Page 1

IRDC3863

SupIRBuck

TM

USER GUIDE FOR IRDC3863 EVALUATION BOARD

DESCRIPTION

TM

The IR3863 SupIRBuck

fully integrated and highly efficient DC/DC

voltage regulator. The onboard constant on

time hysteretic controller and MOSFETs make

IR3863 a space-efficient solution that delivers

up to 6A of precisely controlled output voltage

in a 4mm x 5mm QFN package.

In addition to excellent light load and full load

efficiency, the IR3863 offers features such as:

a 0.5V reference, programmable switching

frequency, temperature compensated over

current protection, thermal shutdown and

optional forced continuous conduction mode.

is an easy-to-use,

Additional features include: pre-bias startup,

soft start, power good output, enable input with

voltage monitoring capability and over/under

voltage protection, making the device a very

flexible solution that is suitable for a broad

range of applications.

This user guide contains the schematic, bill of

materials, and operating instructions of the

IRDC3863 evaluation board. Detailed product

specifications, application information and

performance curves at different operating

conditions are available in the IR3863 data

sheet.

BOARD FEATURES

• V

= +12V

IN

• V

• V

• I

• F

= +5V

CC

= +1.05V

OUT

= 0 to 6A

OUT

= 300kHz @ CCM

S

• L = 2.2µH

• C

• C

= 22µF

IN

= 47µF (ceramic 0805) + 150µF (PC-CON)

OUT

(ceramic 1210) + 68µF (electrolytic)

1

Page 2

IRDC3863

CONNECTIONS and OPERATING INSTRUCTIONS

An input supply in the range of 7 to 16V should be connected from VIN to PGND. A maximum load

of 6A may be connected to V

and PGND. The connection diagram is shown in Fig. 1,

OUT

inputs and outputs of the board are listed in Table 1.

IRDC3863 has two input supplies, one for biasing (VCC) and the other for input voltage (VIN).

Separate supplies should be applied to these inputs. VCC

5.5V supply connected to VCC and PGND. Enable (EN) is controlled

input should be a well regulated 4.5V to

by the first switch of SW1, and

FCCM option can be selected by the second switch of SW1. Toggle the switch to the ON position

(marked by a solid square) to enable switching or to select FCCM. The absolute maximum voltage

of the external signal applied to EN (TP4) and FCCM is +8V.

Table 1. Connections

Connection Signal Name

VIN (TP2) VIN

PGND (TP5) Ground for VIN

and the

VCC (TP16) VCC Input

PGND (TP17) Ground for VCC Input

VOUT (TP7) V

PGND (TP10) Ground for V

EN (TP4) Enable Input

OUT

(+1.05V)

OUT

LAYOUT

The PCB is a 4-layer board. All layers are 1 oz. copper.

on the top and bottom layers of the board.

The power supply decoupling capacitors, bootstrap capacitor and feedback components are located

close to IR3863. To improve efficiency, the circuit board is designed to minimize the length of the onboard power ground current path.

IR3863 and other components are

mounted

2

Page 3

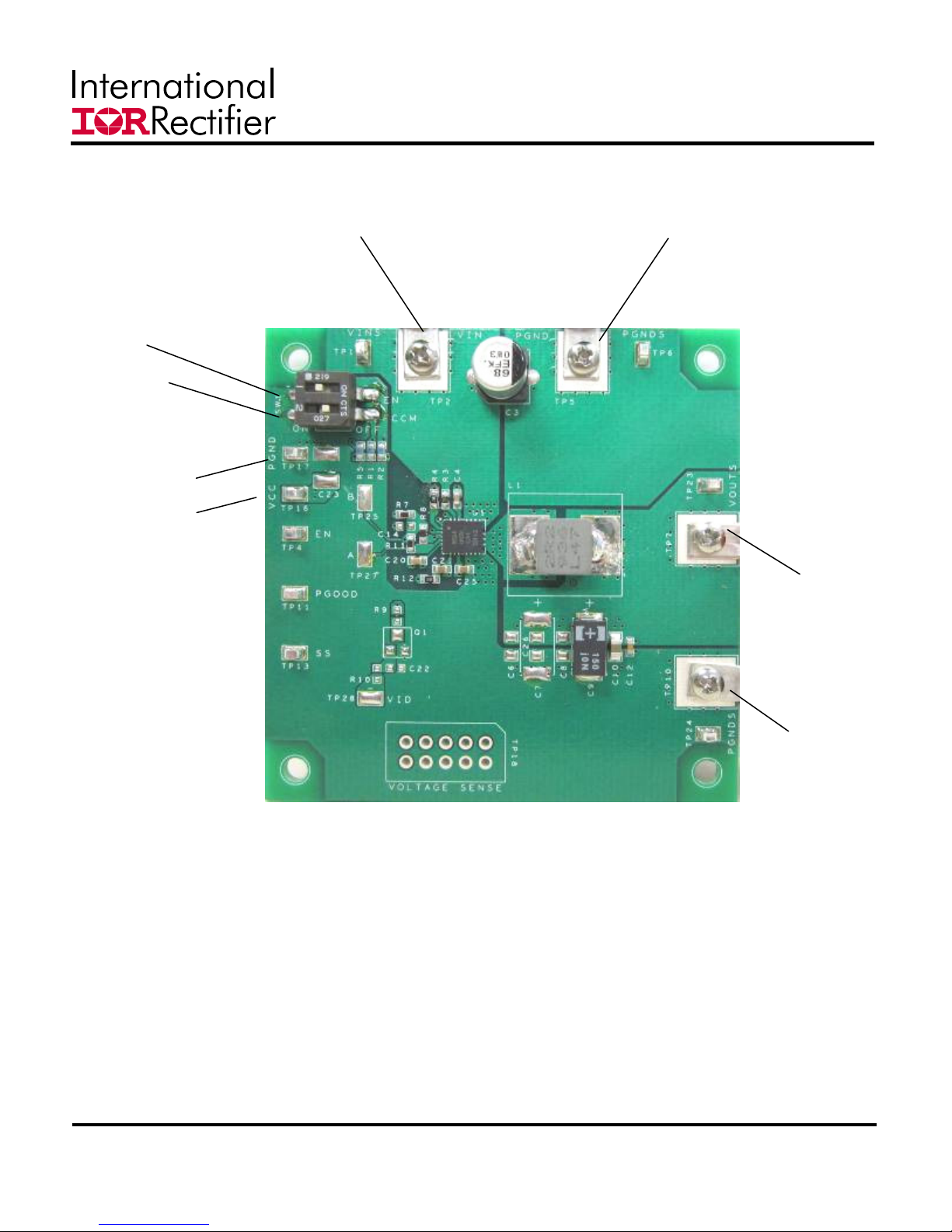

CONNECTION DIAGRAM

IRDC3863

Control Switch for:

EN

FCCM

GROUND

VCC = +5.0V

VIN

GROUND

VOUT = +1.05V

Fig. 1: Connection Diagram of IRDC3863 Evaluation Board

GROUND

3

Page 4

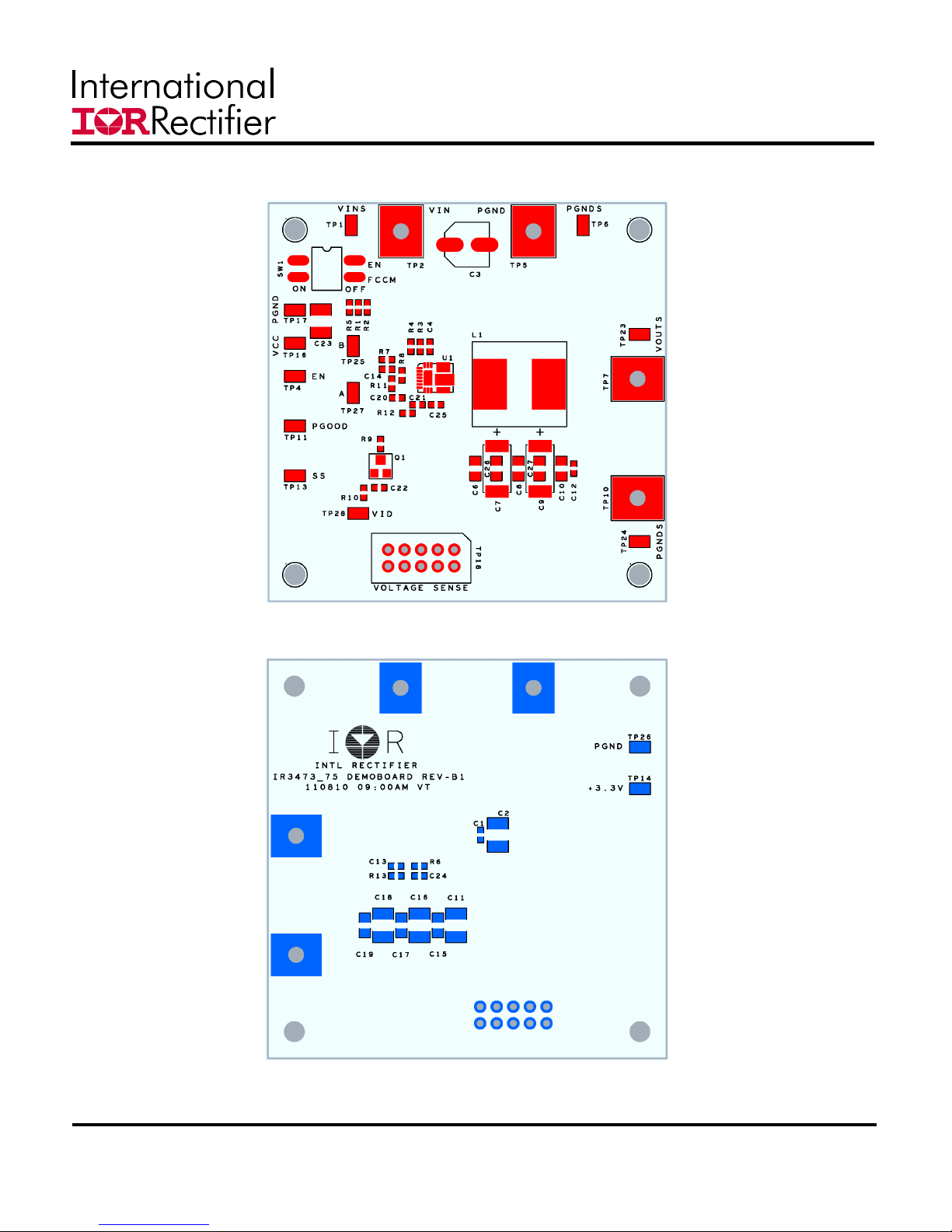

PCB Board Layout

IRDC3863

Fig. 2: Board Layout, Top Components

Fig. 3: Board Layout, Bottom Components

4

Page 5

PCB Board Layout

IRDC3863

Fig. 4: Board Layout, Top Layer

Fig. 5: Board Layout, Bottom Layer

5

Page 6

PCB Board Layout

IRDC3863

Fig. 6: Board Layout, Mid-layer I

Fig. 7: Board Layout, Mid-layer II

6

Page 7

IRDC3863

TP7

VOUT

TP23

VOUTS

VOUT

TP2

VIN

TP1

VINS

VIN

TP5

PGND

TP6

PGNDS

C3

68uF

+

C2

22uF

C1

1uF

L1

2.2uH

VSW

C4

0.22uF

U1

IR3863

13

R3

200K

14

15

16

17

TP10

PGND

TP24

PGNDS

C27

IR3863

GND14FB

5

open

C26

open

C19

open

C18

open

C17

open

C16

open

C15

open

C24

open

PGND

11

VCC

10

NC2

9

3VCBP

8

SS

NC1

6

7

C21

C12

0.1uF

C11

open

C10

47uF

C9

150uF

C8

open

C7

open

C6

open

R13

open

C13

open

R6

open

12

VIN

FF

EN

PHASE

BOOT

GND

FCCM

PGOOD

ISET

1

3

2

TP18

VOLTAGE SENSE

10

9

8

7

6

R7

2.80K

C14

open

C25

1uF

1uF

R12

4.99

+Vout2s5-Vout2s

+Vout1s

-Vout1s

-Vdd2s

-Vdd1s

-Vins

VOUT

4

+Vdd2s

+3.3V

3

+Vdd1s

VCC

2

+Vins

VIN

1

R8

2.55K

R9

open

Q1

open

2

3

1

TP25

B

20

R11

TP27

A

C22

open

R10

open

TP28

VID

Fig. 8: Schematic of the IRDC3863 Evaluation Board

ISET

FCCM

EN

R4

10K

R1

10K

+3.3V

R2

10K

VCC

EN

TP4

VSW

2

3

1

4

SW1

EN / F CCM

C20

PGOOD

R5

10K

+3.3V

TP11

PGOOD

0.1uF

FB

SS

TP13

SS

+3.3V

TP14

+3.3V

TP26

AGND

C23

open

VCC

TP17

PGND

TP16

VCC

7

Page 8

Bill of Materials

IRDC3863

8

Page 9

TYPICAL OPERATING WAVEFORMS

Tested with demoboard shown in Fig. 8, VIN = 12V, VCC = 5V, VOUT

unless otherwise specified

IRDC3863

= 1.05V, Fs = 300kHz, TA= 25oC, no airflow,

EN

PGOOD

SS

VOUT

5V/div

5V/div 1V/div 500mV/div 5ms/div 5V/div 5V/div 1V/div 500mV/div 1ms/div

Fig. 9: Startup

Fig. 10: Shutdown

VOUT

PHASE

i

L

EN

PGOOD

SS

VOUT

VOUT

PHASE

i

L

20mV/div 10V/div 500mA/div 5µs/div 20mV/div 10V/div 2A/div 2µs/div

PGOOD

Fig. 11: DCM (I

OUT

= 0.1A)

Fig. 12: CCM (I

OUT

= 5A)

PGOOD

SS

VOUT

I

OUT

5V/div 1V/div 500mV/div 2A/div 50µs/div5V/div 1V/div 1V/div 5A/div 500µs/div

Fig. 13: Over Current Protection (tested by

shorting VOUT to PGND)

Fig. 14: Over Voltage Protection

(tested by shorting FB to VOUT)

FB

VOUT

i

L

9

Page 10

TYPICAL OPERATING WAVEFORMS

Tested with demoboard shown in Fig. 8, VIN = 12V, VCC = 5V, VOUT

unless otherwise specified

IRDC3863

= 1.05V, Fs = 300kHz, TA= 25oC, no airflow,

VOUT

PHASE

i

L

10V/div

2A/div

Fig. 15: Load Transient 0-2A

50µs/div

50mV/div

10V/div 2A/div 50µs/div50mV/div

Fig. 16: Load Transient 3-5A

TYPICAL PERFORMANCE

VIN = 12V, VCC = 5V, VOUT = 1.05V, Fs = 300kHz, IOUT = 6A, TA= 25oC, no airflow

VOUT

PHASE

i

L

Fig. 17: Thermal Image (IR3863: 60oC, Inductor: 45oC, PCB: 32oC)

10

Page 11

TYPICAL OPERATING DATA

VIN = 12V, VCC = 5V, VOUT = 1.05V, Fs = 300kHz, IOUT = 0 ~ 6A, TA= 25oC, no airflow,

unless otherwise specified

IRDC3863

90%

85%

80%

75%

70%

65%

Efficiency

60%

55%

50%

45%

0.01 0.1 1 10

Load Current (A)

Fig. 18: Efficiency vs. Load Current

1.090

1.085

1.080

1.075

1.070

1.065

1.060

1.055

Output Voltage (V)

1.050

1.045

1.040

0123456

Load Current (A)

350

300

250

200

150

100

50

Switching Frequency (kHz)

0

0123456

Load Current (A)

Fig. 19: Switching Frequency vs. Load Current

1.090

1.085

1.080

1.075

1.070

1.065

1.060

1.055

Output Voltage (V)

1.050

1.045

1.040

7 8 9 10111213141516

Input Voltage (V)

Fig. 20: Load Regulation

Fig. 21: Line Regulation at 6A Load

11

Page 12

IRDC3863

PCB Metal and Components Placement

Lead lands (the 13 IC pins) width should be equal to nominal part lead width. The minimum lead to lead spacing

should be ≥ 0.2mm to minimize shorting.

Lead land length should be equal to maximum part lead length + 0.3 mm outboard extension. The outboard

extension ensures a large toe fillet that can be easily inspected.

Pad lands (the 4 big pads) length and width should be equal to maximum part pad length and width. However, the

minimum metal to metal spacing should be no less than 0.17mm for

Copper, or no less than 0.23mm for 3 oz. Copper.

2 oz. Copper, or no less than 0.1mm for 1 oz.

12

Page 13

IRDC3863

Solder Resist

It is recommended that the lead lands are Non Solder Mask Defined (NSMD). The solder resist should be pulled

away from the metal lead lands by a minimum of 0.025mm to ensure

NSMD pads.

The land pad should be Solder Mask Defined (SMD), with a minimum

0.05mm to accommodate solder resist misalignment.

Ensure that the solder resist in between the lead lands and the pad land is ≥ 0.15mm due to the high aspect ratio of

the solder resist strip separating the lead lands from the pad land.

overlap of the solder resist onto the copper of

13

Page 14

Stencil Design

IRDC3863

The Stencil apertures for the lead lands should be approximately

amount of solder deposited will minimize the occurrences of lead

center pad, the part will float and the lead lands will open.

The maximum length and width of the land pad stencil aperture should be equal to the solder resist opening minus

an annular 0.2mm pull back in order to decrease the risk of shorting the center land to the lead lands when the part

is pushed into the solder paste.

80% of the area of the lead lads. Reducing the

shorts. If too much solder is deposited on the

14

Page 15

IRDC3863

IR WORLD HEADQUARTERS:

233 Kansas St., El Segundo, California 90245, USA Tel: (310) 252-7105

TAC Fax: (310) 252-7903

Visit us at www.irf.com for sales contact information

Data and specifications subject to change without notice. 06/2011

15

Loading...

Loading...