International Comfort Products MF08B1500B1, MF12F1900B1, MF16J2200B1, MF20L2400B1 Installation Manual

INSTALLATION INSTRUCTIONS

Modular Blower (Electric Furnace)

MF08B1500B1, MF12F1900B1, MF16J2200B1, MF20L2400B1

These instructions must be read and understood completely before attempting installation.

Safety Labeling and Signal Words

DANGER, WARNING, CAUTION, and NOTE

The signal words DANGER, WARNING, CAUTION, and

NOTE are used to identify levels of hazard seriousness.

The signal word DANGER is only used on product labels

to signify an immediate hazard. The signal words

WARNING, CAUTION, and NOTE will be used on

product labels and throughout this manual and other

manuals that may apply to the product.

DANGER -- Immediate hazards which will result in

severe personal injury or death.

WARNING -- Hazards or unsafe practices which could

result in severe personal injury or death.

CAUTION -- Hazards or unsafe practices which may

result in minor personal injury or product or property

damage.

NOTE -- Used to highlight suggestions which will result in

enhanced installation, reliability, or operation.

TABLE OF CONTENTS

General Information/Installation 2..................

Installation 2.....................................

Vertical/Horizontal Installation 3....................

Ductwork Connection 4...........................

Filter Installation 4................................

Electrical Connection 4...........................

Blower Performance 8............................

Sequence of Operation 9..........................

Wiring Diagram 10...............................

Replacement Parts 12............................

Signal Words in Manuals

The signal word WARNING is used throughout this

manual in the following manner:

WARNING

!

The signal word CAUTION is used throughout

this manual in the following manner:

!

Signal Words on Product Labeling

Signal words are used in combination with colors and/

or pictures on product labels.

!

ELECTRICAL SHOCK HAZARD

Failure to turn off electric power could result in personal injury or death.

Before installing or servicing system, turn off main

power to the system. There may be more than one disconnect switch, including accessory heater(s).

WARNING

CAUTION

WARNING

442 01 2205 01 Jan 2008

MODULAR BLOWER: MFINSTALLATION INSTRUCTIONS

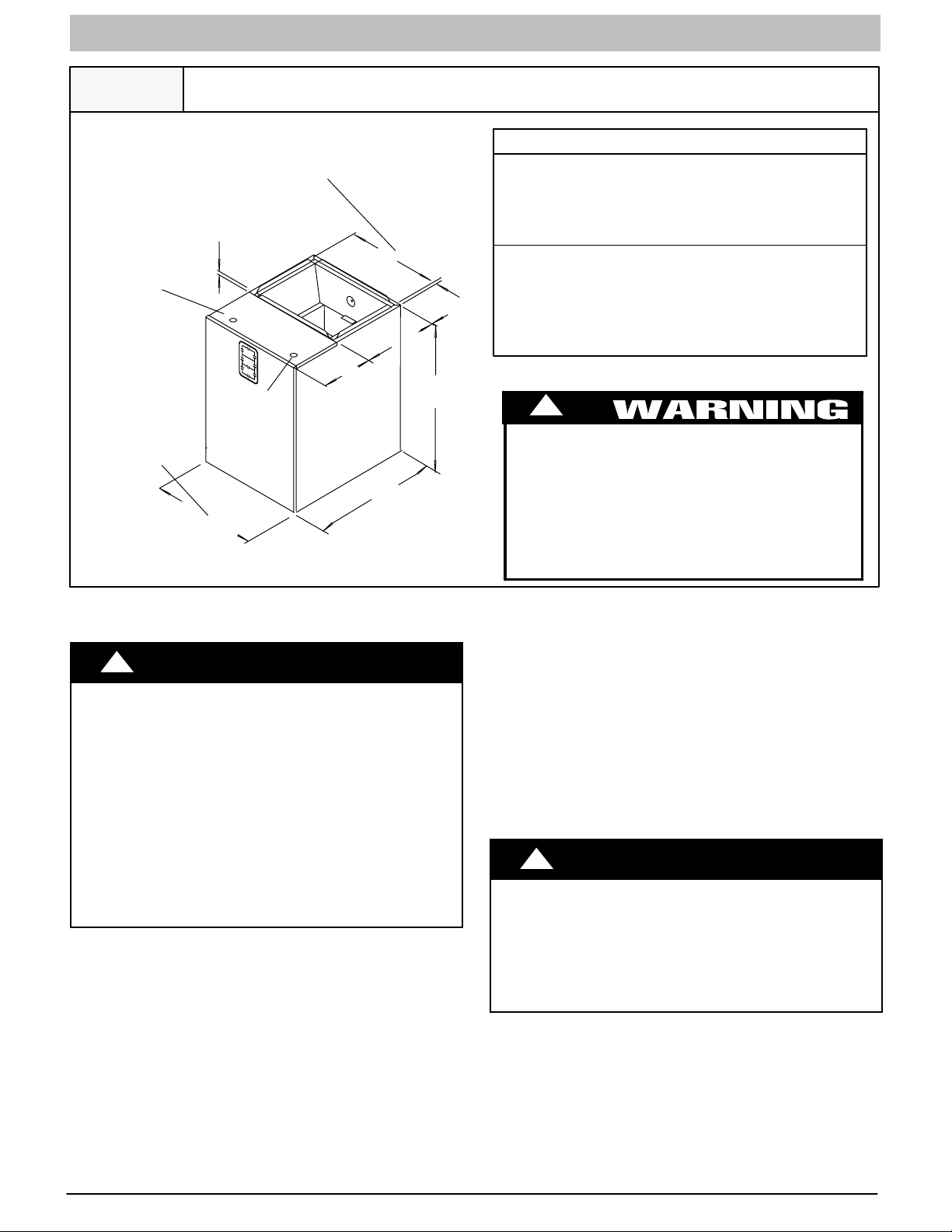

Figure 1

Low Voltage

Entrance

15w (2--22 Ton)

194 (3--32 Ton)

22d (4 Ton)

242 (5 Ton)

Nominal Installation Dimensions and Clearances

14a (2 -- 22 Ton)

17d (3 -- 32 Ton)

212 (4 Ton)

238 (5 Ton)

3/4”

8

Line Voltage

Entrance

ALL DIMENSIONS IN INCHES

1IN=25.4MM

12”

1

/2”

24”

1

20

/2”

NO HEATERS

All Sides 0”..................................

From Supply Duct 0”..........................

Recommended Service From Front 20”(508 mm)..........

(Service for blower, filter if installed)

WITH HEATERS

All Sides 0”..................................

From First Three Feet of Supply Duct

5/8”

to Combustibles 1”...........................

From Duct after Three Feet 0”.................

Recommended Service From Front 20” (508mm)..........

(Service for blower, heaters if installed)

CLEARANCES

!

FIRE HAZARD

Failure to follow this warning could result in

personal injury, death, and/or property damage.

When heaters are installed maintain clearances

from combustible materials as specified on unit

rating plate. Do not use plastic lined or combustible

flexible ducting within 36’’ (914 mm) of the supply

end of the modular unit.

GENERAL INFORMATION

!

PERSONAL INJURY, AND/OR PROPERTY DAMAGE

HAZARD

Failure to carefully read and follow this warning

could result in personal injury, death, equipment

malfunction, and/or property damage.

The information contained in this manual is intended for use by a qualified service technician familiar with safety procedures and equipped with the

proper tools and test instruments.

Installation must conform with local building codes

and with the National Electrical Code NFPA70 current edition.

INTRODUCTION

The MF modular blower cabinet uses a 208/230V PSC blower

motor, with an electronic fan control board. The MF may be used

for cooling or heat pump applications either with or without electric

heat. Installations without electric heat require a NO HEAT KIT

(EHIA00KN10). The cabinet can be installed in an upflow,

downflow or horizontal position. Refer to Figure 3 and 4.

LOCATION

Select the best position which suits the installation site conditions.

The location should provideadequatestructural support, space in

the front of the unit for service access, clearance for return air and

supply duct connections, space for refrigerant piping connections

and condensate drain line connections. If heaters are being

WARNING

installed, make sure adequate clearance is maintained from

supply ductwork, See Clearances and Warning in Figure 1.

If the unit is located in an area of high humidity, nuisance sweating

of casing may occur. On these installations a wrap of 2” (51mm)

fiberglass insulation with a vapor barrier should be used.

HEATER PACKAGES

Factory approved, field installed, UL listed heater packages are

available from the equipment supplier. See unit rating plate for a

list of factory approved heaters (electric heat accesso ry models

EHIA only). Heaters that are not factory approved could cause

damage which would not be covered under the equipment

warranty.

!

CAUTION

CUT HAZARD

Failure to follow this caution may result in personal

injury .

Sheet metal parts may have sharp edges or burrs.

Use care and wear appropriate protective clothing

and gloves when handling parts.

INSTALLATIONS

The unit is ready to install in any position without modifications.

Refer to the co il instructions for information on drain pan

configurations etc. Make sure coil is set up properly for desired

position of blower cabinet.

Coil must be secured to blower cabinet with the three tabs that are

part of the blower cabinet base. Bend the tabs out from the bottom

so they fit over the coil cabinet.

Position coil cabinet in relation to the blower so they will be correct

for desired application.

2

442 01 2205 01

MODULAR BLOWER: MF

INSTALLATION INSTRUCTIONS

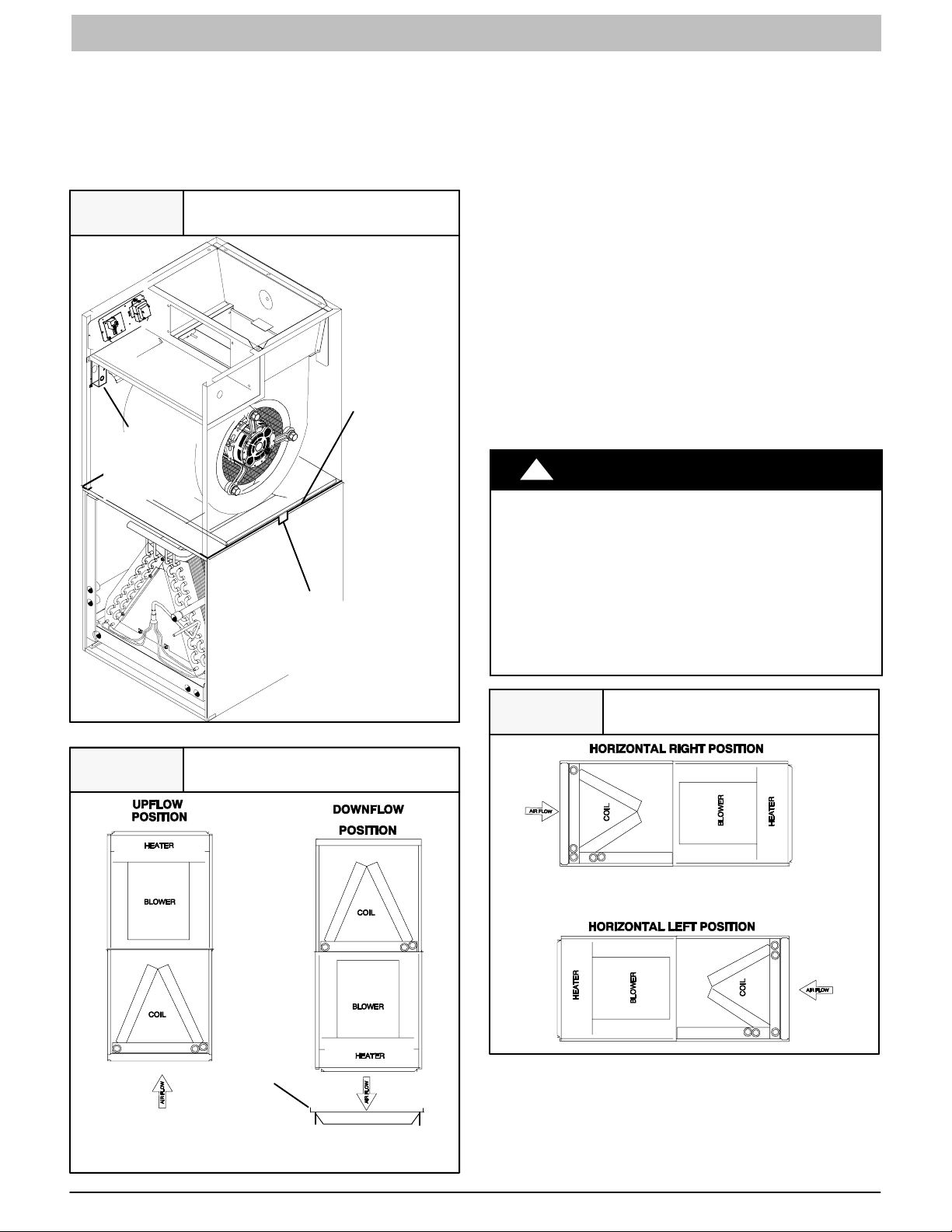

For upflow and horizontal applications apply foam seal strip

around top of coil cabinet. For downflow application apply foam

seal strip around bottom of coil cabinet. Set blower on top of coil

cabinet so they are flush. Secure cabinets together using the

three tabs on the bottom of the cabinet. Bend the tab out from the

bottom so it fits over the coil cabinet. If no pilot holes are present,

drill a hole as required for a screw.

Figure 2

Attach Coil to Blower Cabinet

Panels removed

for clarity only

Place seal

on top of

Coil Cabinet

Low

voltage

around

perimeter

wiring

splice box

Bend Tabs (both sides

and back) on Bottom of

Blower Cabinet to Fit

over Coil Cabinet

DOWNFLOW INSTALLATIONS

Refer to instructions with Subbase Kit.

NON-DUCTED RETURN AIR CLOSET

INSTALLATION

Thecabinetcanbeinstalledinaclosetwithafalsebottomtoform

a return air plenum, or mounted on an open platform inside the

closet. Platform should be high enough to provide a free (open)

area for adequate return airflow into the bottom of the cabinet.

The open area can be on the front side or a combination of front

and sides, providing there is clearance on the sides between

cabinet and closet.Refer to ACCA Manual D for sizing and free

area recommendations.

NOTE: Local codes may limit application of systems without a

ducted return to single story dwellings.

HORIZONTAL LEFT AND RIGHT

INSTALLATIONS

The modular blower cabinets can be installed in either downflow,

horizontal left, or horizontalrightapplications. When a coil cabinet

is applied, refer to the coil installation manual for proper drain pan

and airflow requirements. They must have the drain pan

repositioned for right hand airflow. Refer to coil installation

manual.

!

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property

damage.

A field fabricated auxiliary drain pan, with a separate

drain is REQUIRED for all installations over a finished living space or in any area that may be damaged by overflow from a restricted main drain pan.

In some localities, local codes require an auxiliary

drain pan for ANY horizontal installation.

CAUTION

Figure 3

Airflow Positions

Subbase

Accessory

Figure 4

Airflow Positions

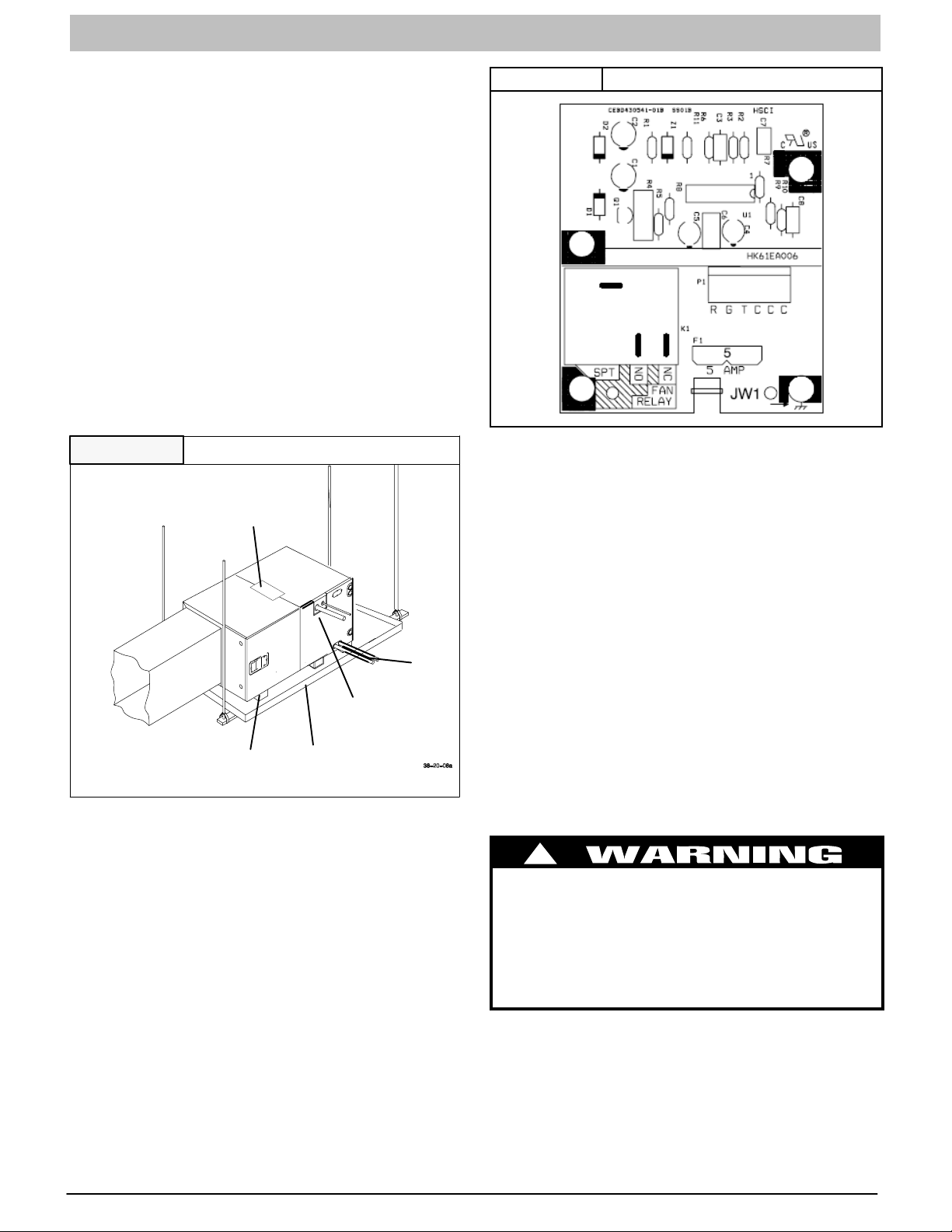

SUSPENDED CABINET INSTALLATION

1. The cabinet may be supported on a frame or shelf, or it may

be suspended.

2. Use metal strapping or threaded rod with angle iron

supports under the auxiliary drain pan to suspend cabinet.

These supports MUST run parallel with the length of the

cabinet. Refer to Figure 5.

442 01 2205 01

3

MODULAR BLOWER: MFINSTALLATION INSTRUCTIONS

3. Ensure that there is adequate room to remove service and

access panels after installing supporting brackets.

4. Place field installed vibration isolators in auxiliary drain pan

to support cabinet.

DUCT CONNECTIONS

Supply Duct

Supply duct must be attached to the outside of flange on outlet

end of unit. Flexible connectors may be used if desired. Maintain

clearances from supply duct to combustibles when heaters are

installed. Refer to Figure 1 and unit rating plate.

Return Duct

Return duct should be attached to bottom of unit using sheet

metal screws or other fasteners.

FILTER INSTALLATION

Filters must be field supplied. A remote filter grille or other means

must be provided. Refer to ACCA Manual D for remote filter

sizing.

Figure 5

Supports MUST run parallel with blower cabinet

Horizontal Installation

See Note

Below

Refrigerant

Lines

Vibration

Isolators

Field-Fabricated

Drain Pan

Drain

Lines

Figure 6 Fan Control Board

All electrical work MUST conform with the requirements of local

codes and ordinances and the National Electrical Code NFPA 70

current edition.

The low voltage transformer and the fan control are standard on

all models and are prewired at the factory. Line voltage

connections are made to the heater accessory or the lugs on the

No Heat Kit.

OVERCURRENT PROTECTION

The power supply wiring to the unit MUST be provided with

overcurrent protection. Governing codes may require this to be

fuses ONLY or circuit breakers.

For blower cabinets without heaters, a 15 amp circuit may be

used.

Before proceeding with electrical connections, make certain that

supply voltage, frequency, phase, and circuit ampacity are as

specified on the unit rating plate. See unit wiring label for proper

field high and low voltage wiring. Make all electrical connections

in accordance with the NEC and any local codes or ordinances

that may apply. Use copper wire only. The unit must have a

separate branch electric circuit with a field--supplied disconnect

switch located within sight from and readily accessible from the

unit.

NOTE: When a pull--out type disconnect is removed from the unit,

only the Load side of the circuit is de--energized. The Line side

remains live until the main (remote) disconnect is turned off.

NOTE: If increased structural strength is needed in the horizontal position, use field supplied two connecting plates in

place of the tabs on the bottom of the blower.

ELECTRICAL CONNECTIONS

The MF modular blower utilizes an electronic fan control board

which has a low voltage circuit protective fuse (5 AMP), and pigtail

connections for thermostat hook up. The fan control also has a

relay for blower operation, and built in 90 second blower--off time

delay relay (TDR). To disable the TDR feature, snip the jumper

wire JW1. Refer to Figure 6.

4

!

ELECTRICAL SHOCK or UNIT DAMAGE HAZARD

Failure to follow this warning could result in personal injury, death, and/or property damage.

If a disconnect switch is to be mounted on unit,

select a location where drill and fasteners will not

contact electrical refrigeration components.

442 01 2205 01

Loading...

Loading...