International Comfort Products CCA924GKA100, HCA924GKA100, TCA924GKA100, CCA936GKA100, HCA936GKA100 User Manual

...

TECHNICAL SUPPORT MANUAL

Two Stage Split System Air Conditioner

(C,H,T)CA9

Safety Labeling and Signal Words

DANGER, WARNING, CAUTION, and

NOTE

The signal words DANGER, WARNING,

CAUTION, and NOTE are used to identify levels of

hazard seriousness. The signal word DANGER is

only used on product labels to signify an immediate

hazard. The signal words WARNING, CAUTION,

and NOTE will be used on product labels and

throughout this manual and other manuals that may

apply to the product.

DANGER -- Immediate hazards which will result in

severe personal injury or death.

WARNING -- Hazards or unsafe practices which

could result in severe personal injury or death.

CAUTION -- Hazards or unsafe practices which

may result in minor personal injury or product or

property damage.

NOTE -- Used to highlight suggestions which will

result in enhanced installation, reliability, or operation.

Signal Words in Manuals

The signal word WARNING is used throughout this

manual in the following manner:

!

The signal word CAUTION is used throughout this

manual in the following manner:

!

Signal Words on Product Labeling

Signal words are used in combination with colors

and/or pictures on product labels.

WARNING

WARNING

CAUTION

TABLE OF CONTENTS

Model Number Identification 2--3...................

R--410A Quick Reference Guide 4..................

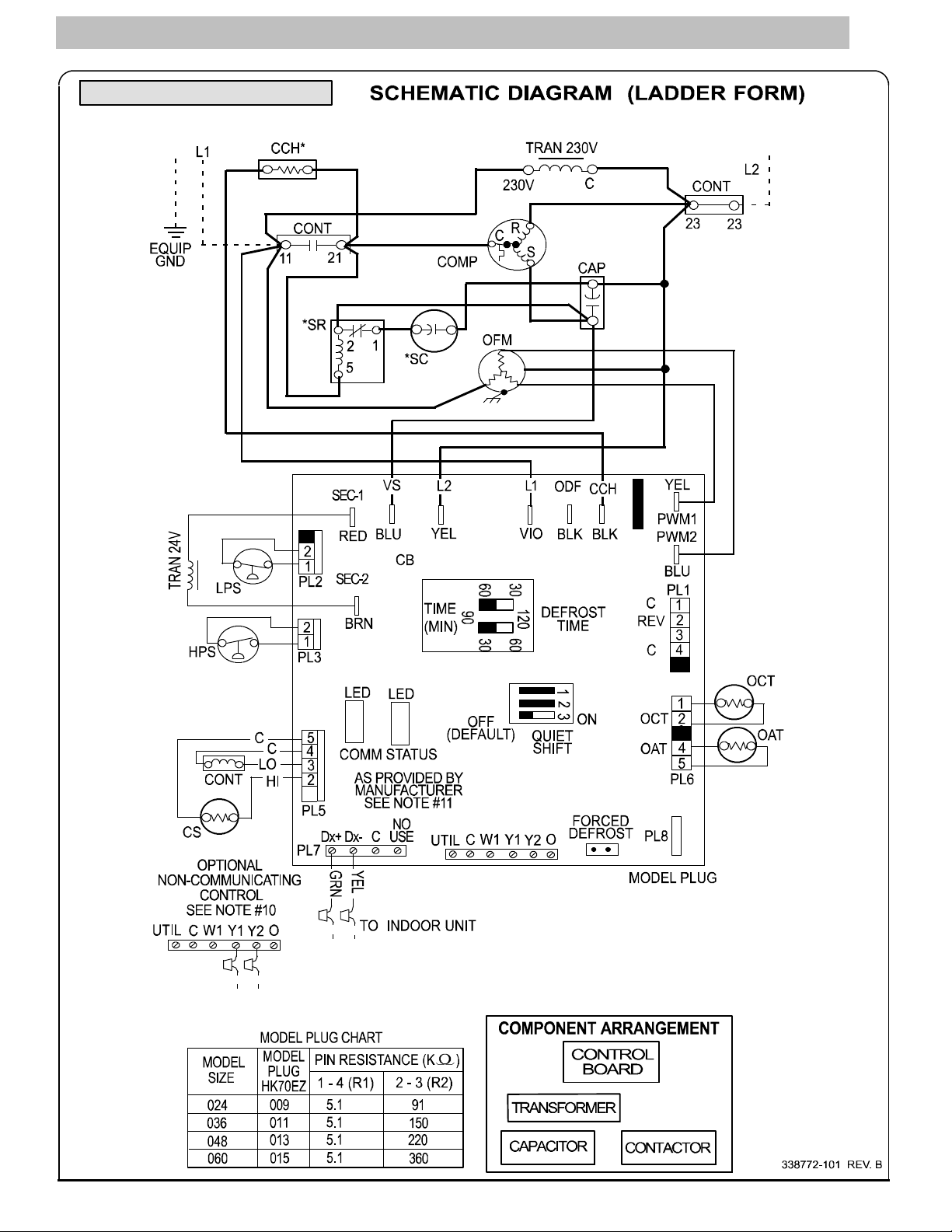

Wiring Diagram Connection 5......................

Wiring Diagram Schematic 6......................

R--410A Charging Chart 7.........................

Flash Code 7....................................

Tech Labels (Expanded Data) 8--10.................

Cooling Multiplying Factors 1 1--37..................

Physical Data 38.................................

Accessories 39..................................

CCA9,HCA9,TCA9 Parts List 40--41................

Exploded Drawings 42-- 44.........................

MODELS

CCA924GKA100 HCA924GKA100 TCA924GKA100

CCA936GKA100 HCA936GKA100 TCA936GKA100

CCA948GKA100 HCA948GKA100 TCA948GKA100

CCA960GKA100 HCA960GKA100 TCA960GKA100

!

DEATH, PERSONAL INJURY, AND/OR PROPERTY

DAMAGE HAZARD

Failure to carefully read and follow this warning

could result in equipment malfunction, property

damage, personal injury and/or death.

Installation or repairs made by unqualified persons couldresult in equipment malfunction, property damage, personal injury and/or death.

The information contained in this manual is intended for use by aqualified service technician familiar with safety procedures and equipped with the

proper tools and test instruments.

Installation must conform with local building

codes and with the National Electrical Code

NFPA70 current edition or Canadian Electrical

Code Part 1 CSA C.22.1.

WARNING

421 04 1801 00 February 2012

TECHNICAL SUPPORT MANUAL Split System Air Conditioner: (C,H,T)CA9

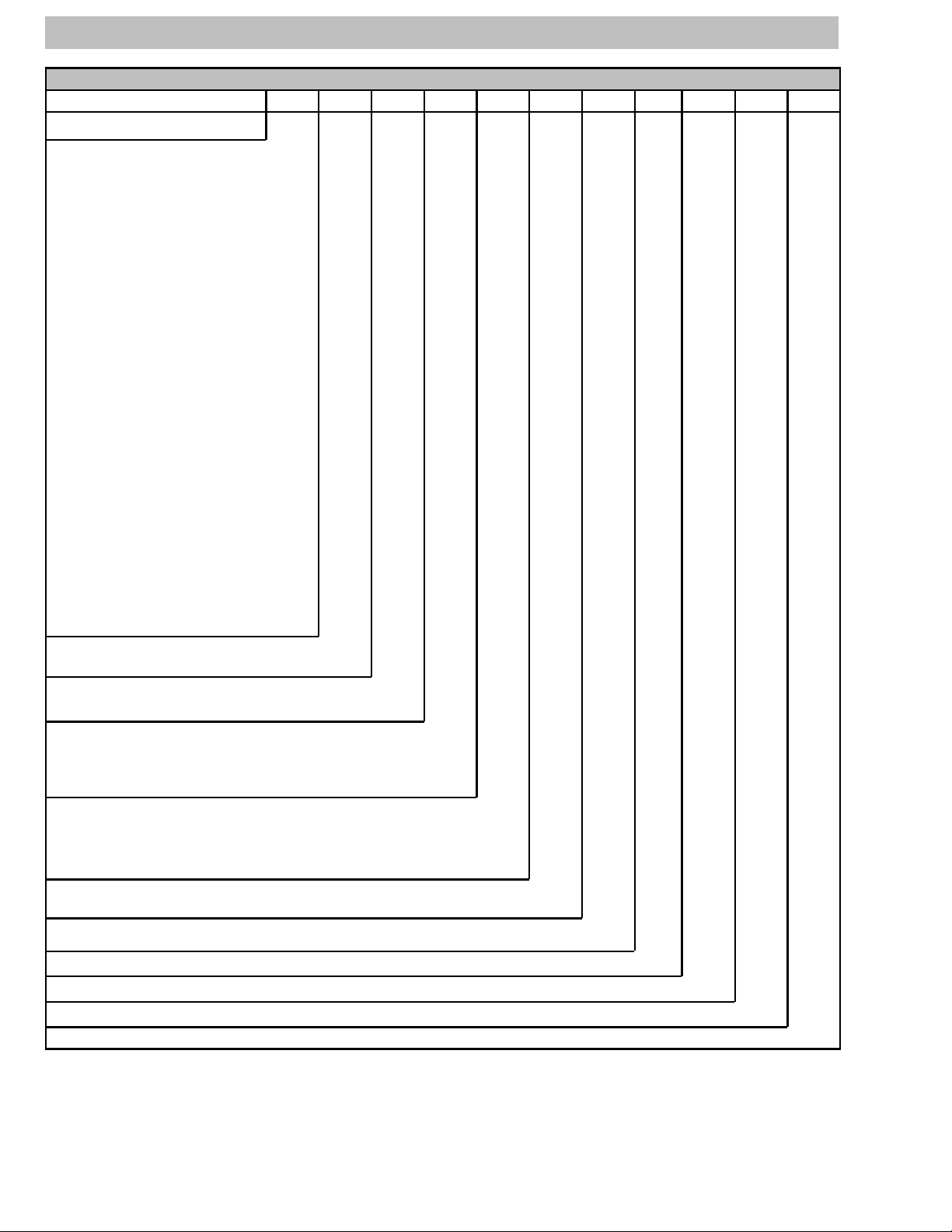

OUTDOOR UNIT MODEL NUMBER IDENTIFICATION GUIDE (single phase)

Digit Position: 1 2 3 4 5, 6 7 8 9 10 11 12

Example Part Number:

HCT C A 9 24 G K A 1 0 0

H = Heil Mainline

T = T empstar Mainline

H = Arcoaire Mainline

C = Comfortmaker Mainline

C = Day & Night Mainline

H = Airquest Mainline

C = Keeprite Mainline

C = Kenmore Mainline

H = Kenmore Mainline

T = Kenmore Mainline

H = ICP Commercial Mainline

N = Tempstar Entry BRANDING

N = Arcoaire Entry BRANDING

N = Comfortmaker Entry BRANDING

N = Day & Night Entry BRANDING

N = Airquest Entry BRANDING

N = Keeprite Entry BRANDING

N = Kenmore Entry BRANDING

N = Kenmore Entry BRANDING

N = Kenmore Entry BRANDING

N = ICP Commercial Entry BRANDING

C = Communicating

CHARACTERISTIC

A = Air Conditioner

H = Heat Pump

6 = 16 SEER

7 = 17 SEER

8 = 18 SEER

9 = 19 SEER

24 = 24,000 BTUH = 2 tons

36 = 36,000 BTUH = 3 tons

48 = 48,000 BTUH = 4 tons

60 = 60,000 BTUH = 5 tons

KEY

TYPE

NOMINAL EFFICIENCY

NOMINAL CAPACITY

G = Coil Guard Grille

K = 208/230--1--60

FEATURES

VOLTAGE

Sales Code

Engineering Revision

Extra Digit

Extra Digit

2 421 04 1801 00

TECHNICAL SUPPORT MANUAL Split System Air Conditioner: (C,H,T)CA9

ACCESSORIES PART NUMBER IDENTIFICATION GUIDE

Digit Position: 1 2 3 4 5 6, 7 8, 9 10, 11

Example Part Number:

N = Non-- Branded

A = Accessory PRODUCT GROUP

S = Split System (AC & HP) KIT USAGE

A = Original

B = 2nd Generation MAJOR SERIES

0 = Generic or Not Applicable

2=R--22

4 = R-- 410A REFRIGERANT

Product Identifier Number

Package Quantity

Type of Kit (Example: CH = Crankcase Heater)

N A S A 0 01 01 CH

421 04 1801 00 3

TECHNICAL SUPPORT MANUAL Split System Air Conditioner: (C,H,T)CA9

R--410A QUICK REFERENCE GUIDE

• R--410A refrigerant operates at 50% -- 70% higher pressures than R--22. Be sure that servicing equipment and

replacement components are designed to operate with R--410A.

• R--410A refrigerant cylinders are rose colored.

• Recovery cylinder service pressure rating must be 400 psig, DOT 4BA400 or DOT BW400.

• R--410A systems should be charged with liquid refrigerant. Use a commercial type metering device in the

manifold hose when charging into suction line with compressor operating.

• Manifold sets should be 750 psig high--side and 200 psig low--side with 520 psig low--side retard.

• Use hoses with 750 psig service pressure rating.

• Leak detectors should be designed to detect HFC refrigerant.

• R--410A, as with other HFC refrigerants, is only compatible with POE oils.

• Vacuum pumps will not remove moisture from oil.

• Do not use liquid line filter--driers with rated working pressures less than 600 psig.

• Do not install a suction line filter--drier in liquid line.

• POE oils absorb moisture rapidly. Do not expose oil to atmosphere.

• POE oils may cause damage to certain plastics and roofing materials.

• Wrap all filter--driers and service valves with wet cloth when brazing.

• A liquid line filter--drier is required on every unit.

• Do not use with an R--22 TXV.

• If indoor unit is equipped with an R--22 TXV, it must be changed to an R--410A TXV.

• Never open system to atmosphere while it is under a vacuum.

• When system must be opened for service, break vacuum with dry nitrogen and replace all filter--driers. Evacuate

to 500 microns before recharging.

• Do not vent R--410A into the atmosphere.

• Do not use capillary tube indoor coils.

• Observe all WARNINGS, CAUTIONS, NOTES, and bold text.

International Comfort Products, LLC

Lewisburg, TN 37091 USA

4 421 04 1801 00

TECHNICAL SUPPORT MANUAL Split System Air Conditioner: (C,H,T)CA9

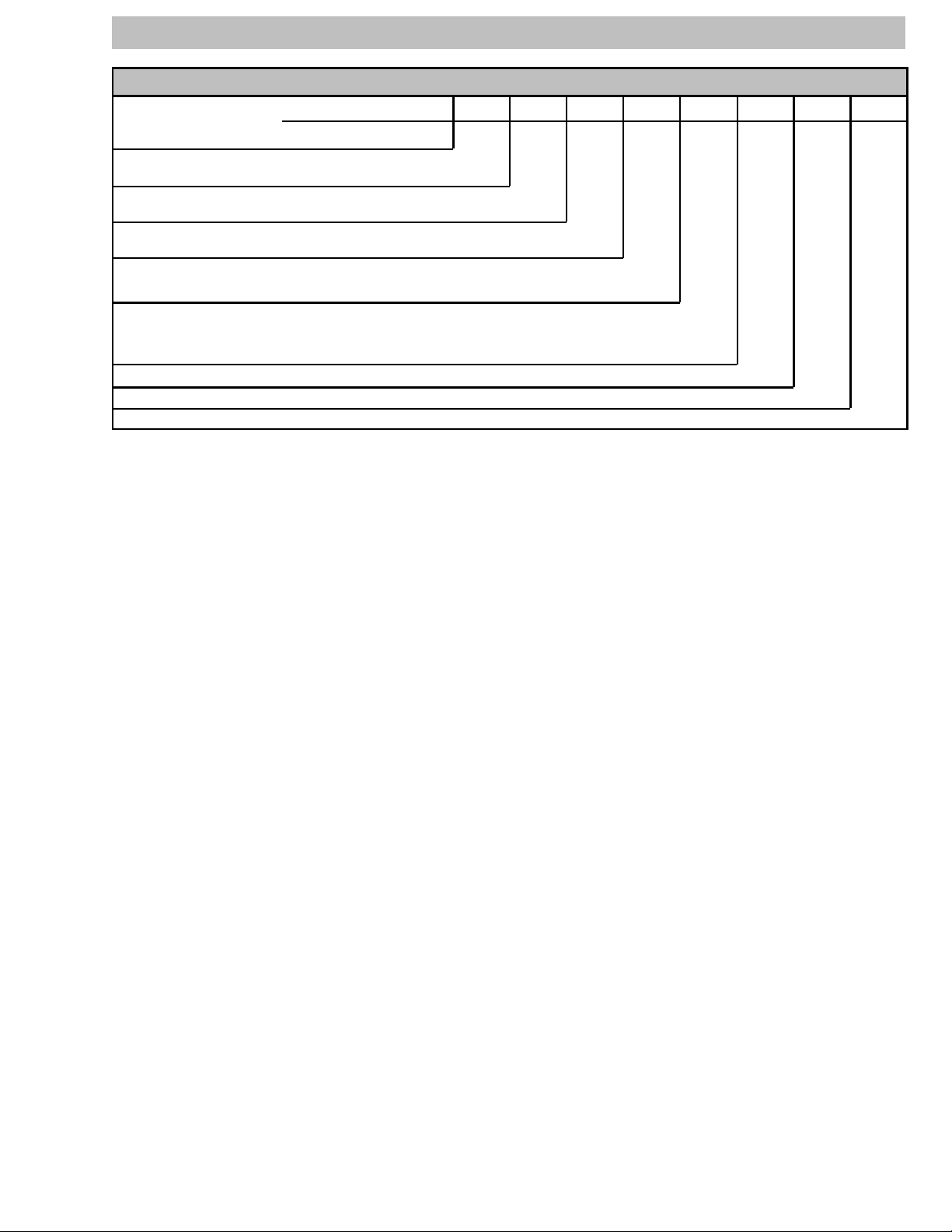

Model Sizes: 24, 36, 48, 60

421 04 1801 00 5

TECHNICAL SUPPORT MANUAL Split System Air Conditioner: (C,H,T)CA9

Model Sizes: 24, 36, 48, 60

6 421 04 1801 00

TECHNICAL SUPPORT MANUAL Split System Air Conditioner: (C,H,T)CA9

R--410A CHARGING CHART

Rating Plate (required) Subcooling Temperature ° F(° C)

Measured Liquid

Pressure (psig)

251 78 26 76 24 74 23 72 22 70 21 68 20

259 80 27 78 26 76 24 74 23 72 22 70 21

266 82 28 80 27 78 26 76 24 74 23 72 22

274 84 29 82 28 80 27 78 26 76 24 74 23

283 86 30 84 29 82 28 80 27 78 26 76 24

291 88 31 86 30 84 29 82 28 80 27 78 26

299 90 32 88 31 86 30 84 29 82 28 80 27

308 92 33 90 32 88 31 86 30 84 29 82 28

317 94 34 92 33 90 32 88 31 86 30 84 29

326 96 36 94 34 92 33 90 32 88 31 86 30

335 98 37 96 36 94 34 92 33 90 32 88 31

345 100 38 98 37 96 36 94 34 92 33 90 32

364 104 40 102 39 100 38 98 37 96 36 94 34

374 106 41 104 40 102 39 100 38 98 37 96 36

384 108 42 106 41 104 40 102 39 100 38 98 37

395 110 43 108 42 106 41 104 40 102 39 100 38

406 112 44 11 0 43 108 42 106 41 104 40 102 39

416 114 46 11 2 44 11 0 43 108 42 106 41 104 40

427 116 47 11 4 46 11 2 44 110 43 108 42 106 41

439 118 48 11 6 47 11 4 46 112 44 11 0 43 108 42

450 120 49 118 48 11 6 47 11 4 46 11 2 44 110 43

462 122 50 120 49 118 48 116 47 114 46 112 44

474 124 51 122 50 120 49 118 48 116 47 11 4 46

° F (° C) ° F (° C) ° F (° C) ° F (° C) F (° C) F (° C)

6 3 8 4 10 6 12 7 14 8 16 9

R-- 410A Required Liquid Line Temperature ° F(° C)

FLASH CODE

On, No Flash

1, Pause

2, Pause

Continuous Flash

16

25

31

32

45

46

47

Short flashes indicate the first digit in the status code, followed by long flashes indicating the second digit of the status code.

This control board contains a five minute short cycle protector. A five minute delay will occur between compressor

off/on cycles. To bypass delay, short forced defrost pins for 1 second then release. The crankcase heater is

energized during off cycle below 65ºF.

FAULT DEFINITION

Standby

Low Stage

High Stage

Emergency Mode

System Communications Failure

Invalid Model Plug

High Pressure Switch Trip

Low Pressure Switch Trip

Control Fault

Brown out (230V)

No 230v with Call to Run

UNIT OPERATION

FLASH CODE

53

55

56

71

72

73

74

81

82

83

84

FAULT DEFINITION

Outdoor Air Temp Sensor

Coil Temp Sensor

Temp Sensor Range Error

Low Stage Thermal Cutout

High Stage Thermal Cutout

Contactor Shorted

Contactor Open (No 230v to Comp)

Low Stage Thermal Lockout (4 HRS)

High Stage Thermal Lockout (4 HRS)

Low Pressure Lockout (4 HRS)

High Pressure Lockout (4 HRS)

421 04 1801 00 7

TECHNICAL SUPPORT MANUAL Split System Air Conditioner: (C,H,T)CA9

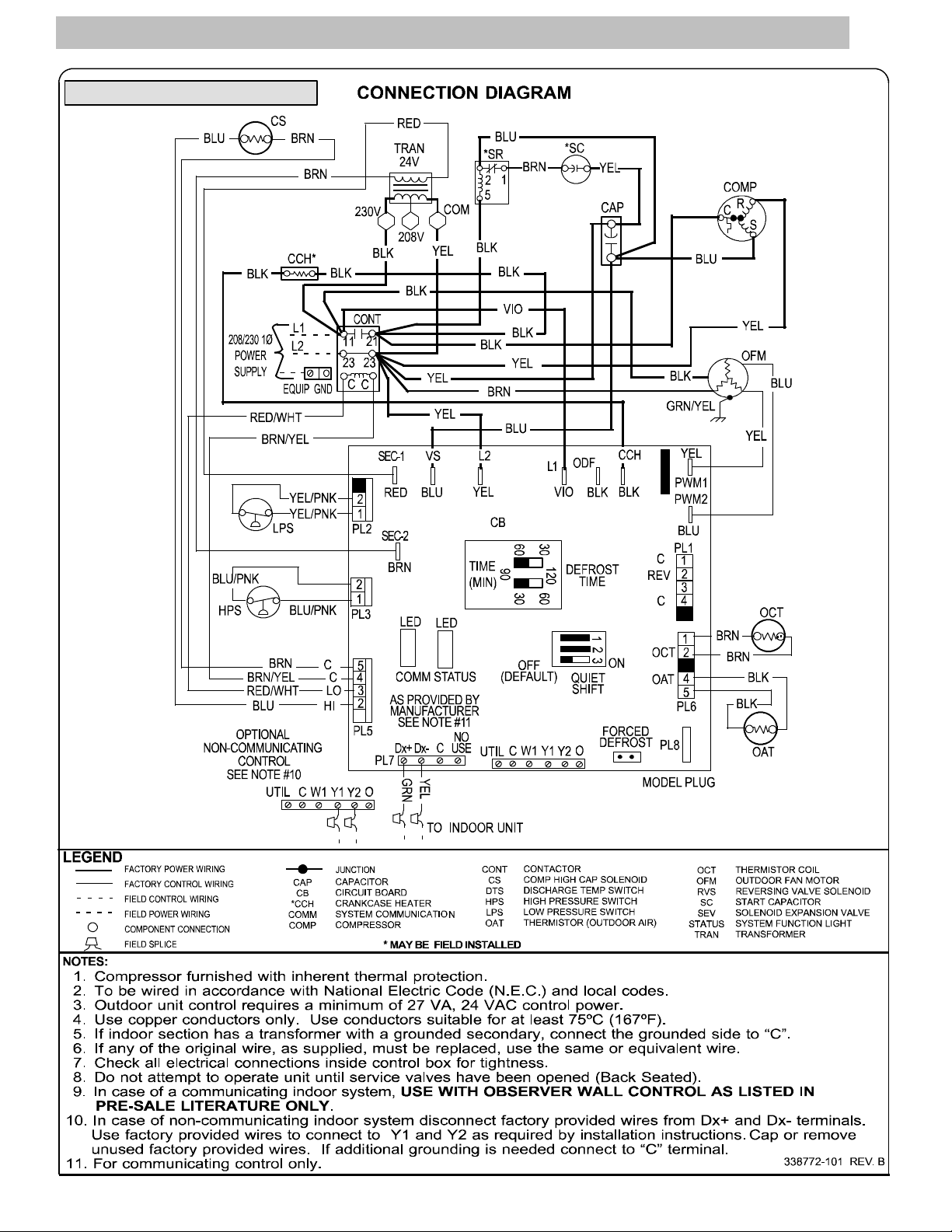

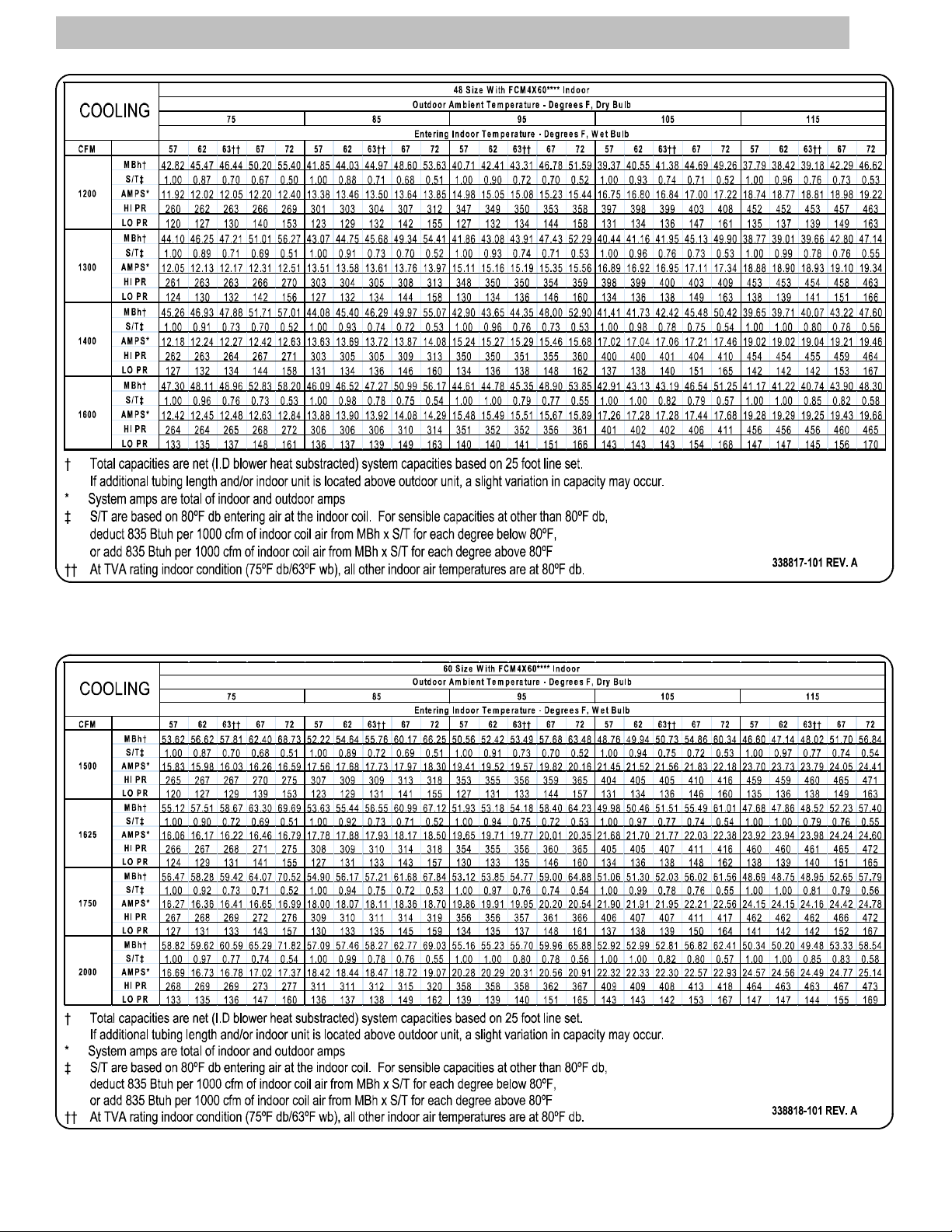

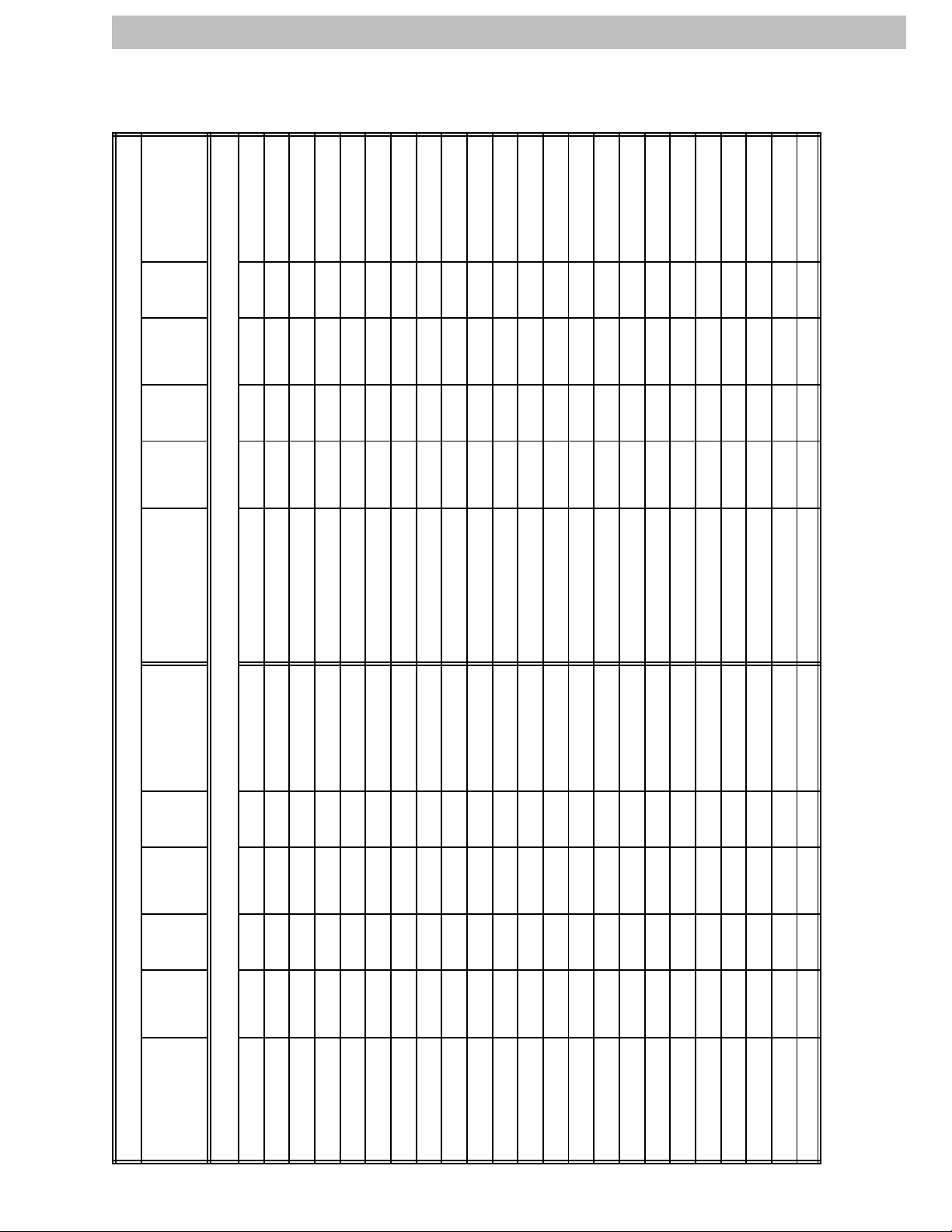

† Total capacities are net (I.D. blower heat subtracted) system capacities based on 25’ line set.

If additional tubing length and/or indoor unit is located above outdoor unit, a slight variation in capacity may occur.

†† At TVA rating indoor condition (75 °F db, 63 °F wb), all other indoor air temperatures are at 80 ° Fdb

If additional tubing length and/or indoor unit is located above outdoor unit, a slight variation in capacity may occur.

^ System amps are total of indoor and outdoor amps.

‡ Chart data is for 80° F indoor dry bulb. For indoor db temperatures other than 80° F, measure Indoor db and Indoor CFM, and plug these

into the

formula below. Measure outdoor db and indoor wet bulb, apply these to the chart above, find MBh and S/T, and plug these into the formula

below.

(Note: if indoor db is the only thing changing, total capacity, MBh, stays the same.).05

Sensible Capacity at Indoor db LOWER than 80 ° F=(MBhxS/T) --

Sensible Capacity at Indoor db HIGHER than 80 ° F=(MBhxS/T) +

( 80 -- Indoor db ) x 835 x Indoor CFM

(

( Indoor db -- 80 ) x 835 x In-

(

door CFM

1000

1000

)

)

8 421 04 1801 00

TECHNICAL SUPPORT MANUAL Split System Air Conditioner: (C,H,T)CA9

421 04 1801 00 9

TECHNICAL SUPPORT MANUAL Split System Air Conditioner: (C,H,T)CA9

10 421 04 1801 00

TECHNICAL SUPPORT MANUAL Split System Air Conditioner: (C,H,T)CA9

POWER FURNACE MODEL

LOW

SPEED

CAPACITY

POWER

HIGH

SPEED

CAPACITY

MODEL

COOLING INDOOR

(C,H,T)CA9 24

POWER FURNACE MODEL

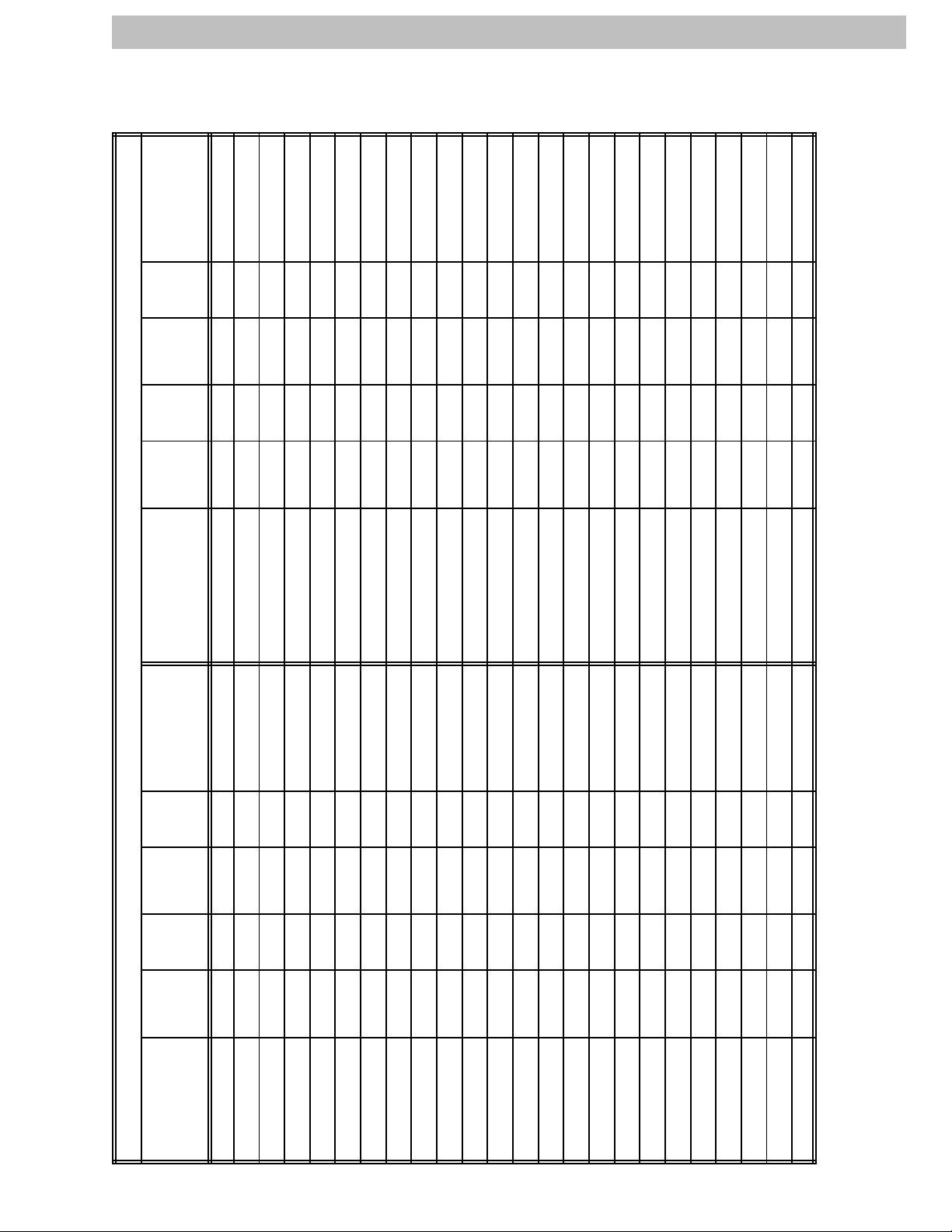

COOLING Multiplying Factors for other Indoor Combinations 33

LOW

SPEED

CAPACITY

POWER

HIGH

SPEED

CAPACITY

MODEL

*FCM4X48**** 1.00 1.00 1.00 1.00 EN(A,D)4X24*17** 0.95 1.02 0.95 1.06 *9MA*0801714A**

EA*4X24*14A* 0.97 1.02 0.96 1.04 *8MV*0701412** EN(A,D)4X24*17** 0.93 1.06 0.9 1.01 *9MV*0401410A**

EA*4X24*14A* 0.94 1.02 0.92 0.98 *8MX*0451408** EN(A,D)4X24*17** 0.94 1.02 0.92 0.99 *9MV*0601714A**

EA*4X24*14A* 0.94 1.06 0.91 1.02 *9MV*0401410A** EN(A,D)4X24*17** 0.94 1.01 0.92 0.98 *9MV*0801716A**

EA*4X24*14A* 0.94 1.12 0.92 1.17 EN(A,D)4X24*17** 0.94 1.10 0.9 1.00 *9MX*0401410A**

EA*4X24*17A* 0.97 1.02 0.97 1.04 *8MV*0701412** EN(A,D)4X24*17** 0.97 1.08 0.95 1.02 *9MX*0601714A**

EA*4X24*17A* 0.97 1.02 0.97 1.02 *8MV*0901716** EN(A,D)4X24*17** 0.95 1.00 0.92 0.95 MV08B15**B*

EA*4X24*17A* 0.95 1.02 0.92 0.98 *8MX*0451408** EN(A,D)4X24*17** 0.97 1.08 0.91 0.96 OLV098A12A

EA*4X24*17A* 0.95 1.04 0.95 1.06 *9MA*0601714A** EN(A,D)4X24*17** 0.95 1.04 0.91 0.96 OMV098J12A

EA*4X24*17A* 0.95 1.02 0.95 1.04 *9MA*0801714A** EN(A,D)4X24*17** 0.97 1.06 0.97 1.03 OMV112K14A

EA*4X24*17A* 0.94 1.06 0.91 1.02 *9MV*0401410A** EN(A,D)4X24*17** 0.94 1.12 0.92 1.16

EA*4X24*17A* 0.94 1.01 0.93 0.99 *9MV*0601714A** EN(A,D)4X30*14** 0.98 1.03 0.97 1.05 *8MV*0701412**

EA*4X24*17A* 0.94 1.02 0.93 0.98 *9MV*0801716A** EN(A,D)4X30*14** 0.95 1.02 0.92 0.98 *8MX*0451408**

EA*4X24*17A* 0.94 1.10 0.9 0.99 *9MX*0401410A** EN(A,D)4X30*14** 0.94 1.06 0.91 1.02 *9MV*0401410A**

EA*4X24*17A* 0.97 1.06 0.95 1.01 *9MX*0601714A** EN(A,D)4X30*14** 0.95 1.11 0.9 0.99 *9MX*0401410A**

EA*4X24*17A* 0.95 0.99 0.92 0.94 MV08B15**B* EN(A,D)4X30*14** 0.95 1.13 0.92 1.17

EA*4X24*17A* 0.97 1.06 0.9 0.95 OLV098A12A EN(A,D)4X30*17** 0.98 1.03 0.97 1.03 *8MV*0701412**

EA*4X24*17A* 0.95 1.02 0.91 0.95 OMV098J12A EN(A,D)4X30*17** 0.98 1.01 0.97 1.01 *8MV*0901716**

EA*4X24*17A* 0.98 1.05 0.97 1.01 OMV112K14A EN(A,D)4X30*17** 0.96 1.03 0.93 0.98 *8MX*0451408**

EA*4X24*17A* 0.94 1.12 0.92 1.17 EN(A,D)4X30*17** 0.96 1.03 0.95 1.05 *9MA*0601714A**

EA*4X30*14A* 0.98 1.03 0.97 1.04 *8MV*0701412** EN(A,D)4X30*17** 0.96 1.03 0.96 1.04 *9MA*0801714A**

EA*4X30*14A* 0.95 1.02 0.92 0.98 *8MX*0451408** EN(A,D)4X30*17** 0.94 1.07 0.91 1.01 *9MV*0401410A**

COOLING INDOOR

EA*4X30*14A* 0.94 1.06 0.91 1.02 *9MV*0401410A** EN(A,D)4X30*17** 0.95 1.02 0.93 0.99 *9MV*0601714A**

421 04 1801 00 11

TECHNICAL SUPPORT MANUAL Split System Air Conditioner: (C,H,T)CA9

FURNACE MODELPOWER

LOW

SPEED

CAPACITY

POWER

COOLING Multiplying Factors for other Indoor Combinations (continued)33

HIGH

LOW

SPEED

MODEL

COOLING INDOOR

FURNACE MODELPOWER

SPEED

CAPACITY

CAPACITY

POWER

HIGH

SPEED

CAPACITY

MODEL

EA*4X30*14A* 0.95 1.11 0.9 0.99 *9MX*0401410A** EN(A,D)4X30*17** 0.95 1.00 0.94 0.99 *9MV*0801716A**

EA*4X30*14A* 0.95 1.13 0.92 1.17 EN(A,D)4X30*17** 0.95 1.11 0.90 0.99 *9MX*0401410A**

EA*4X30*17A* 0.98 1.03 0.97 1.03 *8MV*0701412** EN(A,D)4X30*17** 0.98 1.08 0.95 1.02 *9MX*0601714A**

EA*4X30*17A* 0.98 1.01 0.97 1.01 *8MV*0901716** EN(A,D)4X30*17** 0.96 1.00 0.92 0.94 MV08B15**B*

EA*4X30*17A* 0.96 1.03 0.93 0.98 *8MX*0451408** EN(A,D)4X30*17** 0.98 1.05 0.91 0.95 OLV098A12A

EA*4X30*17A* 0.96 1.03 0.95 1.05 *9MA*0601714A** EN(A,D)4X30*17** 0.96 1.03 0.91 0.95 OMV098J12A

EA*4X30*17A* 0.96 1.01 0.95 1.03 *9MA*0801714A** EN(A,D)4X30*17** 0.98 1.04 0.97 1,00 OMV112K14A

EA*4X30*17A* 0.94 1.07 0.91 1.02 *9MV*0401410A** EN(A,D)4X30*17** 0.95 1.13 0.92 1.17

EA*4X30*17A* 0.95 1.02 0.93 0.99 *9MV*0601714A** EN(A,D)4X31*17** 0.99 1.03 0.99 1.03 *8MV*0701412**

EA*4X30*17A* 0.95 1.00 0.94 0.99 *9MV*0801716A** EN(A,D)4X31*17** 1.00 1.01 1.00 1.02 *8MV*0901716**

EA*4X30*17A* 0.95 1.11 0.9 0.99 *9MX*0401410A** EN(A,D)4X31*17** 0.98 1.03 0.95 0.98 *8MX*0451408**

EA*4X30*17A* 0.98 1.08 0.95 1.02 *9MX*0601714A** EN(A,D)4X31*17** 0.98 1.04 0.98 1.05 *9MA*0601714A**

EA*4X30*17A* 0.96 1.00 0.92 0.94 MV08B15**B* EN(A,D)4X31*17** 0.98 1.02 0.98 1.03 *9MA*0801714A**

EA*4X30*17A* 0.98 1.05 0.9 0.94 OLV098A12A EN(A,D)4X31*17** 0.97 1.06 0.93 1.02 *9MV*0401410A**

EA*4X30*17A* 0.96 1.03 0.91 0.95 OMV098J12A EN(A,D)4X31*17** 0.97 1.02 0.95 0.99 *9MV*0601714A**

EA*4X30*17A* 0.98 1.04 0.97 1.00 OMV112K14A EN(A,D)4X31*17** 0.98 1.01 0.96 1.00 *9MV*0801716A**

EA*4X30*17A* 0.95 1.13 0.92 1.17 EN(A,D)4X31*17** 0.98 1.11 0.92 0.99 *9MX*0401410A**

EA*4X36*14A* 0.98 1.03 0.97 1.04 *8MV*0701412** EN(A,D)4X31*17** 1.01 1.08 0.97 1.02 *9MX*0601714A**

EA*4X36*14A* 0.96 1.03 0.93 0.98 *8MX*0451408** EN(A,D)4X31*17** 0.98 0.99 0.94 0.94 MV08B15**B*

EA*4X36*14A* 0.94 1.07 0.91 1.01 *9MV*0401410A** EN(A,D)4X31*17** 1.00 1.05 0.92 0.94 OLV098A12A

EA*4X36*14A* 0.96 1.12 0.9 0.99 *9MX*0401410A** EN(A,D)4X31*17** 0.98 1.03 0.93 0.95 OMV098J12A

EA*4X36*14A* 0.95 1.13 0.92 1.16 EN(A,D)4X31*17** 1.01 1.04 0.99 1.00 OMV112K14A

EA*4X36*17A* 0.98 1.01 0.97 1.03 *8MV*0701412** EN(A,D)4X31*17** 0.98 1.14 0.94 1.16

COOLING INDOOR

EA*4X36*17A* 0.98 1.01 0.97 1,00 *8MV*0901716** EN(A,D)4X36*21** 0.98 1.01 0.97 1.01 *8MV*0901716**

12 42104180100

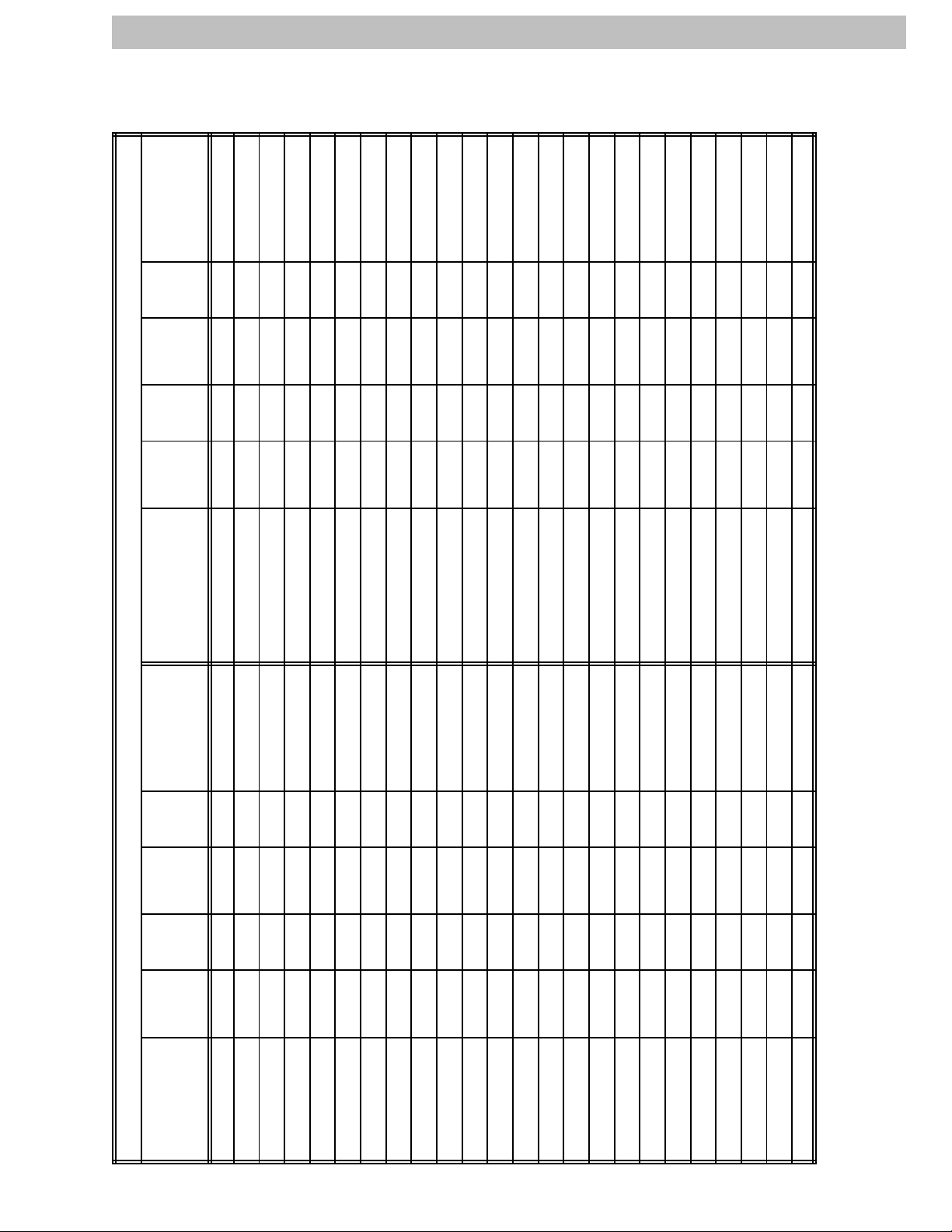

TECHNICAL SUPPORT MANUAL Split System Air Conditioner: (C,H,T)CA9

FURNACE MODELPOWER

LOW

SPEED

CAPACITY

POWER

COOLING Multiplying Factors for other Indoor Combinations (continued)33

HIGH

LOW

SPEED

MODEL

COOLING INDOOR

FURNACE MODELPOWER

SPEED

CAPACITY

CAPACITY

POWER

HIGH

SPEED

CAPACITY

MODEL

EA*4X36*17A* 0.96 1.01 0.93 0.98 *8MX*0451408** EN(A,D)4X36*21** 0.98 1.01 0.97 1.02 *8MV*1102120**

EA*4X36*17A* 0.96 1.03 0.96 1.05 *9MA*0601714A** EN(A,D)4X36*21** 0.96 1.03 0.95 1.05 *9MA*0601714A**

EA*4X36*17A* 0.97 1.02 0.96 1.03 *9MA*0801714A** EN(A,D)4X36*21** 0.96 1.03 0.96 1.05 *9MA*0602120A**

EA*4X36*17A* 0.94 1.06 0.92 1.02 *9MV*0401410A** EN(A,D)4X36*21** 0.96 1.01 0.96 1.04 *9MA*0801714A**

EA*4X36*17A* 0.95 1.02 0.94 0.99 *9MV*0601714A** EN(A,D)4X36*21** 0.97 1.02 0.96 1.02 *9MA*0802120A**

EA*4X36*17A* 0.96 1.01 0.95 0.99 *9MV*0801716A** EN(A,D)4X36*21** 0.97 1.02 0.96 1.02 *9MA*1002122A**

EA*4X36*17A* 0.96 1.12 0.91 0.99 *9MX*0401410A** EN(A,D)4X36*21** 0.95 1.02 0.93 0.99 *9MV*0601714A**

EA*4X36*17A* 0.98 1.08 0.95 1.01 *9MX*0601714A** EN(A,D)4X36*21** 0.95 1.00 0.94 0.99 *9MV*0801716A**

EA*4X36*17A* 0.96 1.00 0.92 0.94 MV08B15**B* EN(A,D)4X36*21** 0.98 1.08 0.95 1.02 *9MX*0601714A**

EA*4X36*17A* 0.98 1.06 0.91 0.95 OLV098A12A EN(A,D)4X36*21** 0.96 1,00 0.92 0.95 MV12F19**B*

EA*4X36*17A* 0.96 1.03 0.92 0.95 OMV098J12A EN(A,D)4X36*21** 0.98 1.05 0.91 0.95 OLV098A12A

EA*4X36*17A* 0.98 1.02 0.97 0.99 OMV112K14A EN(A,D)4X36*21** 0.96 1.03 0.91 0.95 OMV098J12A

EA*4X36*17A* 0.95 1.13 0.92 1.16 EN(A,D)4X36*21** 0.98 1.04 0.97 1.00 OMV112K14A

EA*4X36*21A* 0.98 1.01 0.98 1.01 *8MV*0901716** EN(A,D)4X36*21** 0.95 1.13 0.92 1.17

EA*4X36*21A* 0.98 1.01 0.98 1.01 *8MV*1102120** EN(A,D)4X37*17** 1.01 1.02 1.01 1.03 *8MV*0701412**

EA*4X36*21A* 0.97 1.04 0.96 1.04 *9MA*0601714A** EN(A,D)4X37*17** 1.01 1.02 1.01 1.01 *8MV*0901716**

EA*4X36*21A* 0.97 1.02 0.96 1.03 *9MA*0602120A** EN(A,D)4X37*17** 0.99 1.03 0.95 0.98 *8MX*0451408**

EA*4X36*21A* 0.97 1.02 0.96 1.02 *9MA*0801714A** EN(A,D)4X37*17** 0.99 1.03 0.99 1.05 *9MA*0601714A**

EA*4X36*21A* 0.97 1.00 0.96 1.01 *9MA*0802120A** EN(A,D)4X37*17** 0.99 1.03 0.99 1.03 *9MA*0801714A**

EA*4X36*21A* 0.97 1.00 0.96 1.00 *9MA*1002122A** EN(A,D)4X37*17** 0.98 1.07 0.95 1.02 *9MV*0401410A**

EA*4X36*21A* 0.96 1.01 0.95 1.00 *9MV*0601714A** EN(A,D)4X37*17** 0.98 1.02 0.96 1.00 *9MV*0601714A**

EA*4X36*21A* 0.97 1.02 0.95 1.00 *9MV*0801716A** EN(A,D)4X37*17** 0.99 1.03 0.97 0.99 *9MV*0801716A**

EA*4X36*21A* 0.96 1.00 0.92 0.95 MV12F19**B* EN(A,D)4X37*17** 0.98 1.10 0.93 0.99 *9MX*0401410A**

COOLING INDOOR

EA*4X36*21A* 0.98 1.06 0.91 0.95 OLV098A12A EN(A,D)4X37*17** 1.02 1.07 0.99 1.02 *9MX*0601714A**

421 04 1801 00 13

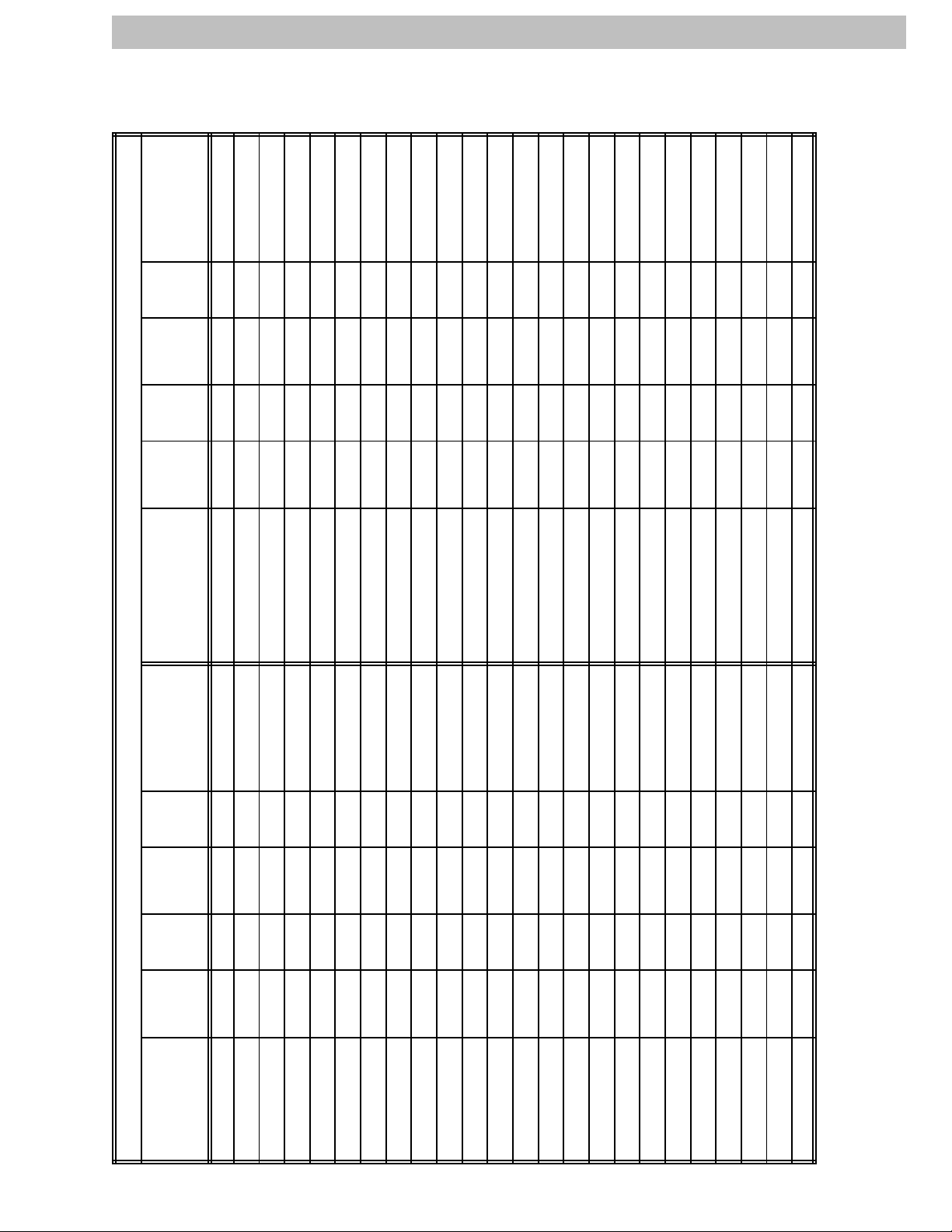

TECHNICAL SUPPORT MANUAL Split System Air Conditioner: (C,H,T)CA9

FURNACE MODELPOWER

LOW

SPEED

CAPACITY

POWER

COOLING Multiplying Factors for other Indoor Combinations (continued)33

HIGH

LOW

SPEED

MODEL

COOLING INDOOR

FURNACE MODELPOWER

SPEED

CAPACITY

CAPACITY

POWER

HIGH

SPEED

CAPACITY

MODEL

COOLING INDOOR

EA*4X36*21A* 0.96 1.01 0.92 0.95 OMV098J12A EN(A,D)4X37*17** 0.98 0.98 0.95 0.94 MV08B15**B*

EA*4X36*21A* 0.99 1.03 0.97 0.98 OMV112K14A EN(A,D)4X37*17** 1.01 1.04 0.93 0.94 OLV098A12A

EA*4X36*21A* 0.95 1.13 0.92 1.16 EN(A,D)4X37*17** 0.98 1.02 0.94 0.95 OMV098J12A

ED*4X24F** 0.95 0.99 0.92 0.94 MV08B15**B* EN(A,D)4X37*17** 0.98 1.15 0.95 1.16

ED*4X24B** 0.95 1.00 0.92 0.95 MV08B15**B* EN(A,D)4X37*17** 1.02 1.03 1.01 1.00 OMV112K14A

ED*4X24F** 0.95 0.99 0.92 0.96 MV12F19**B* EN(A,D,W)4X36*17** 0.98 1.03 0.97 1.03 *8MV*0701412**

ED*4X30F** 0.96 1.00 0.92 0.94 MV08B15**B* EN(A,D,W)4X36*17** 0.96 1.03 0.93 0.98 *8MX*0451408**

ED*4X30B** 0.96 1.00 0.92 0.94 MV08B15**B* EN(A,D,W)4X36*17** 0.98 1.01 0.97 1.01 *8MV*0901716**

ED*4X30F** 0.96 1.00 0.92 0.96 MV12F19**B* EN(A,D,W)4X36*17** 0.96 1.03 0.95 1.05 *9MA*0601714A**

ED*4X36B** 0.96 1.00 0.92 0.94 MV08B15**B* EN(A,D,W)4X36*17** 0.96 1.03 0.96 1.04 *9MA*0801714A**

ED*4X36F** 0.98 1.01 0.97 1.00 *8MV*0901716** EN(A,D,W)4X36*17** 0.94 1.07 0.91 1.01 *9MV*0401410A**

ED*4X36F** 0.98 1.01 0.97 1.01 *8MV*1102120** EN(A,D,W)4X36*17** 0.95 1.02 0.93 0.99 *9MV*0601714A**

ED*4X36F** 0.96 1.03 0.96 1.05 *9MA*0601714A** EN(A,D,W)4X36*17** 0.95 1.00 0.94 0.99 *9MV*0801716A**

ED*4X36F** 0.97 1.02 0.96 1.03 *9MA*0801714A** EN(A,D,W)4X36*17** 0.95 1.11 0.9 0.99 *9MX*0401410A**

ED*4X36F** 0.95 1.02 0.94 0.99 *9MV*0601714A** EN(A,D,W)4X36*17** 0.98 1.08 0.95 1.02 *9MX*0601714A**

ED*4X36F** 0.96 1.01 0.95 0.99 *9MV*0801716A** EN(A,D,W)4X36*17** 0.96 1.00 0.92 0.94 MV08B15**B*

ED*4X36F** 0.98 1.08 0.95 1.01 *9MX*0601714A** EN(A,D,W)4X36*17** 0.98 1.05 0.91 0.95 OLV098A12A

ED*4X36F** 0.96 1.00 0.92 0.94 MV08B15**B* EN(A,D,W)4X36*17** 0.96 1.03 0.91 0.95 OMV098J12A

ED*4X36F** 0.96 1.00 0.92 0.95 MV12F19**B* EN(A,D,W)4X36*17** 0.98 1.04 0.97 1.00 OMV112K14A

ED*4X36F** 0.98 1.06 0.91 0.95 OLV098A12A EN(A,D,W)4X36*17** 0.95 1.13 0.92 1.17

ED*4X36F** 0.96 1.03 0.92 0.95 OMV098J12A ENH4X24*17** 0.97 1.04 0.97 1.06 *8MV*0701412**

ED*4X36F** 0.98 1.02 0.97 0.99 OMV112K14A ENH4X24*17** 0.97 1.02 0.97 1.04 *8MV*0901716**

ED*4X36J** 0.96 1.00 0.92 0.95 MV12F19**B* ENH4X24*17** 0.97 1.02 0.97 1.04 *8MV*1352422**

ED*4X36F** 0.95 1.13 0.92 1.16 ENH4X24*17** 0.97 1.04 0.97 1.06 *8MV*1102120**

14 42104180100

Loading...

Loading...