Break-in

mower

at

half throttle

INTRODUCTION

The International 105 Balanced Mower

is designed for use on the International Cub 8

Lo-Boye, Farmall Cub e, International and

Farmal18 Super A, Super A-l, 100, 130 and

140 Tractors. It is well suited for both industrial and farm use. A completing package

is required to mount on your tractor.

The tractors must be equipped with one of

the following units:

Touch Control for Farmall and hlternational

140 Basic Tractors for use with 105 Mowers

(Factory Application) (Standard Equipment on

hlternational 140 Standard Tractor).

354 467 R99 Special Touch Control for

Farmall and mternational"A", Super A,

100, 130, and 140 Tractors not previously

equipped with Touch Control.

for

first

This mower is especially built for highspeed mowing. It is ruggedly built with an

exclusive new wrist-action drive, balanced

for smooth running for longer machine life

and operator's comfort. It is especially

designed for cutting heavy hay and othervegetation.

or for mowing highway shoulders,

rights-of-way, and other industrial applications. It will operate efficiently with the cutter bar at any angle from. 450 below horizontal

to 900 vertical. This feature makes it desirable for cutting steep highway banks and

slopes. The. free floating action of the cutter

bar permits close operating positions along

the contour of the ground.

The hydraulic system enables the operatorto

raise the cutter bar to clear obstructions

or to raise the mowe r to transport position.

358 119 R 91 Special Touch Control Con-version

Package for Farmall and International

"A", Super A, 100, 130, and 140 Tractors

equipped with Touch Control.

381 223 R91 Restricted Actuator Package

(Factory Application) for International Cub

Lo-Boy, and Farrnall Cub Tractors.

381 228 R9l Restricted Actuator Package

(Field Conversion) for International Cub LoBoy and Farmall Cub Tractors.

Note: The Farmall Cub and International

Cub La-Boy tractors must be equipped withhead

gasket 351 989 R6.

The tractor Fast-Hitch cannot be used in

conjunction with the mower. However, the

Fast-Hitch helper spring parts are required

when the mower is mounted on the Cub or

Cub Lo-Boy Tractors.

The mower is mounted on the right side ofthe

tractor main frame between the front and

rear wheels. Power is transmitted from the

rear power take-off on the tractor through a

roller chain to the universal joint drive shaft.

A heavy-duty V -belt drive transmits the power

to the balanced drive. The entire drive is

completely shielded.

The mower operator can quickly adjust the

cutter bar for height to meet various mowing

conditions, permitting independent control ofthe

inner and outer shoes. A completing pack-

age is required for the International Cub Lo-

Boy and Farmall Cub Tractors.

A 5-foot cutter bar is standard equipment,

A variety of special knife assemblies areavailable

for this cutter bar.

Other special equipment and attachmentsare

as follows:

Outer Shoe Grass Deflector -to prevent

the cut material from falling into the un-

cut material.

Knife Rack Attachment -to carry extraknife

assembly in the field.

Curb Lift Attachment for International Cub

Lo-Boy and Farmall Cub Tractors -will

hold the inner shoe above ground level, up

to lO'l high to enable the cutter bar to be

placed in and position with the working

range of 45 below horizontal to vertical.

10hours

LUBRICA TION

Lubrication Guide

This machine is designed to require a

minimum amount of lubrication; however, regular and sufficient lubrication increases the

life of the machine, saves many dollars in

service parts, and is the best insurance

against delays.

Before starting, lubricate the complete

machine following the "Lubrication Guide",

and thereafter lubricate at regular intervals

as specified.

Care must be taken to see that all bearings

are lubricated their full length. To be certain

that all bearings are properly lubricated, the

lubricant should be forced into them until it

begins to appear at the sides.

Keep the lubricator gun clean and wipe off

all dirt from the lubrication fittings before

using the gun.

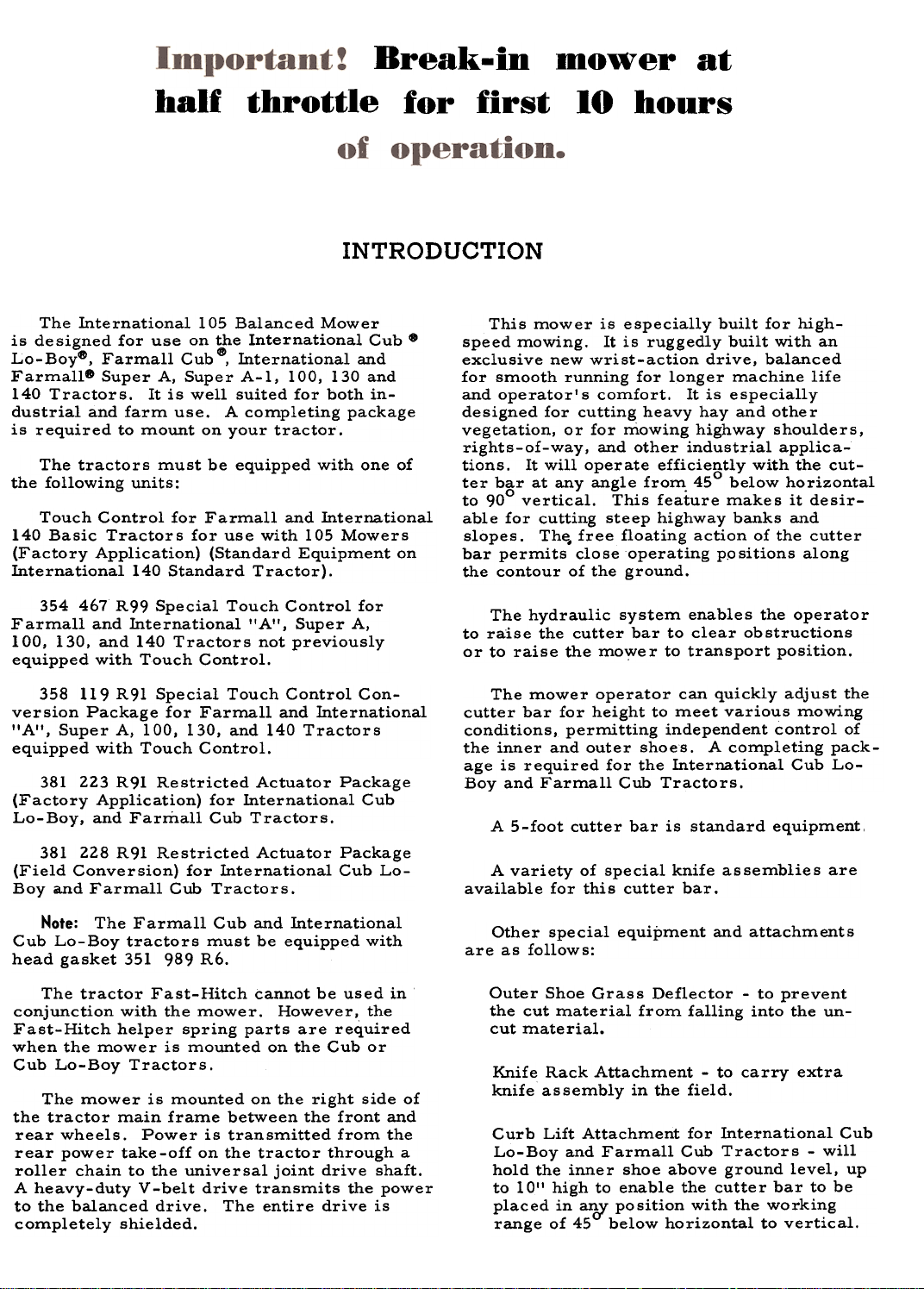

Illust. 2A

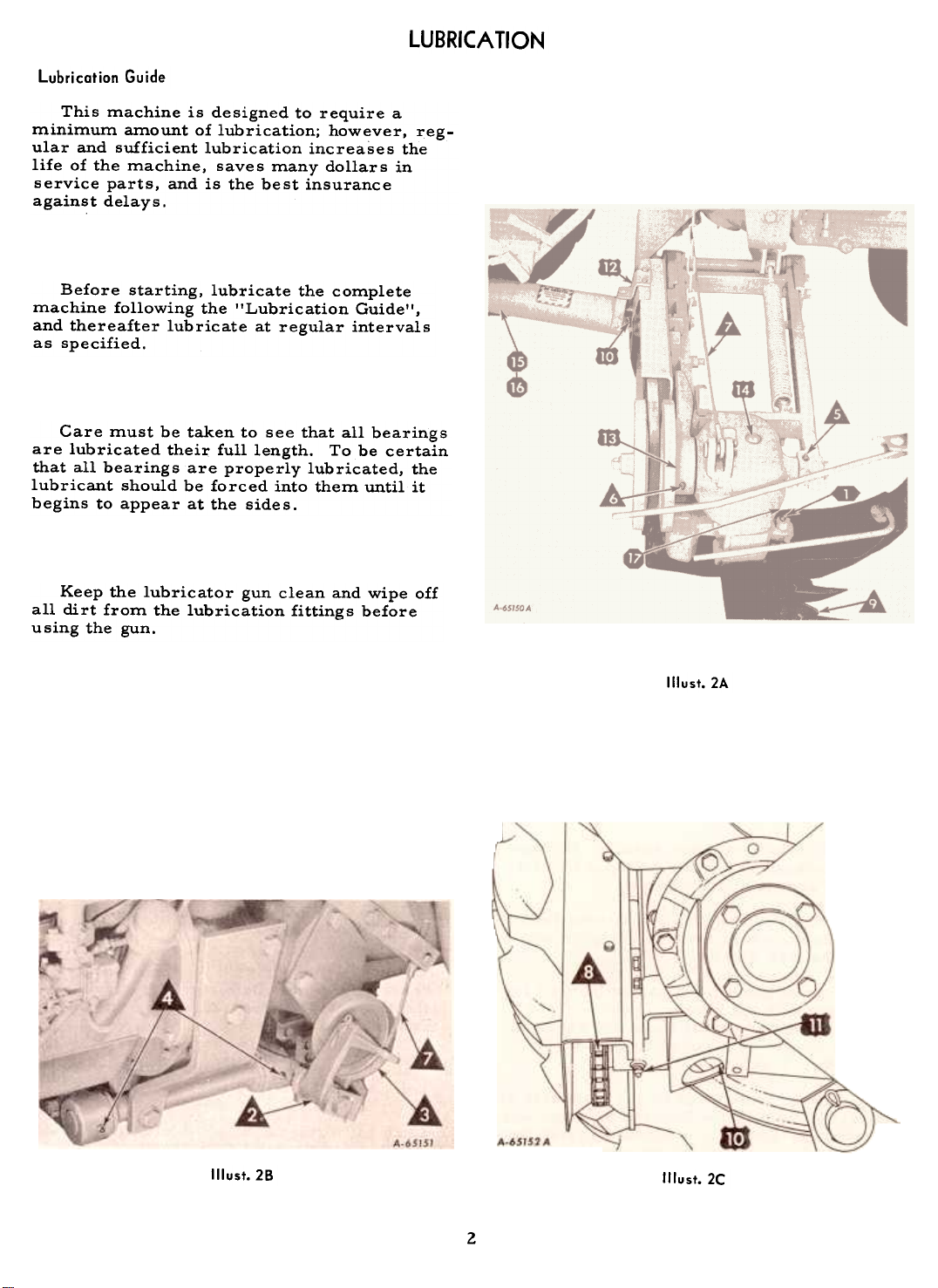

Illust.28

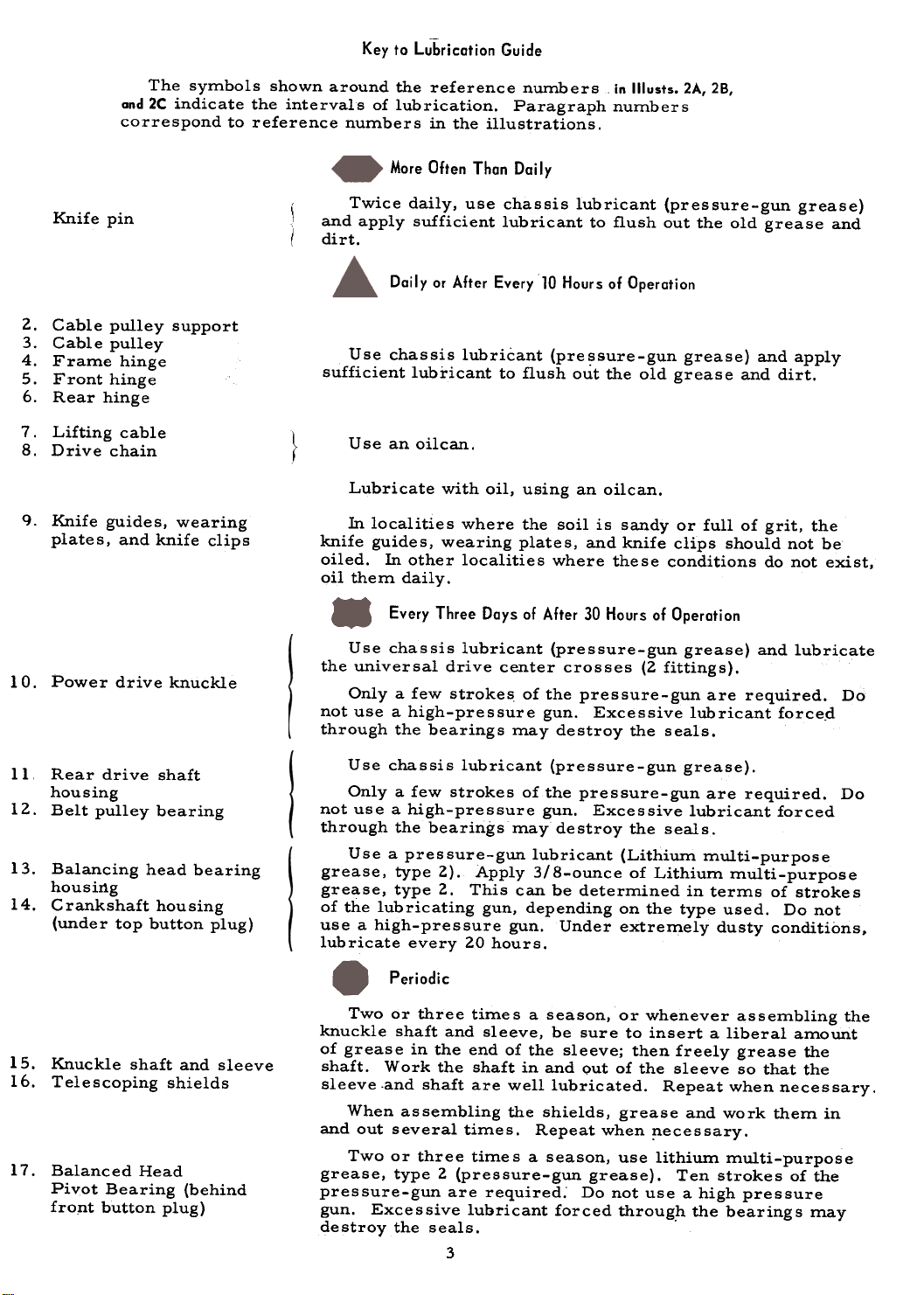

Illust.2C

2

Key to Lubrication Guide

The symbols shown around the reference numbers in Illusts. 2A, 2B,

and 2C indicate the intervals of lubrication. Paragraph numbers

correspond to reference numbers in the illustrations.

More Often Than Daily

Knife pin

2. Cable pulley support

3. Cable pulley4.

Frame hinge5.

Front hinge

6. Rear hinge

7.

Lifting cable

8.

Drive chain

Knife guides, wearing

plates, and knife clips

10.

Power drive knuckle

Twice daily, use chassis lubricant (pressure-gun grease)

and apply sufficient lubricant to flush out the old grease and

dirt.

Daily or After Every 10 Hours of Operation

Use chassis lubricant (pressure-gun grease) and apply

sufficient lubricant to flush out the old grease and dirt.

Use an oilcan.

Lubricate with oil, using an oilcan.

hllocalities where the soil is sandy or full of grit, theknife

guides, wearing plates, and knife clips should not be

oiled. hl other localities where these conditions do not exist,

oil them daily.

Every Three Days of After 30 Hours of Operati on

Use chassis lubricant (pressure-gun grease) and lubricate

the universal drive center crosses (2 fittings).

Only a few strokes of the pressure-gun are required. Do

not use a high-pressure gun. Excessive lubricant force_d

through the bearings may destroy the seals.

Rear drive shafthousing

Belt pulley bearing

13. Balancing head bearing

housirtg14.

Crankshaft housing

(under top button plug)

Knuckle shaft and sleeve16.

Telescoping shields

17. Balanced Head

Pivot Bearing (behind

fro~t button plug)

Use chassis lubricant (pressure-gun grease).

Only a few strokes of the pressure-gun are required. Do

not use a high-pressure gun. Excessive lubricant forced

through the bearings may destroy the seals.

Use a pressure-gun lubricant (Lithium mUlti-purpose

grease, type 2). Apply 3/8-ounce of Lithium mUlti-purpose

grease, type 2. This can be determined in terms of strokes

of the lubricating gun, depending on the type used. Do notuse

a high-pressure gun. Under extremely dusty conditions,lubricate

every 20 hours.

Periodic

Two or three times a season, or whenever assembling the

knuckle shaft and sleeve, be sure to insert a liberal amount

of grease in the end of the sleeve; then freely grease the

shaft. Work the shaft in and Qut of the sleeve so that the

sleeve .and shaft are well lubricated. Repeat when necessary.

When assembling the shields, grease and work them in

and out several times. Repeat when ~ecessary.

Two or three times a season, use lithium multi-purpose

grease, type 2 (pressure-gun grease). Ten strokes of the

pressure-gun are required: Do not use a high pressure

gun. Excessive lubricant forced through the bearings may

destroy the seals. .

3

9.

1112.

15.

ADJUSTING AND OPERATING

OPERATING

Before going into the field, check to see

that your machine is properly set up, adjusted,

and lubricated as in'structed.

Be sure all nuts are tight. They should be

tightened after a few hours of service. Spread

all cotters to keep them from falling out.

The wrist action drive is rugged and simple

designed to insure long life and trouble free

operation, however, its precision construction

requires a certain amount of break-in time.

Therefore, it is suggested that this mower be

run at. half (1/2) throttle under actual field

conditions for approximately the first 10 hours

This should be sufficient break-in time, after

which the mower can be operated at full speed.

During the break-in period the bearings will

run warmer than usual, but will not cause any

undue damage because of the unit being prepacked with "Lithium multi-purpose grease'!

as specified in the lubrication chart.

Farmall and Internatianal Super A, Super A.l, 100, 130, and

140 Tractor: To raise the cutter bar. move the

left Touch-Control lever forward; to lower the

cutter bar. move the lever to the rear. To

raise the mower frame. move the right TouchControl lever forward; to lower the frame move

the lever to the rear.

TOUCH.CONTROL SYSTEM

The Touch-Control power system utilizes

the power of the tractor engine to raise and

lower the cutter bar. A light touch of your

finger on the control lever is sufficient.

The mower can be regulated and adjusted

without stopping work while the tractor is in

motion or while standing still. Power is provided any time the engine is running. Disengaging the engine clutch does not affect the

operation of the hydraulic power system.

Farmall Cub and Internatianal Cub Lo.8oy Tractors: To

raise the cutter bar, move the Touch-Control

lever forward; to lower the cutter bar, move

the Touch-Control lever to the rear. The

cutter bar and mower frame will raise and

lower together. Independent movement of the

cutter bar can be accomplished with the use of

the curb lift attachment.

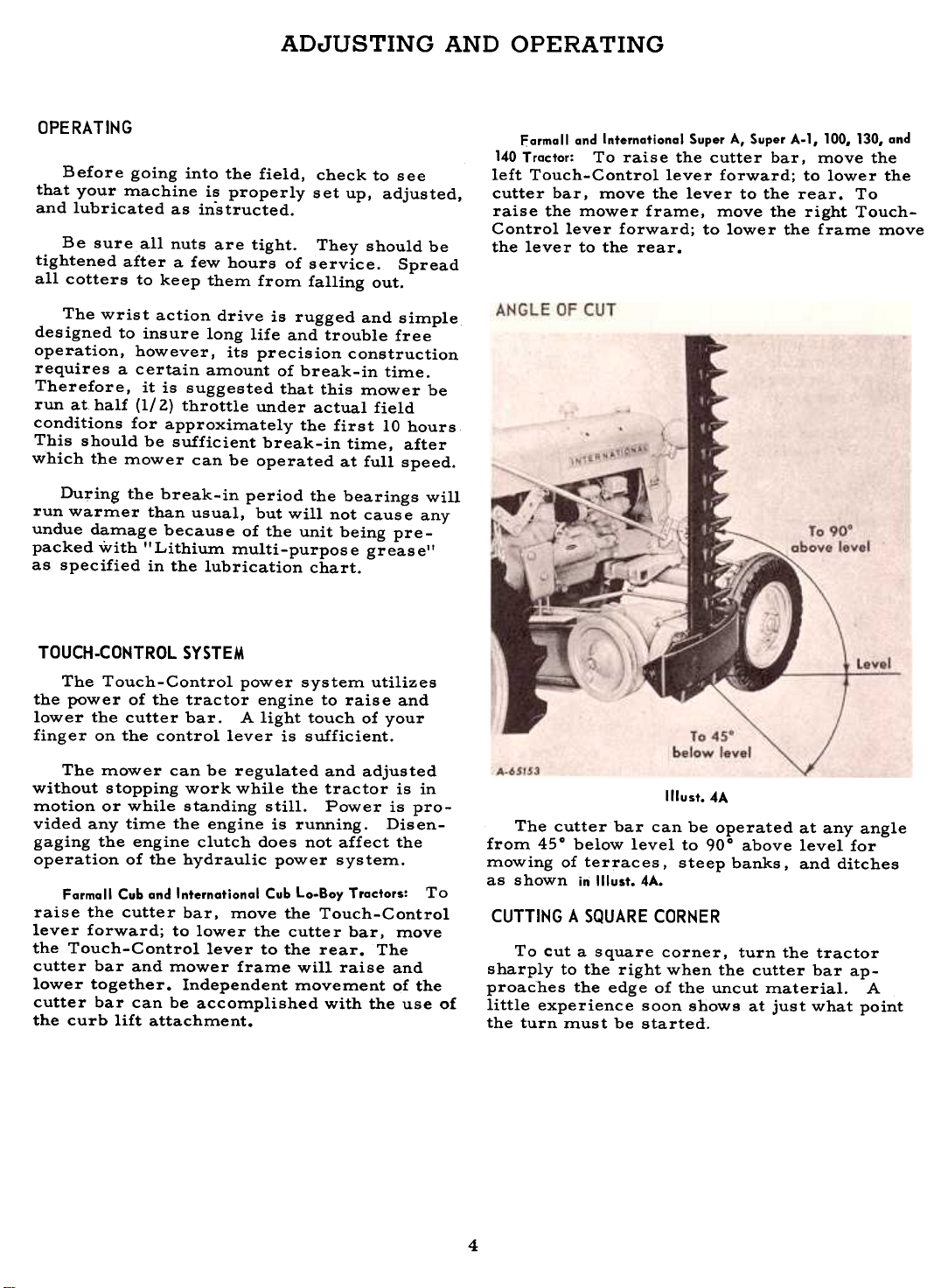

Illust. 4A

The cutter bar can be operated at any angle

from 450 below level to 900 above level for

mowing of terraces. steep banks. and ditches

as shown in Illust. 4A.

CUTTING A SQUARE CORNER

To cut a square corner, turn the tractor

sharply to the right when the cutter bar approaches the edge of the uncut material. A

little experience soon shows at just what point

the turn must be started.

4

CUTTER BAR LIFT

The cutter bar lift cable and lifting chain

should be set so that when the Touch-Control

lever is in the forward position, the cutter bar

will be approximately vertical. If the bar is

not vertical, this can be corrected by adjusting

the length of the cable and chain, either

lengthening or shortening.

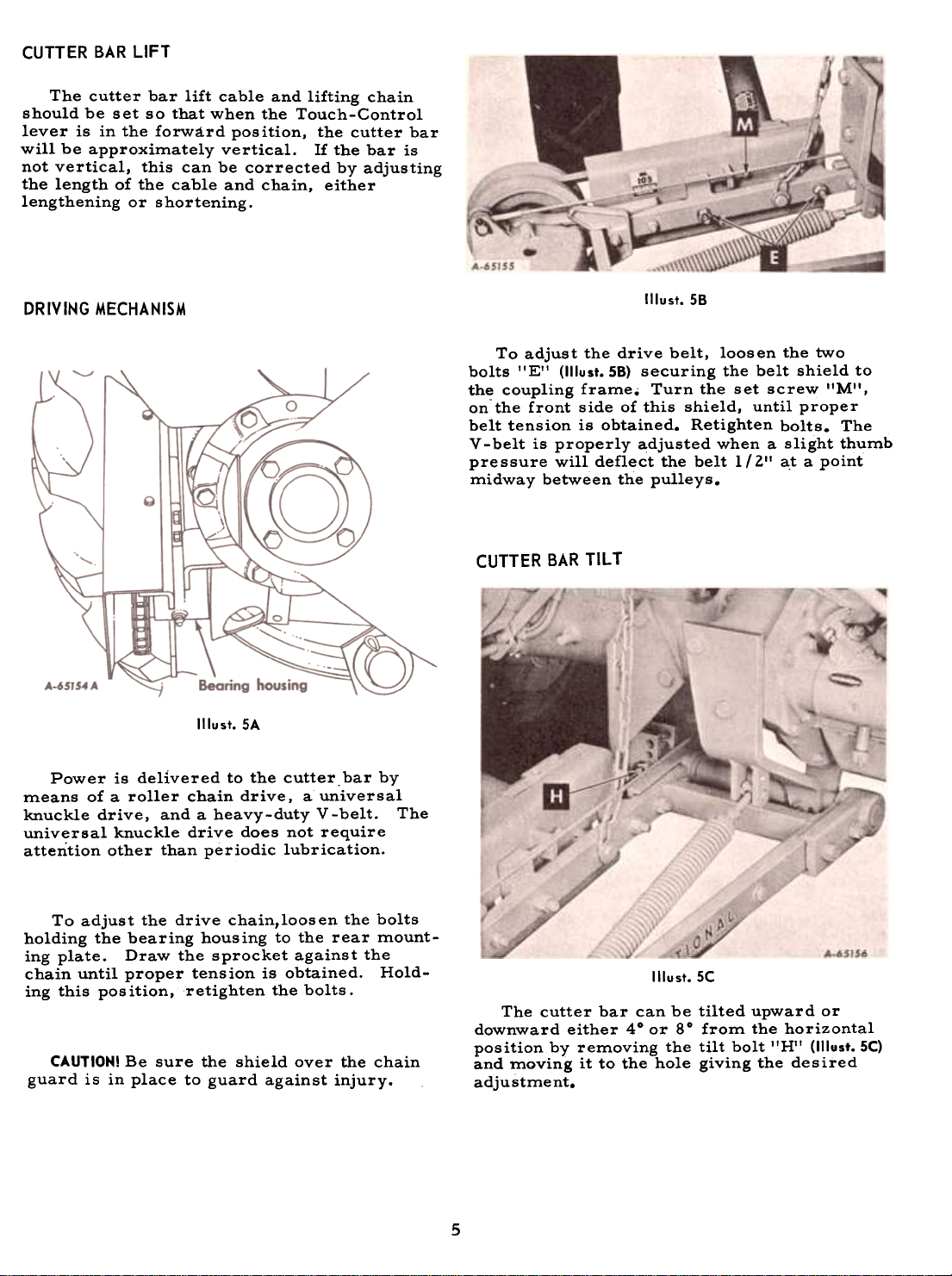

DRIVING MECHANISM

Illust. SA

Power is delivered to the cutter. bar by

means of a roller chain drive, a universal

knuckle drive, and a heavy-duty V-belt. The

univ~rsal knuckle drive does not require

attention other than periodic lubrication.

Illust. 58

To adjust the drive belt, loosen the two

bolts 'IE" (1IIust.58) securing the belt shield to

the coupling frame. Turn the set screw "M",

onthe front side of this shield, until proper

belt tension is obtained. Retighten bolts. The

V -belt is properly adjusted when a slight thumb

pressure will deflect the belt 1 (2" a.t a point

midway between the pulleys.

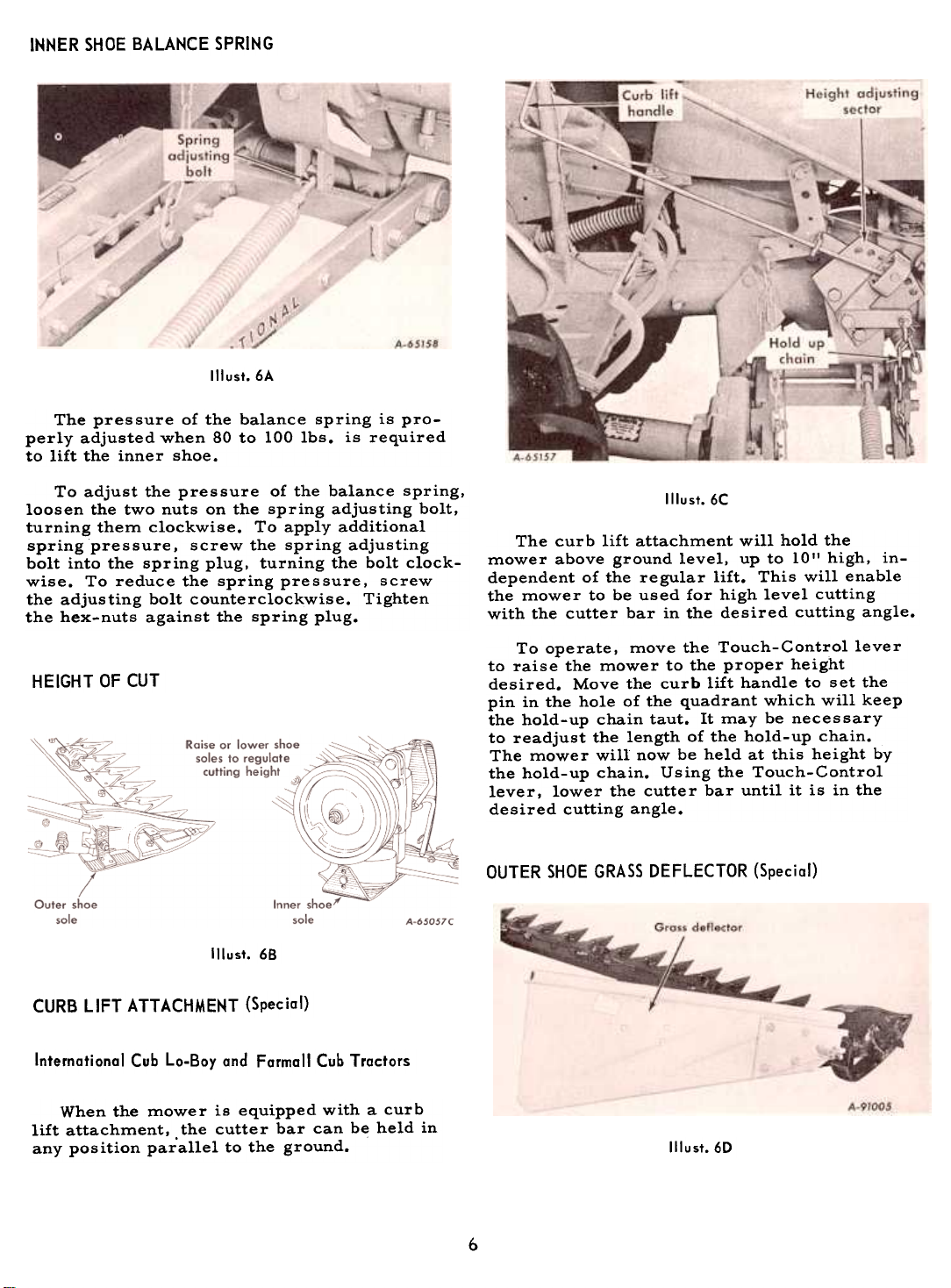

CUTTER BAR TILT

To adjust the drive chain,loosen the bolts

holding the bearing housing to the rear mount-

ing plate. Draw the sprocket against the

chain until proper tension is obtained. Holding this pos ition, retighten the bolts.

CAUTION! Be sure the shield over the chain

guard is in place to guard against injury.

Illust. SC

The cutter bar can be tilted upward or

downward either 40 or 80 from the horizontal

position by removing the tilt bolt "H" (1IIust.5C)

and moving it to the hole giving the desired

adju stme nt.

5

INNER SHOE BALANCE SPRING

Illust.6A

The pressure of the balance spring is pro-

perly adjusted when 80 to 100 Ibs. is required

to lift the inner shoe.

To adjust the pressure of the balance spring,

loosen the two nuts on the spring adjusting bolt,

turning them clockwise. To apply additional

spring pressure, screw the spring adjusting

bolt into the spring plug, turning the bolt clockwise. To reduce the spring pressure, screw

the adjusting bolt counterclockwise. Tightenthe

hex-nuts against the spring plug.

HEIGHT OF CUT

Illust. 68

Illust.6C

The cur b lift attachment will hold the

mower above ground level. up to 10" high, independent of the regular lift. This will enable

the mower to be used for high level cutting

with the cutter bar in the desired cutting angle.

To operate, move the Touch-Control lever

to raise the mower to the proper height

desired. Move the curb lift handle to set the

pin in the hole of the quadrant which will keep

the hold-up chain taut. It may be necessary

to readjust the length of the hold-up chain.

The mower will now be held at this height by

the hold-up chain. Using the Touch-Control

lever, lower the cutter bar until it is in the

desired cutting angle.

OUTER SHOE GRASS DEFLECTOR (Special)

CURB LIFT ATTACHMENT (Special)

International Cub Lo-Boy and Farmall Cub Tractors

When the mower is equipped with a curb

lift attachment. the cutter bar can be held in

any position parallel to the ground. Illust.6D

6

SERVICING THE CUTTER BAR

Increased acreages, mowing of pastures,

higher tractor speeds, and the greatly increased power of modern tractors subject

mowers to more severe usage than in thepast.

Therefore, periodic checking and ser-

vicing of your mower will pay big dividends

in a cleaner job of mowing, less damage to

parts, and decreased draft. Below are a few

suggestions pertaining to daily care of your

cutter bar:

Excessive draft is usually due to the fol-lowing:

A dull knife.

Poor lubrication.

Non-alignment of the cutter bar.

Poor adjustment of the cutter bar parts.

Bent guards must be reset to the proper

height 50 that all guards are at the same

height (level).

Do not hammer or bend down the lips of the

guards. This practice will result in choking

the knife, causing the mower to run hard.

NOTE: Do not raise the bar with the hydraulic

lift when the bar is "plugged" or "hung up" on

an obstruction. You may damage the bar.

Knife Section Riveting Tools

The knife section riveting tools will permit

the knife sections to be replaced without removing the knife assembly.

The knife is permanently registered at the

factory and no further adjustment is needed.

The knife must be straight. It must be supported by the wearing plates so that all sections contact the front of the ledger plate as

shown in Illust. 1A. Keep cutting apparatus in

perfect condition.

Ledger plates must be at the same height

(level) so that all sections contact. (Correct

installation of new guards is very important).

Correct tool usage for riveting

Illust.78

knife sections.

(Guards removed for clarity.)

Insert new rivets into the bottom of the

knife back and position the new knife section

onto the rivets.

Position the anvil tool "A" onto the rivet

head and tighten tool "A" until the tool and

tool holder is snug.

Tighten the heading tool "B" to secure therivet.

7

SERVICING THE CUTTER BAR. Continued

ledger Plate Riveting Tools

The ledger plate riveting tools will permit

the ledger plates to be replaced without re-

moving the guards.

Removing the Knife

Illust.88

Illust. SA

Correct tool usoge for riveting ledger plote.

knife.

Remove the old ledger plate and rivet, using

a 3/16-inch dia. punch at the flared end of the

rivet.

Position the new ledger plate onto the guard

and insert the new tubular rivet into the ledger

plate and guard.

Position the anvil tool rIG It onto the rivet

head an'd tighten tool IIG II until the tool and

tool holder is snug.

Tighten the flaring tool lID).! to flare the

rivet.

Illust.8C

Remove

8

SERVICING THE CUTTER BAR -Continued

Preparing and Replacing Guards

Remove broken guards and all dull ledgerplates.

must be pounded down to the proper height by

striking on the heavy section just ahead of the

plate. See Illust. 9A. Low guards must be raised

by striking the underside of this same loca-

tion.

NOTE: If guards are bent during field opera-

tion, remove the knife and bend the guard so

that it is at the correct height according to thegauge.

Steel Wearing Plates and Clips

The steel wearing plates support the back

of the knife so that the sections will contact

the ledger plate with a shearing action as

shown in Illust. 7A. If they are worn excessively,

the back of the knife will be low and the front

of the section will tip up, resulting in ragged

cutting. When this happens, they should be re-placed.

Illust.9A

When installing new guards make certain

that the bar is free of dirt. Draw the nut up

tight and then strike the guard several hammer

blows on the pad section of the countersunk hole

for the bolt. See Illust. 9A. This will seat the

guard. Then retighten the bolt.

Illust.98

Servicing the Kn ife

Illust. 9C

Check all old guards for correct ledger

plate height after reinstalling them, using the

ledger plate height gauge. The gauge must

rest flat against the slab and be flat on the

ledger plate to within 1/64 to 1/32 of an inch.

See Illust. 98. Guards which have been bent up

Remove all broken and dull sections as

shown in Illust. 9C;

9

DETACHING THE MOWER

Lower the cutter bar to the ground and dis-

connect the lifting cable.

With the lifting chain taut, remove the cap

screws from the left, right, and rear side

mounting plates.

CARE OF THE MOWER DURING STORAGE

STORING THE MACHINE

The life of the machine depends on how well

it is taken care of during the mowing season

and while in storage between seasons. The

storing period of the machine, which is

usually about eight months of each year, is an

important factor in the life of the machine.

Even though the machine is idle and not

subject to operational wear, it can, if not

properly stored, receive costly wear and

serious damage by being exposed to the

weather or by being struck by heavy objects.

No machine should be allowed to stand outside

unprotected from the weather for a long period

of time any more than an automobile.

Lower the mower frame to the ground and

disconnect the lifting chain.

Disconnect the power take-off.

Lubricate all points of the mower as shown

in the lubrication guide, and run the unit for

approximately ten minutes to allow lubricant

to give a protective coating to all bearings and

members subject to rust and corrosion.

Apply a light coating of oil on all expo sed

metal wearing parts.

Make a list of any service parts needed and

order these early. This will give your dealer

ample time to provide the parts and give you

sufficient time to install them before the next

mowing season.

A storage shed is a good investment be-

cause of the savings effected by assuring alonger-lasting

machine, reducing the operating

costs, and continuing the highly efficient mow-

ing performance.

BEFORE STORING THE MACHINE

Clean the machine of all dirt, trash, and

superfluous grease; if left on, it will hold

moisture and thus cause serious damage from

rust.

AFTER REMOVING THE MACHINE FROM STORAGE AND

This can save wasted time and needless expense.

ance with the instructions under "Lubrication"

to make sure that all bearings have a protective coating prior to field operation.

SETTING UP

Remove all wires and arrange the partsconveniently.

..

Lubricate all bearings and moving parts as

you proceed, and see that they work freely.

Bolts must be used in the holes in which

they are found, or in the parts to which they

are attached, unless otherwise shown.

are identified by 3 radial lines on the head and

are washer-faced to assure ma~mum surface

contact. See !llust. l1A.

BEFORE BEGINNING THE MOWING SEASON

the excess grease from the mower.

Make sure th~t all bolts and nuts are properly tightened.

Lubricate the machine thoroughly in accord-

Illust.llA

The cap screws furnished with this mower

Whenever the terms "left" and "right" areused,

it should be understood to mean from a

position behind and facing the machine.

Remove

When assembling this machine, start at the

beginning of the setting up instructions and

follow the sequence of steps for each assembly.

11

SIDE MOUNTING PLATES

Note: Side mounting plate cap screws must be tightened to 172 foot pounds torque.

International Cub Lo-Boy and Farmal! Cub Tractors

Illust. 12A

Left side mounting plates.

NOTE: If the mower is to be equipped with

the Knife Rack, assemble it on the side

mounting plate bolt at this time.

Internatianal and Farmall Super A, Super A-l, 100, 130, and

140 Tractors

Illust. 12C

Left side mounting plates.

NOTE: If the mower is to be equipped with

the Knife Rack, assemble it on the side

mounting plate bolt at this time.

Illust. 126

Right side mounting plotes.

NOTE: If the mower is to be equipped with

the Curb Lift. assemble it on the side mount-

ing plate bolts at this time.

Illust. 12D

Right side mounting plotes.

12

DRIVE SPROCKET AND CHAINS

International Cub Lo-Boy and Farmall Cub Tractors

Illust. 15A

International and Farmall Super A, Super A-l,

100,130, and 140 Tractors.

Illust. 15C

Illust. 158

15

CABLE LIFT ARM

BALANCED HEAD STOP

Illust. 16A

II lust. 16E

Internatianal Cub la-Boy Tractor.

1(lust. 16B

Internatianal Cub La-Bay

and Farmall Cub Tractars.

Illust. 16C

Internatianal Cub La-Bay

and Farmall Cub Tractars.

Note: Hole s are provided in the lift arm to

reposition the hammer strap when desired.

r Attach liftarm to rockshaft, using

1/2 x 2-1/2" and 3/4 x 2-1/2" cap

screws, lock washers and nuts

~- -cable around

I...

A-83375 -11/

Illust. 16D

International and Farmall Super A,

Super A-l, 100, 130, and 140 Tractors.

lift arm pivot

Attach pulley with ~haft

and 3/16x 1 "cotter pins

Farmall Cub and Internatianal and

Farmall Super A, Super A-I, 100, 130, and

Loole or "floppy" clothing should not be worn

by the operator because of the danger of it

wrapping on or getting into the moving parts.

Illust. 16F

140 Tractars.

---1-

16

KNIFE RACK (Special)

Internationa I Cub Lo-Boy Tractor

Assemble as illustrated, using the top bolt of the mounting plate and to

the inside of the fender, using two fender bolts 'IA".

International and Farmall Super A,

Super A-I, '],00, 130, and 140 Tractors

Illust. 19A

Assemble as illustrated.

19

CURB LIFT ATTACHMENT (Special)

International Cub Lo-Boy and Farmall Cub Tractors

Illust.20A

Illust. 208

Illust.20C

20

MEMBER, NATIONAL SAFETY COUNCIL

Accidents

with

No accident-prevention program can be successful without the wholehearted co-operation

of the person who is directly responsible for the

operation of equipment.

To read accident reports from allover the

country is to be convinced that a large number

of accidents can be prevented only by the

operator anticipating the result before the

accident is caused and doing something about

it. No power-driven equip.aent, whether it be

transportation or processing, whether it be on

the highway, in the harvest field or in the

Price $1.00

industrial plant, can be safer than the man who

is at the controls. If accidents are to be prevented-and they can be prevented-it will be

done by the operators who accept a full measure

of their responsibility.

It is true that the designer, the manufacturer,

the safety engineer can help; and they will help,

but their combined efforts can be wiped out by

a single careless act of the operator.

It is said that' 'the best kind of a safety

device is a careful operator. II We ask you

to be that kind of an operator.

Loading...

Loading...