International Comfort Products N4H3, N4H4, C4H3, H4H3, T4H3 Installation Manual

...

INSTALLATION INSTRUCTIONS

R−410A Split System Heat Pump

N4H3, C4H3, H4H3, T4H3,

N4H4, NXH5, CXH5, HXH5, TXH5

These instructions must be read and understood completely before attempting installation.

IMPORTANT: Effective January 1, 2015, all split system and packaged air conditioners must be installed pursuant to

applicable regional efficiency standards issued by the Department of Energy.

Safety Labeling and Signal Words

DANGER, WARNING, CAUTION, and

NOTE

The signal words DANGER, WARNING,

CAUTION, and NOTE are used to identify levels of

hazard seriousness. The signal word DANGER is

only used on product labels to signify an immediate

hazard. The signal words WARNING, CAUTION,

and NOTE will be used on product labels and

throughout this manual and other manuals that may

apply to the product.

DANGER − Immediate hazards which will result in

severe personal injury or death.

WARNING − Hazards or unsafe practices which

could result in severe personal injury or death.

CAUTION − Hazards or unsafe practices which

may result in minor personal injury or product or

property damage.

NOTE − Used to highlight suggestions which

will result in enhanced installation, reliability, or

operation.

Signal Words in Manuals

The signal word WARNING is used throughout this

manual in the following manner:

WARNING

!

The signal word CAUTION is used throughout this

manual in the following manner:

!

Signal Words on Product Labeling

Signal words are used in combination with colors

and/or pictures on product labels.

WARNING

CAUTION

TABLE OF CONTENTS

Inspect New Unit 2...............................

Safety Considerations 2...........................

Location 2.......................................

Clearances 2....................................

Unit Support 2...................................

Refrigeration System 3...........................

Electrical Wiring 7................................

Defrost System 9................................

Start−up Procedure 11............................

Refrigerant Charge 11............................

Sequence of Operation 12.........................

Troubleshooting 16...............................

Maintenance 16..................................

Comfort Alertt Diagnostics Codes 17..............

R−410A Quick Reference Guide 18.................

!

DEATH, PERSONAL INJURY, AND/OR PROPERTY

DAMAGE HAZARD

Failure to carefully read and follow this warning

could result in equipment malfunction, property

damage, personal injury and/or death.

Installation or repairs made by unqualified persons could result in equipment malfunction, property damage, personal injury and/or death.

The information contained in this manual is intended for use by a qualified service technician familiar with safety procedures and equipped with

the proper tools and test instruments.

Installation must conform with local building

codes and with the National Electrical Code

NFPA70 current edition or Canadian Electrical

Code Part 1 CSA C.22.1.

WARNING

428 01 5106 03 6/17/15

INSTALLATION INSTRUCTIONS R−410A Split System Heat Pump

INSPECT NEW UNIT

After uncrating unit, inspect thoroughly for hidden

damage. If damage is found, notify the transportation

company immediately and file a concealed damage

claim.

SAFETY CONSIDERATIONS

Consult a qualified installer, service agency, or the

dealer/distributor for information and assistance. The

qualified installer must use factory authorized kits and

accessories when modifying this product. Refer to the

individual instructions packaged with the kit or accessory

when installing.

The weight of the product requires careful and proper

handling procedures when lifting or moving to avoid

personal injury. Use care to avoid contact with sharp or

pointed edges.

Follow all safety codes. Wear safety glasses, protective

clothing, and work gloves. Use a heat sinking material −

such as a wet rag − during brazing operations. Keep a fire

extinguisher available. Consult local codes and the

National Electric Code (NEC) for special requirements.

Improper installation, adjustment, alteration, service or

maintenance can void the warranty.

!

ELECTRICAL SHOCK HAZARD

Failure to turn off the main (remote) electrical disconnect device could result in personal injury or

death.

Before installing, modifying or servicing system,

turn OFF the main (remote) electrical disconnect

device. There may be more than one disconnect

device. Lock out and tag switch with a suitable

warning label.

!

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property damage

R−410A systems operate at higher pressures than

R−22 systems. When working with R−410A systems, use only service equipment and replacement components specifically rated or approved

for R−410A service.

WARNING

CAUTION

Locate unit in a well drained area, or support unit high

enough so that water runoff will not enter the unit.

Locate unit away from areas where heat, lint, or exhaust

fumes will be discharged onto unit (as from dryer vents).

Locate unit away from recessed or confined areas where

recirculation of discharge air may occur (refer to

CLEARANCES section of this document).

Roof−top installation is acceptable providing the roof will

support the unit and provisions are made for water

drainage and noise/vibration dampening.

NOTE: Roof mounted units exposed to wind may require

wind baffles. Consult the manufacturer for additional

information.

CLEARANCES

When installing, allow sufficient space for airflow

clearance, wiring, refrigerant piping, and service. Allow

24 in. (610 mm) clearance to service end of unit and 48

in. (1219.2 mm) above unit. For proper airflow, a 6 in.

(152.4 mm) clearance on one side of unit and 12 in.

(304.8 mm) on all remaining sides must be maintained.

Maintain a distance of 24 in. (609.6 mm) between units

or 18 in. (457.2 mm) if no overhang within 12 ft.

(3.66m). Position so water, snow, or ice from roof or

eaves cannot fall directly on unit.

On rooftop applications, locate unit at least 6 in.

(152.4mm) above roof surface.

UNIT SUPPORT

NOTE: Unit must be level " 2 degrees [3/8 inch rise or fall

per foot of run (10mm rise or fall per 305 mm of run)] or

compressor may not function properly.

A. GROUND LEVEL INSTALLATION

The unit must be level and supported above grade by

beams, platform, or a pad. Platform or pad can be of open

or solid construction but should be of permanent

materials such as concrete, bricks, blocks, steel, or

pressure− treated timbers approved for ground contact.

Soil conditions must be considered so that the platform or

pad does not shift or settle and leave the unit partially

supported. Minimum pad dimensions are shown in

Figure 1.

If beams or an open platform are used for support, it is

recommended that the soil be treated or area be graveled

to reduce the growth of grasses and weeds.

To minimize vibration or noise transmission, it is

recommended that supports not be in contact with the

building structure. However, slabs on grade constructions

with an extended pad are normally acceptable.

LOCATION

Check local codes for regulations concerning zoning,

noise, platforms, and other issues.

Locate unit away from fresh air intakes, vents, or

bedroom windows. Noise may carry into the openings

and disturb people inside.

2 428 01 5106 03

Specifications subject to change without notice.

!

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property damage.

Top surface of platform must be above estimated snowfall level to prevent snow blocking coil and to allow water

melt to drain from unit.

CAUTION

INSTALLATION INSTRUCTIONS R−410A Split System Heat Pump

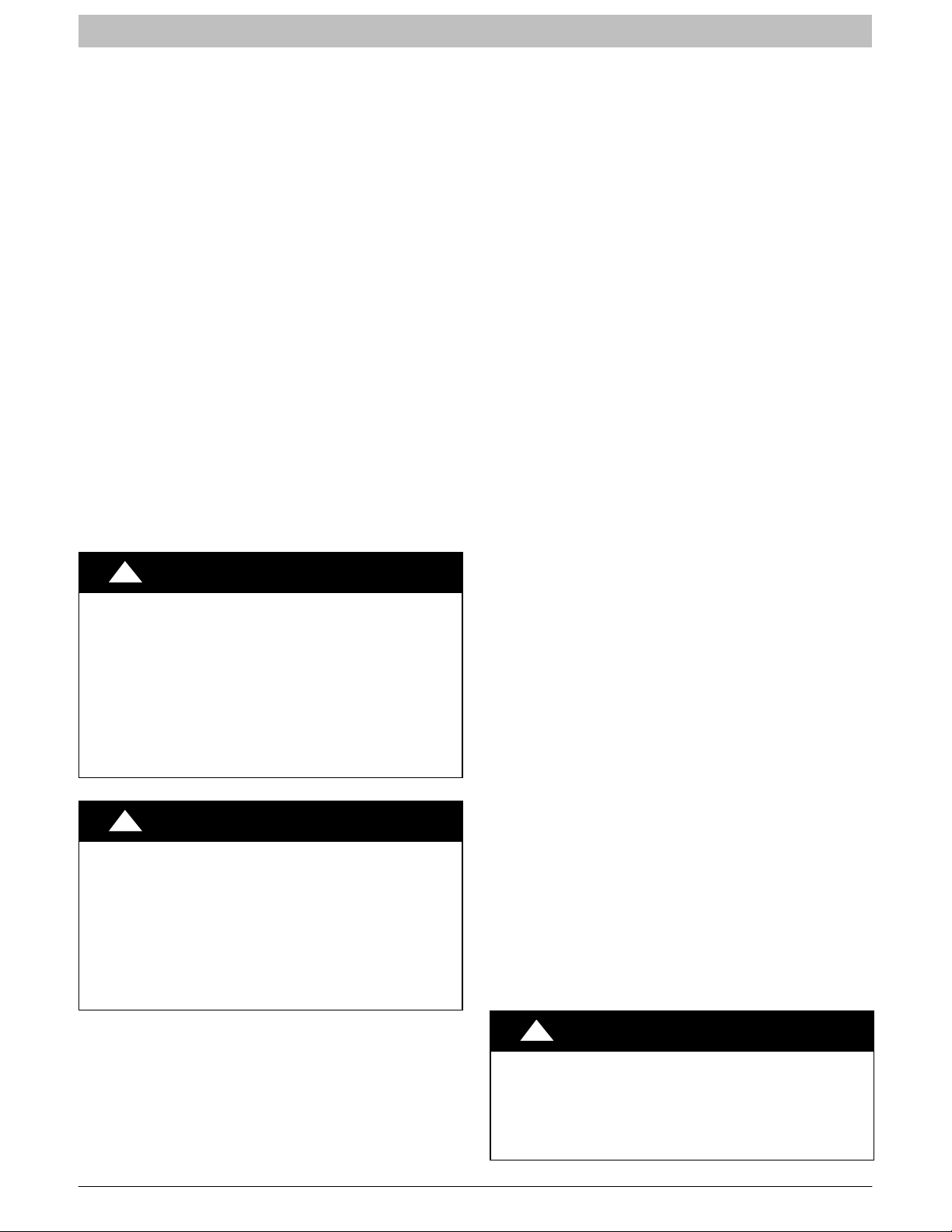

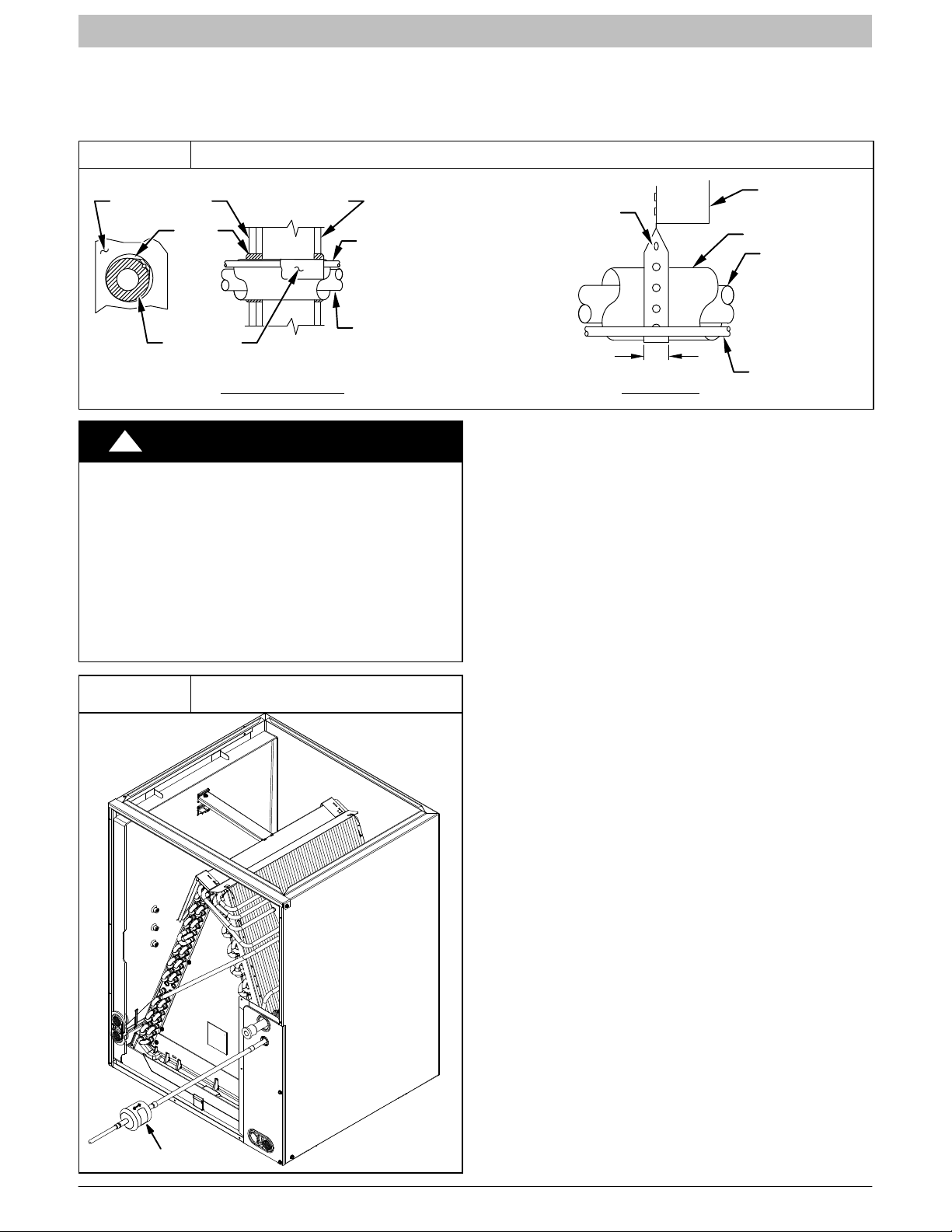

Figure 1 Tie Down Knockouts

a” (10mm) dia. Tie Down Knockouts

In Base Pan (2 places)

A

Base Pan Width

View From Top

Base

Pan

Depth

C

B

Inches (mm)

Base Pan

Width x Depth

23 x 23

(584 x 584)

25−11/16 x

25−11/16

(652 x 652)

31−1/8 x 31−1/8

(791 x 791)

34−15/16 x

34−15/16

(887 x 887)

Tie Down

Knockouts

A B C

7−3/4

4−7/16

(197)

9−1/16

(230)

9−1/16

(230)

9−1/16

(230)

(113)18(457)

4−7/16

(113)

6−1/2

(165)

6−1/2

(165)

21−1/4

(540)

24−5/8

(625)

28−7/16

(722)

Minimum

Mounting Pad

Dimensions

23 x 23

(584 x 584)

26 x 26

(660 x 660)

31−1/2 x 31−1/2

(800 x 800)

35 x 35

(889 x 889)

B. ROOF TOP INSTALLATION

This type of installation is not recommended on wood

frame structures where low noise levels are required.

Supporting structure or platform for the unit must be level.

If installation is on a flat roof, locate unit minimum 6 inches

(152mm) above roof level.

Place the unit over one or more load bearing walls. If there

are several units, mount them on platforms that are

self−supporting and span several load bearing walls.

These suggestions are to minimize noise and vibration

transmission through the structure. If the structure is a

home or apartment, avoid locating the unit over

bedrooms or study.

NOTE: When unit is to be installed on a bonded

guaranteed roof, a release must be obtained from the

building owner to free the installer from all liabilities.

C. FASTENING UNIT DOWN

If conditions or local codes require the unit be attached in

place, remove the knockouts in the base pan and install

tie down bolts through the holes (refer to Figure 1).

Contact local distributor for hurricane hold−down details and

the P.E. (Professional Engineer) certification, when

required.

!

CAUTION

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property damage.

Inadequate unit support may cause excessive vibration,

noise, and/or stress on the refrigerant lines, leading to refrigerant line failure.

REFRIGERATION SYSTEM

A. COMPONENT MATCHES

Check to see that the proper system components are in

place, especially the indoor coil.

R−410A outdoor units can only be used with R−410A

specific indoor coils. If there is a refrigerant mis−match,

consult the indoor coil manufacturer to determine if a

refrigerant conversion kit is available for the indoor coil.

This outdoor unit is designed to achieve maximum

efficiency when used with indoor coils that utilize a TXV

refrigerant metering device or Piston with Teflon ring

metering device. If any other type of metering device is

installed on the indoor coil, consult the indoor coil

manufacturer to determine if a conversion kit is available.

Installing with TXV.

When installing a TXV on an indoor coil, follow the

instructions provided with the new TXV.

A typical TXV installation is shown in Figure 2.

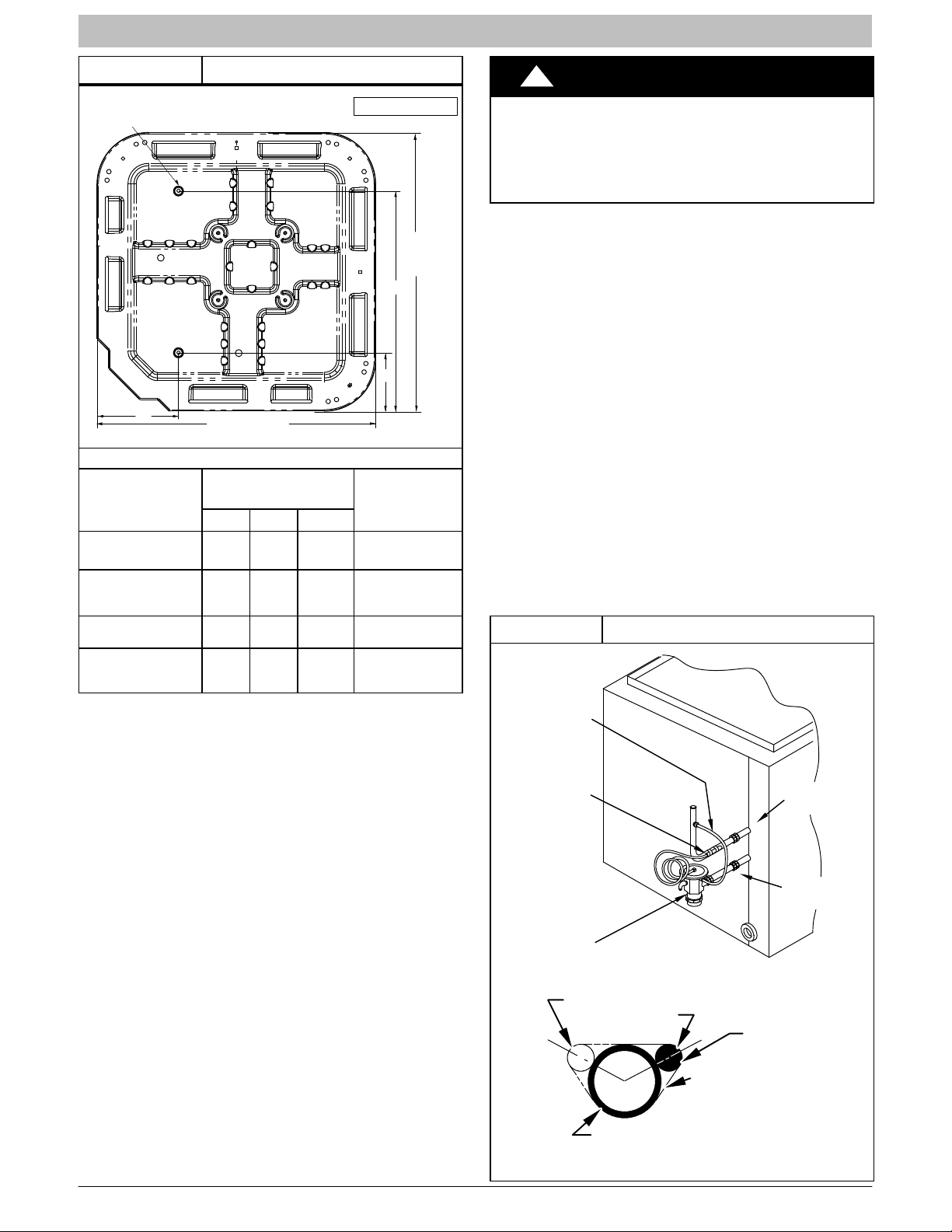

Figure 2 Typical TXV Installation

INDOOR

EQUALIZER

TUBE

SENSING

BULB

TXV

10 O’Clock

7/8

2 O’Clock

SUCTION TUBE

IN. OD & SMALLER

COIL

SUCTION

TUBE

LIQUID

TUBE

SENSING BULB

STRAP

428 01 5106 03 3

Specifications subject to change without notice.

INSTALLATION INSTRUCTIONS R−410A Split System Heat Pump

Installing with Indoor Piston − cooling operation.

(Heat pumps also use an outdoor piston for heating

operation, refer to section F.)

Check piston size shipped with indoor unit to see if it

matches required indoor piston size shown on outdoor

unit rating plate.

If it does not

piston, according to size marked on outdoor unit rating

plate. (Some outdoor models include a cooling piston in

the accessory bag.)

Heating piston is shipped in the service valve − refer to

section F.

Example fan coils with piston: FEM4P, FSM4P, FSU4P,

FMA4P, FMC4P, FMU4P.

See Figure 3.

When changing indoor piston, use a back−up wrench.

Finger tighten hex nut, then tighten with wrench 1/2 turn.

Do not exceed 30 ft−lbs (40.7 N−m).The indoor piston

contains a Teflon ring (or seal) which is used to seat

against the inside of distributor body, and must be

installed properly to ensure proper seating in the direction

for cooling operation.

Figure 3 Indoor (cooling) Piston

match, replace indoor piston with cooling

Refer to Product Specifications and Long Line

Applications Guideline for line set sizing.

NOTE: Total line set length must not exceed 200 feet

(61m).

NOTE: A crankcase heater must be used when the

refrigerant line length exceeds 80 feet (24.4m).

If outdoor unit is more than 10 feet (3m) higher than the

indoor coil, refer to the Long Line Applications Guideline

for instructions.

NOTE: When the outdoor unit is higher than the indoor

coil, the vertical separation must not exceed 100 feet

(30m).

NOTE: When the outdoor unit is lower than the indoor

coil, the vertical separation must not exceed 50 feet

(15.2m).

If it is necessary to add refrigerant line in the field, use

dehydrated or dry, sealed, deoxidized, copper

refrigeration tubing. Do not use copper water pipe.

Do not remove rubber plugs or caps from copper tubing

until connections are ready to be made.

Be extra careful when bending refrigeration tubing.

Tubing can “kink” easily, and if this occurs, the entire

length of tubing must be replaced.

BRASS

HEX NUT

!

PRODUCT OPERATION HAZARD

Failure to follow this caution may result in improper product

operation.

If using a TXV in conjunction with a single−phase reciprocating compressor, a compressor start capacitor and relay are

required. Consult outdoor unit pre−sale literature for start assist kit part number.

B. REFRIGERANT LINE SETS

The refrigerant line set must be properly sized to assure

maximum efficiency and proper oil circulation.

4 428 01 5106 03

TEFLON SEAL

TEFLON RING

PISTON

FLOW IN

COOLING

PISTON

RETAINER

STRAINER

CAUTION

DISTRIBUTOR

BRASS

HEX BODY

!

PERSONAL INJURY HAZARD

Failure to relieve system pressure could result in

personal injury and/or death.

Relieve pressure and recover all refrigerant before

servicing existing equipment, and before final unit

disposal. Use all service ports and open all flow−

control devices, including solenoid valves.

!

UNIT OPERATION HAZARD

Failure to follow this caution may result in improper product operation.

L10S017

Specifications subject to change without notice.

Do not leave system open to atmosphere any longer than absolutely required for installation. Internal system components − especially refrigerant

oils − are extremely susceptible to moisture contamination. Keep ends of tubing sealed during

installation until the last possible moment.

C. ROUTING AND SUSPENDING REFRIGERANT

LINES

Run refrigerant lines as straight and direct as possible,

avoiding unnecessary bends and turns. Always insulate

the entire suction line. Both lines should be insulated

when routed through an attic or when routed through an

underground raceway.

When routing refrigerant lines through a foundation or

wall, do not allow refrigerant lines to come in direct

contact with the building structure. Make openings large

enough so that lines can be wrapped with extra insulation.

Fill all gaps with RTV caulk. This will prevent noise

WARNING

CAUTION

INSTALLATION INSTRUCTIONS R−410A Split System Heat Pump

transmission between the tubing and the foundation or

wall.

Along floor or ceiling joists, suspend refrigerant lines so

that they do not contact the building structure, water

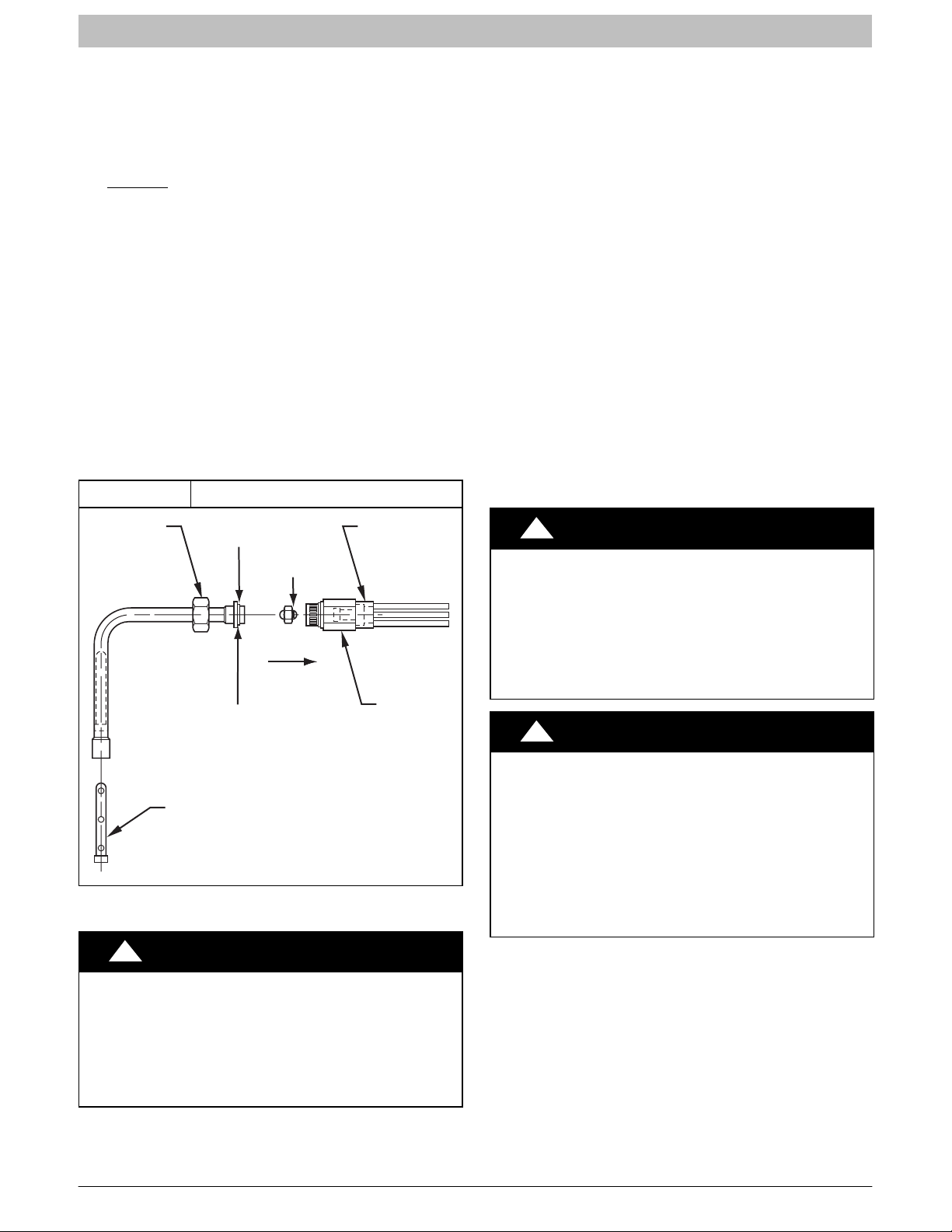

Figure 4

OUTDOOR WALL INDOOR WALL

CAULK

INSULATION

THROUGH THE WALL SUSPENSION

Routing and Suspending Refrigerant Lines

LIQUID TUBE

SUCTION TUBE

pipes, or ductwork. Use insulated or suspension type

hangers. Metal straps must be at least 1” (25mm)wide to

avoid cutting into the tube insulation. Keep the liquid and

suction lines separate. Refer to Figure 4.

JOIST

HANGER STRAP

(AROUND SUCTION

TUBE ONLY)

1” (25mm) MIN

INSULATION

SUCTION TUBE

LIQUID TUBE

D. OUTDOOR UNIT HIGHER THAN INDOOR UNIT

!

UNIT OPERATION HAZARD

Failure to follow this caution may result in improp-

er product operation.

Do not bury more than 36” (1m) of line set under-

ground. Refrigerant may migrate to cooler buried

section during extended periods of unit shut−

down, causing refrigerant slugging and possible

compressor damage at start−up.

If ANY section of the line set is buried underground, provide a minimum 6” (152mm) vertical

rise at the service valve.

Figure 5

CAUTION

Liquid Line Filter−Drier

Installed at Indoor Coil

Proper oil return to the compressor should be maintained

with suction gas velocity. If velocities drop below 1500

fpm (feet per minute), oil return will be decreased. To

maintain suction gas velocity, do not upsize vertical

suction risers.

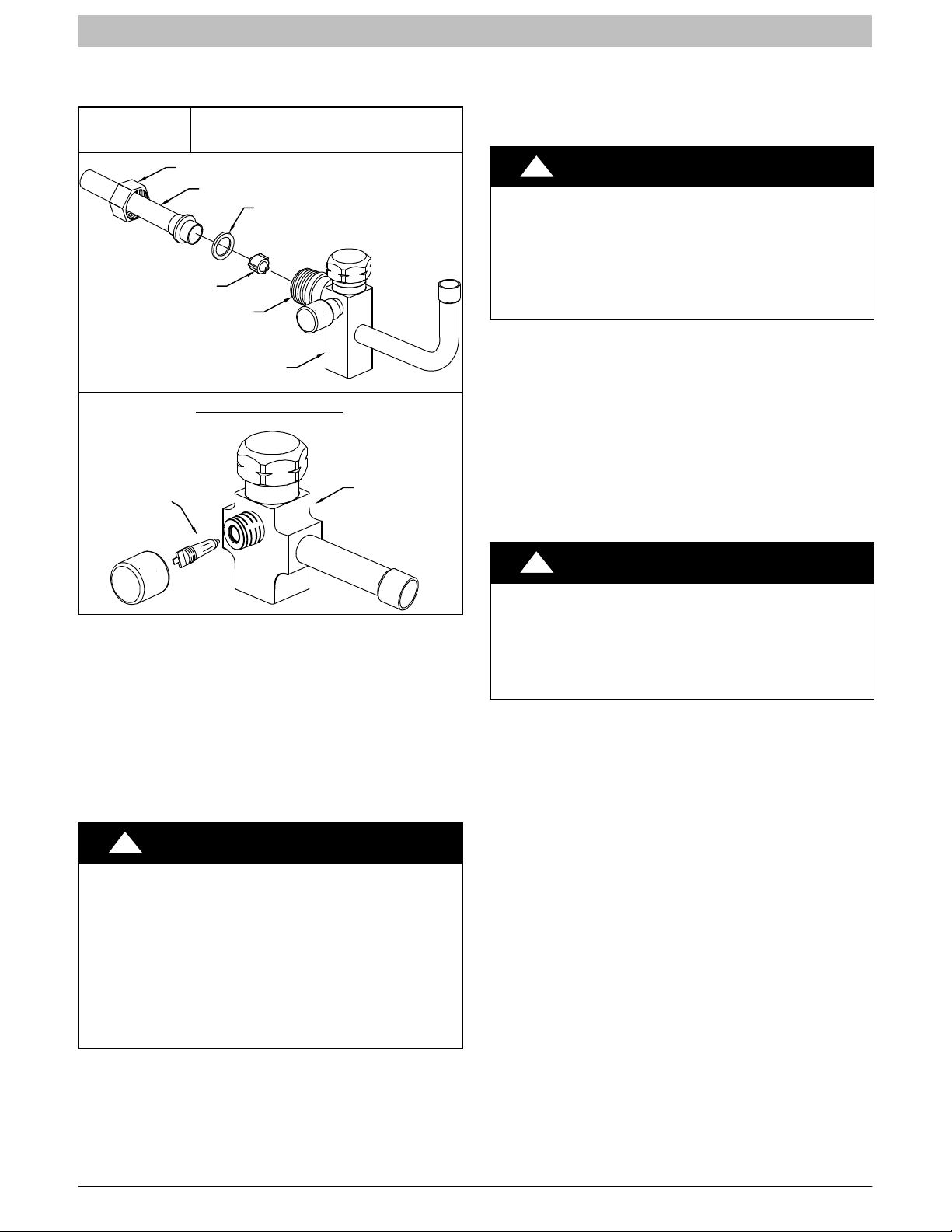

E. LIQUID LINE FILTER−DRIER

Outdoor units are shipped with an appropriate filter−drier

for installation in the liquid line. Leave the plugs in the tube

ends until the filter−drier is installed. The optimal location

for the filter−drier is close to the indoor coil. Heat pump

filter−driers are “bi−flow” type. Either end can be pointed

towards indoor coil. Refer to Figure 5.

F. SERVICE VALVES

Service valves are closed and plugged from the factory.

Outdoor units are shipped with a refrigerant charge

sealed in the unit. Leave the service valves closed until all

other refrigerant system work is complete or the charge

will be lost. Leave the plugs in place until line set tubing is

ready to be inserted.

Heat pumps require a piston metering device in the liquid

service valve for proper heating operation. Piston is

shipped in the piston body of the liquid service valve,

temporarily held in place with a plastic cap. Do not remove

the plastic cap until line set tubing is ready to be installed.

Refer to Figure 6 and follow these steps for piston

installation:

1. Remove plastic cap holding piston in piston body of

liquid service valve.

2. Check that piston size (stamped on side of piston)

matches with number listed on unit rating plate.

Return piston to piston body of liquid service valve

(either direction).

3. Find plastic bag taped to unit containing copper

adapter tube, brass nut, and plastic washer.

4. Install plastic washer in the seat inside piston body.

5. Fit brass nut onto adapter tube and install tube

onto liquid service valve. Tighten nut finger tight,

then wrench additional ½ turn only [15−ft lbs (20.3

Filter−Drier

428 01 5106 03 5

38−11−84

Specifications subject to change without notice.

N−m)]. Over tightening may damage the plastic

washer.

INSTALLATION INSTRUCTIONS R−410A Split System Heat Pump

Service valve bodies are brass and suction tube stub is

copper.

Figure 6

LIQUID SERVICE VALVE

VALVE CORE

Liquid Service Valve with Heating

Piston and Adapter Tube

BRASS NUT

ADAPTER TUBE

PLASTIC WASHER

PISTON

PISTON BODY

Vapor Service Valve

SERVICE VALVE

Apply heat absorbing paste or heat sink product between

service valve and joint. Wrap service valves with a heat

sinking material such as a wet cloth.

Braze joints using a Sil−Fos or Phos−copper alloy.

!

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in product

damage.

Braze with Sil−Fos or Phos−copper alloy on copper−to−copper joints and wrap a wet cloth around

rear of fitting to prevent damage to TXV.

H. EVACUATING LINE SET AND INDOOR COIL

The unit is shipped with a factory refrigerant charge. The

liquid line and suction line service valves have been

closed after final testing at the factory. Do not disturb

these valves until the line set and indoor coil have been

evacuated and leak checked, or the charge in the unit

may be lost.

NOTE: Do not use any portion of the factory charge for

purging or leak testing. The factory charge is for filling the

system only after a complete evacuation and leak check

has been performed.

CAUTION

G. BRAZING CONNECTIONS

NOTE:

For Liquid Service Valve − Braze lineset to adapter tube

BEFORE bolting adapter to valve. This helps prevent

overheating and damage to plastic washer or o−ring.

For Vapor Service Valve − remove valve core from

schrader port on Service Valve BEFORE brazing. This

helps prevent overheating and damage to valve seals

(refer to Figure 6). Replace valve core when brazing is

completed.

!

FIRE HAZARD

Failure to remove refrigerant and oil charge before

brazing could result in personal injury, death, and/

or property damage.

Refrigerant and oil mixture could ignite and burn

as it escapes and contacts brazing torch. Make

sure the refrigerant charge is properly removed

from both the high and low sides of the system before brazing any component or lines.

WARNING

!

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in product

damage.

Never use the outdoor unit compressor as a vacuum pump. Doing so may damage the compressor.

Line set and indoor coil should be evacuated using the

recommended deep vacuum method of 500 microns. If

deep vacuum equipment is not available, the alternate

triple evacuation method may be used by following the

specified procedure.

If vacuum must be interrupted during the evacuation

procedure, always break vacuum with dry nitrogen.

Deep Vacuum Method

The deep vacuum method requires a vacuum pump

capable of pulling a vacuum to 500 microns and a vacuum

gauge capable of accurately measuring this vacuum

level. The deep vacuum method is the most positive way

of assuring a system is free of air and water.

Watch the vacuum gauge as the system is pulling down.

The response of the gauge is an indicator of the condition

of the system (refer to Figure 7).

With no leaks in the system, allow the vacuum pump to

run for 30 minutes minimum at the deep vacuum level.

CAUTION

Clean line set tube ends with emery cloth or steel brush.

Remove any grit or debris.

Insert line set tube ends into service valve tube stubs.

6 428 01 5106 03

Specifications subject to change without notice.

Loading...

Loading...