International Rrectifier IRK.9 User Manual

查询IRKD91-04A供应商

Bulletin I27141 rev. F 10/02

IRK.91 SERIES

STANDARD DIODES

Features

High Voltage

Industrial Standard Package

Thick Al metal die and double stick bonding

Thick copper baseplate

UL E78996 approved

3500V

isolating voltage

RMS

Mechanical Description

The Generation V of Add-A-pak module combine the

excellent thermal performance obtained by the usage

of Direct Bonded Copper substrate with superior

mechanical ruggedness, thanks to the insertion of a

solid Copper baseplate at the bottom side of the device.

The Cu baseplate allow an easier mounting on the

majority of heatsink with increased tolerance of surface

roughness and improve thermal spread.

The Generation V of AAP module is manufactured

without hard mold, eliminating in this way any possible

direct stress on the leads.

Major Ratings and Characteristics

Parameters IRK.91 Units

I

F(AV)

@ T

C

I

F(RMS)

I

@ 50Hz 2020 A

FSM

@ 60Hz 2110 A

I2t @ 50Hz 20.43 KA2s

@ 60Hz 18.65 KA2s

I2√t 204.3 KA2√s

V

range 400 to 1600 V

RRM

T

J

T

STG

100 A

100 °C

157 A

- 40 to 150

- 40 to150

o

C

o

C

ADD-A-pakTM GEN V Power Modules

Benefits

Up to 1600V

Full compatible TO-240AA

High Surge capability

Easy Mounting on heatsink

Al203 DBC insulator

Heatsink grounded

The electrical terminals are secured against axial pull-out:

they are fixed to the module housing via a click-stop

feature already tested and proved as reliable on other IR

modules.

100 A

Electrical Description

These modules are intended for general purpose high

voltage applications such as high voltage regulated power

supplies, lighting circuits, temperature and motor speed

control circuits, UPS and battery charger.

www.irf.com

1

IRK.91 Series

Bulletin I27141 rev. F 10/02

ELECTRICAL SPECIFICATIONS

Voltage Ratings

Voltage V

Type number Code peak reverse voltage repetitive peak rev. voltage @ T

04 400 500

06 600 700

08 800 900

IRK.91 10 1000 1100 10

12 1200 1300

14 1400 1500

16 1600 1700

Forward Conduction

Parameter IRK.91 Units Conditions

I

Max. average forward current 100 A 180° conduction, half sine wave

F(AV)

@ Case temperature 100 °C

Max. average forward current 90 A 180° conduction, half sine wave

I

F(AV)

@ Case temperature 107 °C

I

Max. RMS forward current 157 A DC @ 90°C case temperarure

F(RMS)

I

Max. peak, one-cycle forward, 2020 t = 10ms No voltage

FSM

non-repetitive surge current 2110 t = 8.3ms reapplied

2

I

t Maximum I2t for fusing 20.43 t = 10ms No voltage Initial TJ = TJ max.

2

I

√t Maximum I2Öt for fusing 204.3 KA2√s t = 0.1 to 10ms, no voltage reapplied

Low level value of threshold

V

F(TO)1

voltage

V

High level value of threshold

F(TO)2

voltage

r

Low level value of forward

1

f

slope resistance

r

High level value of forward

2

f

slope resistance

V

Max. forward voltage drop 1.45 V I

FM

, maximum repetitive V

RRM

VVmA

1700 t = 10ms 100% V

1780 t = 8.3ms reapplied Sinusoidal half wave,

18.65 t = 8.3ms reapplied

14.45 t = 10ms 100% V

13.19 t = 8.3ms reapplied

0.79 (16.7% x π x I

0.87 (I > π x I

1.78 (16.7% x π x I

1.57 (I > π x I

A

KA2s

V

mΩ

, maximum non- I

RSM

RRM

RRM

< I < π x I

F(AV)

),TJ = TJ max.

F(AV)

< I < π x I

F(AV)

),TJ = TJ max.

F(AV)

FM

= p x I

, TJ = 25°C, tp = 400µs square wave

F(AV)

), TJ = TJ max.

F(AV)

), TJ = TJ max.

F(AV)

RRM

max.

= 150°C

J

Blocking

Parameter IRK.91 Units Conditions

Max. peak reverse leakage 10 mA T

I

RRM

current

V

RMS isolation voltage 3500 (1 sec) V 50 Hz, circuit to base, all terminals shorted

INS

= 150oC

J

2

www.irf.com

IRK.91 Series

Bulletin I27141 rev. F 10/02

Thermal and Mechanical Specifications

Parameter IRK.91 Units Conditions

TJMax. junction operating temperature range -40 to 150

Storage temperature range -40 to 150

T

stg

Max. thermal resistance, junction to case 0.35 Per junction, DC operation

R

thJC

R

Typical thermal resistance, case to heatsink 0.1 Mounting surface flat, smooth and greased

thCS

T Mounting torque ±10% to heatsink 5

busbar 4

wt Approximate weight 110 (4) g (oz)

Case style TO-240AA JEDEC

∆R Conduction (per Junction)

(The following table shows the increment of thermal resistance R

Devices Units

180

Sine half wave conduction Rect. wave conduction

o

120

o

o

90

60

IRK.91 0.052 0.064 0.082 0.112 0.164 0.043 0.069 0.088 0.115 0.165 °C/W

thJC

o

30

°C

K/W

A mounting compound is recommended and the

Nm

torque should be rechecked after a period of 3 hours

to allow for the spread of the compound

when devices operate at different conduction angles than DC)

o

180o120

o

o

90

o

60

o

30

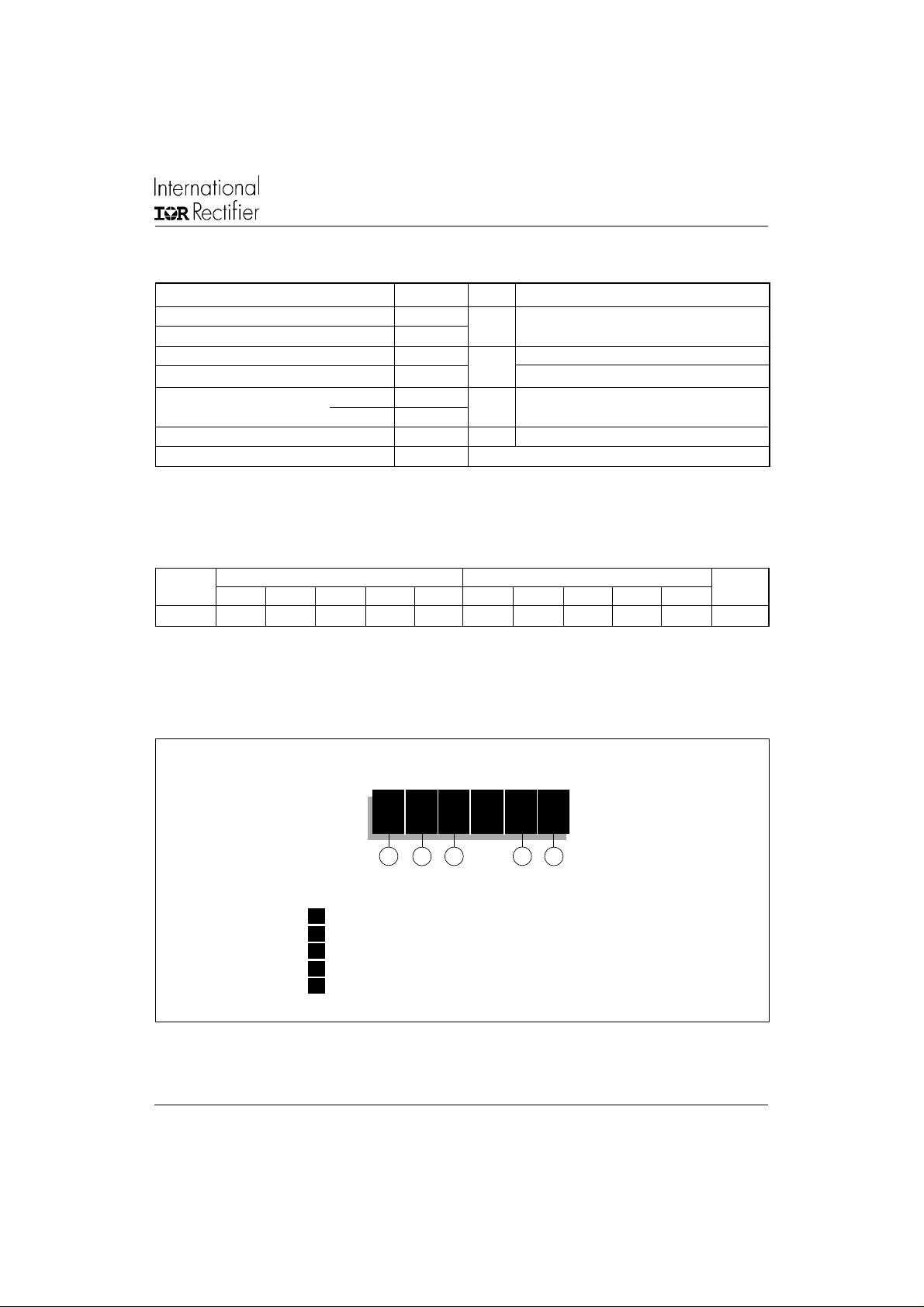

Ordering Information Table

www.irf.com

Device Code

IRK D 91 / 16 A

1

3

2

1 - Module type

2 - Circuit configuration (See Circuit Configuration Table)

3 - Current code

4 - Voltage code (See Voltage Ratings Table)

5 - A: Gen V

5

4

3

Loading...

Loading...