International Rectifier IRDCiP2001-B Reference Design

R

Overview

In this document, table 1 and figure 1 are provided to enable engineers to

easily evaluate the iP2001 in a 3-phase configuration that is capable of

providing up to 60A in a lab environment without airflow. Figures 3, 4, 5 and

6 and the complete bill of materials in table 2 are provided as a reference

design to enable engineers to very quickly and easily design a 3-phase

converter. In order to optimize this design to your specific requirements

refer to the data sheet for the controller listed in the bill of materials. A variety

of other controllers may also be used, but the design will require layout and

control circuit modifications.

Demoboard Quick Start Guide

Initial Settings:

z The output is set to 1.7V, but can be adjusted from 1.1 to 1.85V by setting

z The switching frequency per phase is set to 500kHz with the frequency set resistor R4. This creates an effective

Procedure for Connecting and Powering Up Demoboard:

1. Apply input voltage (5-12V) across VIN (TP18) and PGND (TP14). Note that this input source must be applied first during

2. Apply +5V logic power across +5V (TP19) and PGND (TP20).

3. Apply load across VOUT pads (TP10 - TP12) and PGND pads (TP14 - TP16)

4. Set ENABLE high.

5. Monitor switch node signals (optional) via TP6 - TP8.

6. Adjust load accordingly.

EFERENCE

R

EFERENCE

International Rectifier • 233 Kansas Street, El Segundo, CA 90245 USA

IRDCiP2001-B, 500kHz, 60A, 3-phase Synchronous Buck

S1 according to the VID codes provided in Table 1. Droop control is set to 50mV at 60A, but can be adjusted by

following the instructions in the data sheet for the PWM controller.

output frequency of 1.5MHz. The graph in figure 1 shows the relationship between R4 and the switching frequency

per phase. This frequency may be adjusted by changing R4 according to this graph; however, extreme changes

from the 500kHz set point may require redesigning the control loop and adjusting the values of input and output

capacitors. Also, refer to the SOA graph in the iP2001 datasheet for maximum operating current at different

frequencies.

the power-up sequence.

D

D

Converter using iP2001

ESIGN

ESIGN

IRDCiP2001-B

iP2001 Recommended Operating Conditions

(refer to the iP2001 datasheet for maximum operating conditions)

Input voltage: 5 - 12V

Output voltage: 1.1 - 1.85V

Output current: 20A per phase, 60A total for 3-phase demo board.

Switching Freq: 500kHz per phase, 1.5MHz effective output frequency.

07/19/02

IRDCiP2001-B

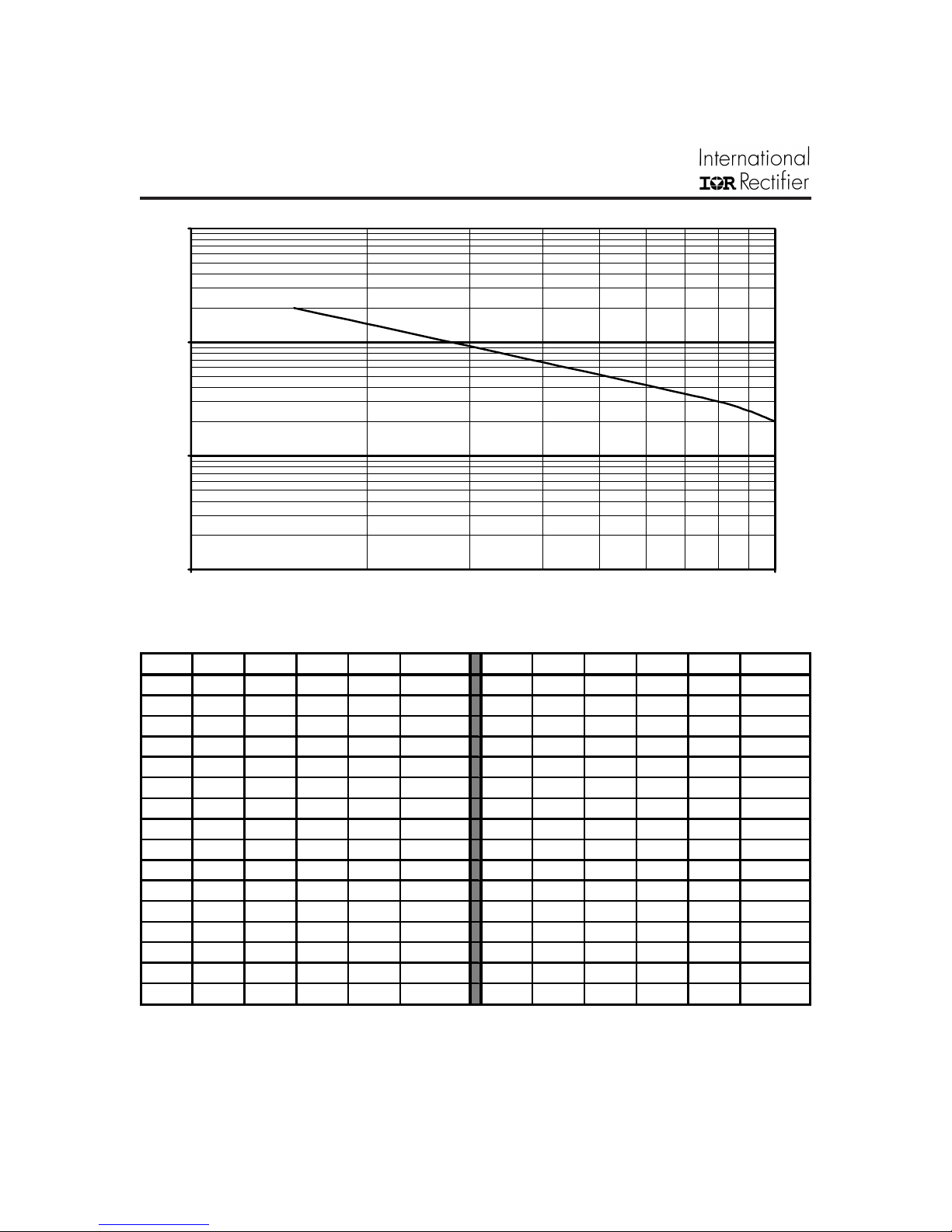

1000

100

)

Ω

Resistance (k

10

1

100 1000

Output Frequency (kHz)

Figure 1 - R4 vs. Frequency per Phase

VID4 VID3 VID2 VID1 VID0 VDAC VID4 VID3 VID2 VID1 VID0 VDAC

11111 Off 011111.475

111101.100 011101.500

111011.250 011011.525

111001.150 011001.550

110111.175 010111.575

110101.200 010101.600

110011.225 010011.625

110001.250 010001.650

101111.275 001111.675

101101.300 001101.700

101011.325 001011.725

101001.350 001001.750

100111.375 000111.775

100101.400 000101.800

100011.425 000011.825

100001.450 000001.850

Table 1 - PWM IC Voltage Identification Codes

www.irf.com2

IRDCiP2001-B

92%

90%

88%

fSW= 500kHz

86%

VIN = 12V

= 1.6V

V

OUT

= 25°C

T

A

0 102030405060

fSW= 1MHz

84%

82%

80%

Efficiency

Output Current (A)

Figure 2 - Typical Efficiency vs. Current

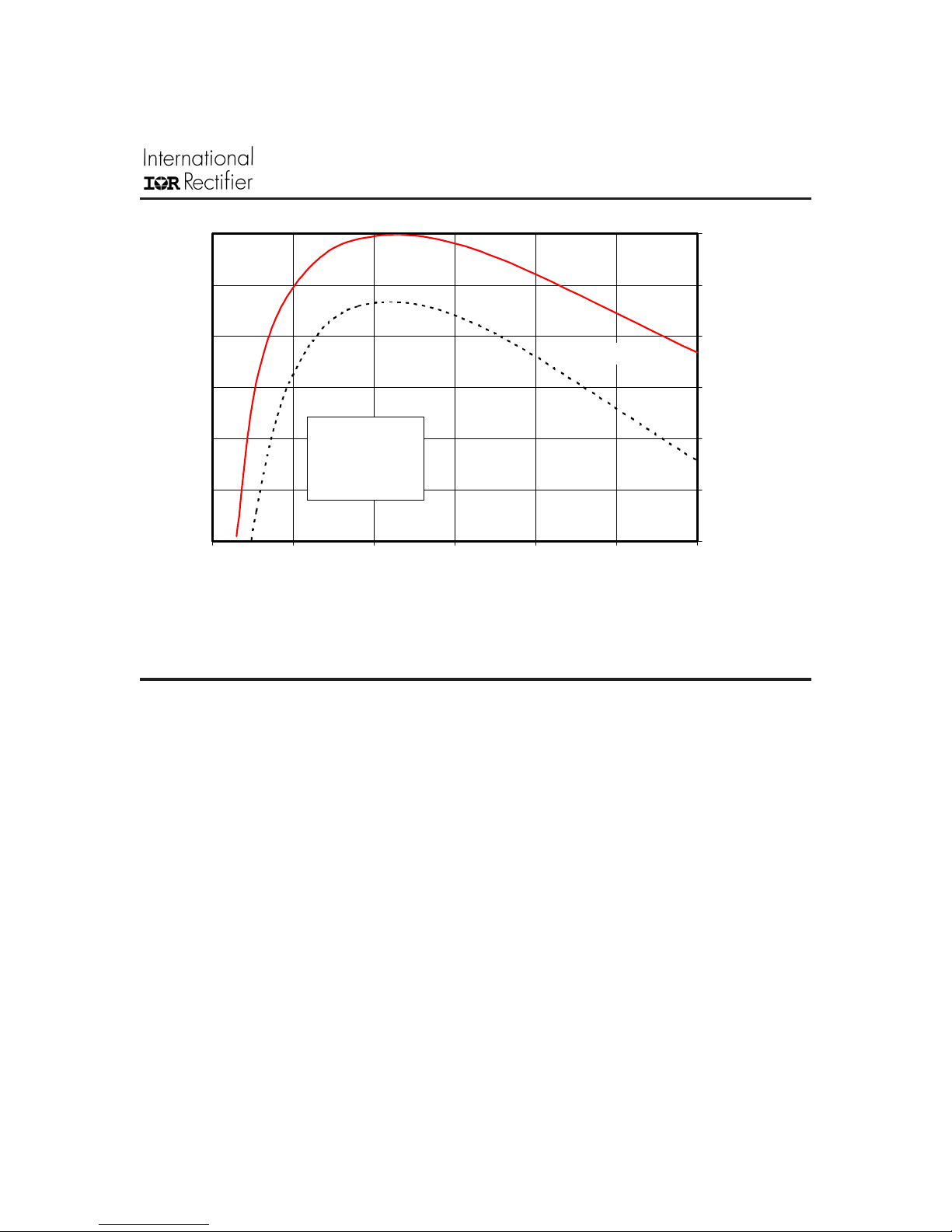

Refer to the following application notes for detailed guidelines and suggestions when

implementing iPOWIR Technology products:

AN-1028: Recommended Design, Integration and Rework Guidelines for International Rectifier’s

iPOWIR Technology BGA Packages

This paper discusses the assembly considerations that need to be taken when mounting iPOWIR BGA’s

on printed circuit boards. This includes soldering, pick and place, reflow, inspection, cleaning and

reworking recommendations.

AN-1029: Optimizing a PCB Layout for an iPOWIR Technology Design

This paper describes how to optimize the PCB layout design for both thermal and electrical performance.

This includes placement, routing, and via interconnect suggestions.

AN-1030: Applying iPOWIR Products in Your Thermal Environment

This paper explains how to use the Power Loss and SOA curves in the data sheet to validate if the

operating conditions and thermal environment are within the Safe Operating Area of the iPOWIR product.

www.irf.com 3

Loading...

Loading...