Page 1

TM

IEI prox.pad

plus Access System

Installation/Programming Manual

www.ieib.com prox.pad plus Installation/Programming

Manual

Copyright 2003 Part Number 6105679, Rev. 1.0

International Electronics, Inc.

PPP, D2

Page 2

For more information, contact:

International Electronics, Inc. © Copyright 2003

427 Turnpike Street International Electronics, Inc.

Canton, MA 02021 U.S.A. All Rights Reserved

Published in U.S.A.

Telephone:

781-821-5566

800- 733-9502 (sales in MA)

800-343-9502 (sales)

Fax: 781-821-4443

Fax

Information

Center: 781-821-0734

Internet:

www.ieib.com

PPP, D2

Page 3

Table of Contents

Chapter 1: Introduction

1.1 About this Manual ............................................... 1-1

1.2 Safety Warnings and Cautions..........................1-1

1.3 Design Change Disclaimer.................................1-1

1.4 Reproduction Disclaimer.................................... 1-1

1.5 Technical Support................................................ 1-1

1.6 Warranty................................................................ 1-2

1.7 Items Supplied from the Factory ...................... 1-3

1.8 Items the Installer Must Supply........................1-3

1.9 General Description............................................. 1-4

1.9.1 Design Function ............................................ 1-4

1.10 prox.pad plus Operation .................................. 1-5

Chapter 2: Installation

2.1 Installation Configurations................................. 2-1

2.2 Other Installation Considerations..................... 2-2

2.2.1 Power Supply/Current Requirements....... 2-2

2.2.2 Gang Box and Mounting .............................2-2

2.2.3 Mounting the Unit on Metal....................... 2-2

2.2.4 RF Interference .............................................. 2-2

2.3 Checking the Cables............................................ 2-3

2.4 Mounting the prox.pad plus Unit .................... 2-7

2.4.1 Performing a Wall Mounted Installation.. 2-7

2.4.2 Performing a Glass Mounted Installation. 2-9

2.4.3 Performing a Secure Installation................2-11

2.5 Inserting Circuit Boards...................................... 2-15

2.6 Defaulting prox.pad plus Memory................... 2-16

prox.pad plus Install/Program. Manual, PPP, D2 iii

Page 4

Table of Contents

Chapter 3: Wiring

3.1 Wiring the prox.pad plus Unit...........................3-1

3.1.1 Wiring the AUX Relay for Use as Alarm

Shunt .........................................................................3-1

3.1.1.A Wiring the Alarm Shunt Relay...........3-1

3.1.2 Wiring the AUX Relay for Use as Forced

Door...........................................................................3-3

3.1.2.A Wiring the Forced Door Relay ...........3-3

3.1.3 Wiring the AUX Relay for Use as

Propped Door ..........................................................3-5

3.1.3.A Wiring the Propped Door Relay........3-5

3.1.4 Wiring the Door Contact Input...................3-7

3.1.5 Wiring the REX Switch (Request to Exit) ..3-9

3.1.6 Wiring the Main Relay..................................3-11

3.2 prox.pad plus Communications ........................3-13

3.3 Networking Multiple prox.pad plus Units

Together .......................................................................3-14

3.4 Testing the prox.pad plus...................................3-16

3.4.1 Testing the Controller/Keypad....................3-16

Chapter 4: Programming

4.1 Programming Overview .....................................4-1

4.1.1 Programming from the Keypad..................4-1

4.1.1.A Master Code (User #1) ........................4-1

4.1.1.B Supervisor Code (user #2) ..................4-2

4.1.1.C Master Code and Supervisor Code

Special Features..................................................4-2

4.1.1.D prox.pad plus Default Settings ..........4-3

4.1.1.E Resetting the Master Code and

System Defaults Only .......................................4-5

4.1.1.F Erasing Entire Memory/Resetting

System Defaults..................................................4-6

iv prox.pad plus Install/Program. Manual, PPP, D2

Page 5

Table of Contents

4.2 Programming Users.............................................4-7

4.2.1 Adding New or Changing Existing

Codes/Cards ............................................................ 4-7

4.2.2 Programming Code and Card Options .... 4-7

4.2.2 Programming User Types............................ 4-8

4.2.2.A Programming User Data,

Command 50, Full Format .............................. 4-9

4.2.2.B Quick Program Feature....................... 4-10

4.2.2.C Programming Code ONLY Use ........4-10

4.2.2.D Programming Code AND Card Use 4-10

4.2.2.E Programming Card ONLY Use ......... 4-11

4.2.2.F Programming Code OR Card............. 4-11

4.2.3 Batch Load Cards by Presentation............. 4-12

4.2.4 Enabling/Disabling Users Command ........ 4-13

4.2.5 Batch Load Cards Manually

(without presentation)........................................... 4-14

4.2.6 Block Delete of Users ...................................4-15

4.2.7 Deleting Users ............................................... 4-15

4.3 Programming Outputs........................................ 4-16

4.3.1 Changing the Lock Output Time............... 4-16

4.3.2 Assigning Outputs ........................................ 4-16

4.3.3 Setting Propped Door Output Time ......... 4-18

4.3.4 Setting Forced Door Output Time ............. 4-18

4.4 Programming Keypad Options and

Parameters................................................................... 4-19

4.4.1 User Lockout Option....................................4-19

4.4.1.A Lockout By Location............................ 4-19

4.4.1.B Lockout By Group................................ 4-20

4.4.2 TimeZone/Holiday Features........................4-21

4.4.2.A Midnight Crossing TimeZones..........4-22

4.4.2.B Holidays .................................................4-23

4.4.2.C Daylight Savings Time ........................ 4-23

4.4.2.D Leap Year .............................................. 4-24

prox.pad plus Install/Program. Manual, PPP, D2 v

Page 6

Table of Contents

4.4.2.E Time/Date Set.........................................4-24

4.4.3 Turning Visual LED/Keypress Indicator

ON/OFF....................................................................4-24

4.4.4 Turning Audio Keypress Feedback

ON/OFF....................................................................4-25

4.4.5 Error Lockout .................................................4-26

4.4.6 Timed Anti-Passback.....................................4-27

4.5 Using the Printing Features................................4-29

4.5.1 Selecting Transaction L og Information......4-29

4.5.2 Printing a Transaction Log...........................4-30

4.5.2.A Programming a Transaction Dump

Code .....................................................................4-31

4.5.2.B Printing a Transaction Log

Manually..............................................................4-31

4.5.2.C Erasing a Transaction Log...................4-32

4.5.2.D Printing a Programmed Users List ....4-32

4.6 Programming Commands ..................................4-34

Chapter 5: Troubleshooting

5.1 Before Calling IEI .................................................5-1

5.2 Flow Charts ...........................................................5-4

5.3 Performing Power Supply Integrity Test .........5-6

5.4 Correcting Possible Water Problems.................5-9

5.4.1 Silicone.............................................................5-9

5.4.2 Wire Run .........................................................5-9

Chapter 6: Miscellaneous

Information

6.1 Customer Service Policy......................................6-1

6.2 RMA Policy ............................................................6-2

vi prox.pad plus Install/Program. Manual, PPP, D2

Page 7

List of Illustrations

Figure 2-1 prox.pad plus Wiring Harness.........2-3

Figure 2-2 Identifying Pin Connectors ..............2-4

Figure 2-3 Performing a Wall Mounted I

nstallation.............................................2-8

Figure 2-4 Performing a Glass Mounted

Installation...........................................2-10

Figure 2-5 Performing a Secure Installation .....2-12

Figure 2-6 Removing/Inserting Printed Circuit

Board ....................................................2-15

Figure 2-7 Program Button Location on Main

Circuit Board .......................................2-17

Figure 3-1 Wiring the Aux Relay for Alarm

Shunt Operation.................................3-2

Figure 3-2 Wiring the Aux Relay for Forced

Door Alarm..........................................3-4

Figure 3-3 Wiring the Aux Relay for Propped

Door Alarm..........................................3-6

Figure 3-4 Wiring the Door Contact Input .......3-8

Figure 3-5 Wiring the REX Switch .....................3-10

Figure 3-6 Electric Strike (Fail Secure)

Wiring Diagram..................................3-11

Figure 3-7 MagLock (Fail Safe) Wiring

Diagram................................................3-12

Figure 3-8 Connecting the prox.pad plus to a

PC COM Port ......................................3-13

Figure 3-9 Connecting the prox.pad plus to a

Network ............................................... 3-14

Figure 3-10 Networking Multiple prox.pad

plus Units Together ...........................3-15

prox.pad plus Install/Program. Manual, PPP, D2 vii

Page 8

List of Illustrations/List of Tables

List of Tables

Table 1-1 prox.pad plus Specifications ............ 1-6

Table 2-1 prox.pad plus Pin Connections .......2-5

Table 2-2 IEI-Supplied Parts/Optional Items.. 2-6

Table 4-1 prox.pad plus Default Settings........ 4-3

Table 4-2 LED Indicators/Sounder

Table 4-3 prox.pad plus User Types ................ 4-8

Table 5-1 Troubleshooting Chart ...................... 5-2

Operations........................................... 4-4

viii prox.pad plus Install/Program. Manual, P PP, D2

Page 9

Chapter 1:

Introduction

1.1 About this

Manual

1.2 Safety

Warnings and

Cautions

1.3 Design

Change

Disclaimer

1.4 Reproduction

Disclaimer

1.5 Technical

Support

This manual is designed for installers of the International Electronics prox.pad plus Access System.

When handling the main printed circuit board, to

guard against possible static discharges, touch a

grounded object BEFORE touching the prox.pad plus

unit. Static shock can render the product unusable.

Due to design changes and product improvements,

information in this manual is subject to change without

notice. IEI assumes no responsibility for any errors that

may appear in this manual.

Neither this manual nor any part of it may be reproduced, photocopied, or electronically transmitted in

any way without the written permission of IEI.

Should you experience any difficulty installing the

prox.pad plus unit, please contact your IEI representative, or IEI at the number listed on page ii. Before

calling IEI for installation assistance, refer to Chapter

5, Troubleshooting. This chapter includes a list of com-

mon system problems, possible causes, and corrective

actions plus easy-to-use diagnostic flow charts.

To contact IEI’s Technical Support department, call

1-800-343-9502 between 8:00 a.m. - 7:00 p.m. (Eastern

Standard Time), Monday through Friday. Questions

can also be submitted through our website at

www.ieib.com. You can also download an electronic

version of this manual from this site.

prox.pad plus Install/Program. Manual, PPP, D2 1-1

Page 10

Chapter 1: Introduction 1.6 Warranty

1.6 Warranty

International Electronics Inc. (IEI) warrants its products to be free from defects in material and workmanship when they have been installed in accordance with

the manufacturer’s instructions and have not been

modified or tampered with. IEI does not assume any

responsibility for damage or injury to person or property due to improper care, storage, handling, abuse,

misuse,normalwearandtear,oranactofGod.

IEI’s sole responsibility is limited to the repair (at IEI’s

option) or the replacement of the defective product or

part when sent to IEI’s facility (freight and insurance

charges prepaid) after obtaining IEI’s Return Material

Authorization. IEI will not be liable to the purchaser

or any one else for incidental or consequential damages arising from any defect in, or malfunction of, its

products.

Except as stated above, IEI makes no warranties, either

expressed or implied, as to any matter whatsoever,

including, and without limitation to, the condition of

its products, their merchantability, or fitness for any

particular purpose.

Warranty Periods Are:

1 Year PowerKey

2 Years Door Gard & Secured Series

Products

2 Years prox.pad and prox.pad plus

2 Years LS Series

2 Years Glass Break

5 Years ‘e’ Series Keypads

All products have date code labeling to determine the

warranty period. A 90-day grace period is added to all

products to account for shelf life.

1-2 prox.pad plus Install/Program. Manual, PPP, D2

Page 11

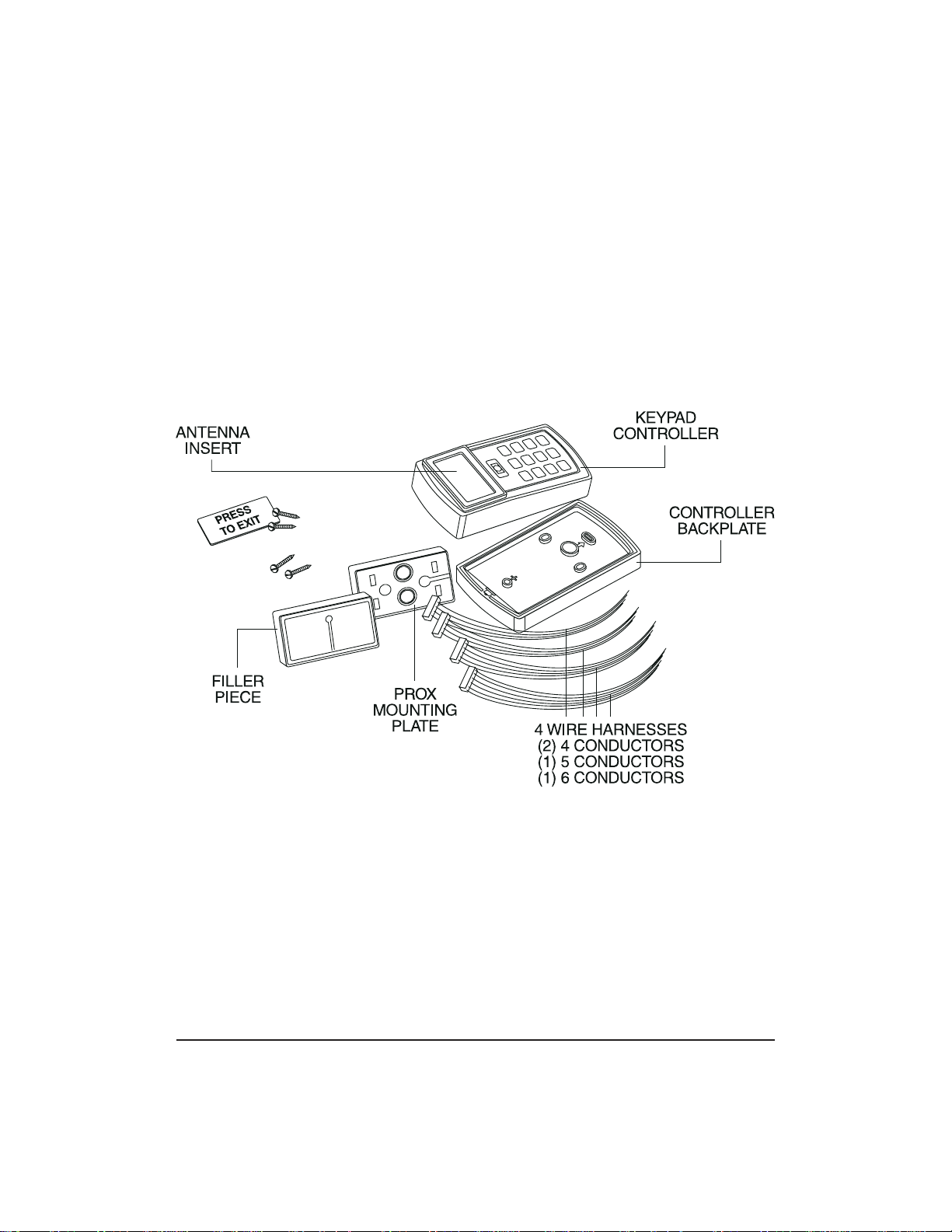

1.7 Items Supplied from the Factory Chapter 1: Introduction

1.7 Items Supplied

from the Factory

1.8 Items the

Installer Must

Supply

The following items are supplied from the factory with

the initial prox.pad plus shipment.

• Controller with Keypad, Faceplate, Request to Exit

(REX) button (also called the “Filler Piece”), three

Wire Harnesses, and various installation Screws.

For each initial prox.pad plus unit installation, the

installer must supply the following items:

• The prox.pad plus unit works with these four

types of cards:

–ProxCardII

–IsoProxII

–DuoProxII

–ProxkeyFOB

• an appropriately rated DC Power Supply (12 VDC)

(filtered and regulated recommended)

• the appropriate installation electrical tools

• the recommended remote antenna cable

[ALPHA 1174C (22AWG) 4-wire, stranded] (this is

required ONLY if you choose to remote the antenna 10 feet away from the keypad/controller)

• RS-485 cable (24AWG), shielded, two twisted-pair

telephone cable with a shunt capacitance of

16 pF/Ft (required only when using software)

• power supply cable (18AWG-22AWG) 2-wire

stranded (depends on distance)

• door lock cable (18AWG-22AWG) 2-wire stranded

(depends on distance)

• door monitor cable (18AWG-22AWG) 2-wire

stranded (depends on distance)

• REX cable (if using remote switch) 2-wire stranded

prox.pad plus Install/Program. Manual, PPP, D2 1-3

Page 12

Chapter 1: Introduction 1.9 General Description

1.9 General

Description

1.9.1 Design Function

The IEI prox.pad plus Access System provides card

and/or keypad access control for a single door. The

unit can be install ed in a one-stage configuration

(which is typical for most users), or a higher security,

two-stage (or “remote”) configuration.

In the “secure” (or remote) configuration, the antenna

can be detached and mullion-mounted up to a maximum of 10 feet away from the controller/keypad. For

installation details, see section 2.4.3.

Theprox.padplusunitiscompatiblewithallHID

proximity cards, with up to 40 bits. Batch programming

without the need for the card can be done only with

26-bit HID cards. All programming is performed using

the built-in keypad.

The prox.pad plus unit is equipped with RS-485 communications, which allows the system to be managed

with a personal computer using Hub Manager

TM

Professional software (ver. 5 or higher). This capability

allows the unit to store up to 8 timezones, including

auto-unlock, and a maximum of 32 holidays. In addition, the unit can store up to 2,000 transactions.

The keypad can store up to 2,000 users.

The specific types of users that can be programmed

with the prox.pad plus unit are listed in Table 1-1 on

page 1-8.

For convenience, proximity cards can be programmed

efficiently in a “batch” mode. A user-programmable

lock time of 1-255 seconds plus a “latch/toggle” mode

are included.

1-4 prox.pad plus Install/Program. Manual, PPP, D2

Page 13

1.10 prox.pad plus Operation Chapter 1: Introduction

1.10 prox.pad plus

Operation

Once installed and programme d successf ully, the

prox.pad plus controller stores all transactions and

controls all outputs. The controller receives data sent

to it from the proximity reader, decides if access should

be provided or not, and then energizes the door lock

or not, locking or unlocking the door.

The prox.pad plus unit includes two relay outputs

(located internally), an internal clock, programming

keypad, and memory chips to store user information

and a transaction data log.

An external IR (infrared) LED/port/transmitter at the

top right of the prox.pad plus controller allows for

printing of the Transaction Log and the Programmed

User List to the optional IEI PDA Data Capture Device

(DCD) software. Chapter 4 discusses printing reports.

NOTE: IEI recommends that first-time installers test

the prox.pad plus unit BEFORE actually mounting

and wiring the unit to become familiar with its operation (see Chapter 2).

prox.pad plus Install/Program. Manual, PPP, D2 1-5

Page 14

Chapter 1: Introduction 1.10 prox.pad plus Operation

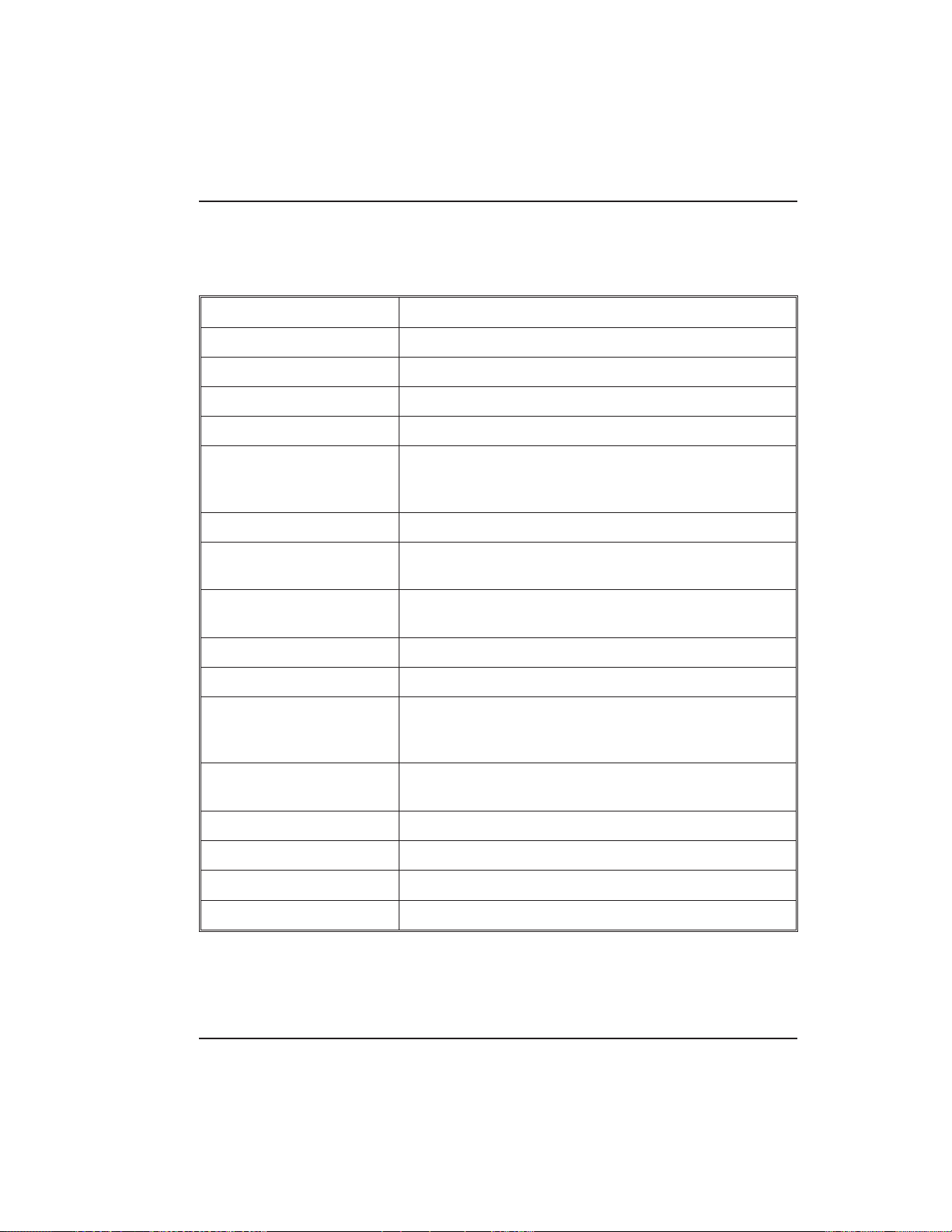

Table 1-1. prox.pad plus Specifications

ELECTRICAL

Power Supply/Current

Requirements

WIRING

Remote Antenna Cable ALPHA 1174C (22AWG) 4-wire, stranded (this is

RS-485 Cable 24AWG, shielded, two twisted-pair telephone cable

Power Supply Cable 18AWG - 22AWG 2-wire stranded (depends on

Door Lock Cable 18AWG - 22AWG 2-wire stranded (depends on

Door Monitor Cable 18AWG - 22AWG 2-wire stranded (depends on

REX Cable (if using remote switch) 2-wire stranded

MECHANICAL

Height 5.25 in (13.3 cm)

Width 2.75in(7cm)

10-15 VDC, linear filtered and regulated power supply

500 mA (not including locking device or peripherals)

required ONLY if you choose to remote the antenna

10 feet away from the keypad/controller)

with a shunt capacitance of 16 pF/Ft (required only

when using software)

distance)

distance)

distance)

Depth 1.375 in (3.5 cm)

RELAY OUTPUTS

Main Relay - Form C (switches up to 4A)

Aux Relay - Form C (switches up to 1A)

MONITOR INPUTS

Door Position (Normally Closed, dry contact)

Request to Exit (REX, Normally Open, dry contact)

1-6 prox.pad plus Install/Program. Manual, PPP, D2

Page 15

1.10 prox.pad plus Operation Chapter 1: Introduction

Table 1-1. prox.pad plus Specifications (continued)

OTHER OUTPUTS

Infrared output to optional IEI DCD PDA program

SOUNDER 4000 Hz, defeatable

LEDs Bi-Color (red/green)

Yellow

COMPATIBLE

PROXIMITY CARDS

UNIT CAPACITY

Users 2,000 users maximum; each user can have a

Transactions 2,000 transactions maximum; each transaction

Lock Time 1-255 seconds

Lock Mode Access Time or Toggle/Latch

ALARM OUTPUT One of these three events can be programmed:

USER ACCESS

CONFIGURATIONS

All 26-bit HID card, including the following: ProxCard

II, IsoProx II, Duo Prox II, and Proxkey FOB; 26-bit

cards are required for manual or batch programming

card/tag, a PIN code, or a card/tag plus a PIN code

includes time, date, user “slot number,” and event

Alarm Shunt Relay, Forced Door Relay, or Propped

Door Relay

Code ONLY

Code AND Card

Card ONLY

Code OR Card

prox.pad plus Install/Program. Manual, PPP, D2 1-7

Page 16

Chapter 1: Introduction 1.10 prox.pad plus Operation

Table 1-1. prox.pad plus Specifications (continued)

PROGRAMMABLE

USER TYPES

SYSTEM USES/

INSTALLATION

CONFIGURATIONS

ENVIRONMENTAL Indoor or outdoor

Operating Temperature -31° to 150° F (-35° to 66° C)

Operating Humidity 5% to 95% relative humidity, non-condensing

Each user is assigned one of the following user types:

0-Toggle/latch strike

1-Normal access

2-log Dump

3-Lockout

4-Extended unlock

5-Single use

6-Relock

7-Emergency

Suitable for small installations or remote locations,

indoors or outdoors

Wall mounted, glass mounted, or secure installation

1-8 prox.pad plus Install/Program. Manual, PPP, D2

Page 17

Chapter 2: Installation

Chapter 2 supplies information about prox.pad plus

installation configurations; installation considerations;

and procedures for checking the cables, mounting the

prox.pad plus unit, inserting circuit boards, and defaulting prox.pad plus memory.

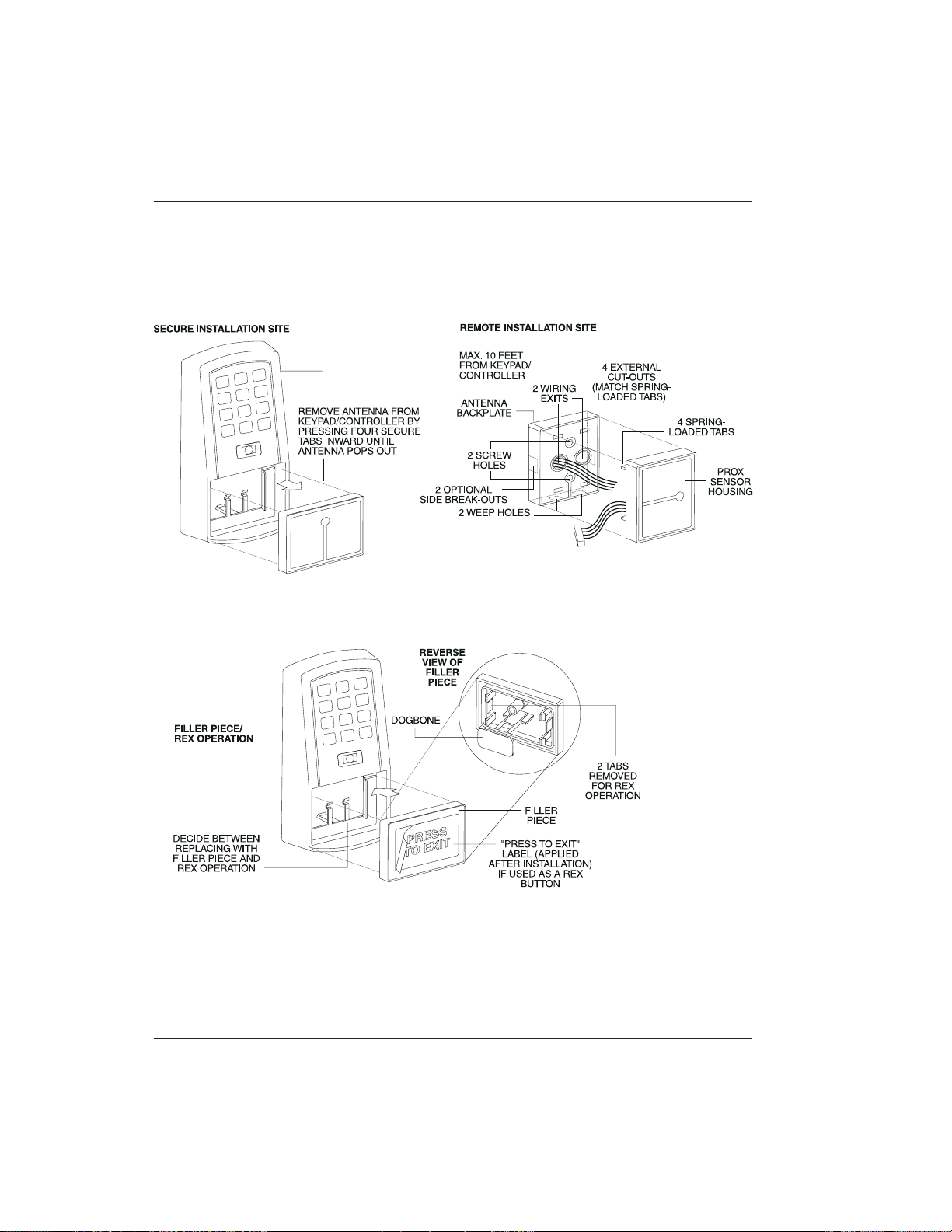

2.1 Installation

Configurations

It is the installer’s responsibility to determine the appropriate prox.pad plus installation configuration,

which differs from installation to installation. These

three installation configurations are possible:

• Wall mounted installation (exterior to the room

to be accessed). In this configuration, a single gang

electrical box can be used. Typically, the pr ox.pad

plus unit is wall mounted (surface mounted) outside the access area on the unsecured side.

• Glass mounted installation, using the four IEI-

supplied pressure-sensitive adhesive pads. In this

configuration, the prox.pad plus unit is affixed

with the adhesive pads to the glass door or the

window adjacent to the door being accessed, on

the interior side of the glass. The side cut-out on

the unit is used to bring the wires out of the side

of the prox.pad plus case.

• Secure installation (or “two-stage” configuration),

for higher security. In this configuration, the

prox.pad plus antenna is located a maximum of

10 feet away from the controller/keypad; the controller/keypad is located on the secure side of the

door.

prox.pad plus Install/Program. Manual, PPP, D2 2-1

Page 18

Chapter 2: Installation 2.2 Other Installation Considerations

2.2 Other

Installation

Considerations

2.2.1 Power

Supply/Current

Requirements

2.2.2 Gang Box and

Mounting

2.2.3 Mounting the

Unit on Metal

Sections 2.2.1-2.2.4 describe important considerations

the installer must decide upon before actually starting

to install and wire the prox.pad plus unit.

Power for the prox.pad plus unit must be from a minimum 10-15 volt DC linear, filtered and regulated

power supply. It is typical for the chosen power supply

to power BOTH the prox.pad plus unit and the selected locking device. When using one power supply

for both the prox.pad plus unit and locking device, be

sure to include both devices in your current requirements calculations.

NOTE: IEI recommends that you ground the power

supply to earth ground.

For the wall mounted installation configuration, a single gang electrical box can be used. (Typically, the

prox.pad plus unit is wall mounted outside the access

areaontheunsecuresideofthedoor.)

The prox.pad plus unit uses radio frequency to transfer

power to and communicate with the proximity card

or keytag. If the antenna is mounted directly on a metal

building or wall, some of the energy is absorbed by

the metal, resulting in less power being transmitted to

the keytag; this causes reduced read range. If you must

mount the prox.pad plus unit on metal, test the unit

in place before permanently installing it. If read range

distance distance is not adequate, a non-metallic spacer

can be fabricated and installed between the unit’s antenna and the metal mounting surface.

2.2.4 RF Interference

2-2 prox.pad plus Install/Program. Manual, PPP, D2

The prox.pad plus unit should not cause interference

to other equipment as it is designed to meet FCC

guidelines. However, other devices can interfere with

prox.pad plus operation.

Page 19

2.3 Checking the Cables Chapter 2: Installation

Avoid locating the prox.pad plus unit closer than 3 feet

(1 meter) to a computer monitor or television or another prox.pad plus unit. If you believe you are experiencing reduced read range due to interference, try

repositioning the prox.pad plus unit, remoting the antenna, or relocating other nearby electrical equipment.

2.3 Checking the

Cables

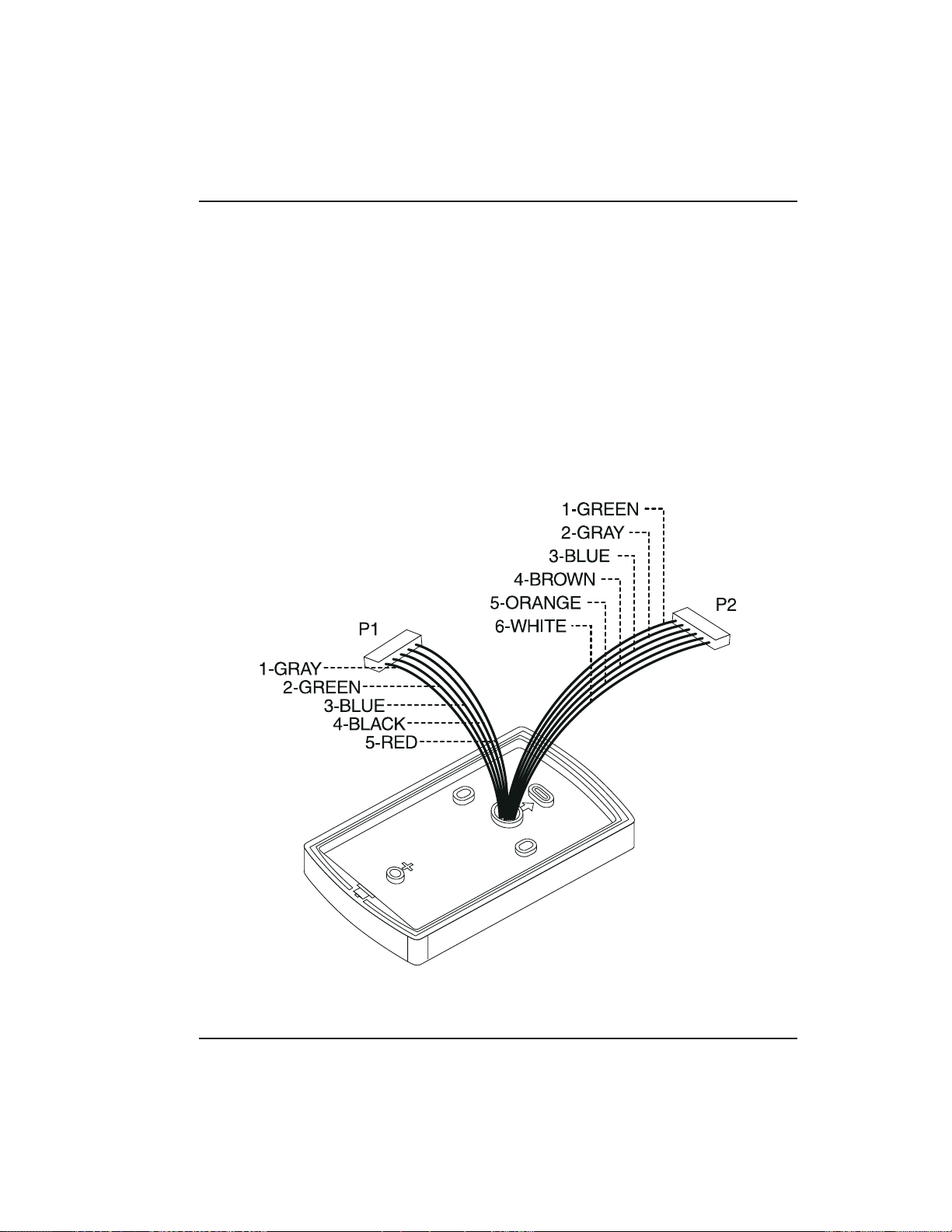

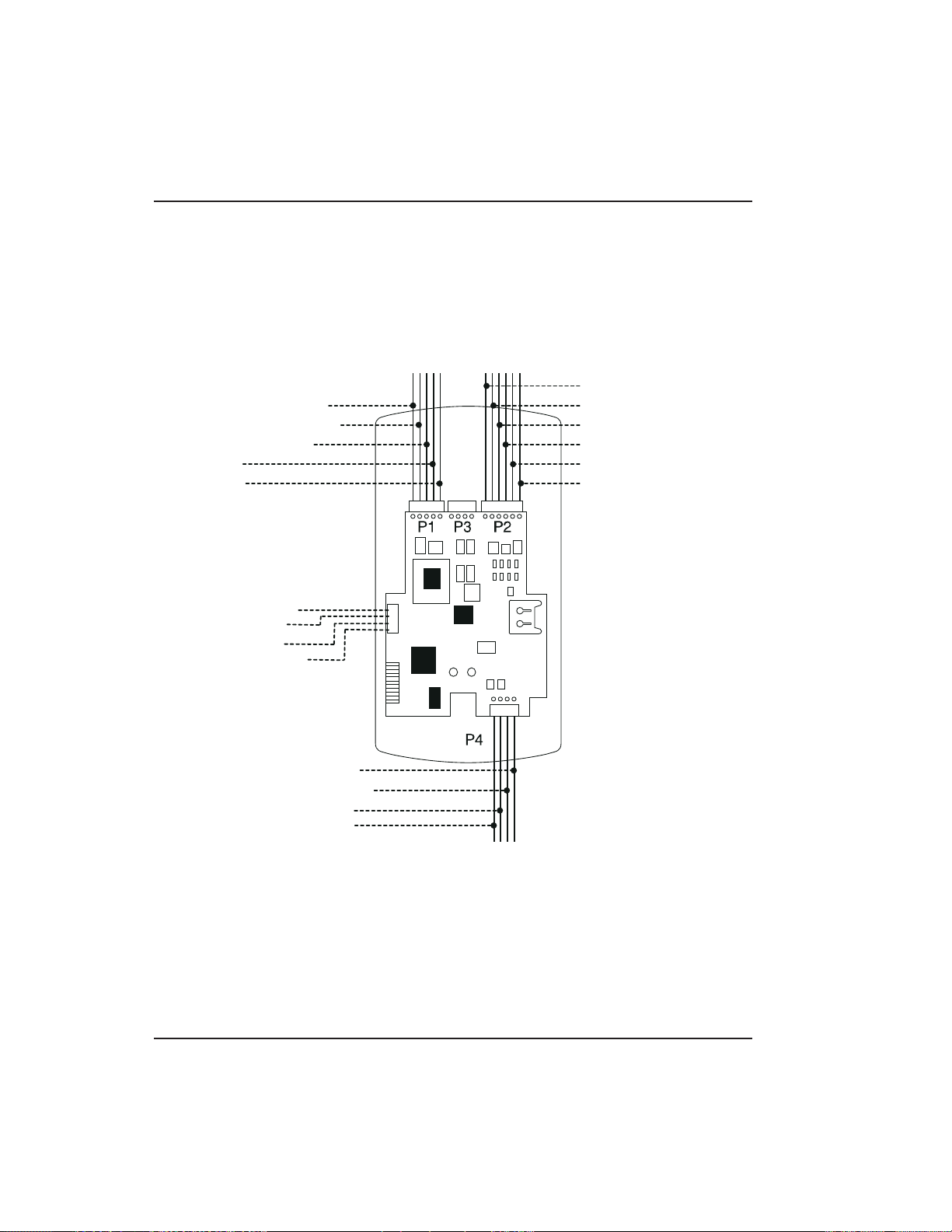

Figure 2-1 below provides a detailed illustration of the

prox.pad plus wiring harness. Figure 2-2 illustrates the

Pin connectors on the main circuit board; Table 2-2

describes these four Pin connectors, P1, P2, P4, and P5.

Figure 2-1 prox.pad plus Wiring Harness

prox.pad plus Install/Program. Manual, PPP, D2 2-3

Page 20

S

F

C

1

2

3

4

5

)

)

n)

Chapter 2: Installation 2.3 Checking the Cables

1-Green (Aux Relay N/O

-Gray (Main Relay N/C)

-Green (Main Relay N/C)

-Blue (Main Relay C)

-Black (-V)

-Red (+V

ystem Power: 12VDC

or RS-485

ommunications

1-Blue (Terminator)

2-Brown (Data A)

3-White (Data B)

4-Green (Data GND)

)

1-Red (Bi Color LED)

2-Black (Bi Color LED)

3-White (Antenna +)

4-White (Antenna -)

P5

Connections for remote

installation of proximity

antenna

2-Gray (Aux Relay N/C

3-Blue (Aux Relay C)

4-Brown (REX Loop)

5-Orange (Door Loop)

6-White (Loop Commo

NOTE: P3 Not Used

Figure 2-2 Identifying Pin Connectors

2-4 prox.pad plus Install/Program. Manual, PPP, D2

Page 21

2.3 Checking the Cables Chapter 2: Installation

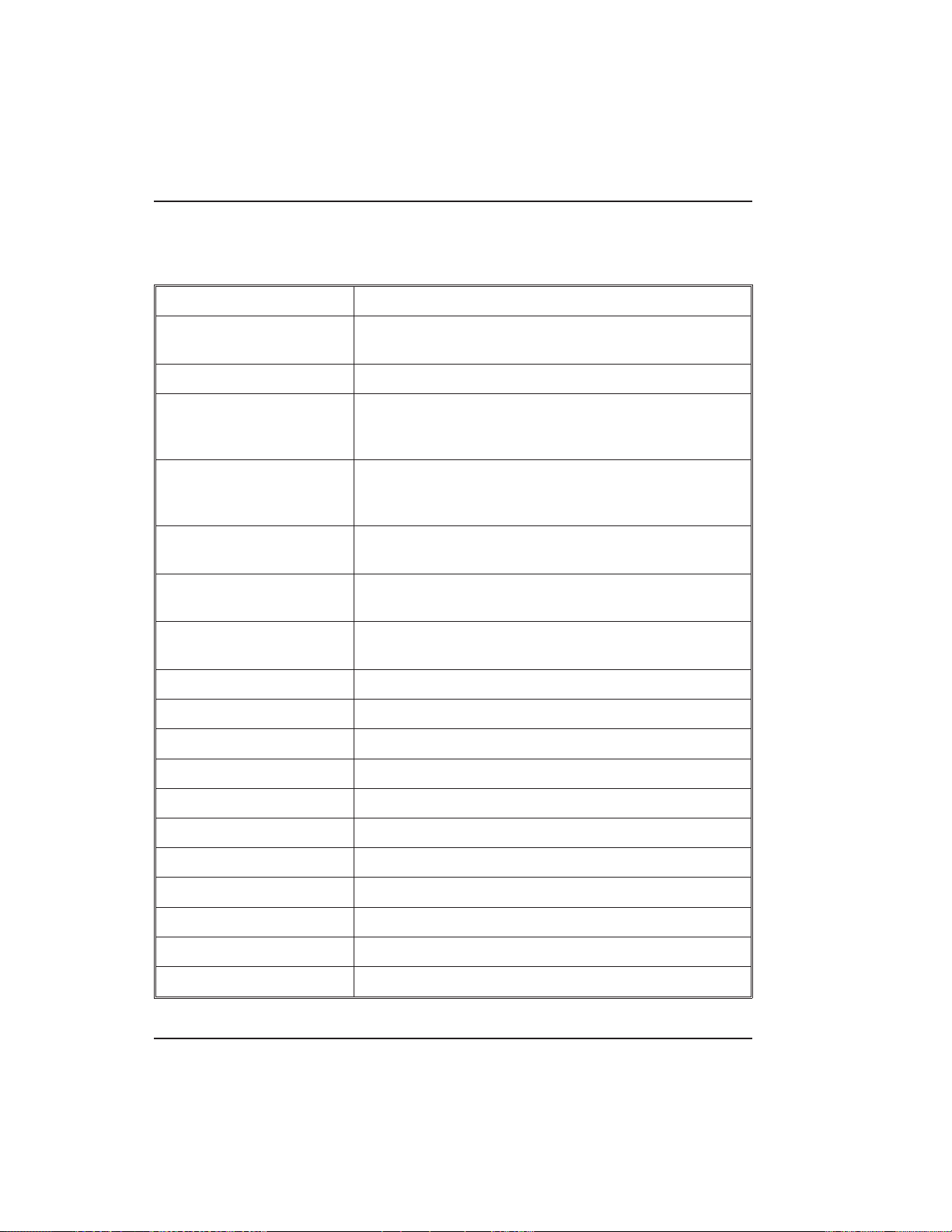

Table 2-2. prox.pad plus Pin Connectors

Pin Connector (on

main circuit board)

P1 (5-pin connector, top

left-most location)

P2 (6-pin connector, top

right-most location)

Description/Use

Pin Wire Color Use

1 GRAY Main Relay, N ormally

Closed (N.C.)

2 GREEN Main Relay, Normally

Open (N.O.)

3 BLUE Main Relay, Common

4BLACK Ground

5RED PowerIn,+12VDC

Pin Wire Color Use

1GREEN AuxRelayN.O.

2 GRAY Aux Relay N.C.

3 BLUE Aux Relay Common

4 BROWN REX Loop (if used) (NO

contact)

5 ORANGE Door Loop Contact (NC

contact)

6 WHITE Loop Common (shared by

REX and door loop)

NOTE: Pins 1, 2, 3 can be wired at the installer’s option for

one of the following alarm outputs, Alarm Shunt, Forced

Door, or Propped Door. Mandatory: If you do not wish to

install door contacts per Figure 2-5, twist white and orange

wires together. If not done, REX input will not work.

P4 (4-pin connector,

bottom location)

Pin Wire Color Use

1 RED Bi-Color LED (Red +)

2 BLACK Bi-Color LED (Green +)

3 WHITE Antenna (no polarity)

4 WHITE Antenna (no polarity)

P-5 (4-pin connector,

left-hand side location)

Pin Wire Color Use

1Blue Terminator

2Brown DataA

3 White Data B

4 Green Data GND

prox.pad plus Install/Program. Manual, PPP, D2 2-5

Page 22

Chapter 2: Installation 2.3 Checking the Cables

Table 2-3. IEI-Supplied Parts/Optional Items

Quantity Description

1 Keypad/control unit assembly, with Prox Sensor, Backplate,

hex socket screw

1 Filler Piece/REX Button

1PresstoExitLabel

4 Wall Anchors

4MountingScrews

1 Antenna Backplate for remote mounting

1 Silicone Rubber “dogbone”

4 Self-Adhering Pads (for glass mounting)

1 Installer Guide

1 CD-ROM containing instruction manuals

4 Cable Assemblies

1TamperScrew

Optional Items

1 Replacement Battery: Panasonic B R1225 or equivalent

lots of 25 only ProxKey Keytags (IEI part number 0297301)

lots of 25 only ProxCard II Cards (IEI part n umber 0297401)

1 Hub Manager

TM

Professional PC Software (version 5 or

higher)

1 IEI Data Collection Device (DCD) PDA Software

2-6 prox.pad plus Install/Program. Manual, PPP, D2

Page 23

2.4 Mounting the prox.pad plus Unit Chapter 2: Installation

2.4 Mounting the

prox.pad plus Unit

2.4.1 Performing a

Wall Mounted

Installation

Select one of these three installation configurations,

wall mount, glass mount, or secure as appropriate for

this installation. Then refer to sections 2.4.1-2.4.3.

This section provides general considerations when

performing a wall mounted installation. T ypically, the

prox.pad plus unit is mounted on a flat, level surface

(drywall, masonry, wood, etc.) exterior to the room to

be accessed. A single-gang electrical box (or “back box”)

can be used. Typically, the prox.pad plus unit is wall

mounted outside the access area on the unsecure side

of the door.

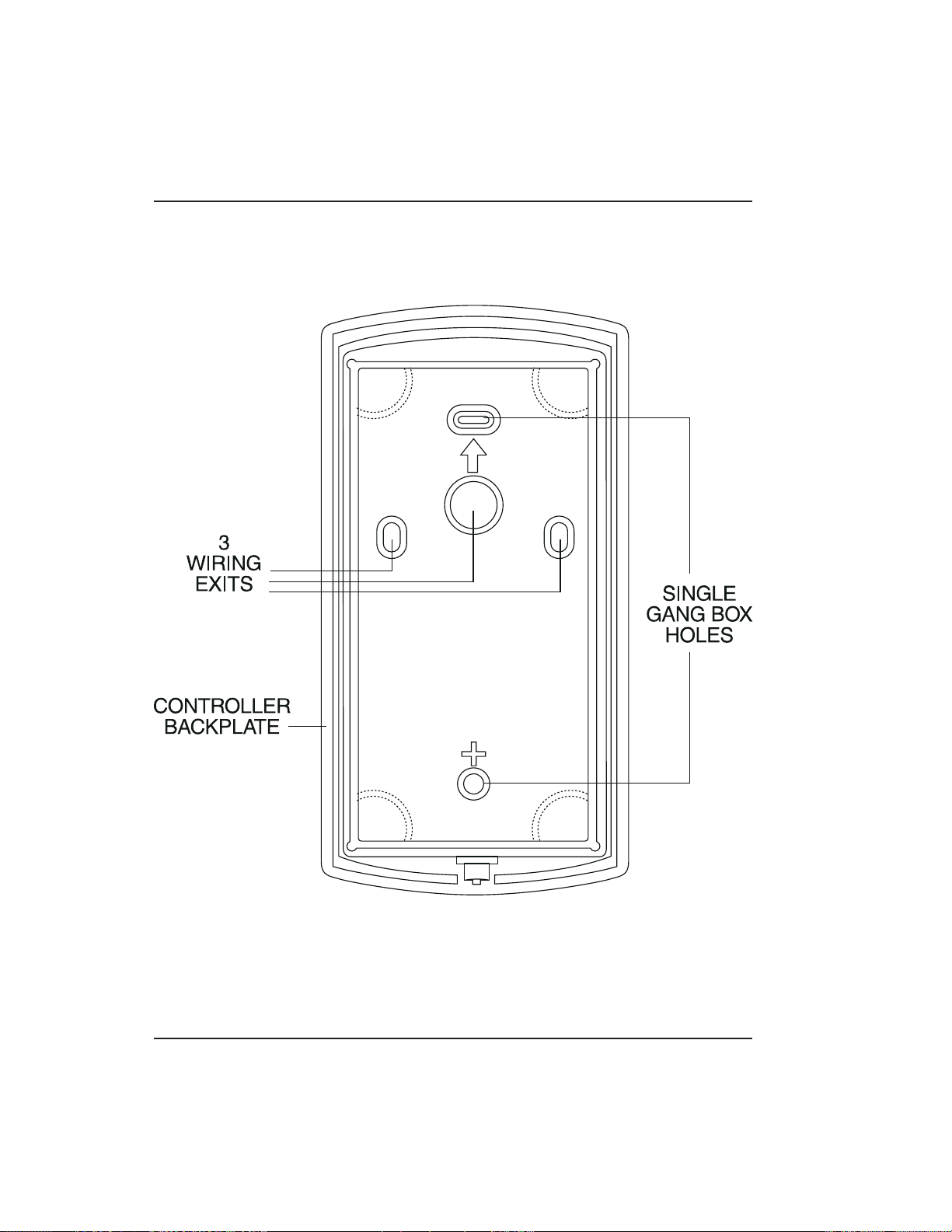

Figure 2-3 illustrates the components on the prox.pad

plus unit used for wall mounting. Two “single-gang

box” holes align with two corresponding holes in the

single-gang box. A “wire” exit knockout is supplied

through which the prox.pad plus wiring is pulled. A

typical wall mounted installation proceeds as follows:

1. Secure a single-gang box to the desired location.

2. “Punch out” the two single-gang box connectors

on the controller backplate of the prox.pad plus

unit.

3. Disconnect the controller backplate of the

prox.pad plus unit from the front keypad/controller. Align the two single-gang box connectors on

the controller backplate over the two corresponding holes on the single-gang box, previously secured at step 1.

4. Secure the backplate to the single-gang box by

inserting/tightening two screws into the two single-gang box holes.

5. Connect the front keypad/controller to the back

housing.

6 Pull the prox.pad plus wiring through the wiring

exit as appropriate.

7. Install the tamper screw into the hole at the bottom

front of the enclosure using a #6 spanner bit (not

included, but available from IEI).

prox.pad plus Install/Program. Manual, PPP, D2 2-7

Page 24

Chapter 2: Installation 2.4 Mounting the prox.pad plus Unit

Figure 2-3 Performing a Wall Mounted

Installation

2-8 prox.pad plus Install/Program. Manual, PPP, D2

Page 25

2.4 Mounting the prox.pad plus Unit Chapter 2: Installation

2.4.2 Performing a

Glass Mounted

Installation

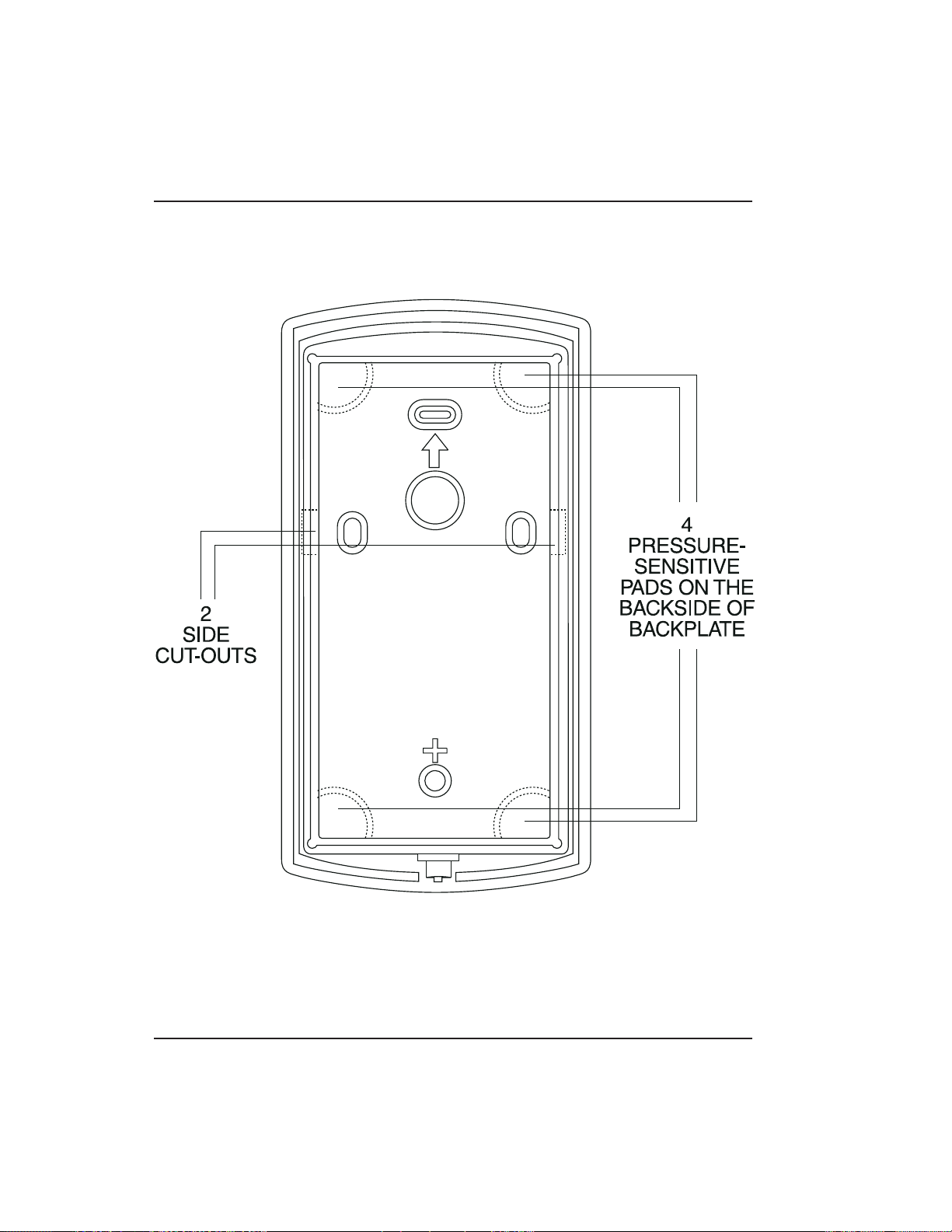

Figure 2-4 shows the four IEI-supplied pressure-sensitive adhesive pads and the two side cut-outs used

for this installation. In this configuration, the prox.pad

plus unit is affixed with the four self-adhesive pads to

the glass or the glass window adjacent to the controlled

door being accessed, on the interior side of the glass.

Oneofthetwosidecut-outsisusedtobringthewires

out of the side of the prox.pad plus case.

A typical glass mounted installation proceeds as follows:

1. Disconnect the back housing from the front keypad/controller. Remove the tape from the four

self-adhesive pads on the back housing and apply

the pads to the four corners of the backplate.

2. Affix the back housing to the glass door or the

glass window adjacent to the controlled door being accessed, on the interior side of the glass.

3. Determine which of the two side cut-outs on the

back housing to use for the wiring and “cut out”

that cut-out using the appropriate cutting tool.

4. Pull the wiring through the selected side cut-out

as required.

5. Connect the front keypad/controller to the back

housing.

6. Install the tamper screw into the hole at the bottom

front of the enclosure using a #6 spanner bit (not

included, but available from IEI).

prox.pad plus Install/Program. Manual, PPP, D2 2-9

Page 26

Chapter 2: Installation 2.4 Mounting the prox.pad plus Unit

Figure 2-4 Performing a Glass Mounted

Installation

2-10 prox.pad plus Install/Program. Manual, PPP, D 2

Page 27

2.4 Mounting the prox.pad plus Unit Chapter 2: Installation

2.4.3 Performing a

Secure Installation

In this configuration, the prox.pad plus prox sensor

housing is removed from the keypad/controller and

located a maximum of 10 feet away. The controller/keypad is located inside a secure area.

1. Remove the antenna from the prox.pad plus keypad/controller as described below:

• Disconnect the backplate of the prox.pad plus unit

from the front keypad/controller.

• When handling the main printed circuit board, to

guard against possible static discharges, touch a

grounded object BEFORE touching the prox.pad

plus unit. Remove the main printed circuit board

by pressing the two spring tabs in the direction of

the arrows as shown in Figure 2-5. Be careful with

the wires.

• Pull on the main circuit board and remove Pin

connector P4 (a 4-pin connector) from the bottom

of the main board. A ribbon cable now holds the

main board to the keypad board. DO NOT pull

this ribbon cable out of its connector! Once the

main board is removed, you can access the interior

of the antenna.

• Remove the antenna housing from the key-

pad/controller by pressing the labeled four secure

tabs inward (see Figure 2-5) until the sensor housing “pops out.”

2. Prepare the wiring and extension wiring as follows:

• Cut off the plastic end of the prox.pad plus sensor

housing harness.

• Splice the recommended remote antenna cable

Alpha 1174C (22AWG), 10-foot maximum length,

to the properly cut antenna cable using standard

electrical techniques.

prox.pad plus Install/Program. Manual, PPP, D2 2-11

Page 28

Chapter 2: Installation 2.4 Mounting the prox.pad plus Unit

KEYPAD/

CONTROLLER

Figure 2-5 Performing a Secure Installation

2-12 prox.pad plus Install/Program. Manual, PPP, D 2

Page 29

2.4 Mounting the prox.pad plus Unit Chapter 2: Installation

3. Mount the antenna backplate in a vertical orientation and secure it to the wall through the two

screw holes using two IEI-provided screws. Ensure that the two “weep holes,” provided to remove possible moisture, are positioned on the

bottom. The wiring exits in the antenna backplate.

(Four external cut-outs on the antenna backplate

match the four spring-loaded tabs on the antenna.)

NOTE: Two side cut-outs are furnished on the

antenna backplate for the wiring, if the installation

does not permit the wiring to run through the

wall.Thesemustbe“cutout”tobeused.

• Once the antenna backplate is mounted properly,

align the antenna to the backplate and connect

the antenna to the antenna backplate. The large

tab in the center of the antenna assembly must be

broken off before being attached to the antenna

backplate.

4. Run the antenna wiring back to the secure keypad/controller and connect it to the main circuit

board, using the 10-inch4-wireharness(red,

black, white, and white) that you plug into connector P4 on the controller board. Connect the red

wire of the antenna to the red wire of the P4

harness, etc. Seal the wire holes with silicone.

5. Select “Filler” or “Request to Exit” (REX) operation

as follows:

• If you elect to use the filler piece as a REX switch,

return to the keypad/controller and break off two

tabs on the filler piece as illustrated in Figure 2-5.

The filler piece replaces the antenna on the front

of the keypad/controller for secure installations.

• If the filler piece is not to be used as a REX switch,

DO NOT remove the two tabs.

prox.pad plus Install/Program. Manual, PPP, D2 2-13

Page 30

Chapter 2: Installation 2.4 Mounting the prox.pad plus Unit

• Select “Filler or “REX” operation and affix the

appropriate IEI-provided label to the filler piece.

For Filler operation, no tabs are brok en off the

filler piece, which merely sits in place of the remotely located antenna, once the main circuit

board and cabling are replaced.

For REX operation, break off the labeled tabs,

which allows a spring-loaded tab to engage the

REX switch on the main circuit board and open

the door.

• Replace the main circuit board into the key-

pad/controller and Pin connector P4 to the main

circuit board.

• Connect the front keypad/controller of the unit to

the back housing.

• Secure with a hex socket screw using the supplied

hex wrench, or secure with a tamper screw

(optional tool required).

2-14 prox.pad plus Install/Program. Manual, PPP, D 2

Page 31

2.5 Inserting Circuit Boards Chapter 2: Installation

2.5 Inserting

Circuit Boards

If it proves necessary to remove or insert the main

circuit board from/into the prox.pad plus controller/keypad, follow the steps below.

1. Disconnect the back housing of the prox.pad plus

unit from the front keypad/controller.

2. (When handling the main printed circuit board,

to guard against possible static discharges, hold

the board by its edges with one hand and then

touch a grounded object BEFORE touching the

prox.pad plus unit.) Remove the main printed

circuit board by pressing the two spring tabs in

the direction of the arrows as shown in Figure 2-6.

Be careful with the wires.

Figure 2-6 Removing/Inserting Printed Circuit

Board

prox.pad plus Install/Program. Manual, PPP, D2 2-15

Page 32

Chapter 2: Installation 2.6 Defaulting prox.pad plus Memory

3. Fold up the main circuit board and remove the P4

connector (a 4-conductor harness) from the bottom of the board.

4. To re-insert, replace the main circuit board into

the keypad/controller and the P4 connector to the

main circuit board.

5. Connect the keypad/controller to the back housing.

2.6 Defaulting

prox.pad plus

Memory

If necessary, the prox.pad plus main memory can be

defaulted. This procedure explains how to do this; see

Figure 2-7 on the next page. You would default the

memory, if, for instance, static discharges have corrupted the prox.pad plus unit, during shipping or installation. You can also do this if you have simply

forgotten the Master Code and you need to enter program mode.

With the power ON, remove the case from the

prox.pad plus front controller/keypad to access the

main circuit board. (For a visual reference of the main

printed circuit board and the related pin connectors,

see Figure 2-2. Table 2-2 describes these pins in detail.)

(When handling the main printed circuit board, to

guard against possible static discharges, touch a

grounded object BEFORE touching the prox.pad plus

unit.)

1. With the power ON, press and hold the Program

button (located on the rear side of the main printed

circuit board) for two seconds.

The yellow LED flashes slowly.

2-16 prox.pad plus Install/Program. Manual, PPP, D 2

Page 33

FORGET MASTER CODE

HOUSING

2.6 Defaulting prox.pad plus Memory Chapter 2: Installation

PCB

MASTER

CODE

SWITCH

(PROGRAM

SWITCH)

(ON REAR SIDE

OF PC BOARD)

CONTROLLER

Figure 2-7 Program Button Location on Main

Circuit Board

prox.pad plus Install/Program. Manual, PPP, D2 2-17

3. Enter the following on the keypad:

46 # 00000 # 00000 # **

The yellow LED flickers for 10 seconds and then

blinks slowly.

4. Once the memory set-up is complete, re-assemble

the unit.

NOTE: CONNECTING DOOR LOOP IN-

PUTBefore powering up the prox.pad plus unit,

connect the Door Loops input to the “Loop Common.” This prevents “Forced Door” or “Propped

Door” conditions from developing upon power-up.

Page 34

Page 35

Chapter 3: Wiring

Chapter 3 provides wiring diagrams and associated

procedures.

3.1 Wiring the

prox.pad plus Unit

3.1.1 Wiring the AUX

Relay for Use as

Alarm Shunt

Select one of these three wiring options, Alarm Shunt,

Forced Door, or Propped Door, depending on how

theprox.padplusunit’sAUXrelayistobeemployed

for this installation (refer to Chapter 4 for programming information). Then refer to sections 3.1.1- 3.1.3

as appropriate.

The Alarm Shunt Relay function may be necessary

when a separate existing security system is in place.

The Alarm Shunt Relay keeps an alarm panel zone

from going into alarm when the door is opened, after

a valid code is entered. The Alarm Shunt function is

assigned to the Aux relay by default. To incorporate

this feature, follow the steps below; see Figure 3-1.

3.1.1.A Wiring the Alarm Shunt Relay

1. Turn OFF power to the prox.pad plus unit, and

then unlatch the keypad from the plastic housing.

2. Locate connector P2 (the 6-pin connector) on the

main circuit board and plug on the 6-pin harness.

(The 2-pin jumper on pins 5 and 6 of connector

P2 must be removed first.)

3. Connect the 6-conductor harness to connector P2

as shown in Figure 2-1.

4. Connect the blue wire to the “Common” side of

the door contact.

5. Connect the green wire to the “Normally Open”

side of the door contact.

6. Make a parallel connection to the green and blue

wires and run the leads to the alarm panel. NOTE:

This feature requires that you use the “Door Contact”inputasshowninFigure3-1.

prox.pad plus Install/Program. Manual, PPP, D2 3-1

Page 36

D

C

G

T

P

R

it

Chapter 3: Wiring 3.1 Wiring the prox.pad plus Unit

TO ALARM PANEL

OOR

ONTACT

OING BACK

O ALARM

ANEL

BLUE ( C )

TO ALARM PANEL

GREEN

(N/O)

P5

ORANGE

SEPARATE DOO

CONTACT BEING

MONITORED BY

THE prox.pad un

WHITE

Figure 3-1 Wiring the Aux Relay

for Alarm Shunt Operation

3-2 prox.pad plus Install/Program. Manual, PPP, D2

Page 37

3.1 Wiring the prox.pad plus Unit Chapter 3: Wiring

3.1.2 Wiring the AUX

Relay for Use as

Forced Door

The Forced Door output function informs personnel

that the door has been opened without authorization.

By default, the Forced Door output is assigned to

Audio Alert #1. To use the Aux Relay, you must first

assign it. See the command below, in the second note.

The Aux relay is rated to handle two amps of current

at 12 VDC, and can turn ON or OFF one leg of the

power to a warning device. (Warning device not included with the IEI unit.) To incorporate this feature,

followthestepsbelow;seeFigure3-2.

3.1.2.A Wiring the Forced Door Relay

1. Turn OFF power to the prox.pad plus unit, and

then unlatch the keypad from the plastic housing.

2. Locate connector P2 (the 6-pin connector) on the

main circuit board.

3. Connect the 6-conductor harness to connector P2.

(The 2-pin jumper on pins 5 and 6 of connector

P2 must be removed first.)

4. Connect the green wire (NO) to V+ on the warning device.

5. Connectthebluewire(C)toV+onthepower

supply.

6. Connect V- from the power supply to V- on the

sounder. The gray wire is not used.

NOTE: To use the default 10-second Forced Door

Relay time, no programming is necessary. To

change this default (from 10 to 990 seconds), use

command 45 # ttt # 0 # ** after the unit is installed

successfully; for details, see section 4.3.4.

NOTE: PROGRAMMING FOR FORCED DOOR:

To assign the Forced Door output to the Aux Relay,

enter the following on the keypad:

10#4#2#**

To disable audio alert #1, enter:

10#0#5#**

prox.pad plus Install/Program. Manual, PPP, D2 3-3

Page 38

D

C

G

T

P

R

it

Chapter 3: Wiring 3.1 Wiring the prox.pad plus Unit

TO ALARM PANEL

OOR

ONTACT

OING BACK

O ALARM

ANEL

BLUE ( C )

TO ALARM PANEL

GREEN

(N/O)

P5

ORANGE

SEPARATE DOO

CONTACT BEING

MONITORED BY

THE prox.pad un

WHITE

Figure 3-2 Wiring the Aux Relay

for Forced Door Alarm

3-4 prox.pad plus Install/Program. Manual, PPP, D2

Page 39

3.1 Wiring the prox.pad plus Unit Chapter 3: Wiring

3.1.3 Wiring the AUX

Relay for Use as

Propped Door

The Propped Door Relay output function informs personnel that the door is being held open, or “propped”

open, after a valid entry. By default, the Propped Door

output is assigned to audio alert #2. To use the Aux

Relay, you must first assign it. See command below.

The Aux relay is rated to handle two amps of current

at 12 VDC, and turns ON or OFF one leg of the power

to a warning device. (Warning device not included

with the IEI unit.) To incorporate this feature, follow

thestepsbelow;seeFigure3-3.

3.1.3.A Wiring the Propped Door Relay

1. Turn OFF power to the prox.pad plus unit, and

then unlatch the keypad from the plastic housing.

2. Locate connector P2 (the 6-pin connector) on the

main circuit board.

3. Connect the 6-conductor harness to connector P2.

(The 2-pin jumper on pins 5 and 6 of connector

P2 must be removed first.)

4. Connect the green wire (NO) to V+ on the

sounder.

5. Connectthebluewire(C)toV+onthepower

supply.

6. Connect V- from the power supply to V- on the

sounder. The gray wire is not used.

NOTE: To use the default 30-second Propped Door

Relay time, no programming is necessary. To

change this default (from 30 to 990 seconds), use

command 44 # ttt # 0 ** after the unit is installed

successfully; for details, see section 4.3.3.

NOTE: PROGRAMMING FOR PROPPED DOOR:

To assign the Propped Door output to the Aux

Relay, enter the following on the keypad:

10#3#2#**

To disable audio alert #2, enter:

10#0#6#**

prox.pad plus Install/Program. Manual, PPP, D2 3-5

Page 40

R

it

Chapter 3: Wiring 3.1 Wiring the prox.pad plus Unit

TO POWER SUPPLY

GREEN

(N/O)

P5

V-

V+

V+

BLUE

( C )

ORANGE

SEPARATE DOO

CONTACT BEING

MONITORED BY

THE prox.pad un

WHITE

Figure 3-3 Wiring the Aux Relay

forProppedDoorAlarm

3-6 prox.pad plus Install/Program. Manual, PPP, D2

Page 41

3.1 Wiring the prox.pad plus Unit Chapter 3: Wiring

3.1.4 Wiring the Door

Contact Input

To solve the problem of people “tailgating” in behind

personnel using valid access p rotocol, the Auto ReLock feature is provided. With Auto Re-Lock, a long

door open time can be programmed. Auto Re-Lock

overrides the lock output timer, resetting the door

open time as soon as the prox.pad plus unit senses

that the door is open. A long door open time allows

people sufficient time to carry packages from the proximity reader/keypad to the door and open it before the

timer runs out.

No programming is required to implement this feature.

After a valid access or egress, the prox.pad plus unit

senses that the door switch is open and drops the main

relay immediately. This disengages the lock, which

locks behind the person regardless of how long it takes

that person to get through the door.

NOTE: This feature requires that you use the “Door

Contact” input as shown in Figure 3-4.

prox.pad plus Install/Program. Manual, PPP, D2 3-7

Page 42

Chapter 3: Wiring 3.1 Wiring the prox.pad plus Unit

P5

Figure 3-4 Wiring the Door Contact Input

3-8 prox.pad plus Install/Program. Manual, PPP, D2

Page 43

3.1 Wiring the prox.pad plus Unit Chapter 3: Wiring

3.1.5 Wiring the REX

Switch (Request to

Exit)

The prox.pad plus unit can be wired to monitor a

remote switching device, which is intended to be installed on the “secure” side of a door. The Request to

Exit (REX) switch is a momentary input closure that

engages the lock output for the same length of time

for which it is programmed. This feature can be stored

in the Transaction Log for viewing.

If you elect to perform a secure installation where the

controller is mounted on the secure side of the door,

you can use the filler piece as a REX switch. To enable

the internal REX switch, enter the following programing command: 30#7#1#**

For other installations, a separate REX switch must be

purchased.

Other REX devices can be used to include a remote

button placed at a receptionist’s desk, a press-to-exit

switch on the inside of a door, or a passive infrared

detector, allowing free and convenient egress. The

external REX feature requires no programming; simply

wire the unit as illustrated in Figure 3-5. To incorporate

this feature, follow the steps below:

1. Turn OFF power to the prox.pad plus unit, and

then unlatch the keypad from the plastic housing.

2. Locate connector P2 on the main circuit board.

3. Plug the 6-conductor harness into connector P2.

(The 2-pin jumper on pins 5 and 6 of connector

P2 must be removed first.)

4. If you do not wish to install the door contacts per

Figure 3-5, twist the white wire and the orange

wires together; this is mandatory. If this is not

done, the REX input will not function.

NOTE: The door contact MUST be closed for the

REX feature to work properly.

prox.pad plus Install/Program. Manual, PPP, D2 3-9

Page 44

Chapter 3: Wiring 3.1 Wiring the prox.pad plus Unit

P5

P5

Figure 3-5 Wiring the REX Switch

3-10 prox.pad plus Install/Program. Manual, PPP, D 2

Page 45

3.1 Wiring the prox.pad plus Unit Chapter 3: Wiring

3.1.6 Wiring the Main

Relay

The door lock is wired to connector P1 on the prox.pad

plus main circuit board. Wiring for this 5-pin connector

is described in Table 2-2, Figure 3-6 provides an Electric

Strike (Fail Secure) wiring diagram, Figure 3-7 a

MagLock (Fail Safe) wiring diagram. Refer to the

power supply recommendations in Table 1-1 if necessary.

P5

Figure 3-6 Electric Strike (Fail Secure) Wiring

Diagram

prox.pad plus Install/Program. Manual, PPP, D2 3-11

Page 46

)

(

Chapter 3: Wiring 3.1 Wiring the prox.pad plus Unit

MAGLOCK

(FAIL SAFE)

V-

POWER

V+

SUPPLY

BLACK

(V-)

BLUE

(MAIN RELAY C

GRAY

MAIN RELAY N/C)

RED

(V + IN)

P1

P3

P2

P5

P4

Figure 3-7 MagLock (Fail Safe) Wiring Diagram

3-12 prox.pad plus Install/Program. Manual, PPP, D 2

Page 47

3.2 prox.pad plus Commu nications Chapter 3: Wiring

3.2 prox.pad plus

Communications

NOTE: The Terminator wire

may not be required.

2-Brown (Data A)

3-White (Data B)

4-Green (Data GND)

The prox.pad plus is equipped with RS-485 communications with a data rate of 19200 bits/sec. This allows

you to connect the unit to a personal computer (PC)

either via the computer’s COM (serial) port or over a

computer network to manage the system using Hub

Manager Professional (version 5 or higher) software.

To connect the prox.pad plus unit to a computer COM

port (which is RS-232), an RS-232 to RS-485 converter

is required. To connect the prox.pad plus unit via a

computer network, the IEI Gateway device is required.

The maximum distance from the RS-485 device is

4,000 feet using the specified cable.NOTE:TheTer-

minator wire may not be required. Figures 3-8 and 3-9

show examples of both connection types. Please see

the instructions for your RS-232 to RS-485 converter

or the instructions for the IEI Gateway for details about

those devices. For details, refer to EIA RS-485 specifications.

P1

P3

P2

RS-232 RS-485

To PC

COM port

P5

ó

RS-232 to RS-485

Converter

P4

Figure 3-8 Connecting the prox.pad plus

to a PC COM Port

prox.pad plus Install/Program. Manual, PPP, D2 3-13

Page 48

T

N

Chapter 3: Wiring 3.3 Networking Multiple prox.pad plus Units Together

2-Brown (Data A)

o Computer

etwork

3-White (Data B)

4-Green (Data GND)

RS-485

ó

Gateway

P5

P1

P3

P2

P4

Figure 3-9 Connecting the prox.pad plus to a

Network

3.3 Networking

Multiple prox.pad

plus Units Together

3-14 prox.pad plus Install/Program. Manual, PPP, D 2

For multiple door applications, the prox.pad plus can

be networked together. When networking prox.pad

plus devices together on an RS-485 system, the

prox.pad plus units are all wired in parallel. This networking capability is available when connecting directly to your personal computer’s COM port or when

communicating over a computer network with the IEI

Gateway. Figure 3-10 shows an example of networking

multiple units together. The maximum number of de-

vicesonanetworkis32.

Page 49

Device #1

3.3 Networking Multiple prox.pad plus Units Together Chapter 3: Wiring

NOTE: The maximum

number of devices on a

single network is 32.

P1

P3

P2

Door #1

P5

2-White (DataA)

3-Brown (Data B)

4-Blue (Data GND)

RS-232 to RS-485

Converter or IEI

Gateway

P4

Device #2

P1

P3

P2

P5

P4

Door #2

Figure 3-10 Networking Multiple prox.pad plus

Units Together

prox.pad plus Install/Program. Manual, PPP, D2 3-15

Page 50

Chapter 3: Wiring 3.4 Testing the prox.pad plus

3.4 Testing the

prox.pad plus

3.4.1 Testing the

Controller/Keypad

At this point in a typical installation, it is assumed that

the prox.pad plus unit has been mounted and wired

successfully as described earlier and that testing can

begin. IEI recommends, however, that first-time in-

stallers test the prox.pad plus unit BEFORE actually

mounting and wiringthe unit to become familiar with

its operation.

1. Connect the positive (+) lead of the power supply

to the V+ input on the prox.pad plus controller/keypad.

2. Connect the negative (-) lead of the power supply

to the V- input on the prox.pad plus controller/keypad.

3. Turn ON the power supply.

4. Ensure that the bi-color LED (red and green) on

the prox.pad plus unit lights red.

5. On the prox.pad plus controller/keypad, press:

7890 # 123456 *

If all 12 key presses are verified, the prox.pad plus

unit enters the self-test mode. The bi-color LED

turns green. The red LED blinks alternately with

theyellowLEDandthenbothturnOFF.Next,

the sounder beeps three times, pauses, and then

beeps once more. If this does not occur, attempt

to enter the self-test mode again by repeating step

5.

NOTE: If you are using the IEI DCD software, you

can capture the self-test data on a PDA. This data

contains information about the device.

6. Enter the master code on the keypad by pressing:

1234 *

The red LED turns OFF and the green LED turns

ON for five seconds while the main relay energizes. To program the unit, see Chapter 4.

3-16 prox.pad plus Install/Program. Manual, PPP, D 2

Page 51

Chapter 4:

Programming

4.1 Programming

Overview

4.1.1 Programming

from the Keypad

Chapter 4 provides information about programming

the IEI prox.pad plus unit.

The first step in programming the prox.pad plus unit

is to place it into Program mode. You can enter Program mode with either the Master code or the Supervisor code. When the prox.pad unit is in Program

mode, the yellow LED blinks slowly; when the yellow

LED stops blinking and is OFF completely, the unit is

no longer in Program mode. If an error is made in

Program mode, the yellow LED remains steadily

lighted; press * to clear the error condition and then

re-enter the command. If the unit does not go into

Program mode, refer to the Troubleshooting Chart in

Chapter 5.

4.1.1.A Master Code (User #1)

TheMastercodeisaspecialcodestoredinuserlocation

one. This code is used to enter Program mode, and

has access to all programming commands.

To place theprox.pad plus unit in Program mode using

the Master code, press:

99 # Master Code *

NOTE: “1234” is the default Master code, which IEI

recommends that you change right away.

To change the Master code, enter:

1 # new master code * new master code *

(example, 1 # 4321 * 4321 *)

NOTE: Codes can be from 1 to 6 digits in length.

prox.pad plus Install/Program. Manual, PPP, D2 4-1

Page 52

Chapter 4: Programming 4.1 Programming Overview

4.1.1.B S upervisor Code (user #2)

The Supervisor code is a special code stored in user

location two. This code has limited access to Program

mode, including commands:

• Adding/Deleting Users (commands #50, #51,

#52, #53, #57, and #58)

• Enabling/Disabling Users (command #56)

• Changing Lock Output Time (command #11)

• Changing Keypad Platform Parameters 5 and 6

(command #32)

By default, user location two is empty, which means

that if you need a Supervisor code, you must program

one. To program a Supervisor code, press:

2 # new supervisor code *

new supervisor code *

(example, 2 # 5678 * 5678 *)

To enter Program mode using the Supervisor code,

press:

99 # supervisor code *

4.1.1.C Master Code and Supervisor Code

Special Features

The following is list of items that pertain only to the

Master and Supervisor codes:

• The Master and Supervisor codes can only be pro-

grammed as standard user types

• The Master and Supervisor codes can be pro-

grammed as “card AND code” or “card OR code”

users.

• The Master and Supervisor codes cannot be pro-

grammed as “card only.”

4-2 prox.pad plus Install/Program. Manual, PPP, D2

Page 53

4.1 Programming Overview Chapter 4: Programming

• When either the Master or Supervisor is pro-

grammed as “card AND code,” both are required

to enter Program mode.

• When they are programmed for “card OR code,”

only the card is required to enter Program mode.

• IftheMasterorSupervisorisprogrammedfor

“card OR code” and you want them to require

both to enter Program mode, enable option 3 using

command30(30#3#1#**).

4.1.1.D prox.pad plus Default Settings

Table 4-1 lists the default settings for the prox.pad plus

unit as shipped from the factory. Subsequent sections

in this chapter explain how to change these default

settings or program additional functions.

Table 4-1. prox.pad plus Default Settings

Parameter Default Setting

Main Relay Lock Output

Auxiliary Relay Alarm shunt function

Audio Alert #1 Forced Door

Audio Alert #2 Propped Door

Master Code (user one) 1234*

Main Relay energizes for Five (5) seconds

Audible Keypress Feedback ON

Propped Door Output activates after Thirty (30) seconds

Forced Door Output activates for Ten (10) seconds

prox.pad plus Install/Program. Manual, PPP, D2 4-3

Page 54

Chapter 4: Programming 4.1 Programming Overview

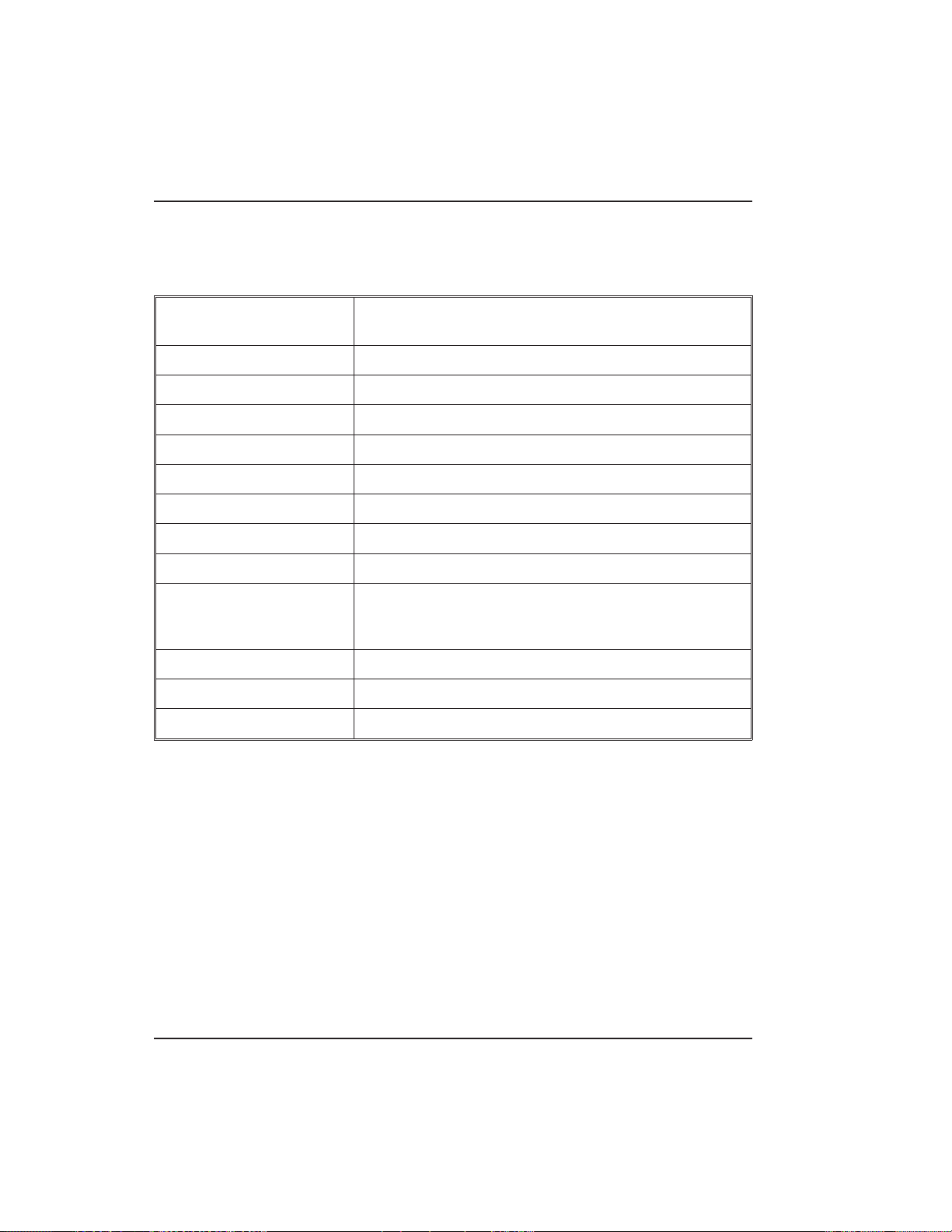

Table 4-2. prox.pad plus LED Indicators/Sounder Operations

LED or Sounder Visual/Audible

Condition

Yellow LED Slow blink Unit is in Program mode

Rapid blink Verify mode is active (checking that the

Steady Program error; to clear, press * or error

Very rapid blink Memory (eeprom) erase is in progress

Bi-color LED Steady red Lock output deenergized

Steady green Lock output is energized (timed or

Red/green

alternating

Green blink Auto-unlock active

Sounder Short beep

(100 ms) every 2

seconds

Sounder 1/2 sec

on, 1/2 sec off

Description

last two values in sequence match)

lockout

(commands 40/46, loop-back)

latched)

Awaiting second PIN during “Card AND

Code” access attempt

Audio alert #2 is active

Audio alert #1 is active

Double beep Lockout is canceled

Pair of double

beeps

3 slow beeps

(250 ms), then

single beep

4-4 prox.pad plus Install/Program. Manual, PPP, D2

Lockout is activated

Self-test is complete

Page 55

4.1 Programming Overview Chapter 4: Programming

Table 4-2. prox.pad plus LED Indicators/

Sounder Operations (continued)

Sounder After

PIN/Card

1 single beep Valid card access

1longbeep

followed by 1

short beep

1longbeep

followed by 2

short beeps

1longbeep

followed by 3

short beeps

3 rapid beeps

after code entered

or card presented

4 quick beeps First-In Auto-unlock

6 quick beeps Toggle mode is active

User disabled

Bad timezone

User lockout

Code or Card is not found

4.1.1.E Resetting the Master Code and System

Defaults Only

Entering command 40 erases everything from the

prox.pad plus memory except the user list and transaction log and restores the default settings. This is

useful if the prox.pad plus unit has experienced programming problems, or you wish to delete earlier programming.

1. Place the prox.pad plus unit in Program mode.

Press:

99 # Master Code * (default is 1234)

A slow blinking yellow LED indicates that the unit is

in Program mode. A steady yellow LED, in contrast,

means that errors were d etected during programming.

prox.pad plus Install/Program. Manual, PPP, D2 4-5

Page 56

Chapter 4: Programming 4.1 Programming Overview

Error states can be cleared by pressing the asterisk *

key.

2. Press:

40 # 00000 # 00000 # **

The yellow LED continues to blink slowly.

3. Press * to exit Program mode.

4.1.1.F Erasing Entire Memory/Resetting System

Defaults

Entering command 46 deletes everything from the

prox.pad plus memory including the user list but not

the transaction log and restores the default settings.

This is used as a last resort if you need to erase a specific

user and could not retrieve the Programmed User List.

1. Place the prox.pad plus unit in Program mode.

Press:

99 # Master Code * (default is 1234)

A slow blinking yellow LED indicates that the unit

is in Program mode. A steady yellow LED, in

contrast, means that errors were detected during

programming. Error states can be cleared by pressing the asterisk * key.

2. Press:

46 # 00000 # 00000 # **

The yellow LED continues to blink slowly.

3. Press * to exit Program mode.

4-6 prox.pad plus Install/Program. Manual, PPP, D2

Page 57

4.2 Programming Users Chapter 4: Programming

4.2 Programming

Users

4.2.1 Adding New or

Changing Existing

Codes/Cards

The most basic prox.pad plus programming is adding

new codes or cards (users), or modifying existing codes

or cards (users). Each user entry consists of three or

four data values: a user type, a location and a keypadPIN, and/or card.

Two methods can be used for adding new or c hanging

existing codes/cards, (1) keypress sequences (manual

entry), and (2) card presentations. Keypad PINs can

be programmed only through a keyp a d sequence,

while card PINs can be programmed manually or by

presenting the card to the proximity reader at a specified time during programming.

Table 4-3 lists the specific types of users that can be

programmed with the prox.pad plus unit and the following section describe the various ways to program

users.

NOTE: When 26-bit cards are used and you choose to

add new cards manually, the facility code MUST be

entered into the unit first. The default facility code is

11. For the programming sequence used to enter the

3-digit facility code, see command 32, parameter 4 (see

table in section 4.6).

4.2.2 Programming

Code and Card

The prox.pad plus unit can be programmed to accept

the four code/card combinations listed below.

Options

• (1) Code ONLY (command 50)

• (2) Code AND Card (command 50 plus present

card to proximity reader)

• (3) Card ONLY (command 50 or command 51)

• (4) Code OR Card (command 52)

NOTE: No user can have the same card and/or

code PIN as another user.

prox.pad plus Install/Program. Manual, PPP, D2 4-7

Page 58

Chapter 4: Programming 4.2 Programming Users

4.2.2 Programming

User Types

Table 4-3 identifies and describes the user types supported by the prox.pad plus unit.

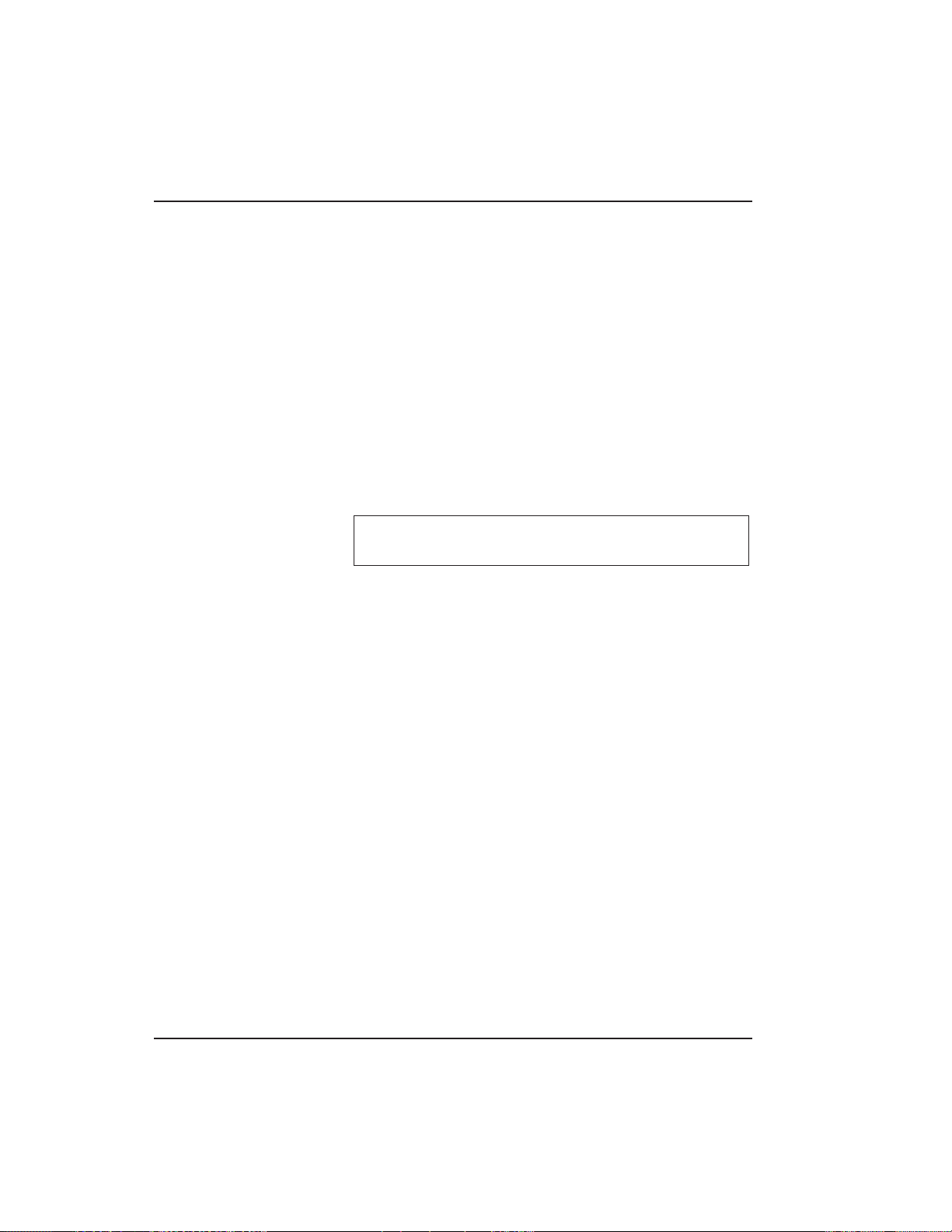

Table 4-3. prox.pad plus User Types

User Type Numeric ID Description

Toggle users latch the lock in the unlock

Toggle 0

Standard 1

Log Dump 2

Lockout 3

Extended Unlock 4

Single Use Code 5

position.Togglemodeisindicatedby6

quick beeps and a solid green LED.

Standard users use the lock duration

programmed in command 11.

For this user-type, the door remains locked

and the Transaction Log is dumped to the

DCD PDA software through the IR LED

when the appropriate code is entered. This

code cannot be used to gain access

through the door. The log is not erased,

only printed.

Lockout users “lock out” other users - see

User Lockout (section 4.4.1). These codes

do not unlock the door.

Extended Unlock Users are like Standard

users except they use the unlock duration

programmed in command 32, parameter 3.

The default unlock time is 10 seconds.

Single Use Codes are codes that can only

be used once. After the code is used, it is

deleted from the keypad. To verify a Single

Use is programmed, enter the sequence

[5# PIN *] and this looks up the PIN and

generates a 1/2 second green flash if the

PIN is programmed as a single use code. If

the PIN is not found, the system generates

three quick beeps and increments the

invalid PIN counter. If PIN is found but is

not programmed as a single use code, the

system does not respond at all.

4-8 prox.pad plus Install/Program. Manual, PPP, D2

Page 59

4.2 Programming Users Chapter 4: Programming

Table 4-3. prox.pad plus User Types (continued)

User Type Numeric ID Description

Relock codes are used to relock the door

when a toggle or auto-unlock is active.

Relock 6

Emergency 7

4.2.2.A Programming User Data, Command 50,

Full Format

The full format of command 50 for programming user

data is as follows:

Entering 00 # prior to a relock code allows

auto-unlock to be re-triggered, when First In

is enabled.

Emergency users are special users that

cannot be locked out and cannot be

disabled.

The user also uses the unlock duration

programmed in command 32 parameter 3.

The default unlock time is 10 seconds.

50 # user-type # user location # keypad

PIN*keypadPIN*

Programming a user’s card with command 50 requires

that you present the card to the proximity reader after

entering the final asterisk *.

A single beep from the sounder indicates that the card

has been read and the data added to the user’s entry.

If the yellow LED lights steadily after the card is presented, it usually indicates one of two problems: (1)

an improper keypress (correct by entering properly),

or (2) the number entered is in use by another user

(correct by employing an unused PIN and card).

prox.pad plus Install/Program. Manual, PPP, D2 4-9

Page 60

Chapter 4: Programming 4.2 Programming Users

4.2.2.B Quick Program Feature

A “quick program” feature has been implemented for

user data, however. You only need to enter the user’s

location and the keypad PIN (or present card), in the

format noted below. Employing the quick feature automatically selects a “Normal” user access type.

loc#PIN*PIN*

OR

loc # ** <present card>

4.2.2.C Programming Code ONLY Use

You can program a user Code ONLY use with command 50. The program sequence is as follows:

50 # user-type # user location # keypad

PIN * keypad PIN *

4.2.2.D Programming Code AND Card Use

The format for programming a user for both Code

AND Card use is as follows:

50 # user-type # user location # keypad

PIN * keypad PIN * <present card>

When a combination code/card user employs the

prox.pad plus unit, that user can present the proximity

cardfirstattheproximityreader,orenterthecode

first at the prox.pad plus keypad as desired.

After the code/card user either presents the card at the

reader or enters the code on the keypad, the red and

green LEDs alternate. This indicates that the unit is

awaiting the second part of the transaction before

granting access. After the secondpart of the transaction

is completed successfully, the bi-color LED turns solid

green and the door opens.

4-10 prox.pad plus Install/Program. Manual, PPP, D 2

Page 61

4.2 Programming Users Chapter 4: Programming

4.2.2.E Programming Card ONLY Use

Card ONLY use can be programmed with command

50. The p rogramming sequence is as follows:

50 # user-type # user location # **

<present card>

4.2.2.F Programming Code OR Card

Finally, you can program a user for either Code OR

Card use as follows:

52 # user-type # user location # keypad

PIN* keypad PIN * <present card>

prox.pad plus Install/Program. Manual, PPP, D2 4-11

Page 62

Chapter 4: Programming 4.2 Programming Users

4.2.3 Batch Load

Cards by Presentation

Command 53 provides a simple method of programming a group of consecutive users by presenting the

appropriate prox cards. This method of programming

cards does not require any knowledge of the prox card

format as long as it contains 39 bits or less of data.

The format of the command is as follows:

53 # user type # start location # * *

present cards one after another

The card loading stops automatically once the current

user location exceeds 2000. Pressing any key on the

faceplate aborts the loading process.

All users programmed through this command are

setup as “Card Only” users. Any existing card or keypad data for that user is erased prior to programming

the new data. Entering the Master or Supervisor user

as the first card in the sequence generates an error

because the Master or Supervisor code cannot be programmedasa“CardOnly”user.

If an existing card is presented, a programming error

is generated. You clear the error condition by pressing

the [*] (asterisk) and continue presenting cards. This

is the only case where pressing a key on the faceplate

does not abort the card programming sequence.

4-12 prox.pad plus Install/Program. Manual, PPP, D 2

Page 63

4.2 Programming Users Chapter 4: Programming

4.2.4

Enabling/Disabling

Users Command

The56#set/clear#userLocation#commandallows

the Master Code or Supervisor Code to disable a particular user location without deleting that user.

To disable a user, enter:

56#1#userlocation#**

To enable a user, enter:

56#0#userlocation#**

• TheMasterCodecanNEVERbedisabled.

• The Master Code can disable the Supervisor user

(user # 2).

• The Supervisor can disable users 3-2000.

The Master Code user cannot be disabled, and the

supervisor user cannot disable his/her self. A disabled

Supervisor cannot access Program mode; a non-programmed user cannot be enabled or disabled (generates a program error).

prox.pad plus Install/Program. Manual, PPP, D2 4-13

Page 64

Chapter 4: Programming 4.2 Programming Users

4.2.5 Batch Load

Cards Manually

(without presentation)

“Batch entry” allows you to enter multiple, sequential

26-bit HID cards into the prox.pad plus unit’s memory

at one time. (Keeping IEI proximity cards in order is

easyasthecodeisprintedonthefrontofeachcard.)

NOTE: The facility code must be programmed into

theunitbeforeanybatchentrycanoccur.Thefacility

code MUST be programmed only once. The default

facility code is 11. For the programming sequence

used to enter the 3-digit facility code, see command

32, parameter 4 (see table in section 4.6).

To add several users from the proximity reader, follow

this procedure:

1. Place the prox.pad plus unit in Program mode.

Press:

99 # Master Code * (default is 1234)

A slow blinking yellow LED indicates that the unit

is in Program mode. A steady yellow LED, in

contrast, means that errors were detected during

programming. Error states can be cleared by pressing the asterisk * key.

2. On the prox.pad plus keypad, press:

57 # (total number of cards to be added) #

(starting user location) # card number *

repeat card number *

NOTE: Never enter one (1) or (2) as the starting user

location since they are reserved for the Master code

and Supervisor code, respectively.

3. On the prox.pad plus keypad, press * to exit Program mode.

Up to 1998 users can be added this way at one

time. (User 1 is reserved for the Master code, User

2fortheSupervisorcode.)

4-14 prox.pad plus Install/Program. Manual, PPP, D 2

Page 65

4.2 Programming Users Chapter 4: Programming

4.2.6 Block Delete of

Users

4.2.7 Deleting Users

Command 58 lets you delete a block of users. To lessen

the chance of accidental deletion, the command sequence requires a double entry of the starting user and

number of users values. If the values entered do not

match, a programming error occurs. The format of the

new command is as follows:

58 # start user # start user # number of

users * number of users *

The yellow led blinks rapidly during the deletion process; it can take several seconds to delete all 2000 users.

To delete a user from the prox.pad plus unit’s memory,

you must know the user location in which the information is stored. Printing a Programmed Users List (as

described in section 4.5) helps you determine this, if

you are using the DCD software. If not, the programmer should have filled out a paper chart listing the

memory location or register in which all users are

stored.

To delete a user, follow the steps below.

1. Place the prox.pad plus unit in Program mode.

Press :

99 # Master Code * (default is 1234)

A slow blinking yellow LED indicates that the unit