International Harvester 274 Operator Manual

e

INTERNATIONAL

274

TRACTOR

OPERATOR'S

MANUAL

®

To The Owner

Y

our

new I nternational

ed

to

meet

ments.

ability

and

ity

your

Your

ested

tractor.

ed

modern

parts

ance.

The

to

work

requirement, and

of

the

hydraulic

work

local

in

the

He

in

the

latest

tools, and original-equipm.ent I H service

which

today's

ease

match

and shorten

International

performance

has

factory

method

assure

Harvester

exacting operating require-

and

comfort

ground

system are intended

your

trained servicemen,

proper

tractor

of

speeds

Harvester dealer

of

to

the

effort

hours on

you

receive

servicing tractors, and

fit

and good

is

operation,

engine

less

to

the

job.

from

perform-

design-

the

power

versatil-

lighten

is

inter-

this

inform-

To

obtain

operation

ing on its use,

'by

your

Before

carefully.

and

New

a

nominal

When in need

and engine serial numbers,

suffix

spaces

top

performance

the

tractor

periodically,

International

you

operate

It

has

been prepared

maintain

copies may

letters.

provided below.

your

price.

of

Write

shou

Harvester Dealer.

the

tractor,

tractor

be

ordered

parts, always specify

these serial numbers in

and assure economical

Id

be

inspected, depend-

or

at

least once a year,

study

th

is

manual

to

help

you

operate

with

utmost

from

including

efficiency.

your

the

prefix

dealer

tractor

at

and

the

METRIC

A standard

been adopted

lents

parentheses.) A conversion

on page 73

of

are used

for

measurement

for

world-wide

throughout

your

reference.

(SI)

known

use

. English

this

manual.

list

of

MEASUREMENTS

as

International

Units

(Metric

commonly

System

followed

Equivalents are given in

used measurements are listed

of

by

Units

Metric

(SI)

has

Equiva-

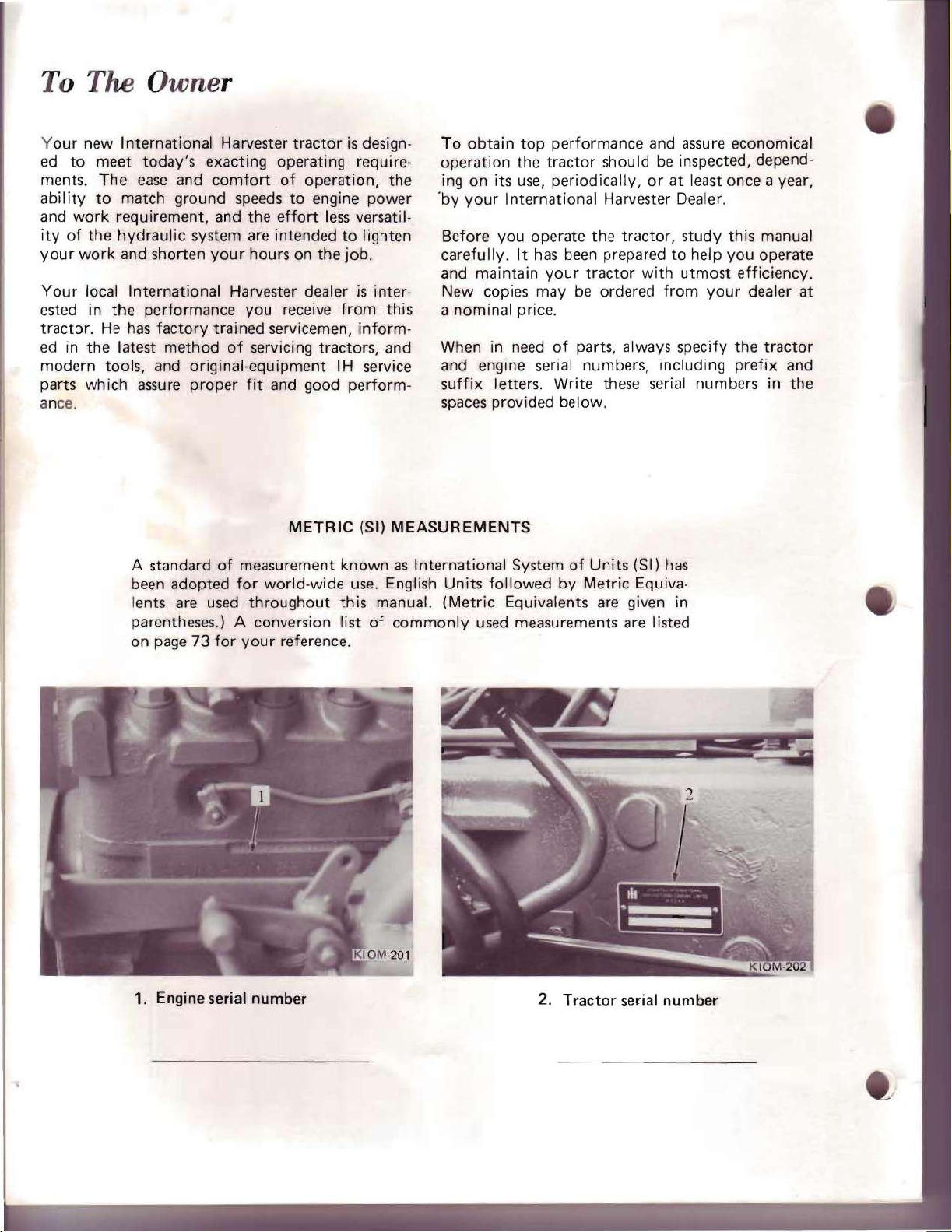

1.

Engine serial

number

2.

Tractor

serial

number

This

time

form

of

delivery.

must

be

filled

DELIVERY

out

by

the dealer and signed by

SERV I

CE

FOR 274 TRACTOR

both

the dealer and the customer at the

Delivered

Street Address

City

State

I have

the Operator's Manual content,

policy

Above equipment and Operator's Manua

instructed

~ ---- --

to

____________

thoroughly

provisions were also explained and reviewed.

as

to

--------

instructed

care, adjustments, safe operation and applicable

DA

TE

___________

Zip

the

buye r on the above described equ,

eq

uipment car

--FOLDBACKHEREANDADDCARBON

l h

Dealer

____

________

Serial No. _

Engine Serial No.

e,

adjustments, and

ave

been

____________________________

_

_________________

_____________________

__________________

received

ipment

safe

DEALER'S

by

me and I have

warranty

OWNER'S

--

-

which

operation. The

SIGNA

policy.

SIGNA

----

review included

TURE

been

TURE

-

--

~

warranty

thoroughly

- -

____

-----

_

---l

_

__

f----

-

---

This

form

must

time

of

delivery.

Delivered

Street Address

City

State Zip

I have

the Operator's Manual content, equi

policy

Above

instructed

to

thoroughly

provisions were also explaine d and reviewed.

equipment

as

-----

be

filled

____________

instructed the buyer on the above described equipment

and Operator's Manual have

to

care, adjustments,

DATE

---

DELIVER

out

by

FOLD

FORWARD HERE

Y SERVICE

the dealer and signed by

---,-

____

pment

safe

operation and applicable

__________

care, adjustments, and

AND

FOR 2

Dealer

Serial No.

Engine

been

received

ADD

CARBON·--

74

TRACTOR

both

the dealer and the cust

______

__

_ _

____ ~ ___

Serial No. _

by

warranty

- -

_____

___ ~ ___________

___

safe

DEALER

me and I have been

policy.

OWNER'S

----

_________

-'-

__' _

__________

which

operation. The

'S

SIGNATURE

SIGNA

- -

___________

review included

TURE

--

-

omer

at the

_ _ _

warranty

thoroughly

_

__

_

-l

>

0..

8

~

a:

w

z

;:

o

r---

This

time

---

for

m must

of delivery.

----

be

filled

---

DELI VERY SERVICE FOR

out

by

------------------------i

the dealer and signed by both the dealer and the customer at the

274

TRACTOR

Delivered

Street Address

C

ity

State

I

have

the Operator's Manual content, equipment ca

policy provisions were also explained and reviewed.

Above equipme

instructed

~------

to

_-,-

_____________________________

thoroughly

as

to care, adjustments,

instructed the buyer on the above described equipment which review in cluded

nt

and Operator's Manual

DATE

-

--

Zip

have

safe operation and applicable warra

------------

Dealer

Serial No.

Engine Serial No.

re,

adjustments, and

been

_______________

rece

ived by me and I have

-

--------

______________

____

safe

operation.

DEALER'S SIGN

nty

policy.

OWNER'S

SIGNATURE

_

______

Th

e warranty

A TURE

been th

--

-------~

_

_

_

_

oroughly

>

Q.

o

<.J

w

<.J

LA.

LA.

o

..J

<

Z

o

e"

w

a:

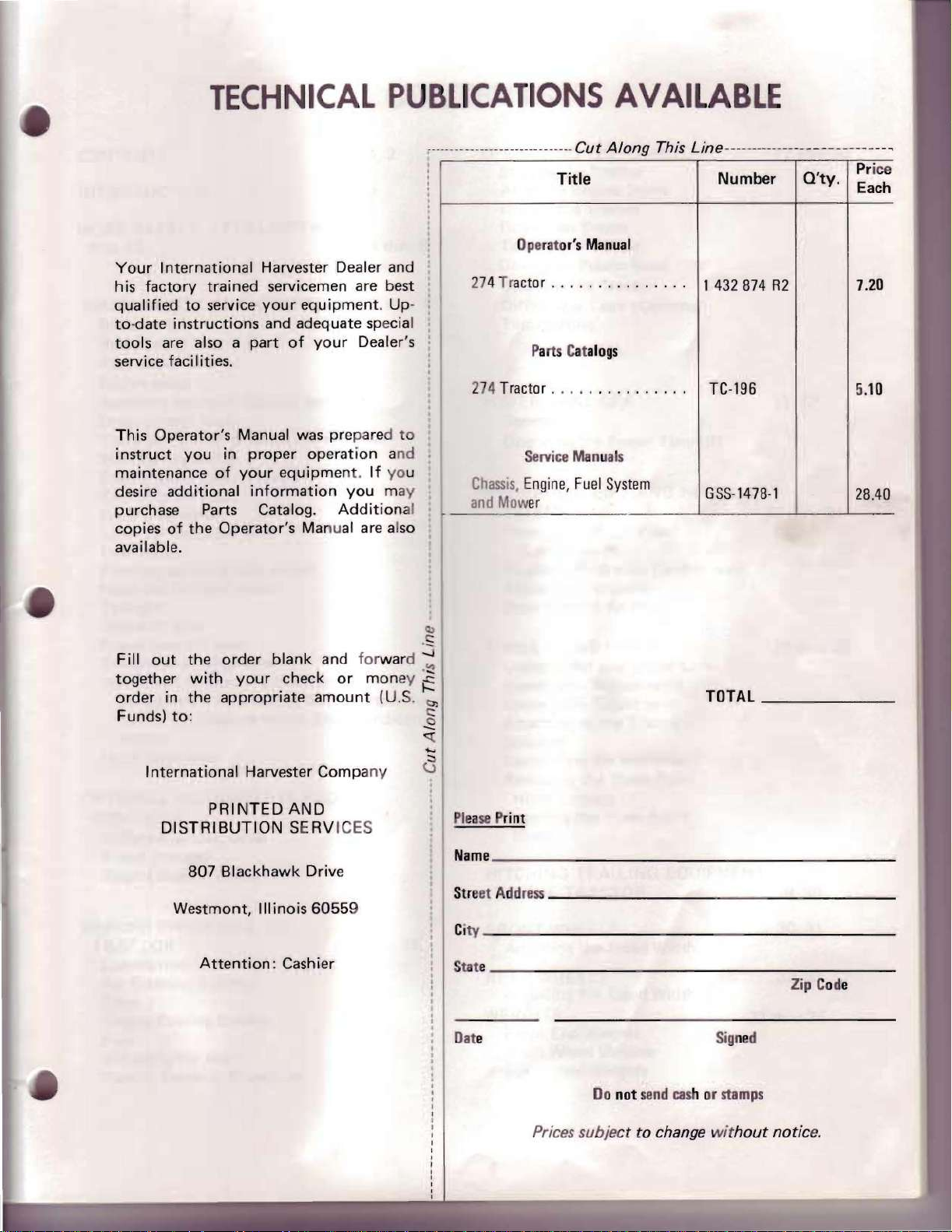

TECHNICAL

PUBLICATIONS

AVAILABLE

Your I nternational Harvester Dealer and ,

his factory trained servicemen are best '

qualified

to-date instructions and adequate special

tools

service faci lities.

This Operator's Manual was prepared

instruct you

maintenance

desire

purchase Parts

copies

available.

to

service

are a'iso a part

of

additional information you may

of

the

your

equipment.

of

your

in

proper

your

Catalog. Additional,

Operator's Manu

operation and •

equipment.

al

Up-

Dealer's

If

you

are also

to

;---------------------------

I

I

I

Operat

274 Tr

actor

........

Pa

rts

27

4 Tractor . . .............

Service

C

hassi

s,

Engine,

r

and Mow

er

--Cut Along

Title

or's

Manual

...

Cat

alogs

Manuals

Fuel

System

This

....

Line

-------

Number

1 432874

TC-196

GSS-1478·1

-----

----------------

Q'ty.

R2

Pr

Each

7.20

5.

10

I

28.40

ice

Fill

out

the

order

together with

order

Funds) to:

in

the

appropriate

International Harvester Company

PRINTED AND

DISTRIBUTION SERVICES

807 Blackhawk Drive

Westmont,

Attention:

blank and forward

your

check

amount

Illinois 60559

Cashier

or

money

(U.S.

OJ

.S

:!

~

tl)

.§

<:(

....

....

Please

Print

Name

__________

Stre

et

Ci

ty

_____

Su

te

___

Dat

e

______________________

Address

__________

________________

___________________

TOTAL

____

____

Signed

__________

____

______

_______

____________

Zip

Code

__

_

_

_

__

Prices

Do

subje

not

send

cas

ct

to change wit

h or

stamps

hout

notic

e.

CONTENTS

CONTENTS

INTRODUCTION

WORK

INSTRUMENTS

OPTIONAL

SAFELY -FOLLOW

RULES

AND

Brake

pedals

Brake pedal latch

Park

brake lever

Clutch pedal

Auxiliary

Drop

Three

Starting

Engine

Fuel

Glow

Low

F

use

Flashing warming

Head and

Taillight

Gearshift lever

Power

Transmission range lever

Instrument Cluster

Speedmeter, Hourmeter, Water temperature

territe,

territe)

Hook

CONTROLS 14

Differential

Fixed drawbar

Engine

hydraulic

control knob

point

hitch

key switch

speed

shut

off

plug signal

fuel

indicator

block

taillight

take-off

Oil pressure tellite, Charge indica tor

open lever

INSTRUMENTS

lock

coolant

control

position control lever

control

knob

lamp

light

switch

lever

(Tachometer,

pedal

heater

THESE

CONTROLS

lever

lever

switch

AND

1,2

3

4thru6

7

thru

13

OPERATING

Starting the

After

Driving the

Driving on Slopes

Tow

ing the

Drivi

ng

Stopping the

Differential Lock (Optional)

Transporti

POWER

General

Op

erating the Power Take-

HYDR

TH

HITCH

AULIC

SYSTEMS

Three

C

ontro

Auxili ary Hydraulic Control lever

Adjustable Stoppers

Dr

op Co

RE

E PO

Low

er Links and Upper Link

Low

er

Upp er

Attaching

Stabilizer

Uncoupling

Rem

oving the Three Point

Hit

ch Linkage

Installing the Three

Hit

ch

ING

TO THE

THE

TRACTOR

Tractor

the Engine Starts

Tractor

Tractor

on Public Road

Tractor

ng

TAKE

-OFF

LIFT

AND

Po

int

Hitch

Position

l I ever

ntrol

Knob

INT

HITCH

Link

Adjustments

Link

Adjustment

to

the Trac

the Implement

TRAILING

TRACTOR

tor

Point

Off

HITCH

EQUIPMENT

17

thru

21,22

22

thru

25thru

29,30

20

24

29

BEFORE O

TRA

Lubricati on

Air

Tires

Engine

Fuel

Adjusting the Seat

Tractor

PERATING

CTOR

Cleaning System

Cooling System

Break-In Procedure

THE

15, 16

FRONT WHEELS

Adjusti ng the Tread Width

REAR

WEIGH

WHEELS

Adjusting the Tread Width

TS

Front End Weights

Fro nt

Wh

eel

Weights

R

ear Wh

eel

Wei

ghts

1

33

0,31

3

32,33

thru

35

CON

TEN

TS

PREVENTIVE

GUIDE

PREVE

NTIVE

Hood 38

Fuel Shut

Filler

Cap

Fuel

Filter

Draining Water

Bowl 40

Venting the Fuel System

Cooling System 41

Adding Coolant

System

Cleaning the Cooling System 42

Filling

Fan Belt

Dry-Type

Electrical System

Charging

Generator 4

Lighting Switch

Headlight Replacement 46

Flashing Warning Light 47

Taillight (Optional) 47

Rear

Work Lamp (Optional)

Fuse

Battery

Tellite Bulb Replacement 49, 50

Rear

Wheels

Adjusting the Toe-in

Tires

Care

of

Infl

at ion

Shipping Tractors Equipped

Pneumatic Tires

Mounting Tires on the Rim

MAINTENANCE

MAINTENANCE

Off

Valve 39

Air

Vent 39

from

Sediment

to

the Cooling

the Cooling System

Tens

ion

Air

Cleaner 4

System and Alternator

Tires

wit

4

48,49

50,

h

36,37

38

40

40

41

42

2,43

3,44

45

5,46

46

47

48

50

51

51

51

51

51

52

STORING TH E TRACTOR

Storage

Removing

COLD WEA TH ER

Fuel System

Electrical

Lubricati on

Cooling System

En

gine C

LUBRICA TION

Checking the

Engine Oil

Checki

Chang

Changing the Engine Oil Filter

Gear Lubricant

Tr

ansmission Breather

Hydraulic Fluid F

Lubrication F

Greasing the

LUBRICATION TABLE

LUBRICA

SPECI

EXTRA EQUIPMENT

F ICATIONS

ACCE

UN

IVE

INSTRUMENTS AND

CONTROLS

from Storage

oolant

ng the Oil Le

ing Engine Oil

TIO

SSO

RIES

RSAL

Heater (Optional)

Oil Le

itting Grease

Front

N GUIDE

SYMBOL

PRE

vel

vel

ilter

Wheels

CAUTI

AND

S FOR

ONS

54,55

55, 56

56 thru

62

63

thru

67

thru

71

72

61

66

70

Traction and Weights

Overloading

Brake

Brake Adjustment

Park Brake Adjustment

Bleeding the Brake

Care

and

Adjustment

Clutch

of

the Engine

52

52

52

52

53

53

54

METR

IC (SI) MEASU REMENTS

73

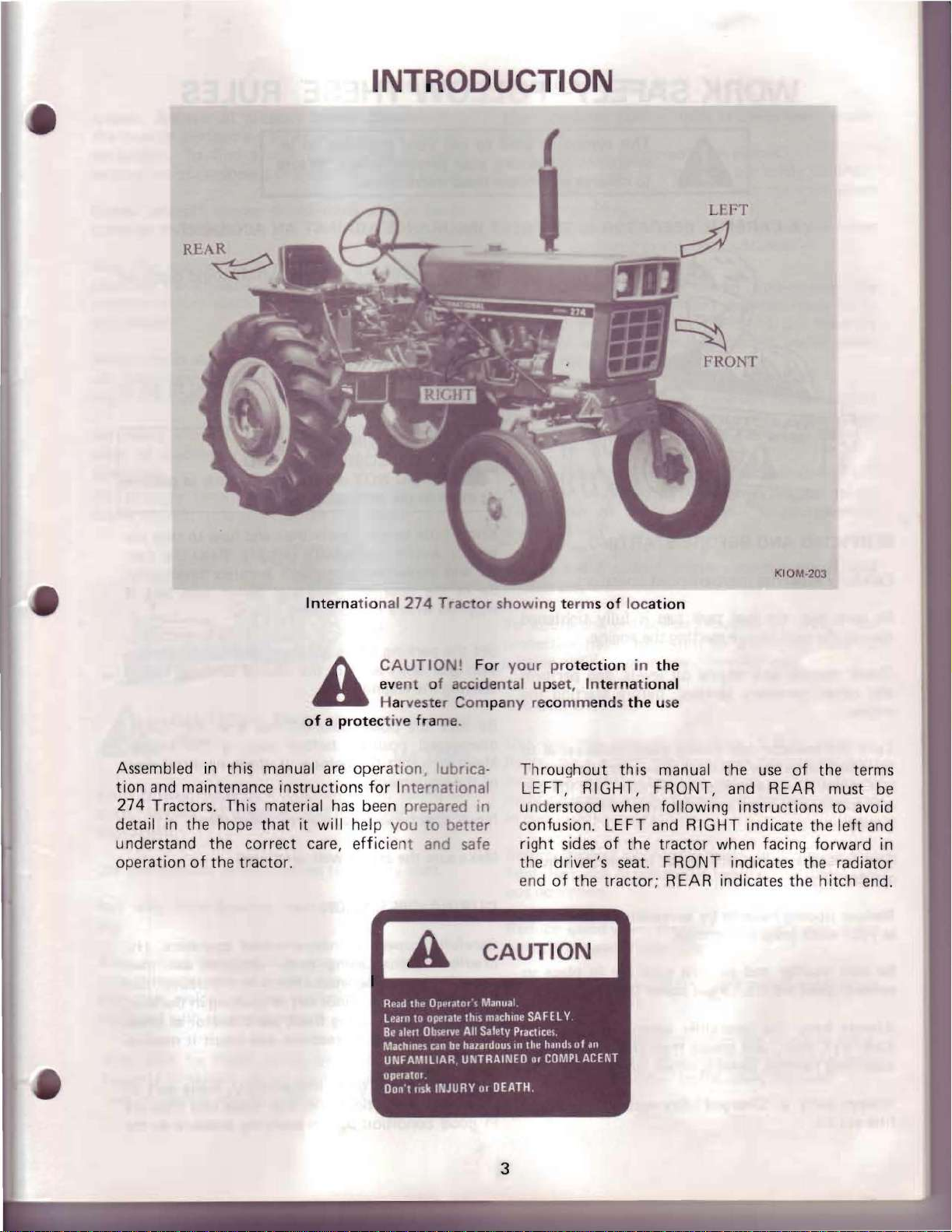

INTRODUCTION

FRONT

Assembled in

tion

and maintenance

274

Tractors. This

detail in

understand

operation

the

of

this

hope

the

the

International

A

of a protec

manual are oper ati on, lubrica-

instructions

material

that

correct

tractor.

it

care,

has

will

help you

efficient

274 Tractor showing terms of loc

CAUTIO

ev

ent

of accide

Harvester Company recomm

tiv e frame.

for

I

nternat

been prepared

to

and safe

NI For

your protection

nta

onal

In

bette

r

CAUTION

in

l upset

. International

ends the

Th

roughout

LEFT,

understood when

c

onfusion.

right

sides

the driver's seat.

end

of

this

RIGHT,

LEFT

of

the

the

tractor; REAR

ation

the

use

manual

FRONT

following

and

RIGHT

tractor

FRONT

KIOM-203

the

use

, and

when facing

indicates

REAR

instructions

indicate

indicates the

of

the

the

must

to

the

left

forward

radiator

hitch

terms

be

avoid

and

in

end.

3

WORK SAFEL V- FOLLOW THESE RULES

A

CAREFUL

_ .

'12"

SERVICING

Carefully supervise

Be

sure

against

Check

any

engine.

Turn

the

any

and

moved.

coolant

other

the

pressure release

steam

continue

AND

that

the

the

stop

before

and

necessary services,

radiator

to

escape;

to

turn

This symbol

structions concerning

to

A

OPERATO R IS THE BEST INSURANCE

BEFORE STARTIN

inexperienced

fuel

tank

cap

starting

engine oil levels,

cap

slowly

point

to

then

press

until

the

observe and

operators.

is

fu

the

engine.

before

counterclockwise

allow

the

down

cap

G_

Ily

and

starting

pressure

on

is free

is

used

follow

tightened

perform

the

to

or

the

cap

to

be

re-

to

call

your

att

ention to in-

your

personal safety. Be sure

these instructions.

AGAINST

Avoid loose-fitting

moving parts.

STARTING

Starting

starting

A

or

ether in the air intake.

Know

tractor

tor

Be

supplied with a

Set

sion gear

starting

Be

disengaged position

Make sure

of

the

Never

how

and

in

the

the

sure

equ

operate

and /

the

Flu

id

(Ether)

the engine.

WARNING!

EXPLOSION

DO NOT

to

use

the

or

implements

implement

operators seat

ROPS frame.

parking

shift

the

brake

lev

er

engi ne.

power take-off

that

the

ipment.

vehic

AN

ACCID E

clothing,

use

controls

operator'

lever

in the neutral

before starting the engine.

helpers

le

in

which

must

not

HAZA

starting aid such

an

RD

and

quickly.

s manuals

and fasten

and

place

rod

or

observers stand

enclosed area.

could

be

used

how

Read

thoroughly.

seat

the

position

is

in the

NT

catch

to

as

gas

to

stop

the

belt if

transmis-

"OF

on

aid

in

oline

the

trac-

before

F"

clear

Check

ments.

Reduce

as

Be sure

exha

Always

Keep d i

mo

Always

fi

brakes and

tipping

your

work

muffler

ust

gases are discharged

keep

rt,

unting handles,

carry

rst aid kit.

program

the

trash,

a "Ch

clutch

hazards

and

exhau

operators

and

grease

steerin

arged"

pedal

for

corre

by

spreading wheels as far

permits.

st

pipe

are in place so

above

the

operator.

compartment

from

the

pedals, steps,

g wheel,

fire e

and

xti

nguisher

controls

ct

adjust-

clean.

.

and

Make

sure the area

DURIN

C

drauli

enough

may also infect a minor

If

Serious

treatment

conne

a

in

G OPERATION

aref

ully supervis

c fluid

force

injured

good

by

infec

is not

ct ions are tight

condition

to

escaping

tion

4

is well

e inexperienced o

escaping

penetrate

or

given

ventilat

under pressure

the

cut

fluid,

reaction

immediately. Make sure all

and

that

before

app

ed.

perat

ors. Hy-

can

sk i

n.

Hydraulic fluid

or

opening

see

a doctor at once.

can

hoses and lines are

lyi

ng

in

the

result it medical

pressure

skin.

to

have

the

WORK SAFEl Y -

system. Relieve all pressure before disconnecting

the

I ines or

lic system.

small piece

Power

place on the

Stop

place

the

position before

any reason.

Always

off

the

ing

or

No riders

clear

operation.

I H strongly recommends a

frame (ROPS).

perform

To

of

cardboard

take-off

tractor.

the

engine, set the parking brake lever and

transmission gear

keep shields in place. Disengage PTO. shut

engine, and remove

unclogging

allowed. Make certain

of

machinery before starting the engine

ing

other

work

on t

he

find

a leak under pressure u

or

wood.

master shield must alw ays

shift

dismounting

power

It

is

driven machinery.

available

Never

lever in t

from

the trac

the

key before adjust·

that

everone

rollover

for

this trac tor.

hydra

se

hands.

he

neutral

tor

prorect

be

u-

se

in

for

IS

or

i e

FO

LLOW

Use

ment:

a

Wi

th trail-behind PTO driven implements

hi

tching

line

m

ay

turning

Check overhead clearance

under

tree branches, enteri

On

ht

rig

distr

chance

THESE

care when

Use

A.

B.

C.

D.

e standard wheel

only

Limit

loads

Don't

backing.

Use

counterweight

suggested in

point

with

the PTO shaft.

pu

II

apart

the

tractor.

power

rear wheel

ibution

of

an

of

overtu rn.

RULES

pulling

approved

turn

on

I ines, guy wires, bridges,

the

loads

or

using heavy equip-

hitch

points.

to

those

you

can safely

too

sharp, and

or

Operator's Manual

the

fixed

If

it

or

create excessive angles when

carefully

ng

or

leavi

weight

to

help maintain

tractor

and

use

wheel weights when

drawbar must

is

not,

ng

bu i

Id i ngs,

must remain on the

proper

to

control.

care when

the

be

the

driveline

before

driving

low

hanging

etc.

weight

decrease the

in

CAUTION!

A

Keep others, especially children,

steps, fenders,

equipment.

Use

P

ull

ing.

Alwa

hill

s. A towed

than

equipp

Stay alert

hazards in terra i n wh ich cou lid cause

loss

riders.

or

the drawbar when

only

from

drawbar; never

ys keep

the weight

ed

of

the

with

for

control

tractor

vehicle having a gro ss weig

its

own

holes, rocks, tree stum

which

Never

drawbar, and away from

hitching

of

the

brakes.

could result

allow

from

to a hea

hit

ch

in gear when going

towing

tracto

in

unauthorized

MA

-168p8

riding

vy load.

to

axl e

ht

r must

ps

an

injury.

tractor

down

greater

and

upset

on

hou

be

other

Always

su

dden stops.

To

pro

cutting,

TRANSP

Use

light

loc

me

in good

Before moving on publ ic roads,

field,

o

s-

or

us

Red

tu

For

moving equipment.

Be

liz

consider

avoid sudden starts, excessive speed, and

assure

tective frame must

al

nt

operation.

uce

rns, and

sure hitches

ed

the

protection

drilling,

ORTING

warning devices (i.e. flags, S.M.V. emblem,

s,

etc.)

government agencies, when moving equip-

on

public

working

lock

speed

your

safety, avoid heavily-traveled roads when

before

ation

or

which

roads. Keep these devices clean and

condition.

the

brake pedals together

when travel ing on rough roads, sharp

down

steep hills.

and/or

towing

for

other

provided

not

be

in any

other

are approved

drawbars are

equipment.

traffic

by

altered

manner.

Be

using

by

for

use

or

from

for

properly

courteous, have

the

design, the

welding,

by

your

field

to

simultane-

stabil-

road.

5

WORK

SAFELY

- FOllOW THESE

RUL

ES

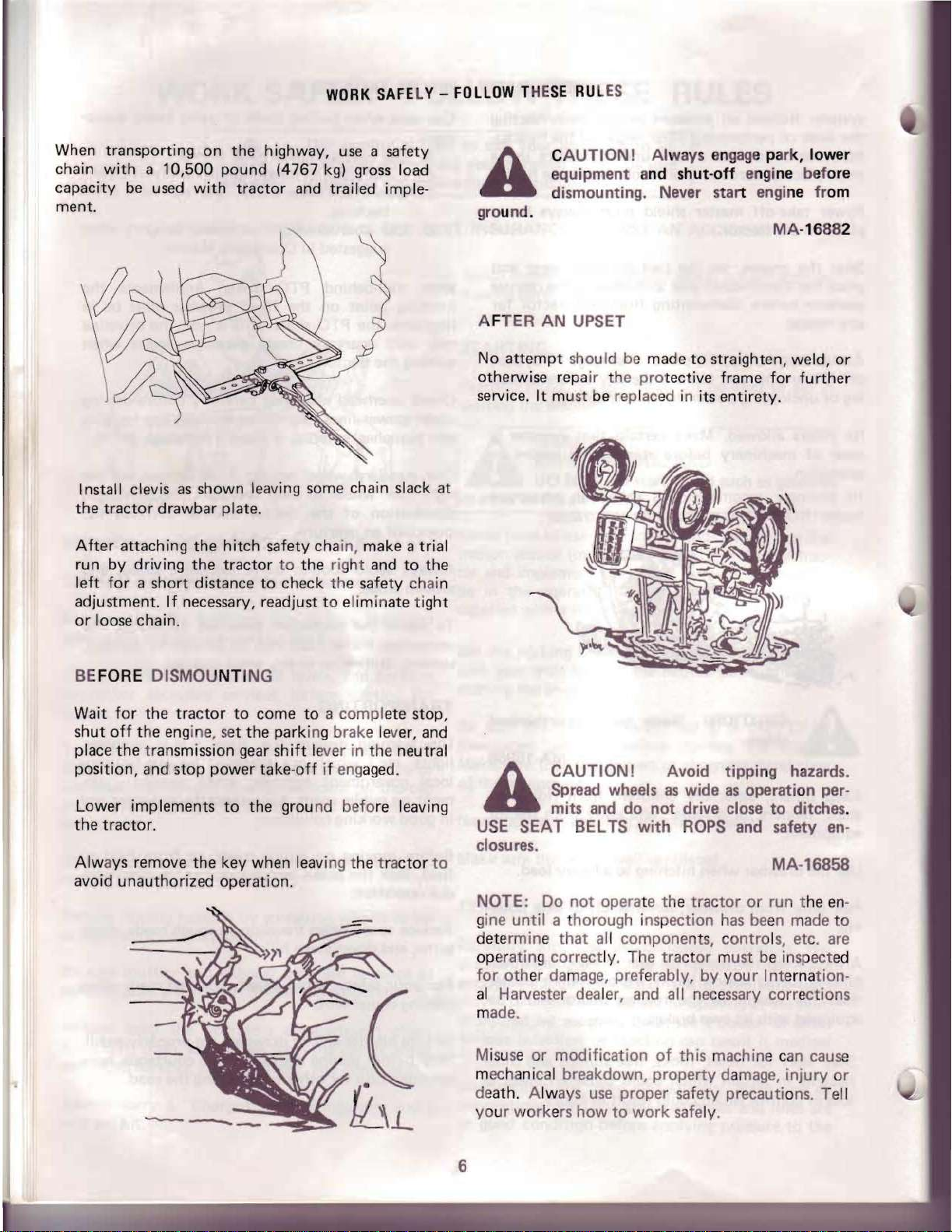

When transporting

chain with a

capacity

ment

the

After

run by driving

left for a

adjustment.

or

be used

.

Install clevis as shown leaving some chain slack

tractor

attaching

short

loose chain.

on

the

highway, use a safety

10,500

drawbar

If

pound

with

plate.

the

hitch safety cha in, make a trial

the

tractor

distance

necessary, readjust to eliminate

(4767

tractor

to

kg)

and trailed imple-

to

the right

check

the safety ch ain

gross load

and

to

tight

at

the

CAUTION I Always engage park, lower

ment and

equip

A

ground.

AFTER AN UPSET

No

otherwise repa

service. It must be replaced in its

dismounting. Nev

attempt

should be made

ir

the

shut-off engine bef

er sta

to

pro

tective frame for

rt

engi ne fr

MA-16882

straighten, weld,

further

entirety

.

ore

om

or

BEFORE

Wait

shut

place

position, and

Lower implements

the

tractor.

Always remove

avoid

DISMOUNTI

for

the

tractor

off

the

engine, set

the

transmission gear

stop

unauthorized

the

NG

to

come

the

parking brake lever, and

shift

power

take-off if engaged.

to

the

grou nd

key when leav i

operation.

to

a compl

lever

ng

in

the

befo

the t ra

ete

stop,

neutral

re leaving

ctor

to

CAUT I

Spread wheels

A

USE SEAT BELTS with ROPS

closures.

NOTE: Do not

gine until a horough inspection has be en made

dete

operatin g

for

al

Harvester dealer, and all necessary correcti ons

ade

m

su

Mi

mechanical

death. A

your work ers

mits and

rmine

correct

oth

er da mage, preferably,

.

se

or

modification

lw

ON

I Avoid tippi ng hazards.

as

wide as operation per-

do

not

drive close

ope

rate th e tra

that ali

breakdown, property

ays use

compone

ly. The tractor

proper

how

to

work

nts

of

this machine can cause

saf

ety

safe ly.

to

ditches

and

safety en -

MA

-16858

ctor

or

run t he en-

, c

ontrols, etc. are

must be inspected

by you r I nterna

damage, injury or

precauti ons. Tell

tion

.

to

-

6

INSTRUMENTS AND CONTROLS

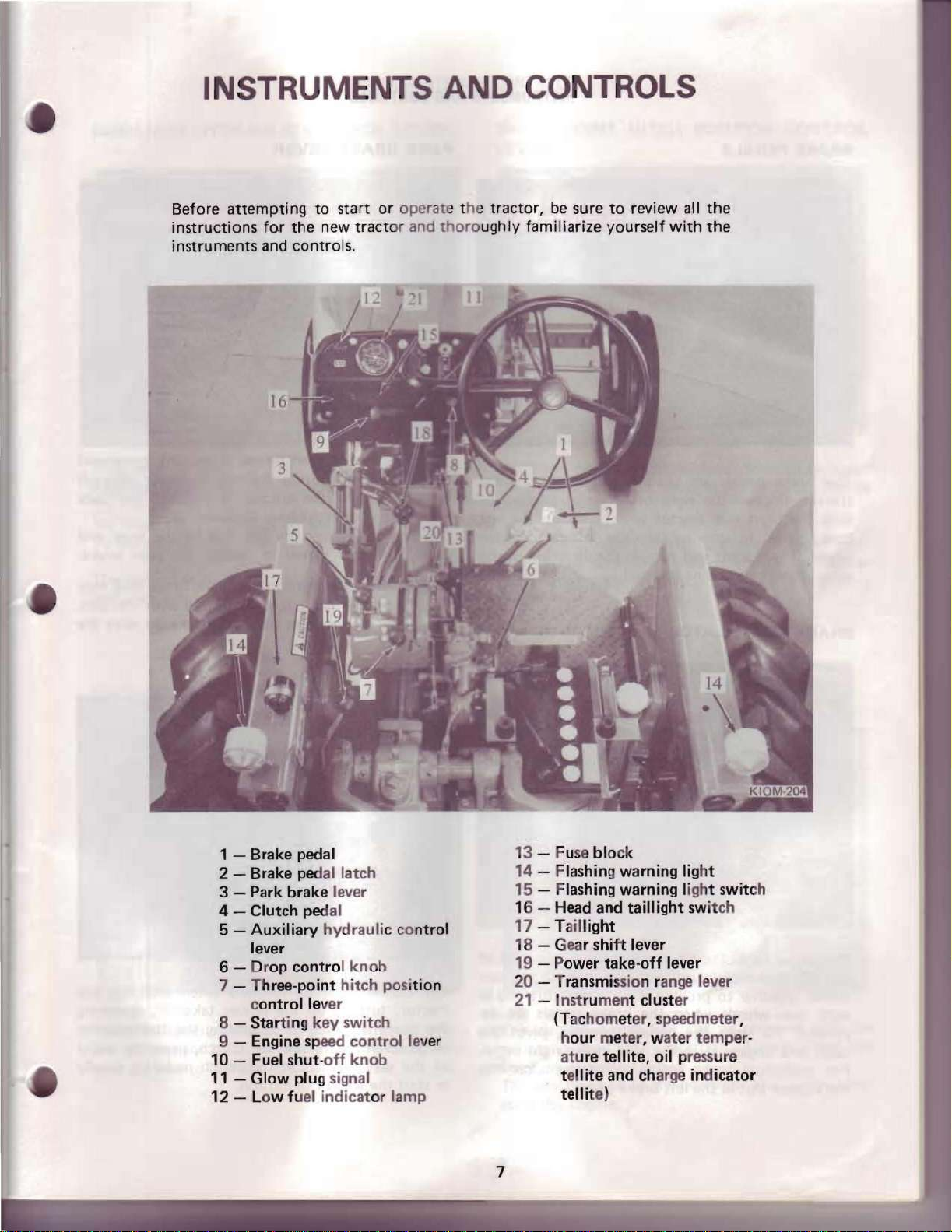

Before

instructions for

instruments and controls.

attempting

the

to

new

start

tract

or

or

operat

and

e the

tractor

thoro

ughly familiarize yourself with

, be sure

to

review

all

the

the

1 - Brake pedal

2 - Brake ped

3 - Park

4 - Clutch pedal

5 - Auxiliary hydraulic control

lever

6 - Dr

7 - Three-point hitch posi

8 9 - Engine speed

10 - Fuel shut11

12 - Low fuel indicator

op

c

ontrol

Starting

- Glow plug signal

al

latch

brake

lever

control knob

lever

key

switch

control lever

off

knob

tion

lamp

13 - Fuse blo ck

14

- Flashing warning

15 - Flashing warning l

16 - Head and taillight

17

- T a ill ight

18 - Gear shi

19 - Power

20

- Transmission range lever

21

- Instrument cluster

(Tachom

h

at

tellite

tellite)

ft

lever

take-off

eter, speed

our

meter, w

ure tellite, oil pressure

and charge indicator

7

lig

lever

ater

ht

igh

t switch

switch

meter

temper

,

-

INSTRUMENTS

AND

CONTROL

S

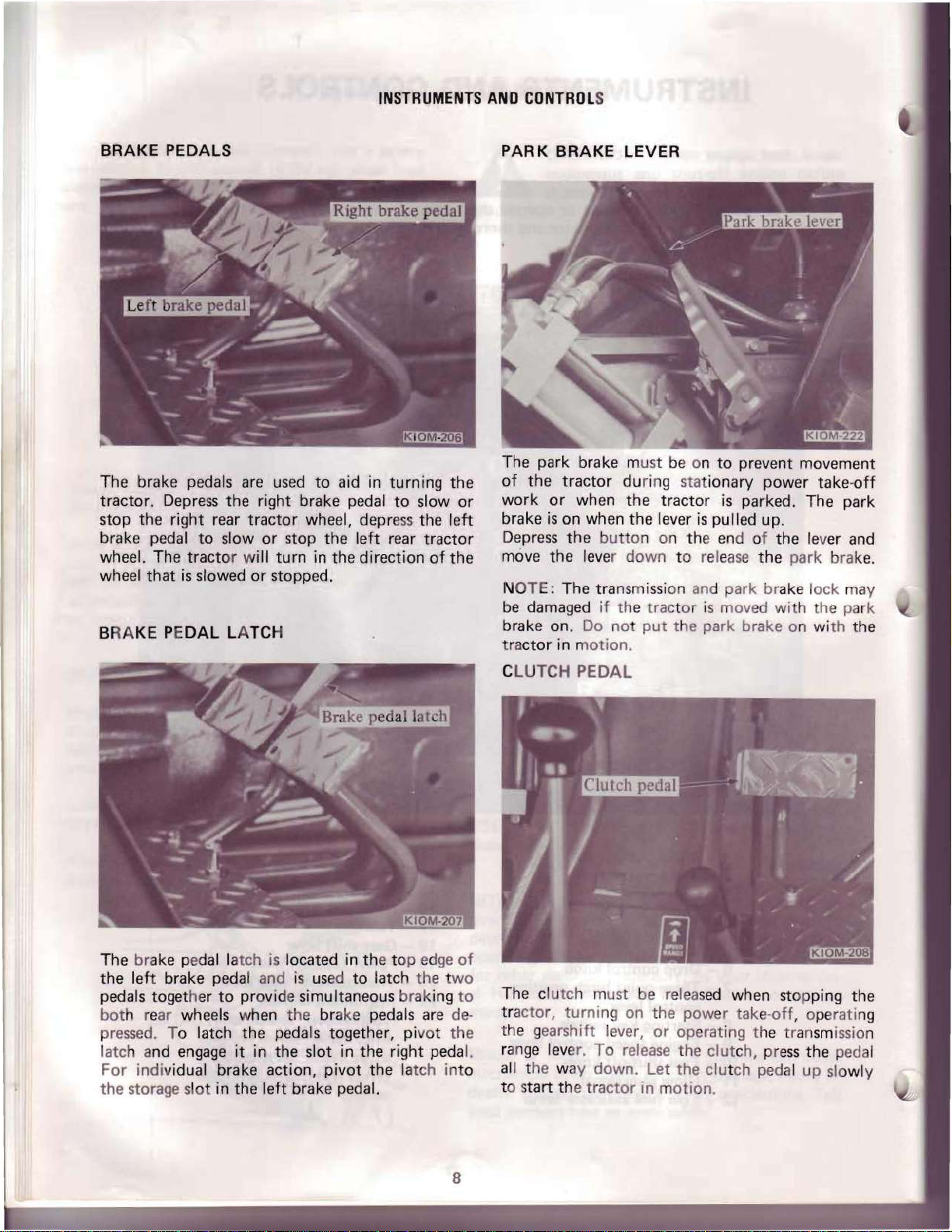

BRAKE PEDALS

The

brake pedals are used

tractor.

stop

brake

wheel.

wheel

BRA

Depress

the

right rear

pedal

that

KE PEDAL

The

to

tract

is

slowed

the

right brake pedal

tractor

slow

or

stop

or w

ill

turn

or

stopped.

LATCH

to

aid

wheel,

the

in

the

in

turning

to

depr

ess

left rear

direction

slow

the

tractor

of

the

or

left

the

PAR K BRAKE

LEVER

The park brake must be on

of

the

tractor during sta t ionary

work

brake

move

NOT

be damaged if the

brake on.

tra

is

Depress

E:

ctor

or

when

on

when

the butt

the

lever

The

tra nsm

Do not

in motion

the

tracto

the

lever

is

on on the en d of

down

to release

iss

ion an d

tra

ctor is moved with t he park

put

the park brake o n wi

.

to

prevent

power

r is parked.

pulled up.

the lev

the

park brake l

movement

take-off

The

park

er

and

park brake.

ock

may

th

the

The brake pedal la

the

left brake pedal

pedals

bot

pressed. To

latch a

For

the

toget

h re

ar

nd

indi vidual

storage s

her

to provide

wheels when the brake pedals are de-

latch

engage it

brake

lot

in

tch

is located

and

is used

in the top edge

to

latch the t

simu Itaneous braking

the

pedals together, pivot the

in

the

slot

in

the

action,

the

left brake pedal.

pivot

the latch int

right peda

of

wo

to

l.

o

CLU

TCH

PEDAL

The clutch must be released when sto pping

tractor,

turn

ing

on

the

pow

er

take-off

, operati

the gearshift lever, or operating the transm

ran

ge

lever. To release the

a

ll

the way down. Let

to s

tart the t

ractor

in m

the

clut

otion.

clut

ch,

pre

ss

the ped

ch

pedal up slowly

issi

the

ng

on

al

8

INS

TRUM

ENTS AND CONTR

OLS

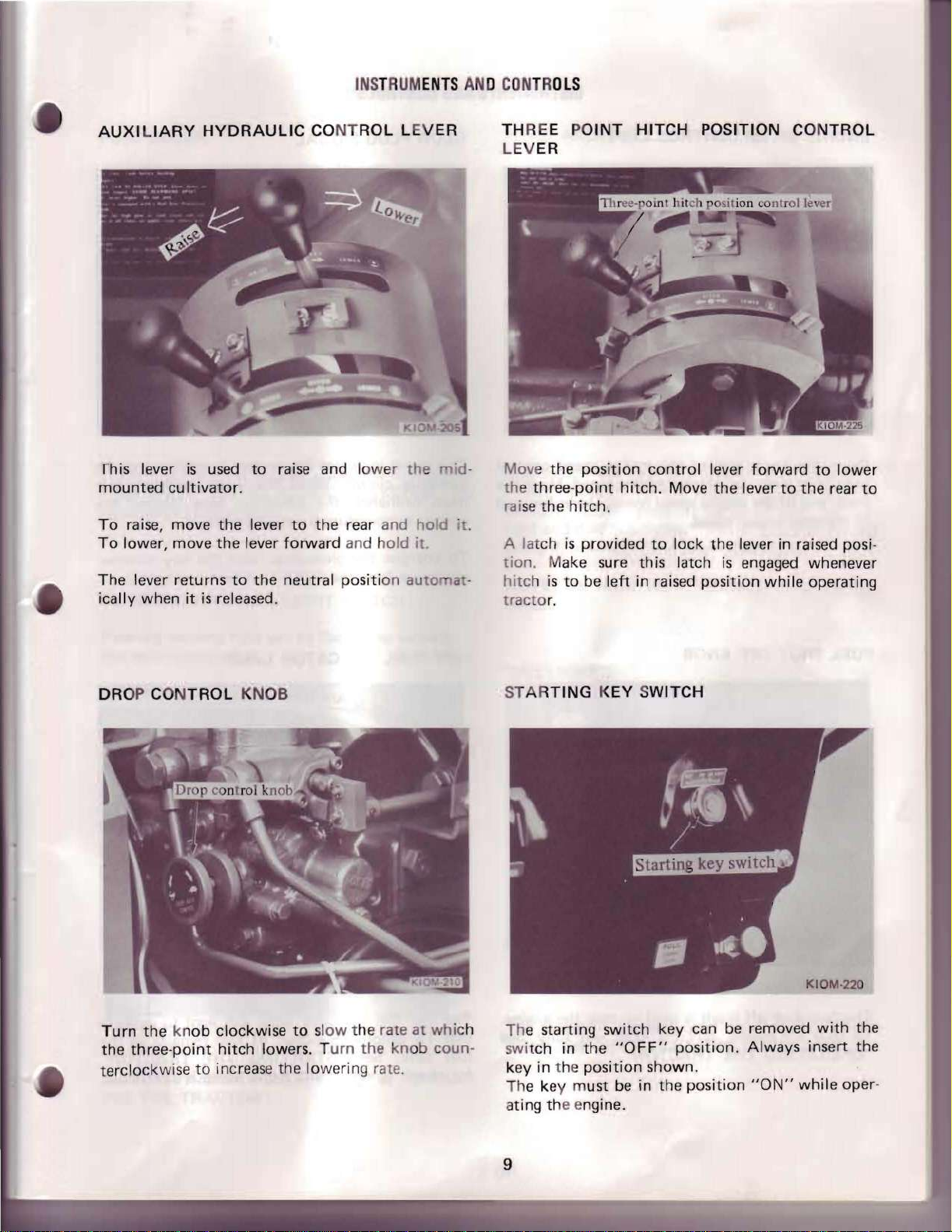

AUXILIARY

rhis lever

mounted cultivator.

To

raise, move the lever

To

lower, move

The lever returns

ically

when

HYDRAULIC CONTROL LEVER

is

used

the

to

it

is

released.

to

raise

and

low

er the

to

the rear and

lever

forward and h

the neutral positi on auto

old it.

mid

hold

it .

err

THREE POINT HITCH POSITION CONTROL

LEV

ER

-

Move the position

th

e three-point h

rai

se

the

A latch is provided

tion.

Make sure this latch

-

hitch is

tracto

to

r.

hitch

be

.

left

control

itch

. Move

to

in raised

lever

forward

the

lever

lock the lever in raised posi-

is

engaged

position

while operating

to

to

lower

the

rear

whenever

to

DROP CONTROL NOB

Turn

the knob

the three-point

terclockwise

clockwise

hitch

lowers. Turn the knob coun-

to

increase the lowering rate.

to slow

the rate at

whi

ch

ST

ARTING KEY SWITCH

The starting switch key can

switch in the

key in the position shown.

The key

ating

th

e engine.

must

"OFF"

be

position. Always insert the

in the position

be

removed

"ON"

with

the

while oper-

9

EN

GINE

SPEED

CONT

ROL LEVE

INSTRUMENTS AND

R

CONT

GLO

ROL

S

W PLUG S

IGNAL

Move the

lever

knob end of the engine speed c

to

decrease engine spee

UEL SHUT OFF

F

to

the

knob

rear

end

of

the engin e speed c

to

increase engine speed. Move

d.

KNOB

ontrol

lever

ontrol

the

forward

This signal indicates

glowplug circu

mum brilliance, the glow

correct tempe

To

energise the glowplu

clockwise

LOW

FUEL

rature for

from

INDICATOR

the correct

it

. When the signal reaches maxi-

engine starting.

the

"OFF"

plu

gs

gs,

turn the key

position and

LAMP

functioning

have reached

count

hold

of

it.

the

the

er-

The fuel shut

To s

top the

"OPERATING

engine, pull the

off

knob

is

THE TRACTO

used

to

stop the engine.

knob

out

R".

fully.

See

10

The

low

fuel

that

1 ~ gallons (5.5

tank.

fuel

for

che

ck to determine

indicator

See

"STARTING

lamp

liter)

if

will

light

to indicate

of

fuel remains in the

THE

TRACTOR"

the tellite

is

functional.

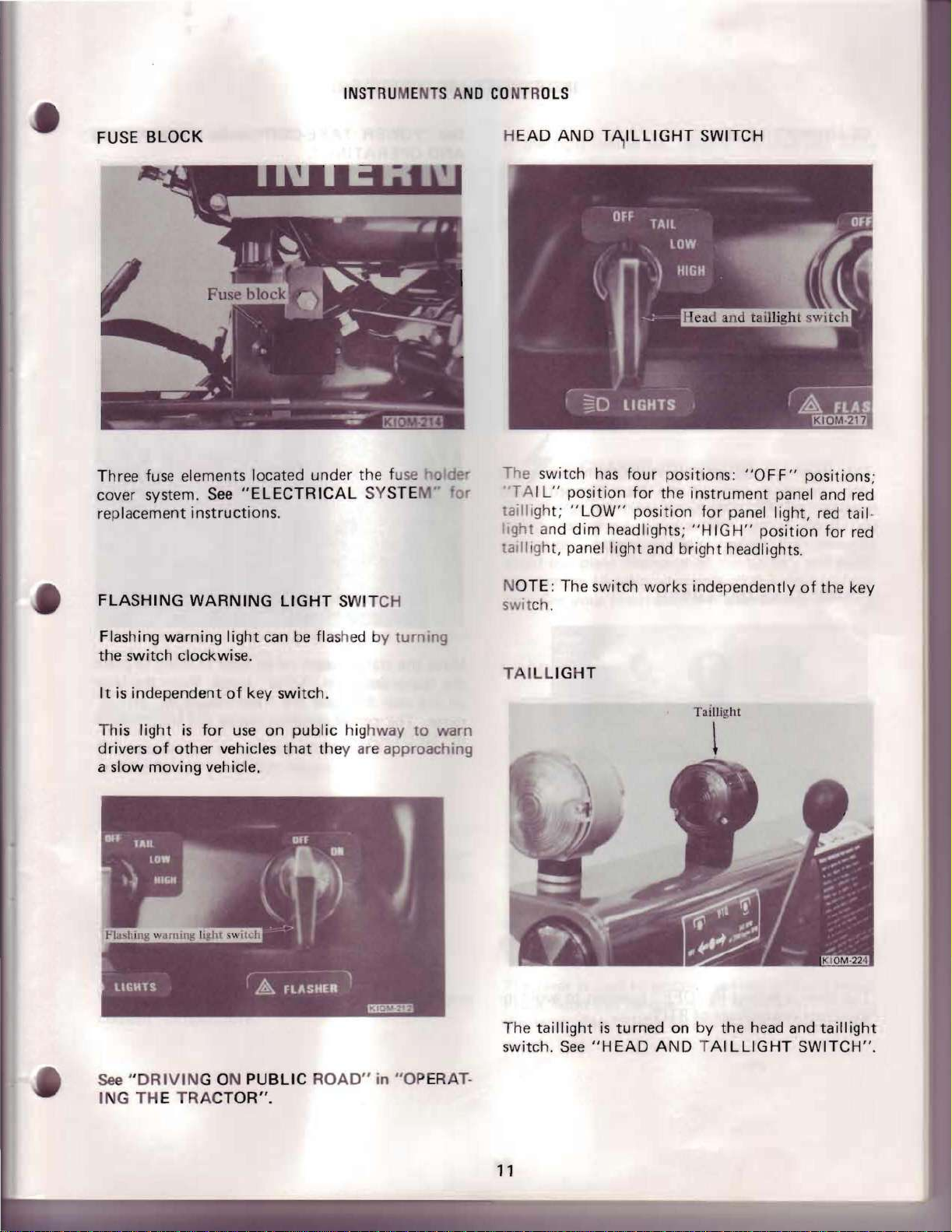

FUSE

BLOCK

INSTRU

MENTS A

ND CONTR

H

EAD

OLS

AND

T~ILLIGHT

SWITCH

Three fuse elements located under the f

cover system.

See

"ELECTRICAL

SYSTE

replacement instructions.

FLASHING

Flashing warning

WARNING

light

LIGHT

can

SWITCH

be flas

hed by turning

the switch clockwise.

It

is

independent

This light

drivers

of

other

is

of

for

vehicles

key switch.

use

on

public

that

hig

hway

they are approachmg

a slow moving vehicle .

use

to

' d

..

warn

or

The switch

"T A I L" position

tailli ght ; "

light

and

has

LOW"

dim

headlights; "

four

positions:

for

the instrument panel and

position

"OF

for

panel light,

HIGH"

position

F"

a,II,ght, panel light and bright headlights.

NOTE : The switch works independently

swit

ch.

TAI

LLI

GHT

Ta

illight

positions;

red

red

tail-

for

red

of

the key

See "

DRIVIN

G ON

PUBLIC

I G THE TRACTOR".

ROAD"

in

"OPERA

T-

The

switch.

11

taillight

See

is

turned on by the head and

"HEAD

AND TAILLIGHT

taillight

SWITCH".

INSTRUMENTS

AND

CONTROLS

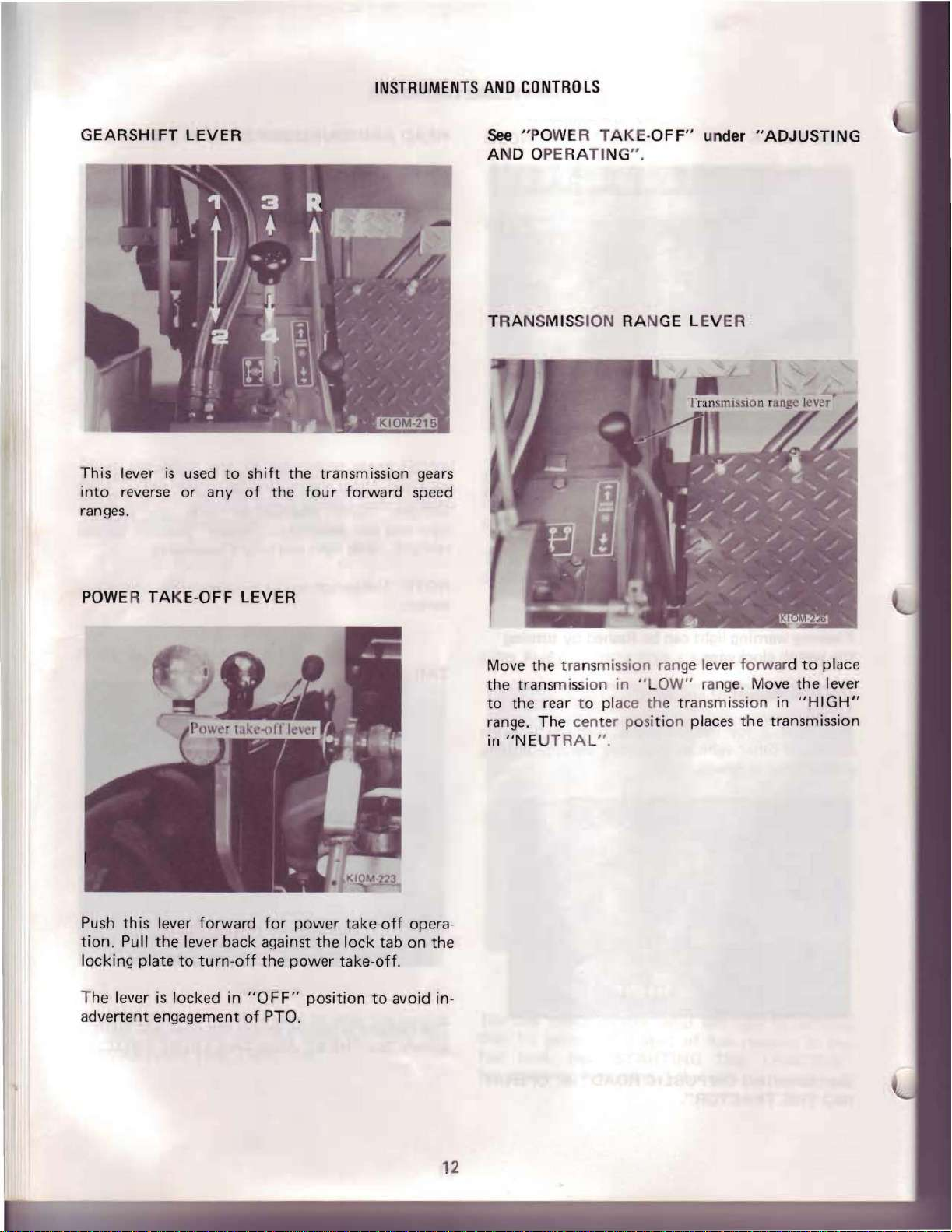

GEARSHIFT

This lever

into

is

reverse

ranges.

LEVER

used

to

or

any

shift

of

the

the

transmission gears

four

forward

speed

See

"POWER TAKE

AND OPERATING",

TRANSMISSION

RA N

-OFF" under

GE

LEVER

"ADJUSTING

POWER TA

Push

this

tion.

Pull

locking

The

a

dvertent

plate

lever

engagement

KE-OFF LEVER

lever

forward

the

lever

back

to

turn-off

is

locked in

"OFF"

of

for

power

against

the

power

PTa

.

take-off

the

lock

take

position

tab

-off.

to

avoid in-

opera

on

the

Move

the

the

trans

to

the

range .

in

"NE

transmission

mission in "LOW"

rear t o place the transmission

The

center position places the transmission

UTR

AL".

ran

ge

lever

forward to

range. Move

in

place

the

lever

"HIGH"

-

IN

STRUMENT

S

AND

CONTROLS

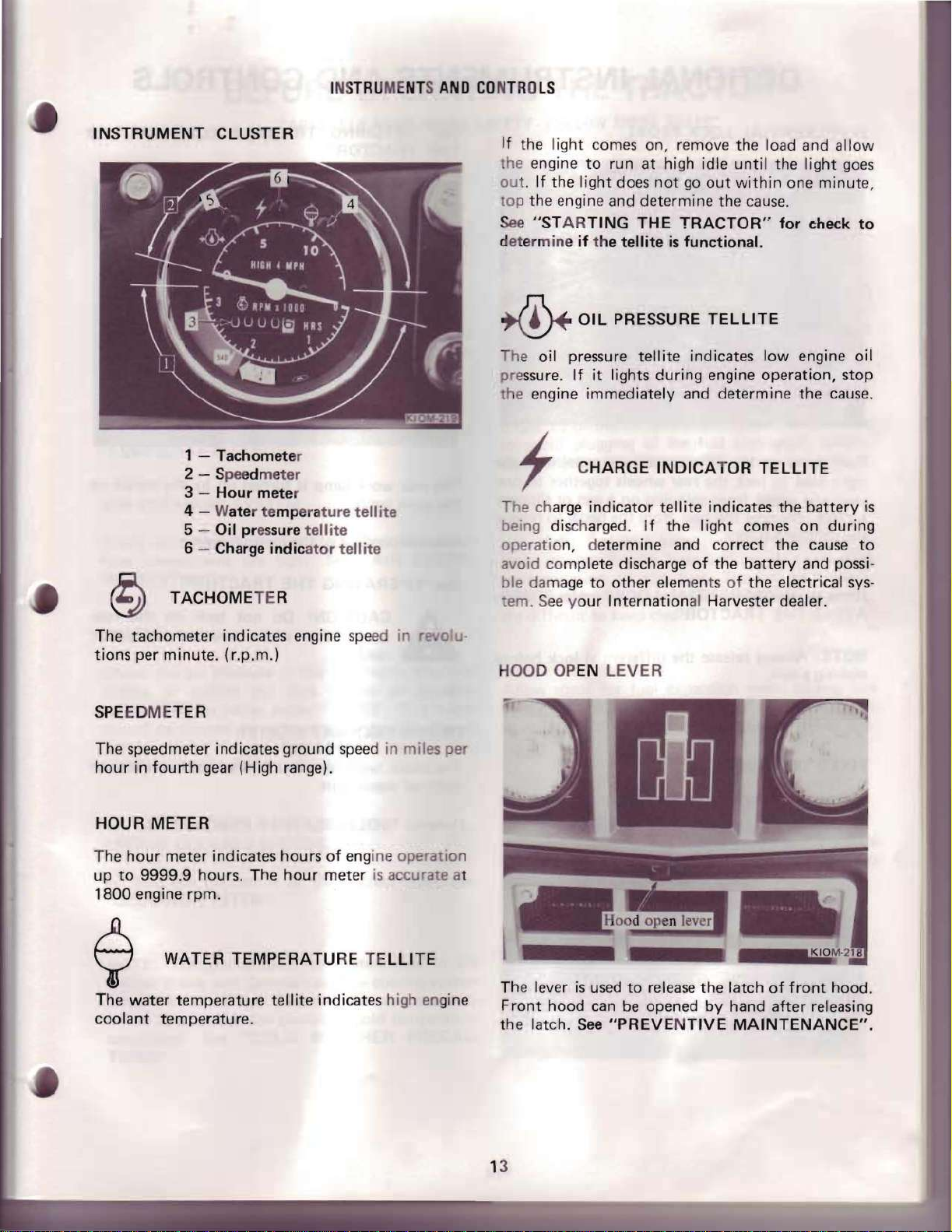

INSTRUMENT

1 - Tachomete r

2 - Speed meter

3 4 - Water te

5 6 - Charge

~

TACHOMETER

CLUSTER

Hour

meter

mp

Oil pres

sure

indic

era

ture

tellite

ator

tellite

tellite

If

the

light

comes on, remove the load and

he

engine

out. If

top

the engine and determine the

See

"STARTING

determine

~

The oil pressure

pressure.

the engine

f CHARGE INDICAT

The ch

being discharged. If the

operation, determine and correct

avoid complete discharge

ble dam

tem.

See your

to

run

at

high idle

the light does

if

the

OIL

If

it

immediately and determine the

not

go

THE

TRACTOR"

tellite

PRESSURE

lights during engine operation, stop

is

tellite

functional.

until

out

within

TELLITE

indicates

OR

arge

age

indicator

to

other

Internation

tellite

elements of the electrical

indicates the

light

of

the

al Harvester dealer.

cause.

comes on during

battery

the

light

one minute,

for

check

low

engine oil

TELLITE

battery

the

cause

and possi-

allow

goes

to

cause.

is

to

sys-

The tachometer indicates engine s

tions per minute. (r.p.m.)

SPEEDME

The speedmeter indicates ground

hour

HOUR

The

up

to

1800

The water temperature

coolant

TER

in

fourth

METER

hour

9999.9

engine

gear (High range).

meter indicates hours

hours. The

rpm

.

WATER

temperature.

TEMPERATURE TELLITE

hour

tellite

spee

of

meter

indicates high engi

pe

ed

in r °

d in miles per

eng

ine operatIon

is

accurate at

u-

ne

HOOD OPEN

The lever

Front

the latch.

is

hood

See

LEVER

used

to

release

can

be

opened

"PREVENTIVE

the latch

by

of

front

hand

after

MAINTENANCE".

hood.

releasing

13

OPTIONAL INSTRUMENTS AND CONTROLS

DIFFERENTI

Push

down on the different

rig

ht

heel to lock t

ve

nt o

ne

surface.

the

diff

erenti al lock.

AL

whe

el

Remove the he

LOCK P

he rear wheel

from spinning on a wet

EDA

ial

el

fro m the p

L

lock

pedal

s together to pre-

edal

wi th t

or

slippery

to

rele

he

ase

S

ee

"HITCHING

THE TR

RE

The rear work lamp

the work

It

is

ACTOR".

AR WORK LAMP

lamp.

independe

nt

of

TRAILING

is

turned on by the switch on

the ignition switch.

EQUIPME

NT

TO

Refer

to

" DIFFERE

ATING

NOTE : Alw

maki

F

IXED

THE

ng

a turn.

DRAWBAR

NTIAL

TRACTOR".

ays

release

LOCK"

the differential lo ck be

under "OPER-

for

See

"OPERATING THE

CAUTION!

work lamp while traveling on public

A

e

ENGINE COOLANT HEATER

he

T

optional equipment.

Refer

road.

block type engin

to

"COLD

WEATHER PRECAUTION".

TRACTOR"

Do

not

e coolant heater is availab

turn

.

on the rear

le

as

14

BEFORE

CA

REFUllY

OPERATING THE TRACTOR

READ "WORK SAFET

Y -FOll

OW THESE

RULES

"

lUBRICATION

Check the oil levels

mission, and all

to

the

correct levels

for t he prevailing temperature . Refer

BRI

CATI

ON GUIDE

NOTE: DO

oil in temperatures above 90° F (

O°F

(-lSoC). See "LUBRIC

Lubricate the entire

"LUBRICAT

AIR

CLEA

Check all

hose connections are tigh

ING

SYSTEM

TIRES

NOT

ION GU

NING

rubber

of

gear

cases

with

",

operate the

SYSTEM

hoses

",

the

tract

IDE"

to

oil

or

_

for cra

engine crankc

see

that

they

of

the p

rop

tract

or

with

320 C) or below

ATION

t.

GUIDE"

as

describ

cks and be sure all

See

"AI

R C LEAN-

ase

, trans -

are filled

er viscosity

to

"lU

shipaway

,

ed

in

the

Never start

antifreeze solution in

FUEL

Grade 2-D diesel fuel

specific

diesel

temperatures

tions entailing considerable

grade fu

fu

el must have a cloud

(-12 .2°

to

avoid plugging of the fuel

e

sp

ecially

clean fuel and keep

Use

anks equipped

ntamination

co

ns,

ca

are d

ifficult

or

operate the engine

ation

must be used

tractor.

C)

and drums

Grade 1-0 diesel fuel may be used at

below

el

for

case

below

the

fuel

to

keep clean.

the lowest anticipated temperature

with

of

is

without

the

cooling system.

conforming

for

proper

+10° F (-12.2°

idling. Use

of starting.

fi

Iters.

hose and nozzle

the· fuel. The

not

recommended because

Winter

point

of

circulation

it

clean. Store fuel in

water

to

ASTM 0-975

operation

C)

or

for

opera-

only

winter

grade diesel

at least +10 ° F

system,

to

prevent

use

of

funnels,

or

of

they

Check the air pressure in

inflate

specified in the tables under

should

that

sonal

E

NGINE

Be

"COOLI

N

United

filled

freeze

conditions. See "COLD

TIONS"

or

deflate the tires to the air pressure

be

cleared

could

injury

COOLING

sure

the

NG

OT

E: Tractors shipped

States and Canada have the cooling syst

with

is

adequate

of

be

thrown

or

damage

coolant

SYSTEM"

antifreeze solution.

for

the

rocks

from

to

the

SYSTEM

is

at the correct leve

,

prevailing cold temperature

pneumatic tires nd

UTI RES" . Tire treads

or

other

foreig

n obj cts

the

tire

causing per-

tir

e.

l. See

to dest inations in the

em

WE

Be sure

ATHER

the ant

PRECAU-

i-

he

space

tank

All ow

to t

if exposed

light.

A

for

fue l expansion when adding fuel

. A tank

to

CAUTION!

cohol

which is

filled

to capacity may

a rise in temperature

Do not add gasoline

to

diesel

extremely

fuel. This creates a vap

or

ex plosive.

overflow

direct

sun-

or

alor

15

BEFORE

OPERATING THE

TRACTOR

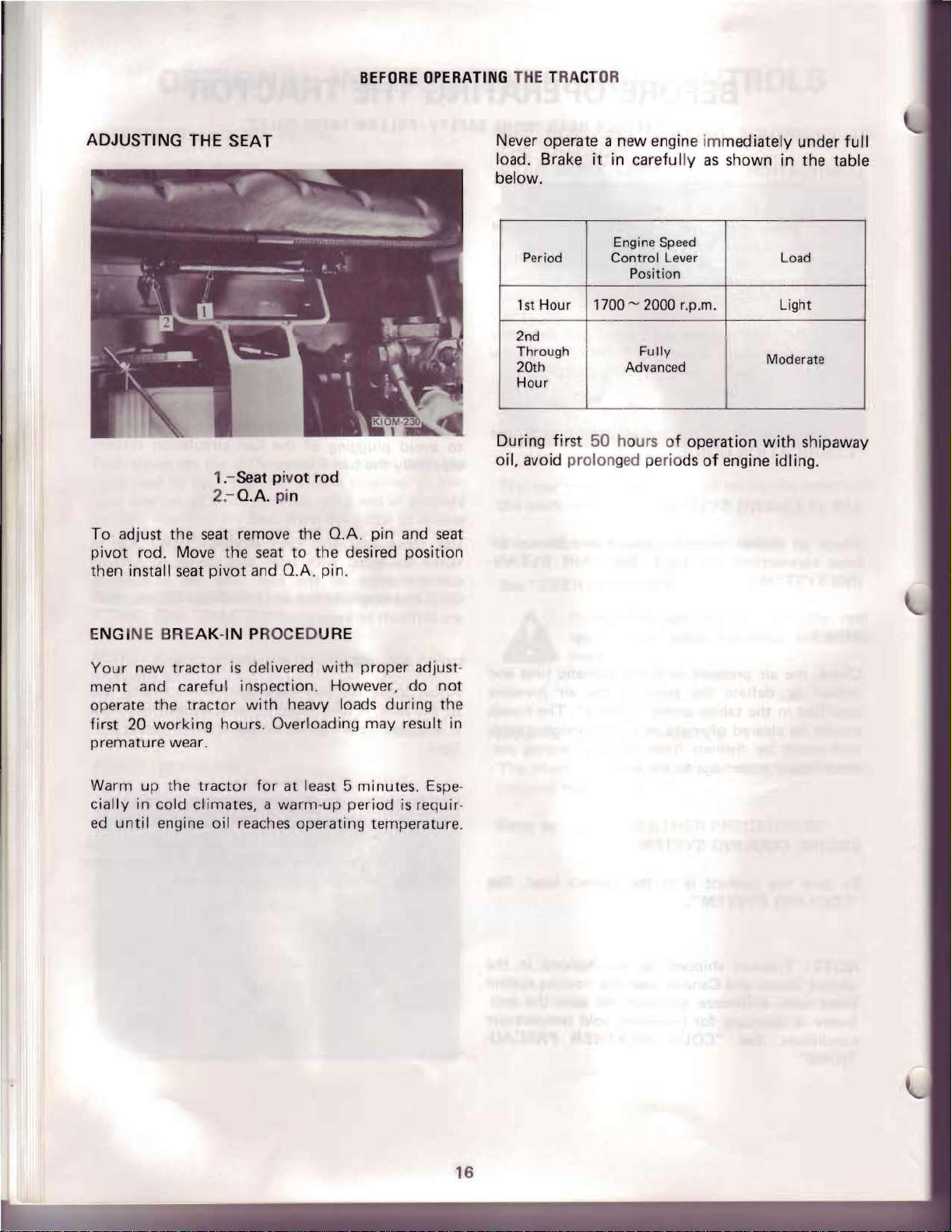

ADJUSTING THE SEAT

1

.-Seat

2.

-Q.A.

To

adjust

pivot

then install seat

the

seat remove the

rod. Move

the

pivot

seat

and

piv

pin

O.A

ot

to

rod

O.A.

the

. pin.

pin

desired

and seat

position

Never operate a

load. Brake

below

.

Period

1

st

Hour

2nd

Th rough

20th

Hour

During first

oil,

avoid

it

1700 ~ 2000 r.p.m.

50

prolon

new

engine immediately

in carefully

Engine

Control

Speed

Lever

Position

Fully

Advanced

hours of

operation

ged periods

as

of

shown

engine

under

in

the

Load

Light

Moderate

with

shipaway

idling.

full

table

ENGINE BREAK-

Your

new

tractor

ment

operate

first

premature

Warm

cially

ed

and careful inspection. However,

the

tractor

20

working

wear.

up

the

tractor

in

cold

climates, a

until

engine

IN PROC

is

with

EDURE

delivered

heavy loads

with

hours. Overloading

for

at

least 5 minutes. Espe·

warm

-up period

oil

reach

es

operating

proper

adjust·

do

during

may

result in

is

requir·

temperature

not

the

.

16

OPERATING THE TRACTOR

STARTING

1.

Open

TEM".

2.

Mount

tractor

3.

Be

sure

the

way

neutral

See

"INSTRUMENT

4.

Push

5.

Set the fuel

Insert

6.

to

the

charge

and

low

you

that

pear,

turn

the

cause determined and corrected.

THE

TRACTOR

the

fuel shut

the

tractor

has

RollOver

the

park brake

down.

position

in

the

"ON"

indicator telli

fuel

it

Place

and

the

fuel shut

control

start switch key and

position. The oil pressure tellite,

indicator

is

operational.

off

the switch,

off

and fasten

Protective Structure.

is

the

turn

AND

off

lever at high

te,

water tem

lamp

remove the key and h

valve.

See

seat

on.

Press

gear

shift

off

the

power

CONT

ROL".

lever fu lIy.

turn

will

light, in

If

the li

"FUEL

belt

the

clutch

lever in

take

idle

position.

it clockwise

perature

ght

s do not ap-

SYS-

if

the

all

the

off.

tellite

forming

ave

AFTER

NOTE:

is

running.

1. As soon

speed

warm up

Immediately

sure tel lite should

off

mine and correct

pressure

A

immediate moving of

the area

and

tion.

THE

ENGINE

Never operate

as

the

control

the

windo

engine

. Exhaust

lever

the

engine.

after

immediately,

will

cause

C

AUTION!

co

nfined

ings any longer than

ws

may

engine starts, push the engine

the

go

the

severe

gases

not

STARTS

the

starter while the en one

to

moderate

engine starts, the

out.

If

the

light

remove the key, deter-

cause.

areas such

Operation

damage

Do

not

run

as

is

the

tractor

are

toxic.

pro

vide adequate ventila-

speed

to

necessary

position

oil

stays on,

without

the

engine.

the

engine in

storage

out

Opening doors

of

build-

for

or

to

pres-

turn

oil

the

into

7.

Turn

the key

to

energize

8.

When the glowplugs

liance,

"START"

NOTE:

need

NOTE:

safety starting switch

clutch

starter

If

the

the key

A

the

turn

position.

If

the

to

be

energized.

The engine can

pedal all

for

more than

engine does

"OFF",

CAUTION!

gasoline) must

plugs

engine.

fully

glowplugs

the key

engine

the

not

wait

are used

counterclockwise and

for

15

to

20 seconds.

indicator

fully

is

warm

only

is

activated by depressing the

way

down.

30

seconds at

start

a few minutes, then

Starting

not

to

reaches the

clockwise

the

glowplugs do

be

started when the

Do

not

operate the

anyone

within

be

this tim

try

flu

id

(ether

used when

aid in starting

to

time.

e,

again.

glow

hold

bril-

the

not

turn

or

-

the

2.

Release

trac

tor

transmission.

TR

OLS

3.

Turn

4.

Adjust

throttle

speed

fined area such

5. Select

tractor.

A

gu

y wires, bridges,

ot

her situations where

or

pulled

jur

y.

the

to

avoid possible damage

See

".

front

wheels in desired

throttle

setting should

setting when moving

the

desired gear range

See

"DRIVING

CAUTION!

lIy

carefu

buildings,

from

the

park brake before moving

to

the

brake and

"IN

STR

UMENTS

direction.

to

desired engine speed. The

be

1/3

the

as

a garage

Check overhead clearance

before en

driving

low

the ope

tractor

or

THE

TRACTOR".

ter

under

hanging tree branches,

rator

resulting in serious in-

AND

or

less

of

the

tractor

storage building.

for

ing

moving

or

power

may

in a con-

leaving

be

struck

the

CON-

full

the

lines,

or

17

OP

ERA

TING THE

TRACTOR

DRIVING THE TRACTO R

To Sh ift Gears

NOTE:

motion.

Depress

Place

lever in

Slowly release

For gr

NOTE: Driving speed depends

A

NOTE:

by

tractor

Do

not

shift gears while the

the

clutch pe dal.

the gear

the

ound

rest ing the feet on t he peda ls while dr

because this wi

shift lever and

desired positions.

the

clutch pedal.

speed, see "SPECIFICATIONS

CAUTION! Bef

always lo

in

the

Do

not

ok

for

area where

"ride

" the clutch

ll

result

transmi

on the load ap plied.

ore

backing

obstacles

the

in

tractor

ssion ran

the

or

tractor

or

brake peda

excessive wear.

is

".

tracto

bystande

will move.

ivin

g the

in

ge

DRIVING

Before

the

slope

rocks , mounds, ruts, stum ps

ularities which cou

Drive up

Back

ments up

intend

the

slope in reverse,

worked .

r,

rs

Us

e first gear in low range when driving

slope. The

advantage

a slop

ls

id

Avo

must be made,

sl

ope greatly increases

a

ON

SLOPES

ope

rati

ng

to

look for possible hazards such

or

down t he face

the

tractor

the steepe

to

work.

CAUTION! This Off-Set, Hi·Clear Trac-

tor

is

more susceptible

left

than

tractor

of

engine braking during operatio n

e.

turns

when driving

turn

the

tractor

ld

cause an upset.

with

front

st

po rtion

If the

the

conventional

must always be

down the slope. Turning up

on any slope, walk

or

other

surface irre g-

of

a slope.

or

mid -m

ounted

of

each slope you

trac

tor

can

not

slope

is

too

steep

to

tipping

tractor.

in

gear

on

a slope.

the

chance of a roll over.

impl

negotia

to

to

on a ste

to

take

If

a

turn

as

e-

te

be

the

ep

on

CAUTION!

br

akes

A

A

When moving on

field, latch brake pedals toge

operation when making a stop

bility

c

ontrol

CA

UTIO

ther when operating t

or

fourth

of

loss

of

control and upset

Use

the

only

at

low speeds

of

the tracto

N!

Pedals must be latched toge-

gear,

in

high range.

public road

ther

brakes as t urning

to

mainta

r.

he

tractor in third

s,

or

from field to

for simultaneous

to

reduce

or

the

collision.

possi-

to

Avoid s

necessary

in

smoo

fl

ipping

TOWING THE TRACTOR

When towing

or

cab

operate the brakes.

When t

the

stea

the

Before

place

recommended

distances because

bec

om

be followed.

pping when driving up a slope. If it

to

stop whi

thly

and carefully

the

tractor

is

le

and have an operato r ste

ow

ing a

power

dy,

time.

of

even pull must be ke

tow

ing

to another

es necessary

le

driving up a slope, start

to

reduce

over backward.

necessary, use a

tractor

both

the

, check

that a tractor

out

tractors should be used. A

tractor,

of

the

to tra

the

safety hazards,

fottowing procedure should

the

possibility of

tow

rope, chain,

er

the

tractor

of

a stuJ:k condition,

pt

on

the

tract

or

nsp

ort

it from one

local laws. It

be towed for great

but

is

when it

is

up

and

all

not

18

OPE

RAT

ING THE TRACTO

R

TOWING

1.

Make sure

position.

2.

A driver must be in t

tractor

3. Do

meters per hour).

DRIVING ON PUBLIC

When travelling on pub lic road,

Moving Vehicle) emblem, flashing arn n9

and

use

Keep these devices cl

condition.

A

THE

TRACTO

the

parking brake is in

and

apply

the brakes.

not

tow

over 9.3

other

warning devices

by your local gove

CAUTIO

lamp

The

motorist

N!

whi

light

and cau

R -Continued

he

tractor seat to steer the

mil

es per

ROAD

which

rnment

ea

Do not use

le

may confuse

agencies.

n and

travelling

se

an accident.

se

are

In

on

the

hour

t e S

app

good

the

public

and

relea

(15 . ira-

rear

bhnd the

sed

ing

work

road.

STOPPING THE TRACTOR

1. Pu

sh

engine speed

rw

ard.

fo

2. Depress the

3.

De

pre

ss

the brake pedal

trac

tor.

NOTE:

parkin

flu

park brake

4.

5. Place

6.

7.

The brak

g,

or

id se

epage

is

Pl

ace

the

the

Slowly

Pu

release the

t the park brake on.

clutch

other

tends

provided

PTa

gearshift lever in the neutral position.

control

pedal.

es

are

not

stationary jobs since normal

to

release

for

this purpose.

control

in

clutch

lever all the way

to

stop and hold

intended

the

"off"

pedal.

the

brake. The

position.

for

use

the

in

Be

sure hitches

before

lized

of

loss

of

Shut

off

power

ing

or

not

For

your

safety avoid heavi ly-traveled roads

moving equipment,

When moving on

field,

lock

operation when making a stop

possibility

Reduce

avoid

Be

using

speed

loss

courteous, have considera

the road. Drive defensively.

and/or

towing

control

to

in

use.

brake pedals together

of

loss

when traveling on rou

of

control

drawb

equipme

and upset

any attachment wh

if

at

public roads

of

control and upset

and upset

nt

or

all possib

ars

to

co llision.

, or

or

tion

are

pro

e I stabi-

reduce poss'bility

en

tra

sort

le.

from

for

to

collision.

for

'eld

simultaneous

reduce the

or

collIsion.

gh

roads to

other traffi

en

to

NOTE:

may

Do

cause

not rely on having

the

possibili

ty

of

tractor

coasting

down

8. Lower equipment 0 ground before leavin g trac-

tor

to avoid the possibility of the equipment drop-

·

ping and causing inj ury.

9.

Turn off

10.

Pu

11. Turn the key

NOTE:

load ,

temperature

contro

engine.

c

lights.

II the fuel shut

to

If

the engine h

allow the engine to idle

is

reduced, then push the engine

l lever all the way forward and stop the

off

lever

the " OFF" position.

as

just operated under heavy

at

1500 r.p.m.

in

gear.

a slope.

unt

speed

It

il

19

OPERATING

THE

TRACTOR

STOPPING THE TRACTOR - Continued

12. Remove the key.

13. Dismount

ing implements have stopped.

NOTE:

valve

of

"PREVENTIVE

DIFFE

The

when one wheel

conditions than the other . Continual engagement

of

wearing parts and may improve performance

tractor

apparent . However, the

disengaged before

It

if

the engine

time. See

RENTIAL LOCK (OPTIONA

differential

the

differential

even

from

the

is

advisable

is

"FUEL

MAINTENANCE"

to

to

be

tractor

SHUT

only

after all

close the fuel

stopped

for

VALVE"

.

L)

lock

equalizes drive wheel slip

is

operating under poorer

lock

is

not

harmful

when excessively unequal slip

differential

attempting

turns.

lock

rotat

shut-off

any length

under

traction

to

the

of

the

is

not

must

be

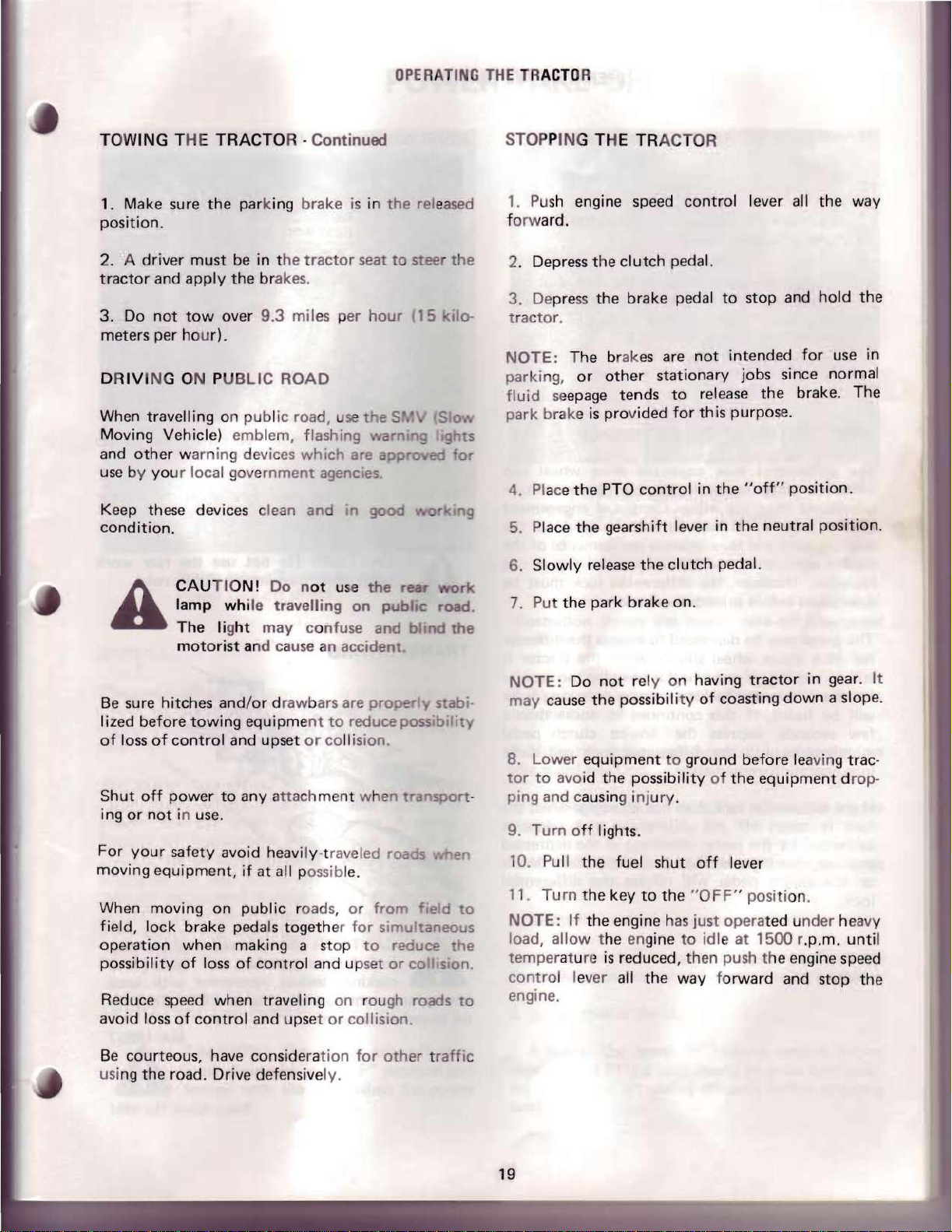

REAR WORK LAMP (OPTIO

-

The rear

on the

The lamp should

is

operated in the field.

la

work

mp.

lamp

CAUTION!

lamp while traveling on public road.

A

be

is

turned on

used

only

Do

not

NAL)

by

when the

use

the rear work

the switch

tractor

ed

The p

tial lock under wheel slip

st ill in motion.

for

will

few seconds,

momentarily and the differential

into

If the differential

f

oot

evidenc

position, quick pre

or

lock.

al may

the differential

be

heard.

operation

is

tak

ed

the

clut

be

depressed

If

one wheel

lock

If

this continues f

depr

ess

immediately.

lock

en

off the

by the pedal remaining in

ssure

ch pedal

to engage the

or

when

is spinning too rapid

to

engage,

the engine

does not disengage when the

differ

ential lock pedal

on

one

of

will

release the

differen

the

tra

ctor

a cl

icking

or

mor

clutch

lock will come

the

the

brake pedals

noise

e than a

pedal

depressed

differ

ential

-

TRANSPORTING

is

ly

as

A

law enforcement

on towed

CAUTIONI

lock brakes together,

When

road transporting.

use

making devices consistent

equ

agencies.

ipment.

Use

SAFETY CHAINS

lighting and

with

local

MA-16857

20

Loading...

Loading...