International Comfort Products ENA4X18L14A, ENA4X19L17A, ENA4X24L14A, ENA4X24L17A, ENA4X30L14A Installation Manual

...

INSTALLATION INSTRUCTIONS

Uncased N Coil, Upflow−Downflow

ENA4X

NOTE: Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical

shock, or other conditions which may cause death, personal

injury or property damage. Consult a qualified installer,

service agency, or your distributor or branch for information

or assistance. The qualified installer or agency must use

factory−authorized kits or accessories when modifying this

product. Refer to the individual instructions packaged with

the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective

clothing, and work gloves. Use quenching cloth for brazing

operations. Have fire extinguisher available. Read these

instructions thoroughly and follow all warning or cautions

included in literature and attached to the unit. Consult local

building codes and the current editions of the National

Electrical Code (NEC) NFPA 70.

In Canada, refer to the current editions of the Canadian

Electrical Code CSA C22.1.

Recognize safety information. When you see this symbol

on the unit and in instructions or manuals, be alert to the

potential for personal injury. Understand the signal words

DANGER, WARNING, CAUTION, and NOTE. These words

are used with the safety−alert symbol. DANGER identifies

the most serious hazards which will result in severe personal

injury or death. WARNING signifies hazards which could

result in personal injury or death. CAUTION is used to

identify unsafe practices which may result in minor personal

injury or product and property damage. NOTE is used to

highlight suggestions which will result in enhanced

installation, reliability, or operation.

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing or servicing system, always turn off

main power to system. There may be more than one

disconnect switch. Tag disconnect switch with a

suitable warning label. Turn off accessory heater

power if applicable.

UNIT OR PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in product or

property damage.

This coil contains Nitrogen precharge of 15 PSI.

Release of this pressure through the center of the

rubber plugs is required before removing the plugs.

WARNING

!

CAUTION

!

CAUTION

CUT HAZARD

Failure to follow this caution may result in personal

injury.

Sheet metal parts may have sharp edges or burrs. Use

care and wear appropriate protective clothing and

gloves when handling parts.

IMPORTANT: Nitrogen can leak out through the hole that the

needle pierced in the plugs. This does not indicate a leaking

coil nor warrant return of the coil.

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS 1.........................

INTRODUCTION 2....................................

INSTALLATION 2.....................................

Inspect Equipment 2................................

Select Installation 3................................

Installation of Evaporator Coil 3......................

Connect Refrigerant Piping 4........................

Connect Refrigerant Liquid and Suction Lines 4........

Condensate Drain Line Connection 5.................

Humidifier Application 6.............................

Table 1

MODEL

NUMBER

ENA4X18L14A 1-1/2

ENA4X19L17A 1-1/2

ENA4X24L14A 2

ENA4X24L17A 2

ENA4X30L14A 2-1/2

ENA4X30L17A 2-1/2

ENA4X31L17A 2-1/2

ENA4X36L17A 3

ENA4X36L21A 3

ENA4X37L17A 3

ENA4X42L21A 3-1/2

ENA4X43L24A 3-1/2

ENA4X48L21A 4

ENA4X48L24A 4

ENA4X60L24A 5

ENA4X61L24A 5

ENA4X Uncased Coil Information

COLLAR SIZE

inches (mm)

Tons

Depth Width Liquid Suction

19-3/8

(492)

19-3/8

(492)

19-3/8

(492)

19-3/8

(492)

19-3/8

(492)

19-3/8

(492)

19-3/8

(492)

19-3/8

(492)

19-3/8

(492)

19-3/8

(492)

19-3/8

(492)

19-3/8

(492)

19-3/8

(492)

19-3/8

(492)

19-3/8

(492)

19-3/8

(492)

12-7/8

16-1/4

12-7/8

16-1/4

12-7/8

16-1/4

16-1/4

16-1/4

19-5/8

16-1/4

19-5/8

23-1/8

19-5/8

23-1/8

23-1/8

23-1/8

COIL CONNECTION

(327)

(413)

(327)

(413)

(327)

(413)

(413)

(413)

(498)

(413)

(498)

(587)

(498)

(587)

(587)

(587)

3/8 (10) 5/8 (16)

3/8 (10) 3/4 (19)

3/8 (10) 5/8 (16)

3/8 (10) 5/8 (16)

3/8 (10) 3/4 (19)

3/8 (10) 3/4 (19)

3/8 (10) 3/4 (19)

3/8 (10) 3/4 (19)

3/8 (10) 3/4 (19)

3/8 (10) 7/8 (22)

3/8 (10) 7/8 (22)

3/8 (10) 7/8 (22)

3/8 (10) 7/8 (22)

3/8 (10) 7/8 (22)

3/8 (10) 7/8 (22)

3/8 (10) 7/8 (22)

TUBE SIZE

inches (mm)

Specifications subject to change without notice.

484 01 3801 04 3/28/18

INTRODUCTION

Use this instruction manual to install indoor coils on upflow or

downflow furnaces. (See Figure 1) Do not install coil in

horizontal position. ENA4X coils have factory−installed

thermostatic expansion valves (TXVs) and are used with

R−410A refrigerant systems.

INSTALLATION

These units can be installed in either upflow or downflow

configurations. Before installation, there are several

performance requirements that must be considered because

poor installation can negatively alter performance. This

section will briefly discuss those factors.

Airflow

Airflow amount and distribution are vital to adequate system

performance. Problems that can be experienced with

incorrect airflow include:

S low system performance

S restricted TXV

S frosted coil

S poor humidity control

S water blow−off

When attaching the coil and building the plenum, pay special

attention to the effect these details will have on airflow. After

system start−up, check the cfm to insure that it is correct.

(Generally, the cfm should be 350 to 400 cfm/ton during

normal cooling operation.)

Condensate Management

With proper installation, these coils will manage the

condensate without blow−off into the duct work. See detailed

instructions for more info.

Procedure 1 — Inspect Equipment

File claim with shipper if equipment is damaged.

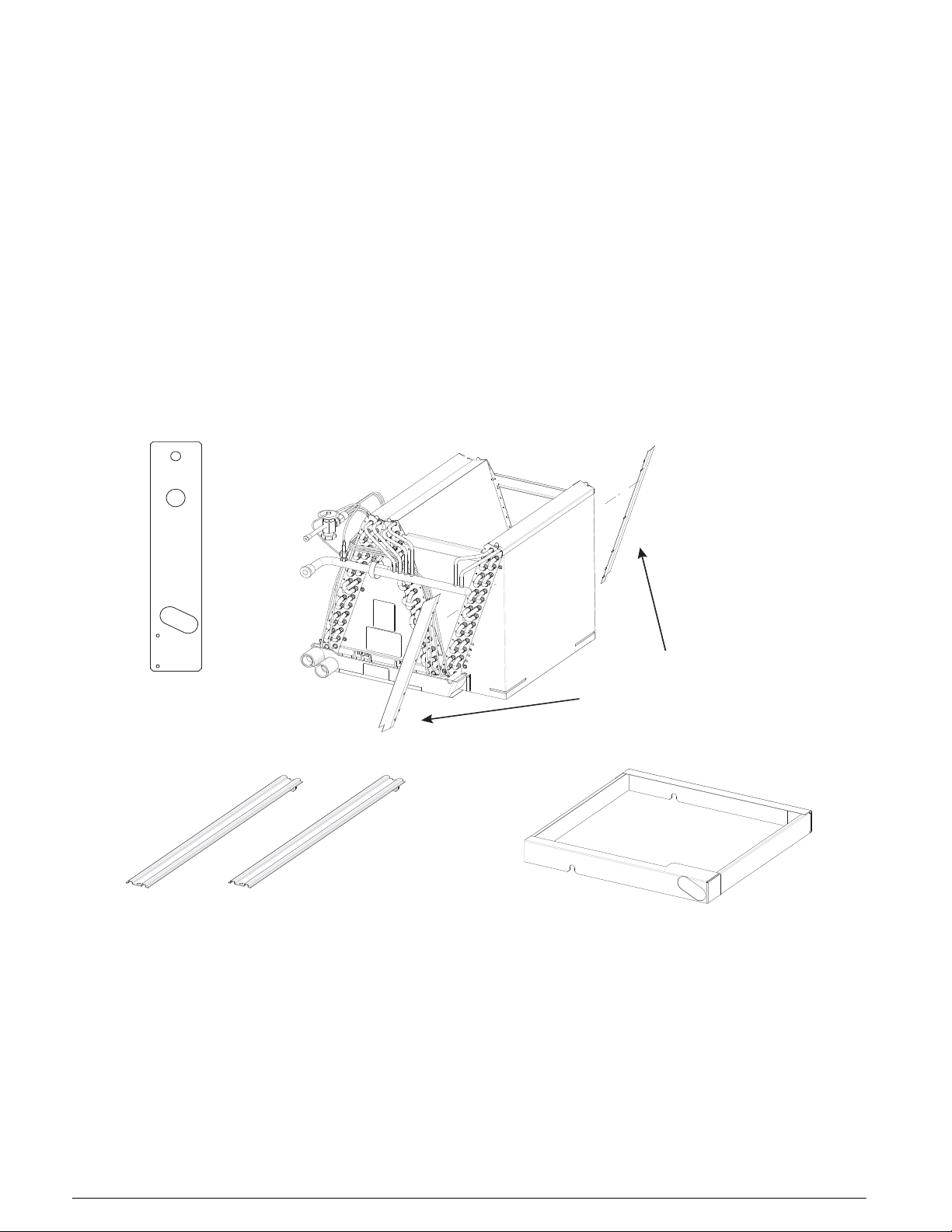

The following parts are included with this coil (See Figure 1),

depending on your application different components will be

required.

COMPONENT QUANTITY

Support Rails 2

Collar 1

Header Plate 1

Grommets 2

Extension Air Baffles 2

Header Plate

1 pc.

Support Rails

2 pcs.

Extension Air Baffles

2 pcs. (Attached to coil)

Uncased N-coil

Collar

1 pc.

A06362

Figure 1 − Uncased N−Coil Components

2 484 01 3801 04

Specifications subject to change without notice.

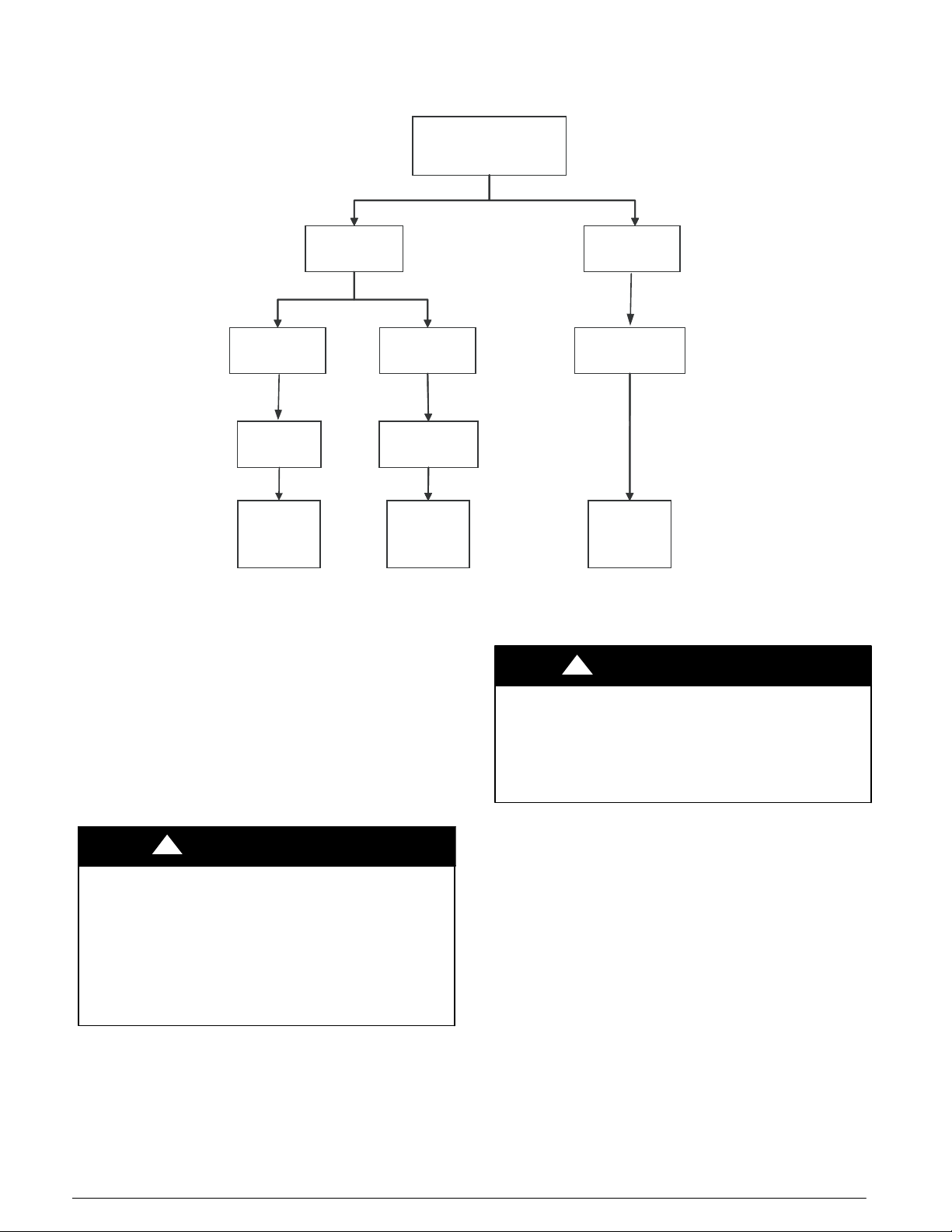

Procedure 2 — Select Installation

Select and follow the installation instruction that best suits your needs:

8QFDVHG 1 &RLO

$SSOLFDWLRQV

5HSODFHPHQW

$SSOLFDWLRQV

&DVHG

&DVHG

$SSOLFDWLRQ

$SSOLFDWLRQV

&DVHG ´ 1 µ

)ROORZ

SURFHGXU H

$

V

3OHQXP

$SSOLFDWLRQV

8QFDVHG ´ $ µ

)ROORZ

SURFHGXU H

%

)LJXUHï 8QFDVHG1ï&RLO$SSOLFDWLRQV

Figure 2 − Uncased N−Coil Applications

See Table 1 for dimensions and overhang options. Note

instructions for placement of coil casing on furnace.

For replacement applications using an existing cased N−coil

assembly follow Procedure 3A.

For replacement applications using an existing uncased

A−coil plenum installation follow Procedure 3B.

For new applications using a field−fabricated plenum

installation follow Procedure 3C.

Procedure 3 — Installation of Evaporator Coil

!

CAUTION

UNIT OR PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property

damage.

Take precautions to ensure Aluminum tubes do not

come in direct contact or allow for condensate run

off with a dissimilar metal. Dissimilar metals can

cause galvanic corrosion and possible premature

failure.

1HZ

$SSOLFDWLRQV

3OHQXP

$SSOLFDWLRQV

)ROORZ

SURFHGXUH

&

A06363

!

CAUTION

CUT HAZARD

Failure to follow this caution may result in personal

injury.

Sheet metal parts may have sharp edges or burrs. Use

care and wear appropriate protective clothing and

gloves when handling parts.

NOTE: Upflow and downflow applications using an

existing A−coil casing is not approved:

N-coils will not properly fit into A-Coil casings and retrofitting

is not approved. Only replace an uncased N-coil in a N-coil

casing.

3A. Upflow and downflow applications using an existing

N−coil casing.

1. Remove and keep front access and tubing header panel.

2. Remove old N−coil from casing and discard coil.

3. Slide new N−coil into casing.

4. Cut holes for liquid, suction and drain connections in

the existing header panel. Use new header plate

supplied with coil as template to locate holes. Align

header plate to the header panel using the upper hole

as indicated in Figure 3.

484 01 3801 04 3

Specifications subject to change without notice.

Loading...

Loading...