International comfort products PAT3 Series, WTA3 Series Installation Instructions Manual

Installation Instructions

WTA3 & PAT3 Series

PACKAGED AIR CONDITIONER

TABLE OF CONTENTS

Page

SAFE INSTALLATION REQUIREMENTS 2........

INTRODUCTION 2.............................

RECEIVING AND INSTALLATION 2...............

Check Equipment 2...........................

Provide Unit Support 2 -- 3.....................

Install Duct Connections 3.....................

Dimensions 4................................

Connect Condensate Drain 5..................

Install Electrical Connections 5 -- 10............

PRE--START--UP 11............................

START--UP 11..................................

Check for Refrigerant Leaks 11.................

Start--Up Cooling & Make Adjustments 11 -- 12..

Check and Adjust Charge 12 -- 14............

Airflow 15..................................

Sequence of Operation 15 -- 16..............

Page

MAINTENANCE 16.............................

Air Filter 16..................................

Unit Top Removal 16..........................

Indoor Blower and Motor 17....................

Outdoor & Indoor Coil, Condensate Drain Pan 17.

Outdoor Fan 17..............................

Electrical Controls and Wiring 18...............

Refrigeration Circuit 18........................

Evaporator Airflow 18.........................

Metering Devices 18..........................

Liquid Line Strainers 18.......................

High Flow Valves 18..........................

AIRFLOW CHARTS 19 -- 20.....................

COOLING TROUBLESHOOTING GUIDE 21.......

CHECKLIST FORM 22..........................

International Comfort Products, LLC

Lewisburg, TN. 37091

Printed in U.S.A.

426 01 1302 00 11--18--08

SAFE INSTALLATION REQUIREMENTS

FIGURE 1

Installation and servicing of this equipment can be

hazardous due to mechanical and electrical components.

Only trained and qualified personnel should install, repair,

or service this equipment.

Untrained personnel can perform basic maintenance

functions such as cleaning and replacing air filters. All other

operations must be performed by trained service

personnel. When working on this equipment, observe

precautions in the literature, on tags, andon labels attached

to or shipped with the unit and other safety precautions that

may apply.

Follow all safety codes. Installation must be in compliance

with local andnational building codes.Wear safety glasses,

protective clothing, and work gloves. Have fireextinguisher

available. Read these instructions thoroughly and follow all

warnings or cautions included in literature and attached to

the unit.

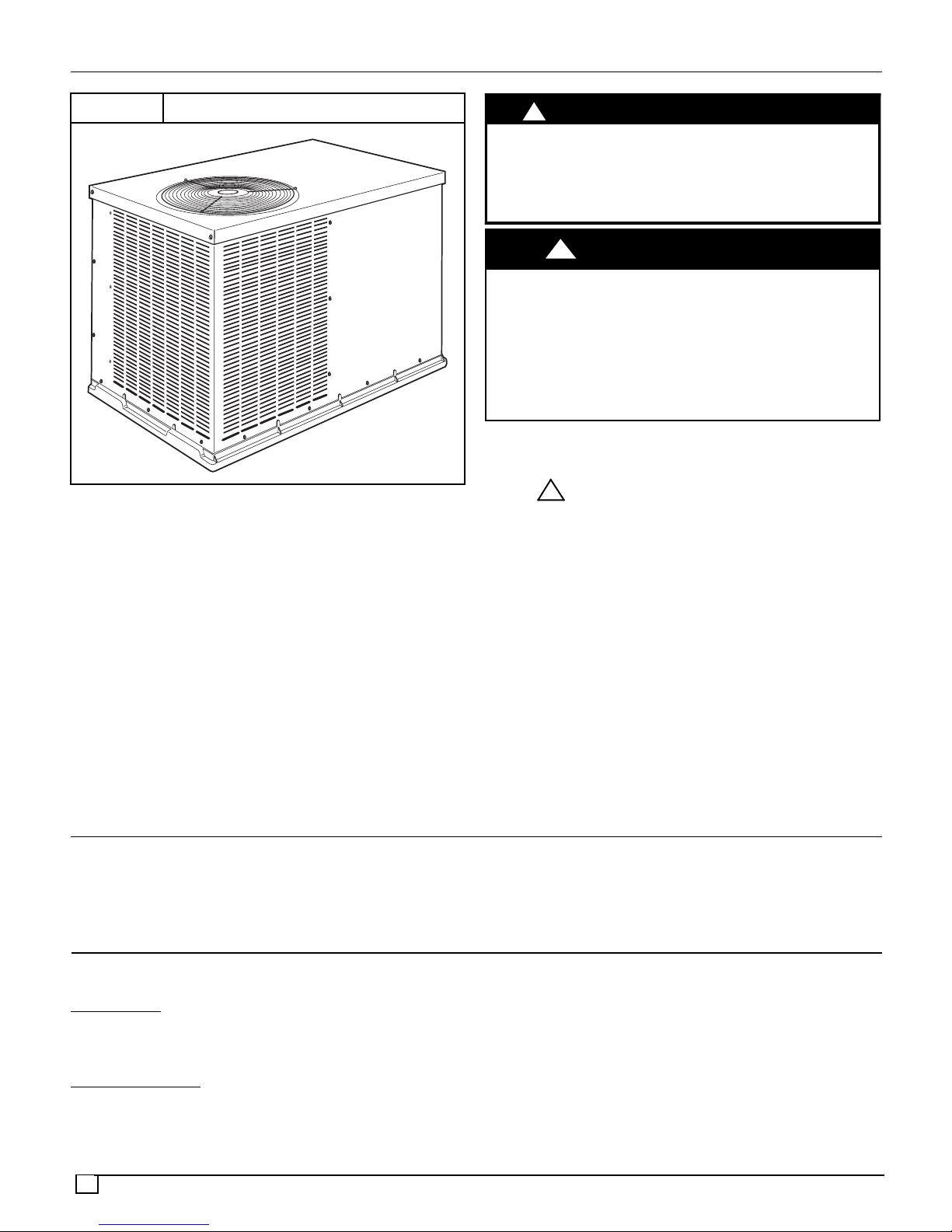

PACKAGED AIR CONDITIONER

!

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate protective clothing and gloves when

handling parts.

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing or servicing system, always turn off

main power to system. There may be more than one

disconnect switch. Turn off accessory heater power

switch if applicable. TAG DISCONNECT SWITCH

WITH LOCKOUT TAG.

Recognize safety information. This is the safety--alert

symbol . When you see this symbol in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING,

CAUTION, and NOTE. These words are used with the

safety--alert symbol. DANGER identifies the most serious

hazards which will result in serious injury or death.

WARNING signifies a hazard which could result in serious

injury or death. CAUTION is used to identify unsafe

practices which may result in minor personal injury or

product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation,

reliability, or operation.

!

CAUTION

WARNING

INTRODUCTION

The packaged unit is a fully self--contained air conditioner

designed for outdoor installation (see Figure 3 for unit

dimensions). All unit sizes have return and discharge

openings for horizontal airflow.

RECEIVING AND INSTALLATION

STEP 1 — Check Equipment

Identify

The unit model number and serial number are stamped on

the unit information plate. Check this information against

shipping papers.

Inspect

Inspect for shipping damage while unit is still on shipping

pallet. If unit appears to be damaged or is torn loose from

its anchorage, have it examined by transportation

inspectors before removal.Forward claim papers directly to

2

Unit

Shipment

Units may be installed either on a rooftop, ground level

cement slab, or directly on the ground if local codes allow.

transportation company. Manufacturer is not responsible

for any damage incurred in transit. Check all items against

shipping list. Immediately notify the nearest equipment

distribution office if any item is missing. To prevent loss or

damage, leave all parts in original packages until

installation.

STEP 2 — Provide Unit Support

For hurricane tie downs, contact distributor for details and

PE (Professional Engineering) Certificate, if required.

Slab Mount

Place the unit on a solid, level concrete pad that is a

minimum of 4” (102mm) thick with 2” (51mm) above grade.

The slab should extend approximately 2” (51mm) beyond

the casing on all 4 sides of the unit. Do not secure the unit

to the slab except when required by local codes.

A 6” (152mm) wide gravel apronshould be used around the

flat surface to prevent airflow blockage by grass or shrubs.

The unit should be level within ¼”. This is necessary for the

unit drain to function properly.

Ground

Mount

The unit may be installed either on a slab or placed

directly on the ground, if local codes permit. Place the

unit on level ground prepared with gravel for condensate

discharge.

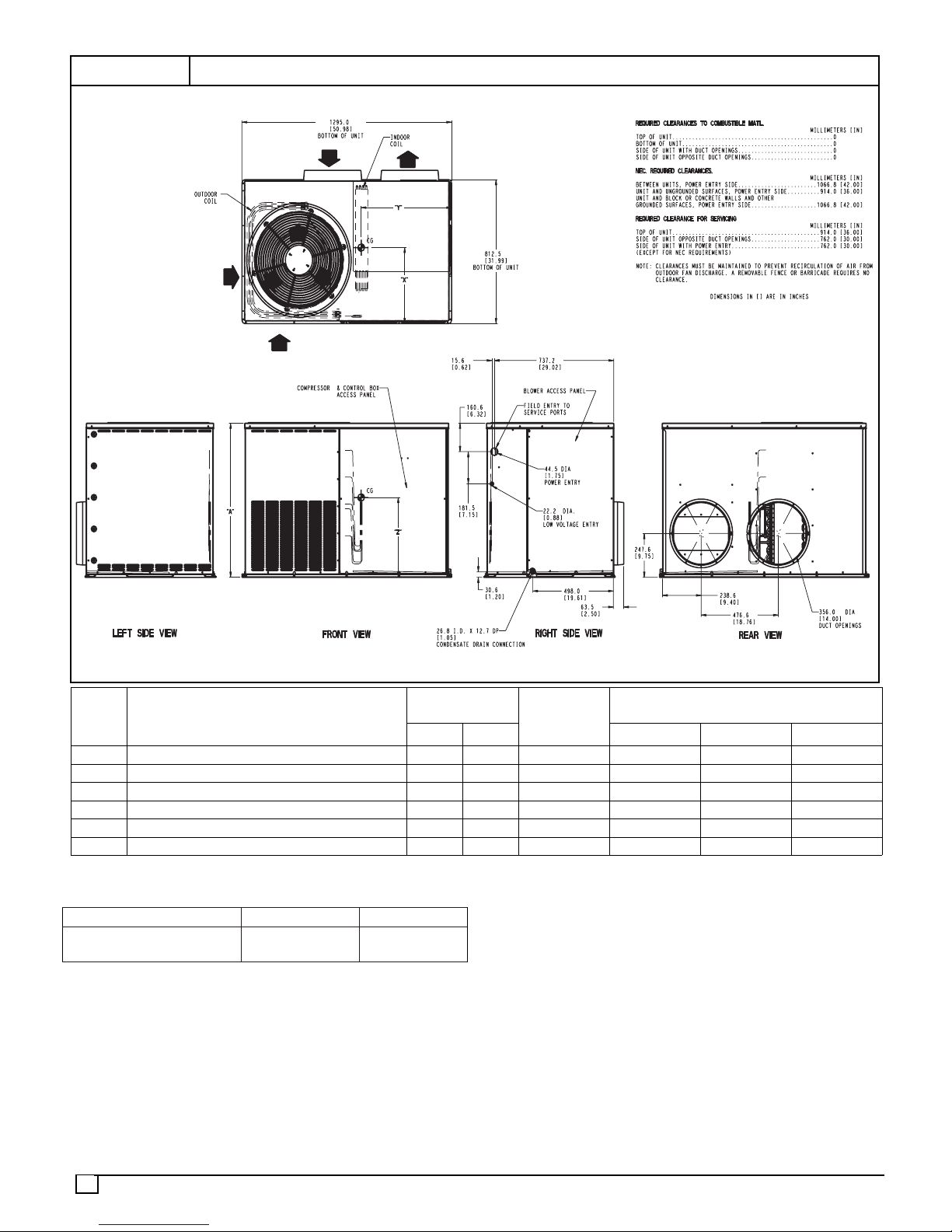

STEP 3 — Provide Clearances

The required minimum operating and service clearances

are shown in Figure 3. Adequate ventilation and condenser

air must be provided.

NOTE: Do not restrict outdoor airflow. An air restriction at

either the outdoor--air inlet or the fan discharge may be

detrimental to compressor life.

The condenser fan pulls air through the condenser coil and

discharges it through the top grille. Be sure that the fan

discharge does not recirculate to the condenser coil. Do not

locate the unit in either a corner or under an overhead

obstruction. The minimum clearance under a partial

overhang (such as a normal house overhang) is 48”

(1219mm). above the unit top. The maximum horizontal

extension of a partial overhang must not exceed 48”

(1219mm).

Do not place the unit where water, ice, or snow from an

overhang or roof will damage or flood the unit. Do not install

the unit on carpeting or other combustible materials.

Slab--mounted units should be at least 4” (102mm) above

the highest expected water and runoff levels. Do not use

unit if it has been under water.

Adhere to the following criteria when selecting, sizing, and

installing the duct system:

1. All units should have field--supplied filters installed in

the return--air side of the unit. Recommended sizes for

filters are shown in Table 1.

2. Avoid abrupt duct size increases and reductions.

Abrupt change in duct size adversely affects air

performance.

3. Size ductwork for cooling air quantity (CFM). The

minimum air quantity for proper electric heater

operation is listed in Table 10. Heater limit switches may

trip at air quantities below those recommended.

4. Seal, insulate, and weatherproof all external ductwork.

Seal, insulate and cover with a vapor barrier all

ductwork passing through conditioned spaces. Follow

latest Sheet Metal and Air Conditioning Contractors

National Association (SMACNA) and Air Conditioning

Contractors Association (ACCA) minimum installation

standards for residential heating and air conditioning

systems.

5. Secure all ducts to building structure. Flash,

weatherproof, and vibration--isolate duct openings in

wall or roof according to good construction practices.

6. Flash, weatherproof, and vibration isolate all openings

in building structure in accordance with local codesand

good building practices.

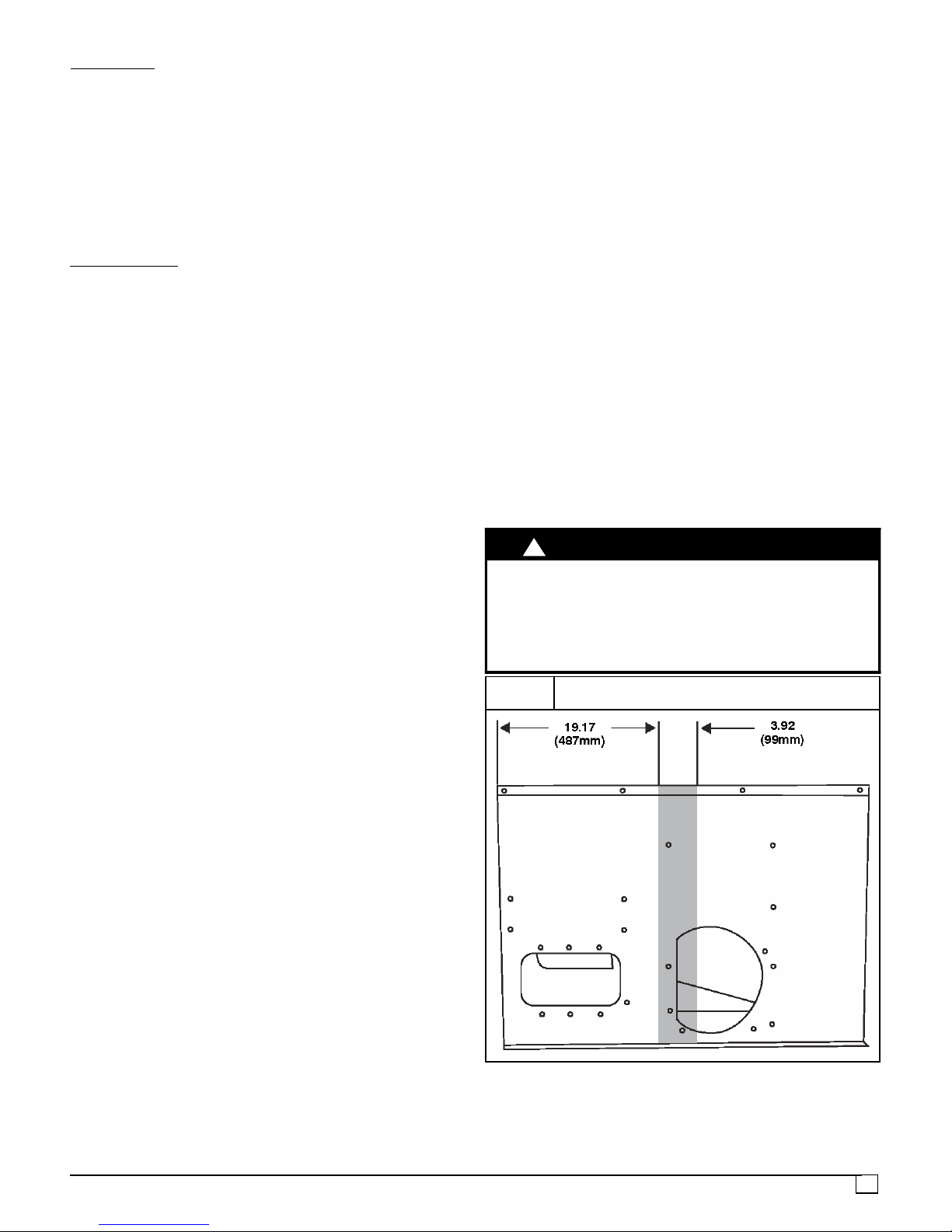

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in damage to unit

components.

When connecting ductwork to unit, do not drill deeper than

¾” (19mm) in shaded area shown in Figure 2 or coil may be

damaged.

FIGURE 2

Do Not Drill Shaded Area Deeper Than ¾” (19mm)

CAUTION

STEP 4 — Install Duct Connections

The design and installation of the duct system must be in

accordance with the standards of the NFPA for

installation of non--residence type air conditioning and

ventilating systems, NFPA 90A or residence type, NFPA

90B and/or local codes and ordinances.

Select and size ductwork, supply air registers, and return

air grilles according to ASHRAE (American Society of

Heating, Refrigeration, and Air Conditioning Engineers)

recommendations.

Use the duct flanges provided on the supply and return

openings on theside of the unit. See Figure 3 for connection

sizes and locations. The 14” (356mm) round duct collars

are shipped inside the unit attached to the base pan in the

indoor blower compartment. They are for field installation

and must be removed from the indoor blower compartment

prior to start--up, even if they are not used for installation.

3

FIGURE 3

UNIT DIMENSIONS

Model

Size

24 208/230--1--60 268 121.6 30.13 [765] 14.0 [356] 19.0 [483] 15.0 [381]

30 208/230--1--60 299 135.6 34.13 [867] 14.0 [356] 19.0 [483] 16.0 [406]

36 208/230--1--60 352 159.7 42.13 [1070] 14.0 [356] 19.0 [483] 19.8 [503]

42 208/230--1--60 364 165.1 42.13 [1070] 14.0 [356] 19.0 [483] 21.9 [556]

48 208/230--1--60 359 162.8 42.13 [1070] 14.0 [356] 19.0 [483] 19.8 [503]

60 208/230--1--60 408 185.1 42.13 [1070] 14.0 [356] 19.0 [483] 21.9 [556]

ELECTRICAL

CHARACTERISTICS

UNIT WEIGHT

lbs kg X Y Z

UNIT

HEIGHT

in. [mm]

“A”

CENTER OF GRAVITY

inches [mm]

Table 1—Filter Data -- Throw--away Type

MODEL SIZE: 24, 30, 36 42, 48, 60

RETURN--AIR FILTER*

inches (mm)

24x24x1

(610x610x25)

30x30x1

(762x762x25)

* Required filter sizes shown are based on the larger of the

ARI (Air Conditioning and Refrigeration Institute) rated

cooling airflow or the heating airflow velocity of 300 feet per

minute for throwaway type or 450 feet per minute for

high--capacity type. Air filter pressure drop for

non--standard filters must not exceed 0.08 inches water

column.

4

STEP 5 — Connect Condensate Drain

NOTE: When installing condensate drain connection be

sure to comply with local codes and restrictions.

The packaged unit disposes of condensate water through

a w” NPT fitting which exits through the base on the

evaporator coil access side. See Figure 3 for location.

Condensate water can be drained directly onto the roof in

rooftop installations (where permitted) or onto a gravel

apron in ground level installations.Install a field--supplied 2”

(51mm) condensate trap at the end of condensate

connection to ensure proper drainage. Make sure that the

outlet of the trap is at least 1” (25mm) lower than the

drain--pan condensate connection to prevent the pan from

overflowing (see Figure 4). Prime the trap with water. When

using a gravel apron, make sure it slopes away from the

unit.

Connect a drain tube using a minimum of w” PVC or w”

copper pipe (all field--supplied) at the outlet end of the 2”

(51mm) trap. Do not undersize the tube. Pitch the draintube

downward at a slope of at least 1” (25mm). for every 10 feet

(3.0m) of horizontal run. Be sure to check the drain tube for

leaks.

FIGURE 4

Condensate Drain

!

UNIT COMPONENT DAMAGE HAZARD

Failure to follow this caution may result in damage to the

unit being installed.

1. Make all electrical connections in accordance with

NEC NFPA 70 (latest edition) and local electrical

codes governing such wiring. In Canada, all

electrical connections must be in accordance with

CSA standard C22.1 Canadian Electrical Code Part

1 and applicable local codes. Refer to unit wiring

diagram.

2. Use only copper conductor for connections between

field--supplied electrical disconnect switch and unit.

DO NOT USE ALUMINUM WIRE.

3. Be sure that high--voltage power to unit is within

operating voltage range indicated on unit rating

plate. Consult local power company for correction of

improper voltage and/or phase imbalance.

4. Insulate low--voltage wires for highest voltage

contained within conduit when low--voltage control

wires are in same conduit as high--voltage wires.

5. Do not damage internal components when drilling

through any panel to mount electrical hardware,

conduit, etc.

CAUTION

1” Min.

(25.4mm)

STEP 6 — Install Electrical Connections

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

The unit cabinet must have an uninterrupted, unbroken

electrical ground. This ground may consist of an

electrical wire connected to the unit ground screw in the

control compartment, or conduit approved for electrical

ground when installed in accordance with NEC, NFPA 70

National Fire Protection Association (latest edition) (in

Canada, Canadian Electrical Code CSA C22.1) and

local electrical codes.

WARNING

2” Min.

(51 mm)

High Voltage Connections

The unit must have a separate electrical service with a

field--supplied, waterproof disconnect switch mounted at, or

within sight from, the unit. Refer to the unit rating plate,NEC

and local codes for maximum fuse/circuit breaker size and

minimum circuit amps (ampacity) for wire sizing.

The field--supplied disconnect switch box may be mounted

on the unit over the high--voltage inlet hole when the

standard power and low--voltage entry points are used (see

Figure 3 and 5 for acceptable location).

When routing power leads into unit, use only copper wire

between disconnect and unit. The high voltage leads

should be in a conduit until they enter the duct panel;

conduit termination at the duct panel must be watertight.

See unit wiring label and Figures 10 -- 13 for reference when

making high voltage connections. Proceed as follows to

complete the high--voltage connections to the unit.

Single--phase units:

1. Run the high--voltage (L1, L2) and ground lead into the

control box.

2. Connect ground lead to chassis ground connection.

3. Locate the black and yellow wires connected to the line

side of the contactor.

4. Connect field L1 to black wire on connection 11 of the

compressor contactor.

5. Connect field wire L2 to yellow wire on connection 23 of

the compressor contactor.

5

Special Procedures For 208 Volt Operation

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing or servicing system, always turn off

main power to system. with disconnect switch open,

move black wire from transformer (x””) terminal marked

230 to terminal marked 208. This re--taps transformer to

primary voltage of 208 VAC.

WARNING

Control Voltage Connections

Do not use any type of power--stealing thermostat. Unit

control problems may result.

Use no. 18 American Wire Gage (AWG) color--coded,

insulated (35_C minimum) wires to make the control

voltage connections between the thermostat and the unit.

If the thermostat is located more than 100 feet from the unit

(as measured along the control voltage wires), use no. 16

AWG color--coded, insulated (35_C minimum) wires.

Standard

Connection

Form a drip--loop with the thermostat leads before routing

them into the unit. Route the thermostat leads through

grommeted hole provided in unit into unit control box (see

Figure 8). Connect thermostat leads and unit power leads

as shown in Figures 7, 8, and 9.

The unit transformer supplies 24 VAC power for the

complete system including accessory electrical heater.

Transformer is factory wired for 230 Volt operation.

Accessory Electric Heat W

iring

Refer to accessory electric heat installation instructions for

information on installingaccessory electric heat. Accessory

electric heat wiring is shown in Figure 12.

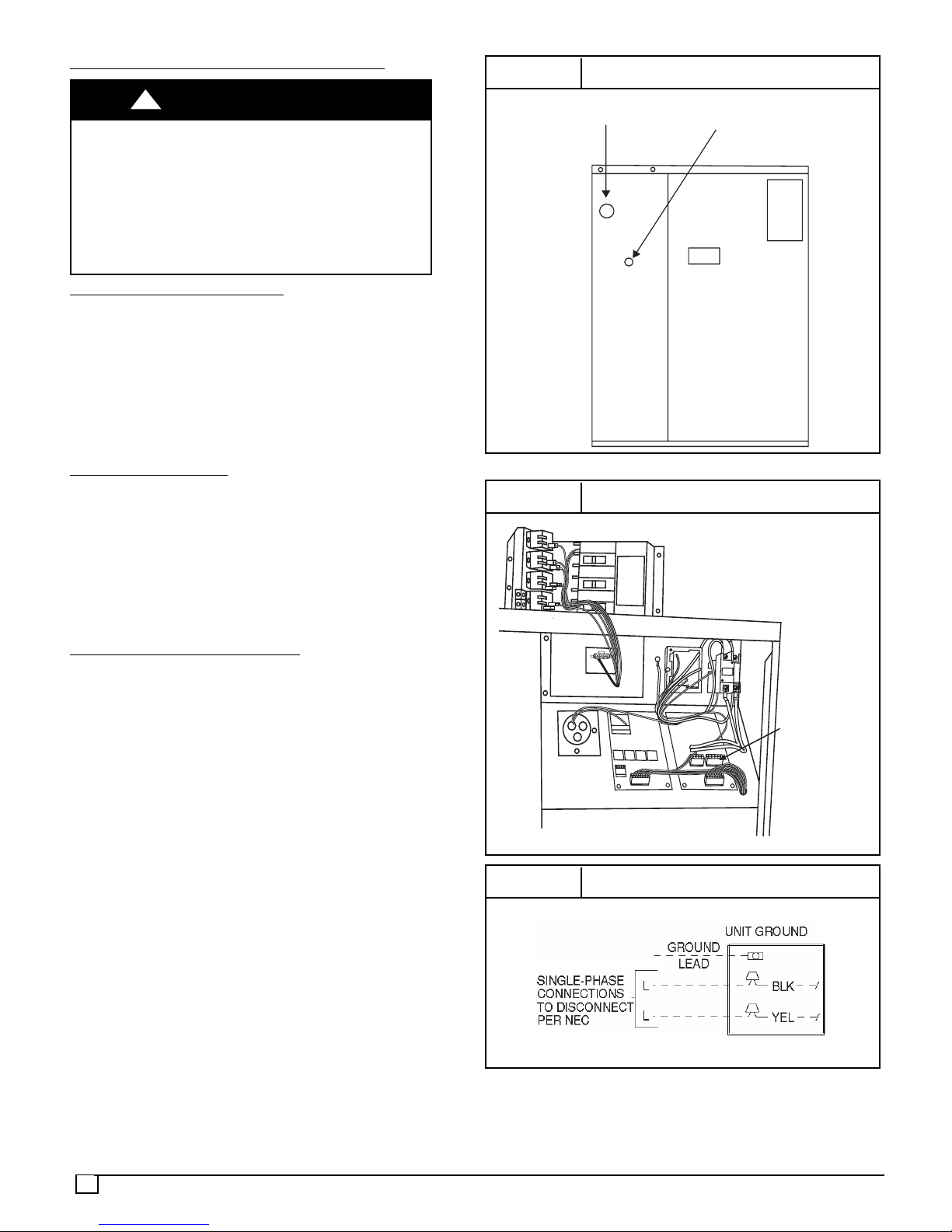

FIGURE 5

HIGH-VOLTAGE POWER

WIRING ENTRY HOLE

FIGURE 6

Electrical Entry Locations

LOW-VOLTAGE WIRING

ENTRY HOLE

Control Box Wiring

HEATER LOW

VOLTAGE PLUG

6

FIGURE 7

High Voltage (Line) Connections

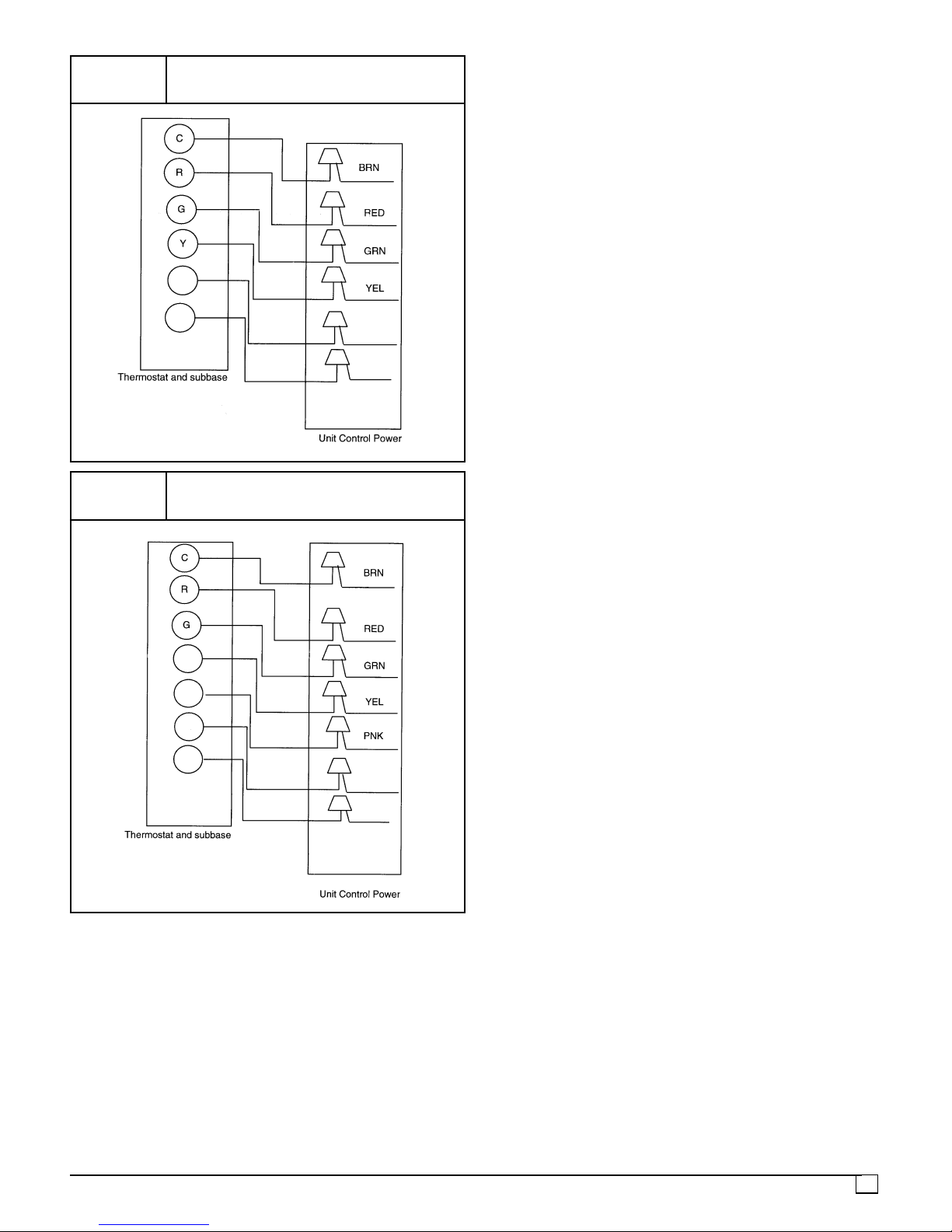

FIGURE 8

Low Voltage (Control) Connections,

Model Sizes 24, 30, 36, 42, 48

W2

FIGURE 9

W3

WHT

VIO

Low Voltage (Control) Connections,

Model Size 60

Y1

Y2

W2

W3

WHT

VIO

7

Loading...

Loading...