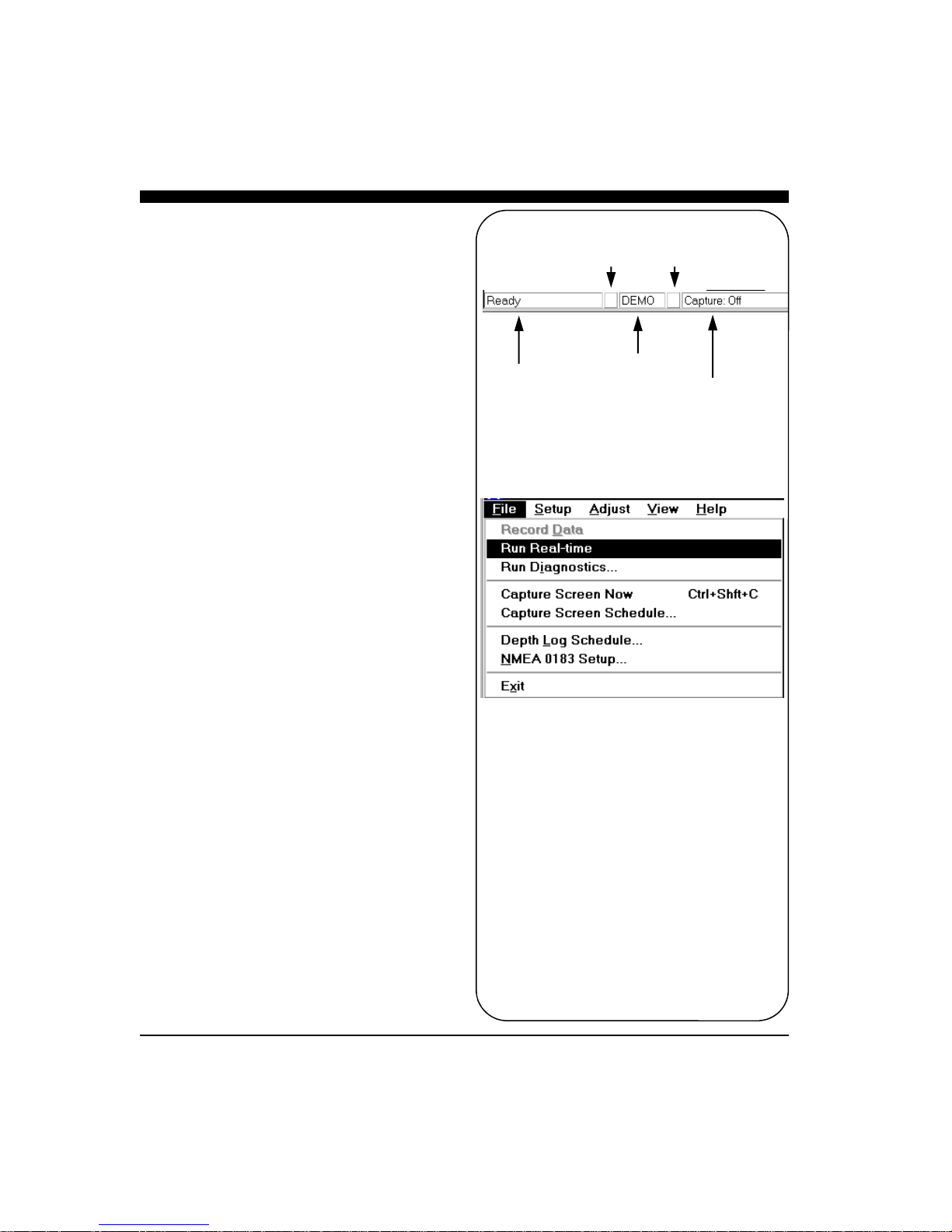

The Status Bar

The Status Bar displays current information about

Ultrascan PC90 operation including:

• Status Message,

• Ping Light, which alternates between red and

green on consecutive pings,

• Mode, Live or Playback,

• Capture Light, which flashes blue during a

screen capture, and

• Capture Status, showing the screen capture

schedule and remaining hard disk space.

Operating Modes

Ultrascan PC90 operates in one of two modes: Live

and Playback. If all components have been installed,

all cables are connected and the Beamformer Module

is on when you start the software, Ultrascan PC90

will immediately begin to collect and display data in

Live Mode. If a recording is being viewed the unit

will be in the Playback Mode.

Use the File Menu to switch between Playback and

Live modes.

Playback Mode

In Playback Mode, Ultrascan PC90 will continuously

display the recorded data that was installed with the

software or other user recorded videos. Ultrascan

PC90 will look for the recorded data in a folder called

‘Data’ in the Ultrascan PC90 program folder. If no

recording is selected, the display window will remain

blank.

Live Mode

When the Live Mode is selected, Ultrascan PC90 will

attempt to find the beamformer module. When communications begins the ping light on the lower toolbar

will blink between red and green.

Ping Light Capture Light

Status Message

Status Bar

Mode

Capture Status

23

Before Level Adjust

After Level Adjust

Setting System

Parameters

There are several system parameters that you will

usually need to set only once. Set these parameters

using the Beamformer and Transducer commands on

the Setup menu.

Beamformer I.P. Address

The default I.P. address for the Ultrascan beamformer

module is set to 192.168.1.20. Make sure your computer’s network I.P is set to the same subnet mask (i.e.

192.168.1) and the device number is different than the

beamformer's “.20”. For example, set your computer’s

IP network address to 192.168.1.3 or 192.168.1.4, etc.

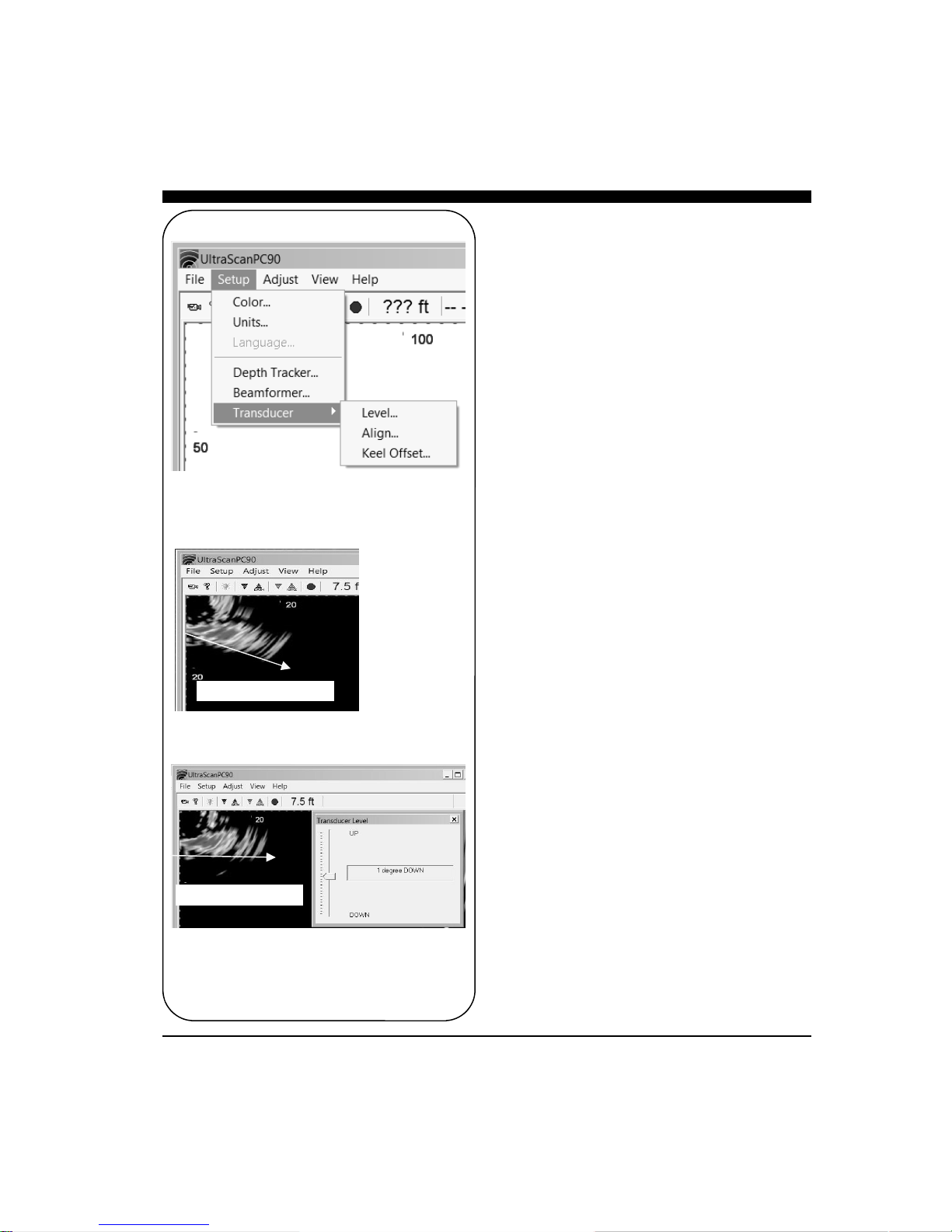

Transducer Mount Corrections

The Ultrascan PC90 software can compensate for minor

transducer misalignments. These are important

corrections, particularly if Ultrascan PC90 is being used

as a collision avoidance aid. For example, if the

vertical scanning transducer is tilted forward, a level

bottom will appear to be getting shallower at greater

distances. If it is tilted back, a level bottom will appear

to be getting deeper.

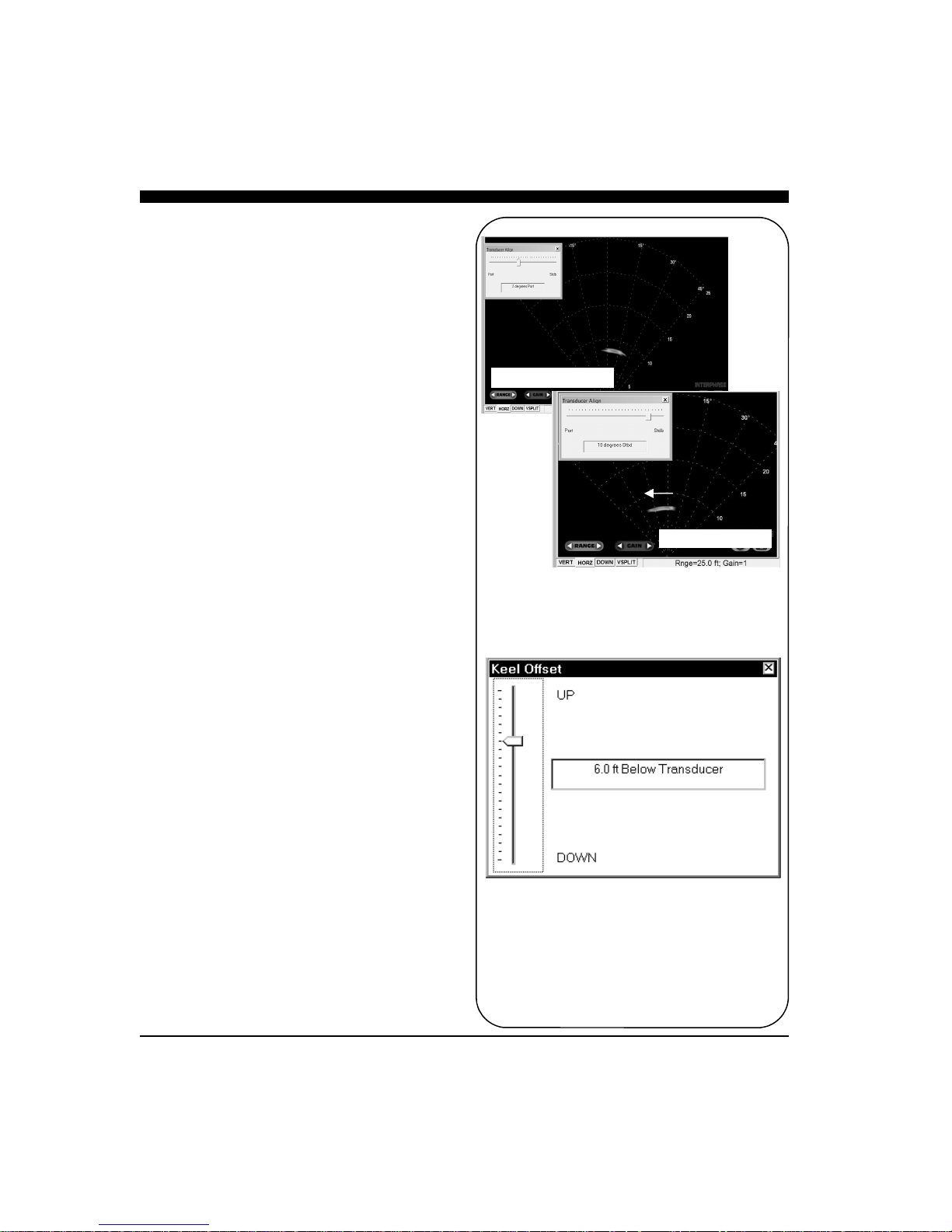

Level Adjustment

In case the vertical scanning transducer has been

mounted with a fore or aft tilt, Ultrascan PC90 can

compensate for up to 14 degrees of tilt in either

direction.

To set the Transducer Level parameter, Run Ultrascan

PC90 when the boat is over a known level bottom. The

vertical display should also appear level. If, however,

the bottom display is slanted upward (as shown in the

“Before Level Adjust” picture at left), it means that the

transducer was mounted with its nose pointing down

slightly. If the bottom slopes upwards by 10 degrees,

the Transducer Level correction should be 10 degrees

DOWN. If the bottom slopes downward, adjust the

Transducer Level in the UP direction to compensate.

After setting the Transducer Level, view the VERT

display to verify the correction.

24

Align Adjustment

In case the horizontal scanning transducer has been

mounted such that it points in a direction other than

dead ahead, Ultrascan PC90 can compensate for up to

14 degrees of misalignment in either the port or

starboard direction.

To set the Transducer Align correction, point the boat

directly toward a target (such as a piling, etc.) The

target should appear at the center of the horizontal

scanning display. If, however, the target is off to the

port (as shown on the “Before Align Adjust” picture

at right), it means that the transducer was mounted

pointing slightly in the starboard direction. If the

target is offset to the port by 7 degrees, the

Transducer Align correction should be 7 degrees

Stbd. If the target appears off to the right (Stbd),

adjust to the Port direction to bring the target back to

the center position.

After setting the Transducer Align, view the HORZ

display to verify the correction.

Keel Offset

If the transducer(s) are mounted in a position above

the deepest point of your boat’s keel, Ultrascan PC90

can automatically adjust the depth scale bars to

compensate for the offset. This will allow you to

always work with depths that are relative to the

bottom of your boat’s keel.

Move the slide bar to specify the depth of the keel

beneath the transducer(s).

Before Align Adjust

After Align Adjust

25

Displays

Ultrascan PC90 has four different scanning sonar

display windows. They are VERT, HORZ, DOWN,

and VSPLIT, as shown at right. View a display by

clicking on its tab at the bottom of the window.

Each display fills the current Ultrascan PC90

window. Change the size and/or aspect ratio of the

Ultrascan PC90 window by dragging the sides or

corners of the window.

Setting Color and Units

The color scheme and distance units can be changed

to suit your operating conditions and preferences.

Access Color and Units controls using the Setup

menu. Both parameters are consistent in Ultrascan

PC90 regardless of which scanning display window is

active. The units are also consistent in the depth

window but the color scheme of the depth window

cannot be changed.

Display windows can be viewed in one of three color

schemes:

• Normal, a color palette varying from light blue

through red on a black background which is

useful for operation in normal daytime

conditions.

• Sunny, a gray-scale palette on a white back-

ground which allows you to view contrast in

very bright conditions

• Night, black, dark red and bright red which

enable you to see contrast while preserving your

night vision.

Each display includes scale bars showing distance in

the selected Units. Units options include Feet, Meters

and Fathoms. The selected units are displayed in the

Status Bar for reference.

In the pop-up window shown at left, there is also an

adjustable slider labeled Noise Floor. When the

slider is at the bottom the Ultrascan will displays the

full dynamic range of echo signals Signal strength is

related to color with red being the strongest. Raising

the slider will eliminate the lower signal strength

colors (blue) which can help reduce clutter in shallow

water situations.

26

DISPLAY MODES

Vertical Display

Vertical Split-Screen Display

Horizontal Display

Downlooker Display

27

Scanning Directions.

Vertical Scan mode

shown above and

Horizontal Scan

mode below

VERT: Vertical Scan Display

The VERT display shows the image created by

the vertical scanning transducer elements. This

array scans through a maximum of 90 degrees in

a sector starting horizontally in the direction that

the boat is heading and ending vertically beneath

the transducer (see figure at left).

The vertical scan is shown with the transducer at

the upper left corner of the display window with

the selected range extending to the lower right

corner of the window. As a result, the scale bars

will usually indicate maximum distances that are

less than the selected range.

HORZ: Horizontal Scan Display

The HORZ display shows the image created by

the horizontal scanning transducer elements. This

array scans through a maximum of 90 degrees in

a sector centered about the boat’s heading and

tilted downward from horizontal by about 10

degrees (see figure at left, center).

The horizontal scan is shown with the transducer

at the bottom of the display window and the

selected range extending to the top of the

window, regardless of the window’s width. Thus,

data will be clipped on the sides of a tall, narrow

display (see figure at bottom left).

DOWN: Downlooker Display

The downlooker display shows the region directly

beneath the boat over time. The right edge of the

display always shows the most recent ping.

Since Ultrascan PC90 does not know boat speed,

the downlooker display cannot be used to

determine horizontal distances. Thus, there is no

horizontal scale bar in the downlooker display.

Ultrascan PC90 can only extract DOWN data

from the vertical array.

28

VSPLIT: Vertical Split-Screen

Display

The VSPLIT display shows downlooker data in the

left portion of the window and the forward vertical

scan in the right portion of the window. The

downlooker data occupies one quarter of the

horizontal dimension of the window and the vertical

scan occupies the remainder of the space.

Both portions of the display are equivalent in function

to the individual DOWN and VERT displays.

However, Ultrascan PC90 will always use the Gain,

Range and Alarm settings that are associated with the

vertical scan.

29

Adjusting the Gain and

Range

The Gain and Range adjustments are perhaps the

most critical features of Ultrascan PC90 in optimizing

the system performance for different operating

conditions.

Gain and Range can be set manually or, alternatively,

Ultrascan PC90 can set and vary the Gain and Range

settings automatically. It is important to note that

each scanning direction has its own Gain and Range

settings. To change the Gain and Range settings for

the current display, select Gain and Range... from the

Adjust menu.

Gain Adjustment

The Gain level controls the intensity of the signals

shown on the display by varying the amplification of

the sonar signals that Ultrascan PC90 receives. Click

on the Auto box to turn Auto Gain on and off. A

check in the box indicates that Auto Gain is on. The

default setting is off.

In the manual mode, Ultrascan PC90 allows you to

choose from 32 different Gain levels, numbered from

1 to 32. The default level is 16. Select the Gain by

sliding the pointer on the Gain bar. Level 1 provides

the smallest amount of Gain. At this level, the screen

will display little or no data. Higher Gain numbers

will brighten the display. The Gain level required to

see a specific target will vary with target range, water

clarity and background noise. In addition, Range

changes may also require changes in Gain.

In the Auto Gain mode, Ultrascan PC90 will adjust

the gain level automatically depending on the strength

of the sonar signal returns. Note that it is still

possible to make manual adjustments in the Auto

Gain mode, but any adjustments you make could be

changed by Ultrascan PC90.

Range Adjustment

The Range is the maximum distance at which features

will be displayed by Ultrascan PC90. In general,

features at greater distances will be less clearly

resolved. In addition, the water conditions will help

to determine the greatest distance at which Ultrascan

30

PC90 can accurately image features. Click on the

Auto box to turn Auto Range on and off. A check

in the box indicates that Auto Range is on. The

default setting is off.

In the manual mode, Ultrascan PC90 allows you to

choose one of twelve preset Ranges. Range can be

varied between 25 and 1000 feet, 8 and 300 meters,

or 4 and 160 fathoms. Select the desired Range by

sliding the pointer on the Range bar. The default

setting is the minimum range (25 feet).

In the Auto Range mode, Ultrascan PC90 will

adjust the Range automatically to keep the bottom

within the center three-quarters of the range scale.

If Ultrascan PC90 cannot find the bottom, it will

step through the Ranges until the bottom is found.

It is possible to make manual adjustments in the

Auto Range mode.

NOTE

Each Ultrascan PC90 gain setting is

actually a Time-Varied Gain (TVG)

curve which applies higher gains to later

returns. This is an important feature

which works to counteract the inherent

weakening of the acoustic signals with

distance from the transducer.

Leave the Gain and Range and/or

Alarm boxes open if you plan to make

frequent manual adjustments. Move a

box by dragging it to a desired position

TIP

Auto Gain and Auto Range are always

turned off when you exit Ultrascan

PC90.

NOTE

31

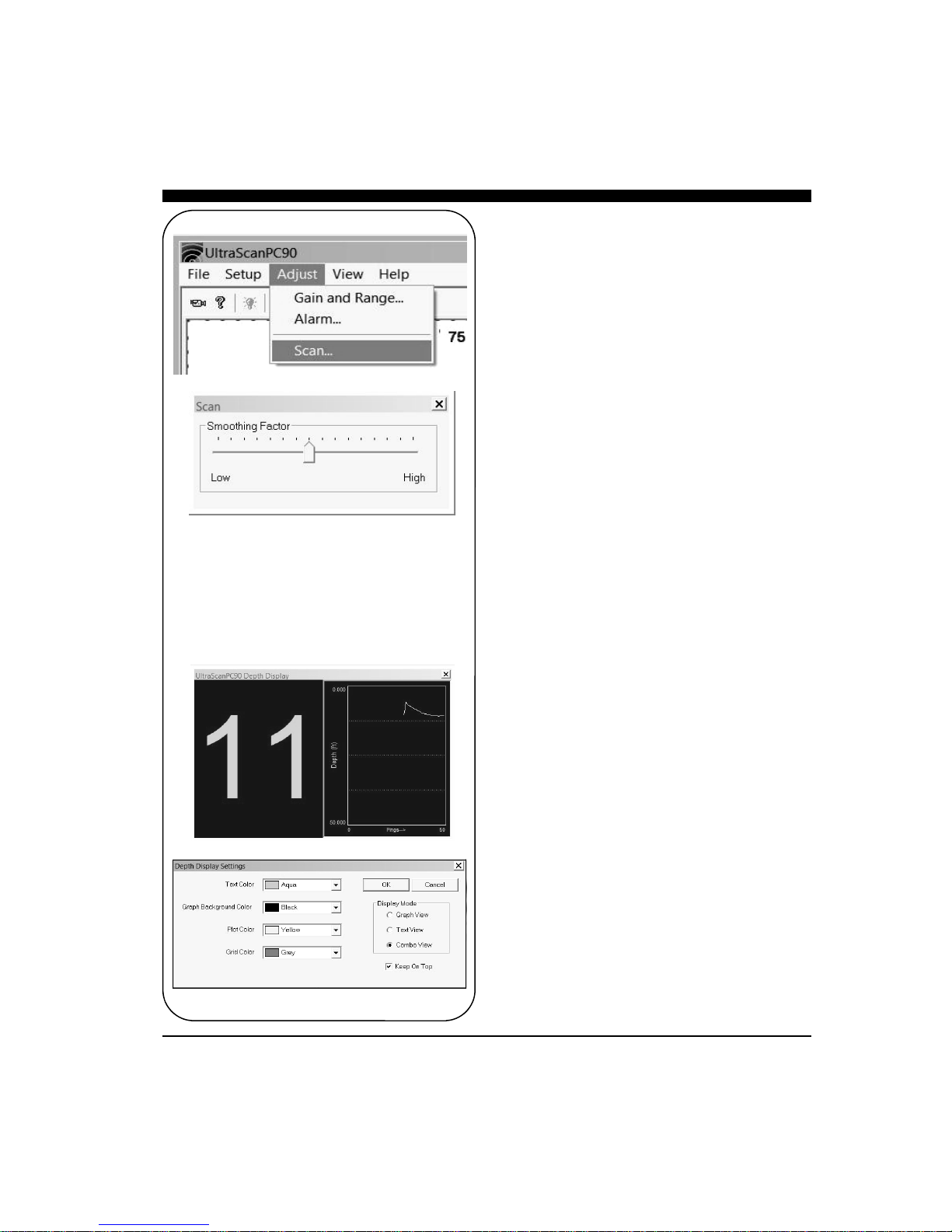

Display Smoothing

In turbulent or rough sea conditions, the picture may

become cluttered. To minimize random noise and

interference, use Ultrascan’s smoothing factor adjustment to average between multiple display frames.

Go to ADJUST—>SCAN as shown in the menu at

left to open a Smoothing Factor window with a horizontal slider control.

The default slider position is mid-range, For less

smoothing move the slider to the left or for more,

move the slider to the right.

Depth Window

In addition to the four scanning sonar displays, Ultrascan PC90 includes a separate depth window that

can be moved and resized to fill any portion of the

screen. Open the window by selecting Depth Display

from the View menu.

The depth window includes a large numerical display

as well as a graphical display of the depth over time.

The window stays open when the Ultrascan PC90

application is minimized. Note that, if you use AltTab to select Ultrascan PC90 from several

applications running under Windows, an open depth

display will remain in the background. Select Depth

Display from the View menu to bring the window to

the front.

32

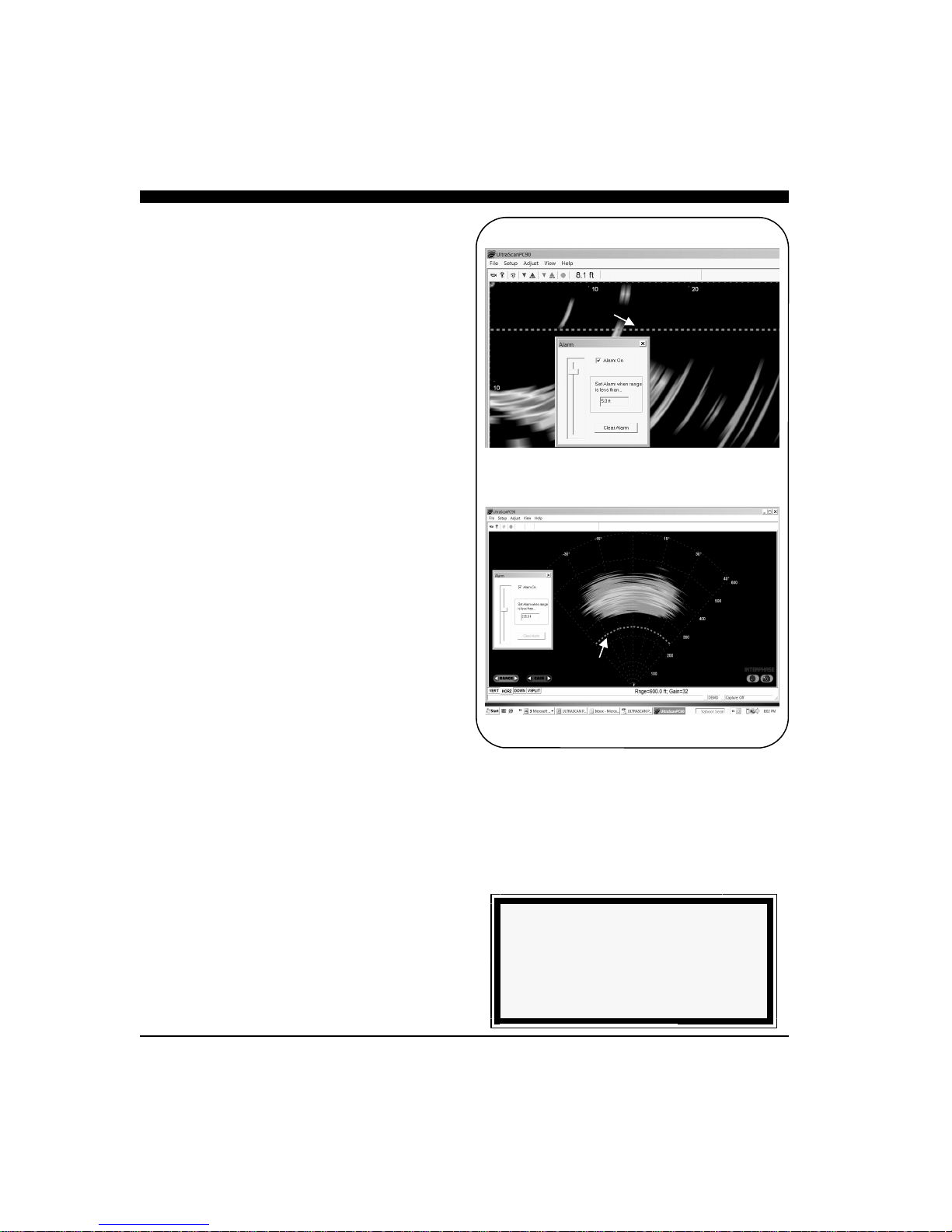

Using the Alarm

Ultrascan PC90 provides an audible alarm to alert you

to nearby and shallow features. VERT, HORZ and

DOWN displays use independent alarm settings.

VSPLIT and HSPLIT displays use the vertical and

horizontal alarm settings, respectively.

Change the alarm settings by selecting Alarm from

the Adjust menu. Turn the alarm on and off by

clicking on the Alarm On box. Select an alarm

distance by moving the slide bar.

The distance covered by the alarm will appear in the

scale bar of the display as a solid magenta bar, and a

magenta line or arc will cross the display at the

specified distance or depth. Vertical and downlooker

alarms are triggered whenever a solidly displayed

target appears shallower than the depth indicated by

the alarm bar. The horizontal alarm is triggered

whenever a solidly displayed target appears closer to

the boat than the range indicated by the alarm arc.

Once the Alarm has been triggered, it will continue

sounding until it has been reset. Reset the Alarm by

clicking on the Clear Alarm button in the Alarm box

or by clicking on the yellow light bulb in the Toolbar.

Vertical Alarm Bar

Horizontal Alarm Bar

NOTE

An alarm setting of zero is equivalent to

having the alarm off.

33

NOTE

Depth Tracker settings always return to

the defaults when you exit Ultrascan

PC90.

Adjusting the Depth

Tracker (Digital Depth)

With every vertical array ping, the Depth Tracker

attempts to find the bottom. The depth that is found

is displayed in the toolbar as well as the depth

window if it is open (see p.22 for a discussion of the

depth display). If the depth tracker cannot find the

bottom, a question mark will be displayed in the

toolbar. The tracked depth can be saved to a file and

sent out over a serial port. Refer to Chapter 5 for a

discussion of this utility.

If Auto Range is on, Ultrascan PC90 will use the

tracked depth to adjust the range (see p.30 for a

description of Auto Range). If the depth tracker

cannot find the bottom, Auto Range will step through

the available range scales until the bottom is found.

To adjust the parameters used by the depth tracker,

select Depth Tracker... from the Setup menu.

Surface Masking

The Surface Masking feature allows you to specify a

range near the water surface in which the depth

tracker will ignore any incoming returns. The default

Surface Masking is off.

Surface Masking is useful if there is a strong surface

return, abundant floating debris, bubbles under the

hull or surface bait schools. With blanking off in

such situations, the depth tracker could mistake these

shallow returns for the bottom.

The maximum masking range is about 10 feet, 3

meters, or 1.6 fathoms. Use the slide bar to select the

masking range. The selected masking range is shown

in all display windows.

Threshold

To avoid errant depth tracking on noise and

suspended features, the depth tracker applies a

Threshold. Normal is the default setting which

should be used in most situations.

However, if the gain is set so that the screen is dark,

revealing only obstacles and very bright mid-water

targets, the Low threshold setting may be required in

order to continue to track the depth.

34

Alternatively, if the gain is set high so that

everything is bright, the High threshold may be

necessary to avoid tracking depth on bait balls and

other strong mid-water returns.

Saving Data with Screen

Capture

Images displayed in Ultrascan PC90 can be saved

using the Screen Capture feature. There are four

ways to capture an image:

1) Select Capture Screen Now from the File

Menu.

2) Use the keyboard shortcut Ctrl+Shft+C.

3) Click on the Screen Capture button of the

Toolbar.

4) Use the Screen Capture Scheduler accessed

from the File Menu to automatically create

periodic screen captures.

Ultrascan PC90 will not carry out a requested or

scheduled screen capture if there is less than 20

megabytes of space remaining on your hard disk.

Whenever Ultrascan PC90 does a screen capture,

the screen capture indicator (to the left of the screen

capture status box in the Status Bar) flashes blue.

Each screen capture image is saved in the folder

specified in the Screen Capture Scheduler. The

default folder is the Data folder in the Ultrascan

PC90 program folder:

C:\Program Files\Interphase\Ultrascan PC90\Data

The Scheduler allows you to turn auto-saving on or

off (click on the box labeled Enable Screen

Capture) and specify the frequency of auto-saving.

Files are saved in the JPEG (*jpg) format and each

picture is approximately 40kB in size.

Screen Capture

File Name Format

20101118164240R0048G31.jpg

Year Range

Month Gain

Day

Hour Format

Minute (jpg)

Second

35

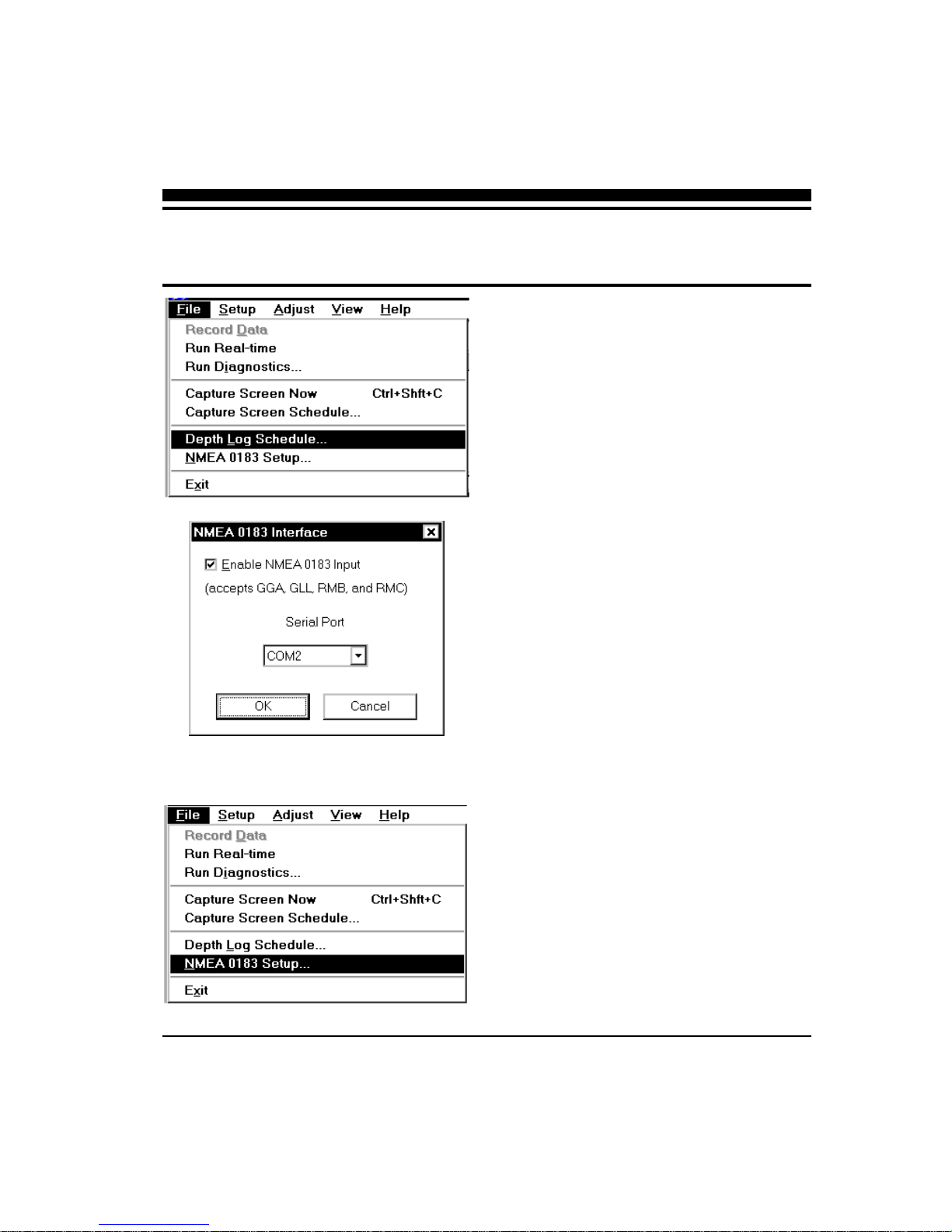

5 Advanced Operation

Working with NMEA

Navigation

Ultrascan PC90 reads standard NMEA 0183

navigation strings from a serial or USB port, extracts

the latitude and longitude and displays this

information in the toolbar.Ultrascan PC90 accepts

GGA, GLL, RMB and RMC strings. To activate this

feature, select NMEA 0183 Setup… from the File

menu, click in the check box labeled Enable NMEA

0183 Input and select the serial or USB port to which

navigation input is connected.

When NMEA 0183 input is enabled, the Ultrascan

PC90 will look for data coming from the serial or

USB port. If the NMEA strings are successfully

parsed, the Ultrascan PC90 will display the most recent latitude and longitude in the navigation box on

the toolbar. If no data is detected coming from the

serial or USB port, a series of dashes will be displayed in the navigation box. A blank navigation box

indicates that NMEA 0183 input is disabled.

Use the following connections to your serial port. If

you have a 9-pin serial port:

Pin#2 = RX = Out

Pin #3 = TX = In

Pin #5 = Ground

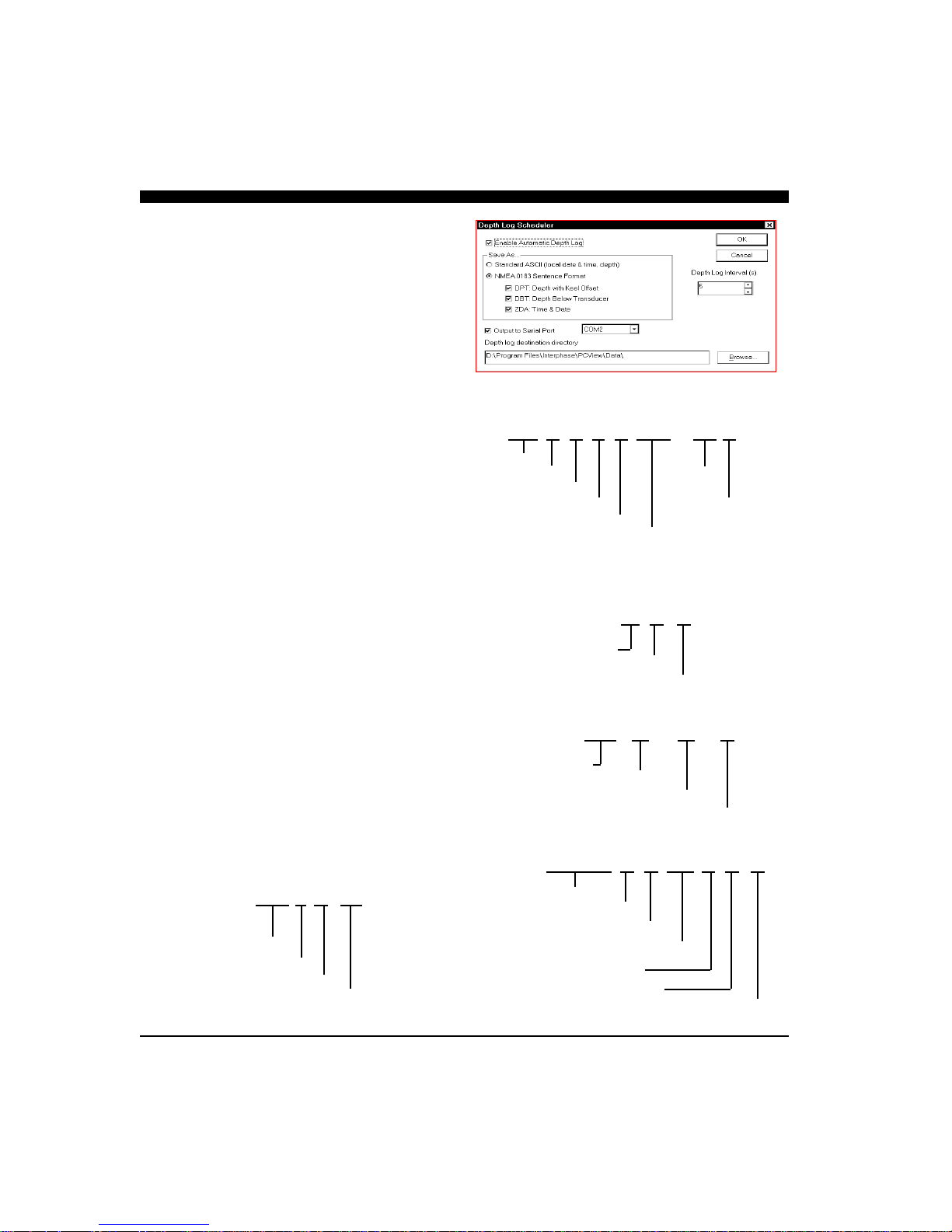

Logging Depth

Ultrascan PC90 can log the tracked depth in a file and

send it out over a serial port. To activate this feature,

select Depth Log Schedule… from the File menu and

click in the check box labeled Enable Automatic

Depth Log. Next, select a format for the logged depth.

Choose ASCII format or NMEA 0183 sentence

format. The ASCII format includes the date, the time

and the depth below the transducer in the current

Units.

For the NMEA 0183 format, any or all of three

sentence types can be saved. NMEA 0183 format

36

(and Position)

sentences begin with a dollar sign followed by the

two-character talker identification followed by the

three-character sentence type. The talker

identification for Ultrascan PC90 is SS, for

scanning sonar. Data fields in the sentences are

comma-delimited and the sentences end with a star

followed by the checksum. Ultrascan PC90 uses the

following three sentence types:

DPT - Depth with Keel Offset. This sentence

includes the water depth, in meters, relative to the

transducer followed by the offset from the

transducer in meters.

DBT - Depth Below Transducer. This sentence

includes the water depth in feet; the water depth in

meters and the water depth in fathoms, all

referenced to the transducer.

ZDA - Time and Date. This sentence includes, the

Universal Time Coordinated (UTC), the day, the

month, and the year, all in UTC, and the local zone

hours and minutes (Atlantic Standard Time is local

zone 05 hours, 00 minutes).

Once you have selected the depth log format, select

a depth log frequency interval in seconds. If the

frequency is set at 5, Ultrascan PC90 will log the

depth every 5 seconds. Ultrascan PC90 will always

log the depth to a file named with the current local

date (year month day) and a file extension of .dep

(e.g. 20100401.dep). By default, the file will be

saved in the Ultrascan\Data directory

(D:\Program Files\UltrascanPC90

\Data\).

Depth Log

File Name Format

ASCII Depth Format

2010/03/31 16:43:29.01 12.2 ft.

Year

Month Depth

Day

Hour Units

Minute

NMEA Sentence Formats

$SSDPT,4.2,0.0*46

Water Depth (m)

Keel Offset (m)

Checksum

$SSDBT,13.0,f,4.0,M,2.2,F*27

Depth in feet

Depth in meters

Depth in fathoms

Checksum

$SSZDA,004635.18,01,04,2010,08,00*79

20100401.dep

Year

Month

Day

Depth file extension

UTC (hhmmss.ss)

Day (UTC)

Month (UTC)

Year (UTC)

Local zone hours

Local zone minutes

Checksum

37

$GPGLL,2457.250,N,12120.714,E,104439.02,A*61

Latitude, N/S

Longitude, E/W

UTC(hhmmss.ss)

Status

A=data valid

V=data not valid

Checksum

If you wish to save to another directory, specify the new

directory in the Depth log destination directory box. To

send the depth information out a serial port as well,

click in the box labeled Output to Serial Port and select

a serial port from the pull-down menu. Ultrascan PC90

will automatically configure the protocol of the selected

serial port to the NMEA 0183 standard.

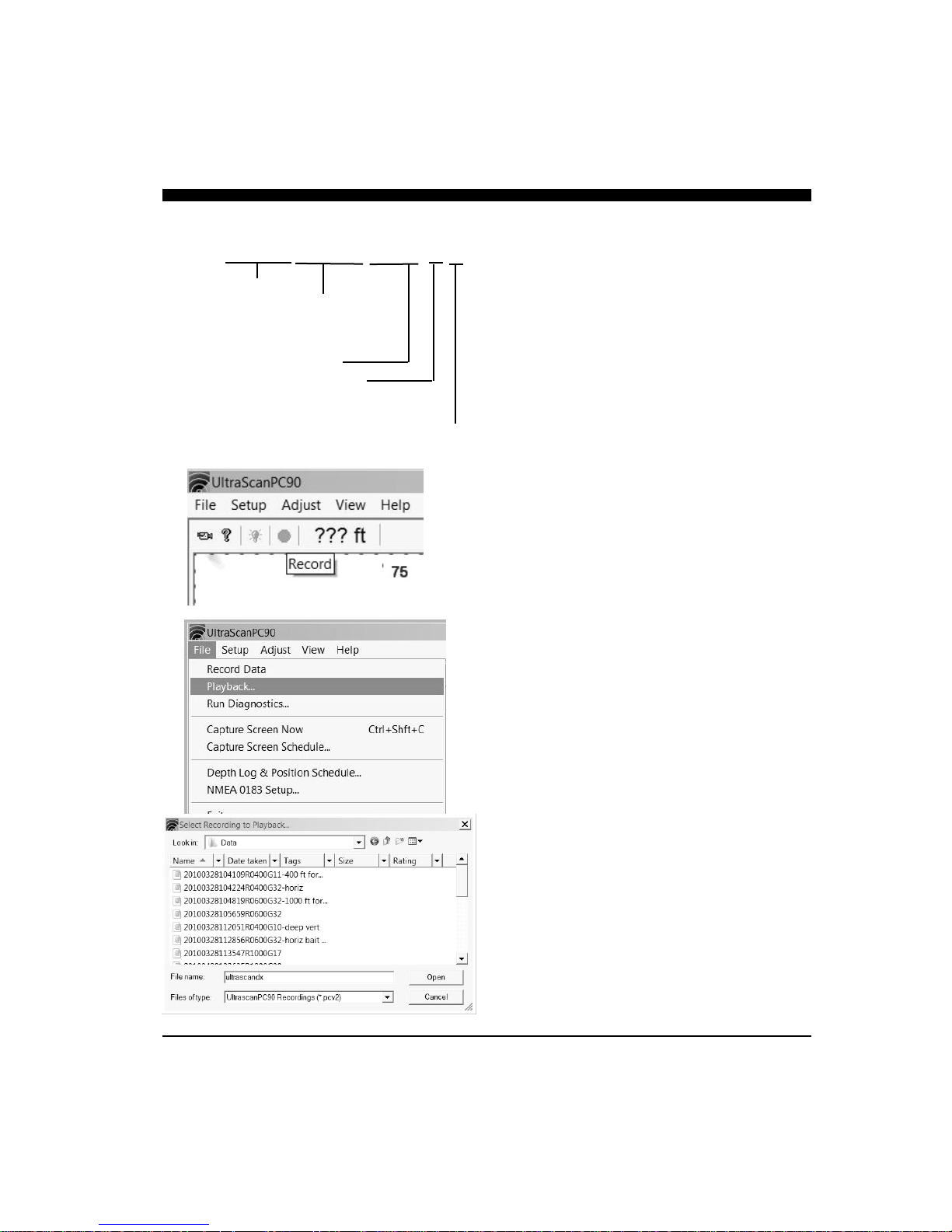

Recording Live Data

Ultrascan PC90 can record the actual raw sonar that’s

transmitted over the Ethernet from the beamformer

module to the PC. The data can be saved and later

played back through the Ultrascan PC90 program.

The Ultrascan will only record raw video data when the

PC is actually receiving it from the beamformer module. Therefore, the Record button will not work when

viewing previously recorded data.

When video recording of the raw data is available, the

record button will be a bright red color.

To start the recording, depress the RED record button.

When recording, the bottom toolbar will say RECORDING and the small box to the right will turn a

blue color as shown at right.

Recording will automatically be saved in the Program

Files/Ultrascan PC90/Data file, unless another folder

has been chosen in the record schedule file.

To replay the raw data file, got o FILE—>PLAYBACK

and choose the desired file. When running the recorded file, you can make adjustments to most of the

controls—except for the range. Also, if the recording

was made in the vertical mode, it should be played back

in the vertical mode, etc.

If you are viewing a recording and wish to change to a

different recording, you must first go to FILE—>RUN

LIVE, and then go back to FILE—>PLAYBACK to

choose a different file.

38

Using the Diagnostics

The Ultrascan PC90 Diagnostics provide

information about your computer system and the

Ultrascan PC90 software. This tool enhances the

ability of the Interphase Technical Support staff to

troubleshoot any problem that you might have with

your Ultrascan PC90.

To gain the most information about your system, be

sure that the Ultrascan PC90 hardware is connected

to your computer and turned on before selecting

Run Diagnostics… from the File menu.

To save the results of the diagnostics, click on the

Copy to Clipboard button and then paste into any

word processor, any email application or the

notepad. If you contact Interphase Technical

Support via fax or email, it will be useful to include

the diagnostics results in your correspondence.

39

6 Interpreting Displays

Principles

The Ultrascan PC90 system provides a display of

acoustic echoes from the underwater area beneath and

Weak Return From Far-Forward

Strong Return from

Up-sloping Bottom

ahead of your vessel. The Phased Array Transducer

steers an acoustic beam over a sector which can be

adjusted from approximately 6 to 90 degrees in width.

As the Ultrascan PC90 steers the beam to different

positions, it transmits a pulse of energy and then waits

a defined period of time (depending on the range

selected) to receive any returning echoes. As the

energy from this acoustic beam strikes underwater

objects or the bottom, a portion of the energy is

reflected as an echo back to the transducer. When the

echo is received at the transducer, it’s converted into

a small electrical signal and processed for display.

Since the Ultrascan PC90 knows the direction in

which it sent the transmit pulse and the time it took to

receive the return echo, it can determine the location

of the object or bottom that created the return echo.

As the Ultrascan PC90 sequentially steps through the

scan sector, the computer’s display shows a

continuously updated image of the returning echoes in

their approximate positions relative to the vessel.

Interpreting the Vertical

Display

In the vertical mode, Ultrascan PC90 scans forward

from horizontal down to vertical beneath the vessel.

Since the resulting display shows only the acoustic

echoes that are returned to the transducer, it cannot

show forward bottom conditions that are hidden from

its field of view or are hidden due to obstructions in

the acoustic beam’s path through the water.

Forward Imaging Capabilities

The distance ahead of the vessel over which the

Ultrascan PC90 is capable of imaging features is

dependent upon water depth, bottom structure and

water conditions. Under typical conditions, the

40

Ultrascan PC90 will show level or shallowing bottom

contours for a distance forward of between 4-times

and 8-times the water depth beneath the transducer.

Obstructions in the water may be seen at much

greater distances (within the Ultrascan PC90’s 1200foot maximum range).

Smooth bottom conditions far forward of the vessel

are difficult to image as very little of the acoustic

energy is reflected back as an echo (see the diagram

at top left). Bottoms that are rough and rocky or are

sloping upward will reflect more acoustic energy

back to the transducer and will show strong farforward returns (see diagram at bottom left).

It is important to note that even if the bottom is

smooth and does not show up far-forward,

acoustically reflective obstructions in the same farforward region (sea walls, large rocks, underwater

shelves, submerged buoys, etc.) will typically send

back strong echoes, as the diagram at right indicates.

Regardless of the actual vertical dimension of such

far-forward obstructions, they will often appear on

the Ultrascan PC90 display as a vertical line or arc.

Transducer Sidelobe Effect

The Ultrascan PC90’s transducer, like all transducers,

does not form a perfect beam of acoustic energy.

Some of the energy is contained in areas outside of

the main beam called sidelobes (see diagram at

right). In some situations, sidelobes can lead to

echoes that are not placed in the proper position on

the display.

As the Ultrascan PC90 sends off its acoustic beam in

a specific direction, it assumes that any return echoes

are within the main beam. However, if the sidelobe

energy strikes a reflective object (such as the

bottom), creating a strong echo, the Ultrascan PC90

will display the “false” return as if it were located

within the main beam.

The most typical display of sidelobe echoes appears

in the vertical display as an arc at the same distance

as the bottom depth (see diagram on following page).

After using the Ultrascan PC90 in different

situations, with different gain settings, you should

become proficient in identifying the bottom echoes

caused by the transducer’s sidelobes. A gain

reduction will help to minimize the sidelobe effect.

NOTE

Poor water conditions such as surface

chop, temperature inversion layers and

muddy water may degrade the Ultrascan

PC90’s performance

Strong Return from Wall Far-Forward

Transducer

Sidelobes

Main Beam

Sidelobe

Main Beam

False

Echoes

41

“False” Echoes Caused by Sidelobe Returns.

200 ft Forward Range, Water Depth of 36 Ft

Bait

However, in some situations, you may want to ignore

the sidelobe effect and increase the gain to achieve a

better display of the bottom far-forward of the vessel.

In general, Ultrascan PC90’s adjustable gain settings

help to minimize the sidelobe effect. This is because

each gain setting represents a time-varied-gain

(TVG) curve. These curves use lower gains for

earlier returns, which may include unwanted sidelobe

echoes, and higher gains for later returns which

include the desired echoes. Refer to page 30 for a

discussion of gain settings.

Interpreting the

Horizontal Display

In the horizontal scanning mode the Ultrascan PC90

scans from left to right across the vessel’s bow. The

forward scanning elements in the transducer are

positioned so that the plane of the horizontal scan is

angled downward approximately 10 degrees from the

water’s surface (see the diagrams at left and on p.21).

This downward angle is designed to help reduce the

effects of surface noise clutter when the water is

choppy and to allow easier mounting of the

transducer to the transom of smaller boats.

Imaging the Bottom

As the acoustic beam is projected away from the

boat, the cross-sectional area of the beam increases.

At a range of approximately 3 to 3.5 times the depth

of the water the sound beam will begin intersecting

the bottom and some of the sound energy that

intersects the bottom will be reflected back and will

appear on the Ultrascan PC90’s screen as bottom

echoes. Refer to the diagram at left.

It is important to understand that the Ultrascan PC90

will often see the bottom and will show it on the

forward display. This display information can be

used to help understand the structure of the bottom

ahead of the boat, but the bottom echoes can also

mask or be confused with other desired targets. In

the diagram at left, for example, a bait ball or school

of fish is lost in the bottom echoes. However, as the

vessel approaches the target, it will become distinct

from the bottom echoes as it moves into the nearer

42

ranges.

Special Situations

With experience you should be able to use the fact

that the forward beam will show the bottom, to

your advantage. You will learn to recognize

bottom structure such as varying water depths

across the sector, drop-offs, ledges, and rocky

patches on the bottom ahead. Two examples of

changing bottom conditions are shown in the

diagrams at right.

In the upper diagram, a shallow bottom in the

starboard direction is clearly imaged in the

horizontal scan. In the lower diagram, a channel is

imaged. The deepest point of the channel ahead of

the vessel is indicated by the gap in the bottom

echoes.

Forward Imaging Capabilities

If the horizontal range setting is greater than the

forward distance to the bottom, the Ultrascan PC90

can detect targets at distances beyond where the

beam hits the bottom. This is because the acoustic

beam can bounce off the bottom and keep going

forward until it strikes a solid object and then

returns as an echo.

Even in shallow water it is possible to see several

hundred feet ahead by using this “bounce”

technique. When looking far-forward in shallow

situations such as this, it is advisable to adjust the

gain manually. Otherwise the Auto Gain feature

will reduce the gain because of the strong close-in

bottom reflections. Refer to page 30 for a

discussion of gain settings.

Deeper water

to port (left)

of boat.

Sides of

Underwater

Trench

43

Maintenance

The Ultrascan PC90 Forward Scanning Sonar has been designed to provide reliable, trouble-free performance

for years. Follow the maintenance tips below to ensure that your Ultrascan PC90 remains problem-free.

1) Keep your Ultrascan PC90 Beamformer Module clean and dry.

2) If the power cord in-line fuse is blown, replace it with a 2 amp fuse. NEVER REPLACE WITH A

HIGHER AMP RATING ! If the fuse continues to blow, check the polarity of your 12 VDC power

source. If the polarity is correct, check with the Technical Service Department at (408)477-4944.

3) In order to protect your transducer from water damage, we suggest painting it with a water based antifouling paint. DO NOT use a ketone-based paint. Brands such as MDR, Woolsey and Pettit all make

water based anti-fouling paints that can be found at your local marine supply store. Words like aqua or

hydro on a paints label indicate a water based product. Never use spray paint on a transducer.

4) DO NOT allow any solvents, i.e. gasoline, acetone, to come in contact with the transducer or head

unit as these may dissolve the material.

44

Troubleshooting Guide

If you are experiencing trouble with your Ultrascan PC90, please refer to the following checklist:

PROBLEM

Beamformer Module will not turn on.

Power cord in-line fuse blows

repeatedly.

Will not run in Live Mode. Verify that the Ethernet l cable is connected to the

Screen remains blank in PLAYBACK

Mode.

Loses picture at speed.

Screen is full of noise, or has dots

running through it.

Known flat bottom slopes up/down.

Digital water depth not working.

SOLUTION

Check power cord in-line fuse, battery voltage and

power connections. Also, check for continuity

through the in-line fuse holder

Wiring is reversed or there is excessive current from

the battery. The red wire should be “+” (positive) and

have continuity with pin #1 on the female side of the

power supply lead. Check the voltage to the

Beamformer Module. It should be less than 16V and

ideally 12-13V.

Beamformer Module and your computer, and that the

Beamformer Module is on. Check to see that the

proper I.P address is selected. Select Run Live from

the File menu

Ultrascan PC90 cannot find the PLAYBACK data.

Move the data files (*.pcv) back into the Data folder

in the Ultrascan PC90 program folder.

Adjust the transducer angle or placement. Make sure

that the transducer is installed in the area which has

the least amount of water turbulence.