IRPLCFL8U

Simplified Three Level Dimming CFL Fluorescent

Ballast using the IRS2530D DIM8

Table of Contents

1. Features ...........................................................................................2

TM

Page

2. Overview ..........................................................................................2

3. Circuit Schematic ............................................................................. 8

4. Electrical Characteristics ..................................................................9

5. Fault Protection Characteristics ....................................................... 9

6. Functional Description....................................................................10

7. Fault Conditions .............................................................................15

8. Ballast Design ................................................................................19

9. Bill of Materials...............................................................................22

10. IRPLCFL8U PCB Layout..............................................................23

11. Inductor Specifications .................................................................27

www.irf.com

RD0803

- 1 -

1. Features

Drives 1 x 32W Spiral CFL Lamp

Input Voltage: 120Vac

High Frequency Operation

Lamp Filament Preheating

Lamp Fault Protection with Auto-Restart

Low AC Line/Brownout Protection

IRS2530D DIM8TM HVIC Ballast Controller

2. Overview

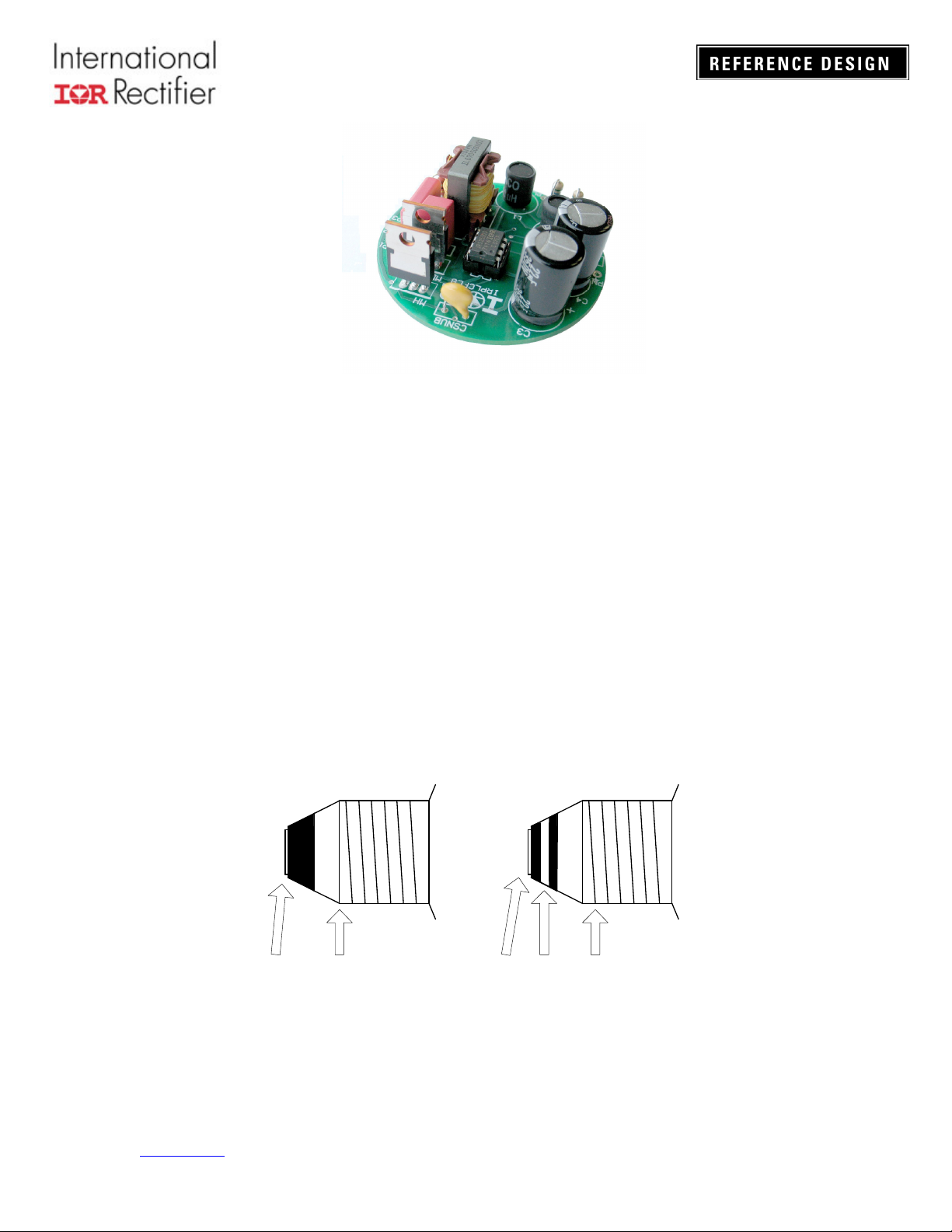

The 3 way dimming system widely adopted in the US with conventional filament lamps

consists of a light bulb that has a modified Edison screw type base which allows 3

connections to be made to a special lamp socket that also has 3 connections.

Standard Edison Screw

Base

Live

Neutral

Figure 2.1: Three way dimming Edison screw base

The 3 way dimming light bulb has two filaments inside which produce different light

outputs when connected to the AC line. These filaments are connected in series such that

the mid point goes to the line common and the two ends can be connected to the live

3 Way Dimming Edison

Screw Base

Live 1 Live 2

Neutral

www.irf.com

RD0803

- 2 -

either independently or both together. Thus with an external switch that has four positions,

it is possible to obtain 3 different light levels or to switch off.

3 Way Dimming Switch

3 Way Dimming Light Bulb

Live

120V AC Line

Neutral

1 2

0

Figure 2.2: Three way dimming filament lamp system

3 0

1 2

3

40W Filament60W Filament

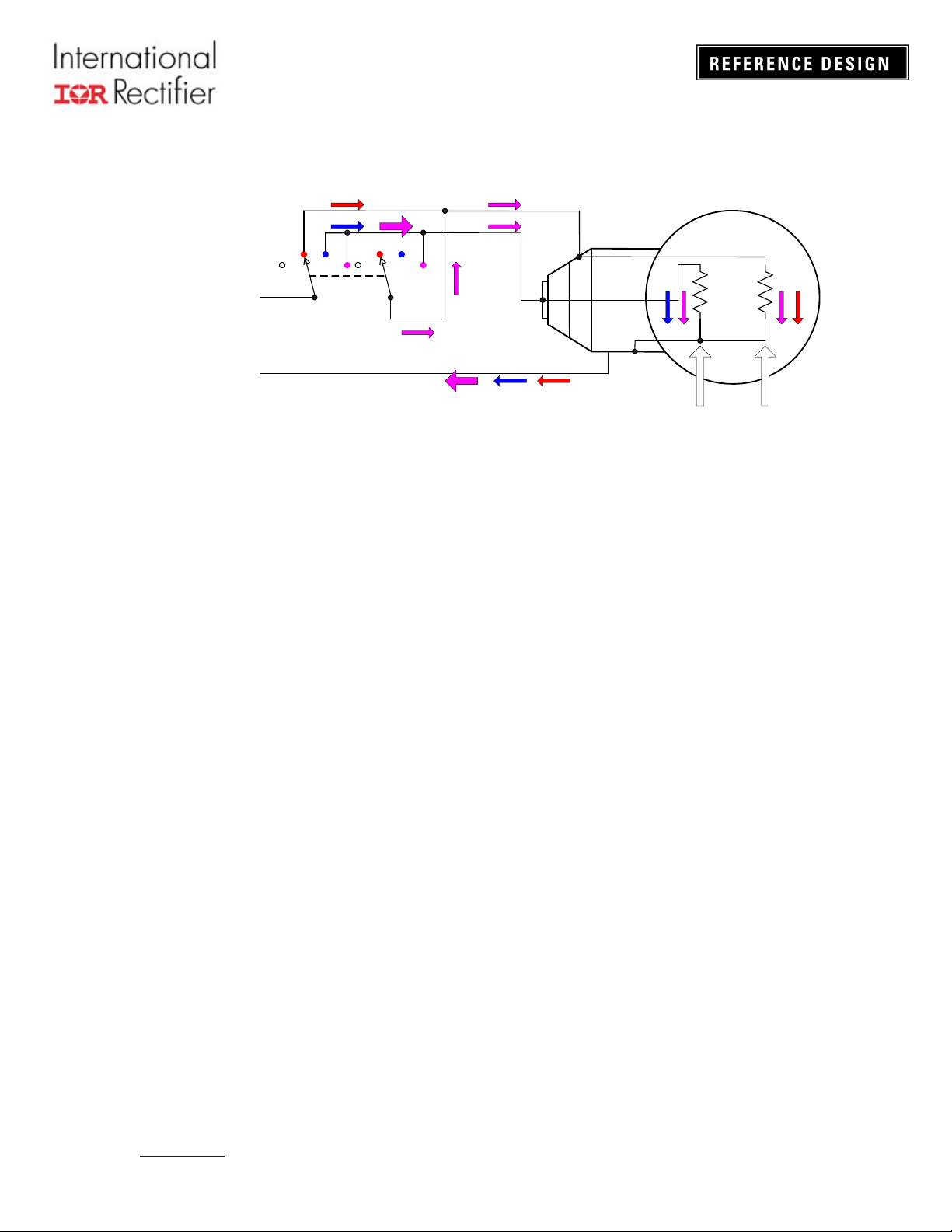

Figure 2.2 shows how the live and the neutral connect for 4 different configurations

(position 0, 1, 2, and 3). The flow of current for each position is also shown with colored

arrow; no current flows for position 0 (switch off), red arrow for position 1, blue arrow for

position 2, and magenta arrow for position 3. In position 1, the current will flow through

the 40W filament resistor (the lowest dimming level). In position 2, the current will flow

through the 60W filament resistor (intermediate dimming level). In position 3, current

will flow through both filaments, and the system will be at the maximum dimming level.

Existing Ballast Solution

There are in existence CFL ballast designs that provide three way dimming based on

the same switching arrangement shown above. A common approach is a system

whereby the line voltage is full wave rectified when one live input is connected and a

voltage doubler circuit comes into operation when the other live input is connected or

both are connected together thereby having two DC bus voltages in the ballast during

dim level settings. This type of design also operates at two different frequencies, a low

frequency (typically 40-45kHz) when both live inputs are connected providing a high

lamp current and a higher frequency (for example 70-75kHz) when either of the two

lives is connected alone which will produce a lower lamp current. In this way the

following combinations are achieved:

1. Low DC bus (150V) / high frequency ….. minimum output

2. High DC bus (300V) / high frequency …... medium output

3. High DC bus (300V) / low frequency …… maximum output

This approach has some serious drawbacks:

Firstly, since the ballast must be designed to give 100% light output for the lamp when

the bus voltage is 300V and the frequency is 40kHz, it is not easy to achieve

satisfactory preheat and ignition when the bus voltage is at 150V because of the

limitations in the peak voltage that the output circuit is able to produce from a 150Vpp

half bridge voltage.

www.irf.com

RD0803

- 3 -

One strategy that has been used is to omit the preheating phase and steer the

oscillator frequency to resonance during ignition using feedback from the output circuit.

This ensures that at switch-on the highest possible ignition voltage will be applied to the

lamp. In this way the lamp will ignite in whichever position the 3 way switch is set.

Such a scheme could reliably ignite the lamp when the DC bus is at 300V, however

without correct preheating the ignition voltage of the lamp and consequently the peak

current in the MOSFET half bridge during ignition will be higher. Also the life of the

lamp is substantially reduced when there is no preheat due to far greater stress

occurring on the cathodes at the point of ignition.

Ignition when the DC bus voltage is at 150V is very difficult. Tests indicated that

sweeping the frequency down through resonance sometimes failed to produce

sufficient ignition voltage leaving the ballast in open circuit running mode. The

conclusion from this is that the ballast needs to oscillate at resonance for an extended

period of time in order for the lamp to ignite at 150V considering that the output inductor

and capacitor have been designed to produce 100% lamp power at 300VDC bus when

the frequency is 40-45kHz.

Many CFL ballast designs do not incorporate a current sense and shutdown function to

protect the circuit in the case of ignition failure and so the ballast would eventually fail if

left switched on due to the high MOSFET switching losses causing thermal destruction.

This would not matter with and integrated ballast / lamp type product when the lamp

has failed.

It has also been observed that hard switching occurs at the MOSFET half bridge when

the DC bus voltage is low in position 1 since when the ballast is running it will be close

to resonance, bearing in mind that the resonant frequency shifts downwards in run

mode. Hard switching is very undesirable because of the high peak currents that occur

when each MOSFET switches on. This has been shown to result in a higher rate of

field failures in ballasts due to MOSFET failure.

The conclusion is that the approach to design described above is unable to provide a

reliable ballast.

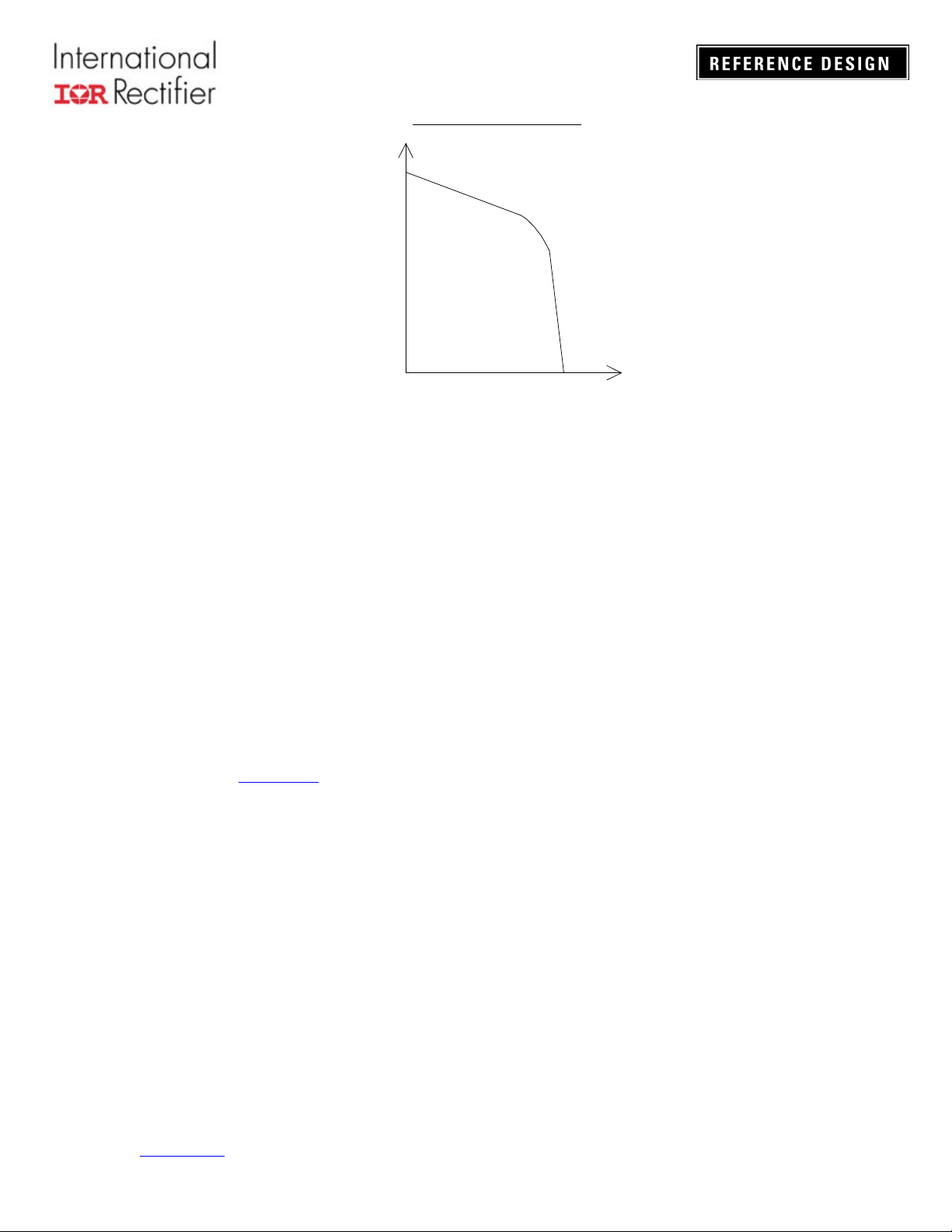

The dimming level can also be controlled by simply changing the frequency. By

changing the frequency between 3 defined settings, however, it was found to be

extremely difficult to set a point where the dim level is 50%. The problem with this is

that the lamp current against ballast frequency characteristic of the system exhibits a

very sharp knee such that as the frequency increases the lamp current is gradually

reduced up to a point at which a small increase of frequency will result in a very large

reduction in the lamp current.

www.irf.com

RD0803

- 4 -

Ballast / Lamp Operati ng Characteristic

Lamp

Current

Ballast Running

Frequency

Figure 2.3: Lamp current against ballast frequency

To obtain 50% output, the frequency would have to be very precisely set. This is not

practical since the tolerances of the output inductor, capacitor and oscillator timing

components do not allow this. Even if each ballast was individually adjusted in

production variations in lamp behavior over temperature would mean that under some

conditions the lamp arc would extinguish at this setting leaving the system in

permanent preheat which would burn out the cathodes eventually.

This explains why the 150VDC bus solution has been adopted in some designs as this

allows 50% output to be achieved without this problem. However as discussed in the

previous section this approach is not without some major disadvantages.

IRPLCFL4 Reference Design

It is however necessary in order to create a reliable design to include a closed loop

feedback system that controls the lamp current by adjusting the ballast frequency from

a VCO (voltage controlled oscillator) driven by the output of an error amplifier that

senses the lamp arc current directly and compares it with a reference. This has been

used in the IRPLCFL4 reference design “A 3 Way Dimming CFL Ballast” and has been

demonstrated to be capable of controlling the lamp output down to approximately 10%

arc current maintaining stability. This also compensates for tolerances in the

components of the circuit or the lamp.

www.irf.com

RD0803

- 5 -

∑

Regulated Lamp Current Control System

VCO

&

DRIVER

+

Lamp Arc Current

Reference

-

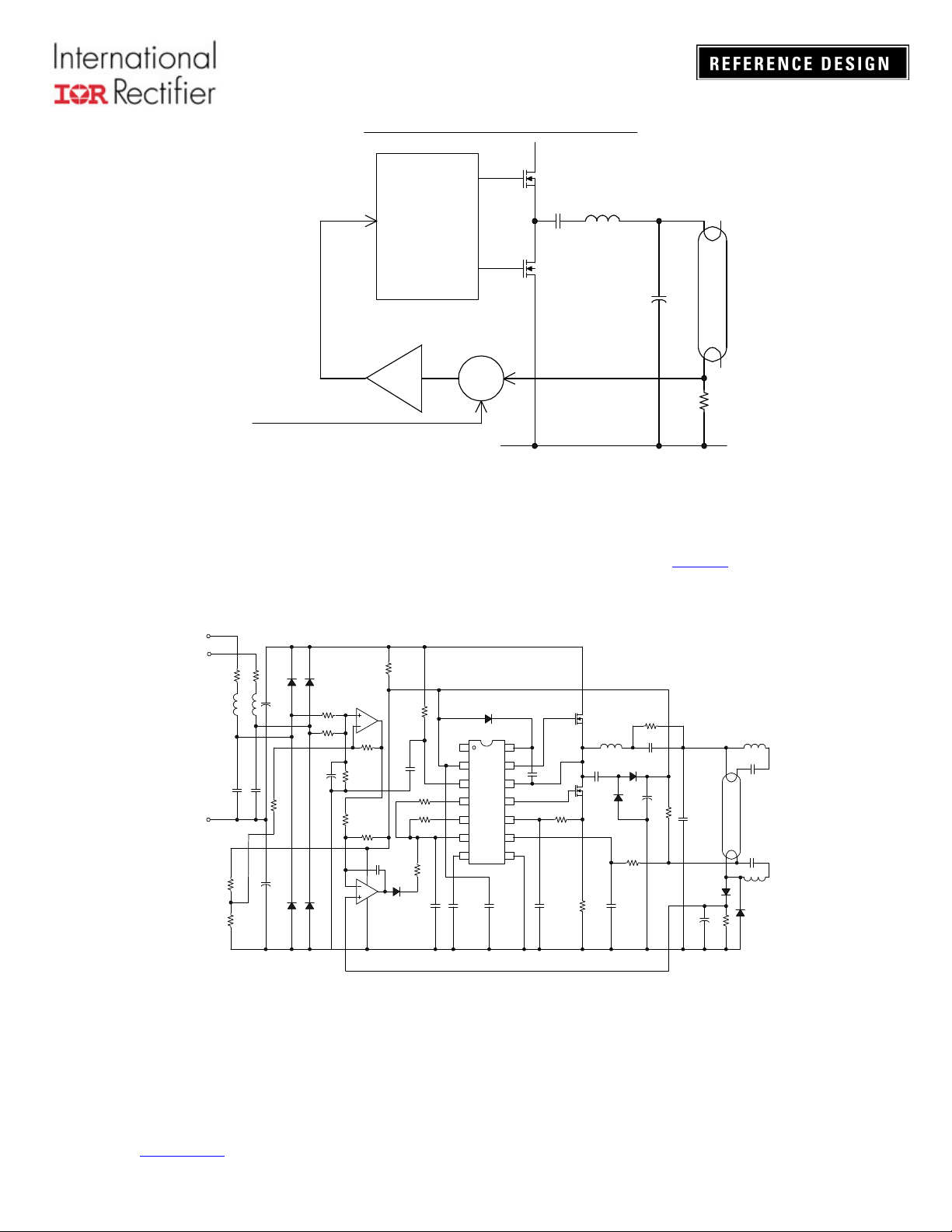

Figure 2.4: Closed loop lamp arc current regulation

Many of the design issues described above have also been overcome in the ballast

circuit of reference design IRPLCFL4. The design, however, required two additional

operational amplifiers and additional circuitry since it is based on the IR2156 control IC,

which does not incorporate the necessary dimming circuitry. This circuit therefore has a

relatively high component count.

L1

L2

COMMON

R4

R5

R1

L1

C1 C2

R2

L2

D1 D2

C3

R6

C4

D3

R7

R8

C7

D4

5

6

R10

R12

2

3

IC1a

R11

R9

8

4

R3

R15

7

NC

VCC

VDC

R16

RT

R17

RPH

CT

CPH

C9 C10 C11

C8

1

IC1b

C20

D7

R18

D8

IC2

IR2156

VB

14

HO

13

VS

12

LO

11

CS

10

SD

9

COM

8

C6

1

2

3

4

5

6

7

Q1

L3

R19

C13

Q2

D10

C19

R20

C5

C14

R21

R13

C15

D9

R9

C16

C12

L3a

C17

C18

L3b

D5

D6

R14

Figure 2.5: IRPLCFL4 Circuit Schematic

The component count for the IRPLCFL4 design shown in figure 2.5 is 56 parts.

www.irf.com

RD0803

- 6 -

New Solution: IRPLCFL8U

A completely new approach has been developed that overcomes all of the above

limitations. The IRPLCFL8U reference design kit consists of a dimming Fluorescent

ballast, with a 3 way dimming switch, driving a single 32W CFL lamp. The design

contains an EMI filter and a dimming ballast control circuit using the

IRS2530D(

50 parts. This demo board is intended to help with the evaluation of the IRS2530D

dimming ballast control IC, demonstrate PCB layout techniques and serve as an aid in

the development of production ballasts using the IRS2530D.

DIM8

TM

). The component count for the IRPLCFL8U, shown in figure 3.1, is

www.irf.com

RD0803

- 7 -

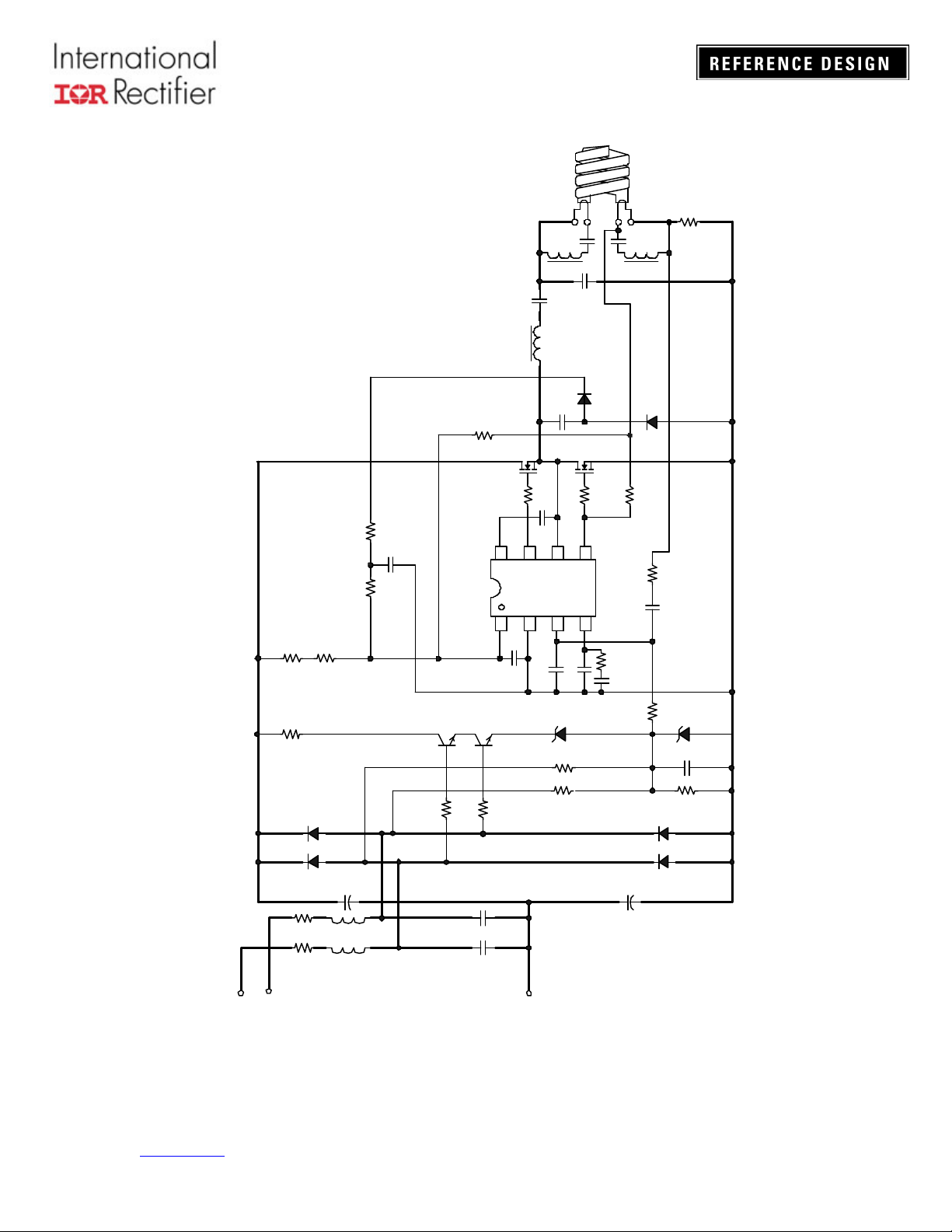

3. Circuit Schematic

SPIRAL

CFL LAMP

CH1

LRES : B

CDC

LRES:A

RLMP2

MHS

RHO

VB

HO

8

7

RVCC2 RVCC1

CVCC1

RS1

RS2

IRS2530D

1

2

VCC

COM

CVCC2

CRES

CSNUB

RLO

CBS

LO

VS

6

3

DIM

VCO

CVCO

CDIM

CH2

DCP2

MLS

RLMP1

5

4

RVCO

CCPH

RCS

LRES :C

DCP1

RFB

CFB

RDIM

RPU

D2

D1

C3

R2

PL2

PL1

L2

R1

L1

Q1

Q2

R3

R4

C1 C2

DZ1

R5 R6

C4

COMMON

DZ2

C5

R7

D4

D3

Figure 3.1: IRPLCFL8U Circuit Schematic

www.irf.com

RD0803

- 8 -

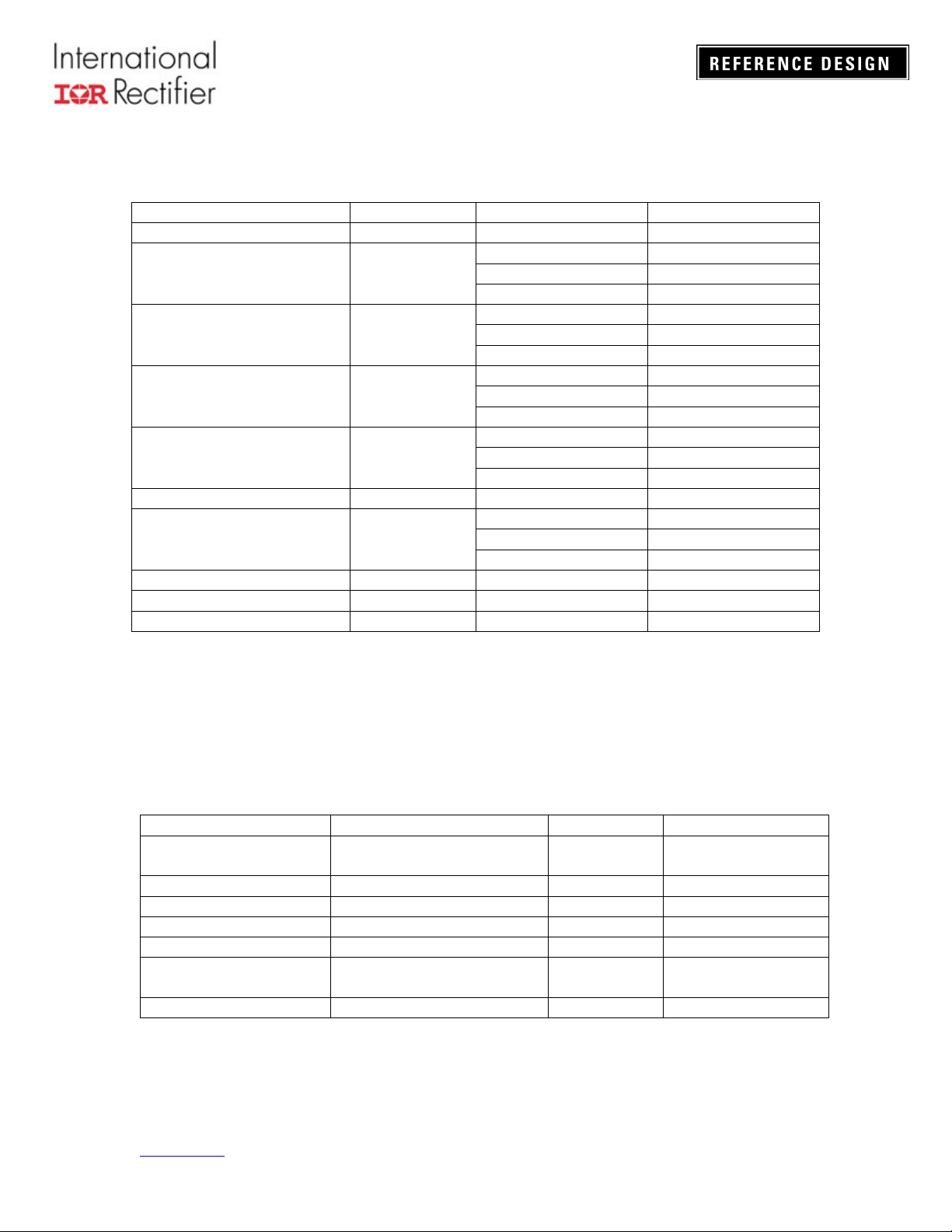

4. Electrical Characteristics

Parameter Units Dimming Level Value

Lamp Type 32W CFL

Maximum 31

Input Power [W]

Input Current [mArms]

Lamp Running Voltage [Vpp]

Lamp Running Current [mArms]

Start Frequency [kHz] 115

Run Frequency [kHz]

Preheat Time [s] 0.5

Input AC Voltage Range [VACrms] 60 - 180

Ballast turn-off voltage [VACrms] 60

TABLE 4.1: Ballast Parameters.

Intermediate 22

Minimum 15

Maximum 386

Intermediate 260

Minimum 175

Maximum 370

Intermediate 540

Minimum 630

Maximum 190

Intermediate 80

Minimum 27

Maximum 42

Intermediate 59

Minimum 60

5. Fault Protection Characteristics

Fault Protection Ballast Restart Operation

Brown-out Non-ZVS Increase

frequency

Upper filament broken Crest Factor Over Current Deactivates Lamp exchange

Lower filament broken Crest Factor Over Current Deactivates Lamp exchange

Lamp removed Crest Factor Over Current Deactivates Lamp inserted

Failure to ignite VVCOFLT+ Deactivates Lamp exchange

No lamp VLOSD- Does not

start

End of life Crest Factor Over Current Deactivates Lamp exchange

TABLE 5.1: Fault Protections Characteristics.

Line voltage

increase

Lamp inserted

www.irf.com

RD0803

- 9 -

6. Functional Description

The IRS2530D design utilizes a voltage doubler at the front end in all modes of operation

giving a fixed DC bus voltage approximately 300V. By correctly selecting value of the

snubber capacitor it is not difficult to achieve soft switching in all modes of operation.

The front end of the IRPLCFL8U ballast circuit shows the neutral line input (i.e. the one

that is always connected) connected to the center point of the DC bus storage capacitors

C3 and C4. Live inputs L1 and L2 are connected to two completely separate voltage

doubler diode pairs which are connected to the DC bus. These four diodes are all

contained within the bridge BR1 (This is shown as D1, D2, D3 and D4 in the schematic of

Fig 6). If live input L1 is connected to the line, a 60Hz sinusoidal AC voltage will be present

at the point where the anode of D1 joins the cathode of D3. This voltage will swing

between the 300V DC bus voltage and the 0V COM point of the circuit. If live input L1 is

not connected to the line this point will be floating with only residual voltage present. The

same applies with live input L2 at the point where the anode of D2 meets the cathode of

D4. These two points are fed via resistors R5 and R6 to the parallel combination of R7 and

C5, which are connected to 0V COM. The value of C5 is high enough to ensure that the

amount of ripple that is present at the junction of C5 and RDIM will be negligible so a DC

voltage will effectively appear there. This sets the reference voltage level for the dimming

feedback loop.

As a result this dimming control voltage will change depending on whether live input L1 is

connected only, live input L2 is connected only or both are connected, which depends on

the three way dimming rotary switch position. The values of R5 and R6 will be chosen so

that this voltage is substantially different if either live input L1 of live input L2 are

connected alone and these values are selected to set the desired low and mid light levels.

In this application R5 can be selected to give the correct reference voltage to provide 50%

light output as perceived by the human eye, which occurs at a point somewhat lower than

50% ballast power and R6 can be chosen for 75% which is at about 50% of the nominal

total ballast power at full light output.

The design problem overcome here is that the dimming control voltage obtained through

R5 and R6, where the values have been selected to provide minimum and medium light

outputs, is not sufficiently high to provide maximum light output when both live inputs are

connected. This being the case it was necessary to add the two pull up transistors Q1 and

Q2. When both inputs L1 and L2 are connected, i.e. when the rotary switch is in the fully

on position, the voltage at RDIM will be pulled high enough to ensure that the ballast

operates at maximum output since the transistors Q1 and Q2 will both be switched on in

this case.

Q1 and Q2 are small signal NPN devices, however they need to be rated to 300V VCEO

to prevent any conduction if either one is switched off. The zener diode DZ1 had been

added to ensure that Q1 and Q2 can fully switch off. This is because even when not

connected to the line some voltage appears at the bases of these devices. Since Q1 and

Q2 are configured as emitter followers the base voltage must exceed the breakdown

voltage of DZ1 (68V) in order to switch on, which can only occur when the corresponding

line input is connected through the rotary switch.

www.irf.com

RD0803

- 10 -

The closed loop regulation dimming ballast section, unlike in the IRPLCFL4 design, is

incorporated within the 8 pin package of the IRS2530D “simple dim” ballast controller

greatly simplifying the circuit design.

Since we are sensing the lamp arc current with a resistor it is necessary to use voltage

mode preheating to avoid detecting the sum of the current in the arc and the current in the

resonant output capacitor CRES. This has an additional advantage that during preheat

and prior to ignition of the lamp the arc current will always be zero and consequently the

feedback circuit will not influence the oscillator frequency until the lamp is running.

Consequently the preheat will occur in exactly the same way regardless of which of the

live inputs are connected, thus achieving optimum preheat and ignition under all

conditions.

A resistor parallel with CDC can be added if necessary to remove

the lamp that may occur at low dimming levels. However this has not been necessary in

this reference design.

R1 and R2 are fusible resistors that are optional and L1, L2, C1 and C2 are recommended

for EMI filtering but have no bearing on the functional operation of the ballast.

striations

(dark rings) in

Figure 6.1 shows the voltage at the DIM pin for all 3 dimming level.

Maximum Dim Level Intermediate Dim Level

Minimum Dim Level

www.irf.com

Figure 6.1: IRS2530D DIM pin voltages

RD0803

- 11 -

Figure 6.2 shows the voltage at the VCO pin, and the VS (half-bridge) voltage for all 3

dimming level.

Maximum Dim Level Intermediate Dim Level

Minimum Dim Level

Figure 6.2: IRS2530D VCO (red) and VS (yellow) pin voltages

www.irf.com

RD0803

- 12 -

Figure 6.3 shows the voltage across the lamp, and the current through the lamp for all 3

dimming level.

Maximum Dim Level Intermediate Dim Level

Minimum Dim Level

Figure 6.3: Lamp Voltage and Arc Current

www.irf.com

RD0803

- 13 -

Figure 6.4: Lamp Voltage and Arc Current during preheat and ignition

www.irf.com

RD0803

- 14 -

7. Fault Conditions

In case of fault conditions such as open filaments, failure to strike, or lamp removal, the

IRS2530D will go into Fault Mode. In this mode, the internal fault latch is set, HO is off, LO

is open circuit, and the IRS2530D consumes an ultra-low micro-power current. The

IRS2530D can be reset with a lamp exchange (as detected by the LO pin) or a recycling of

VCC below and back above the UVLO thresholds.

Failure to Strike

At initial turn-on of the ballast, the frequency will ramp down from f

resonance frequency. When the lamp fails to strike, the VCO voltage continues to

increase and the frequency continues to decrease until the VCO voltage exceeds

VVCOFLT+ (4.0V, typical), and the IRS2530D enters Fault Mode and shuts down

(Figure 7.1). It should be noted that in case of failure to strike, the system will operate in

capacitive side of resonance, but only for short period of time.

toward the

MAX

Figure 7.1: Lamp non-strike: CH1 is the VCO voltage, CH4 is the voltage across lamp

AC Mains Interrupt / Brown-Out Conditions

This protection relies on the non-ZVS circuit of IRS2530D, enabled in the Dim Mode.

During an AC mains interrupt or brown-out condition, the DC bus can decrease and

cause the system to operate too close to, or, on [the] capacitive side of resonance. The

result is non-ZVS switching that causes high peak currents to flow in the half-bridge

MOSFETs that can damage or destroy them.

To protect against this, the IRS2530D will detect non-ZVS by measuring the VS voltage

at each rising edge of LO. If the voltage is greater than VZVSTH (4.5V, typical), the IC

will reduce the voltage at VCO pin, and thus increase the frequency until ZVS is

reached again (Figure 7.2).

www.irf.com

RD0803

- 15 -

In case the DC bus decreases too far and the lamp extinguishes, the VCC voltage will

go below VCCUV- and the ignition/preheat ramp will be reset to re-ignite the lamp

reliably.

Figure 7.2: Brown-out conditions: CH1 is the VCO voltage, CH2 is the VS voltage

Lamp Removal

When the lamp is removed, the IRS2530D uses the Crest Factor Over-current

Protection to enter the Fault mode and shut down. During lamp removal, the output

stage will transition to a series-LC configuration, and the frequency will move towards

resonance until the inductor saturates. The IRS2530D uses the VS-sensing circuitry

and the RDSon of the low-side half-bridge MOSFET to measure the MOSFET current

for detecting an over-current fault. Should the peak current exceed the average current

by a factor of 5.5 (CF>5.5) during the on-time of LO, the IRS2530D will enter Fault

Mode, where the half-bridge is off. Performing crest factor measurement provides a

relative current measurement that cancels temperature and/or tolerance variations of

the RDSon of the low-side half-bridge MOSFET.

Figure 7.3 shows the voltage across the lamp and the VS voltage when the lower

filament of the lamp is removed. Figure 7.4 shows these voltages when the upper

filament of the lamp is removed. In both cases, the IRS2530D will enter the Fault Mode

and shut down after detecting that the crest factor exceeds 5 during the on-time of LO.

Figure 7.5 shows the VS pin, inductor current, and voltage across lamp when the

inductor saturates and the ballast shuts down.

www.irf.com

RD0803

- 16 -

Figure 7.3: Lower filament removed: CH2 is the VS voltage, CH4 is the voltage across the lamp

Figure 7.4: Upper filament removed: CH2 is the VS voltage, CH4 is the voltage across the lamp

www.irf.com

RD0803

- 17 -

Figure 7.5: Inductor saturation: CH1 is the LO voltage, CH2 is the VS voltage, CH3 is the current

through the resonant inductor, and CH4 is the voltage across the lamp

Figure 7.6 shows the VS voltage and the voltage across the lamp when the IC undergoes

reset with a lamp exchange. When the lamp is removed, crest factor protection is

triggered, and the IC enters the Fault mode and shuts down. Since the lamp is removed,

LO pins is pulled above VLOSD+, and the IC goes to UVLO mode. When the lamp is reinserted, the IC goes back to the Preheat / Ignition mode, and the half-bridge starts to

oscillate again.

Figure 7.6: Lamp exchange: CH1 is the LO voltage, CH2 is the VS voltage, and CH4 is the voltage across

the lamp

www.irf.com

RD0803

- 18 -

8. Ballast Design

Layout Guidelines

Proper care should be taken when laying out a PCB board to minimize noise effects

due to high-frequency switching and to ensure proper functionality of the IRS2530D.

1. There should be a star point for all of the 0V returns, particularly IC1 pin 2,

CVCC, CDIM, CVCO, CCPH, R7 and C5, which is then connected to the source

of the lower half-bridge MOSFET(ML) via a single trace which is as short as

possible. This avoids potential ground loop problems.

2. The VCC decoupling capacitor (CVCC2) should be placed as close to the

IRS2530D VCC (pin 1) and COM (pin 2) as possible with the shortest possible

traces.

3. Double filter at VCC (RVCC1, CVCC1, RVCC2, and CVCC2) should be utilized

to filter high current spikes that can cause large voltage spikes to occur on VCC.

4. All IC programming and filter components should be placed as close as possible

between their respective pins and COM (CVCO, RVCO, CCPH, CDIM, CFB,

RFB).

5. Keep RCS, RFB and CFB as far away as possible from the VS node to prevent

high-frequency, high-voltage switching noise from interfering with dimming

feedback signal.

6. The high-side gate-drive ground (VS) should be connected to half-bridge midpoint at one connection only.

7. The anode of charge pump diode DCP1 should be connected to the power

ground not the signal ground.

8. Use gate resistors (RLO, RHO) between all gate driver outputs and the gate of

their respective power MOSFETs.

IRS2530D

SIGNAL GROUND

STAR POINT AT IC COM

IC PROGRAMMING AND

FILTER COMPONENTS

CFB, RFB, AND RCS ARE AS FAR

AWAY AS POSSIBLE FROM VS NODE

Figure 8.1: Critical traces on the bottom side of the PCB

www.irf.com

RD0803

VS NODE

SINGLE TRACE JOINING

VS-PIN AND HALF-BRIDGE

MID-POINT

VCC DECOUPLING

CAPACITOR

- 19 -

ANODE OF CHARGE PUMP

DIODE DCP1 IS CONNECTED TO

POWER GROUND

Figure 8.2: Critical traces on the top side of the PCB

SINGLE TRACE JOINING STAR

POINT AND THE SOURCE OF

LOWER HALF-BRIDGE MOSFET

Components Selection

The output inductor and capacitor values should be chosen to allow the ballast to run at

maximum brightness around 40-45kHz. This will minimize losses in the inductor. For

this example the

IR Ballast Designer

software * has been used to select the required

preheat, ignition and run frequencies for a 32W spiral CFL lamp giving an LRES of

2.2mH and CRES of 4.7nF.

Output Inductor Design

The output inductor LRES should be designed to allow a high peak ignition current

without saturating. This is important as the IRS2530D shutdown will be triggered if the

inductor saturates. The ignition current depends on the type of lamp being used and

must be kept to a minimum by ensuring the preheat is sufficient. To minimize losses in

the inductor multi-stranded wire should be used in combination with Ferrite cores of

adequate quality. The best approach to design is to wind as many turns as possible of

multi-stranded wire and have the largest gap possible to achieve the correct

inductance. This will produce the highest available peak current before saturating the

inductor. It is important to be aware that when the cores are hot the saturation point and

hence the peak current for the inductor will be lower therefore a poorly designed

inductor may result in the ballast shutting down during an attempted hot re-strike.

The inductor design process can be greatly simplified by using the

software produced by I.R. For this application and lamp size it is recommended to fix

the core size to EF20.

www.irf.com

RD0803

Ballast Designer

- 20 -

Ballast Designer

Lamp Preheating

The lamp must be sufficiently preheated before ignition. The correct preheat current

can be determined from published data or from International Rectifiers

software.

The preheat time can be set by adjusting the value of CPH. As a general rule the lamp

filament should glow red before ignition. If preheat is insufficient the ballast is likely to

shutdown during ignition because the output inductor will be unable to operate at the

high current required. The number of turns in the auxiliary cathode windings of the

output inductor LRES should be chosen to provide sufficient preheat. In designs for

ballasts with integral lamps the shutdown pin can be grounded so that the inductor may

saturate without shutting down the circuit.

The lamp filament (Cathode) resistance over the range of dimming levels should be

between 3 and 5.5 times the resistance when cold. A simple method for determining

the hot resistance is to first connect one cathode to a DC power supply via an ammeter

and slowly increase the voltage from zero, noting the current at 1V intervals. This

should be done until the cathode can be seen to be glowing red. When this occurs the

voltage should not be increased further in order to prevent possible cathode damage.

The resistance can then be calculated for each voltage and hence the acceptable

voltage range can be found to comply with the 3 to 5.5 times cold resistance, which can

be easily measured with a digital multi-meter (DMM).

Then when the ballast is being run a true RMS digital voltmeter can be connected

across one cathode and the voltage can be observed at maximum and minimum

brightness. The cathode voltage increases as the ballast is dimmed. The values of

CH1 and CH2 will control how much it increases by, reducing the capacitance will

reduce the amount by which the voltage rises. The values should be chosen to prevent

the voltage exceeding the upper limit at minimum output.

It is important to consider that using additional windings on the inductor to provide

cathode heating means that power is now being transferred through the core and

consequently the core losses will increase and hence the core operating temperature.

The core will reach its highest operating temperature when the ballast is running at

minimum brightness.

www.irf.com

RD0803

- 21 -

9. Bill of Materials

Item # Qty Manufacturer Part Number Description Reference

1 1 International Rectifier IRS2530D Ballast Controller IC1

2 2 International Rectifier IRF730 MOSFET MH,ML

3 2 Fairchild MMBTA42 Transistor 300V, SOT-23 Q1,Q2

4 1 Diodes Inc ZMM5266B-7 Zener Diode 68V DZ1

5 1 Diodes Inc ZMM5230B-7 Zener Diode, 4V7 DZ2

6 2 Diodes Inc LL4148-13 Small Signal Diode SMD DCP1, DCP2

7 1 Fairchild DF10S Bridge SMD BR1

8 2 Renco RL-5480-3-2700 Filter Inductor L1,L2

9 1 Vogt IL 070 503 11 02 Inductor 2.2mH EF20 LRES

10 2 Panasonic-ECG ECQ-E2104KB Capacitor 100nF, 250V C1,2

11 2 Panasonic-ECG ECA-2EHG330 Capacitor, 33uF 250V 105C

Electrolytic

12 1 Panasonic-ECG ECJ-3YX1C106K Capacitor 10u, 16V, 1206 C5

13 2 Panasonic-ECG ECJ-3YB1C225K Capacitor 2u2, 16V, 1206 CVCC1, CVCC2

14 1 Panasonic-ECG ECJ-3YC2D102J Capacitor 1nF, 200V, 1206 CDIM

15 1 Panasonic-ECG ECJ-3VB1C334K Capacitor 0.33uF, 16V, 1206 CCPH

16 1 Panasonic-ECG ECJ-3VC2A222J Capacitor 2n2, 100V, 1206 CVCO

17 2 Panasonic-ECG ECJ-3VB1H104K Capacitor 100nF, 50V, 1206 CFB, CBS

18 2 Panasonic-ECG ECJ-3YB1H224K Capacitor 220nF, 50V, 1206 CH1, CH2

19 1 Panasonic-ECG ECK-A3A102KBP Capacitor 1nF, 1kV, Ceramic CSNUB

20 1 Wima MKS2 Series Capacitor 47nF, 400V CDC

21 1 Wima MKP10 Series Capacitor 4.7nF, 1600V,

15mm, Pulse

22 2 Yageo CFR-50JB-5R6 5.6R 1/2W Axial R1, R2

23 4 Panasonic-ECG ERJ-8GEYJ105V Resistor, 1M, 0.25W, 1206 R3, R4, R6,

24 1 Panasonic-ECG ERJ-8GEYJ334V Resistor, 330K, 0.25W, 1206 R5

25 1 Panasonic-ECJ ERJ-8GEYJ202V Resistor, 2K, 0.25W 1206 R7

26 1 Panasonic-ECJ ERJ-8GEYJ154V Resistor, 150K, 0.25W, 1206 RPU

27 2 Panasonic-ECJ ERJ-8GEYJ100V Resistor, 10R, 0.25W, 1206 RVCC1, RVCC2

28 1 Panasonic-ECJ ERJ-8GEYJ103V Resistor, 10K, 0.25W, 1206 RDIM

29 1 Panasonic-ECJ ERJ-8GEYJ152V Resistor, 1K5, 0.25W, 1206 RVCO

30 1 Panasonic-ECJ ERJ-8GEYJ102V Resistor, 1K, 0.25W, 1206 RFB

31 2 Panasonic-ECJ ERJ-8GEYJ220V Resistor, 22R, 0.25W, 1206 RHO, RLO

32 1 Panasonic-ECJ ERJ-8GEYJ474V Resistor, 470K, 0.25W, 1206 RLMP1

33 2 Panasonic-ECJ ERJ-8GEYJ274V Resistor, 270K, 0.25W, 1206 RS1, RS2

34 1 Phoenix Passive

Components

TABLE 9.1: IRPLCFL8U Bill of Materials.

5073NW15R00J12

AFX

Resistor, 15R, 1W, Axial RCS

C3,4

CRES

RLMP2

www.irf.com

RD0803

- 22 -

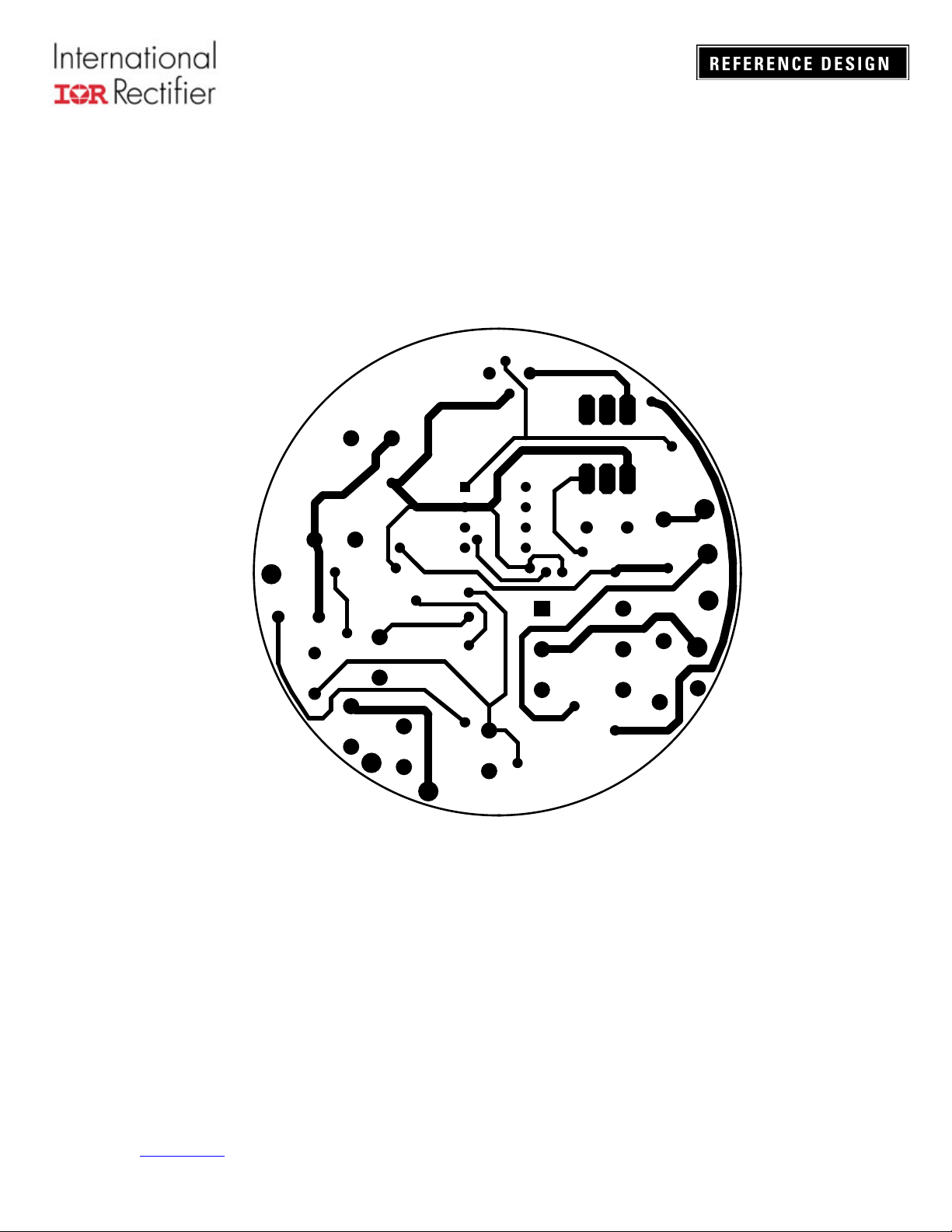

10. IRPLCFL8U PCB Layout

Top Assembly

www.irf.com

RD0803

- 23 -

Top Copper

www.irf.com

RD0803

- 24 -

Bottom Assembly

www.irf.com

RD0803

- 25 -

Bottom Copper

www.irf.com

RD0803

- 26 -

11. Inductor Specifications

Vogt # IL 070 503 11 02

BI Technologies # HM00-07544

INDUCTOR SPECIFICATION

CORE SIZE

GAP LENGTH

CORE MATERIAL

NOMINAL INDUCTANCE

TEST TEMPERATURE C

WINDING START PIN

MAIN

CATHODE

CATHODE

PHYSICAL LAYOUT

( Vertical 6- Pin Bobbin)

1

2 5

3 4

E20/10/ 6 (EF20)

1.0

mm

Philips 3C85 , Siemens N27 or equivalent

2.3

mH

100

FINISH PIN TURNS WIRE DIAMETER (mm

6

240*

5.5

5.5

10/ 38 Multistranded

26 awg insulated

26 awg insulated

0.4"

6

1

)

Pin View

5

2

0.4"

34

TEST

MAIN WINDING INDUCTANCE

TEST TEMPERATURE C

100

MIN 2.1

mH

MAX 2.4

* Adjust turns for specified Inductance

mH

www.irf.com

RD0803

- 27 -

Loading...

Loading...