International comfort products C9MPV050F12D1, C9MPT050F12C1, H9MPT050F12C1, T9MPT050F12C1, C9MPT075F14C1 Technical Support Manual

...

Four Position Furnace

Models

Dual Certified

*9MPT050F12C1

*9MPT075F14C1

*9MPT100J16C1

*9MPT125L20C1

*9MPV050F12D1

*9MPV075F12D1

*9MPV100J20D1

*9MPV125L20D1

*9MVX040F12A1

*9MVX060F12A1

*9MVX080J20A1

*9MVX100L20A1

Technical Support (*9MPT) 2................

Circulation Air Blower Data (*9MPT) 3.........

Wiring Diagram (*9MPT) 4..................

Parts (*9MPT) 5..........................

Technical Support (*9MPV) 8...............

Circulation Air Blower Data (*9MPV) 9.........

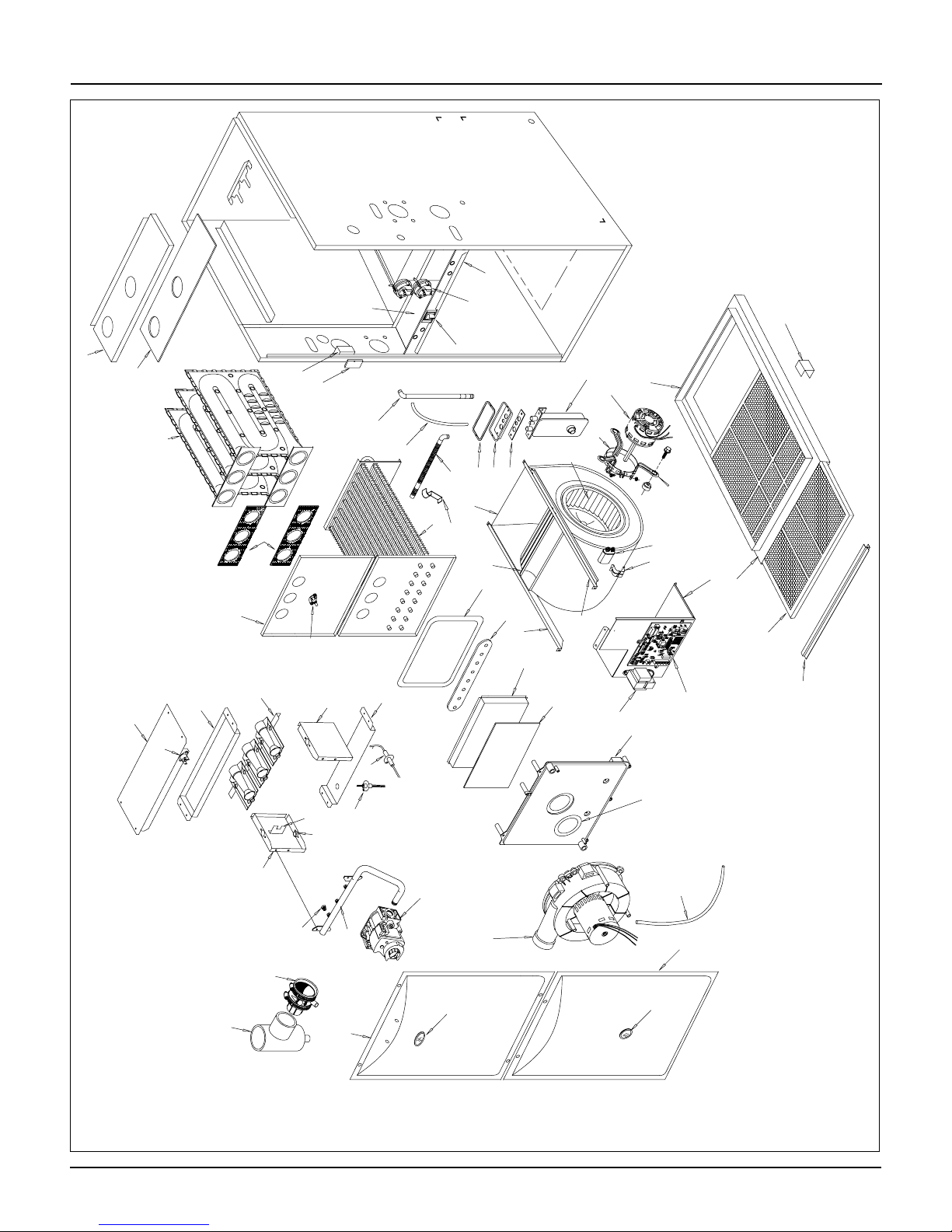

Exploded Parts View (*9MPV & *9MVX) 17......

Parts (*9MPV) 19..........................

Technical Support (*9MVX) 20...............

Circulation Air Blower Data (*9MVX) 21.........

Parts (*9MVX) 30..........................

Wiring Diagram (*9MPV & *9MVX) 32...........

Save This Manual For Future Reference

440 04 2024 01 Feb. 2009

* Denotes Brand (C, H, T)

International Comfort Products, LLC

Lewisburg, TN 37091 U.S.A.

1

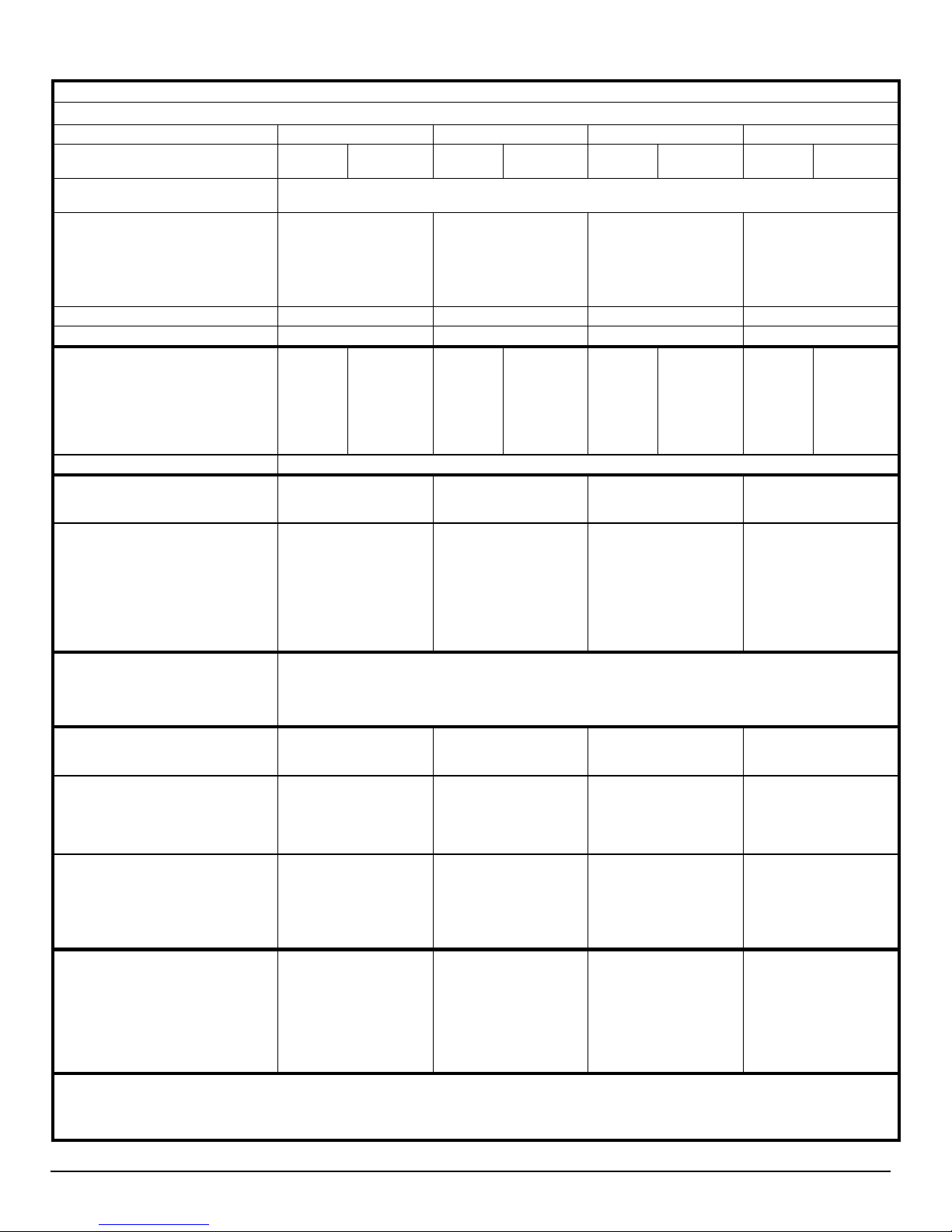

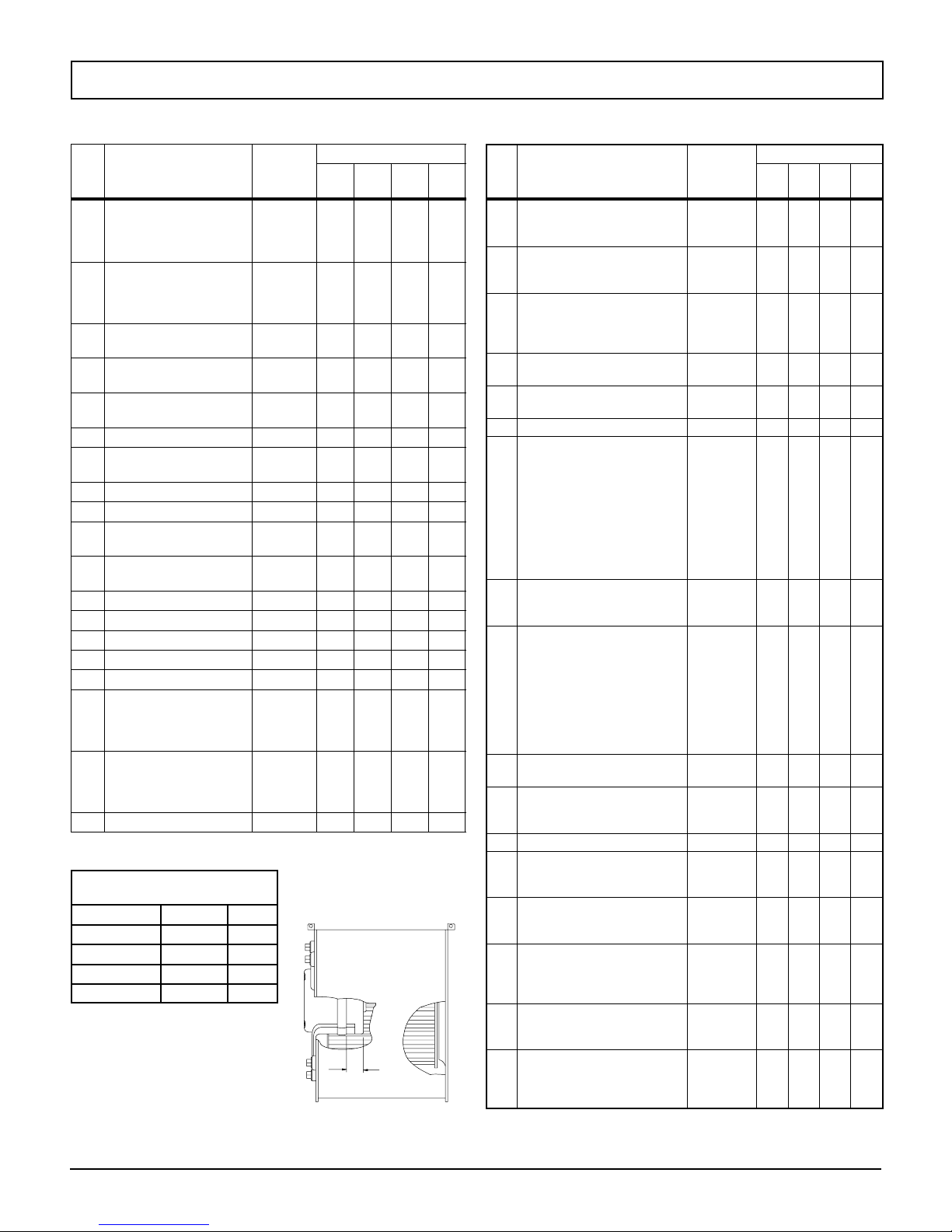

TECHNICAL SUPPORT

Manufacturers Number (Mfr No --SeeRatingPlate) ALL Models

Specifications

*9MPT050F12 *9MPT075F14 *9MPT100J16 *9MPT125L20

General

Gas Type

Transformer Size (VA)

T’stat Heat Anticipator

Input (Btuh) Std/Alt. HI Heat

LO Heat

Output (Btuh) Std/Alt. HI Heat

Tem p. Ri s e (

oF/o

LO Heat

C) HI Heat

LO Heat

Electrical (Volts/Hz) 115/60 115/60 115/60 115/60

Rating Plate Amps 11. 8 11. 8 11. 8 14.0

Gas & Ignition

Gas Type

Std. Main Orifices (No/Size)

Gas Valve (Honeywell)

Regulation Type

Manifold Press. HI Heat (in wc/Pa)

LO Heat (in wc/Pa)

Ignition Type/Series Hot Surface

Combustion

Flue Outlet Size (Inches)

Std. Outlet Temp (

oF/o

C)

@Blower/ @ Transition Box (HI Heat)

Std. Pressures (in wc/Pa)

5′ No Elbows

40′ +5--90° DWV Elbows

@Blower/ @ Transition Box (LO Heat)

Std. Pressures (in wc/Pa)

5′ No Elbows

40′ +5--90° DWV Elbows

Furnace Controls

Furnace Control (Type)

Furnace Control On

(Timed--secs) Off

Limits & Controls

Rollout Switch (

Limit Control Setting (

oF/o

C)

oF/o

C)

Std. Pressure Sw. (in wc/Pa) Part No

Blower Switch Pressure (Close)

Blower Switch Pressure (Open)

Transition Switch Pressure (Close)

Transition Switch Pressure (Open)

High Alt. Pressure Sw. (in wc/Pa)

Part No

Blower Switch Pressure (Close)

Blower Switch Pressure (Open)

Transition Switch Pressure (Close)

Transition Switch Pressure (Open)

Blower Data

Blower Size -- D x W inches(mm)

Motor Amps/RPM

Motor Type/H.P.

Cap. Mfd/Volts

Filter Type & Size (qty.) in(mm)

Cool Cap. (Tons) @ .5 in wc (125 Pa)

L, ML, MHi & HI

Gas Conversion Kits All Models

Nat to Propane NAHA002LP (1172959*)

Propane to Nat NAHA002NG (1172961*)

*Order from Service Parts

Nat Propane Nat Propane Nat Propane Nat Propane

40

.50

50,000

35,000

46,000

32,000

35--65/19--46

25--55/14--30

Nat.

2/42

VR8205Q

SNAP

3.5/872

1.7/423

Propane

2/54

VR8205Q

SNAP

10.0/2490

4.9/1221

2

<140/60

--1.80/--2.60(--448/--647)

--1.30/--2.30(--324/--573)

--1.20/--1.90(--299/--473)

--1.00/--1.80(--249/--448)

VR8205Q

3.5/872

1.7/423

--1.80/--2.60(--448/--647)

--1.30/--2.30(--324/--573)

--1.20/--1.90(--299/--473)

--1.00/--1.80(--249/--448)

Nat.

3/42

SNAP

75,000

53,000

70,000

49,000

40--70/22--38

30--60/17--33

Propane

VR8205Q

10.0/2490

4.9/1221

2

<140/60

3/54

SNAP

100,000

70,000

93,000

65,000

40--70/22--38

30--60/17--33

Nat.

4/42

VR8205Q

SNAP

3.5/872

1.7/423

Propane

4/54

VR8205Q

SNAP

10.0/2490

4.9/1221

3

<140/60

--1.80/--2.60(--448/--647)

--1.70/--2.50(--423/--623)

--1.20/--1.90(--299/--473)

--1.00/--1.80(--249/--448)

125,000

87,500

117,000

82,000

40--70/22--38

30--60/17--33

Nat.

5/42

VR8205Q

SNAP

3.5/872

1.7/423

3

<140/60

--1.80/--2.60(--448/--647)

--1.70/--2.50(--423/--623)

--1.30/--2.30(--324/--573)

--1.20/--2.20(--299/--548)

Integrated

30 HI /45 LO

60,100,140,180

300/149

260/127

1013515

0.95(237)

0.80(199)

1.70(423)

1.50(374)

1013165

0.70(174)

0.55(137)

1.40(349)

1.20(299)

11 x 8(279 x 203)

10/1050

1

/

PSC/

2

10/370

16x25x1

1.5 thru 3

300/149

210/99

1013515

0.95(237)

0.80(199)

1.70(423)

1.50(374)

1013165

0.70(174)

0.55(137)

1.40(349)

1.20(299)

11 x 10(279 x 254)

10/1050

1

/

PSC/

2

10/370

16x25x1

1.5 thru 3.5

300/149

240/116

1013515

0.95(237)

0.80(199)

1.70(423)

1.50(374)

1013165

0.70(174)

0.55(137)

1.40(349)

1.20(299)

11 x 10(279 x 254)

10/1050

1

/

PSC/

2

10/370

16x25x1

2.5 thru 4

300/149

180/82

1013166

1.30(324)

1.10(274)

1.80(448)

1.60(398)

1013157

0.85(212)

0.70(174)

1.70(423)

1.50(374)

11 x 10(279 x 254)

13/900

PSC/

40/370

16x25x1 (2)

3.5 thru 5

Propane

5/54

VR8205Q

SNAP

10.0/2490

4.9/1221

3

/

4

2

Specifications are subject to change without notice.

440 04 2024 01

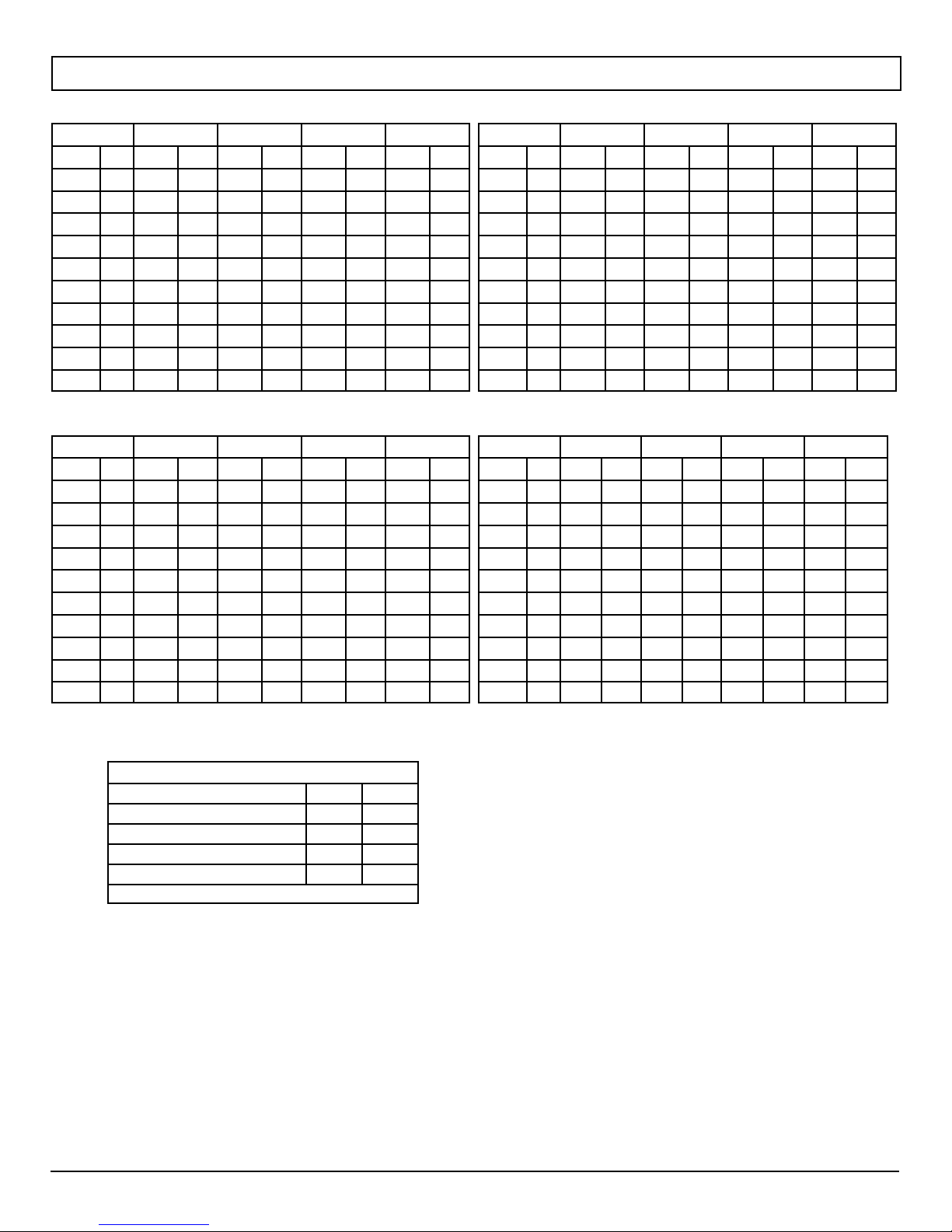

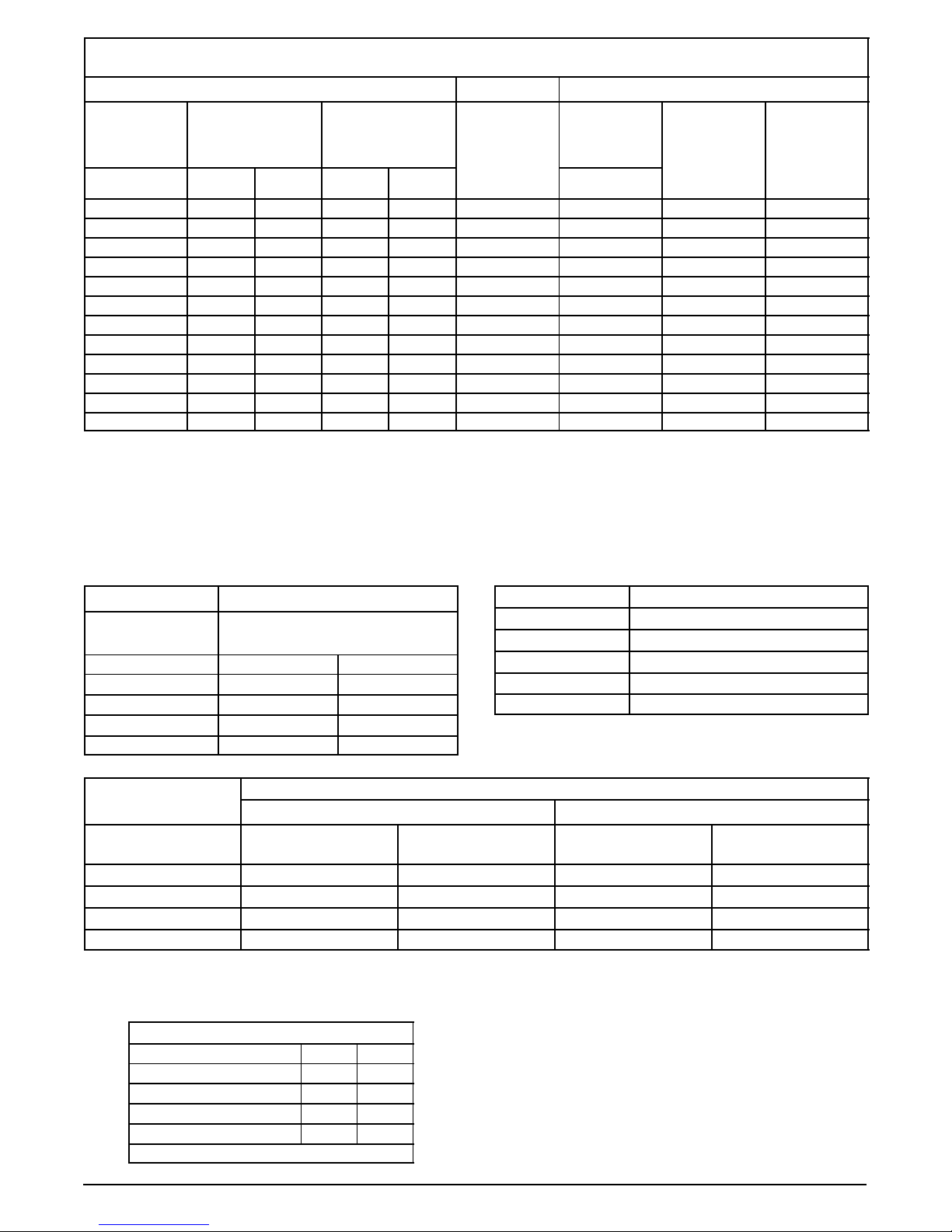

Circulation Air Blower Data - *9MPT

*9MPT050F12 (1) * Denotes Brand

Speed Tap

in wc Pa CFM L/s CFM L/s CFM L/s CFM L/s

0.1 25 826 389 1083 511 1301 614 1408 667

0.2 50 804 379 1050 495 1242 586 1347 638

0.3 75 770 363 1028 485 1195 564 1295 611

0.4 100 735 346 985 465 1153 544 1237 583

0.5 125 698 329 952 499 1093 516 1183 558

0.6 150 657 310 909 429 1040 491 111 8 528

0.7 175 -- -- -- -- -- -- 863 407 935 441 1053 497

0.8 200 -- -- -- -- -- -- 812 383 865 408 976 461

0.9 225 -- -- -- -- -- -- -- -- -- -- -- -- 802 378 887 419

1.0 250 -- -- -- -- -- -- -- -- -- -- -- -- 720 340 787 371

Low Med L Med H Hi

*9MPT100J16 (1) * Denotes Brand

Speed Tap

in wc Pa CFM L/s CFM L/s CFM L/s CFM L/s

0.1 25 823 388 1109 523 1527 721 1850 873

0.2 50 795 375 1087 513 1482 699 1791 845

0.3 75 747 353 1056 498 1426 673 1720 812

0.4 100 677 319 1016 479 1382 652 1648 778

0.5 125 617 591 970 458 1317 622 1575 743

0.6 150 544 257 857 403 1245 588 1485 701

0.7 175 -- -- -- -- -- -- 763 360 1154 545 1401 661

0.8 200 -- -- -- -- -- -- 652 308 1043 492 1284 606

0.9 225 -- -- -- -- -- -- -- -- -- -- -- -- 905 427 1161 548

1.0 250 -- -- -- -- -- -- -- -- -- -- -- -- 737 348 1028 485

Low Med L Med H Hi

*9MPT075F14 (1) * Denotes Brand *9MPT125L20 (2) * Denotes Brand

Speed Tap

in wc Pa CFM L/s CFM L/s CFM L/s CFM L/s

0.1 25 395 328 1025 484 1455 687 1724 814

0.2 50 374 318 1001 472 1410 655 1662 784

0.3 75 653 308 951 449 1365 644 1601 756

0.4 100 631 298 921 435 1309 3118 1530 722

0.5 125 609 287 891 420 1252 591 1460 689

0.6 150 569 268 845 399 1187 560 1380 651

0.7 175 529 250 799 377 1122 529 1300 613

0.8 200 490 231 730 345 1030 486 1190 562

0.9 225 -- -- -- -- -- -- 680 321 950 448 1080 510

1.0 250 -- -- -- -- -- -- -- -- -- -- -- -- 831 392 969 457

Low Med L Med H Hi

Speed Tap Low Med L Med H Hi

in wc Pa CFM L/s CFM L/s CFM L/s CFM L/s

0.1 25 1720 812 1910 901 2127 1004 2315 1092

0.2 50 1686 796 1881 888 2087 985 2268 1070

0.3 75 1644 776 1833 912 2024 955 2201 1039

0.4 100 1600 755 1777 839 1961 925 2131 1006

0.5 125 1533 723 1720 812 1891 892 2029 958

0.6 150 1494 705 1647 777 1804 851 1948 919

0.7 175 1413 667 1571 741 1708 806 1820 859

0.8 200 1306 616 1470 694 1604 757 1730 816

0.9 225 -- -- -- -- -- -- 1349 637 1484 700 1614 762

1.0 250 -- -- -- -- -- -- -- -- -- -- -- -- 1328 627 1430 675

NOTE: (1) Data based on Bottom Only or One Side return.

(2) Data based on Both Sides or Bottom plus One Side

MAX CFM (L/s) for Factory Washable Filters

Filter Size (in/mm) CFM L/s

14″ X25″ (356 x 635) 1400 661

16″ X25″ (406 x 635) 1600 755

20″ X25″ (508 x 635) 2000 944

24″ X25″ (610 x 635) 2500 1180

Max CFM (L/s) based on 600 FPM (3.0 m/s)

NOTE: Disposable filters are typically rated at 300 FPM (1.5 m/s). These filters

only allow half the airflow when compared to 600 FPM (3.0 m/s) filters.

# CFM -- Cubic feet per minute airflow (L/s -- Liters per second) Filter

required for each return--air inlet. Airflow performance includes 1″ (25.4mm)

washable 600 FPM (283 m/s) max filter media.

440 04 2024 01

Specifications are subject to change without notice.

3

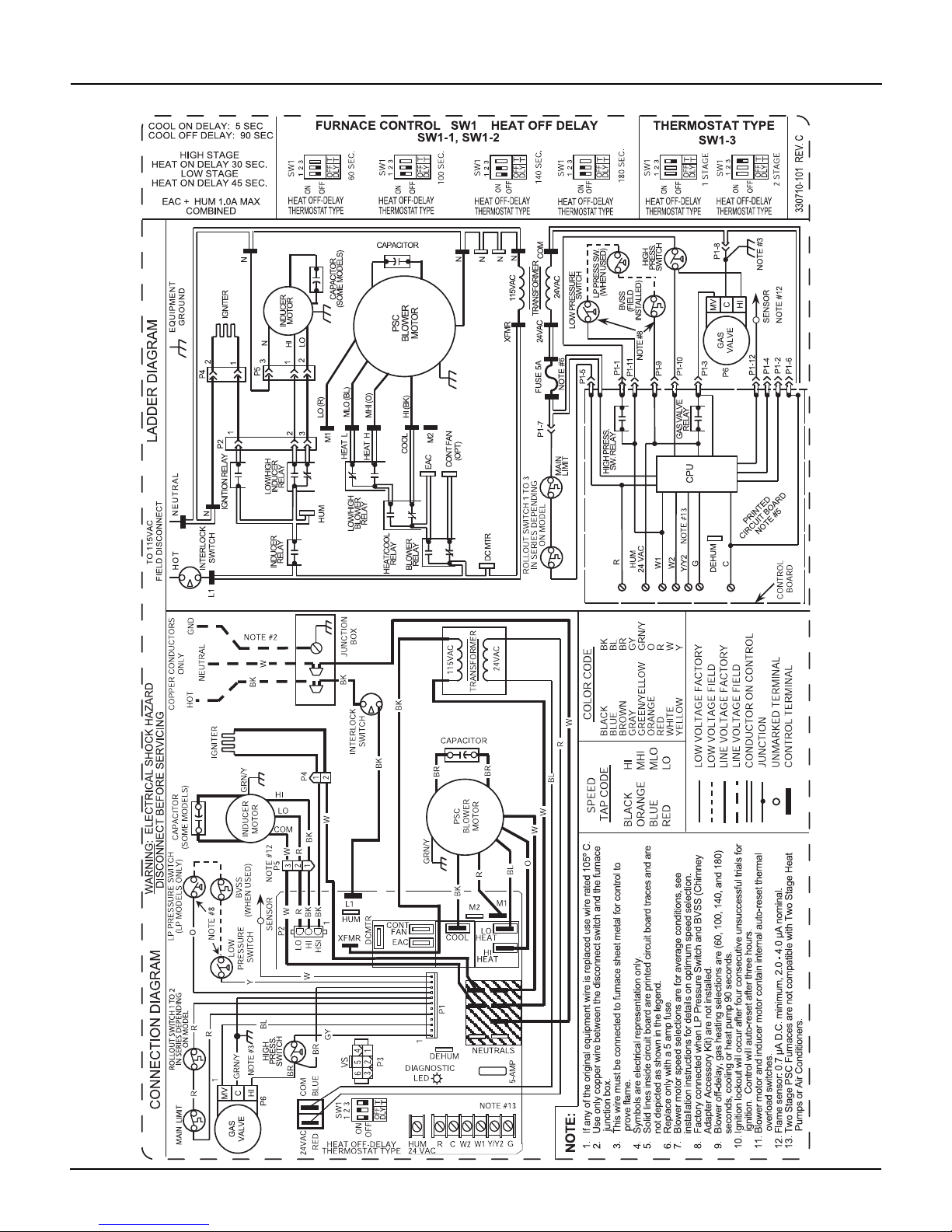

Wiring Diagram *9MPT (Two Stage Heating with PSC Motor)

4

Specifications are subject to change without notice.

440 04 2024 01

*9MPT Parts

25--24- -75a--4

M

TT

9

10

SSHRR

QQ

PP

KK

MM

3

4

5

F

A

B

1

Y

X

UU

VV

2

W

V

18

XX

7

J

U

T

K

K

D

HH

NN

20

S

OO

EE

DD

17

FF

CC

R

8

6

P

16

13

Q

14

GG

16

FF

Representative drawing only, some models may vary in appearance.

15

WW

YY

12

BB

N

O

F

F

O

11

LL

N

Specifications are subject to change without notice.

JJ

L

ZZ

5440 04 2024 01

Replacement Parts - *9MPT

Models -- *9MPT050F12C1, *9MPT075F14C1, *9MPT100J16C1 & *9MPT125L20C1 (Natural Gas)

Replacement part supplied will be current active part. For parts not listed, consult place of purchase.

Key

No.

1 Heat Exchanger, Primary 1012850

2 Heat Exchanger, Secondary 1013762

3 Motor, Blower 1/1151/2CCW

4

5 Wheel, Blower 1013011

6 Transformer 1172810 1 1 1 1

7 Capacitor, 10Mfd., 370V

8 Control 1175594 1 1 1 1

9 Switch, Interlock 1171981 1 1 1 1

10 Switch, Pressure 1013166

11 Blower, Exhaust 1172826

12 Valve, Gas Nat. 2 Stage 1172822 1 1 1 1

13 Flame Sensor 1172827 1 1 1 1

14 Igniter 1172533 1 1 1 1

15 Orifice, Burner #42 Nat. 1011351 2 3 4 5

16 Switch, Limit (Rollout) 1013102 2 2 2 2

17 Burner Assembly 1172884

18 Switch, Limit (Main) 1320366

20 Filter,HH 16X25X1/2” 1010365 1 1 2 2

*See Table below for bellyband location on motor

Model *9MPT inches mm

050F12 2.09 53.1

075F14 1.81 46

100J16 1.81 46

125L20 1.65 41.9

Description

Functional

3

/4CCW

1/115

Mount, Motor kit*

40Mfd., 370V

Bellyband Location

on Motor -- A Dimensions

Part

Number

1012854

1012858

1012862

1013763

1013765

1013767

1172488

11724891--

1014824

10148231--

10114201--

1171929

11719821--

1013515--1--1

11728251--

1172965

1172966

1172967

34335002

1008445

34335001

050

F12

*9MPT

075

100

F14

J16

1

--

--

--

--

1

--

--

--

1

--

--

--

1

--

--

--

A

--

1

--

--

1

--

--

--

--

1

--

--

1

--

--

1

1

--

--

--

--

1

1

--

--

1

1

1

1

--

--

-1

1

1

--

--

--

--

1

--

-- --

1

-- --

--

--

--

--

1

--

--

1

--

125

L20

Key

No.

--

--

-1

--

--

-1

-1

-1

-1

-1

1

--

-1

--

--

-1

--

-1

--

A Panel, Top 1012866

B Gasket, Top Panel 1012603

F Partition, Blower 1172008

H Housing, Blower 1172885

J Panel, Blower Cutoff 721020013

K Hanger, Blower 1012328 2 2 2 2

L Door, Blower (Comfortmaker only)

M Bracket Asy., Door Filler 1172232

N Door, Front (Comfortmaker only)

O Clamp, Capacitor 1170643

P Transition Assembly 1172228

Q Gasket, Blower 1014425 1 1 1 1

R Board, Insulating 1012418

S Box, Collector 1012244

T Gasket, Transition 1013263

U Gasket, Collector Box 1012594

V Partition, Front Heat Exchanger 1012650

Description

Non- Functional

(Comfortmaker only)

(Comfortmaker only)

(Heil only)

(Heil only)

(Heil only)

(Tempstar only)

(Tempstar only)

(Tempstar only)

(Comfortmaker only)

(Comfortmaker only)

(Heil only)

(Heil only)

(Heil only)

(Tempstar only)

(Tempstar only)

(Tempstar only)

Part

Number

1012867

1012868

1012604

1012605

1172005

1172006

1172007

11729691----1--1--1

7210200081----1--1--1

1173035

1173036

1173073

1173038

1173039

1173076

1173078

1173079

1173080

1172233

1172234

1013148

1013149

1013150

1013145

1013146

1013147

1173086

1173087

1173088

10143151--1--1----1

1172229

1172230

1012419

1012420

1012245

1012246

1013080

1013083

1013084

1012595

1012596

1012648

1012651

1012653

050

F12

*9MPT

075

F14

1

1

--

--

--

--

1

1

--

--

--

--

1

--

--

1

--

--

--

--

1

1

--

--

--

--

1

1

--

--

--

--

1

1

--

--

--

--

1

1

--

--

--

--

1

1

--

--

--

--

1

1

--

--

--

--

1

1

--

--

--

--

1

1

--

--

--

--

1

1

--

--

--

--

1

1

--

--

--

--

1

--

--

1

--

--

--

--

1

1

--

--

--

--

1

--

--

1

--

--

--

--

100

J16

125

L20

--

--

1

--

--

1

--

--

1

--

--

1

--

--

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

--

--

1

--

--

1

--

--

1

--

--

1

--

--

--

--

1

--

--

1

6

Specifications are subject to change without notice.

440 04 2024 01

Replacement Parts - *9MPT

Models -- *9MPT050F12C1, *9MPT075F14C1, *9MPT100J16C1 & *9MPT125L20C1 (Natural Gas)

Replacement part supplied will be current active part. For parts not listed, consult place of purchase.

Key

No.

W Gasket, Attachment Plate 1012542

X Cover, Junction Box 1012350 1 1 1 1

Y Box, Junction 1172860 1 1 1 1

BB Manifold 1012970

CC Bottom, Burner Box 1172847

DD Baffle, Burner Box 1012338

EE Top, Burner Box 1013702

FF Bracket, Manifold Support 1012377 2 2 2 2

GG Bracket, Burner Box Side 1012532 2 2 2 2

HH Bracket, Control Mounting 1172845 1 1 1 1

JJ Tube, Sensor 1172238

KK Trap, Drain Assembly 1171917 1 1 1 1

LL Sightglass

MM Wrapper, Filter Rack 741010039 1 1 2 2

NN Front, Filter Rack 741020001 1 1 2 2

OO Cover, Filter 2791043 1 1 2 2

PP Clip, Filter 1008482 3 3 3 3

QQ Gasket, Trap 1013701 1 1 1 1

RR Bracket, Trap 1171986 1 1 1 1

SS Gasket, Trap Bracket 1171987 1 1 1 1

TT Tube, Drain Coll. Box5/8″ ID 1172245 1 1 1 1

UU Tube, Drain Tee1/2″ ID 1171989 1 1 1 1

VV Tube, Relief 1172012 1 1 1 1

WW Drain Vent 1014003 1 1 1 1

XX Clip, Retainer 1175788 1 1 1 1

YY Tee, Drain 1171915 1 1 1 1

ZZ Sightglass 1172768 1 1 1 1

)( PART NOT ILLUSTRATED

)( Door Screws 1014488 4 4 4 4

)( Door Screw Grommets 1171990 4 4 4 4

)( Coupling, Air Intake 1012284 1 1 1 1

)( Gasket, Air Intake 1012583 1 1 1 1

)( Clamp, Hose5/8” 1012975 4 4 4 4

)( Clamp, Hose3/4” 1012976 2 2 2 2

)( Coupling, Discharge 1002522 1 1 1 1

)( Clamp Hose 1013830 4 4 4 4

)( Grommet, Vent 1012697 1 1 1 1

)( Bushing, Strain Relief 1945287 1 1 1 1

)( Grommet, Vinyl (Gas Inlet) 1009535 1 1 1 1

)( Harness, Wire 1172818 1 1 1 1

)( Grommet,Casing 1171997 1 1 1 1

Description

Functional

(Tempstar only)

Part

Number

1012543

1012544

1012545

1012971

1012278

1012279

1172849

1172850

1012339

1012340

1013703

1013704

117224111111111

1013235

101323611111111

050

F12

*9MPT

075

100

F14

J16

2

--

--

--

--

1

--

--

-1

--

--

1

--

--

1

--

--

--

2

--

--

2

--

--

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

125

L20

Key

No.

--

--

-2

--

--

-1

--

-1

--

-1

--

-1

)( Trap, Drain Tee 1171916 1 1 1 1

)( Tube, Drain1/2”IDDrain 1171991 1 1 1 1

)( Tube,1/2” Elbow 1171992 2 2 2 2

)( Coupling,1/2” Barbed 1171993 1 1 1 1

)( Tubing,5/8”IDDrain 1171994 1 1 1 1

)( Connector,3/4”X1/2” 1171995 1 1 1 1

)( Elbow,1/2” CPVC street 1171996 1 1 1 1

)( Tube, Relief Ext. 1172239 1 1 1 1

)( Connector, Relief Tube 1171998 1 1 1 1

)( Plate, Cover 1171999 1 1 1 1

)( Gasket, Cover Plate 1172000 1 1 1 1

)( Cap, Drain Tee 1172255 1 1 1 1

)( Clamp, Tee Cap 1172256 1 1 1 1

)( Manual, Users 44102201200 1 1 1 1

)( Manual, Installation 44001202401 1 1 1 1

)( Manual, Technical 44004202401 1 1 1 1

Gas Conversion Kits -- All models

Nat to Propane NAHA002LP (1172959*)

Propane to Nat NAHA002NG (1172961*)

* Must be ordered from Service Parts

Description

Functional

Number

Part

050

F12

*9MPT

075

F14

100

J16

125

L20

440 04 2024 01

Specifications are subject to change without notice.

7

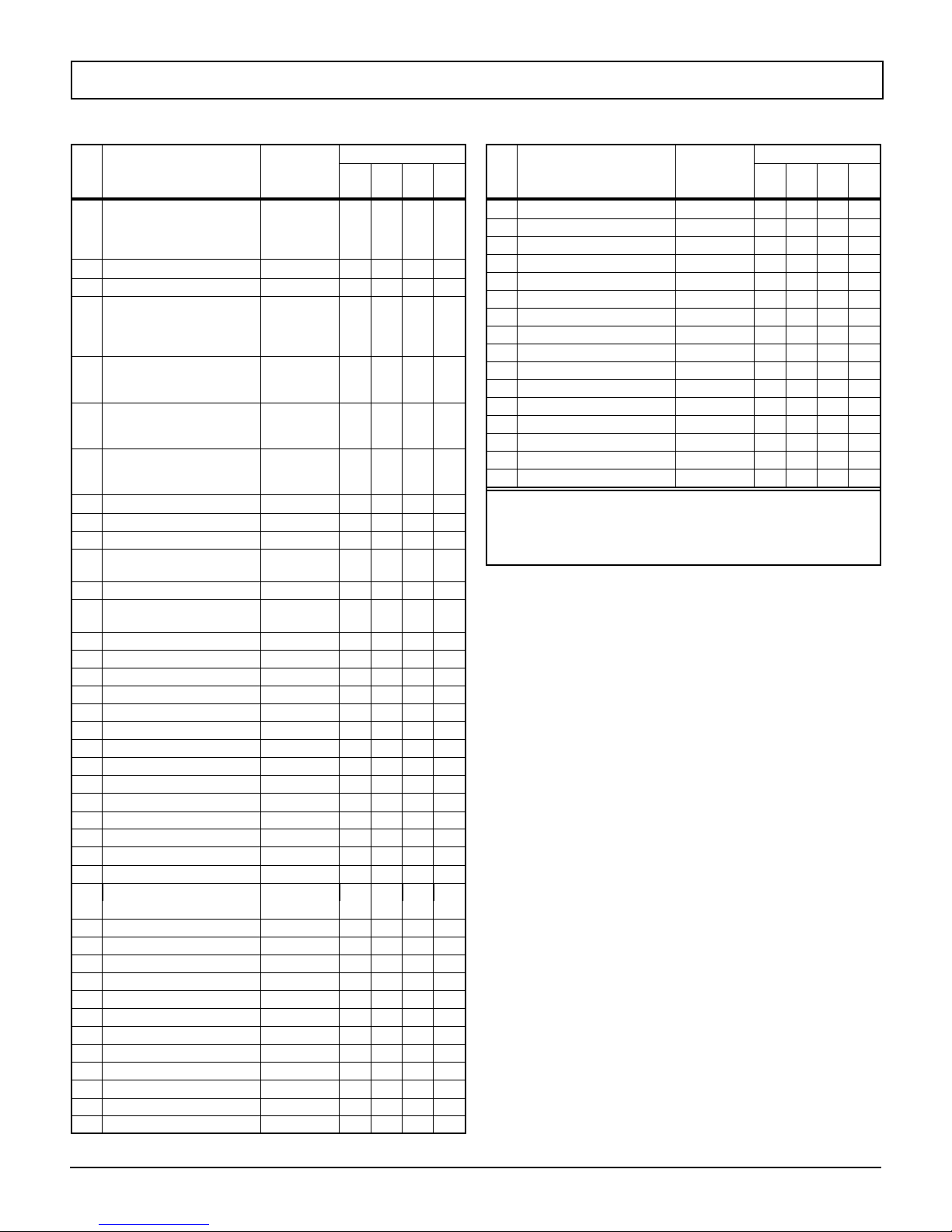

TECHNICAL SUPPORT

Manufacturers Number (Mfr No --SeeRatingPlate) ALL Models

Specifications

*9MPV050F12 *9MPV075F12 *9MPV100J20 *9MPV125L20

General

Gas Type

Transformer Size (VA)

T’stat Heat Anticipator

Input (Btuh) Std/Alt. HI Heat

LO Heat

Output (Btuh) Std/Alt. HI Heat

Tem p. Ri s e (

oF/o

LO Heat

C) HI Heat

LO Heat

Electrical (Volts/Hz) 115/60 115/60 115/60 115/60

Rating Plate Amps 9.5 11.4 14.6 15.4

Gas & Ignition

Gas Type

Std. Main Orifices (No/Size)

Gas Valve Honeywell

Regulation Type

Manifold Press. HI Heat (in wc/Pa)

LO Heat (in wc/Pa)

Ignition Type

Combustion

Flue Outlet Size (Inches)

Std. Outlet Temp (less than)

Comb. Blower (MFD/Volts)

@Blower/ @ Transition Box (HI Heat)

Std. Pressures in wc(Pa)

5′ No Elbows

40′ +5--90° DWV Elbows

@Blower/ @ Transition Box (LO Heat)

Std. Pressures in wc(Pa)

5′ No Elbows

40′ +5--90° DWV Elbows

Limits & Controls

Rollout Switch (

Limit Control Setting (

oF/o

C)

oF/o

C)

Furnace Control (Type)

Furnace Control On

(Timed--secs) Off

Std. Pressure Sw. in wc(Pa) Part No

(HI Heat)Blwer Switch Press (Close)

Blower Switch Pressure (Open)

(LO Heat)Trans Switch Press (Close)

Transition Switch Pressure (Open)

High Alt. Pressure Sw. in wc(Pa)

Part No

(HI Heat)Blwer Switch Press (Close)

Blower Switch Pressure (Open)

(LO Heat)Trans Switch Press (Close)

Transition Switch Pressure (Open)

Blower Data

Wheel Size D x W in(mm)

FLA Motor Amps/Max RPM

Motor Type/H.P.

Filter Type & Size in(mm) (qty)

Min. Cool Cap. (Tons)

Max. Cool Cap. (Tons)

Gas Conversion Kits All Models

Nat to Propane NAHA002LP (1172959*)

Propane to Nat NAHA002NG (1172961*)

*Order from Service Parts

Nat Propane Nat Propane Nat Propane Nat Propane

40

.50

Nat.

2/42

VR8205Q

SNAP

3.5/872

1.7/423

50,000

35,000

46,000

32,000

35--65/19--46

35--65/19--46

Propane

2/54

VR8205Q

SNAP

10.0/2490

4.9/1221

40--70/22--38

40--70/22--38

Nat.

3/42

VR8205Q

SNAP

3.5/872

1.7/423

75,000

52,500

70,000

48,000

Propane

3/54

VR8205Q

SNAP

10.0/2490

4.9/1221

40--70/22--38

40--70/22--38

Nat.

4/42

VR8205Q

SNAP

3.5/872

1.7/423

100,000

70,000

93,000

65,000

Propane

4/54

VR8205Q

SNAP

10.0/2490

4.9/1221

125,000

87,500

118,000

82,000

40--70/22--38

40--70/22--38

Nat.

5/42

VR8205Q

SNAP

3.5/872

1.7/423

Hot Surface

2

o

140

F/60oC

4/370

--1.80/--2.60(--448/--647)

--1.30/--2.30(--324/--573)

--1.20/--1.90(--299/--473)

--1.00/--1.80(--249/--448

300/149

260/127

--1.80/--2.60(--448/--647)

--1.30/--2.30(--324/--573)

--1.20/--1.90(--299/--473)

--1.00/--1.80(--249/--448

140

2

o

F/60oC

4/370

300/149

210/99

3

o

140

F/60oC

4/370

--1.80/--2.60(--448/--647)

--1.70/--2.50(--423/--623)

--1.20/--1.90(--299/--473)

--1.00/--1.80(--249/--448

300/149

240/116

3

o

140

F/60oC

4/370

--1.80/--2.60(--448/--647)

--1.70/--2.50(--423/--623)

--1.30/--2.30(--324/--573)

--1.20/--2.20(--299/--548)

300/149

190/88

Integrated

30 HI /45 LO

60,100,140,180

1013515

0.95(237)

0.80(199)

1.70(423)

1.50(374)

1013165

0.70(174)

0.55(137)

1.40(349)

1.20(299)

11 x 8(279 x 203)

7.7/1240

1

/

ECM/

16x25x1(406x635x25)

2

1.5

3

1013515

0.95(237)

0.80(199)

1.70(423)

1.50(374)

1013165

0.70(174)

0.55(137)

1.40(349)

1.20(299)

11 x 10(279 x 254)

9.6/1240

3

/

ECM/

16x25x1(406x635x25)

4

1.5

3

1013515

0.95(237)

0.80(199)

1.70(423)

1.50(374)

1013165

0.70(174)

0.55(137)

1.40(349)

1.20(299)

11 x 10(279 x 254)

12.8/1240

ECM/1

16x25x1(406x635x25) (2)

2

5

1013166

1.30(324)

1.10(274)

1.80(448)

1.60(398)

1013157

0.85(212)

0.70(174)

1.70(423)

1.50(374)

11 x 10(279 x 254)

12.8/1240

ECM/1

16x25x1(406x635x25) (2)

2

5

Propane

5/54

VR8205Q

SNAP

10.0/2490

4.9/1221

8

Specifications are subject to change without notice.

440 04 2024 01

Circulation Air Blower Data - *9MPV050

Cooling Adjustment Heating Rise Adjustment

DIP Switch

(OFF = 0 and

ON = 1)

High Cool @ .50

in wc(125 Pa)

Low Cool (80%

of High Cool)

** Adjust

Jumper

DIP Switch

(OFF = 0 and

Setting

5&6 CFM L/s CFM L/s 3&4

ON = 1)

High Heat

Rise

Change @

0.20 in wc

(50 Pa)

Low Heat

Rise

Change at

Resultant

Static

00 1246 588 997 471 + 00 -- 4 -- 3

*00 1211 571 969 457 *NOM *00 0 0

00 1122 529 898 424 -- 00 5 5

01 1105 521 884 417 + 01 3 4

01 1027 485 822 388 NOM 01 7 7

01 945 446 756 357 -- 01 13 14

10 892 421 714 337 + 10 -- 1 0

10 820 387 656 310 NOM 10 4 5

10 745 352 596 281 -- 10 9 9

11 688 325 550 260 + 11 -- 1 5 -- 1 5

11 609 287 487 230 NOM 11 -- 1 3 -- 1 2

11 541 255 433 204 -- 11 -- 9 -- 9

Airflow performance includes 1” washable filter media.

*Factory Setting

**Adjust Jumper Setting (+, NOM, --) is applied to both Cooling and Heating

Note 1: HP Mode Jumper provides a 10% reduction in airflow when in Comfort position and a call for low or high cooling is

present with the ”O” line off. This feature is to provide lower airflow for running in HP Heating Mode if desirable.

Note 2: DEHUM mode (24VAC on DEHUM terminal) provides a 20% airflow reduction during cooling calls.

Note 3: Low Heat ESP is a result of High Heat ESP (-- is decrease in rise).

Note 4: High and low heat rise values are approximate air temperature change from return air temperature when at factory

default settings.

Table 2 Airflow

DIP Switch

(OFF=0andON=1)

Continuous Fan @

0.10 in wc (25 Pa) ESP

1&2 CFM L/s

*00 592 279

01 1021 482

Table 3 SW2 DIP Assignments

DIP Switch Blower Parameter

1&2 Cont Fan Adj

3&4 Heat Speed Adj

5&6 Cool Speed Adj

7&8 Cool On/Off Delay

10 1346 635

11 1346 635

* Factory Setting

Table 4

DIP SW2 -- 7/8

(OFF=0andON=1)

ON DELAY OFF DELAY

Timed ON (sec)

Cooling Delay Options (SW2 -- 7, 8)

Airflow during on

delay

Timer OFF (sec)

Airflow during off

delay

*00 5 OFF 90 100%

01 5 OFF 0 OFF

10 30 50% 30 100%

11 30 50% 180 50%

Airflow % is of High Cool airflow demand determined from SW2--5/6 Table 1

Airflow resumes to 100% after on delay time is completed

Airflow stops (or switches to continuous fan speed) after off delay time is completed

* Factory Setting

MAX CFM (L/s) for Factory Washable Filters

Filter Size (in/mm) CFM L/s

14″ X25″ (356 x 635) 1400 661

16″ X25″ (406 x 635) 1600 755

20″ X25″ (508 x 635) 2000 944

24″ X25″ (610 x 635) 2500 1180

Max CFM (L/s) based on 600 FPM (3.0 m/s)

NOTE: Disposable filters are typically rated at 300 FPM (1.5 m/s).

These filters only allow half the airflow when compared to 600 FPM

(3.0 m/s) filters.

440 04 2024 01

Specifications are subject to change without notice.

9

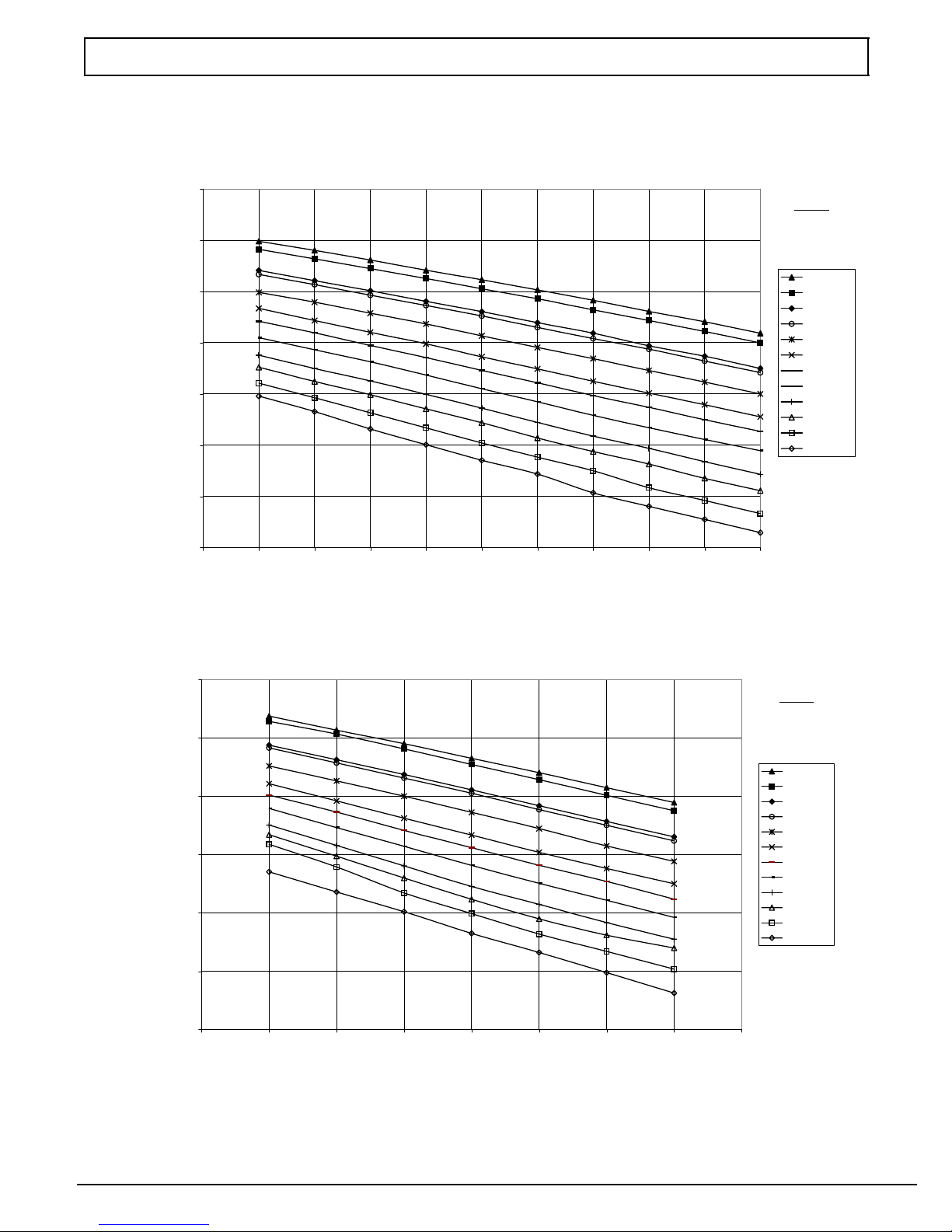

1600

1400

1200

1000

CFM

Circulation Air Blower Data - *9MPV050

Cooling Airflow Settings

High Cooling Airflows

*9MPV050F12

800

600

400

Legend

Airflow

Selection is

from Highest to

Lowest

00 (+)

00 (NOM)

00 (-)

01 (+)

01 (NOM)

01 (-)

10 (+)

10 (NOM)

10 (-)

11 (+)

11 (NOM)

11 (-)

200

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

ESP (in. w.c.)

Low Cooling Airflows

*9MPV050F12

1200

1000

800

600

CFM

400

200

Legend

Airflow

Selection is

from Highest to

Lowest

00 (+)

00 (NOM)

00 (-)

01 (+)

01 (NOM)

01 (-)

10 (+)

10 (NOM)

10 (-)

11 (+)

11 (NOM)

11 (-)

0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

NOTE: OFF = 0 and ON = 1

10

ESP (in. w.c.)

Specifications are subject to change without notice.

440 04 2024 01

Circulation Air Blower Data - *9MPV075

Cooling Adjustment Heating Rise Adjustment

DIP Switch

(OFF = 0 and

ON = 1)

High Cool @ .50

in wc(125 Pa)

Low Cool (80%

of High Cool)

** Adjust

Jumper

DIP Switch

(OFF = 0 and

Setting

5&6 CFM L/s CFM L/s 3&4

ON = 1)

High Heat

Rise

Change @

0.20 in wc

(50 Pa)

Low Heat

Rise

Change at

Resultant

Static

00 1342 633 1074 507 + 00 -- 4 -- 4

*00 1210 571 968 457 *NOM *00 0 0

00 1053 497 842 397 -- 00 5 4

01 1135 536 908 429 + 01 1 1

01 1020 481 816 385 NOM 01 6 5

01 872 412 698 329 -- 01 12 10

10 965 455 772 364 + 10 -- 1 -- 1

10 840 396 672 317 NOM 10 3 3

10 680 321 544 256 -- 10 9 8

11 708 334 566 267 + 11 -- 6 -- 6

11 590 278 472 223 NOM 11 -- 2 -- 3

11 488 230 390 184 -- 11 3 2

Airflow performance includes 1” washable filter media.

*Factory Setting

**Adjust Jumper Setting (+, NOM, --) is applied to both Cooling and Heating

Note 1: HP Mode Jumper provides a 10% reduction in airflow when in Comfort position and a call for low or high cooling is

present with the ”O” line off. This feature is to provide lower airflow for running in HP Heating Mode if desirable.

Note 2: DEHUM mode (24VAC on DEHUM terminal) provides a 20% airflow reduction during cooling calls.

Note 3: Low Heat ESP is a result of High Heat ESP (-- is decrease in rise).

Note 4: High and low heat rise values are approximate air temperature change from return air temperature when at factory

default settings.

Table 2 Airflow

DIP Switch

(OFF=0andON=1)

Continuous Fan @

0.10 in wc (25 Pa) ESP

1&2 CFM L/s

*00 612 289

01 1096 517

Table 3 SW2 DIP Assignments

DIP Switch Blower Parameter

1&2 Cont Fan Adj

3&4 Heat Speed Adj

5&6 Cool Speed Adj

7&8 Cool On/Off Delay

10 1403 662

11 1403 662

* Factory Setting

Table 4

DIP SW2 -- 7/8

(OFF=0andON=1)

ON DELAY OFF DELAY

Timed ON (sec)

Cooling Delay Options (SW2 -- 7, 8)

Airflow during on

delay

Timer OFF (sec)

Airflow during off

delay

*00 5 OFF 90 100%

01 5 OFF 0 OFF

10 30 50% 30 100%

11 30 50% 180 50%

Airflow % is of High Cool airflow demand determined from SW2--5/6 Table 1

Airflow resumes to 100% after on delay time is completed

Airflow stops (or switches to continuous fan speed) after off delay time is completed

* Factory Setting

MAX CFM (L/s) for Factory Washable Filters

Filter Size (in/mm) CFM L/s

14″ X25″ (356 x 635) 1400 661

16″ X25″ (406 x 635) 1600 755

20″ X25″ (508 x 635) 2000 944

24″ X25″ (610 x 635) 2500 1180

Max CFM (L/s) based on 600 FPM (3.0 m/s)

NOTE: Disposable filters are typically rated at 300 FPM (1.5 m/s).

These filters only allow half the airflow when compared to 600 FPM

(3.0 m/s) filters.

440 04 2024 01

Specifications are subject to change without notice.

11

1800

1600

1400

1200

1000

CFM

Circulation Air Blower Data - *9MPV075

Cooling Airflow Settings

High Cooling Airflows

*9MPV075F12

800

600

400

Legend

Airflow

Selection is

from Highest to

Lowest

00 (+)

00 (NOM)

01 (+)

00 (-)

01 (NOM)

10 (+)

01 (-)

10 (NOM)

11 (+)

10 (-)

11 (NOM)

11 (-)

200

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

ESP (in. w.c.)

Low Cooling Airflows

*9MPV075F12

1400

1200

1000

800

CFM

600

400

200

Legend

Airflow

Selection is

from Highest to

Lowest

00 (+)

00 (NOM)

01 (+)

00 (-)

01 (NOM)

10 (+)

01 (-)

10 (NOM)

11 (+)

10 (-)

11 (NOM)

11 (-)

0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

NOTE: OFF = 0 and ON = 1

12

ESP (in. w.c.)

Specifications are subject to change without notice.

440 04 2024 01

Circulation Air Blower Data - *9MPV100

Cooling Adjustment Heating Rise Adjustment

DIP Switch

(OFF = 0 and

ON = 1)

High Cool @ .50

in wc(125 Pa)

Low Cool (80%

of High Cool)

** Adjust

Jumper

DIP Switch

(OFF = 0 and

Setting

5&6 CFM L/s CFM L/s 3&4

ON = 1)

High Heat

Rise

Change @

0.20 in wc

(50 Pa)

Low Heat

Rise

Change at

Resultant

Static

00 2144 1012 1715 809 + 00 -- 4 -- 4

*00 2013 950 1610 760 *NOM *00 0 0

00 1842 869 1474 696 -- 00 5 5

01 1772 836 1418 669 + 01 2 1

01 1624 766 1299 613 NOM 01 8 7

01 1471 694 1177 555 -- 01 14 14

10 1367 645 1094 516 + 10 0 -- 1

10 1227 579 982 463 NOM 10 6 5

10 1077 508 862 407 -- 10 13 11

11 930 439 744 351 + 11 -- 6 -- 7

11 808 380 646 305 NOM 11 -- 2 -- 2

11 634 299 507 239 -- 11 3 3

Airflow performance includes 1” washable filter media.

*Factory Setting

**Adjust Jumper Setting (+, NOM, --) is applied to both Cooling and Heating

Note 1: HP Mode Jumper provides a 10% reduction in airflow when in Comfort position and a call for low or high cooling is

present with the ”O” line off. This feature is to provide lower airflow for running in HP Heating Mode if desirable.

Note 2: DEHUM mode (24VAC on DEHUM terminal) provides a 20% airflow reduction during cooling calls.

Note 3: Low Heat ESP is a result of High Heat ESP (-- is decrease in rise).

Note 4: High and low heat rise values are approximate air temperature change from return air temperature when at factory

default settings.

Table 2 Airflow

DIP Switch

(OFF=0andON=1)

Continuous Fan @

0.10 in wc (25 Pa) ESP

1&2 CFM L/s

*00 1007 475

01 1742 822

Table 3 SW2 DIP Assignments

DIP Switch Blower Parameter

1&2 Cont Fan Adj

3&4 Heat Speed Adj

5&6 Cool Speed Adj

7&8 Cool On/Off Delay

10 2204 1040

11 2204 1040

* Factory Setting

Table 4

DIP SW2 -- 7/8

(OFF=0andON=1)

ON DELAY OFF DELAY

Timed ON (sec)

Cooling Delay Options (SW2 -- 7, 8)

Airflow during on

delay

Timer OFF (sec)

Airflow during off

delay

*00 5 OFF 90 100%

01 5 OFF 0 OFF

10 30 50% 30 100%

11 30 50% 180 50%

Airflow % is of High Cool airflow demand determined from SW2--5/6 Table 1

Airflow resumes to 100% after on delay time is completed

Airflow stops (or switches to continuous fan speed) after off delay time is completed

* Factory Setting

MAX CFM (L/s) for Factory Washable Filters

Filter Size (in/mm) CFM L/s

14″ X25″ (356 x 635) 1400 661

16″ X25″ (406 x 635) 1600 755

20″ X25″ (508 x 635) 2000 944

24″ X25″ (610 x 635) 2500 1180

Max CFM (L/s) based on 600 FPM (3.0 m/s)

NOTE: Disposable filters are typically rated at 300 FPM (1.5 m/s).

These filters only allow half the airflow when compared to 600 FPM

(3.0 m/s) filters.

440 04 2024 01

Specifications are subject to change without notice.

13

2700

A

2200

1700

CFM

1200

Circulation Air Blower Data - *9MPV100

Cooling Airflow Settings

High Cooling Airflows

*9MPV100J20

Legend

Airflow

Selection is

from Highest to

Lowest

00 (+)

00 (NOM)

00 (-)

01 (+)

01 (NOM)

01 (-)

10 (+)

10 (NOM)

10 (-)

11 (+)

11 (NOM)

11 (-)

700

200

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

ESP (in. w.c.)

Low Cooling Airflows

*9MPV100J20

2000

1800

1600

1400

1200

1000

CFM

800

600

400

Legend

irflow Selection

is from Highest

to Lowest

00 (+)

00 (NOM)

00 (-)

01 (+)

01 (NOM)

01 (-)

10 (+)

10 (NOM)

10 (-)

11 (+)

11 (NOM)

11 (-)

200

0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

NOTE: OFF = 0 and ON = 1

14

ESP (in. w.c.)

Specifications are subject to change without notice.

440 04 2024 01

Circulation Air Blower Data - *9MPV125

Cooling Adjustment Heating Rise Adjustment

DIP Switch

(OFF = 0 and

ON = 1)

High Cool @ .50

in wc(125 Pa)

Low Cool (80%

of High Cool)

** Adjust

Jumper

DIP Switch

(OFF = 0 and

Setting

5&6 CFM L/s CFM L/s 3&4

ON = 1)

High Heat

Rise

Change @

0.20 in wc

(50 Pa)

Low Heat

Rise

Change at

Resultant

Static

00 2150 1015 1720 812 + 00 -- 4 -- 4

*00 2025 956 1620 764 *NOM *00 0 0

00 1856 876 1485 700 -- 00 4 5

01 1755 828 1404 663 + 01 1 2

01 1615 762 1292 610 NOM 01 6 7

01 1452 685 1162 548 -- 01 12 13

10 1338 631 1070 505 + 10 -- 1 0

10 1201 567 961 454 NOM 10 3 4

10 1069 504 855 403 -- 10 9 10

11 909 429 727 343 + 11 -- 6 -- 6

11 800 377 640 302 NOM 11 -- 3 -- 3

11 627 296 502 237 -- 11 3 3

Airflow performance includes 1” washable filter media.

*Factory Setting

**Adjust Jumper Setting (+, NOM, --) is applied to both Cooling and Heating

Note 1: HP Mode Jumper provides a 10% reduction in airflow when in Comfort position and a call for low or high cooling is

present with the ”O” line off. This feature is to provide lower airflow for running in HP Heating Mode if desirable.

Note 2: DEHUM mode (24VAC on DEHUM terminal) provides a 20% airflow reduction during cooling calls.

Note 3: Low Heat ESP is a result of High Heat ESP (-- is decrease in rise).

Note 4: High and low heat rise values are approximate air temperature change from return air temperature when at factory

default settings.

Table 2 Airflow

DIP Switch

(OFF=0andON=1)

Continuous Fan @

0.10 in wc (25 Pa) ESP

1&2 CFM L/s

*00 1032 487

01 1778 839

Table 3 SW2 DIP Assignments

DIP Switch Blower Parameter

1&2 Cont Fan Adj

3&4 Heat Speed Adj

5&6 Cool Speed Adj

7&8 Cool On/Off Delay

10 2178 1028

11 2178 1028

* Factory Setting

Table 4

DIP SW2 -- 7/8

(OFF=0andON=1)

ON DELAY OFF DELAY

Timed ON (sec)

Cooling Delay Options (SW2 -- 7, 8)

Airflow during on

delay

Timer OFF (sec)

Airflow during off

delay

*00 5 OFF 90 100%

01 5 OFF 0 OFF

10 30 50% 30 100%

11 30 50% 180 50%

Airflow % is of High Cool airflow demand determined from SW2--5/6 Table 1

Airflow resumes to 100% after on delay time is completed

Airflow stops (or switches to continuous fan speed) after off delay time is completed

* Factory Setting

MAX CFM (L/s) for Factory Washable Fil-

ters

Filter Size (in/mm) CFM L/s

14″ X25″ (356 x 635) 1400 661

16″ X25″ (406 x 635) 1600 755

20″ X25″ (508 x 635) 2000 944

24″ X25″ (610 x 635) 2500 1180

Max CFM (L/s) based on 600 FPM (3.0 m/s)

NOTE: Disposable filters are typically rated at 300 FPM (1.5 m/s).

These filters only allow half the airflow when compared to 600 FPM

(3.0 m/s) filters.

440 04 2024 01

Specifications are subject to change without notice.

15

2700

2200

1700

CFM

1200

Circulation Air Blower Data - *9MPV125

Cooling Airflow Setting

High Cooling Airflows

*9MPV125L20

Legend

Airflow

Selection is

from Highest to

Lowest

00 (+)

00 (NOM)

00 (-)

01 (+)

01 (NOM)

01 (-)

10 (+)

10 (NOM)

10 (-)

11 (+)

11 (NOM)

11 (-)

700

CFM

200

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

ESP (in. w.c.)

Low Cooling Airflows

*9MPV125L20

2000

1800

1600

1400

1200

1000

800

600

400

Legend

Airflow

Selection is

from Highest to

Lowest

00 (+)

00 (NOM)

00 (-)

01 (+)

01 (NOM)

01 (-)

10 (+)

10 (NOM)

10 (-)

11 (+)

11 (NOM)

11 (-)

200

0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

NOTE: OFF = 0 and ON = 1

16

ESP (in. w.c.)

Specifications are subject to change without notice.

440 04 2024 01

*9MPV & *9MVX Parts

MM

PP

M

F

B

A

V

GG

EE

14

17

FF

Y

X

UU

VV

W

18

24

25

DD

CC

10

9

KK

2

5

QQ

SSHRR

TT

2

XX

T

J

K

K

U

S

22

R

P

21

3

4

NN

HH

20

OO

(2) CELL MODEL ONLY

24

*9MVX040 UNIT ONLY

23

8

6

Representative drawing only, some models may vary in appearance.

GG

13

16

FF

YY

440 04 2024 01

15

WW

16

12

BB

LL

N

Specifications are subject to change without notice.

Q

JJ

11

L

ZZ

17

Replacement Parts - *9MPV

Models -- *9MPV050F12D1, *9MPV075F12D1, *9MPV100J20D1 & *9MPV125L20D1 (Natural Gas)

Replacement part supplied will be current active part. For parts not listed, consult place of purchase.

Key

No.

1 Heat Exchanger, Primary 1012850

2 Ht Exchanger, Secondary 1013762

3 Motor, Blower 1172828

4

5 Wheel, Blower 1013011

6 Transformer 1172810 1 1 1 1

8 Control 1175594 1 1 1 1

9 Switch, Interlock 1171981 1 1 1 1

10 Switch, Pressure 1013166

11 Blower, Exhaust 1172826

12 Valve, Gas Nat. 2 Stg 1172822 1 1 1 1

13 Flame Sensor 1172827 1 1 1 1

14 Igniter 1172533 1 1 1 1

15 Orifice, Burner #42 Nat. 1011351 2 3 4 5

16 Switch, Limit (Rollout) 1013102 2 2 2 2

17 Burner Assembly 1172884

18 Switch, Limit (Main) 1320366

20 Filter,HH 16X25X1/2” 1010365 1 1 2 2

22 Board, Tap Select Interface 1174894 1 1 1 1

21 Control, Motor Variable Spd 1174887

23 Choke, Power 1172838 -- -- 1 1

*See Table below for bellyband

location on motor

Model *9MPV inches mm

040F12 13/

060F12 27/

080J20 27/

100L20 27/

Description

Functional

Mount, Motor kit*

Bellyband Location

on Motor -- A Dimensions

8

8

8

8

Part

Number

1012854

1012858

1012862

1013763

1013765

1013767

11728291--

1014822 1 1 1 1

11721291--

1013515--1

11728251--

1172965

1172966

1172967

34335001

1320367

1008445

1174888

1174889

1174895

34.9

73

73

73

050

F12

1

--

--

-1

--

--

--

1

--

--

-1

--

--

--

1

--

--

--

075

F12

*9MPV

-1

--

--

-1

--

--

-1

-1

-1

1

--

-1

--

--

-1

--

--

-1

--

--

100

J20

--

-1

--

--

-1

--

-1

-1

-1

1

--

--

-1

--

--

-1

--

--

-1

--

125

L20

Key

No.

--

--

--

1

--

--

-1

-1

-1

1

--

-1

--

--

-1

--

--

-1

--

--

-1

A Panel, Top 1012866

B Gasket, Top Panel 1012603

F Partition, Blower 1172008

H Housing, Blower 1172885

J Panel, Blower Cutoff 721020013

K Hanger, Blower 1012328 2 2 2 2

L Door, Blwer (Cmaker only)

M Bracket Asy., Door Filler 1172232

N Door, Front (Cmaker only)

P Transition Assembly 1172228

Q Gasket, Exhaust Blower 1014425 1 1 1 1

R Board, Insulating 1012418

S Box, Collector 1012244

T Gasket, Transition 1013263

U Gasket, Collector Box 1012594

Description

(Cmaker only)

(Cmaker only)

(Heil only)

(Heil only)

(Heil only)

(Tstar only)

(Tstar only)

(Tstar only)

(Cmaker only)

Cmaker only)

(Heil only)

(Heil only)

(Heil only)

(Tstar only)

(Tstar only)

(Tstar only)

Part

Number

1012867

1012868

1012604

1012605

1172005

1172006

1172007

11729691--

7210200081--

1175025

1175026

1175042

1175028

1175029

1175043

1175031

1175032

1175044

1172233

1172234

1013148

1013149

1013150

1013145

1013146

1013147

1173086

1173087

1173088

1172229

1172230

1012419

1012420

1012245

1012246

1013080

1013083

1013084

1012595

1012596

050

F12

1

--

--

1

--

--

1

--

--

--

1

--

-1

--

-1

--

--

1

--

--

1

--

-1

--

-1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

--

1

--

--

*9MPV

075

F12

1

--

--

1

--

--

--

1

--

--

--

1

--

1

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

--

1

--

--

1

--

--

100

J20

125

L20

--

--

1

--

--

1

--

--

1

--

--

1

--

--

--

--

1

--

--

1

--

--

1

1

--

--

1

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

1

--

--

--

--

1

--

--

1

--

--

1

--

--

1

18

A

Specifications are subject to change without notice

440 04 2024 01

Replacement Parts - *9MPV

Models -- *9MPV050F12D1, *9MPV075F12D1, *9MPV100J20D1 & *9MPV125L20D1 (Natural Gas)

Replacement part supplied will be current active part. For parts not listed, consult place of purchase.

*9MPV

075

F12

Key

No.

V Partition, Front Ht Exchger 1012650

W Gasket, Attachment Plate 1012542

X Cover, Junction Box 1012350 1 1 1 1

Y Box, Junction 1172860 1 1 1 1

BB Manifold 1012970

CC Bottom, Burner Box 1172847

DD Baffle, Burner Box 1012338

EE Top, Burner Box 1013702

FF Bracket, Manifold Support 1012377 2 2 2 2

GG Bracket, Burner Box Side 1012532 2 2 2 2

HH Bracket, Control Mounting 1172845 1 1 1 1

JJ Tube, Sensor 1172238

KK Trap, Drain Assembly 1171917 1 1 1 1

LL Sightglass

MM Wrapper, Filter Rack 741010039 1 1 2 2

NN Front, Filter Rack 741020001 1 1 2 2

OO Cover, Filter 2791043 1 1 2 2

PP Clip, Filter 1008482 3 3 3 3

QQ Gasket, Trap 1013701 1 1 1 1

RR Bracket, Trap 1171986 1 1 1 1

SS Gasket, Trap Bracket 1171987 1 1 1 1

TT Tube, Drain Coll. Box5/8″ ID 1172245 1 1 1 1

UU Tube, Drain Tee1/2″ ID 1171989 1 1 1 1

VV Tube, Relief 1172012 1 1 1 1

WW Drain Vent 1014003 1 1 1 1

XX Clip, Retainer 1175788 1 1 1 1

YY Tee, Drain 1171915 1 1 1 1

ZZ Sightglass 1172768 1 1 1 1

Description

(Tstar only)

Part

Number

1012648

1012651

1012653

1012543

1012544

1012545

1012971

1012278

1012279

1172848

1172849

1172850

1012339

1012340

1013703

1013704

117224111

1013235

101323611

050

F12

1

--

--

--

2

--

--

--

1

--

--

--

1

--

--

--

1

--

--

1

--

--

075

F12

-1

--

--

-2

--

--

-1

--

--

-1

--

--

1

--

--

1

--

--

1

1

1

1

*9MPV

100

J20

125

L20

--

-1

--

--

-2

--

--

-1

--

--

-1

--

-1

--

-1

--

1

1

1

1

Key

No.

)( PART NOT ILLUSTRATED

-)( Door Screws 1014488 4 4 4 4

--

--

)( Door Screw Grommets 1171990 4 4 4 4

1

)( Coupling, Air Intake 1012284 1 1 1 1

--

)( Gasket, Air Intake 1012583 1 1 1 1

-)( Clamp, Hose5/8” 1012975 4 4 4 4

-)( Clamp, Hose3/4” 1012976 2 2 2 2

2

)( Coupling, Discharge 1002522 1 1 1 1

)( Clamp Hose 1013830 2 2 2 2

)( Grommet, Vent 1012697 1 1 1 1

-)( Bushing, Strain Relief 1945287 1 1 1 1

--

--

)( Grommet, Vinyl (Gas Inlet) 1009535 1 1 1 1

1

)( Harness, Wire 1172818 1 1 1 1

--

)( Harness, Wire Blower V.S. 1174758 1 1 1 1

-)( Trap, Drain Tee 1171916 1 1 1 1

-)( Tube, Drain1/2”IDDrain 1171991 1 1 1 1

1

)( Tube,1/2” Elbow 1171992 2 2 2 2

-)( Coupling,1/2” Barbed 1171993 1 1 1 1

--

1

)( Tubing,5/8”IDDrain 1171994 1 1 1 1

--

)( Connector,3/4”X1/2” 1171995 1 1 1 1

-)( Elbow,1/2” CPVC street 1171996 1 1 1 1

1

)( Grommet, Casing 1171997 1 1 1 1

)( Tube, Relief Ext. 1172239 1 1 1 1

)( Connector, Relief Tube 1171998 1 1 1 1

)( Plate, Cover 1171999 1 1 1 1

)( Gasket, Cover Plate 1172000 1 1 1 1

1

1

)( Cap, Drain Tee 1172255 1 1 1 1

)( Clamp, Tee Cap 1172256 1 1 1 1

)( Manual, Users 44102201200 1 1 1 1

1

1

)( Manual, Installation 44001202401 1 1 1 1

)( Manual, Technical 44004202401 1 1 1 1

Gas Conversion Kits -- All models

Nat to Propane NAHA002LP (1172959*)

Propane to Nat NAHA002NG (1172961*)

* Must be ordered from Service Parts

Description

Part

Number

050

F12

100

J20

125

L20

440 04 2024 01

Specifications are subject to change without notice.

19

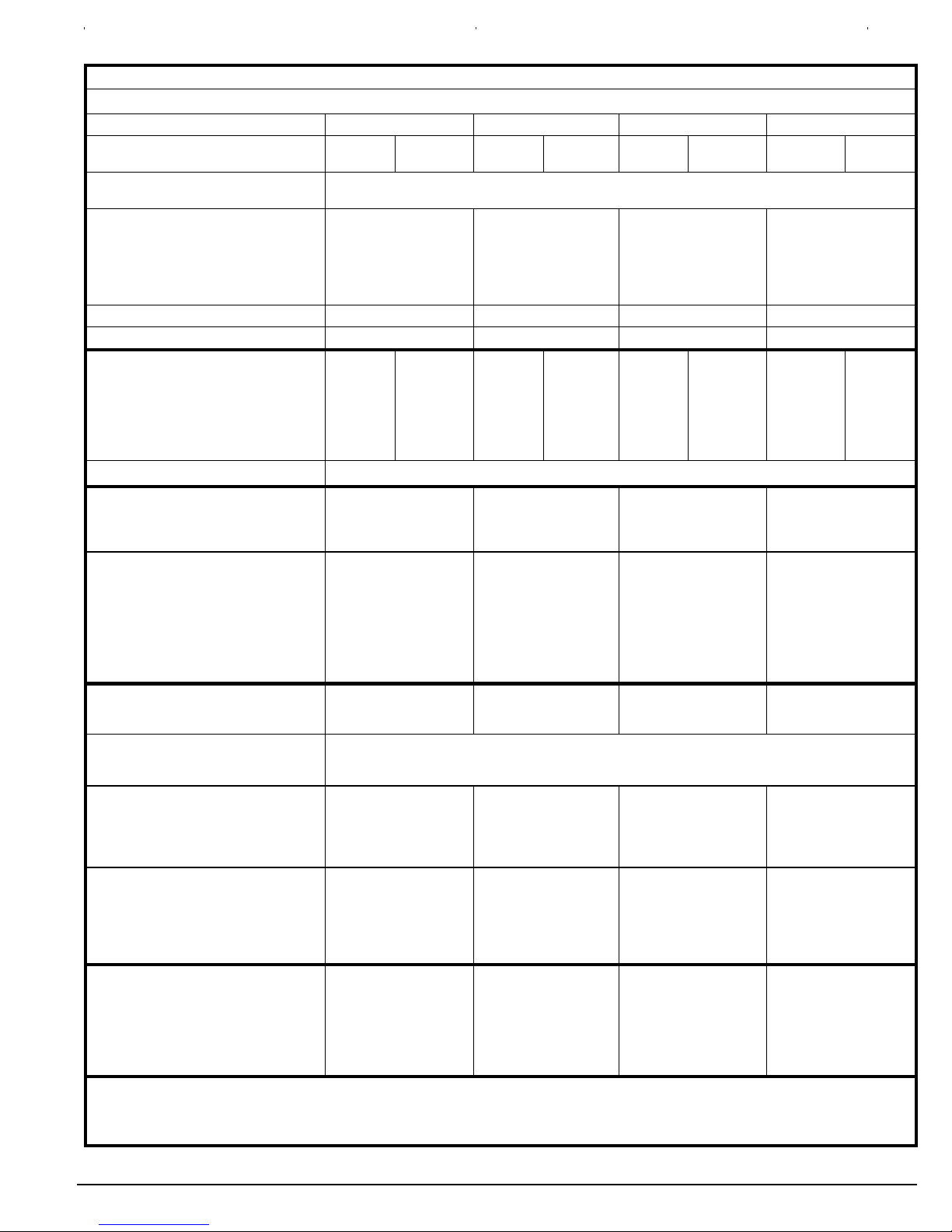

TECHNICAL SUPPORT

Manufacturers Number (Mfr No --SeeRatingPlate)

ALL Models

Specifications

*9MVX040F12 *9MVX060F12 *9MVX080J20 *9MVX100L20

General

Gas Type

Transformer Size (VA)

T’stat Heat Anticipator

Input (Btuh) Std/Alt. HI Heat

LO Heat

Output (Btuh) Std/Alt. HI Heat

Tem p. Ri s e (

oF/o

LO Heat

C) HI Heat

LO Heat

Electrical (Volts/Hz) 115/60 115/60 115/60 115/60

Rating Plate Amps 9.5 11. 4 14.6 14.6

Gas & Ignition

Gas Type

Std. Main Orifices (qty/size)

Gas Valve Honeywell

Regulation Type

Manifold Press. HI Heat (in wc/Pa)

LO Heat (in wc/Pa)

Nat Propane Nat Propane Nat Propane Nat Propane

40

.50

25--55/14--31

25--55/14--31

Nat.

2/44

VR8205Q

SNAP

3.5/872

1.7/423

40000

28000

38000

27000

Propane

2/55

VR8205Q

SNAP

10/2490

4.9/1221

30--60/17--33

30--60/17--33

Nat.

3/44

VR8205Q

SNAP

3.5/872

1.7/423

60000

42000

58000

41000

Propane

3/55

VR8205Q

SNAP

10/2490

4.9/1221

30--60/17--33

30--60/17--33

Nat.

4/44

VR8205Q

SNAP

3.5/872

1.7/423

80000

56000

77000

54000

Propane

4/55

VR8205Q

SNAP

10/2490

4.9/1221

100000

70000

96000

67000

30--60/17--33

30--60/17--33

Nat.

5/44

VR8205Q

SNAP

3.5/872

1.7/423

Propane

5/55

VR8205Q

SNAP

10/2490

4.9/1221

Ignition Type Hot Surface

Combustion

Flue Outlet Size inches(mm)

Std. Outlet Temp (less than)

Comb. Blower (MFD/Volts)

(oF/o

2(50.8)

C)

140/60

4/370

2(50.8)

140/60

4/370

@Blower/ @ Transition Box (HI Heat)

Std. Pressures -- in wc(Pa)

54 No Elbows

404 +5--905 DWV Elbows

2.10/3.47(523/864)

--3.38/--1.90(--842/--473)

2.26/3.52(563/877)

--2.77/--1.52(--690/--378)

--3.28/--1.93(--817/--481)

@Blower/ @ Transition Box (LO Heat)

Std. Pressures -- in wc(Pa)

54 No Elbows

404 +5--905 DWV Elbows

Limits & Controls

Rollout Switch (

Limit Control Setting (

oF/o

C)

oF/o

C)

Furnace Control (Type)

Furnace Control On

(Timed--secs) Off

Std. Pressure Sw. -- in wc(Pa) Part No

(HI Heat)Blwer Switch Press (Close)

Blower Switch Pressure (Open)

(LO Heat)Trans Switch Press (Close)

Transition Switch Pressure (Open)

High Alt Pressure Sw.--in wc(Pa) Part No

(HI Heat)Blwer Switch Press (Close)

Blower Switch Pressure (Open)

(LO Heat)Trans Switch Press (Close)

Transition Switch Pressure (Open)

1.38/2.29(344/570)

--2.21/--1.22(--550/--304)

300/149

210/99

1177762

0.65(162)

0.50(125)

1.85(461)

2.11(525)

1177766

0.65(162)

0.50(125)

1.58(393)

1.40(349)

1.50/2.35(374/585)

--2.06/--1.16(--513/--289)

300/149

230/110

30 HI /45 LO

60,100,140,180

1177767

0.58(144)

0.43(107)

1.73(431)

1.70(423)

1177767

0.58(144)

0.43(107)

1.48(369)

1.31(326)

--2.34/--1.33(--583/--331)

Integrated

Blower Data

Wheel Size D x W in(mm)

FLA Motor Amps/Max RPM

Motor Type/H.P.

Filter Type & Size (qty.) Permanent -- in(mm)

Min. Cool Cap. (Tons)

Max. Cool Cap. (Tons)

11 x 8(279 x 203)

1

ECM/

/

16x25x1(406x635x25)

2

1.5

3

11 x 10(279 x 254)

3

ECM/

/

16x25x1(406x635x25)

4

1.5

3

16x25x1(406x635x25) (2)

Gas Conversion Kits All Models

Nat to Propane NAHA00601LP

Propane to Nat NAHA00601NG

3(76.2)

140/60

4/370

2.05/3.34(510/832)

1.55/2.45(386/610)

300/149

240/116

1177764

0.95(237)

0.80(199)

1.89(471)

1.55(386)

1177768

0.95(237)

0.80(199)

1.61(401)

1.43(356)

11 x 10(279 x 254)

ECM/1

2

5

3(76.2)

140/60

4/370

2.34/3.45(583/859)

--3.29/--2.16(--819/--538)

1.84/2.70(458/672)

--2.61/--1.72(--650/--428)

300/149

180/82

1177765

1.56(396)

1.38(344)

2.32(578)

1.66(413)

1177769

1.30(324)

1.14(384)

1.97(491)

1.78(443)

11 x 10(279 x 254)

ECM/1

16x25x1(406x635x25) (2)

2

5

20

Specifications are subject to change without notice.

440 04 2024 01

Circulation Air Blower Data - *9MVX040

Cooling Adjustment Heating Rise Adjustment

DIP Switch

(OFF = 0

ON = 1)

High Cool @ .50

in wc(125 Pa)

Low Cool (80%

of High Cool)

** Adjust

Jumper

DIP Switch

Setting

5&6 CFM L/s CFM L/s 3&4

(OFF = 0

ON = 1)

High Heat

Rise

Change @

0.20 in wc

(50 Pa)

Low Heat

Rise

Change at

Resultant

Static

00 1244 587 995 470 + 00 -- 3 -- 3

*00 1206 569 965 455 *NOM *00 0 0

00 1126 531 901 425 -- 00 4 4

01 1109 523 887 419 + 01 2 2

01 1032 487 826 390 NOM 01 6 6

01 941 444 753 355 -- 01 13 10

10 901 425 721 340 + 10 0 -- 1

10 828 391 662 313 NOM 10 3 3

10 757 357 606 286 -- 10 8 7

11 705 333 564 266 + 11 -- 1 2 -- 1 3

11 633 299 506 239 NOM 11 -- 1 0 -- 1 0

11 556 262 445 210 -- 11 -- 8 -- 8

Airflow performance includes 1” washable filter media.

*Factory Setting

**Adjust Jumper Setting (+, NOM, --) is applied to both Cooling and Heating

Note 1: HP Mode Jumper provides a 10% reduction in airflow when in Comfort position and a call for low or high cooling is

present with the ”O” line off. This feature is to provide lower airflow for running in HP Heating Mode if desirable.

Note 2: DEHUM mode (24VAC on DEHUM terminal) provides a 20% airflow reduction during cooling calls.

Note 3: Low Heat ESP is a result of High Heat ESP (-- is decrease in rise).

Note 4: High and low heat rise values are approximate air temperature change from return air temperature when at factory

default settings.

Table 2 Airflow

DIP Switch

(OFF = 0 / ON = 1)

Continuous Fan @

0.10 in wc (25 Pa) ESP

1&2 CFM L/s

*00 592 279

01 1021 482

Table 3 SW2 DIP Assignments

DIP Switch Blower Parameter

1&2 Cont Fan Adj

3&4 Heat Speed Adj

5&6 Cool Speed Adj

7&8 Cool On/Off Delay

10 1346 635

11 1346 635

* Factory Setting

Table 4

DIP SW2 -- 7/8

(OFF = 0 / ON = 1)

ON DELAY OFF DELAY

Timed ON (sec)

Cooling Delay Options (SW2 -- 7, 8)

Airflow during on

delay

Timer OFF (sec)

Airflow during off

delay

*00 5 OFF 90 100%

01 5 OFF 0 OFF

10 30 50% 30 100%

11 30 50% 180 50%

Airflow % is of High Cool airflow demand determined from SW2--5/6 Table 1

Airflow resumes to 100% after on delay time is completed

Airflow stops (or switches to continuous fan speed) after off delay time is completed

* Factory Setting

MAX CFM (L/s) for Factory Washable Filters

Filter Size (in/mm) CFM L/s

14″ X25″ (356 x 635) 1400 661

16″ X25″ (406 x 635) 1600 755

20″ X25″ (508 x 635) 2000 944

24″ X25″ (610 x 635) 2500 1180

Max CFM (L/s) based on 600 FPM (3.0 m/s)

NOTE: Disposable filters are typically rated at 300 FPM (1.5 m/s).

These filters only allow half the airflow when compared to 600 FPM

(3.0 m/s) filters.

440 04 2024 01

Specifications are subject to change without notice.

21

1400

1200

1000

CFM

Circulation Air Blower Data - *9MVX040

Cooling Airflow Settings

*9MVX040F12

High Cool Airflow

800

600

400

200

00 +

00 NOM

00 01 +

01 NOM

01 10 +

10 NOM

10 11 +

11 NOM

11 -

0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

ESP (inches of wc)

*9MVX040F12

Low Cool Airflow

1200

1000

800

600

CFM

400

200

00 +

00 NOM

00 01 +

01 NOM

01 10 +

10 NOM

10 11 +

11 NOM

11 -

0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

NOTE: OFF = 0 and ON = 1

22

ESP ( inches of wc)

Specifications are subject to change without notice.

440 04 2024 01

Circulation Air Blower Data - *9MVX060

Cooling Adjustment Heating Rise Adjustment

DIP Switch

(OFF = 0

ON = 1)

High Cool @ .50

in wc(125 Pa)

Low Cool (80%

of High Cool)

** Adjust

Jumper

DIP Switch

Setting

5&6 CFM L/s CFM L/s 3&4

(OFF = 0

ON = 1)

High Heat

Rise

Change @

0.20 in wc

(50 Pa)

Low Heat

Rise

Change at

Resultant

Static

00 1377 650 1102 650 + 00 -- 3 -- 3

*00 1239 585 991 585 *NOM *00 0 0

00 1097 518 878 518 -- 00 3 3

01 1165 550 932 550 + 01 1 2

01 1044 493 835 493 NOM 01 4 4

01 889 420 711 420 -- 01 8 8

10 966 456 773 456 + 10 -- 1 0

10 848 400 678 400 NOM 10 2 2

10 715 337 572 337 -- 10 7 7

11 74 353 599 353 + 11 -- 5 -- 4

11 650 307 520 307 NOM 11 -- 2 -- 2

11 523 247 418 247 -- 11 1 1

Airflow performance includes 1” washable filter media.

*Factory Setting

**Adjust Jumper Setting (+, NOM, --) is applied to both Cooling and Heating

Note 1: HP Mode Jumper provides a 10% reduction in airflow when in Comfort position and a call for low or high cooling is

present with the ”O” line off. This feature is to provide lower airflow for running in HP Heating Mode if desirable.

Note 2: DEHUM mode (24VAC on DEHUM terminal) provides a 20% airflow reduction during cooling calls.

Note 3: Low Heat ESP is a result of High Heat ESP (-- is decrease in rise).

Note 4: High and low heat rise values are approximate air temperature change from return air temperature when at factory

default settings.

Table 2 Airflow

DIP Switch

(OFF = 0 / ON = 1)

Continuous Fan @

0.10 in wc (25 Pa) ESP

1&2 CFM L/s

*00 612 475

01 1096 822

Table 3 SW2 DIP Assignments

DIP Switch Blower Parameter

1&2 Cont Fan Adj

3&4 Heat Speed Adj

5&6 Cool Speed Adj

7&8 Cool On/Off Delay

10 1403 1040

11 1403 1040

* Factory Setting

Table 4

DIP SW2 -- 7/8

(OFF = 0 / ON = 1)

ON DELAY OFF DELAY

Timed ON (sec)

Cooling Delay Options (SW2 -- 7, 8)

Airflow during on

delay

Timer OFF (sec)

Airflow during off

delay

*00 5 OFF 90 100%

01 5 OFF 0 OFF

10 30 50% 30 100%

11 30 50% 180 50%

Airflow % is of High Cool airflow demand determined from SW2--5/6 Table 1

Airflow resumes to 100% after on delay time is completed

Airflow stops (or switches to continuous fan speed) after off delay time is completed

* Factory Setting

MAX CFM (L/s) for Factory Washable Fil-

ters

Filter Size (in/mm) CFM L/s

14″ X25″ (356 x 635) 1400 661

16″ X25″ (406 x 635) 1600 755

20″ X25″ (508 x 635) 2000 944

24″ X25″ (610 x 635) 2500 1180

Max CFM (L/s) based on 600 FPM (3.0 m/s)

NOTE: Disposable filters are typically rated at 300 FPM (1.5 m/s).

These filters only allow half the airflow when compared to 600 FPM

(3.0 m/s) filters.

440 04 2024 01

Specifications are subject to change without notice.

23

CFM

Circulation Air Blower Data - *9MVX060

Cooling Airflow Settings

*9MVX060F12

High Cool Ai r flow chart

1800

1600

1400

1200

1000

800

600

400

200

00+

00NOM

0001+

01NOM

0110+

10NOM

1011+

11NOM

11-

0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

ESP (inches of wc)

*9M VX06 0F12

Low Cool Airflow chart

1400

1200

1000

800

CFM

600

400

200

00+

00NOM

0001+

01NOM

0110+

10NOM

1011+

11NOM

11-

0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

NOTE: OFF = 0 and ON = 1

24

ESP (inches of wc)

Specifications are subject to change without notice.

440 04 2024 01

Circulation Air Blower Data - *9MVX080

Cooling Adjustment Heating Rise Adjustment

DIP Switch

(OFF = 0

ON = 1)

High Cool @ .50

in wc(125 Pa)

Low Cool (80%

of High Cool)

** Adjust

Jumper

DIP Switch

Setting

5&6 CFM L/s CFM L/s 3&4

(OFF = 0

ON = 1)

High Heat

Rise

Change @

0.20 in wc

(50 Pa)

Low Heat

Rise

Change at

Resultant

Static

00 2146 1013 1717 1013 + 00 -- 3 -- 3

*00 2009 948 1607 948 *NOM *00 0 0

00 1843 870 1474 870 -- 00 5 5

01 1779 840 1423 840 + 01 3 3

01 1645 776 1316 776 NOM 01 6 8

01 1498 707 1198 707 -- 01 11 11

10 1409 665 1127 665 + 10 0 0

10 1294 611 1035 611 NOM 10 6 4

10 1147 541 918 541 -- 10 10 9

11 1005 474 804 474 + 11 -- 5 -- 6

11 887 419 710 419 NOM 11 -- 2 -- 2

11 757 357 606 357 -- 11 3 2

Airflow performance includes 1” washable filter media.

*Factory Setting

**Adjust Jumper Setting (+, NOM, --) is applied to both Cooling and Heating

Note 1: HP Mode Jumper provides a 10% reduction in airflow when in Comfort position and a call for low or high cooling is

present with the ”O” line off. This feature is to provide lower airflow for running in HP Heating Mode if desirable.

Note 2: DEHUM mode (24VAC on DEHUM terminal) provides a 20% airflow reduction during cooling calls.

Note 3: Low Heat ESP is a result of High Heat ESP (-- is decrease in rise).

Note 4: High and low heat rise values are approximate air temperature change from return air temperature when at factory

default settings.

Table 2 Airflow

DIP Switch

(OFF = 0 / ON = 1)

Continuous Fan @

0.10 in wc (25 Pa) ESP

1&2 CFM L/s

*00 1007 475

01 1742 822

Table 3 SW2 DIP Assignments

DIP Switch Blower Parameter

1&2 Cont Fan Adj

3&4 Heat Speed Adj

5&6 Cool Speed Adj

7&8 Cool On/Off Delay

10 2204 1040

11 2204 1040

* Factory Setting

Table 4

DIP SW2 -- 7/8

(OFF = 0 / ON = 1)

ON DELAY OFF DELAY

Timed ON (sec)

Cooling Delay Options (SW2 -- 7, 8)

Airflow during on

delay

Timer OFF (sec)

Airflow during off

delay

*00 5 OFF 90 100%

01 5 OFF 0 OFF

10 30 50% 30 100%

11 30 50% 180 50%

Airflow % is of High Cool airflow demand determined from SW2--5/6 Table 1

Airflow resumes to 100% after on delay time is completed

Airflow stops (or switches to continuous fan speed) after off delay time is completed

* Factory Setting

MAX CFM (L/s) for Factory Washable Fil-

ters

Filter Size (in/mm) CFM L/s

14″ X25″ (356 x 635) 1400 661

16″ X25″ (406 x 635) 1600 755

20″ X25″ (508 x 635) 2000 944

24″ X25″ (610 x 635) 2500 1180

Max CFM (L/s) based on 600 FPM (3.0 m/s)

NOTE: Disposable filters are typically rated at 300 FPM (1.5 m/s).

These filters only allow half the airflow when compared to 600 FPM

(3.0 m/s) filters.

440 04 2024 01

Specifications are subject to change without notice.

25

2400

2000

1600

1200

CFM

Circulation Air Blower Data - *9MVX080

Cooling Airflow Settings

*9MVX080J20

High Cool Airflows

00 +

00 NOM

00 01 +

01 NOM

0110 +

10 NOM

10 11 +

11 NOM

11 -

800

400

0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

ESP (inches of wc)

*9MVX 080J20

Low Cool A irflow

2000

1800

1600

1400

1200

1000

CFM

800

600

400

00 +

00 NOM

00 01 +

01 NOM

01 10 +

10 NOM

10 11 +

11 NOM

11 -

200

0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

NOTE: OFF = 0 and ON = 1

26

ES P (inches of wc)

Specifications are subject to change without notice.

440 04 2024 01

Circulation Air Blower Data - *9MVX100

Cooling Adjustment Heating Rise Adjustment

DIP Switch

(OFF = 0

ON = 1)

High Cool @ .50

in wc(125 Pa)

Low Cool (80%

of High Cool)

** Adjust

Jumper

DIP Switch

Setting

5&6 CFM L/s CFM L/s 3&4

(OFF = 0

ON = 1)

High Heat

Rise

Change @

0.20 in wc

(50 Pa)

Low Heat

Rise

Change at

Resultant

Static

00 2108 995 1686 995 + 00 -- 3 -- 3

*00 1974 932 1579 932 *NOM *00 0 0

00 1812 855 1450 855 -- 00 4 5

01 1712 808 1370 808 + 01 1 1

01 1587 749 1270 749 NOM 01 4 5

01 1422 671 1138 671 -- 01 9 10

10 1312 619 1050 619 + 10 -- 2 -- 1

10 1197 565 958 565 NOM 10 1 2

10 1056 498 845 498 -- 10 5 7

11 919 434 735 434 + 11 -- 5 -- 6

11 797 376 638 376 NOM 11 -- 3 -- 3

11 641 303 513 303 -- 11 2 2

Airflow performance includes 1” washable filter media.

*Factory Setting

**Adjust Jumper Setting (+, NOM, --) is applied to both Cooling and Heating

Note 1: HP Mode Jumper provides a 10% reduction in airflow when in Comfort position and a call for low or high cooling is

present with the ”O” line off. This feature is to provide lower airflow for running in HP Heating Mode if desirable.

Note 2: DEHUM mode (24VAC on DEHUM terminal) provides a 20% airflow reduction during cooling calls.

Note 3: Low Heat ESP is a result of High Heat ESP (-- is decrease in rise).

Note 4: High and low heat rise values are approximate air temperature change from return air temperature when at factory

default settings.

Table 2 Airflow

DIP Switch

(OFF = 0 / ON = 1)

Continuous Fan @

0.10 in wc (25 Pa) ESP

1&2 CFM L/s

*00 1032 487

01 1778 839

Table 3 SW2 DIP Assignments

DIP Switch Blower Parameter

1&2 Cont Fan Adj

3&4 Heat Speed Adj

5&6 Cool Speed Adj

7&8 Cool On/Off Delay

10 2178 1028

11 2178 1028

* Factory Setting

Table 4

DIP SW2 -- 7/8

(OFF = 0 / ON = 1)

ON DELAY OFF DELAY

Timed ON (sec)

Cooling Delay Options (SW2 -- 7, 8)

Airflow during on

delay

Timer OFF (sec)

Airflow during off

delay

*00 5 OFF 90 100%

01 5 OFF 0 OFF

10 30 50% 30 100%

11 30 50% 180 50%

Airflow % is of High Cool airflow demand determined from SW2--5/6 Table 1

Airflow resumes to 100% after on delay time is completed

Airflow stops (or switches to continuous fan speed) after off delay time is completed

* Factory Setting

MAX CFM (L/s) for Factory Washable Fil-

ters

Filter Size (in/mm) CFM L/s

14″ X25″ (356 x 635) 1400 661

16″ X25″ (406 x 635) 1600 755

20″ X25″ (508 x 635) 2000 944

24″ X25″ (610 x 635) 2500 1180

Max CFM (L/s) based on 600 FPM (3.0 m/s)

NOTE: Disposable filters are typically rated at 300 FPM (1.5 m/s).

These filters only allow half the airflow when compared to 600 FPM

(3.0 m/s) filters.

440 04 2024 01

Specifications are subject to change without notice.

27

CFM

2600

2200

1800

1400

1000

600

Circulation Air Blower Data - *9MVX100

Cooling Airflow Settings

*9MVX 100L20

High Cooling Airflows

00 (+)

00 (NOM)

00(-)

01(+)

01(NOM)

01(-)

10(+)

10(NOM)

10(-)

11(+)

11(NOM)

11(-)

200

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

ESP (inches of wc)

*9MVX100L20

Low Cool Airflow

2000

1800

1600

1400

1200

1000

CFM

800

600

400

00+

00NOM

0001+

01 NOM

01 10+

10 NOM

10 11+

11 NOM

11 -

200

0

0.0 0.2 0.4 0.6 0.8 1.0

NOTE: OFF = 0 and ON = 1

28

ESP (inches of wc)

Specifications are subject to change without notice.

440 04 2024 01

Variable Speed (9MPV & 9MVX) Tap Select Interface Board (TSIB)

TO FURNACE BOARD

P3

BLU WHT

GRN BLK

BRN YEL

TO FURNACE

CONTROL24VAC

FROM 24V

TRANS RED

ON = 1

18

OFF

= 0

J1

+NOM --

P7

RED

SW2

1234 6578

ON

OFF

CONT

HEAT

FAN

+NOM--

BLOWER ADJUST

COOL

COOL

DLY

J1

J2

AC/HP EFFICIENCY

HP COMFORT

SELECTION

HP MODE

SELECT

Y1

O

SW2

1234 6578

CONT

FAN

HEAT

COOL

COOL

DLY

BLOWER ADJUST

INCREASE/NO CHANGE/DECREASE

J2

AC/HP EFFICIENCY

HP COMFORT

HP MODE

SELECT

HEAT PUMP EFFICIENCY OR

HP COMFORT SELECTION

CONTINUOUS

CFM SELECT

HEATING RISE

SELECT

COOLING CFM

SELECT

COOLING ON/OFF

DELAY PROFILES

25--25--54

440 04 2024 01

International Comfort Products, LLC

Lewisburg, TN 37091 U.S.A.

Specifications are subject to change without notice.

29

Replacement Parts - *9MVX

Models -- *9MVX040F12A1, *9MVX060F12A1, *9MVX080J20A1 & *9MVX100L20A1 (Natural Gas)

Replacement part supplied will be current active part. For parts not listed, consult place of purchase.

A

060

F12

*9MVX

-1

--

--

-1

--

--

-1

-1

-1

--

--

-1

--

--

-1

--

--

-1

--

--

-1

--

--

080

J20

--

-1

--