PD-97657

SupIRBuck

TM

INTEGRATED 12A SYNCHRONOUS BUCK REGULATOR

Features

• Greater than 96% Maximum Efficiency

• Wide Input Voltage Range 1.5V to 16V

• Wide Output Voltage Range 0.7V to 0.9*Vin

• Continuous 12A Load Capability

• Integrated Bootstrap-diode

• High Bandwidth E/A for excellent transient

performance

• Programmable Switching Frequency up to 1.5MHz

• Programmable Over Current Protection

• PGood output

• Hiccup Current Limit

• Precision Reference Voltage (0.7V, +/-1%)

• Programmable Soft-Start

• Enable Input with Voltage Monitoring Capability

• Enhanced Pre-Bias Start-up

• Seq input for Tracking applications

o

• -40

• Thermal Protection

• Pin compatible option for 4A, 8A, and 14A devices

• 5mm x 6mm Power QFN package, 0.9 mm height

• Lead-free, halogen-free and RoHS compliant

C to 125oC operating junction temperature

IR3840WMPbF

HIGHLY EFFICIENT

Description

The IR3840W SupIRBuck

fully integrated and highly efficient DC/DC

synchronous Buck regulator. The MOSFETs copackaged with the on-chip PWM controller make

IR3840W a space-efficient solution, providing

accurate power delivery for low output voltage

applications.

IR3840W is a versatile regulator which offers

programmability of start up time, switching

frequency and current limit while operating in

wide input and output voltage range.

The switching frequency is programmable from

250kHz to 1.5MHz for an optimum solution.

It also features important protection functions,

such as Pre-Bias startup, hiccup current limit and

thermal shutdown to give required system level

security in the event of fault conditions.

TM

is an easy-to-use,

Applications

• Server Applications

• Storage Applications

• Embedded Telecom Systems

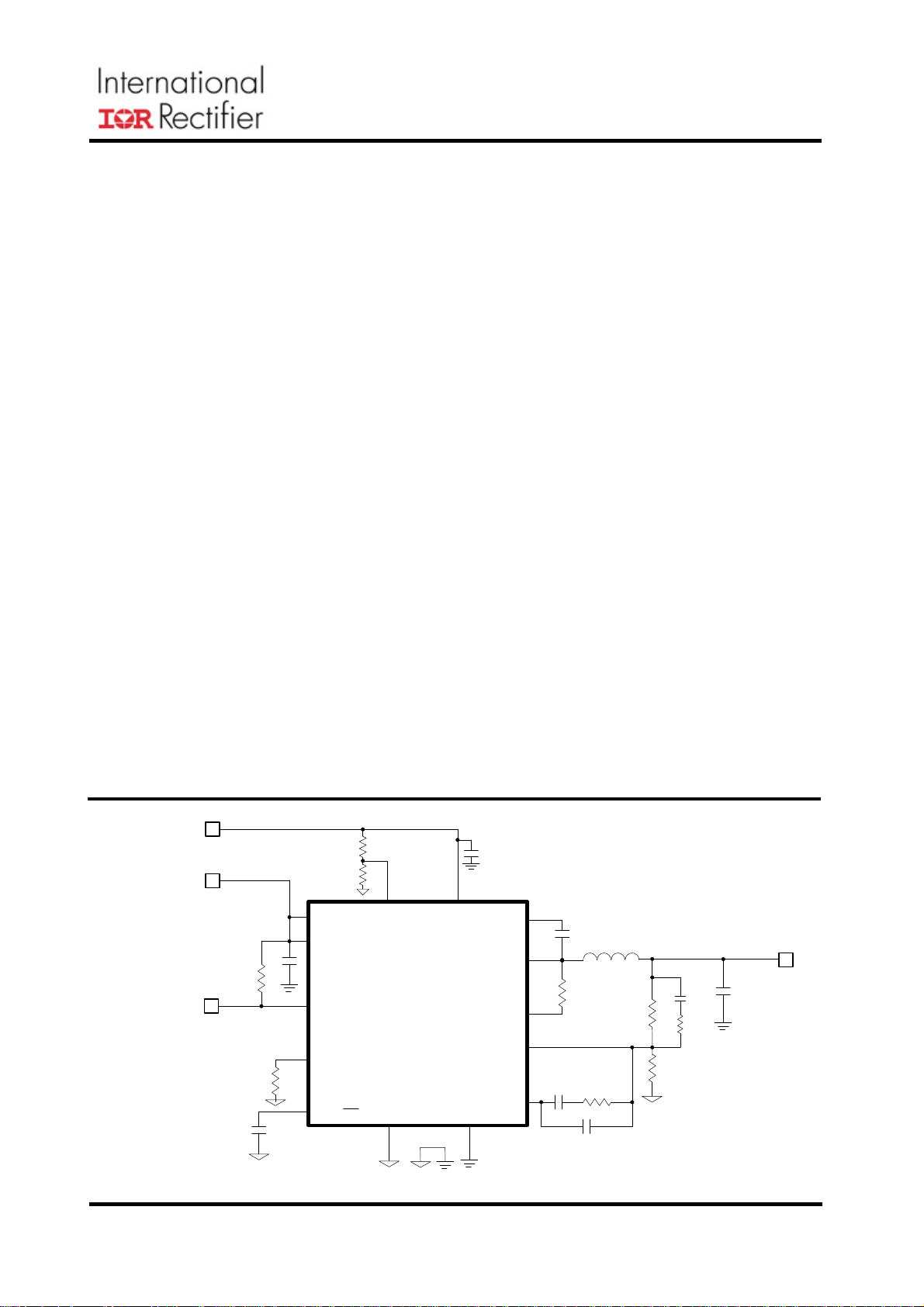

1.5V <Vin<16V

4.5V <Vcc<5.5V

PGood

Seq

Vcc

PGood

Rt

SS/ SD

Enable

Gnd

• Distributed Point of Load Power Architectures

• Netcom Applications

• Computing Peripheral Voltage Regulators

• General DC-DC Converters

Vin

Boot

SW

OCSet

Fb

Comp

PGnd

Vo

Rev 12.0

Fig. 1. Typical application diagram

1

PD-97657

IR3840WMPbF

ABSOLUTE MAXIMUM RATINGS

(Voltages referenced to GND unless otherwise specified)

• Vin ……………………………………………………. -0.3V to 25V

• Vcc ……………….….…………….……..……….…… -0.3V to 8V (Note2)

• Boot ……………………………………..……….…. -0.3V to 33V

• SW …………………………………………..……… -0.3V to 25V(DC), -4V to 25V(AC, 100ns)

• Boot to SW ……..…………………………….…..….. -0.3V to Vcc+0.3V (Note1)

• OCSet ………………………………………….……. -0.3V to 30V, 30mA

• Input / output Pins ……………………………….. ... -0.3V to Vcc+0.3V (Note1)

• PGND to GND ……………...………………………….. -0.3V to +0.3V

• Storage Temperature Range ................................... -55°C To 150°C

• Junction Temperature Range ................................... -40°C To 150°C (Note2)

• ESD Classification …………………………… ……… JEDEC Class 1C

• Moisture sensitivity level………………...………………JEDEC Level 2@260 °C (Note5)

Note1: Must not exceed 8V

Note2: Vcc must not exceed 7.5V for Junction Temperature between -10

o

C and -40oC

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the

device. These are stress ratings only and functional operation of the device at these or any other

conditions beyond those indicated in the operational sections of the specifications are not implied.

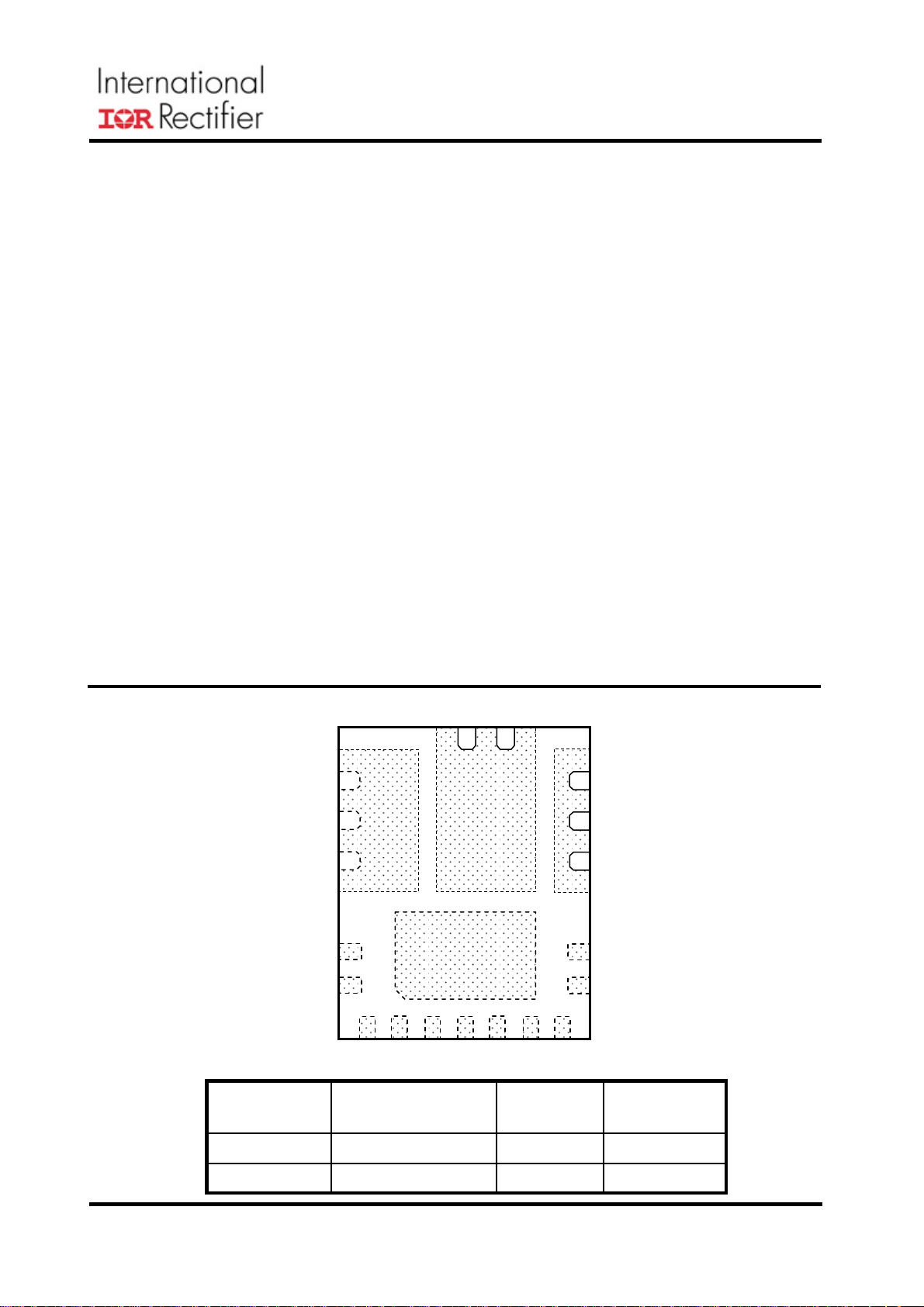

PACKAGE INFORMATION

SW

5mm x 6mm POWER QFN

V

ORDERING INFORMATION

IN

Boot

Enable

12

13

14

1

23

Seq FB COMP Gnd Rt SS OCSet

15

Gnd

4

11

PGnd

10

=

JA

-

PCBJ

V

9

8

5

7

6

CC

PGood

=

o

W/C35θ

o

W/C2θ

Rev 12.0

PACKAGE

DESIGNATOR

M

PACKAGE

DESCRIPTION

IR3840WMTR1PbF

PIN

COUNT

15

PARTS PER

REEL

400015IR3840WMTRPbFM

750

2

PD-97657

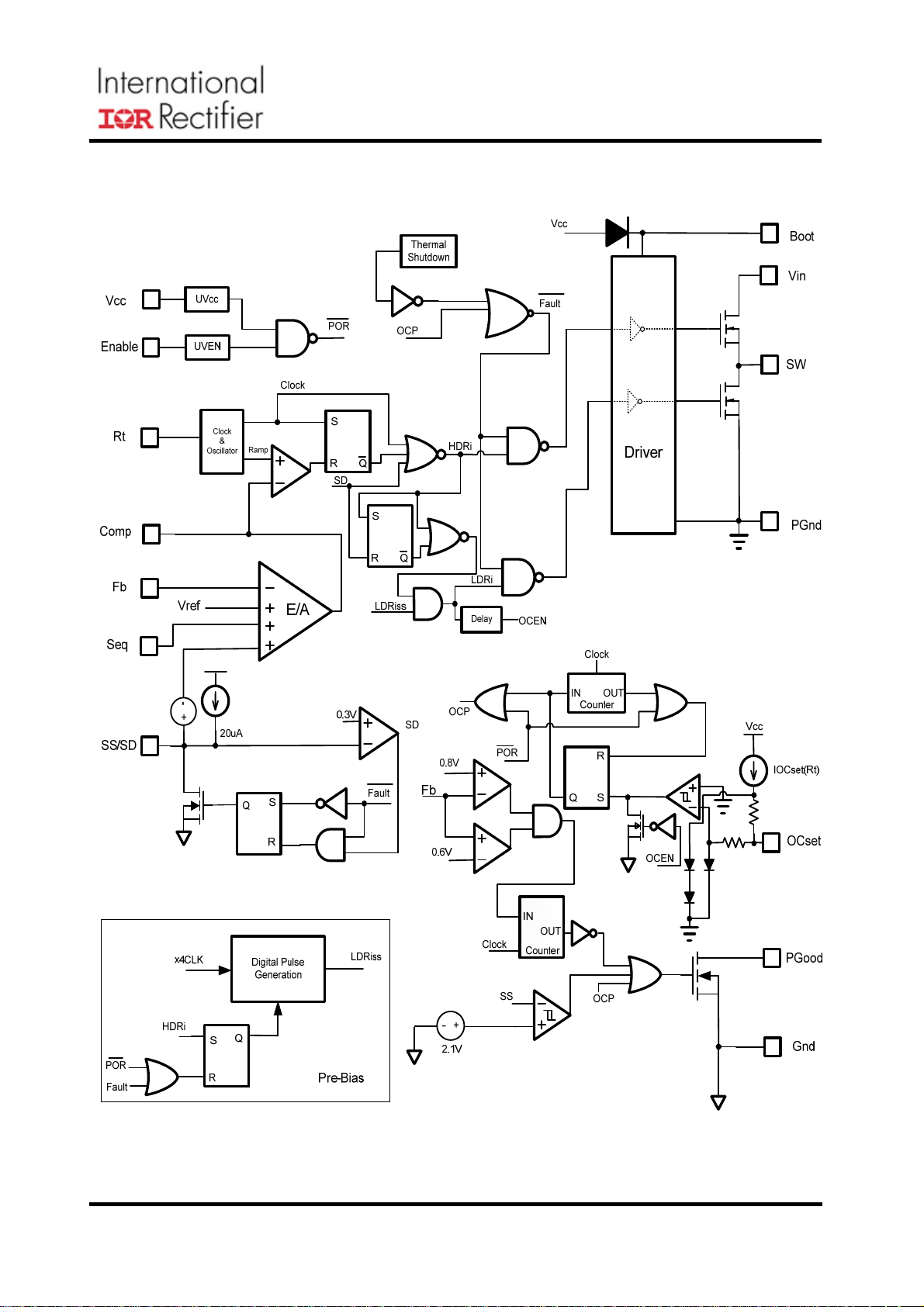

Block Diagram

IR3840WMPbF

Rev 12.0

Fig. 2. Simplified block diagram of the IR3840W

3

PD-97657

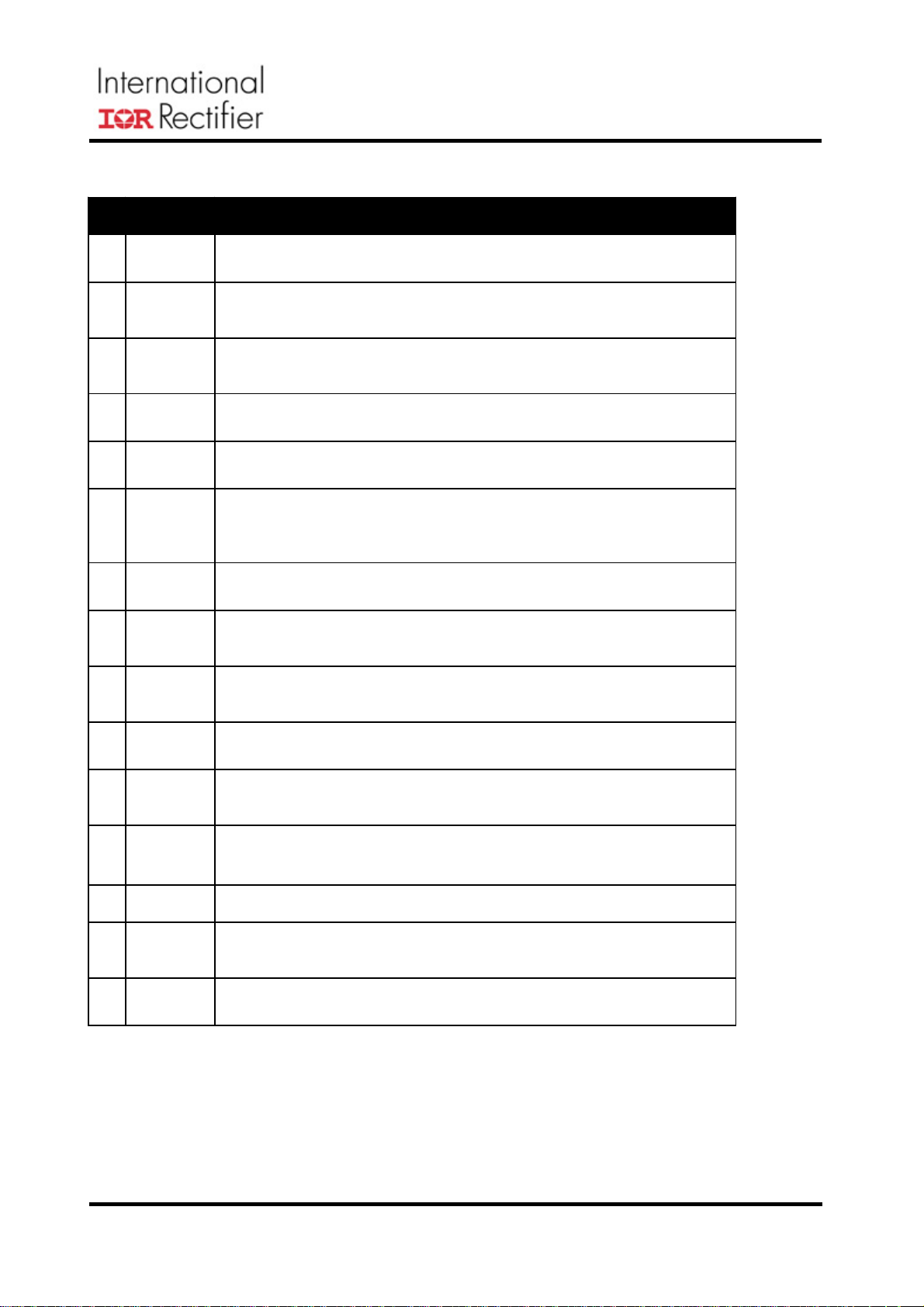

Pin Description

Pin Name Description

1 Seq

2 Fb

3 Comp

4 Gnd Signal ground for internal reference and control circuitry.

5 Rt

6 SS/SD¯¯

7 OCSet

Sequence pin. Use two external resistors to set Simultaneous Power up

sequencing. If this pin is not used connect to Vcc.

Inverting input to the error amplifier. This pin is connected directly to the

output of the regulator via resistor divider to set the output voltage and

provide feedback to the error amplifier.

Output of error amplifier. An external resistor and capacitor network is

typically connected from this pin to Fb pin to provide loop

compensation.

Set the switching frequency. Connect an external resistor from this pin

to Gnd to set the switching frequency.

Soft start / shutdown. This pin provides user programmable soft-start

function. Connect an external capacitor from this pin to Gnd to set the

start up time of the output voltage. The converter can be shutdown by

pulling this pin below 0.3V.

Current limit set point. A resistor from this pin to SW pin will set the

current limit threshold.

IR3840WMPbF

8 PGood

9

10 PGnd

11

12

13 Boot

14 Enable

15 Gnd Signal ground for internal reference and control circuitry.

V

CC

SW

V

IN

Power Good status pin. Output is open drain. Connect a pull up resistor

from this pin to Vcc. If unused, it can be left open.

This pin powers the internal IC and the drivers. A minimum of 1uF high

frequency capacitor must be connected from this pin to the power

ground (PGnd).

Power Ground. This pin serves as a separated ground for the MOSFET

drivers and should be connected to the system’s power ground plane.

Switch node. This pin is connected to the output inductor.

Input voltage connection pin.

Supply voltage for high side driver. A 0.1uF capacitor must be

connected from this pin to SW.

Enable pin to turn on and off the device. Use two external resistors to

set the turn on threshold (see Enable section). Connect this pin to Vcc if

it is not used.

Rev 12.0

4

PD-97657

IR3840WMPbF

Recommended Operating Conditions

Symbol Definition Min Max Units

V

mΩ

%

Vin Input Voltage 1.5 16

Vcc Supply Voltage 4.5 5.5

Boot to SW Supply Voltage 4.5 5.5

Vo Output Voltage 0.7 0.9*Vin

Io Output Current 0 12 A

Fs Switching Frequency 225 1650 kHz

Tj Junction Temperature -40 125 oC

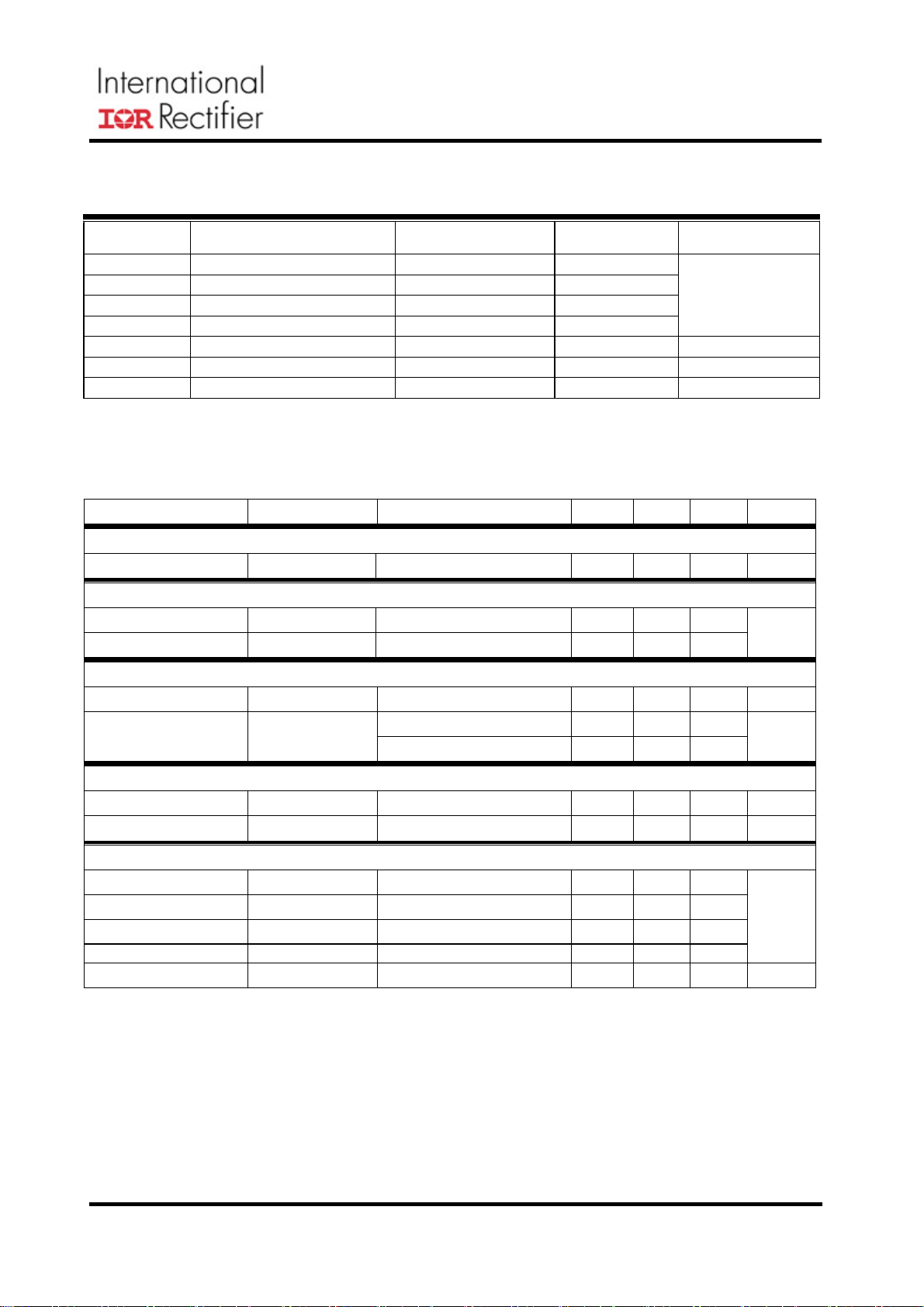

Electrical Specifications

Unless otherwise specified, these specification apply over 4.5V< Vcc<5.5V, Vin=12V, 0oC<Tj< 125oC.

Typical values are specified at T

Parameter Symbol Test Condition Min TYP MAX Units

Power Loss

Power Loss P

MOSFET R

Top Switch R

Bottom Switch R

Reference Voltage

Feedback Voltage VFB 0.7 V

ds(on)

= 25oC.

a

Vcc=5V, Vin=12V, Vo=1.8V, Io=12A,

loss

ds(on)_Top

ds(on)_Bot

Fs=600kHz, L=0.6uH, Note4

V

=5V, ID=14A, Tj=250C

Boot -Vsw

Vcc=5V, ID=14A, Tj=250C

0oC<Tj<125oC -1.0 +1.0 Accuracy

o

C<Tj<125oC,

-40

Note3

-2.0 +2.0

2.5 W

8.4 10.6

5.7 6.9

Supply Current

Vcc Supply Current (Standby)

Vcc Supply Current (Dyn) I

I

SS=0V, No Switching, Enable low 500 uA

CC(Standby)

SS=3V, Vcc=5V, Fs=500kHz

CC(Dyn)

Enable high

15 mA

Under Voltage Lockout

Vcc-Start-Threshold VCC_UVLO_Start Vcc Rising Trip Level 3.95 4.15 4.35

Vcc-Stop-Threshold VCC_UVLO_Stop Vcc Falling Trip Level 3.65 3.85 4.05

Enable-Start-Threshold Enable_UVLO_Start Supply ramping up 1.14 1.2 1.36

Enable-Stop-Threshold Enable_UVLO_Stop Supply ramping down 0.9 1.0 1.06

Enable leakage current Ien Enable=3.3V 15 uA

V

Rev 12.0

5

PD-97657

IR3840WMPbF

Electrical Specifications (continued)

Unless otherwise specified, these specification apply over 4.5V< Vcc<5.5V, Vin=12V, 0oC<Tj< 125oC.

Typical values are specified at T

Parameter Symbol Test Condition Min TYP MAX Units

Oscillator

Rt Voltage

Frequency F

Ramp Amplitude Vramp

Ramp Offset Ramp (os)

Min Pulse Width Dmin(ctrl)

Fixed Off Time

Max Duty Cycle Dmax Fs=250kHz 92 %

Error Amplifier

Input Offset Voltage Vos Vfb-Vseq,

Input Bias Current IFb(E/A) -1 +1

Input Bias Current IVp(E/A) -1 +1

Sink Current Isink(E/A) 0.40 0.85 1.2

Source Current Isource(E/A) 8 10 13

Slew Rate SR

Gain-Bandwidth Product GBWP

DC Gain Gain

Maximum Voltage Vmax(E/A)

Minimum Voltage Vmin(E/A)

Common Mode Voltage

Soft Start/SD

Soft Start Current ISS Source 14 20 26

Soft Start Clamp Voltage Vss(clamp) 2.7 3.0 3.3

Shutdown Output

Threshold

Over Current Protection

OCSET Current I

OC Comp Offset Voltage V

SS off time SS_Hiccup 4096 Cycles

Bootstrap Diode

Forward Voltage I(Boot)=30mA 180 260 470 mV

Deadband

Deadband time

= 25oC.

a

S

SD 0.3

OCSET

OFFSET

Rt=59K 225 250 275

Rt=28.7K 450 500 550

Rt=9.31K, Note4

Note4

Note4

Note4

Note4

Vseq=0.8V

Note4

Note4

Note4

Vcc=4.5V

Note4

Fs=250kHz 20.8 23.6 26.4

Fs=500kHz 43 48.8 54.6

Fs=1500kHz 136 154 172

Note4

Note4

0.665 0.7 0.735 V

1350 1500 1650

1.8 Vp-p

0.6 V

50

130 200

-10 0 +10 mV

7 12 20

20 30 40 MHz

100 110 120 dB

3.4 3.5 3.75 V

120 220 mV

0 1 V

-10 0 +10 mV

5 10 30 ns

kHz

ns

μA

mA

V/μs

μA

V

μA

Rev 12.0

6

PD-97657

IR3840WMPbF

Electrical Specifications (continued)

Unless otherwise specified, these specification apply over 4.5V< Vcc<5.5V, Vin=12V, 0oC<Tj< 125oC.

Typical values are specified at T

Parameter SYM Test Condition Min TYP MAX Units

Thermal Shutdown

Thermal Shutdown

Hysteresis

Power Good

Power Good upper

Threshold

Upper Threshold

Delay

Power Good lower

Threshold

Lower Threshold

Delay

Delay Comparator

Threshold

Delay Comparator

Hysteresis

PGood Voltage Low PG(voltage) I

Leakage Current I

VPG(upper) Fb Rising 0.770 0.805 0.840 V

VPG(upper)_Dly Fb Rising 256/Fs s

VPG(lower) Fb Falling 0.560 0.595 0.630 V

VPG(lower)_Dly Fb Falling 256/Fs s

PG(Delay) Relative to charge voltage, SS rising 2 2.1 2.3 V

Delay(hys)

leakage

= 25oC.

a

Note4 140

Note4 20

Note4

=-5mA 0.5 V

PGood

0 10

260 300 340 mV

o

μA

C

Switch Node

Isw

SW=0V, Enable=0V SW Bias Current

SW=0V,Enable=high,SS=3V,Vseq=0V,

Note4

6

μA

Note3: Cold temperature performance is guaranteed via correlation using statistical quality control. Not tested in production.

Note4: Guaranteed by Design but not tested in production.

Note5: Upgrade to industrial/MSL2 level applies from date codes 1227 (marking explained on application note AN1132

Products with prior date code of 1227 are qualified with MSL3 for Consumer market.

page 2).

Rev 12.0

7

V

PD-97657

IR3840WMPbF

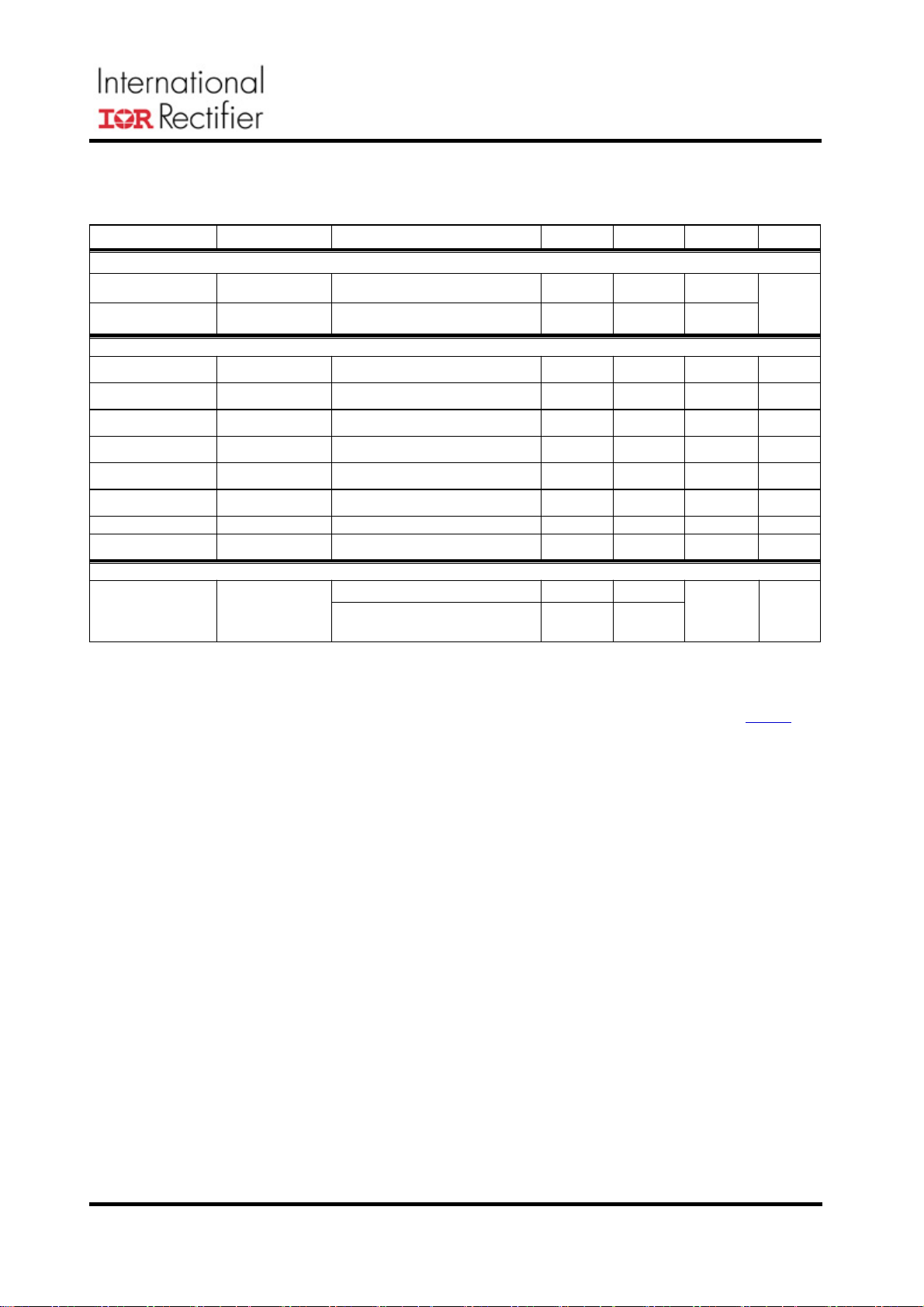

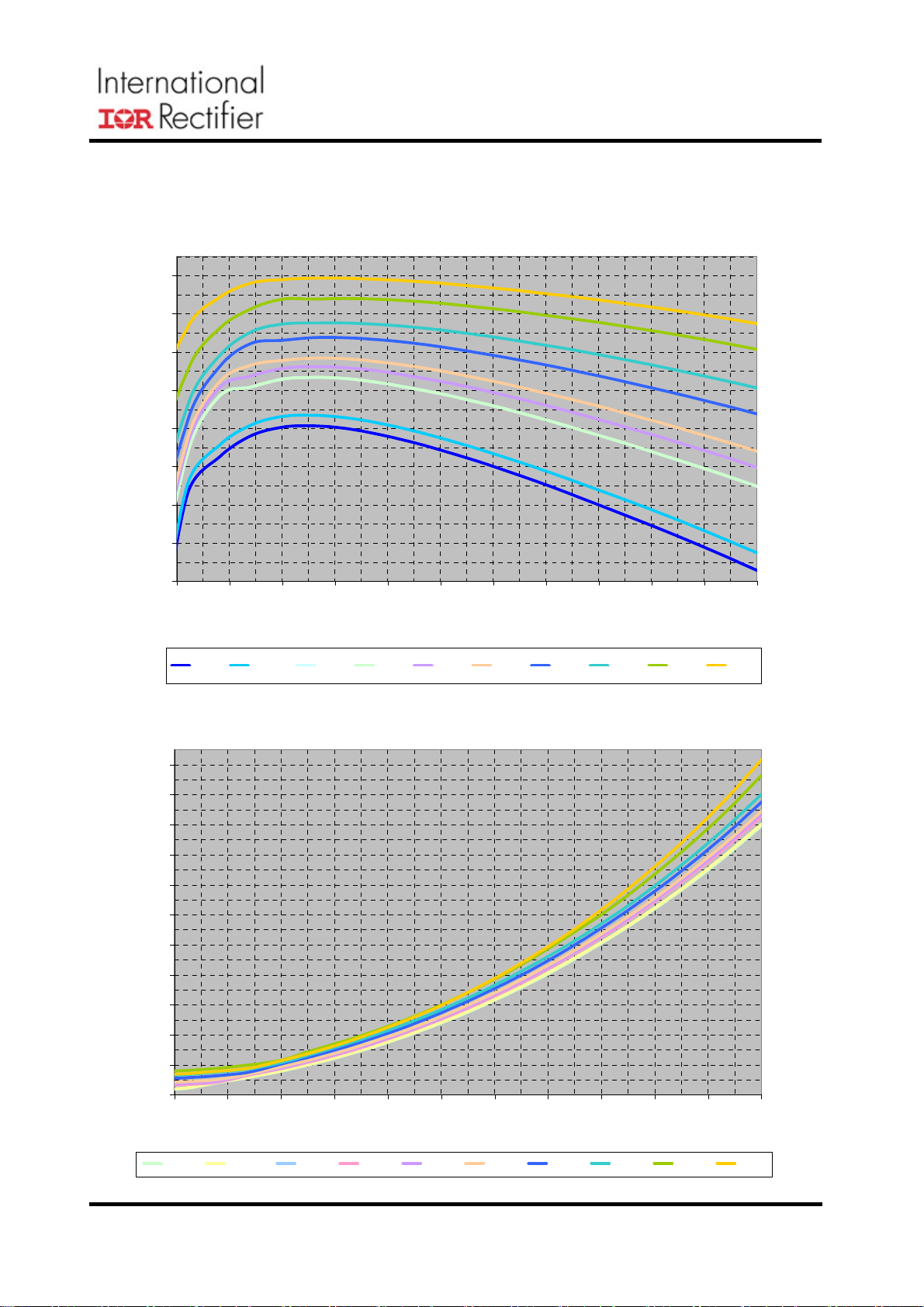

Typical Efficiency and Power Loss Curves

Vin=12V, Vcc=5V, Io=2A-12A, F

=600kHz, Room Temperature, No Air Flow

s

The table below shows the inductors used for each of the output voltages

in the efficiency measurement.

o (V) L (uH) P/N DCR (mOHm)

0.9 0.3 59PR9874N 0.29

1.0 0.3 59PR9874N 0.29

1.1 0.4 59PR9875N 0.29

1.2 0.4 59PR9875N 0.29

1.5 0.5 59PR9876N 0.29

1.8 0.5 59PR9876N 0.29

2.5 0.6 MPL104-0R6 1.5

3.3 1.0 MPL105-1R0 2.3

5.0 1.0 MPL105-1R0 2.3

98

96

94

92

90

88

Efficiency (%)

86

84

82

80

23456789101112

Load Current (A)

0.9V 1.0V 1.1V 1.2V 1.5V 1.8V 2.5V 3.3V 5.0V

3.2

3.0

2.8

2.6

2.4

2.2

2.0

1.8

1.6

1.4

1.2

Power Loss (W)

1.0

0.8

0.6

0.4

0.2

123456789101112

Load Current (A)

0.9V 1.0V 1.1V 1.2V 1.5V 1.8V 2.5V 3.3V 5.0V

Rev 12.0

8

PD-97657

IR3840WMPbF

Typical Efficiency and Power Loss Curves

Vin=5V, Vcc=5V, Io=1A-12A, Fs=600kHz, Room Temperature, No Air Flow

For all the output voltages, L=0.3uH (DCR=0.29 mΩ, P/N: 59PR9874N)

97

95

93

91

89

Efficiency (%)

87

85

83

81

1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0

Load Current (A)

0.7V 0.75V 0.9V 1.0V 1.1V 1.2V 1.5V 1.8V 2.5V 3.3V

2.3

2.1

1.9

1.7

1.5

1.3

1.1

0.9

Power Loss (W)

0.7

0.5

0.3

0.1

Rev 12.0

123456789101112

Load Current (A)

0.7V 0.75V 0.9V 1.0V 1.1V 1.2V 1.5V 1.8V 2.5V 3.3V

9

PD-97657

IR3840WMPbF

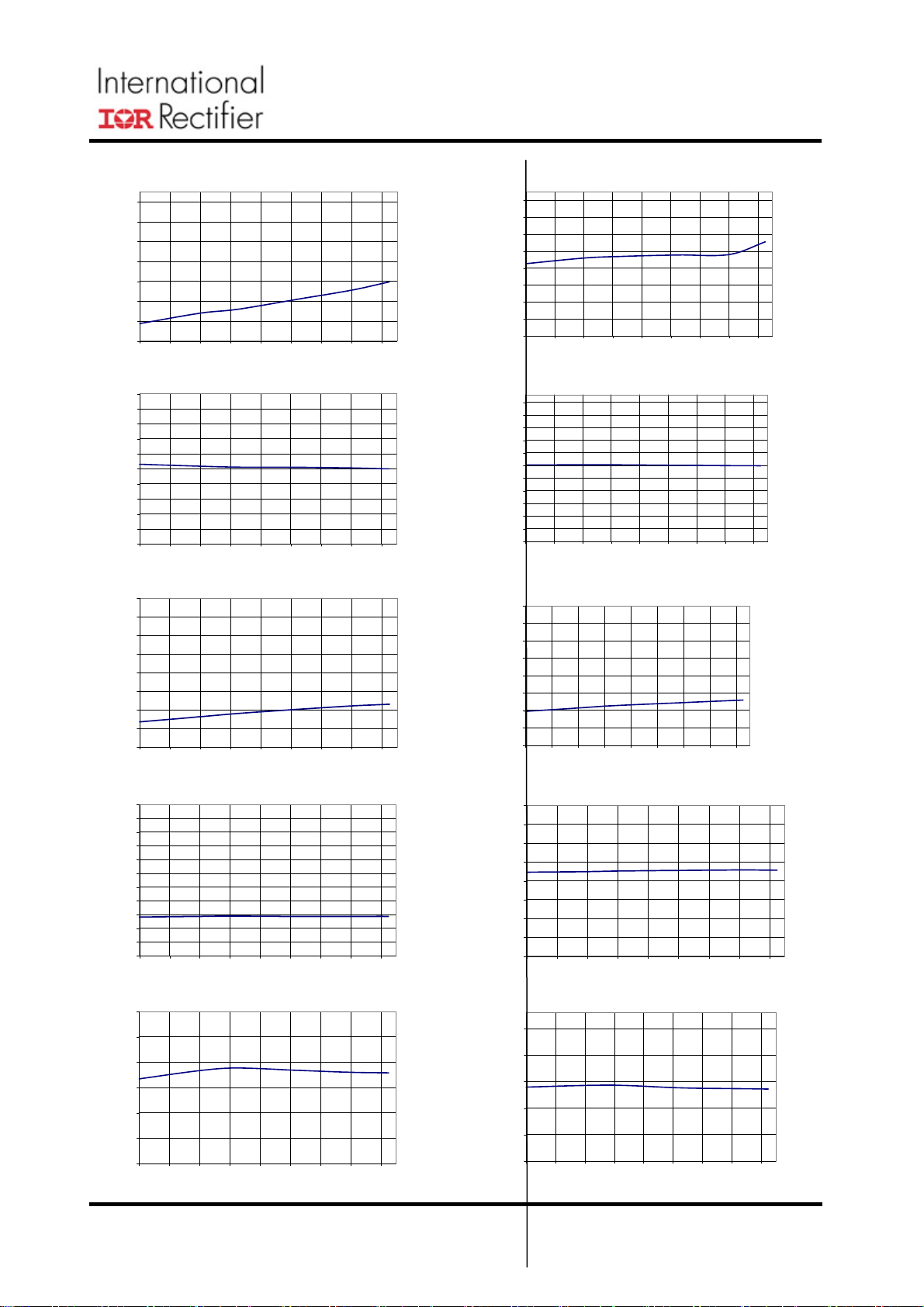

TYPICAL OPERATING CHARACTERISTICS (-40oC - 125oC) Fs=500 kHz

Icc(Standby)

290

270

250

230

[uA]

210

190

170

150

-40 -20 0 20 40 60 80 100 120

550

540

530

520

510

500

[kHz]

490

480

470

460

450

-40 -20 0 20 40 60 80 100 120

4.46

4.41

4.36

4.31

4.26

[V]

4.21

4.16

4.11

4.06

-40-200 20406080100120

Temp[ oC]

FREQUENCY

Temp[

Vcc(UVLO) Start

o

C]

Temp[ oC]

1.36

Enable(UVLO) Start

1.34

1.32

1.30

1.28

1.26

[V]

1.24

1.22

1.20

1.18

1.16

1.14

-40 -20 0 20 40 60 80 100 120

Temp[ oC]

26.0

24.0

22.0

20.0

[uA]

18.0

16.0

14.0

-40-200 20406080100120

ISS

Temp[ oC]

13.5

12.5

11.5

10.5

9.5

[mA]

8.5

7.5

6.5

5.5

-40-200 20406080100120

54.0

53.0

52.0

51.0

50.0

49.0

[uA]

48.0

47.0

46.0

45.0

44.0

43.0

-40-20 0 20406080100120

4.16

4.11

4.06

4.01

3.96

[V]

3.91

3.86

3.81

3.76

-40-20 0 20406080100120

1.06

1.04

1.02

1.00

0.98

[V]

0.96

0.94

0.92

0.90

-40 -20 0 20 40 60 80 100 120

711

706

701

[mV]

696

691

686

-40-20 0 20406080100120

Icc(Dyn)

Temp[ oC]

IOCSET(500kHz)

Temp[ oC]

Vcc(UVLO) Stop

Temp[ oC]

Enable(UVLO) Stop

Temp[

Vfb

Temp[ oC]

ο

C]

Rev 12.0

10

PD-97657

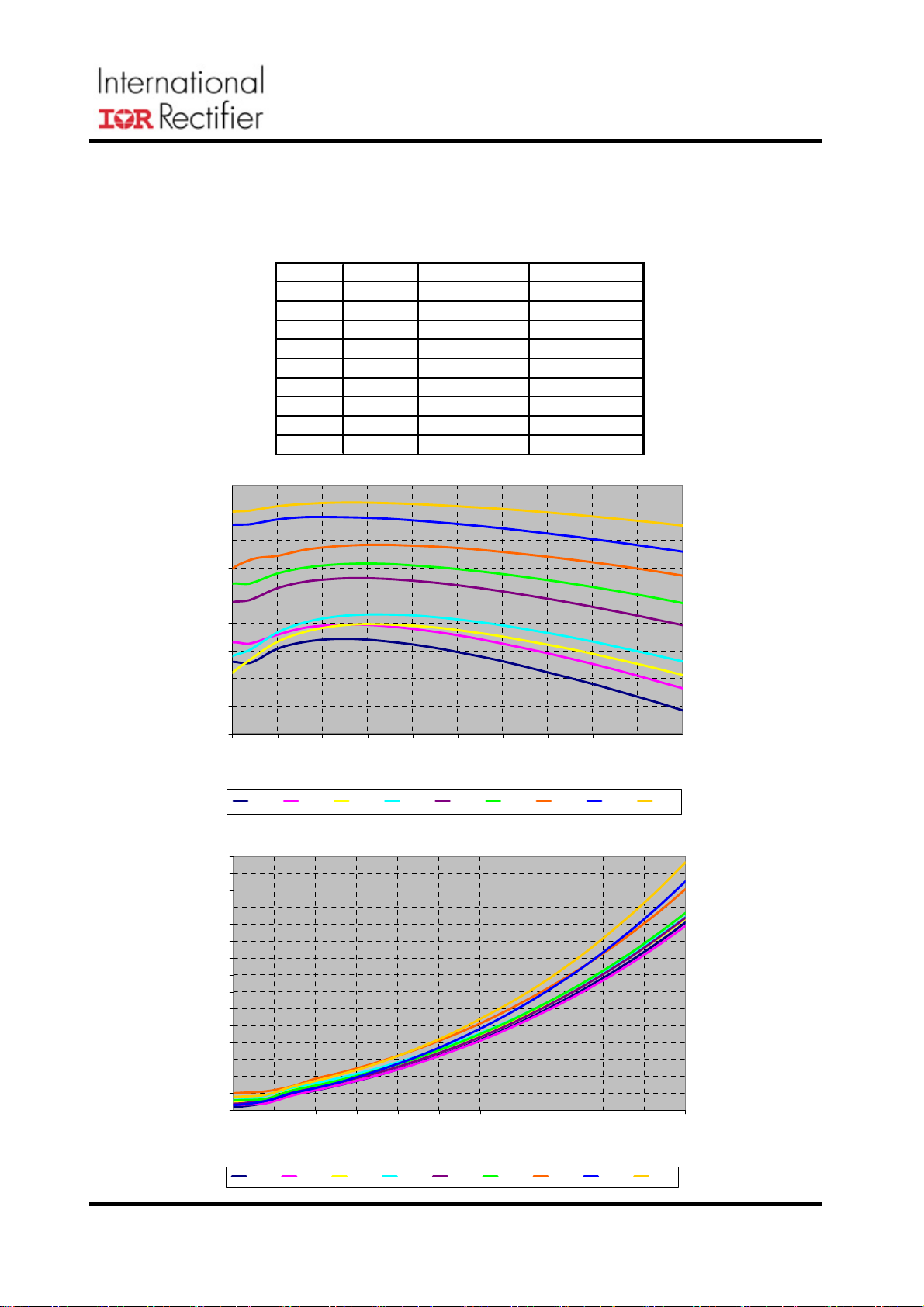

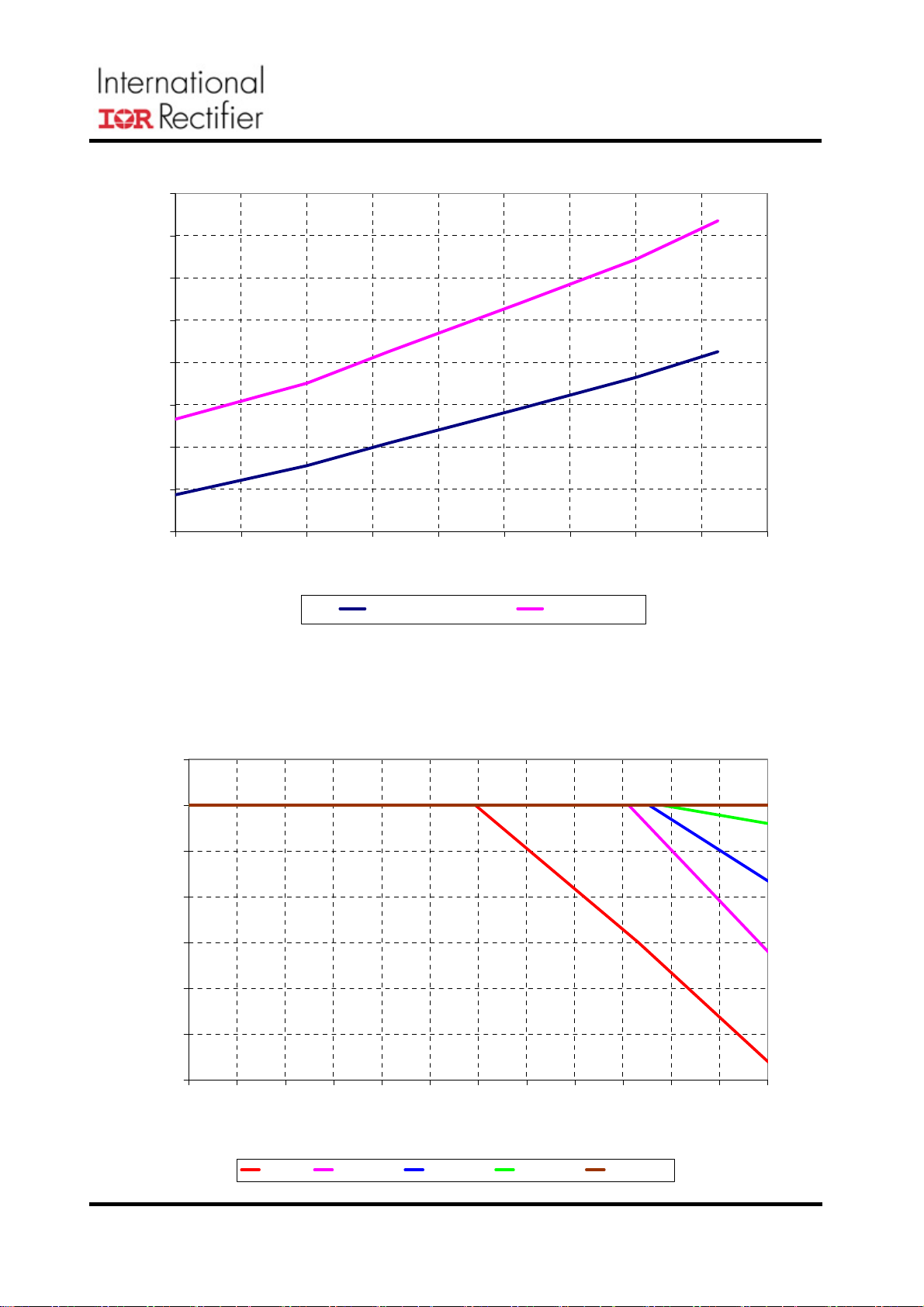

Rdson of MOSFETs Over Temperature at Vcc=5V

12

11

10

]

Ω

9

8

7

Resistance [m

6

5

4

-40 -20 0 20 40 60 80 100 120 140

Temperature [°C]

IR3840WMPbF

Sync-FET Ctrl-FET

Thermal De-rating Curves

Test Conditions: Vin=12V, Vout=1.8V, Vcc=5V, Fs=600kHz, 0- 400LFM

L=0.6uH (MPL104-0R6IR)

12.5

12

11.5

11

10.5

10

Maximum Load Curent (A)

9.5

Rev 12.0

9

25 30 35 40 45 50 55 60 65 70 75 80 85

Ambient Temperature [°C]

0 LFM 100 LFM 200 LFM 300 LFM 400 LFM

11

PD-97657

Circuit Description

THEORY OF OPERATION

Introduction

The IR3840W uses a PWM voltage mode control

scheme with external compensation to provide

good noise immunity and maximum flexibility in

selecting inductor values and capacitor types.

The switching frequency is programmable from

250kHz to 1.5MHz and provides the capability of

optimizing the design in terms of size and

performance.

IR3840W provides precisely regulated output

voltage programmed via two external resistors

from 0.7V to 0.9*Vin.

The IR3840W operates with an external bias

supply from 4.5V to 5.5V, allowing an extended

operating input voltage range from 1.5V to 16V.

IR3840WMPbF

If the input to the Enable pin is derived from the

bus voltage by a suitably programmed resistive

divider, it can be ensured that the IR3840W does

not turn on until the bus voltage reaches the

desired level. Only after the bus voltage reaches

or exceeds this level will the voltage at Enable

pin exceed its threshold, thus enabling the

IR3840W. Therefore, in addition to being a logic

input pin to enable the IR3840W, the Enable

feature, with its precise threshold, also allows the

user to implement an Under-Voltage Lockout for

the bus voltage V

for high output voltage applications, where we

might want the IR3840W to be disabled at least

until V

exceeds the desired output voltage level.

in

. This is desirable particularly

in

The device utilizes the on-resistance of the low

side MOSFET as current sense element, this

method enhances the converter’s efficiency and

reduces cost by eliminating the need for external

current sense resistor

IR3840W includes two low R

using IR’s HEXFET technology. These are

specifically designed for high efficiency

applications.

Under-Voltage Lockout and POR

The under-voltage lockout circuit monitors the

input supply Vcc and the Enable input. It assures

that the MOSFET driver outputs remain in the off

state whenever either of these two signals drop

below the set thresholds. Normal operation

resumes once Vcc and Enable rise above their

thresholds.

The POR (Power On Ready) signal is generated

when all these signals reach the valid logic level

(see system block diagram). When the POR is

asserted the soft start sequence starts (see soft

start section).

.

MOSFETs

ds(on)

Fig. 3a. Normal Start up, Device turns on

when the Bus voltage reaches 10.2V

Figure 3b. shows the recommended start-up

sequence for the non-sequenced operation of

IR3840W, when Enable is used as a logic input.

Enable

The Enable features another level of flexibility for

start up. The Enable has precise threshold which

is internally monitored by Under-Voltage Lockout

(UVLO) circuit. Therefore, the IR3840W will turn

on only when the voltage at the Enable pin

exceeds this threshold, typically, 1.2V.

Rev 12.0

Fig. 3b. Recommended startup sequence,

Non-Sequenced operation

12

(

PD-97657

Figure 3c. shows the recommended startup

sequence for sequenced operation of IR3840W

with Enable used as logic input.

Fig. 3c. Recommended startup sequence,

Sequenced operation

Pre-Bias Startup

IR3840W is able to start up into pre-charged

output, which prevents oscillation and

disturbances of the output voltage.

The output starts in asynchronous fashion and

keeps the synchronous MOSFET off until the first

gate signal for control MOSFET is generated.

Figure 4 shows a typical Pre-Bias condition at

start up.

The synchronous MOSFET always starts with a

narrow pulse width and gradually increases its

duty cycle with a step of 25%, 50%, 75% and

100% until it reaches the steady state value. The

number of these startup pulses for the

synchronous MOSFET is internally programmed.

Figure 5 shows a series of 32, 16, 8 startup

pulses.

IR3840WMPbF

Fig. 5. Pre-Bias startup pulses

Soft-Start

The IR3840W has a programmable soft-start to

control the output voltage rise and to limit the

current surge at the start-up. To ensure correct

start-up, the soft-start sequence initiates when

the Enable and Vcc rise above their UVLO

thresholds and generate the Power On Ready

(POR) signal. The internal current source

(typically 20uA) charges the external capacitor

C

linearly from 0V to 3V. Figure 6 shows the

ss

waveforms during the soft start.

The start up time can be estimated by:

)

C

*0.7-1.4

T =

start

During the soft start the OCP is enabled to

protect the device for any short circuit and over

current condition.

SS

μ

A20

(1) --------------------

Fig. 6. Theoretical operation waveforms

during soft-start

Fig. 4. Pre-Bias startup

Rev 12.0

13

∗

=

PD-97657

Operating Frequency

The switching frequency can be programmed

between 250kHz – 1500kHz by connecting an

external resistor from R

tabulates the oscillator frequency versus R

Table 1. Switching Frequency and I

External Resistor (R

(kΩ)

(kΩ)

t

t

pin to Gnd. Table 1

t

)

t

I

I

ocset

ocset

29.430047.5

29.430047.5

39.240035.7

39.240035.7

48.750028.7

48.750028.7

59.0760023.7

59.0760023.7

68.270020.5

68.270020.5

78.680017.8

78.680017.8

88.690015.8

88.690015.8

97.9100014.3

97.9100014.3

110.2110012.7

110.2110012.7

121.7120011.5

121.7120011.5

130.8130010.7

130.8130010.7

143.414009.76

143.414009.76

150.315009.31

150.315009.31

OCSet

(μA)Fs (kHz)R

(μA)Fs (kHz)R

.

t

vs.

IR3840WMPbF

1400

I

OCSet

Table 1. shows I

frequencies. The internal current source

develops a voltage across R

side MOSFET is turned on, the inductor current

flows through the Q2 and results in a voltage at

OCSet which is given by:

Fig. 7. Connection of over current sensing resistor

)μA(Ω=

)(k

R

t

at different switching

OCSet

. When the low

OCSet

OCSetOCSetOCSet

RRIV

∗−

L

)

(onDS

.(3).......... ) () (

)2.....(..............................

I

Shutdown

The IR3840W can be shutdown by pulling the

Enable pin below its 1 V threshold. This will tristate both, the high side driver as well as the low

side driver. Alternatively, the output can be

shutdown by pulling the soft-start pin below 0.3V.

Normal operation is resumed by cycling the

voltage at the Soft Start pin.

Over-Current Protection

The over current protection is performed by

sensing current through the R

DS(on)

of low side

MOSFET. This method enhances the converter’s

efficiency and reduces cost by eliminating a

current sense resistor. As shown in figure 7, an

external resistor (R

) is connected between

OCSet

OCSet pin and the switch node (SW) which sets

the current limit set point.

An internal current source sources current (I

OCSet

) out of the OCSet pin. This current is a function

of the switching frequency and hence, of R

.

t

An over current is detected if the OCSet pin goes

below ground. Hence, at the current limit

threshold, V

setting I

Limit,ROCSet

R

OCSet

=

=0. Then, for a current limit

OCset

is calculated as follows:

*

IR

)(

LimitonDS

I

OCSet

(4) ........................

An overcurrent detection trips the OCP

comparator, latches OCP signal and cycles the

soft start function in hiccup mode.

The hiccup is performed by shorting the soft-start

capacitor to ground and counting the number of

switching cycles. The Soft Start pin is held low

until 4096 cycles have been completed. The

OCP signal resets and the converter recovers.

After every soft start cycle, the converter stays in

this mode until the overload or short circuit is

removed.

The OCP circuit starts sampling current typically

160 ns after the low gate drive rises to about 3V.

This delay functions to filter out switching noise.

Rev 12.0

14

PD-97657

Thermal Shutdown

Temperature sensing is provided inside

IR3840W. The trip threshold is typically set to

o

140

C. When trip threshold is exceeded, thermal

shutdown turns off both MOSFETs and

discharges the soft start capacitor.

Automatic restart is initiated when the sensed

temperature drops within the operating range.

There is a 20

shutdown threshold.

Output Voltage Sequencing

The IR3840W can accommodate user

programmable sequencing options using Seq,

Enable and Power Good pins.

o

C hysteresis in the thermal

Vo1

Vo2

1.5V <Vin<16V

4.5V <Vcc<5.5V

PGood

1.5V <Vin<16V

4.5V <Vcc<5.5V

Vo(master)

PGood

RE

RF

Vcc

PGood

Seq

Rt

SS/ SD

IR3840WMPbF

Enable

Vcc

PGood

Seq

Rt

SS/ SD

Gnd

Enable

Gnd

Vin

PGnd

Vin

PGnd

Boot

SW

OCSet

Fb

Comp

Boot

SW

OCSet

Fb

Comp

Vo(master)

RA

RB

Vo(slave)

RC

RD

Simultaneous Powerup

Fig. 8a. Simultaneous Power-up of the slave

with respect to the master.

Through these pins, voltage sequencing such as

simultaneous and sequential can be

implemented. Figure 8. shows simultaneous

sequencing configurations. In simultaneous

power-up, the voltage at the Seq pin of the slave

reaches 0.7V before the Fb pin of the master. For

R

E/RF=RC/RD

, therefore, the output voltage of

the slave follows that of the master until the

voltage at the Seq pin of the slave reaches 0.7 V.

After the voltage at the Seq pin of the slave

exceeds 0.85V, the internal 0.7V reference of

the slave dictates its output voltage.

Fig. 8b. Application Circuit for Simultaneous

Sequencing

Power Good Output

The IC continually monitors the output voltage via

Feedback (Fb pin). The feedback voltage forms

an input to a window comparator whose upper

and lower thresholds are 0.805V and 0.595V

respectively. Hence, the Power Good signal is

flagged when the Fb pin voltage is within the

PGood window, i. e., between 0.595V to 0.805V,

as shown in Fig .9 The PGood pin is open drain

and it needs to be externally pulled high. High

state indicates that output is in regulation. Fig. 9a

shows the PGood timing diagram for nontracking operation. In this case, during startup,

PGood goes high after the SS voltage reaches

2.1V if the Fb voltage is within the PGood

comparator window. Fig. 9a. and Fig 9.b. also

show a 256 cycle delay between the Fb voltage

entering within the thresholds defined by the

PGood window and PGood going high.

Rev 12.0

15

PD-97657

IR3840WMPbF

TIMING DIAGRAM OF PGOOD FUNCTION

Fig.9a IR3840W Non-Tracking Operation (Seq=Vcc)

Rev 12.0

Fig.9b IR3840W Tracking Operation

16

PD-97657

Minimum on time Considerations

The minimum ON time is the shortest amount of

time for which the Control FET may be reliably

turned on, and this depends on the internal

timing delays. For the IR3840W, the typical

minimum on-time is specified as 50 ns.

Any design or application using the IR3840W

must ensure operation with a pulse width that is

higher than this minimum on-time and preferably

higher than 100 ns. This is necessary for the

circuit to operate without jitter and pulseskipping, which can cause high inductor current

ripple and high output voltage ripple.

D

t

on

In any application that uses the IR3840W, the

following condition must be satisfied:

(min)

t

(min)

on

The minimum output voltage is limited by the

reference voltage and hence V

Therefore, for V

=

F

=

in

tt

≤

≤∴

FV

sin

out(min)

s

V

out

V

×

onon

V

V

≤×∴

t

on

= 0.7 V,

F

out

s

×

out

(min)

FV

sin

out(min)

= 0.7 V.

IR3840WMPbF

Maximum Duty Ratio Considerations

A fixed off-time of 200 ns maximum is specified

for the IR3840W. This provides an upper limit on

the operating duty ratio at any given switching

frequency. It is clear, that higher the switching

frequency, the lower is the maximum duty ratio at

which the IR3840W can operate. To allow a

margin of 50ns, the maximum operating duty

ratio in any application using the IR3840W

should still accommodate about 250 ns off-time.

Fig 10. shows a plot of the maximum duty ratio

v/s the switching frequency, with 250 ns off-time.

Max Duty Cycle

95

90

85

80

75

70

65

60

Max Duty Cycle (%)

55

250 450 650 850 1050 1250 1450 1650

Switching Frequency (kH z)

Fig. 10. Maximum duty cycle v/s switching

frequency.

V

V

≤×∴

F

in

s

V

F

in

s

(min)

out

t

on

(min)

V0.7

6

V/s

ns 100

107 ×=≤×∴

Therefore, at the maximum recommended input

voltage 16V and minimum output voltage, the

converter should be designed at a switching

frequency that does not exceed 440 kHz.

Conversely, for operation at the maximum

recommended operating frequency 1.65 MHz

and minimum output voltage, any voltage above

4.2 V may not be stepped down without pulseskipping.

Rev 12.0

17

−

≅

=

PD-97657

Application Information

Design Example:

The following example is a typical application for

IR3840W. The application circuit is shown on

page 23.

V

V

I

ΔV

F

in

V1.8=

o

A12 =

o

54mV

≤

o

s

kHz 600=

max)13.2V ( V 12=

Enabling the IR3840W

As explained earlier, the precise threshold of

the Enable lends itself well to implementation of

a UVLO for the Bus Voltage.

V

in

IR3840W

R

1

Enable

R

2

For a typical Enable threshold of V

R

V

For a V

(min)

=

in (min)

RR

2

RR

+

21

V

min

EN

−

12

==

ENin

VV

EN)in(

=10.2V, R1=49.9K and R2=7.5K is a

good choice.

Programming the frequency

For Fs= 600 kHz, select Rt= 23.7 kΩ, using

Table. 1.

Output Voltage Programming

Output voltage is programmed by reference

voltage and external voltage divider. The Fb pin

is the inverting input of the error amplifier, which

is internally referenced to 0.7V. The divider is

ratioed to provide 0.7V at the Fb pin when the

output is at its desired value. The output voltage

is defined by using the following equation:

⎛

⎜

VV

refo

⎜

⎝

⎞

R

8

⎟

+∗=

1

⎟

R

9

⎠

EN

= 1.2 V

(6) ..........

V

(5) .......... 1.2*

.....(7)..............................

IR3840WMPbF

When an external resistor divider is connected to

the output as shown in figure 11.

Equation (5) can be rewritten as:

⎛

⎜

∗=

RR

89

⎜

⎝

For the calculated values of R8 and R9 see

feedback compensation section.

IR3840W

IR3624

Fig. 11. Typical application of the IR3840W for

programming the output voltage

Soft-Start Programming

The soft-start timing can be programmed by

selecting the soft-start capacitance value. From

(1), for a desired start-up time of the converter,

the soft start capacitor can be calculated by

using:

Where T

is the desired start-up time (ms).

start

For a start-up time of 3.5ms, the soft-start

capacitor will be 0.099μF. Choose a 0.1μF

ceramic capacitor.

Bootstrap Capacitor Selection

To drive the Control FET, it is necessary to

supply a gate voltage at least 4V greater than

the voltage at the SW pin, which is connected

the source of the Control FET . This is achieved

by using a bootstrap configuration, which

comprises the internal bootstrap diode and an

external bootstrap capacitor (C6), as shown in

Fig. 12. The operation of the circuit is as follows:

When the lower MOSFET is turned on, the

capacitor node connected to SW is pulled down

to ground. The capacitor charges towards V

through the internal bootstrap diode, which has a

forward voltage drop V

the bootstrap capacitor C6 is approximately

given as

When the upper MOSFET turns on in the next

cycle, the capacitor node connected to SW rises

to the bus voltage V

C6 is appropriately chosen,

⎞

V

ref

⎟

⎟

−

VV

refo

⎠

V

OUT

R

8

(8) ..................................

Fb

R

9

TC

startSS

. The voltage Vcacross

D

Dccc

. However, if the value of

in

(9) .......... 0.02857 ) ms ( )μF( ×

cc

VVV

(10) ..........................

Rev 12.0

18

Δ

e

PD-97657

the voltage V

unchanged and the voltage at the Boot pin

becomes

Fig. 12. Bootstrap circuit to generate

A bootstrap capacitor of value 0.1uF is suitable

for most applications.

Input Capacitor Selection

The ripple current generated during the on time of

the upper MOSFET should be provided by the

input capacitor. The RMS value of this ripple is

expressed by:

V

D =

V

Where:

D is the Duty Cycle

is the RMS value of the input capacitor

I

RMS

current.

Io is the output current.

For I

=12A and D = 0.15, the I

o

Ceramic capacitors are recommended due to

their peak current capabilities. They also feature

low ESR and ESL at higher frequency which

enables better efficiency. For this application, it is

advisable to have 4x10uF 16V ceramic capacitors

ECJ-3YX1C106K from Panasonic. In addition to

these, although not mandatory, a 1X330uF, 25V

SMD capacitor EEV-FK1E331P may also be

used as a bulk capacitor and is recommended if

the input power supply is not located close to the

converter.

across C6 remains approximately

c

VVVV −+≅

DccinBoot

Vc voltage

oRMS

o

in

−∗∗= 1

RMS

....(12)....................)( DDII

(13) ................................

= 4.28A.

IR3840WMPbF

Inductor Selection

The inductor is selected based on output power,

operating frequency and efficiency requirements.

A low inductor value causes large ripple current,

(11) ........................................

resulting in the smaller size, faster response to a

load transient but poor efficiency and high output

noise. Generally, the selection of the inductor

value can be reduced to the desired maximum

ripple current in the inductor . The optimum

point is usually found between 20% and 50%

ripple of the output current.

For the buck converter, the inductor value for the

desired operating ripple current can be

determined using the following relation:

i

oin

()

t

Δ

VVL

∗−=

oin

Δ

LVV

∗=−

Dt

;

∗=Δ

F

V

o

FiV

Δ∗

*

sin

Where:

=

V

in

=

V

o

=

Δi

=

F

s

=

Δt

=

D

If Δi ≈ 35%(I

VoltageOutput

time on Turn

cycleDuty

), then the output inductor is

o

input Maximum

current ripple Inductor

frequency Switching

calculated to be 0.607μH. Select L=0.6 μH.

The MPL104-0R6 from Delta provides a compact,

low profile inductor suitable for this application.

)( i

1

s

voltag

(14) ...............................

.

Rev 12.0

19

Δ

PD-97657

Output Capacitor Selection

The voltage ripple and transient requirements

determine the output capacitors type and values.

The criteria is normally based on the value of the

Effective Series Resistance (ESR). However the

actual capacitance value and the Equivalent Series

Inductance (ESL) are other contributing

components. These components can be described

as

+Δ+Δ=Δ

VVVV

)()()(

CoESLoESRoo

Δ=Δ

*

)(

⎛

⎜

V

V

o

=Δ

)(

ESLo

⎜

⎝

=Δ

V

)(

Co

=Δ

ESRIV

LESRo

−

VV

⎞

oin

⎟

*

ESL

⎟

L

⎠

Δ

I

L

FC

**

8

so

ripple voltage Output

IR3840WMPbF

The output LC filter introduces a double pole,

–40dB/decade gain slope above its corner

resonant frequency, and a total phase lag of 180

(see figure 13). The resonant frequency of the LC

filter is expressed as follows:

=

LC

Figure 13 shows gain and phase of the LC filter.

Since we already have 180

output filter alone, the system runs the risk of

being unstable.

Gain

(15) .........................

0 dB

1

π

2

-40dB/decade

CLF∗∗

oo

o

phase shift from the

Phase

0

0

o

(16) ................................

=Δ

I

L

current ripple Inductor

Since the output capacitor has a major role in the

overall performance of the converter and

determines the result of transient response,

selection of the capacitor is critical. The

IR3840W can perform well with all types of

capacitors.

As a rule, the capacitor must have low enough

ESR to meet output ripple and load transient

requirements.

The goal for this design is to meet the voltage

ripple requirement in the smallest possible

capacitor size. Therefore it is advisable to select

ceramic capacitors due to their low ESR and ESL

and small size. Six of the Panasonic ECJ2FB0J226ML (22uF, 6.3V, 3mOhm) capacitors is

a good choice.

Feedback Compensation

The IR3840W is a voltage mode controller. The

control loop is a single voltage feedback path

including error amplifier and error comparator. To

achieve fast transient response and accurate

output regulation, a compensation circuit is

necessary. The goal of the compensation

network is to provide a closed-loop transfer

function with the highest 0 dB crossing frequency

o

and adequate phase margin (greater than 45

).

0

F

LC

Frequency

-180

F

LC

Frequency

Fig. 13. Gain and Phase of LC filter

The IR3840W uses a voltage-type error amplifier

with high-gain (110dB) and wide-bandwidth. The

output of the amplifier is available for DC gain

control and AC phase compensation.

The error amplifier can be compensated either in

type II or type III compensation.

Local feedback with Type II compensation is

shown in Fig. 14.

This method requires that the output capacitor

should have enough ESR to satisfy stability

requirements. In general the output capacitor’s

ESR generates a zero typically at 5kHz to 50kHz

which is essential for an acceptable phase

margin.

The ESR zero of the output capacitor is

expressed as follows:

F

ESR

=

∗

2

1

*ESR*C

π

o

(17) ...........................

Rev 12.0

20

=

PD-97657

Fig. 14. Type II compensation network

and its asymptotic gain plot

IR3840WMPbF

Where:

= Maximum Input Voltage

V

in

= Oscillator Ramp Voltage

V

osc

= Crossover Frequency

F

o

= Zero Frequency of the Output Capacitor

F

ESR

= Resonant Frequency of the Output Filter

F

LC

= Feedback Resistor

R

8

To cancel one of the LC filter poles, place the

zero before the LC filter resonant frequency pole:

FF

%

LCz

F

75075=

z

Use equations (20), (21) and (22) to calculate

C4.

One more capacitor is sometimes added in

parallel with C4 and R3. This introduces one

more pole which is mainly used to suppress the

switching noise.

The additional pole is given by:

1

*.

2

CL

π

*

oo

(22) .....................................

The transfer function (Ve/Vo) is given by:

1

V

e

V

o

Z

f

sH

Z

IN

CsR

+

−=−==

43

CsR

48

(18) ..... )(

The (s) indicates that the transfer function varies

as a function of frequency. This configuration

introduces a gain and zero, expressed by:

R

3

()

sH

=

R

8

F

z

1

=

2

π

CR

**

43

(19) ............................. .........

(20) ............................

First select the desired zero-crossover frequency

):

(F

o

≤>

()

o

FFF *1/10~1/5 F and

sESRo

Use the following equation to calculate R3:

***

RFFV

ESRoosc

R =

3

8

2

*

FV

LCin

(21) ...........................

F+=

P

2

π

1

*

CC

POLE

4

**

R

3

CC

POLE

4

...(23)..............................

The pole sets to one half of the switching

frequency which results in the capacitor C

C

POLE

=

1

1

−

*F*R

π

s

3

C

4

1

≅

*F*R

π

s

3

POLE

:

(24)......................

For a general solution for unconditional stability

for any type of output capacitors, and a wide

range of ESR values, we should implement local

feedback with a type III compensation network.

The typically used compensation network for

voltage-mode controller is shown in figure 15.

Again, the transfer function is given by:

By replacing Z

V

e

V

o

and Zfaccording to figure 15,

in

Z

sH

f

−== )(

Z

IN

the transfer function can be expressed as:

[]

−

=

)(

sH

)(

⎡

++

)(

sRCCsR

⎢

⎢

⎣

()

11

⎛

⎜

3348

⎜

⎝

+++

RRsCCsR

108743

⎤

⎞

*

CC

34

⎟

11

+

⎥

⎟

+

CC

⎥

34

⎠

⎦

CsR

710

(25) ....

)(

Rev 12.0

21

(

PD-97657

OUT

C

10

R

Gain(dB)

V

3

C

7

8

R

Fb

9

R

REF

V

3

R

E/A

C

IN

Z

H(s) dB

1

Z

F

2

Z

F

2

P

F

P

F

Fig.15. Type III Compensation network and

its asymptotic gain plot

4

Comp

Frequency

3

IR3840WMPbF

Compensator

Compensator

Type

Type

f

Z

Type III

Ve

Type III

F

F

vs F

vs F

ESR

ESR

F

F

LC<FES R<Fo<Fs

LC<FES R<Fo<Fs

F

F

LC<Fo<FESR

LC<Fo<FESR

The higher the crossover frequency, the

potentially faster the load transient response.

However, the crossover frequency should be low

enough to allow attenuation of switching noise.

Typically, the control loop bandwidth or crossover

frequency is selected such that

)

F F *1/10~1/5≤

so

The DC gain should be large enough to provide

high DC-regulation accuracy. The phase margin

should be greater than 45

o

for overall stability.

o

o

Output

Output

Capacitor

Capacitor

Electrolytic

Electrolytic

/2Type II

/2Type II

Tantalum

Tantalum

Tantalum

Tantalum

Ceramic

Ceramic

The compensation network has three poles and

two zeros and they are expressed as follows:

0

F

=

P

1

F

=

P

2

=

F

P

3

F

=

Z

1

F

=

Z

2

1

2

π

2

π

CR

**

710

1

⎛

⎜

R

*

3

⎜

⎝

≅

⎞

CC

*

34

⎟

⎟

CC

+

34

⎠

1

2

π

CR

**

1

2

π

2

CR

**

43

1

≅

+

1

2

ππ

**)(**

......(26)............................................................

) .......(27........................................

(28) ...............

33

.....(29)........................................

RCRRC

871087

(30)..........

Cross over frequency is expressed as:

V

=

o

in

CRF

73

1

***

**

CLV

π

2

ooosc

(31) ................................

Based on the frequency of the zero generated by

the output capacitor and its ESR, relative to

crossover frequency, the compensation type can

be different. The table below shows the

compensation types for relative locations of the

crossover frequency.

For this design we have:

V

=12V

in

V

=1.8V

o

V

=1.8V

osc

V

=0.7V

ref

L

=0.6uH

o

C

=6x22uF, ESR=3mOhm each

o

It must be noted here that the value of the

capacitance used in the compensator design

must be the small signal value. For instance, the

small signal capacitance of the 22uF capacitor

used in this design is 12uF at 1.8 V DC bias and

600 kHz frequency. It is this value that must be

used for all computations related to the

compensation. The small signal value may be

obtained from the manufacturer’s datasheets,

design tools or SPICE models. Alternatively, they

may also be inferred from measuring the power

stage transfer function of the converter and

measuring the double pole frequency F

LC

and

using equation (16) to compute the small signal

C

.

o

These result to:

F

=24.2 kHz

LC

F

=4.4 MHz

ESR

F

/2=300 kHz

s

Select crossover frequency F

Since FLC<Fo<Fs/2<F

ESR

=100 kHz

o

, TypeIII is selected to

place the pole and zeros.

Rev 12.0

22

PD-97657

Detailed calculation of compensation TypeIII

o

=Θ

70 Margin Phase Desired

Θ−

sin

1

=

FF

oZ

2

1

1

=

FF

oP

2

1

3

R

3

FF

=

7

π

2

R

3

=

Θ+

sin

Θ+

sin

=

Θ−

sin

50

FF

ZZ

==

sP

kHz 17.63

kHz 567.1

==

21

and kHz 8.82 *. :Select

kHz 300*0.5

nF 2.2C :Select

: and , Calculate

CCR

433

*

VCLF

***

oscooo

R

*

VC

in

7

k 1.87 :Select

Ω=

3

kΩ 1.85;

==

IR3840WMPbF

Programming the Current-Limit

The Current-Limit threshold can be set by

connecting a resistor (R

to the OCSet pin. The resistor can be calculated

by using equation (4). This resistor R

be placed close to the IC.

The R

DS(on)

has a positive temperature

coefficient and it should be considered for the

worst case operation.

∗

R

==

==≅

*

==

sOCSet

OCSet

II

)on(DS

==

)(

criticalLSET

75

*

)LIM(oSET

Setting the Power Good Threshold

A window comparator internally sets a lower

Power Good threshold at 0.6V and an upper

Power Good threshold at 0.8V. When the voltage

at the FB pin is within the window set by these

thresholds, PGood is asserted.

) from the SW pin

OCSET

IR

OCSetOCSet

)(

onDS

mΩ 7.1251.25mΩ .R

A 181.5A 12II

kHz) 600F (at μA 59.07I

kΩ 2.15R Select kΩ 2.17R

==

7

OCSET

) current output nominal over (50%

must

(32) .......................

C

4

1

**2

π

RF

Z

1

3

CC

nF 10 :Select nF, 9.65 ;

===

44

The PGood is an open drain output. Hence, it is

necessary to use a pull up resistor R

PG

from

PGood pin to Vcc. The value of the pull-up

C

3

1

**

π

2

RF

P

33

CC

33

pF 220 :Select ,pF 283.7 ;

===

resistor must be chosen such as to limit the

current flowing into the PGood pin, when the

output voltage is not in regulation, to less than 5

mA. A typical value used is 10kΩ.

: and , Calculate

RRR

9810

R

10

R

8

1

FC

**

π

2

2

π

P

27

1

-

RR

==

FC

**

Z

27

810

RR

1010

Ω 130 :Select ,Ω 128 ;

===

,kΩ 3.97 ;

R

8

V

R

ref

VV

-

kΩ 3.92:Select

=

RRR

refo

9989

kΩ 2.49 :Select kΩ 2.49 ;*

===

Rev 12.0

23

PD-97657

Application Diagram:

IR3840WMPbF

Fig. 16. Application circuit diagram for a 12V to 1.8 V, 12 A Point Of Load Converter

Suggested Bill of Materials for the application circuit:

Part Reference Quantity Value Description Manufacturer Part Number

Cin

Lo 1 0.6uH 11.5x10x4mm, 20%, 1.7mOhm Delta MPL104-0R6

Co 6 22uF 0805, 6.3V, X5R, 20% Panasonic ECJ-2FB0J226ML

R1 1 49.9k Thick Film, 0603,1/10 W,1% Rohm MCR03EZPFX4992

R2 1 7.5k Thick Film, 0603,1/10W,1% Rohm MCR03EZPFX7501

R

t

R

ocset

R

PG

C

C6

ss

R3 1 1.87k Thick Film, 0603,1/10W,1% Rohm MCR03EZPFX1871

C3 1 220pF 50V, 0603, NPO, 5% Panasonic ECJ-1VC1H221J

C4 1 10nF 0603, 50V, X7R, 10% Panasonic ECJ-1VB1H103K

R8 1 3.92k Thick Film, 0603,1/10W,1% Rohm MCR03EZPFX3921

R9 1 2.49k Thick Film, 0603,1/10W,1% Rohm MCR03EZPFX2491

R10 1 130 Thick Film, 0603,1/10W,1% Rohm ERJ-3EKF1300V

C7 1 2200pF 0603, 50V, X7R, 10% Panasonic ECJ-1VB1H222K

C

Vcc

U1 1 IR3840W SupIRBuck, 12A, PQFN 5x6mm International Rectifier IR3840WMPbF

1 330uF SMD Elecrolytic, Fsize, 25V, 20% Panasonic EEV-FK1E331P

4 10uF 1206, 16V, X5R, 20% TDK C3216X5R1E106M

1 0.1uF 0603, 25V, X7R, 10% Panasonic ECJ-1VB1E104K

1 23.7k Thick Film, 0603,1/10W,1% Rohm MCR03EZPFX2372

1 2.15k Thick Film, 0603,1/10W,1% Rohm MCR03EZPFX2151

1 10k Thick Film, 0603,1/10W,1% Rohm MCR03EZPFX1002

2 0.1uF 0603, 25V, X7R, 10% Panasonic ECJ-1VB1E104K

1 1.0uF 0603, 16V, X5R, 20% Panasonic ECJ-BVB1C105M

Rev 12.0

24

PD-97657

IR3840WMPbF

TYPICAL OPERATING WAVEFORMS

Vin=12.0V, Vcc=5V, Vo=1.8V, Io=0-12A, Room Temperature, No Air Flow

Fig. 17: Start up at 12A Load

Ch

, Ch2:Vo, Ch3:Vss, Ch4:Enable

1:Vin

Fig. 18: Start up at 12A Load,

Ch

, Ch2:Vo, Ch3:Vss, Ch4:V

1:Vin

PGood

Fig. 19: Start up with 1.62V Pre

Bias, 0A Load, Ch

2:Vo

Fig. 21: Inductor node at 12A load

Ch

:LX

2

Rev 12.0

, Ch3:V

SS

Fig. 20: Output Voltage Ripple, 12A

load Ch

: V

2

out

Fig. 22: Short (Hiccup) Recovery

Ch

1:Vout

, Ch3:V

ss

25

PD-97657

TYPICAL OPERATING WAVEFORMS

Vin=12V, Vcc=5V, Vo=1.8V, Io=6A-12A, Room Temperature, No Air Flow

IR3840WMPbF

Rev 12.0

Fig. 23: Transient Response, 6A to 12A step 2.5A/μs

Ch

2:Vout

, Ch4:I

out

26

PD-97657

TYPICAL OPERATING WAVEFORMS

Vin=12V, Vcc=5V, Vo=1.8V, Io=12A, Room Temperature, No Air Flow

IR3840WMPbF

Fig. 24: Bode Plot at 12A load shows a bandwidth of 99kHz and phase margin of 54

degrees

Rev 12.0

27

PD-97657

Simultaneous Tracking at Power Up and Power Down

Vin=12V, Vo=1.8V, Io=12A, Room Temperature, No Air Flow

3.92K

2.49K

3.3V

IR3840W

R

s1

R

s2

IR3624

Seq

Fb

V

OUT

IR3840WMPbF

3.92K

R

8

2.49K

R

9

Rev 12.0

Fig. 25: Simultaneous Tracking a 3.3V input at power-up and shut-down

Ch2: SS (1.8V) Ch3:Vo Ch4: SEQ

28

PD-97657

Layout Considerations

The layout is very important when designing high

frequency switching converters. Layout will affect

noise pickup and can cause a good design to

perform with less than expected results.

Make all the connections for the power

components in the top layer with wide, copper

filled areas or polygons. In general, it is desirable

to make proper use of power planes and

polygons for power distribution and heat

dissipation.

The inductor, output capacitors and the IR3840W

should be as close to each other as possible.

This helps to reduce the EMI radiated by the

power traces due to the high switching currents

through them. Place the input capacitor directly at

the Vin pin of IR3840W.

The feedback part of the system should be kept

away from the inductor and other noise sources.

The critical bypass components such as

capacitors for Vcc should be close to their

respective pins. It is important to place the

feedback components including feedback

resistors and compensation components close to

Fb and Comp pins.

IR3840WMPbF

The connection between the OCSet resistor and

the Sw pin should not share any trace with the

connection between the bootstrap capacitor and

the Sw pin. Instead, it is recommended to use a

Kelvin connection of the trace from the OCSet

Vin

resistor and the trace from the bootstrap

Vin

capacitor at the Sw pin.

In a multilayer PCB use one layer as a power

ground plane and have a control circuit ground

AGnd

(analog ground), to which all signals are

referenced. The goal is to localize the high

current path to a separate loop that does not

interfere with the more sensitive analog control

AGnd

function. These two grounds must be connected

together on the PC board layout at a single point.

The Power QFN is a thermally enhanced

package. Based on thermal performance it is

recommended to use at least a 4-layers PCB. To

effectively remove heat from the device the

exposed pad should be connected to the ground

plane using vias. Figure 26 illustrates the

implementation of the layout guidelines outlined

above, on the IRDC3840W 4 layer demoboard.

PGnd

PGnd

Vout

Vout

Compensation parts

should be placed as close

as possible to

the Comp pin.

Resistors Rt and

Rocset should be

placed as close as

possible to their pins.

PGnd

Vin

Vin

PGnd

AGnd

AGnd

Fig. 26a. IRDC3840W demoboard layout

considerations – Top Layer

Vout

Vout

Enough copper &

minimum length

ground path between

Input and Output

All bypass caps

should be placed as

close as possible to

their connecting

pins.

Rev 12.0

29

PD-97657

Feedback

trace should

be kept

away form

noise

sources

Analog

Ground

plane

Fig. 26b. IRDC3840W demoboard layout

considerations – Bottom Layer

IR3840WMPbF

PGnd

Single point

connection between

AGND & PGND,

should be close to

the SupIRBuck, kept

away from noise

sources.

Fig. 26c. IRDC3840W demoboard layout

considerations – Mid Layer 1

Power

Vin

Ground

Plane

AGnd

Use separate traces

for connecting Boot

cap and Rocset to the

switch node and with

the minimum length

traces. Avoid big

loops.

Rev 12.0

Fig. 26d. IRDC3840W demoboard layout

considerations – Mid Layer 2

30

PD-97657

IR3840WMPbF

PCB Metal and Components Placement

Lead lands (the 11 IC pins) width should be equal to nominal part lead width. The

minimum lead to lead spacing should be ≥ 0.2mm to minimize shorting.

Lead land length should be equal to maximum part lead length + 0.3 mm outboard

extension. The outboard extension ensures a large and inspectable toe fillet.

Pad lands (the 4 big pads other than the 11 IC pins) length and width should be equal to

maximum part pad length and width. However, the minimum metal to metal spacing

should be no less than 0.17mm for 2 oz. Copper; no less than 0.1mm for 1 oz. Copper

and no less than 0.23mm for 3 oz. Copper.

Rev 12.0

31

PD-97657

IR3840WMPbF

Solder Resist

It is recommended that the lead lands are Non Solder Mask Defined (NSMD). The solder

resist should be pulled away from the metal lead lands by a minimum of 0.025mm to ensure

NSMD pads.

The land pad should be Solder Mask Defined (SMD), with a minimum overlap of the solder

resist onto the copper of 0.05mm to accommodate solder resist mis-alignment.

Ensure that the solder resist in-between the lead lands and the pad land is ≥ 0.15mm due

to the high aspect ratio of the solder resist strip separating the lead lands from the pad land.

Rev 12.0

32

PD-97657

IR3840WMPbF

Stencil Design

• The Stencil apertures for the lead lands should be approximately 80% of the area of

the lead lads. Reducing the amount of solder deposited will minimize the

occurrences of lead shorts. If too much solder is deposited on the center pad the part

will float and the lead lands will be open.

• The maximum length and width of the land pad stencil aperture should be equal to

the solder resist opening minus an annular 0.2mm pull back to decrease the

incidence of shorting the center land to the lead lands when the part is pushed into

the solder paste.

Rev 12.0

33

PD-97657

BOTTOM VIEW

IR3840WMPbF

Rev 12.0

IR WORLD HEADQUARTERS:

This product has been designed and qualified for the Industrial market (Note5)

Data and specifications subject to change without notice. 08/12

233 Kansas St., El Segundo, California 90245, USA Tel: (310) 252-7105

TAC Fax: (310) 252-7903

Visit us at www.irf.com for sales contact information

34

Loading...

Loading...