International Harvester Company 102, 122, 71, 123, Cub Cadet 102 Operator's Manual

...

!

E

U

71,1

22 ant

TRACT0

ATi

,CADET

#

123

L

iNTEFINATIONA,L

E AT

!

®

A in u_r _:_

pmr®d _m _,!eLmi Lo !e p y,_u betl;em urcimrm_amd

_he e@rr.@_ care a_:,::f ef icfes_ opera[ o of yeur

Yok:_r Iota] ! _te Ha_;w)_:R_t dealer

_, Tr_)_ EOr }s4S

:o_ain afmin_ k_st.r_._cdon r_ ui ud, i[: is

r;_a.f:ni:_:_i_;;_U_: the _a< 8, r Disve£;ard tkH:-

_'}pAi't:}_ k:r{! nLH73-

:)_£_ c_d ,.9_'_c c r r <:{s [H:)tHi w:t} [[ _ p a _ze _ 0 m wts [c h

£o£FT a_d :[%];G_IT nd cai:<_ tke 1e£[ a_d right

driver' 5e_I:, Refere_ce t:o NkON'F indR:_,_s

<h_:: £_Nle e:_;d of the. actor[ le REAR, the

8rawbar <w_d

INTRODUCTION

Illust. 1

International Cub Cadet 122 Tractor.

Illust. 1A

International Cub Cadet 102 Tractor.

INTRODUCTION

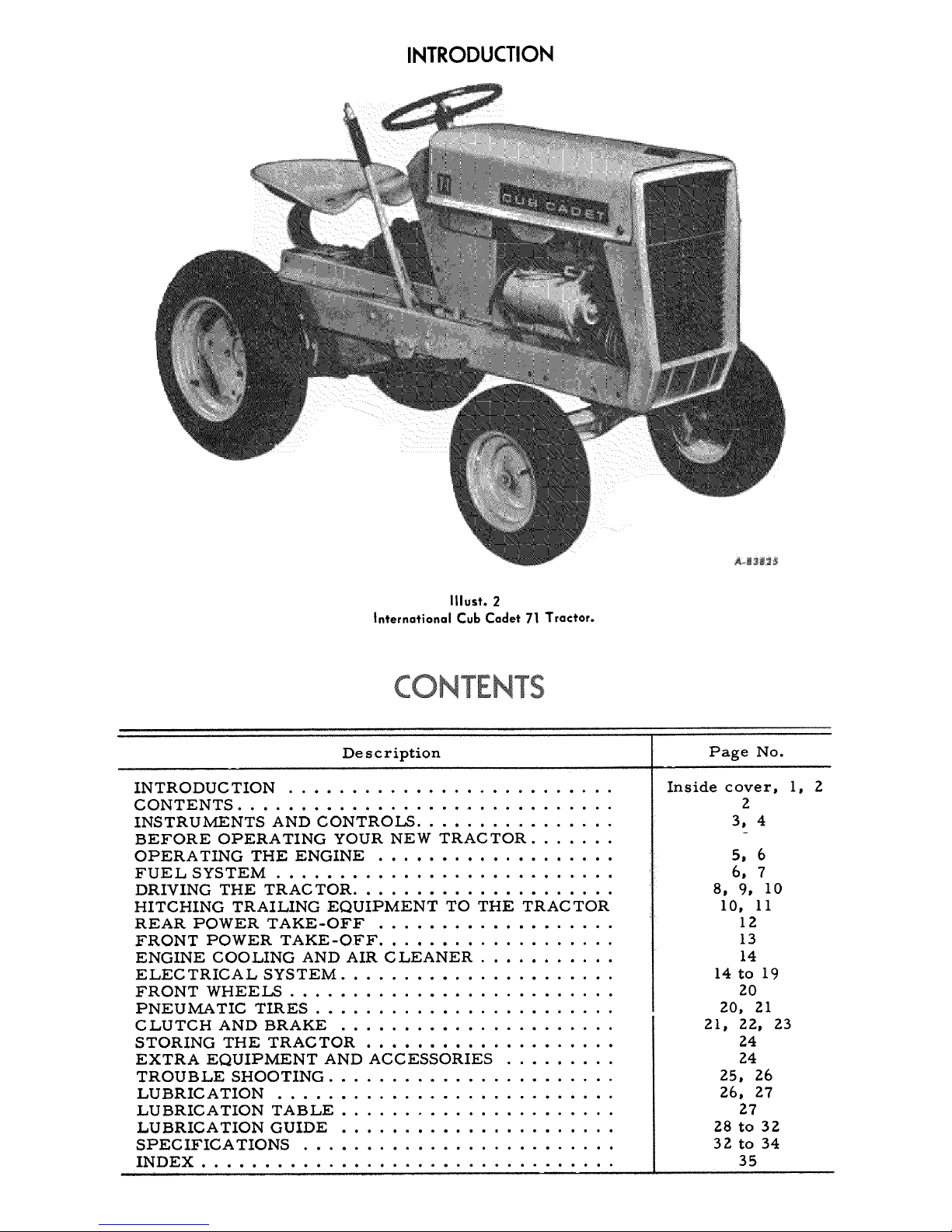

Illust. 2

{nternational Cub Cadet 71 Tractor.

De scription Page No.

INTRODUC TION ..........................

CONTENTS ...............................

INSTRUMENTS AND CONTROJ._ ................

BEFORE OPERATING YOUR NEW TRACTOR .......

OPERATING THE ENGINE ...................

FUEL SYSTEM ...........................

DRIVING THE TRACTOR .....................

HITCHING TRAILING EQUIPMENT TO THE TRACTOR

REAR POWER TAKE-OFF ...................

FRONT POWER TAKE-OFF ...................

ENGINE COOLING AND AIR CLEANER ...........

ELEC TRICAL SYSTEM ......................

FRONT WHEELS ..........................

PNEU 1ViATIC TIRES ........................

CLUTCH AND BRAKE ......................

STORING THE TRACTOR ....................

EXTRA EQUIPMENT AND ACCESSORIES .........

TROUBLE SHOOTING .......................

LUBRIC ATION ...........................

LUBRICATION TABLE ......................

LUBRICATION GUIDE ......................

SPECIFICA TIONS .........................

INDEX .................................

Inside cover, 1, Z

Z

3, 4

5, 6

6, 7

8, 9, I0

I0, II

IZ

13

14

14 to 19

ZO

ZO, Zl

21, 22, 23

24

24

25, 26

Z6, 27

27

28 to 32

32 to 34

35

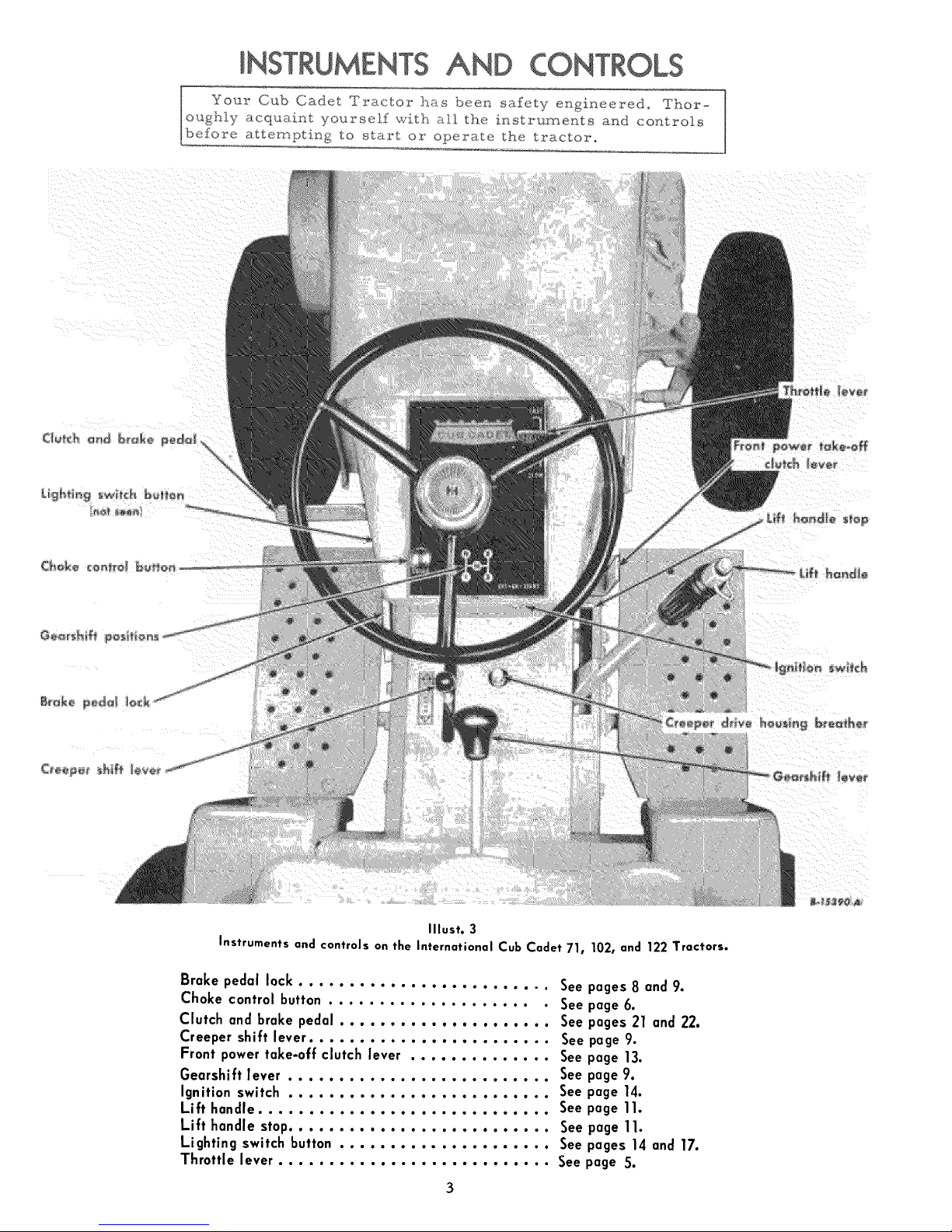

Your Cub Cadet Tractor has been safety engi_'_eered, Thor-

oughly acquaint yourself with a,ll the i_strurr_ents and controls

befoxoe attempting to start oz.- operate the tractor,

Illust. 3

Instruments and controls on the International Cub Cadet 71,

Brake pedal lock ......................... See

Choke control button ..................... See

Clutch and brake pedal ..................... See

Creeper shift lever ........................ See

Front power take-off clutch lever .............. See

Gearshift lever .......................... See

Ignition switch .......................... See

Lift handle ............................. See

Lift handle stop.......................... See

Lighting switch button ..................... See

Throttle lever ........................... See

102, and 122 Tractors.

pages 8 and 9.

page 6.

pages 21 and 22.

page 9.

page 13.

page 9.

page 14.

page 11.

page 11.

pages 14 and 17.

page 5.

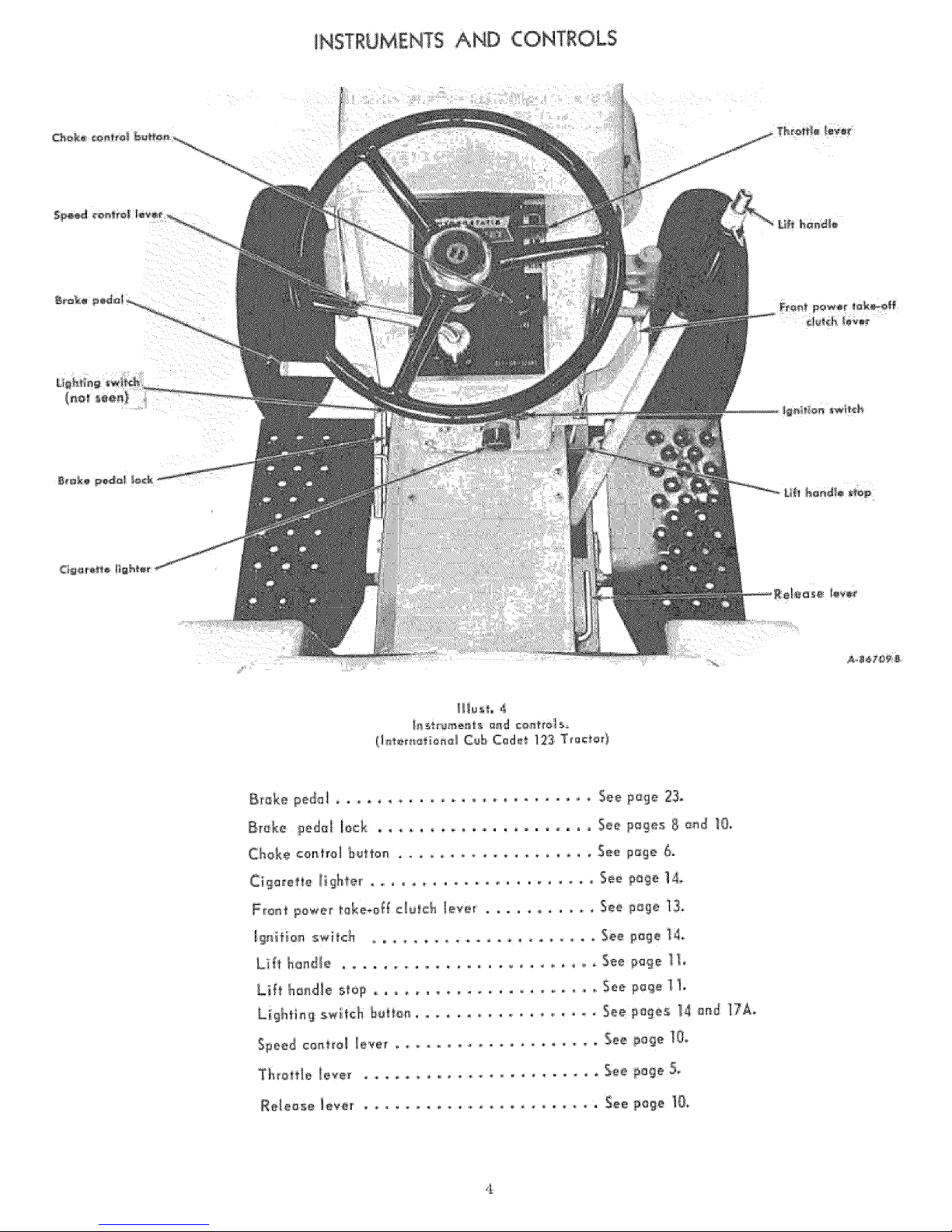

iNSTRUMENTS AND CONTROLS

BEFOREOPERATING YOUR NEW TRACTOR

Lubrication ...... Lubricate the entire tractor. See pages 26 to 32.

Tires .......... Check the air pressure. See pages 20 and 21.

Fuel system ..... Fill the fuel tank with gasoline. See page 6.

Illust. 5

Fuel system and controls on International Cub Cadet 123 Tractor.

(international Cub Cadet 71, 102 and 122 Tractors are similar.)

THROTTLE LEVER

This lever controls the speed of the engine.

When set in a given position, it will maintain

a uniform engine speed.

LIFTING THE HOOD

The tractor hood is arranged to swing up

and forward to make the engine and fuel tank

readily accessible.

GOVERNOR

The governor is set at the time the engine

is assembled and should not require readjust-

ment unless the governor arm is removed or

loosened from the governor shaft. Consult

your International Harvester dealer if the

governor does not function properly.

To raise the hood, take hold of each side of

the hood at the rear, pull outward, and raise

it upward and forward to its stop.

STARTING THE ENGINE

OPERATING

Be sure the fuel shut-off valve is open.

Z. Pull the choke control button all the way

out {see Illust.3 or4). More or less choking may be

necessary due to variations in temperature,

grade of fuel, etc. Little or none will be

needed when the engine is warm.

3. Place the throttle lever halfway between

"SLOW" and "FAST". See Illust.3 or 4.

4.Electric Starting: The engine cannot be

started unless the brake pedal is pressed all

the way down to activate the safety starting

switch.

International Cub Cadet 71, I02, and Igg

Tractors: Check to see that the gearshift lever

is in the neutral position. S,e illust.3.

International Cub Cadet 123 Tractor: Check

to see that the speed control lever is in the

"N" position. See Illust. 4.

All Models: Turn the ignition key clock-

wise to the "START" position and release it

as soon as the engine starts; however do not

operate the motor-generator for more than

30 seconds at any one time. If the engine does

not start within this time, turn the key "OFF"

and wait a few minutes, then try again.

5. After the engine starts, slowly release

the brake pedal and gradually push the choke

THE ENGINE

control button all the way in. Do not use the

choke to enrich the fuel mixture, except when

necessary to start the engine.

Manual Starting: (Tractors without electric

starting). Raise the tractor hood. The retract-

able starter is mounted on a support plate at

the front of the engine at the right side of the

tractor.

l°ut the gearshift lever in the neutral posi-

tion and lock the brake. Turn the key ignition

switch clockwise.

Give a quick steady pull on the retractable

starter handle to start the engine. Do not jerk,

or pull it out to its very end in a rough manner.

A steady pull will accomplish just as much.

Always pull the handle so the cord is in a

straight line through the guide. Maintain your

hold on the handle and allow the cord to return

slowly. Releasing the handle when the cable is

extended will shorten the life of the starter.

5. After the engine starts, slowly release

the clutch pedal and gradually push the choke

control button all the way in. Do not use the

choke to enrich the fuel mixture, except when

necessary to start the engine.

STOPPINGTHE ENGINE

Move the throttle lever to the "SLOW" po-

sition and allow the engine to idle for a short

time before stopping. Then turn the key to the

"OFF" position.

FUEL SYSTEM

Fill the fuel tank with clean, fresh, regular

grade gasoline, preferably at the end of each

day's use. This will force out any moisture-

laden air and prevent condensation in the fuel

tank. Do not mix oil with the gasoline.

The fuel tank filler cap has an air vent.

Keep the vent open at all times to assure

proper flow of the fuel.

Caution! Never remove the fuel tank cap

or fill the fuel tank when the engine is running,

is hot, or when near an open flame. Do not

smoke when working around inflammable fuel,

as the air around the tractor is mixed with a

highly explosive vapor. When pouring fuel,

keep the container or hose nozzle in contact

with the metal of the fuel tank to avoid the

possibility of an electric spark igniting the

gas. Do not spill gasoline on a hot engine.

FUEL SHUT.OFF VALVE

Be sure the shut-off valve on the fuel

strainer under the gasoline tank is open.

Screw out the needle stem (Shut-off valve) un-

til the seat on the stem is tight against the

stop, to prevent leakage or seepage when the

valve is in its full-open position.

CLEANING THE FUEL STRAINER AND SEDIMENT BOWL

After every Z5 hours of operation, clean

he fuel strainer as follows:

i. Close the shut-off valve. See lllusts.7and 7A).

Loosen the knurled nut under the sediment

bowl and remove the bowl and screen.

Z. Clean the sediment bowl and screen.

3. When reassembling, be sure the gasket

between the bowl and the main body is in good

condition and does not leak. Use a new gasket

if necessary.

FUEL SYSTEM

Illust. 7

Carburetor and fuel strainer.

(International Cub Cadet 71 Tractor)

CARBURETOR ADJUSTMENTS

The carburetor is adjusted at the factory

and under normal operating conditions it will

not require readjusting. If this adjustment has

been disturbed for any reason, proceed as

follows:

Adjusting the High-Speed Adjustment Screw

Turn the high speed adjustment screw (lllusts.

7 and 7A) counter-clockwise approximately two

turns from the closed position and start the en-

gine.

After the engine has reached normal oper-

ating temperature, accelerate the engine and

check its response.

Place the engine under load and turn the

high speed adjustment screw (lllusts. 7 and 7A) to

the leanest mixture that will allow satisfactory

acceleration and steady governor operation.

If the engine misses and backfires under

load, the high speed mixture is too lean. The

high speed adjustment screw must be turned

counter-clockwise 1/4 turn at a time until the

condition is corrected.

If the engine shows a sooty exhaust and is

sluggish under load, the high speed mixture is

too rich. The high speed adjustment screw

must be turned clockwise 1/4 turn at a time

until the condition is corrected.

7

Illust. 7A

Carburetor and fuel strainer.

(International Cub Cadet 102, 122 and 123 Tractors)

For a final check of the high speed adjust-

ment, operate the engine under load and make

any corrections necessary for smooth opera-

tion.

Adjusting the Idle Adjustment Screw

After the high speed adjustment screw is

adjusted, it may be necessary to readjust the

idle adjustment screw (IIlusts.7 and 7A),as each

affects the other.

Close the idle adjustment screw to its seat

by turning it clockwise; then open it one turn.

Start the engine and operate it at fast idling

speed (without any load) until thoroughly warm.

While the engine is running at fast idle

speed, it is advisable to screw in the throttle

stop screw ([llusts.Tand 7A)a few turns to keep

the engine from stopping when the throttle

lever is moved to the fully retarded "SLOW"

position. The engine will then be idling at a

fairly high speed and the throttle stop screw

can be backed out a littleat a time until the

desired idle speed is obtained.

If the engine misses or rolls while backing

out the throttle stop screw, the idle adjustment

screw may be adjusted in or out until the en-

gine operates smoothly. Speed up the engine

for a few seconds; then recheck the idle ad-

justment. A slight adjustment in or out will

give the smoothest idle.

PREPARING THE TRACTOR FOR EACH DAY'S WORK

Fill the fuel tank at the end of each day's

run. See page 6.

Check the crankcase oil level and add new

oil if necessary. See page 26.

Clean the air cleaner element if necessary.

See page 14.

Inspect the tires for general condition. See

pages 20 and 21.

ADJUSTING THE SEAT

Illust. 8A

Adjusting the seat.

(International Cub Cadet 102 Tractor.)

Illust. 8

Adjusting the seat.

(International Cub Cadet 122 and 123 Tractors)

Before starting the tractor, adjust the seat

to the most comfortable driving position by

loosening the four cap screws in the seat sup-

port (Illust. 8) or seat bracket (lllust. SA) or seat

spring clamping plate (Illust. 8B) and sliding the

seat assembly forward or rearward to the

position which is most comfortable for the

operator.

Retighten the cap screws after the seat is

adjusted.

The International Cub Cadet 122 and 123

Tractors features a seat which can be tilted

forward over the steering wheel, for conven-

ience in adjusting the seat and to keep out

rain and snow. See |llust. 8.

Illust. 8B

Adjusting the seat.

(International Cub Cadet 71 Tractor.)

Illust. 8C

Brake pedal lock in the engaged position.

DRIVING THE TRACTOR

(InternationalCub Cadet 71, 102 and 122 Tractors)

CLUTCH AND BRAKE PEDAL

The combination clutch and brake pedal is

used to disengage the engine from the trans-

mission when shifting gears and to actuate the

brake to stop the tractor. The pedal must be

pressed all the way down to activate the safety

starting switch when starting the engine.

To disengage the clutch, press the pedal

approximately half way down. To stop the trac-

tor press the pedal all the way down.

LOCKING THE BRAKE

Always lock the brake when the tractor is

parked on a grade. To lock the brake, press

down on the brake pedal; then place the brake

pedal lock in the engaged position. To disen-

gage the lock, press down on the brake pedal

liftthe lock up and place it in the disengaged

position behind the brake pedal as shown in

Illust. 17A.

Note:Do not rest your foot on the pedal

while driving the tractor, as this will result

in excessive clutch lining wear.

Always be sure the rear wheels are free

to turn. Under any adverse conditions, do not

attempt to free the tractor by speeding up the

engine and suddenly engaging the clutch. Try

backing out instead of going forward.

STOPPING THE TRACTOR

Disengage the clutch by pressing the pedal

all the way down. Move the gearshift lever to

the neutral position.

CREEPER SHIFT LEVER

The creeper drive provides a slower speed

in each respective gear, by a four-to-one re-

duction in speed from direct drive. When the

creeper shift lever is all the way forward, it

is in direct drive, or all the way rearward, it

is in creeper drive. See Illust. 3. Note: Do not

use a mid-point position on the creeper drive

as neutral. Neutral position must be selected

only with the standard transmission gearshift

lever.

GEARSHIFT LEVER

This lever is used to select various gear

ratios provided in the transmission. There

are three forward speeds and one reverse

speed. See Illust. 3. Refer to "SPECIFICATIONS"

on page 32.

OPERATING THE CREEPER DRIVE

To operate the tractor in creeper drive,

move the creeper shift lever (illust. 3) all the

way rearward. Then select the speed desired

and proceed as instructed under "Starting the

Tractor".

STARTING THE TRACTOR

1. Advance the throttle lever slightly. See

Illust. 3.

Z. Disengage the clutch by pressing the

clutch pedal all the way down, and move the

gearshift lever to the desired speed.

3. Start the tractor in motion by slowly

releasing the clutch pedal and moving the

throttle lever to the position where the engine

operates best for the load to be handled.

Note: Do not shift gears while the engine

clutch is engaged or while the tractor is in

motion.

The following table shows the speeds avail-

able in each of the three forward gears and the

reverse gear.

Miles Per Hour

Gear

First

Second

Third

Reverse

Direct

Drive

Z. 3

3.9

6.8

Z. 5

Creeper

Drive

.6

1.0

1.7

.6

DRIVING THE TRACTOR

(InternationalCub Cadet 123 Tractor)

BRAKE PEDAL

The brake pedal must q_e pressed all the

way down to activate the safety starting switch.

When the brake pedal is in the depressed posi-

tion it automatically moves the speed control

lever to the "N" position.

The tractor can be stopped either by

pressing the pedal all the way down, or placing

the speed control lever in the "N" position.

LOCKING THE BRAKE

Always lock the brake when dismounting

from the tractor. To lock the brake, press

down on the brake pedal; then place the brake

pedal lock in the engaged position. See lllust.8C.

To disengage the lock, press down on the brake

pedal_ lift the lock up and place it in the dis-

engaged position behind the brake pedal as

shown inllIust.17A.

SPEED CONTROL LEVER

This lever is used to select any speeds

from a standstill "N" position to eight miles

per hour in the forward direction and to four

miles per hour in the reverse direction.

Moving the speed control lever forward

provides increased forward speeds, and mov-

ing the lever rearward provides the reversed

speeds.

Note: Do not rest your foot on the brake

pedal while driving the tractor as this would

cause the speed control lever to return to the

"N" position.

STARTING THE TRACTOR

I. Advance the throttle lever slightly.

Illust. 4.

See

g. Depress the brake pedal by pressing the

pedal all the way down, and move the towing

lever (Illust.4) in drive (horizontal) position,

then move the throttle lever to the position

where the engine operates best for the load to

be handled.

3. Start the tractor in motion by moving

the speed control lever forward or rearward

as de scribed above.

RELEASE LEVER

To push or move tractor for a short distance

or when working on the engine, the release le-

ver (Illust. 4) must be locked in the release

(down) position and the speed control lever must

be in the "N" position. Gaution: Do Not Tow.

STOPPINGTHE TRACTOR

Move the speed control lever to the "N"

position or use the brake. Before dismounting

always depress the brake pedal.

TRAILING EQUIPMENT TO THE

Trailing-type equipment must be hitched to

the tractor only at the hitch hole in the draw-

bar. Seelllusts. 11 and llA.

When the tractor has a three-point hitch

(lllusts. 11 and 11A) equipment adaptable to the

10

three-point hitch is raised and lowered with

the lift handle. The lift handle can be set to

hold the equipment at various positions by use

of the six notches in the lift handle quadrant.

The lower mounting bracket has three holes

which are used for additional adjustment.

Loading...

Loading...