International Comfort Products F9MAC0601714A, F9MAC0602120A, F9MAC0801714A, F9MAC0802120A, F9MAC1002122A TECHNICAL MANUAL

...

SERVICE AND TECHNICAL

(

SUPPORT MANUAL

Modulating, Variable Speed Blower Motor

35” Tall, High Efficiency Condensing Gas Furnace

F/G)9MAC

Save this manual for future reference.

Safety Labeling and Signal Words

DANGER, WARNING, CAUTION, and NOTE

The signal words DANGER, WARNING,

CAUTION, and NOTE are used to identify levels of

hazard seriousness. The signal word DANGER is

only used on product labels to signify an immediate

hazard. The signal words WARNING, CAUTION,

and NOTE will be used on product labels and

throughout this manual and other manual that may

apply to the product.

DANGER − Immediate hazards which will result in

severe personal injury or death.

WARNING − Hazards or unsafe practices which

could result in severe personal injury or death.

CAUTION − Hazards or unsafe practices which

may result in minor personal injury or product or

property damage.

NOTE − Used to highlight suggestions which will

result in enhanced installation, reliability, or

operation.

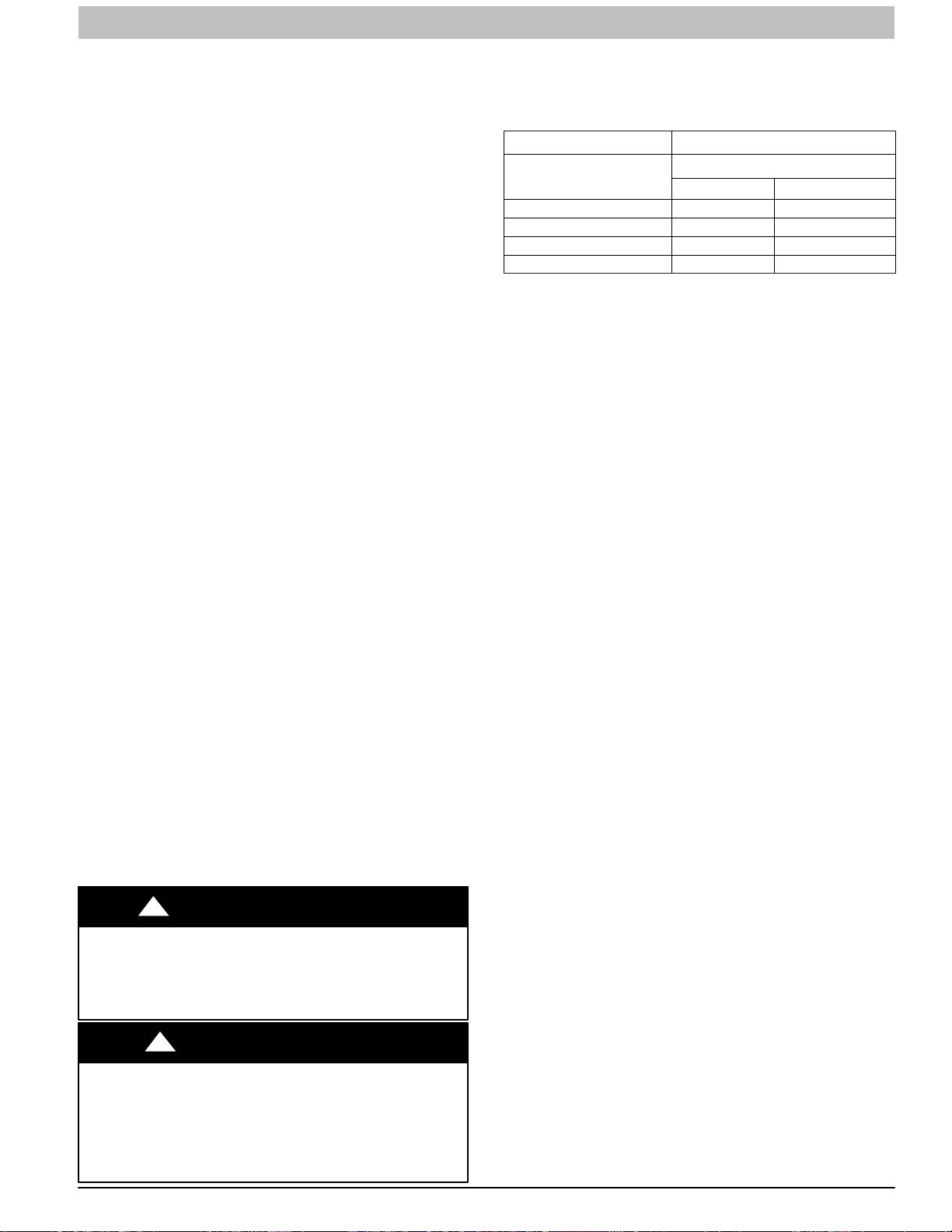

Signal Words in Manuals

The signal word WARNING is used throughout

this manual in the following manner:

!

WARNING

The signal word CAUTION is used throughout

this manual in the following manner:

!

CAUTION

Signal Words on Product Labeling

Signal words are used in combination with

colors and/or pictures or product labels.

Safety−alert symbol

When you see this symbol on the unit and in

instructions or manuals, be alert to the

potential for personal injury.

TABLE OF CONTENTS

START−UP, ADJUSTMENT, AND SAFETY CHECK 4...........

SELECT SETUP SWITCH POSITIONS 4.....................

PRIME CONDENSATE TRAP WITH WATER 4.................

PURGE GAS LINES 5......................................

ADJUSTMENTS 5.........................................

ADJUST TEMPERATURE RISE 8............................

ADJUST BLOWER OFF DELAY (HEAT MODE) 9..............

ADJUST COOLING AIRFLOW 9.............................

ADJUST CONTINUOUS FAN AIRFLOW 9....................

ADJUST THERMOSTAT HEAT ANTICIPATOR 11...............

CHECK SAFETY CONTROLS 12.............................

CHECKLIST 12.............................................

COOLING AND HEATING AIR DELIVERY 17...................

SERVICE AND MAINTENANCE PROCEDURES 21.............

ELECTRICAL CONTROLS AND WIRING 21...................

CLEANING AND/OR REPLACING AIR FILTER 23..............

CLEANING BURNERS AND FLAME SENSOR 25...............

SERVICING HOT SURFACE IGNITER 26......................

FLUSHING COLLECTOR BOX AND DRAINAGE SYSTEM 27....

CLEANING CONDENSATE DRAIN AND TRAP 27..............

WINTERIZATION 28........................................

SERVICE LABEL 29.........................................

TROUBLESHOOTING CHART − FLOW CHART 31.............

TROUBLESHOOTING GUIDE − FLOW CHART 32..............

SEQUENCE OF OPERATION 34.............................

PARTS REPLACEMENT INFORMATION GUIDE 38.............

PRODUCT NOMENCLATURE 39.............................

MODELS

(F/G)9MAC0601714A

(F/G)9MAC0602120A

(F/G)9MAC0801714A

(F/G)9MAC0802120A

(F/G)9MAC1002122A

(F/G)9MAC1202422A

Use of the AHRI Certified TM Mark indicates a

manufacturer’s participation in the program.

For verification of certification for individual

products, go to www.ahridirectory.org .

Printed in U.S.A. 440 04 4201 03 July 2012

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical shock,

or other conditions which may cause death, personal injury, or

property damage. Consult a qualified installer, service agency,

or your distributor or branch for information or assistance. The

qualified installer or agency must use factory−authorized kits or

accessories when modifying this product. Refer to the individual

instructions packaged with the kits or accessories when

installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Use quenching cloth for brazing operations.

Have fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions included in

literature and attached to the unit. Consult local building codes,

the current editions of the National Fuel Gas Code (NFCG)

NFPA 54/ANSI Z223.1, and the National Electrical Code (NEC)

NFPA 70.

In Canada refer to the current editions of the National standards

of Canada CAN/CSA−B149.1 and .2 Natural Gas and Propane

Installation Codes, and Canadian Electrical Code CSA C22.1.

Recognize safety information. This is the safety−alert symbol

. When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand these signal words; DANGER, WARNING, and

CAUTION. These words are used with the safety−alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies hazards

which could result in personal injury or death. CAUTION is used

to identify unsafe practices which may result in minor personal

injury or product and property damage. NOTE is used to

highlight suggestions which will result in enhanced installation,

reliability, or operation.

!

WARNING

PERSONAL INJURY, AND/OR PROPERTY DAMAGE

HAZARD

Failure to carefully read and follow this warning could

result in equipment malfunction, property damage,

personal injury and/or death.

Installation or repairs made by unqualified persons could

result in equipment malfunction, property damage,

personal injury and/or death.

The information contained in this manual is intended for

use by a qualified service technician familiar with safety

procedures and equipped with proper tools and test

instruments.

Installation must conform with local building codes and

with the Natural Fuel Gas Code (NFCG) NFPA 54/ANSI

Z223.1, and National standards of Canada

CAN/CSA−B149.1 and .2 Natural Gas and Propane

Installation Codes.

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal

injury or death.

Before performing service or maintenance operations

on unit, always turn off main power switch to unit and

install lockout tag. Unit may have more than one power

switch.

!

WARNING

WARNING

CARBON MONOXIDE POISONING AND FIRE

HAZARD

Failure to follow safety warnings could result in personal

injury, death, and/or property damage.

This furnace is not designed for use in mobile homes,

trailers or recreational vehicles.

!

CAUTION

CUT HAZARD

Failure to follow this caution may result in damage

personal injury.

Sheet metal parts may have sharp edges or burrs. Use

care and wear appropriate protective clothing, safety

glasses and gloves when handling parts and servicing

furnaces.

2

Specifications are subject to change without notice.

440 04 4201 03

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MAC

START−UP CHECK SHEET

For Variable Speed Models (F/G)9MAC

(This sheet is optional. Keep for future reference.)

Date of Start−Up:

Dealer Name:

Address:

City, State(Province), Zip or Postal Code:

Phone:

Owner Name:

Address:

City, State(Province), Zip or Postal Code:

Model Number:

Serial Number:

Setup Checks

Check the box when task is complete.

All Electrical Connections Tight?

Have hoses been relocated for furnace U/D/H

application?

Condensate Drain Connected?

Condensate Drain Trapped?

Manual Gas Shut−off Upstream of Furnace/Drip Leg

Heating Check

Measured Line Pressure During High Heat:

Measured Manifold Pressure: Max Heat

Min Heat

Temperature of Supply Air: Max Heat

Min Heat

Temperature of Return Air:

Temperature Rise (Supply − Return): Max Heat

Min Heat

In Rise Range (see furnace rating plate)?

Static Pressure (Ducts) High Heat: Supply

Return

Optional Check: CO?

CO2?

Cooling Check

Temperature of Supply Air:

Temperature of Return Air:

Temperature Difference:

Static Pressure (Ducts) Cooling: Supply

Return

Gas Valve turned ON?

Dealer Comments:

Type of Gas: Natural: Propane:

Filter Type and Size:

Shade in Final Furnace Settings Below:

Calculated Input (BTU) Rate: (See Checks and

Adjustments Section).

440 04 4201 03 3

Specifications subject to change without notice.

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MAC

START−UP, ADJUSTMENT, AND SAFETY

CHECK

General

1. Furnace must have a 115-v power supply properly

connected and grounded.

NOTE: Proper polarity must be maintained for 115-v wiring.

Control status indicator light flashes code 10 and furnace does

not operate if polarity is incorrect or if the furnace is not

grounded.

2. Thermostat wire connections at terminals R, W/W1, G,

Y/Y2, etc. must be made at 24-v terminal block on

furnace control. See communicating wall control

instructions for proper wiring of communicating controls.

3. Natural gas service pressure must not exceed 0.5 psig

(14- in. w.c., 350 Pa), but must be no less than 0.16 psig

(4.5-in. w.c., 1125 Pa).

4. Blower door must be in place to complete 115-v

electrical circuit and supply power to furnace.

!

CAUTION

UNIT OPERATION HAZARD

Failure to follow this caution may result in intermittent unit

operation or performance dissatisfaction.

These furnaces are equipped with a manual reset limit

switch in burner assembly. This switch opens and shuts off

power to the gas valve if an overheat condition (flame

rollout) occurs in the burner assembly/enclosure. Correct

inadequate combustion-air supply, improper gas pressure

setting, improper burner or gas orifice positioning, or

improper venting condition before resetting switch. DO

NOT jumper this switch.

Before operating furnace, check flame rollout manual reset

switch for continuity. If necessary, press button to reset switch.

EAC-1 terminal is energized whenever blower operates. HUM

terminal is only energized when blower is energized in heating.

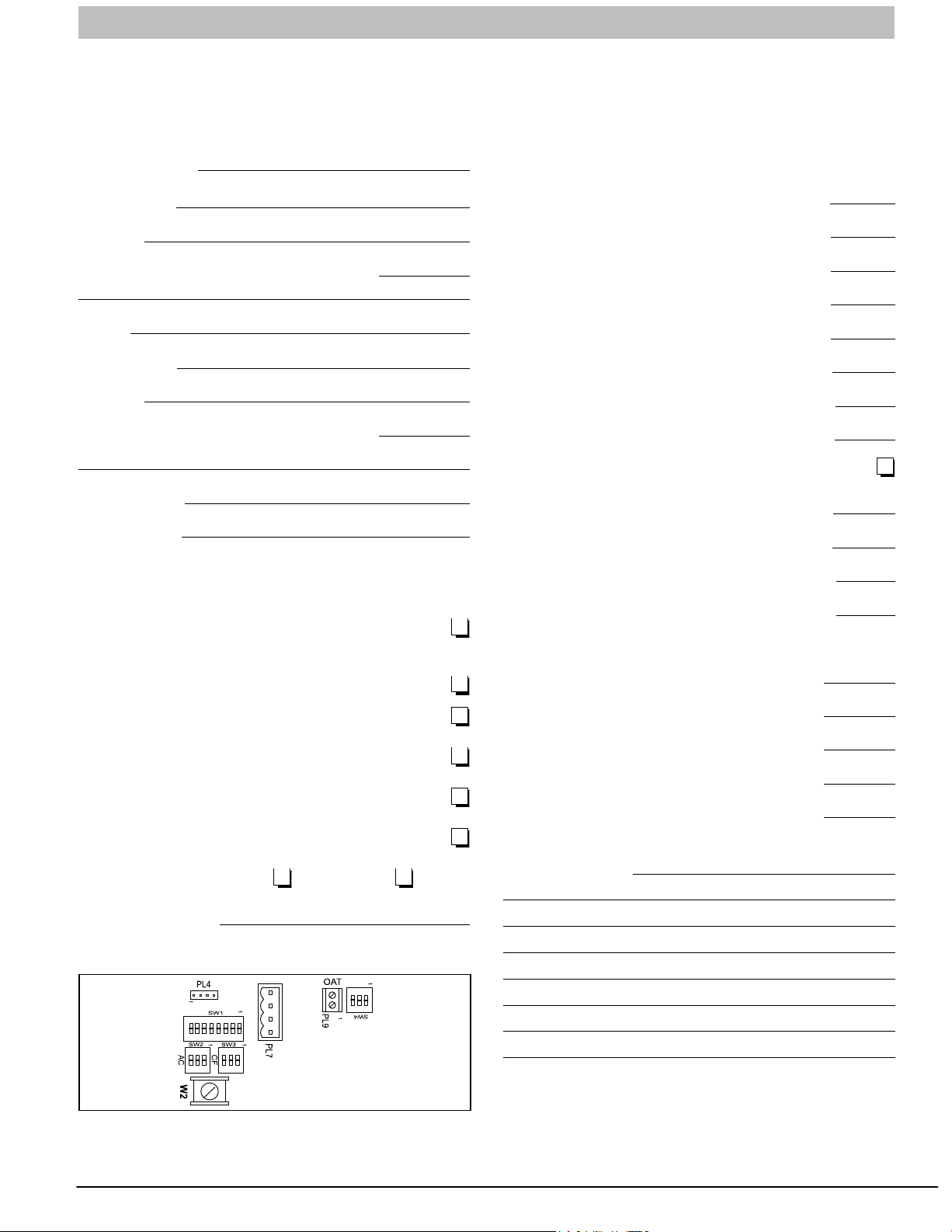

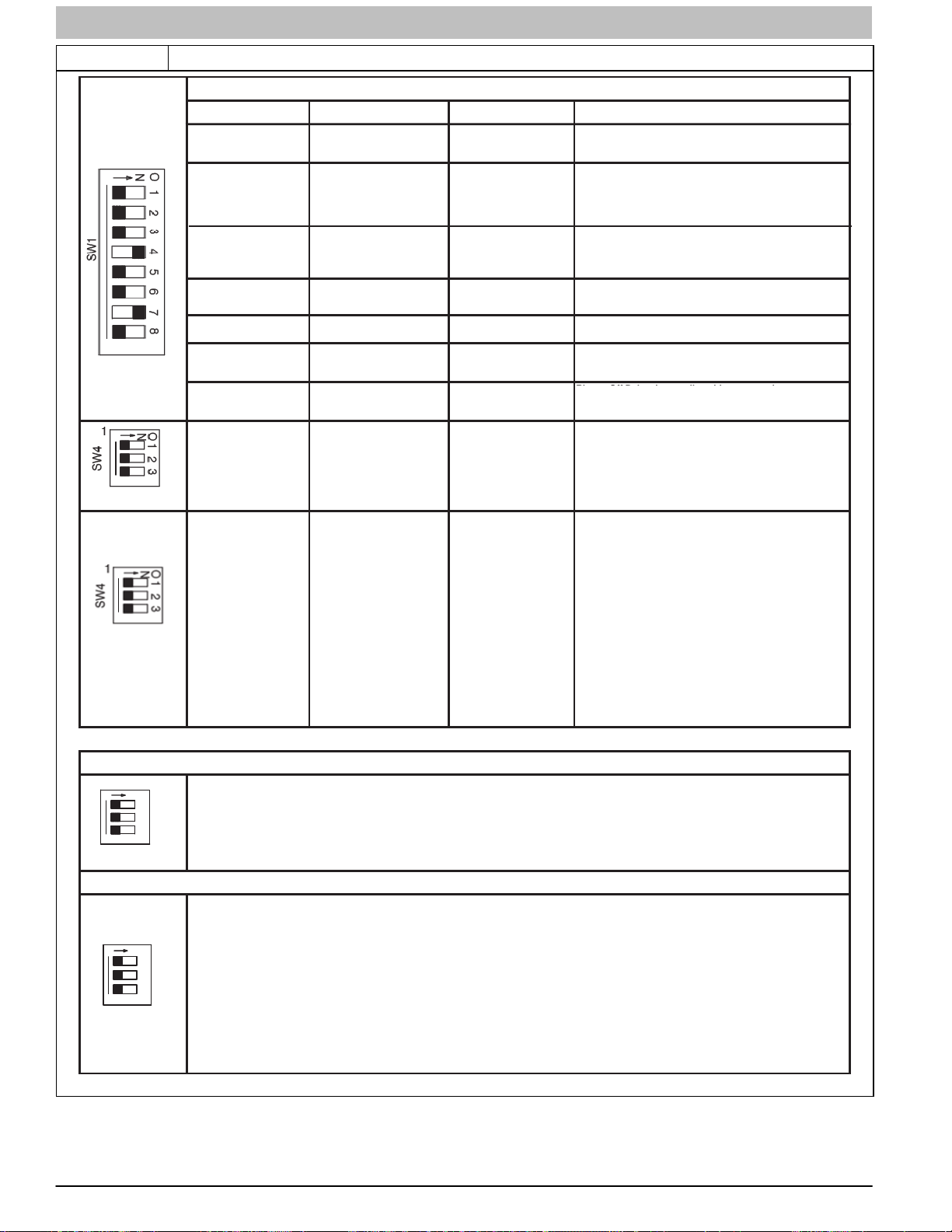

Select Setup Switch Positions

There are four sets of setup switches on the furnace control

board. These switches configure the furnace for correct

application requirement. They also select the airflow settings for

Air Conditioning and Continuous Fan airflows.

The Setup Switch locations are shown and described on

Figure 3, Figure 4, Table 3 and Table 6. The set up switches

are also shown on the unit wiring label.

Setup Switches (SW1)

The furnace control has eight setup switches that may be set to

meet the application requirements. Refer to Figure 4 and

Adjustments section for set up switch configurations.

To set these setup switches for the appropriate requirement:

1. Remove blower door.

2. Locate setup switches on furnace control.

3. Configure the set-up switches as necessary for the

application.

4. Replace blower door.

NOTE: If a bypass humidifier is used, setup switch SW1-3

(Min/Int Rise Adjust) should be in ON position. This

compensates for the increased temperature in return air

resulting from bypass.

NOTE: If modulating dampers are used, blower motor

automatically compensates for modulating dampers.

Air Conditioning (A/C) Setup Switches (SW2)

The air conditioning setup switches are used to match furnace

airflow to required cooling airflow or high stage cooling airflow

4 440 04 4201 03

Specifications subject to change without notice.

when a two−stage outdoor unit is used. Refer to Figure 4 and

the Adjustments section for set up switch configurations.

To set the desired cooling airflow:

1. Remove blower door.

2. Locate A/C setup switches on furnace control.

3. Determine air conditioning tonnage used.

4. Configure the switches for the required cooling airflow.

NOTE: Incorrect airflow caused by improper A/C switch setup

may cause condensate blow−off or a frozen indoor coil in the

cooling mode.

5. Replace blower door.

Continuous Fan (CF) Setup Switches (SW3)

The CF setup switches are used to select desired airflow when

thermostat is in continuous fan mode or to select low-cooling

airflow for two-speed cooling units. Refer to Figure 4 and the

Adjustments section for set up switch configurations.

1. Remove blower door.

2. Locate CF setup switches on furnace control.

3. Determine desired continuous fan airflow or low-cooling

airflow.

4. Configure the switches for the required continuous fan or

low−cooling airflow.

5. Replace blower door.

Additional Setup Switches (SW4)

The furnace control has three additional setup switches labeled

SW4.

Setup switch SW4-2 can be used to lock the furnace into

intermediate heat. When setup switch SW4-2 is ON it will over

ride setup switch SW1-2 if it is ON. SW4−3 is used to adjust

airflow. Refer to Figure 4 and the Adjustments section for set

up switch configurations.

1. Remove blower door.

2. Locate setup switch SW4 on furnace control.

3. Configure the switches for the required heat stages air

flow if necessary.

4. Replace blower door.

Prime Condensate Trap with Water

! WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow these warnings could result in personal injury

or death.

Failure to use a properly configured trap or NOT

water-priming trap before operating furnace may allow

positive pressure vent gases to enter the structure through

drain tube. Vent gases contain carbon monoxide which is

tasteless and odorless.

!

CAUTION

UNIT OPERATION HAZARD

Failure to follow this caution may result in intermittent unit

operation or performance satisfaction.

Condensate trap must be PRIMED or proper draining may

not occur. The condensate trap has two internal

chambers which can ONLY be primed by pouring water

into the inducer drain side of condensate trap.

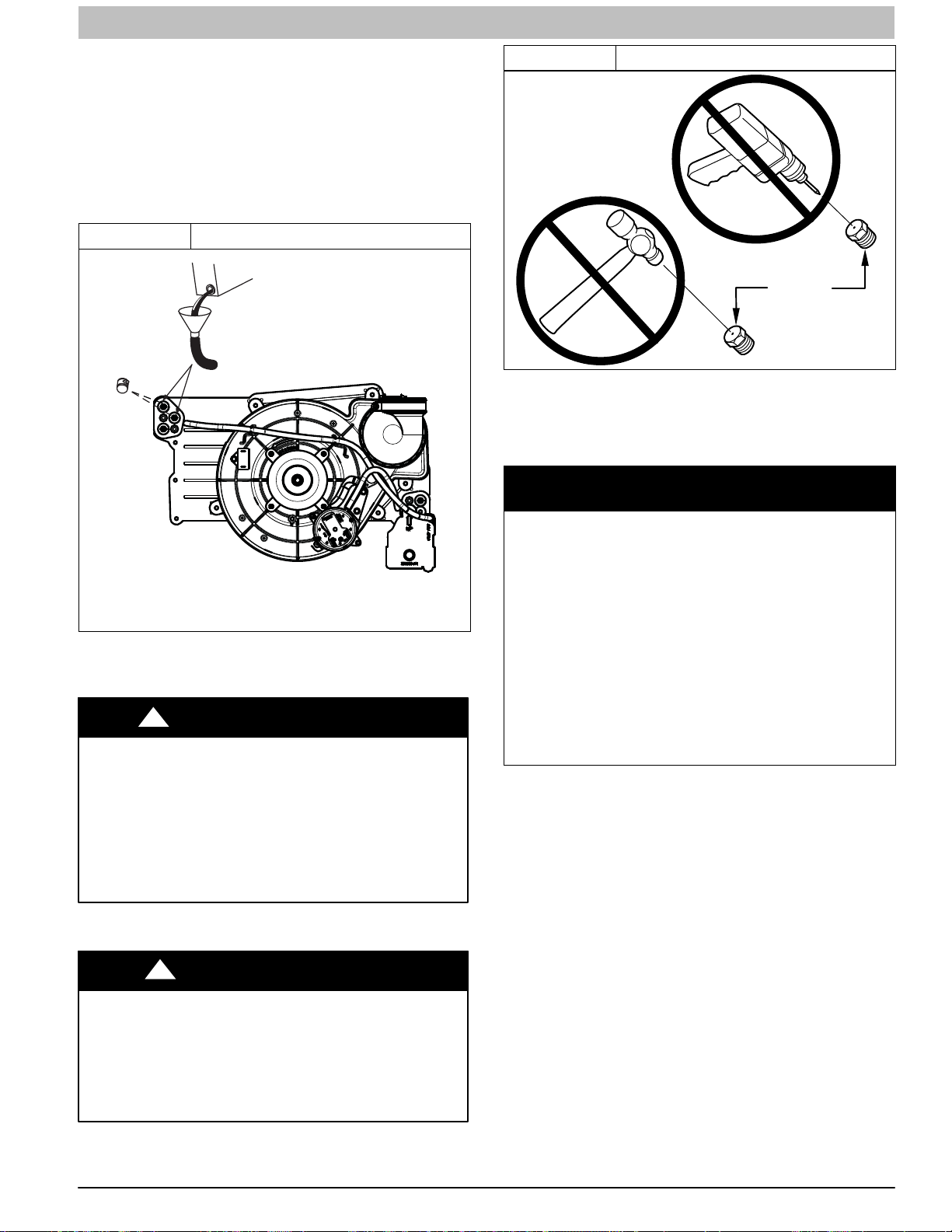

1. Remove upper and middle collector box drain plugs

opposite of the condensate trap. (See Figure 1)

2. Connect field-supplied 5/8-in. (16 mm) ID tube with

attached funnel (see Figure 1) to upper collector box

drain connection.

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MAC

3. Pour one quart (liter) of water into funnel/tube. Water

should run through collector box, overfill condensate

trap, and flow into open field drain.

4. Remove funnel; replace collector box drain plug.

5. Connect field-supplied 5/8-in. (16 mm) ID tube to middle

collector box drain port.

6. Pour one quart (liter) of water into funnel/tube. Water

should run through collector box, overfill condensate

trap, and flow into open field drain.

7. Remove funnel and tube from collector box and replace

collector box drain plug.

Figure 1 Priming Condensate Drain

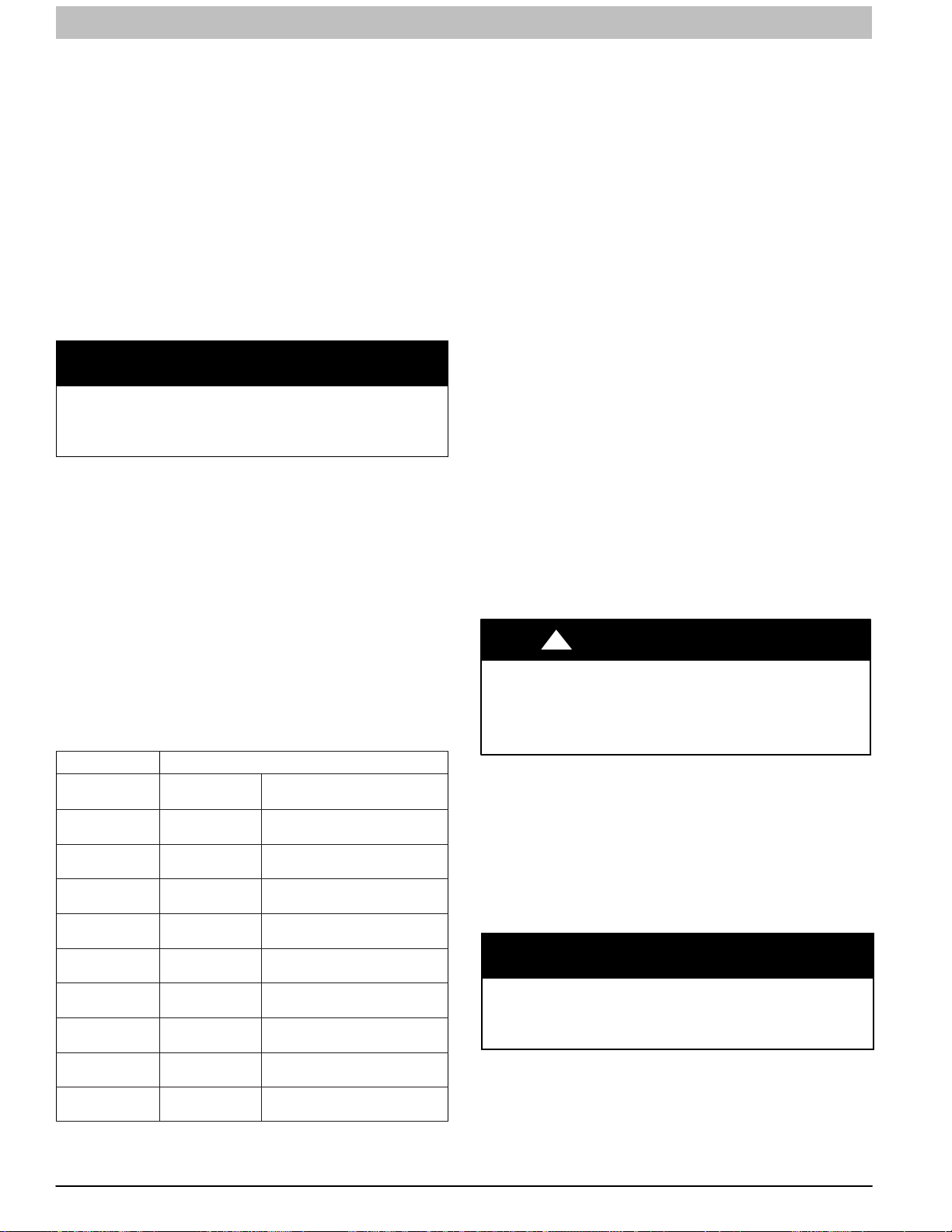

Figure 2 Orifice Hole

BURNER

ORIFICE

A93059

For proper operation and long term reliability, the Furnace input

rate must be within +/− 2 percent of input rate on furnace rating

plate, or as adjusted for altitude.

The gas input rate on rating plate is for installations at altitudes

up to 2000 ft. (610 M).

NOTICE

Representative drawing only, some models may vary in appearance.

L11F065

Purge Gas Lines

If not previously done, purge the lines after all connections

have been made and check for leaks.

!

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

Never purge a gas line into a combustion chamber. Never

test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for the detection

of leaks to check all connections. A fire or explosion may

result causing property damage, personal injury or loss of

life.

WARNING

Adjustments

!

CAUTION

FURNACE DAMAGE HAZARD

Failure to follow this caution could result in reduced

furnace life.

DO NOT push or force gas valve adjusting screw. This

can result in damage to the adjustment screw resulting in

incorrect manifold pressure, which can result in a no heat

situation or shorten the life of the heat exchangers.

The NATURAL GAS manifold pressure adjustments in Table 4

and Table 5 compensate for BOTH altitude AND gas heating

value. DO NOT apply an additional de−rate factor to the

pressures shown in Table 4 or Table 5. The values in these

Tables are NOT referenced to sea level; they are

AS−MEASURED AT ALTITUDE.

The heating content of natural gas at altitude may already

provide for a reduction in capacity or the furnace. Be sure to

obtain the expected in−season gas heating value of the gas

from the gas supplier BEFORE making any adjustments for

capacity or altitude. Refer to Table 4 or Table 5. No

adjustments to the furnace may be necessary at altitude for

certain gas heating values.

Refer to the instructions provided in the factory-specified

LP/Propane conversion kit for instructions for setting gas

manifold pressures for LP/Propane applications.

In the USA, the input rating for altitudes above 2000 ft. (610 M)

must be reduced by 2 percent for each 1000 ft. (305 M) above

sea level. Refer to Table 1. The natural gas manifold pressures

in Table 4 and Table 5 adjust for BOTH altitude and natural gas

heating value.

In Canada, the input rating must be reduced by 5 percent for

altitudes of 2000 ft. (610 M) to 4500 ft. (1372 M) above sea

level. The natural gas manifold pressures in Table 4 and

Table 5 adjust for BOTH altitude and natural gas heating value.

NOTE: For Canadian altitudes of 200 to 4500 ft. (610 to 1372

M), use USA altitudes of 2001 to 3000 ft. (611 to 914 M) in

Table 4 and Table 5.

To adjust manifold pressure to obtain the proper input rate, first,

determine if the furnace has the correct orifice installed. At

higher altitudes or different gas heat contents, it may be

necessary to change the factory orifice to a different orifice.

Tables have been provided in the furnace Service and

Technical Manual to match the required orifice to the manifold

pressure to the heat content and specific gravity of the gas.

NOTE: There are two sets of manifold pressure tables. Use

Table 4 for all models EXCEPT *9MAC0602120 Btuh model.

Use Table 5 for only the *9MAC0602120 model.

440 04 4201 03 5

Specifications subject to change without notice.

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MAC

To do this:

1. Obtain average heat value (at installed altitude) from

local gas supplier.

2. Obtain average specific gravity from local gas supplier.

3. Find installation altitude range for your installation in the

manifold pressure tables. See Table 4 for the 20,000

Btuh Max−Heat/8,000/Btuh Min−Heat per burner models

or Table 5 for model *9MAC0602120 only (20,200 Btuh

Max−Heat/8,000 Btuh Min−Heat per burner).

4. Find closest natural gas heat value and specific gravity in

Table 4 or Table 5 depending on furnace gas input rate.

5. Follow heat value and specific gravity lines to point of

intersection to find orifice size and maximum and

minimum manifold pressure settings for proper operation.

6. Check and verify burner orifice size in furnace. Never

assume orifice size. NEVER ASSUME ORIFICE SIZE.

ALWAYS CHECK AND VERIFY.

NOTICE

If orifice hole appears damaged or it is suspected to have been

redrilled, check orifice hole with a numbered drill bit of correct

size. Never redrill an orifice. A burr−free and squarely aligned

orifice hole is essential for proper flame characteristics.

7. Replace orifice with correct size, if required by Table 4

or Table 5 depending on furnace gas input rate. Use only

factory−supplied orifices. See EXAMPLE 1.

EXAMPLE 1:

(See Table 4)

0 - 2000 ft. (0 - 609.6M) altitude

Heating value = 1050 Btu/cu ft.

Specific gravity = 0.62

Therefore: Orifice No. 44

(Furnace is shipped with No. 44 orifices. In this example, all

main burner orifices are the correct size and do not need to be

changed to obtain proper input rate.)

Manifold pressure: 3.4-in. w.c. (847 Pa) for Maximum heat,

.55-in. w.c. (349 Pa) for Minimum heat

NOTE: To convert gas manifold Table pressures to Pascals,

multiply the in.w.c. value by 249.1 Pa/in. w.c. (1 in. wc. = 249.1

Pa).

Table 1 Altitude Derate Multiplier for U.S.A.

ALTITUDE

FT. (M)

0–2000

(0−610)

2001–3000

(610−914)

3001–4000

(914−1219)

4001–5000

(1219−1524)

5001–6000

(1524−1829)

6001–7000

(1829−2134)

7001–8000

(2134−2438)

8001–9000

(2438−2743)

9001–10,000

(2743−3048)

* Derate multiplier factors are based on midpoint altitude for altitude range.

PERCENT

OF DERATE

0 1.00

4−6 0.95

6−8 0.93

8−10 0.91

10−12 0.89

12−14 0.87

14−16 0.85

16−18 0.83

18−20 0.81

DERATE MULTIPLIER

FACTOR*

NOTE: For Canadian altitudes of 2000 to 4500 ft. (610 to

1372 M), use USA altitudes of 2001 to 3000 ft. (610 to 914

M).

Check Inlet Gas Pressure

The inlet gas pressure must be checked with the furnace

operating in maximum heat. This is necessary to make sure the

inlet gas pressure does not fall below the minimum pressure of

4.5−in. w.c. for natural gas. The maximum inlet gas pressure is

13.6−in. w.c. If the inlet pressure is too low, you will not be able

to adjust the manifold pressure to obtain the proper input rate.

To check the inlet gas pressure:

1. Make sure the gas supply is turned off to the furnace and

at the electric switch on the gas valve.

2. Remove the 1/8 inch NPT plug from the inlet pressure

tap on the gas valve.

3. Connect a manometer to the inlet pressure tap on gas

valve.

4. Turn on furnace power supply.

5. Turn gas supply manual shutoff valve to ON position.

6. Turn furnace gas valve switch to ON position.

7. Jumper the R to W/W1 and W2 thermostat connections

at the furnace control board.

8. When main burners ignite, confirm inlet gas pressure is

Between 4.5−in. w.c. and 13.6−in. w.c.

9. Remove jumper across thermostat connections to

terminate call for heat. Wait until the blower off delay is

completed.

10. Turn furnace gas valve electric switch to OFF position.

11. Turn gas supply manual shutoff valve to OFF position.

12. Turn off furnace power supply.

13. Remove manometer from the inlet pressure tap of the

gas valve.

!

FIRE HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Re−install manifold pressure tap plug in gas valve to

prevent gas leak.

14. Apply pipe dope sparingly to end of inlet gas pipe plug

and re−install in the gas valve.

WARNING

Adjust Manifold Pressure−Maximum Heat

The modulating furnace manifold pressure is set at two points.

The first point is Maximum Heat.

The second point is Minimum Heat. Do not adjust Intermediate

Heat manifold pressure. Intermediate Heat manifold pressure is

checked as part of the temperature rise, but is not adjustable.

Always adjust Maximum Heat first, then Minimum Heat.

NOTICE

DO NOT set maximum heat manifold pressure less than 3.2−in.

w.c. (947 Pa) for natural gas. If required manifold pressure is

outside this range, change main burner orifices to obtain

manifold pressure in this range.

To adjust manifold pressure to obtain input rate for Maximum

Heat:

1. Make sure the gas supply is turned off to the furnace and

at the electric switch on the gas valve.

6 440 04 4201 03

Specifications subject to change without notice.

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MAC

2. Remove the 1/8 inch NPT plug from the outlet pressure

tap on the gas valve.

3. Connect a manometer to the outlet pressure tap on gas

valve.

4. Turn on furnace power supply.

5. Turn gas supply manual shutoff valve to ON position.

6. Turn furnace gas valve switch to ON position.

7. Jumper the R to W/W1 and W2 thermostat connections

at the furnace control board.

8. After the main burners ignite and the blower starts,

confirm Maximum Heat manifold pressure is correct,

based on the manifold pressure tables in the installation

instructions.

9. To adjust the Maximum Heat manifold pressure, slowly

turn adjusting screw counterclockwise to decrease

manifold pressure or clockwise to increase manifold

pressure. Turn adjustment no more than one click per

second until you obtain the required manifold pressure.

10. Main burner flame should be clear blue, almost

transparent.

11. After adjusting the Maximum Heat manifold pressure,

remove jumpers across thermostat connections to

terminate the call for heat.

12. Wait for blower off-delay to finish then reset 115-v power

to furnace.

Adjust Manifold Pressure−Minimum Heat

To adjust manifold pressure to obtain input rate for Minimum

Heat:

1. Turn SW1−2 ON at the furnace control. Set up switch

SW4−2 must be OFF.

2. Jumper R and W/W1 thermostat connections on control

to start furnace.

3. After the main burners ignite and the blower starts,

confirm Minimum Heat manifold pressure is correct,

based on the manifold pressure tables in the installation

instructions.

4. To adjust the Minimum Heat manifold pressure, slowly

turn adjusting screw counterclockwise (out) to decrease

manifold pressure or clockwise (in) to increase manifold

pressure. Turn adjustment no more than one click per

second until you obtain the required manifold pressure.

5. After adjusting the manifold pressure, remove jumpers

across thermostat connections to terminate the call for

heat. Wait until the blower off delay is completed.

6. Move setup switch SW1-2 to the OFF position.

7. Turn gas supply manual shutoff valve to OFF position.

8. Turn off furnace power supply.

!

FIRE HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Re−install manifold pressure tap plug in gas valve to

prevent gas leak.

9. Remove manometer from the inlet pressure tap of the

gas valve.

10. Apply pipe dope sparingly to end of inlet gas pipe plug

and re-install in the gas valve.

WARNING

11. Re-install cap over adjustment screw on the top of the

gas valve.

Clocking the Meter

Verify natural gas input rate by clocking meter.

NOTE: Contact your HVAC distributor or gas supplier for metric

gas meter Tables, if required.

1. Turn off all other gas appliances and pilots served by the

meter.

2. Move setup switches SW1-2 to ON position and SW4-2

to OFF. This keeps furnace locked in Minimum Heat

operation when only W/W1 is energized or Maximum

Heat operation when R to W/W1 and W2 are jumpered.

3. Jumper R to W/W1 and W2. Run furnace for 3 minutes in

Maximum Heat operation.

4. Measure time (in sec) for gas meter to complete one

revolution and note reading. The 2 or 5 cubic feet dial

provides a more accurate measurement of gas flow.

5. Refer to Table 3 for cubic ft. of gas per hr. Multiply gas

rate cu ft./hr by heating value (Btuh/cu ft.) to obtain input

rate.

6. If clocked rate does not match required input from Step

5, increase manifold pressure to increase input or

decrease manifold pressure to decrease input. Repeat

steps 3 through 5 until correct maximum heat input is

achieved.

7. Remove jumpers across thermostat connections to

terminate the call for heat. Wait until the blower off delay

is completed then reset 115-v power to furnace.

8. Jumper R and W/W1 thermostat connections on control

to start furnace.

NOTE: Setup switches SW1-2 must be ON and SW4-2 must

be OFF. This keeps furnace locked in minimum heat operation

when R to W/W1 is energized. Repeat items 3 through 6 for

minimum heat operation until minimum heat input is achieved

9. Restore furnace to normal operating condition.

10. Remove jumpers across thermostat connections to

terminate the call for heat. Wait until the blower off delay

is completed.

11. Disconnect 115 VAC power to furnace.

12. Turn gas valve ON/OFF switch to OFF.

13. Remove water column manometer or similar device from

manifold pressure tap (if still connected).

!

FIRE HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Re−install manifold pressure tap plug in gas valve to

prevent gas leak.

14. Replace manifold pressure tap plug to gas valve.

15. Turn gas valve ON/OFF switch to ON.

16. Move setup SW1-2 on furnace control to position

required for attached thermostat (OFF for single-stage

thermostats, ON for two-stage thermostats).

17. Check for gas leaks and verify furnace operation.

WARNING

440 04 4201 03 7

Specifications subject to change without notice.

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MAC

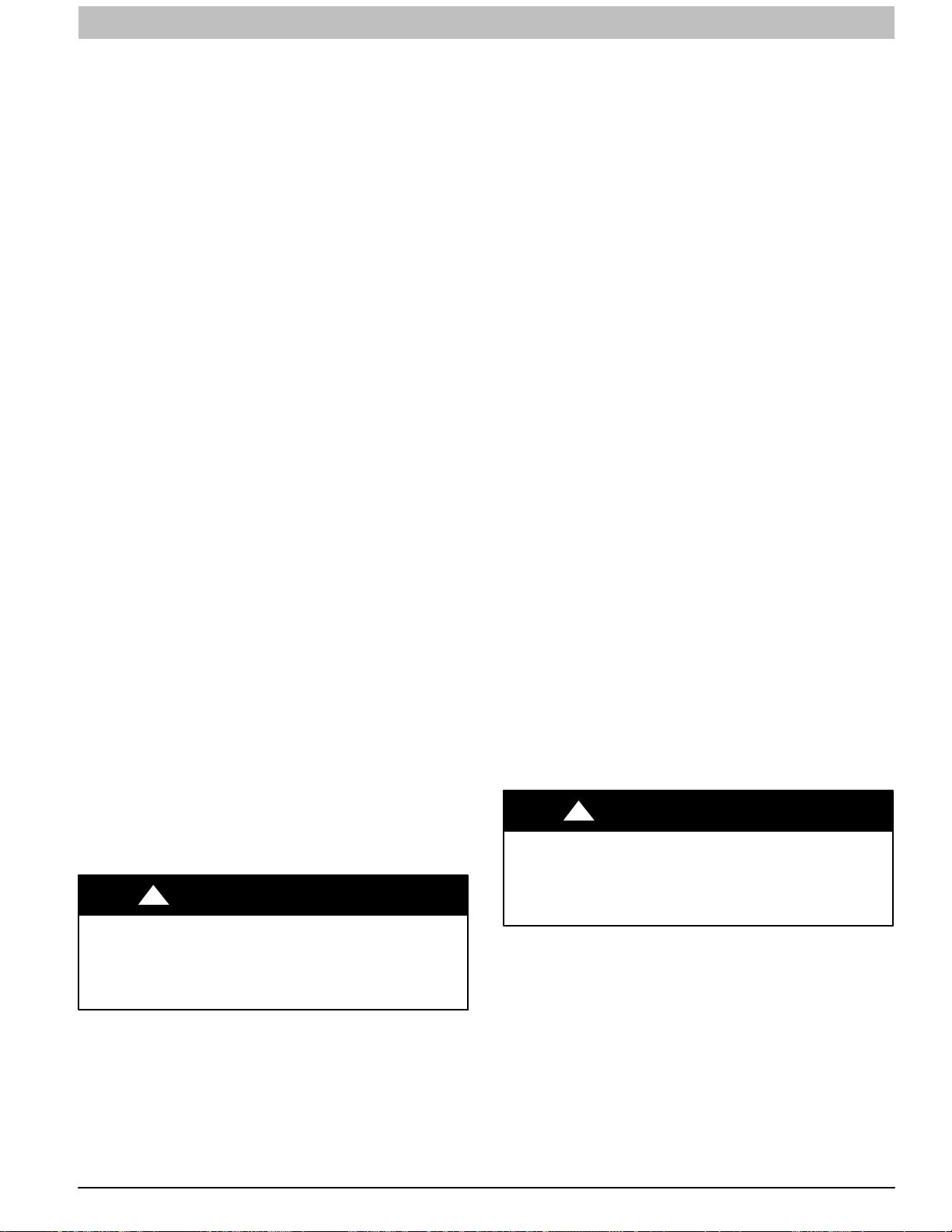

Figure 3 Variable Speed Furnace Control for ECM Blower Motor (Modulating)

MODEL PLUG

CONNECTOR

SW1 SETUP

SWITCHES AND

BLOWER OFFï

DELAY

AIR CONDITIONING

(A/C) AIRFLOW

SETUP SWITCHES

24ïV THERMOSTAT

TERMINALS

STATUS AND COMM

LED LIGHTS

3ïAMP FUSE

TRANSFORMER 24ïVAC

CONNECTIONS

COMMUNICATION

CONNECTOR

CONTINUOUS FAN

(CF) AIRFLOW

SETUP SWITCHES

OUTDOOR

IR TEMP

CONNECTOR

SW4 SETUP

SWITCHES

PL8 ï MODULATING

GAS VALVE

CONNECTOR

HUMIDIFIER

TERMINAL (24AVAC

0.5 AMP MAX.

UPGRADE

CONNECTOR

(FACTORY

PL3 ć ECM BLOWER

HARNESS

CONNECTOR

ï

FLASH

ONLY)

115ïVAC (L2) NEUTRAL

CONNECTIONS

PART NUMBER AND

PL1 ć LOW VOLTAGE MAIN

HARNESS CONNECTOR

SOFTWARE

VERSION

DATE CODE WWYY

(115ïVAC 1.0 AMP MAX.)

Adjust Temperature Rise

NOTE: Blower door must be installed when taking temperature

rise reading. Leaving blower door off will result in incorrect

temperature measurements.

EACï1 TERMINAL

115ïVAC (L1) LINE

VOLTAGE CONNECTIONS

NOTE: Temperature rise can be determined for Minimum Heat,

Intermediate Heat and Maximum Heat operation by locking the

furnace in each mode of operation. The mode of operation is

based on the position of Set-up switch SW1-2 and SW4-2 on

the furnace control board.

PL2 ć HOT SURFACE

IGNITER & INDUCER

MOTOR CONNECTOR

The furnace is capable of automatically providing proper airflow

!

CAUTION

FURNACE DAMAGE HAZARD

Failure to follow this caution may result in:

S Overheating the heat exchangers or condensing

flue gases in heat exchanger areas not designed

for condensate

S Shortened furnace life

S Component damage

Temperature rise must be within limits specified on furnace

rating plate. Recommended operation is at midpoint of rise

range or slightly above.

Furnace must operate within ranges of temperature rise

specified on the furnace rating plate. When setup switch SW1-4

is ON, operation will be near the high end of the rise range for

improved comfort.

Determine air temperature rise as follows:

1. Place thermometers in return and supply ducts as near

furnace as possible. Be sure thermometers do not see

heat exchanger so that radiant heat does not affect

readings. This practice is particularly important with

straight-run ducts.

2. When thermometer readings stabilize, subtract return-air

temperature from supply-air temperature to determine air

temperature rise.

8 440 04 4201 03

Specifications subject to change without notice.

to maintain the temperature rise within the range specified on

furnace rating plate. If temperature rise is outside this range,

proceed as follows:

a. Check gas input for Minimum, Intermediate, and

Maximum heat operation.

b. Check derate for altitude if applicable.

c. Check all return and supply ducts for excessive

restrictions causing static pressure greater than 0.5-in.

w.c.

d. Ensure Min/Int Rise Adjust switch SW1−3 on furnace

control is in ON position when a bypass humidifier is

used. (See Figure 3 for switch location.)

e. Check Troubleshooting Guide for Variable−Speed Step

Modulating Condensing Furnaces.

f. Verify correct model plug is installed.

To lock the furnace in Minimum Heat:

1. Turn SW1−2 ON at the furnace control. Set up switch

SW4−2 must be OFF.

2. Connect a jumper across R and W/W1 at the thermostat

terminals at the furnace control.

3. Allow the burners to ignite and the blower to turn on.

4. Allow the supply temperature to stabilize and verify the

proper rise range.

If the temperature rise is too high or too low in Minimum

Heat:

1. Remove jumpers from R and W/W1.

L11F091

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MAC

2. Wait until the blower off delay is completed.

3. Turn 115 VAC power off.

4. Check the position of Set up switch SW1−3. When set to

ON, airflow is raised 18% for Minimum Heat and for

Intermediate Heat. Factory default position is OFF.

5. Turn 115 VAC power on.

6. Re−check Minimum Heat Temperature Rise.

To lock the furnace in Intermediate Heat:

1. Turn SW1−2 OFF and SW4−2 ON at the furnace control.

2. Connect a jumper across R and W/W1 at the thermostat

terminals at the furnace control.

3. Allow the burners to ignite and the blower to turn on.

4. Allow the supply temperature to stabilize and verify the

proper rise range.

If the temperature rise is too high or too low in Intermediate

Heat:

1. Remove jumpers from R and W/W1.

2. Wait until the blower off delay is completed.

3. Turn 115 VAC power off.

4. Check the position of Set up switch SW1−3. When set to

ON, airflow is raised 18% for Minimum Heat and for

Intermediate Heat. Factory default position is OFF.

5. Turn 115 VAC power on.

6. Re−check Intermediate Heat Temperature Rise .

To lock the furnace in Maximum Heat:

1. Connect a jumper across R and W/W1 and W2 at the

thermostat terminals at the furnace control.

2. Allow the burners to ignite and the blower to turn on.

3. Allow the supply temperature to stabilize and verify the

proper rise range.

If the temperature rise is too high or too low in Maximum

Heat:

1. Remove jumpers from R and W/W1 and W2.

2. Wait until the blower off delay is completed.

3. Turn 115 VAC power off.

4. Check the position of Set up switch SW1−4. When set to

OFF, and SW1−3 is set to OFF, airflow is raised 10% for

Minimum Heat, 7.5% for Intermediate Heat and 17.5%

for Maximum Heat. Factory default position is ON. If

SW1−3 is ON and SW1−4 is OFF, airflow is raised 18%

for Minimum and Intermediate heat and 10% for

Maximum Heat.

5. Turn 115 VAC power on.

6. Re−check Maximum Heat Temperature Rise.

After the temperature rise has been verified:

1. Remove jumpers from thermostat terminals.

2. Allow the blower off delay to complete.

3. Turn Set up switches SW1−2 and SW4−2 to the OFF

position unless two−stage thermostat operation is

desired. (See Figure 4)

4. Proceed to “Adjust Blower Off Delay” or install blower

door if complete.

!

FIRE HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Reinstall manifold pressure tap plug in gas valve to

prevent gas leak.

WARNING

Adjust Blower Off Delay (Heat Mode)

a. Remove blower door if installed.

b. Turn Dip switch SW−7 or SW−8 ON or OFF for

desired blower off delay. (See Table 2, Figure 3 and

Figure 4)

Table 2 Blower Speed Taps

DESIRED HEATING MODE

BLOWER OFF DELAY

(SEC.)

90 OFF OFF

120 ON OFF

150 OFF ON

180 ON ON

SETUP SWITCH POSITION

SW1-7 SW1-8

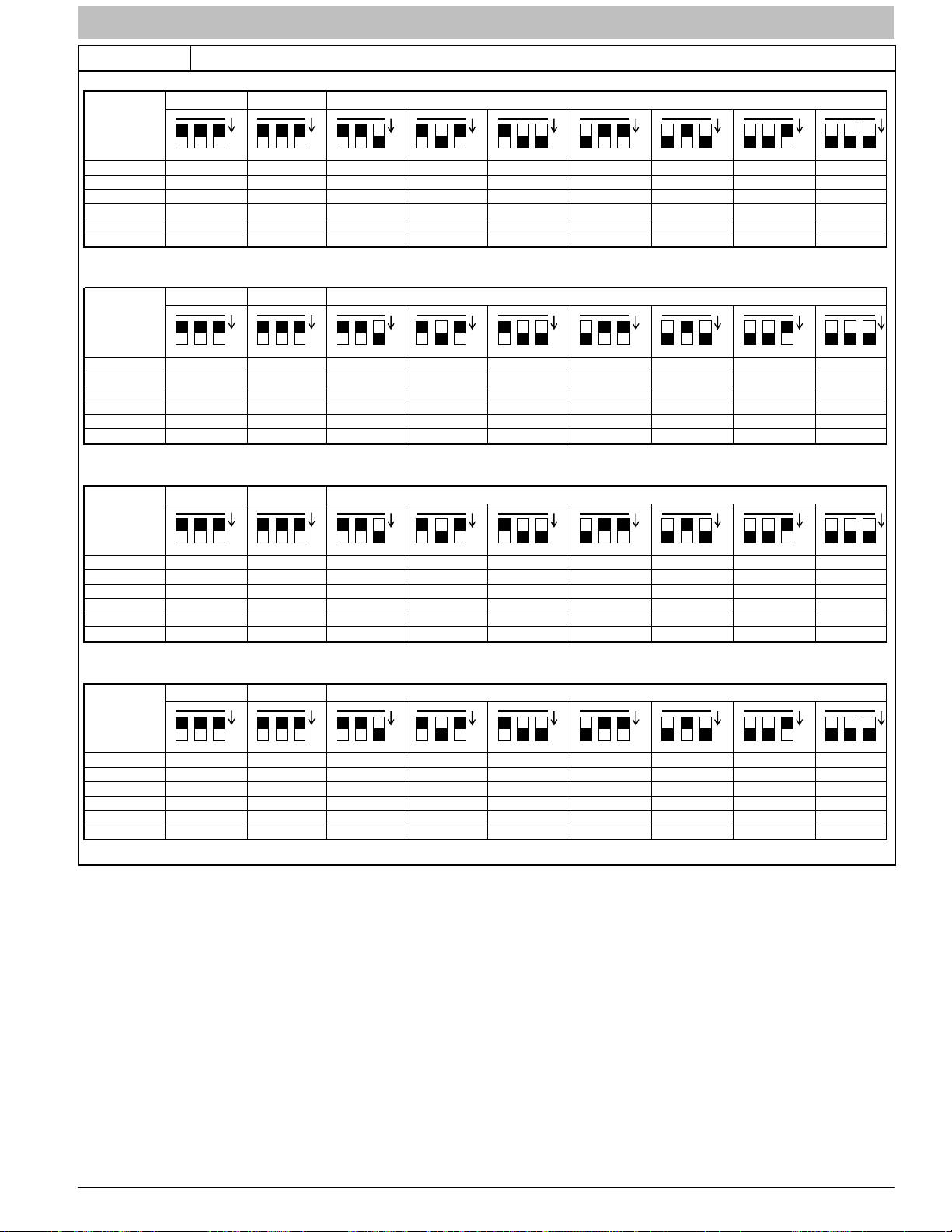

Adjust Cooling Airflow − High−Speed and

Low−Speed Cooling

The ECM blower can be adjusted for a range of airflows for

low−speed or high−speed cooling. See Table 3 − Airflow

Switch Table, Table 6 − Air Delivery − CFM (with Filter) and

Figure 4. Furnace Setup Switches and Descriptions.

Depending on the model size, the cooling airflow can be

adjusted from 1.5 tons to 6 tons of nominal cooling based on

350 CFM ton.

NOTE: 6 ton airflow will truncate at 2200 CFM on applicable

models.

The high−speed or single−speed cooling airflow is adjusted by

turning setup switches SW2−1, SW2−2 and SW2−3 either ON

or OFF. Select the required airflow from Table 6. Table 6 is

based on 350 CFM per ton. For other CFM per ton setup switch

selections, see Table 3, Figure 4 and Figure 15.

The Continuous Fan airflow selection via setup switches SW3

is also the airflow for low−speed cooling when the furnace is

used with a two−speed cooling or heat pump unit. Adjust the

Continuous Fan CFM setup switches SW3 to match the airflow

required for low−speed cooling. Select the required airflow from

Table 6 and Figure 4.

NOTE: The airflow selected via SW3 (low−speed cooling

airflow) cannot exceed the airflow selected via SW2

(high−speed cooling airflow). For other CFM per ton setup

switch selections, see Table 3 and Figure 4.

NOTE: The airflow settings for SW2 and SW3 selections are

the same, EXCEPT for the default values. (See Table 6)

For a complete explanation of cooling airflow, refer to the

section titled “Sequence of Operation.”

Adjust Continuous Fan Airflow/Low Speed

Cooling Airflow

NOTE: When the furnace is used with a two−speed cooling or

heat pump unit, the airflow selected for Continuous Fan via

setup switch SW3 will also be the airflow used for low−speed

cooling, and vice versa.

NOTE: When the furnace is used with a two−speed cooling or

heat pump unit, adjust the Continuous Fan CFM setup

switches SW3 to match the airflow required for low−speed

cooling.

Select the required Continuous Fan airflow using setup

switches SW3 as shown in Table 3, Figure 4 and Figure 15.

!

CAUTION

FURNACE OVERHEATING HAZARD

Failure to follow this caution may result in reduced furnace

life.

Recheck temperature rise. It must be within limits specified

on the rating plate. Recommended operation is at the

mid−point of rise range or slightly above.

440 04 4201 03 9

Specifications subject to change without notice.

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MAC

T

Bl

Off Del

Allows additional CFM per ton selections when used with SW

p

p

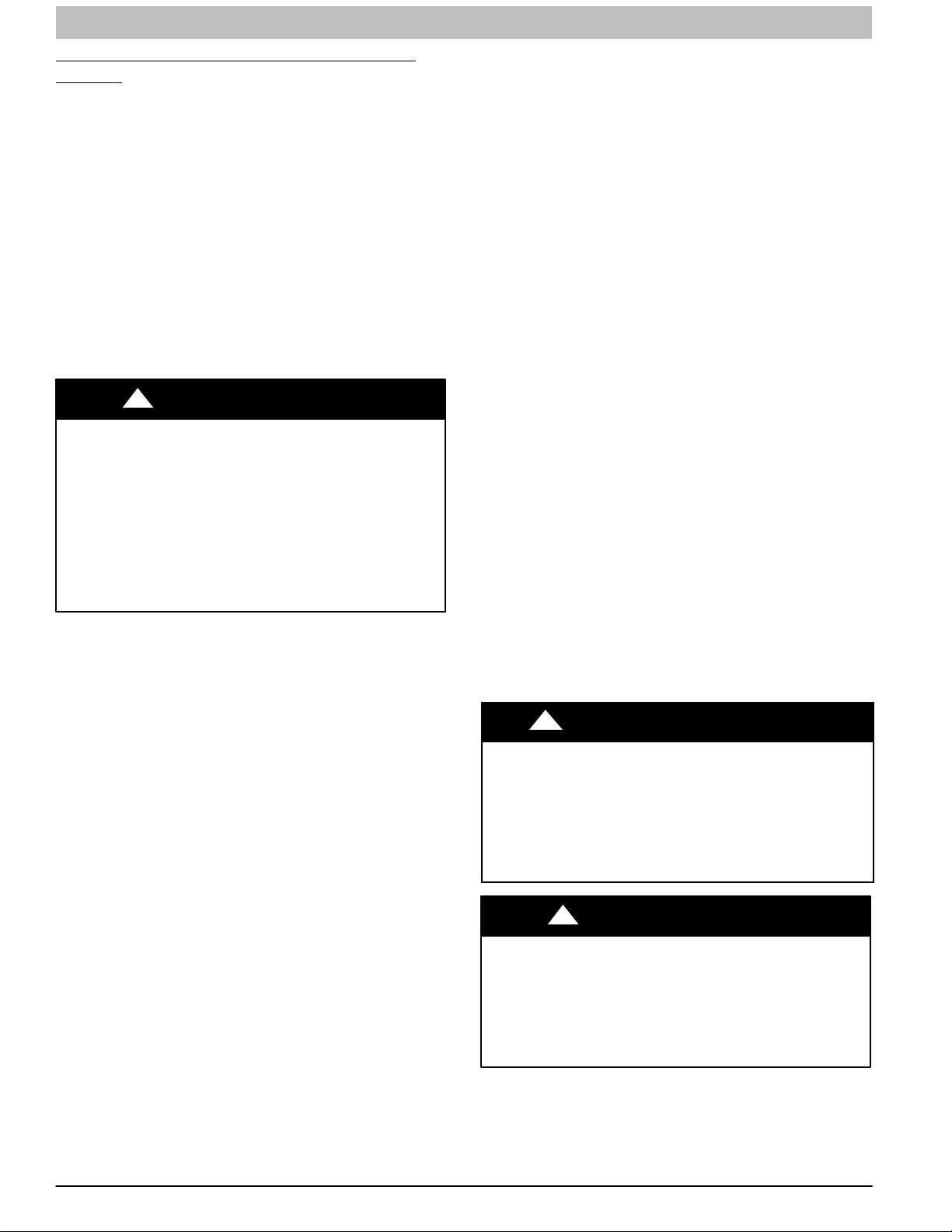

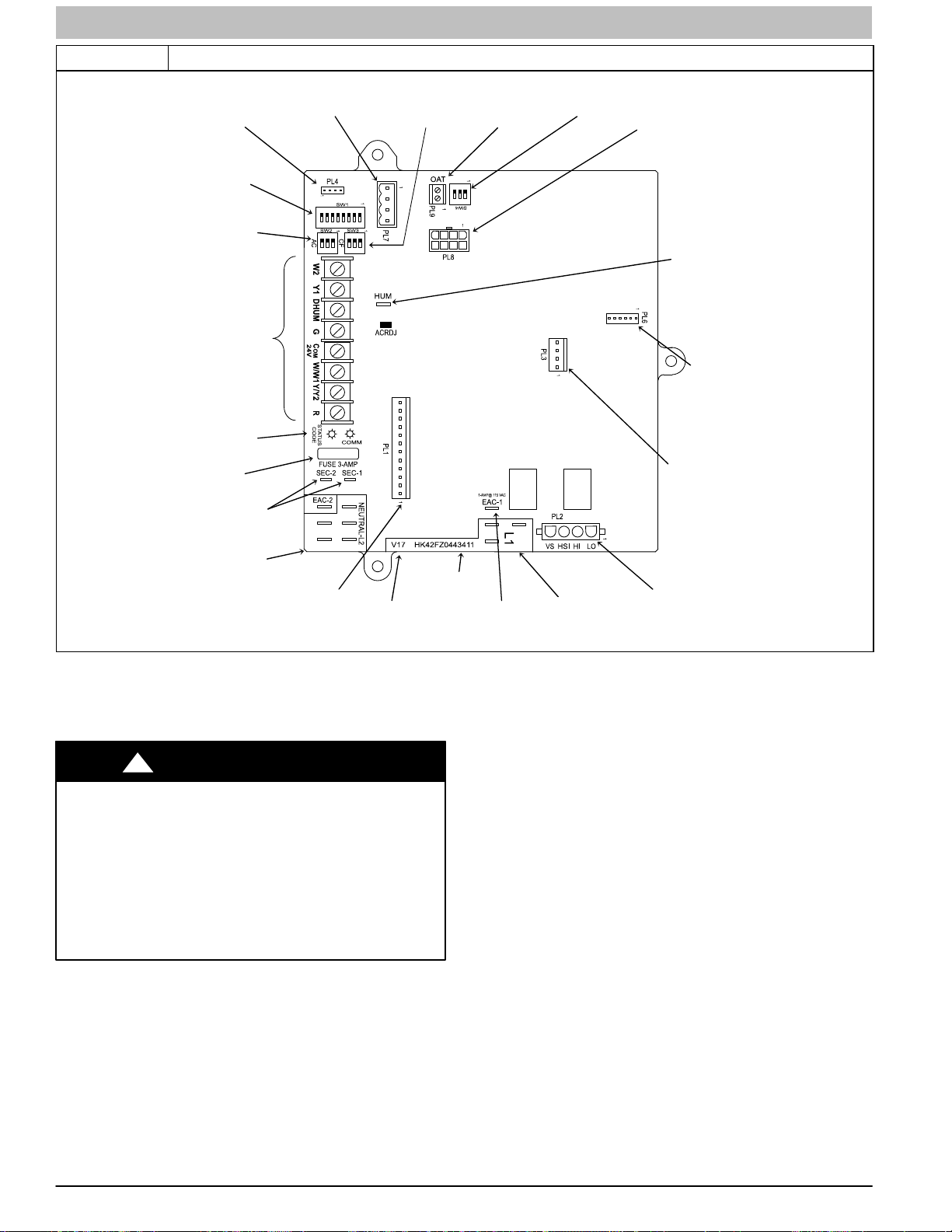

Figure 4 Furnace Setup Switch Description

Furnace Setup Switch Description

ESU FO NOITPIRCSEDNOITISOP LAMRONEMAN HCTIWSHCTIWS PUTES

SW1-1 Status Code Recovery OFF

Minimum Heat Only

SW1-2

SW1-3

SW1-4

SW1-5 CFM per ton adjust OFF

SW1-6 Component Self Test OFF

SW1-7 & SW1-8 Blower OFF delay ON or OFF

SW4-2

(Adaptive Heat Mode

when SW1-2 and SW4-2

are OFF)

Min/Int Heat Rise

Adjustment

Comfort/Efficiency

Adjustment

Intermediate Heat

Only

(Adaptive Heat Mode

when both SW1-2 and

SW4-2 are OFF)

OFF

OFF

ON

OFF

Turn ON to retrieve up to 7 stored status codes for

troubleshooting assistance when R thermostat lead is

disconnected.

When SW1-2 and SW4-2 are OFF allows Modulating operation

with a single stage thermostat. Turn ON SW1-2 when using

two-stage thermostat to allow Minimum Heat operation when

R to W/W1 closed and a Maximum heat operation when R to

W/W1 and R to W2 close.

urn ON to increase Minimum Heat and Intermediate Heat

airflow by 18 percent. This compensates for increased return

air temperature caused with bypass humidifier. This also

increases the Intermediate Heat inducer speed 15 percent.

Turn ON to decrease Minimum heat airflow by 10 percent,

Intermediate Heat airflow 7.5 percent and Maximum Heat

airflow 17.5 percent for maximum comfort.

Turn ON for 400 CFM per ton, Turn OFF for 350 CFM per ton.

See also SW4.

Turn ON to initiate Component Self Test for troubleshooting

assistance when R thermostat lead is disconnected. Turn

OFF when Self Test is completed.

ower

seconds. See table in Adjustments section or refer to unit

wiring diagram.

When SW1-2 and SW4-2 are OFF allows Modulating operation

with a single stage thermostat. Turn ON SW4-2 when using

two-stage thermostat to allow Intermediate Heat operation

when R to W/W1 closed and a Maximum heat operation when

R to W/W1 and R to W2 close.

ay time – adjustable 90 seconds to 180

1

SW2

1

SW3

AC

CF

1-5

325 CFM per ton (nominal) when SW 4-3 ON and SW 1-5 OFF

350 CFM per ton (nominal) when SW 4-3 OFF and SW 1-5 OFF

SW4-3

O

N

1

2

3

O

N

1

2

3

SW 2, AC (Cooling Airflow) SETUP SWITCHES

The AC setup switch selects desired cooling or high stage cooling (two stage units) airflow.

See Cooling Air Delivery Tables for specific switch settings

SW 3, CF (Continuous Fan) SETUP SWITCHES

The CF setup switch selects desired Continuous Fan Airflow

The CF switch position is the Low Cooling airflow selection for two stage cooling units.

SW 3 cannot be set for airflow higher than SW 2

See Continuous Fan Air Delivery Tables for specific switch settings

CFM per ton Adjust

AIR CONDITIONING (A/C) SETUP SWITCHES

CONTINUOUS FAN (CF) SETUP SWITCHES

OFF

370 CFM per ton (nominal) when SW4-3 ON and SW 1-5 ON

400 CFM per ton (nominal) when SW 1-5 ON and SW 4-3 OFF

See Air Delivery Tables for model specific CFM vs. static

ressure

10 440 04 4201 03

A11575

Specifications subject to change without notice.

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MAC

321N321

N 321N 321N 321N 321N 321N 321N 321N

321N321

N 321N 321N 321N 321N 321N 321N 321N

321N321

N 321N 321N 321N 321N 321N 321N 321N

321N321

N 321N 321N 321N 321N 321N 321N 321N

060-14

080-14

060-20

080-20

100-22

120-22

1860

1860

1116

1116

976

976

1200

1200

1860

2100

1488

1860

2100

930

744

930

1116

1302

1488

744

744

930

1116

1302

1860

744

744

930

1116

1302

1488

1860

1860

1860

744

744

930

1116

1302

1488

1860

1860

1302

1302

1302

558

558

744

930

1116

1302

558

558

744

930

1116

1302

1302

1627

1953

NOMINAL AIRFLOW BASED ON 370 CFM/TON (SW1-5 = ON, SW4-3 = ON)

Model Size

SW2 Clg Defa ult

SW3 CF Default

COOLING (SW2) AND CONTINUOUS FAN (SW3) AIRFLOW: SET-UP SWITCH POSITIONS

1302

1627

1953

1627

814

651

814

976

1139

1302

1627

651

651

814

976

1139

1627

651

651

814

976

1139

1302

1627

1627

1627

651

651

814

976

1139

1302

1627

1627

1139

1139

1139

488

488

651

814

976

1139

488

488

651

814

976

1139

1139

2000

2100

NOMINAL AIRFLOW BASED ON 325 CFM/TON (SW1-5 = OFF, SW4-3 = ON)

Model Size

SW2 Clg Defa ult

SW3 CF Default

COOLING (SW2) AND CONTINUOUS FAN (SW3) AIRFLOW: SET-UP SWITCH POSITIONS

1600

2000

2100

2000

1000

800

1000

1200

1400

1600

2000

800

800

1000

1200

1400

2000

800

800

1000

1200

1400

1600

2000

2000

2000

800

800

1000

1200

1400

1600

2000

2000

1400

1400

1400

600

600

800

1000

1200

1400

600

600

800

1000

1200

1400

1400

1400

1750

2100

NOMINAL AIRFLOW BASED ON 400 CFM/TON (SW1-5 = ON, SW4-3 = OFF)

Model Size

SW2 Clg Defa ult

SW3 CF Default

COOLING (SW2) AND CONTINUOUS FAN (SW3) AIRFLOW: SET-UP SWITCH POSITIONS

1750

875

700

875

1050

1225

1750

700

700

875

1050

1225

1400

1750

2100

1750

700

700

875

1050

1225

1400

1750

1750

1750

700

700

875

1050

1225

1400

1750

1750

1050

525

525

700

875

1050

1225

1225

1225

NOMINAL AIRFLOW BASED ON 350 CFM/TON (Factory Default - SW1-5 = OFF, SW4-3 = OFF)

Model Size

SW2 Clg Defa ult

SW3 CF Default

COOLING (SW2) AND CONTINUOUS FAN (SW3) AIRFLOW: SET-UP SWITCH POSITIONS

1050

525

525

700

875

1050

1225

1225

1225

Table 3 Airflow Switch Table

OOOOOOOOO

060-14

080-14

060-20

080-20

100-22

120-22

OOOOOOOOO

060-14

080-14

060-20

080-20

100-22

120-22

OOOOOOOOO

060-14

080-14

060-20

080-20

100-22

120-22

OOOOOOOOO

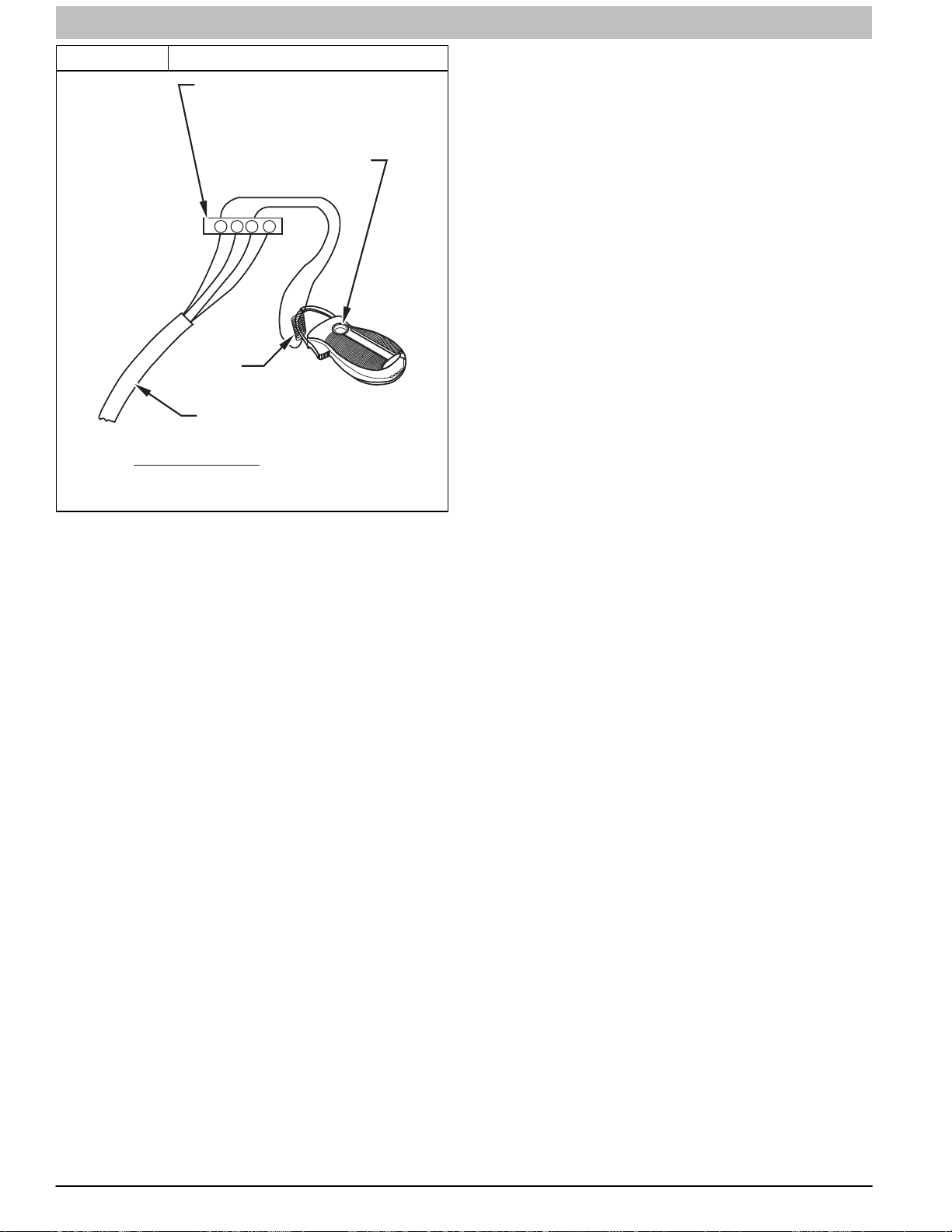

Adjust Thermostat Heat Anticipator

a. Mechanical thermostat. Set thermostat heat

anticipator to match the amp. draw of the electrical

components in the R−W/W1 circuit. Accurate amp.

draw readings can be obtained at the wires normally

connected to thermostat subbase terminals, R and W.

The thermostat anticipator should NOT be in the

circuit while measuring current.

(1.) Set SW1−2 switch on furnace control board to

ON.

(2.) Remove thermostat from subbase or from wall.

L11F092

(3.) Connect an amp. meter as shown in Figure 5

across the R and W subbase terminals or R and

W wires at wall.

(4.) Record amp. draw across terminals when

furnace is in minimum heat and after blower

starts.

(5.) Set heat anticipator on thermostat per thermostat

instructions and install on subbase or wall.

(6.) Turn SW1−2 switch OFF.

(7.) Install blower door.

b. Electronic thermostat: Set cycle rate for three cycles

per hr.

440 04 4201 03 11

Specifications subject to change without notice.

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MAC

Figure 5 Amp. Draw Check with Ammeter

THERMOSTAT SUBBASE

TERMINALS WITH

THERMOSTAT REMOVED

(ANITICIPATOR, CLOCK, ETC.,

MUST BE OUT OF CIRCUIT.)

HOOK-AROUND

AMMETER

R Y W G

10 TURNS

FROM UNIT 24-V

CONTROL TERMINALS

EXAMPLE:

5.0 AMPS ON AMMETER

10 TURNS AROUND JAWS

0.5 AMPS FOR THERMOSTAT

=

ANTICIPATOR SETTING

A96316

Check Safety Controls

The flame sensor, gas valve, and pressure switch were all

checked in the Start−up procedure section as part of normal

operation.

1. Check Main Limit Switch

This control shuts off combustion system and energizes

air−circulating blower motor, if furnace overheats. By

using this method to check limit control, it can be

established that limit is functioning properly and will

operate if there is a restricted return−air supply or motor

failure. If limit control does not function during this test,

cause must be determined and corrected.

a. Run furnace for at least five minutes.

b. Gradually block off return air with a piece of

cardboard or sheet metal until the limit trips.

c. Unblock return air to permit normal circulation.

d. Burners will re−light when furnace cools down.

2. Check Pressure Switch(es)

This control proves operation of the draft inducer blower.

a. Turn off 115−v power to furnace.

b. Disconnect inducer motor lead wires from wire

harness.

c. Turn on 115−v power to furnace.

d. Set thermostat to “call for heat” and wait 1 minute.

When pressure switch is functioning properly, hot

surface igniter should NOT glow and control

diagnostic light flashes a status code 3. If hot surface

igniter glows when inducer motor is disconnected,

shut down furnace immediately.

e. Determine reason pressure switch did not function

properly and correct condition.

f. Turn off 115−v power to furnace.

g. Reconnect inducer motor wires, replace blower door,

and turn on 115−v power.

h. Blower will run for 90 seconds before beginning the

call for heat again.

i. Furnace should ignite normally.

Checklist

1. Put away tools and instruments. Clean up debris.

2. Verify that switches SW1−1 and SW1−6 are OFF and

other setup switches are set as desired. Verify that

switches SW1−7 and SW1−8 for the blower OFF DELAY

are set as desired per Table 2.

3. Verify that blower and control doors are properly

installed.

4. Cycle test furnace with room thermostat.

5. Check operation of accessories per manufacturer’s

instructions.

6. Review Home Owner’s Information with owner.

7. Attach literature packet to furnace.

12 440 04 4201 03

Specifications subject to change without notice.

Loading...

Loading...