International Harvester Company 105 Operator's Manual

Break-in

at

mower

for

10hours

first

INTRODUCTION

The International 105 Balanced Mower

is designed for use on the International Cub 8

Lo-Boye, Farmall Cub e, International and

Farmal18 Super A, Super A-l, 100, 130 and

140 Tractors. It is well suited for both industrial and farm use. A completing package

is required to mount on your tractor.

This mower is especially built for highspeed mowing. It is ruggedly built with an

exclusive new wrist-action drive, balanced

for smooth running for longer machine life

and operator's comfort. It is especially

designed for cutting heavy hay and othervegetation.

or for mowing highway shoulders,

rights-of-way, and other industrial applications. It will operate efficiently with the cutter bar at any angle from. 450 below horizontal

to 900 vertical. This feature makes it desirable for cutting steep highway banks and

slopes. The. free floating action of the cutter

bar permits close operating positions along

the contour of the ground.

The tractors must be equipped with one of

the following units:

Touch Control for Farmall and hlternational

140 Basic Tractors for use with 105 Mowers

(Factory Application) (Standard Equipment on

hlternational 140 Standard Tractor).

354 467 R99 Special Touch Control for

Farmall and mternational"A", Super A,

100, 130, and 140 Tractors not previously

equipped with Touch Control.

The hydraulic system enables the operatorto

raise the cutter bar to clear obstructions

or to raise the mowe r to transport position.

The mower operator can quickly adjust the

cutter bar for height to meet various mowing

conditions, permitting independent control ofthe

inner and outer shoes. A completing pack-

age is required for the International Cub Lo-

Boy and Farmall Cub Tractors.

358 119 R 91 Special Touch Control Con-version

Package for Farmall and International

"A", Super A, 100, 130, and 140 Tractors

equipped with Touch Control.

381 223 R91 Restricted Actuator Package

(Factory Application) for International Cub

Lo-Boy, and Farrnall Cub Tractors.

A 5-foot cutter bar is standard equipment,

381 228 R9l Restricted Actuator Package

(Field Conversion) for International Cub LoBoy and Farmall Cub Tractors.

A variety of special knife assemblies areavailable

for this cutter bar.

Note: The Farmall Cub and International

Cub La-Boy tractors must be equipped withhead

gasket 351 989 R6.

Other special equipment and attachmentsare

as follows:

The tractor Fast-Hitch cannot be used in

conjunction with the mower. However, the

Fast-Hitch helper spring parts are required

when the mower is mounted on the Cub or

Cub Lo-Boy Tractors.

Outer Shoe Grass Deflector -to prevent

the cut material from falling into the un-

cut material.

Knife Rack Attachment -to carry extraknife

assembly in the field.

The mower is mounted on the right side ofthe

tractor main frame between the front and

rear wheels. Power is transmitted from the

rear power take-off on the tractor through a

roller chain to the universal joint drive shaft.

A heavy-duty V -belt drive transmits the power

to the balanced drive. The entire drive is

completely shielded.

Curb Lift Attachment for International Cub

Lo-Boy and Farmall Cub Tractors -will

hold the inner shoe above ground level, up

to lO'l high to enable the cutter bar to be

placed in and position with the working

range of 45 below horizontal to vertical.

half throttle

LUBRICA TION

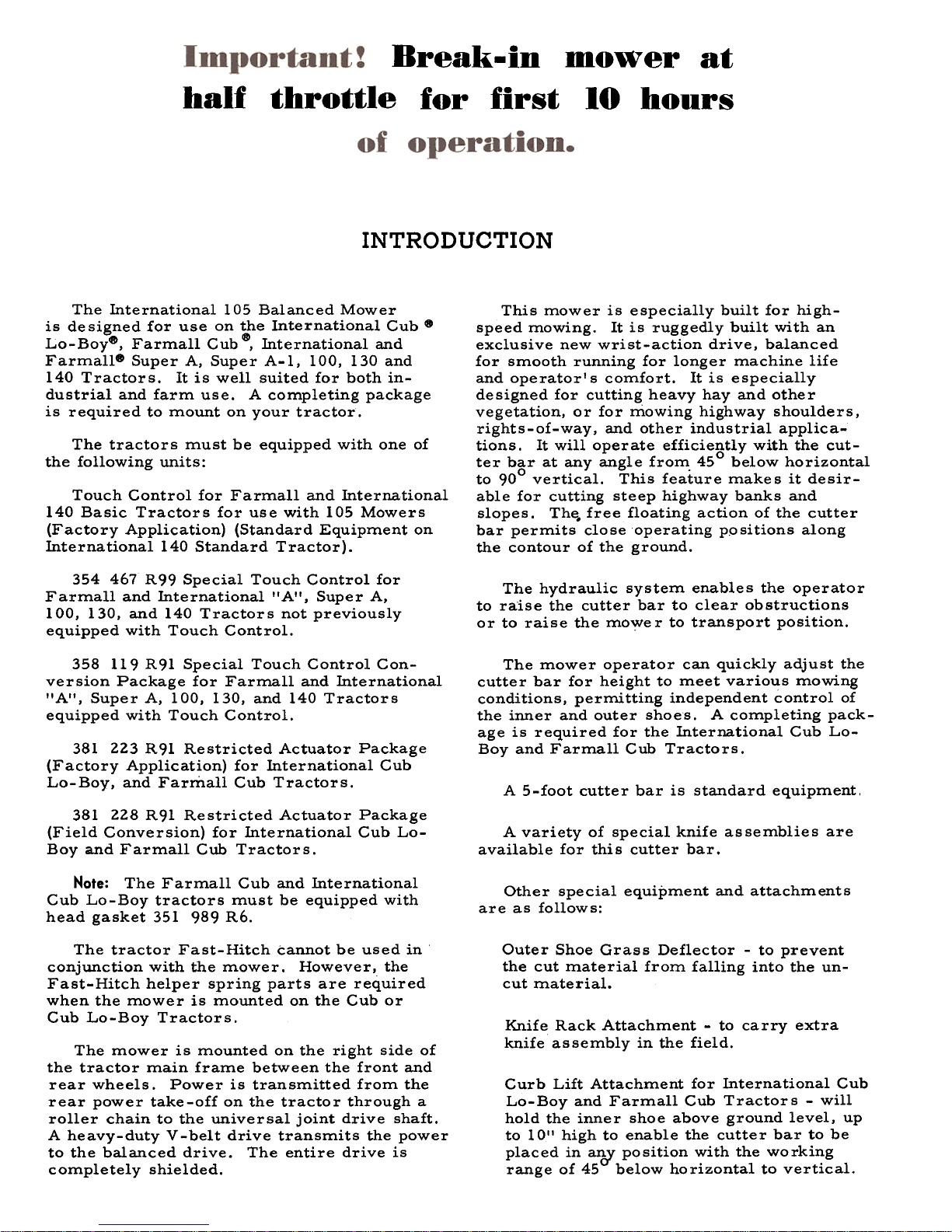

Lubrication Guide

This machine is designed to require a

minimum amount of lubrication; however, regular and sufficient lubrication increases the

life of the machine, saves many dollars in

service parts, and is the best insurance

against delays.

Before starting, lubricate the complete

machine following the "Lubrication Guide",

and thereafter lubricate at regular intervals

as specified.

Care must be taken to see that all bearings

are lubricated their full length. To be certain

that all bearings are properly lubricated, the

lubricant should be forced into them until it

begins to appear at the sides.

Keep the lubricator gun clean and wipe off

all dirt from the lubrication fittings before

using the gun.

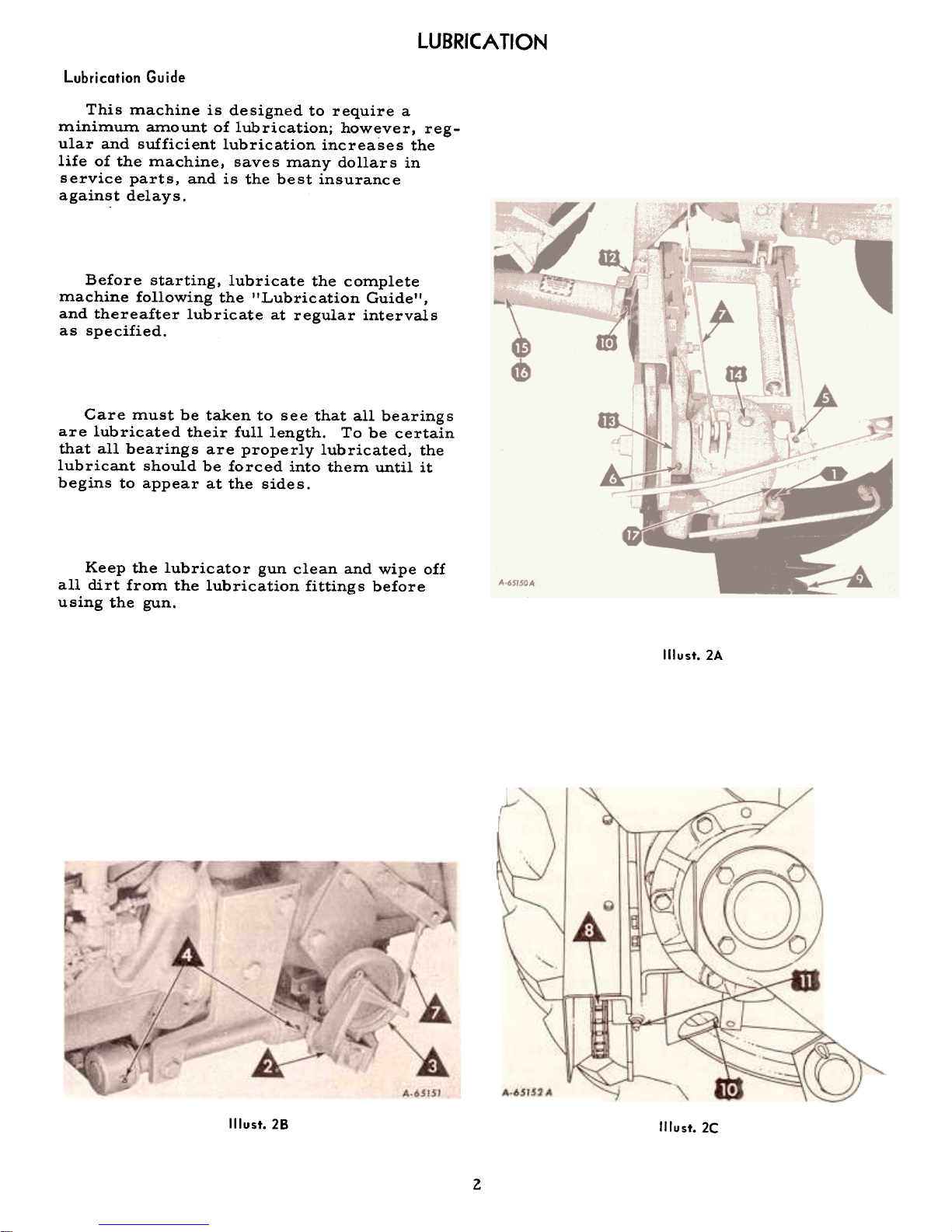

Illust. 2A

Illust.28

Illust.2C

2

Key to Lubrication Guide

The symbols shown around the reference numbers in Illusts. 2A, 2B,

and 2C indicate the intervals of lubrication. Paragraph numbers

correspond to reference numbers in the illustrations.

More Often Than Daily

Twice daily, use chassis lubricant (pressure-gun grease)

and apply sufficient lubricant to flush out the old grease and

dirt.

Knife pin

Daily or After Every 10 Hours of Operation

2. Cable pulley support

3. Cable pulley4.

Frame hinge5.

Front hinge

6. Rear hinge

Use chassis lubricant (pressure-gun grease) and apply

sufficient lubricant to flush out the old grease and dirt.

7.

8.

Lifting cable

Drive chain

Use an oilcan.

Lubricate with oil, using an oilcan.

9.

Knife guides, wearing

plates, and knife clips

hllocalities where the soil is sandy or full of grit, theknife

guides, wearing plates, and knife clips should not be

oiled. hl other localities where these conditions do not exist,

oil them daily.

Every Three Days of After 30 Hours of Operati on

10.

Power drive knuckle

Use chassis lubricant (pressure-gun grease) and lubricate

the universal drive center crosses (2 fittings).

Only a few strokes of the pressure-gun are required. Do

not use a high-pressure gun. Excessive lubricant force_d

through the bearings may destroy the seals.

1112.

Rear drive shafthousing

Belt pulley bearing

Use chassis lubricant (pressure-gun grease).

Only a few strokes of the pressure-gun are required. Do

not use a high-pressure gun. Excessive lubricant forced

through the bearings may destroy the seals.

Use a pressure-gun lubricant (Lithium mUlti-purpose

grease, type 2). Apply 3/8-ounce of Lithium mUlti-purpose

grease, type 2. This can be determined in terms of strokes

of the lubricating gun, depending on the type used. Do notuse

a high-pressure gun. Under extremely dusty conditions,lubricate

every 20 hours.

13. Balancing head bearing

housirtg14.

Crankshaft housing

(under top button plug)

Periodic

15.

Knuckle shaft and sleeve16.

Telescoping shields

Two or three times a season, or whenever assembling the

knuckle shaft and sleeve, be sure to insert a liberal amount

of grease in the end of the sleeve; then freely grease the

shaft. Work the shaft in and Qut of the sleeve so that the

sleeve .and shaft are well lubricated. Repeat when necessary.

When assembling the shields, grease and work them in

and out several times. Repeat when ~ecessary.

Two or three times a season, use lithium multi-purpose

grease, type 2 (pressure-gun grease). Ten strokes of the

pressure-gun are required: Do not use a high pressure

gun. Excessive lubricant forced through the bearings may

destroy the seals. .

3

17. Balanced Head

Pivot Bearing (behind

fro~t button plug)

ADJUSTING AND OPERATING

OPERATING

Before going into the field, check to see

that your machine is properly set up, adjusted,

and lubricated as in'structed.

Farmall and Internatianal Super A, Super A.l, 100, 130, and

140 Tractor: To raise the cutter bar. move the

left Touch-Control lever forward; to lower the

cutter bar. move the lever to the rear. To

raise the mower frame. move the right TouchControl lever forward; to lower the frame move

the lever to the rear.

Be sure all nuts are tight. They should be

tightened after a few hours of service. Spread

all cotters to keep them from falling out.

The wrist action drive is rugged and simple

designed to insure long life and trouble free

operation, however, its precision construction

requires a certain amount of break-in time.

Therefore, it is suggested that this mower be

run at. half (1/2) throttle under actual field

conditions for approximately the first 10 hours

This should be sufficient break-in time, after

which the mower can be operated at full speed.

During the break-in period the bearings will

run warmer than usual, but will not cause any

undue damage because of the unit being prepacked with "Lithium multi-purpose grease'!

as specified in the lubrication chart.

TOUCH.CONTROL SYSTEM

The Touch-Control power system utilizes

the power of the tractor engine to raise and

lower the cutter bar. A light touch of your

finger on the control lever is sufficient.

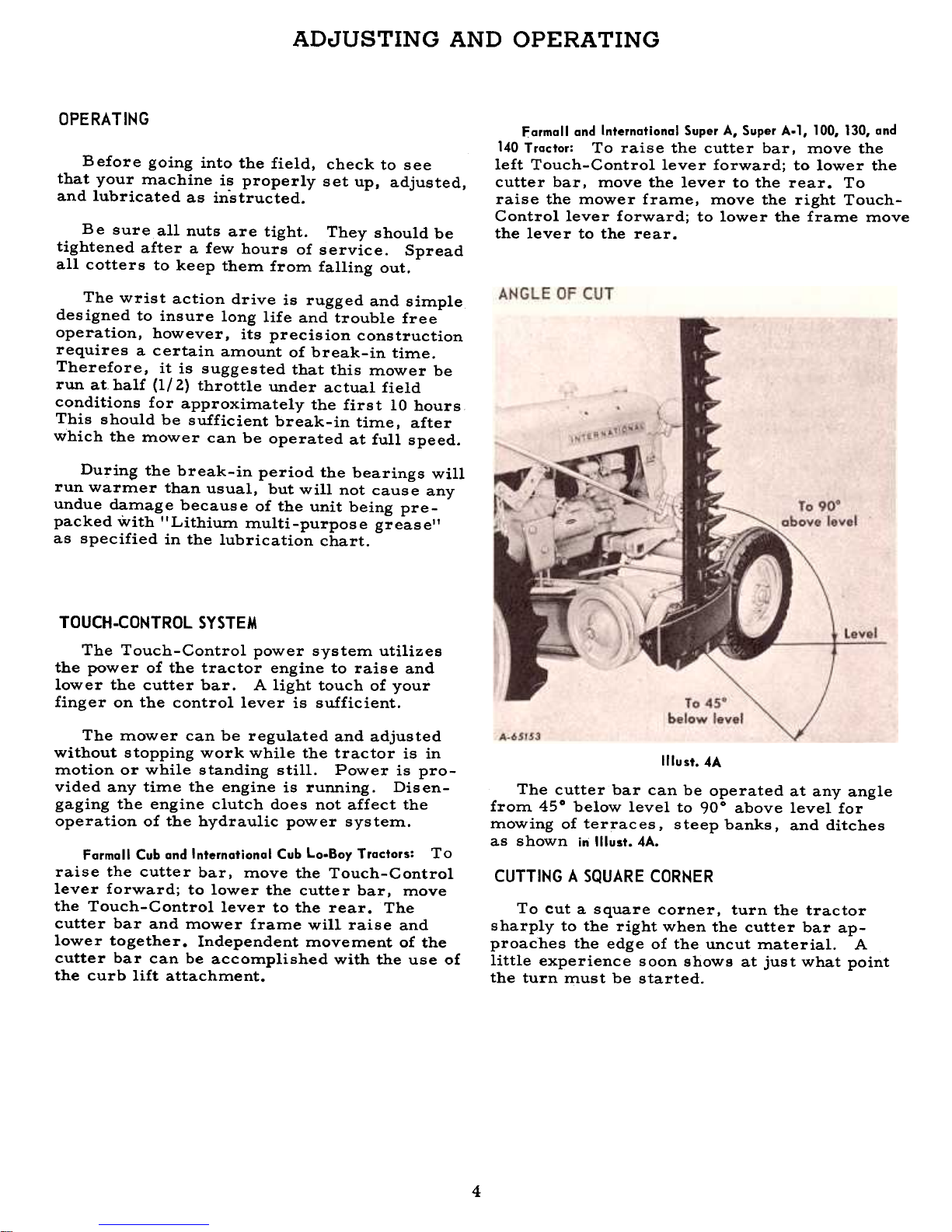

Illust. 4A

The cutter bar can be operated at any angle

from 450 below level to 900 above level for

mowing of terraces. steep banks. and ditches

as shown in Illust. 4A.

The mower can be regulated and adjusted

without stopping work while the tractor is in

motion or while standing still. Power is provided any time the engine is running. Disengaging the engine clutch does not affect the

operation of the hydraulic power system.

Farmall Cub and Internatianal Cub Lo.8oy Tractors: To

raise the cutter bar, move the Touch-Control

lever forward; to lower the cutter bar, move

the Touch-Control lever to the rear. The

cutter bar and mower frame will raise and

lower together. Independent movement of the

cutter bar can be accomplished with the use of

the curb lift attachment.

CUTTING A SQUARE CORNER

To cut a square corner, turn the tractor

sharply to the right when the cutter bar approaches the edge of the uncut material. A

little experience soon shows at just what point

the turn must be started.

4

CUTTER BAR LIFT

The cutter bar lift cable and lifting chain

should be set so that when the Touch-Control

lever is in the forward position, the cutter bar

will be approximately vertical. If the bar is

not vertical, this can be corrected by adjusting

the length of the cable and chain, either

lengthening or shortening.

Illust. 58

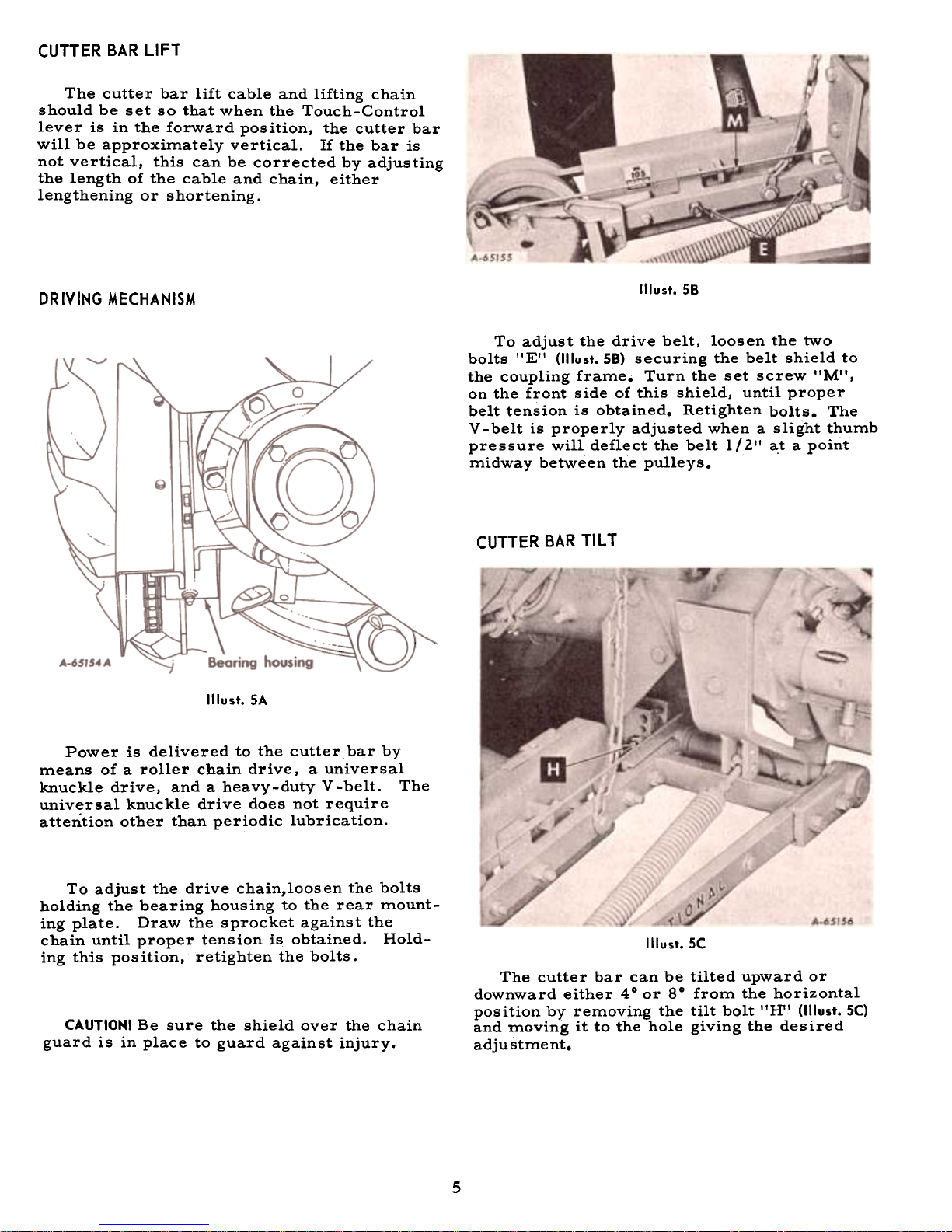

DRIVING MECHANISM

To adjust the drive belt, loosen the two

bolts 'IE" (1IIust.58) securing the belt shield to

the coupling frame. Turn the set screw "M",

onthe front side of this shield, until proper

belt tension is obtained. Retighten bolts. The

V -belt is properly adjusted when a slight thumb

pressure will deflect the belt 1 (2" a.t a point

midway between the pulleys.

CUTTER BAR TILT

Illust. SA

Power is delivered to the cutter. bar by

means of a roller chain drive, a universal

knuckle drive, and a heavy-duty V-belt. The

univ~rsal knuckle drive does not require

attention other than periodic lubrication.

To adjust the drive chain,loosen the bolts

holding the bearing housing to the rear mounting plate. Draw the sprocket against the

chain until proper tension is obtained. Holding this pos ition, retighten the bolts.

Illust. SC

The cutter bar can be tilted upward or

downward either 40 or 80 from the horizontal

position by removing the tilt bolt "H" (1IIust.5C)

and moving it to the hole giving the desired

adju stme nt.

CAUTION! Be sure the shield over the chain

guard is in place to guard against injury.

5

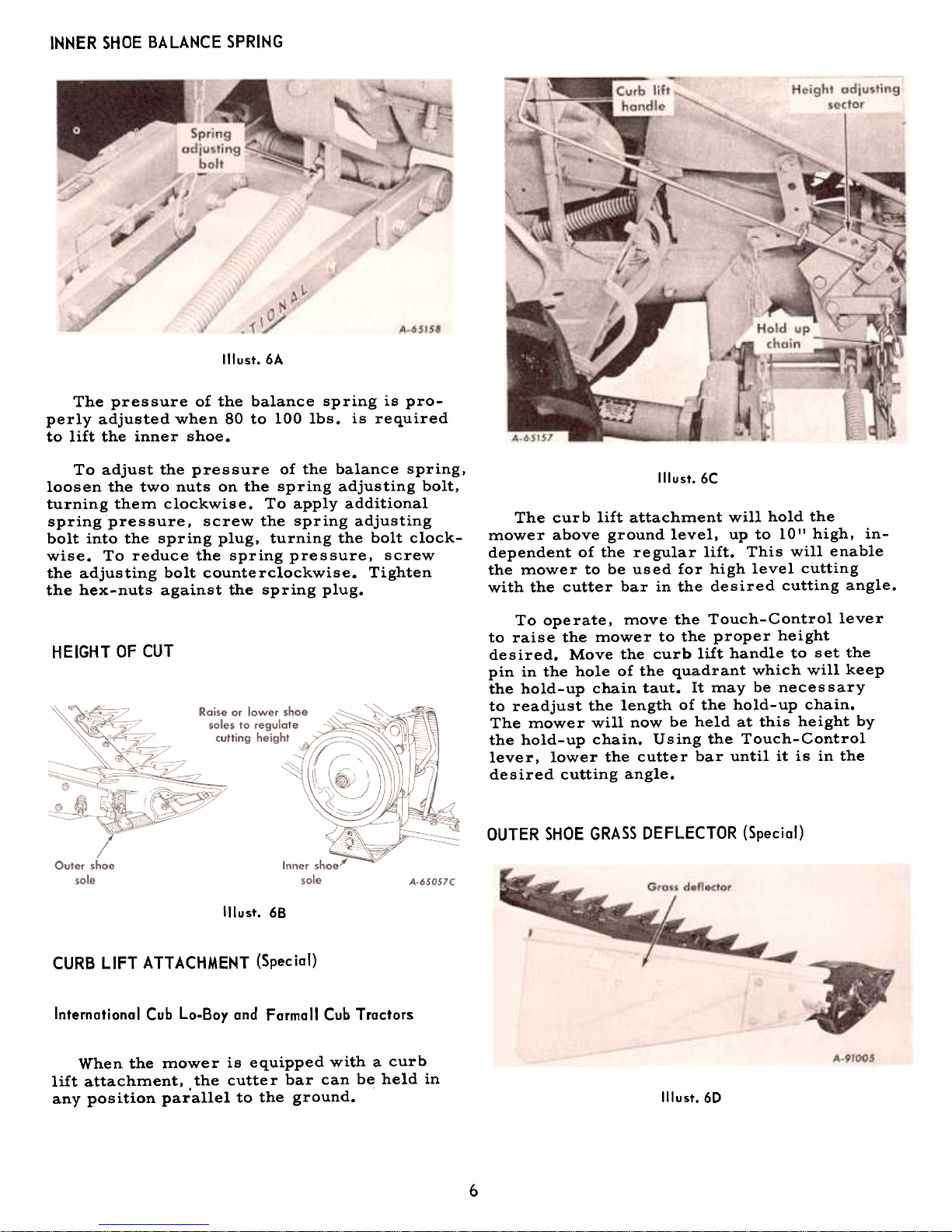

INNER SHOE BALANCE SPRING

Illust.6A

The pressure of the balance spring is pro-

perly adjusted when 80 to 100 Ibs. is required

to lift the inner shoe.

To adjust the pressure of the balance spring,

loosen the two nuts on the spring adjusting bolt,

turning them clockwise. To apply additional

spring pressure, screw the spring adjusting

bolt into the spring plug, turning the bolt clockwise. To reduce the spring pressure, screw

the adjusting bolt counterclockwise. Tightenthe

hex-nuts against the spring plug.

Illust.6C

The cur b lift attachment will hold the

mower above ground level. up to 10" high, independent of the regular lift. This will enable

the mower to be used for high level cutting

with the cutter bar in the desired cutting angle.

HEIGHT OF CUT

To operate, move the Touch-Control lever

to raise the mower to the proper height

desired. Move the curb lift handle to set the

pin in the hole of the quadrant which will keep

the hold-up chain taut. It may be necessary

to readjust the length of the hold-up chain.

The mower will now be held at this height by

the hold-up chain. Using the Touch-Control

lever, lower the cutter bar until it is in the

desired cutting angle.

OUTER SHOE GRASS DEFLECTOR (Special)

Illust. 68

CURB LIFT ATTACHMENT (Special)

International Cub Lo-Boy and Farmall Cub Tractors

When the mower is equipped with a curb

lift attachment. the cutter bar can be held in

any position parallel to the ground. Illust.6D

6

Loading...

Loading...