International Comfort Products EAM4X18L14A, EAM4X19L17A, EAM4X24L14A, EAM4X24L17A, EAM4X25L17A Installation Manual

...

INSTALLATION INSTRUCTIONS

Evaporator Coils, Multipoise

EAM4X18−61 & WLAM 19−61

NOTE: Read the entire instruction manual before starting the

installation.

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS 1.............................

INTRODUCTION 1........................................

INSTALLATION 1.........................................

Inspect Equipment 1.....................................

Select Installation Procedure 2............................

Installation of Evaporator Coils 3...........................

Connect Refrigerant Piping 4..............................

Connect Lines 4.........................................

Refrigerant Metering Device 4.............................

Condensate Drain Line Connection 4.......................

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal injury or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory−authorized kits or

accessories when modifying this product. Refer to the individual

instructions packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Use quenching cloth for brazing operations.

Have fire extinguisher available. Read these instructions

thoroughly and follow all warning or cautions included in literature

and attached to the unit. Consult local building codes and the

current editions of the National Electrical Code (NEC) NFPA 70.

In Canada, refer to the current editions of the Canadian Electrical

Code CSA C22.1.

Recognize safety information. When you see this symbol

the unit and in instructions or manuals, be alert to the potential for

personal injury. Understand the signal words DANGER,

WARNING, CAUTION, and NOTE. These words are used with

the safety−alert symbol. DANGER identifies the most serious

hazards which will result in severe personal injury or death.

WARNING signifies hazards which could result in personal injury

or death. CAUTION is used to identify unsafe practices which

may result in minor personal injury or product and property

damage. NOTE is used to highlight suggestions which will result

in enhanced installation, reliability, or operation.

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or

death.

Before installing, modifying or servicing system, always turn

off main power to system. There may be more than one

disconnect switch. Lock out and tag switch with a suitable

warning label.

WARNING

on

!

CAUTION

UNIT OR PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property damage.

Take precautions to ensure Aluminum tubes do not come in

direct contact or allow for condensate run off with a dissimilar

metal. Dissimilar metals can cause galvanic corrosion and

possible premature failure.

!

!

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate protective clothing and gloves when

handling parts.

!

PERSONAL INJURY HAZARD

Failure to follow this caution may result in personal injury.

This coil contains Nitrogen precharge of 15 PSIG. Release

of this pressure through the center of the rubber plugs is

required before removing the plugs.

IMPORTANT: Nitrogen can leak out through the hole that the

needle pierced in the plugs. This does not indicate a leaking coil

nor warrant return of the coil.

WARNING

EXPLOSION HAZARD

Failure to follow this warning could result

in death, serious personal injury, and/or

property damage.

Never use air or gases containing oxygen

for leak testing or operating refrigerant

compressors. Pressurized mixtures of air

or gases containing oxygen can lead to an

explosion.

CAUTION

CAUTION

INTRODUCTION

Use this instruction manual to install EAM4X & WLAM indoor coils

on multipoise furnaces. EAM4X & WLAM models are enclosed in

a casing.

Specifications subject to change without notice.

484 01 3905 00 3/23/17

INSTALLATION

INSPECT EQUIPMENT

File claim with shipper if equipment is damaged.

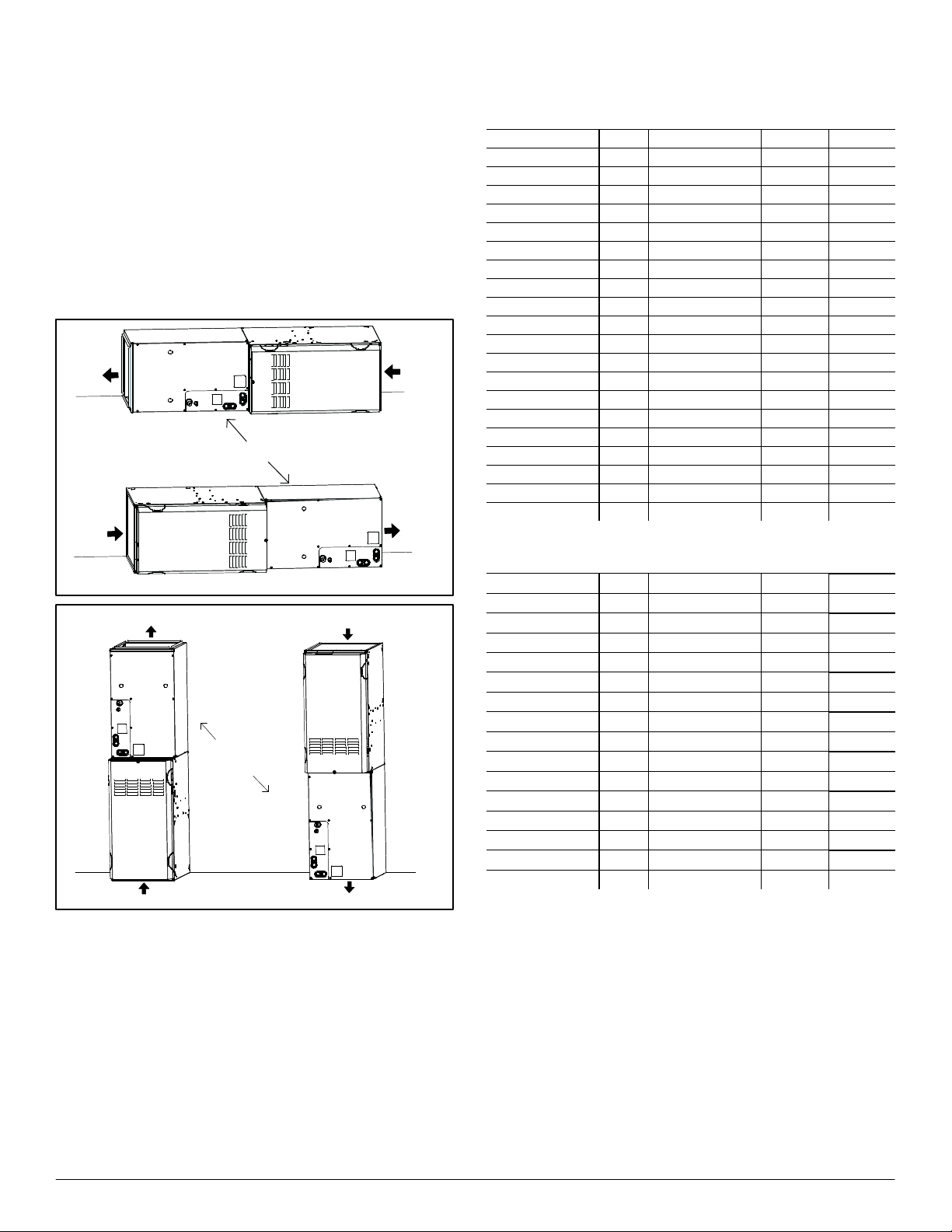

SELECT INSTALLATION

For upflow application follow:

A. Upflow coil installation.

See Table 1 for dimensions. Note instructions for placement of

coil casing on furnace.

For downflow application follow:

B. Downflow coil installation.

For horizontal application follow:

C. Horizontal coil Installation

Supply

Return

Upflow

Furnace

Installation

Horizontal Right Furnace Installation

Supply

Return

Horizontal Left Furnace Installation

Evaporator

Coil

Evaporator

Coil

Return

Supply

Return

Supply

A05400

Downflow

Furnace

Installation

A05401

Table 1

COIL INFORMATION

Coil Connection

Tube Size

inches

Model Number Tons

Flush to fit

Furnace width

inches (mm) Liquid Suction

EAM4X18L14A 1*1/2 14*3/16 (360) 3/8 5/8

EAM4X19L17A 1*1/2 17*1/2 (445) 3/8 3/4

EAM4X24L14A 2 14*3/16 (360) 3/8 5/8

EAM4X24L17A 2 17*1/2 (445) 3/8 5/8

EAM4X25L17A 2 17*1/2 (445) 3/8 3/4

EAM4X30L14A 2*1/2 14*3/16 (360) 3/8 3/4

EAM4X30L17A 2*1/2 17*1/2 (445) 3/8 3/4

EAM4X36L14A 3 14*3/16 (360) 3/8 3/4

EAM4X36L17A 3 17*1/2 (445) 3/8 3/4

EAM4X36L21A 3 21 (533) 3/8 3/4

EAM4X37L17A 3 17*1/2 (445) 3/8 3/4

EAM4X37L21A 3 21 (533) 3/8 7/8

EAM4X42L21A 3*1/2 21 (533) 3/8 7/8

EAM4X42L24A 3*1/2 24*1/2 (622) 3/8 7/8

EAM4X43L21A 3*1/2 21 (533) 3/8 7/8

EAM4X48L17A 4 17*1/2 (445) 3/8 7/8

EAM4X48L21A 4 21 (533) 3/8 7/8

EAM4X48L24A 4 24*1/2 (622) 3/8 7/8

EAM4X60L21A 5 21 (533) 3/8 7/8

EAM4X60L24A 5 24*1/2 (622) 3/8 7/8

EAM4X61L24A 5 24*1/2 (622) 3/8 7/8

Coil Connection

Tube Size

inches

Model Number Tons

Flush to fit

Furnace width

WLAM184AA 1*1/2 14*3/16 (360) 3/8 5/8

WLAM194BA 1*1/2 17*1/2 (445) 3/8 3/4

WLAM244AA 2 14*3/16 (360) 3/8 5/8

WLAM244BA 2 17*1/2 (445) 3/8 5/8

WLAM254BA 2 17*1/2 (445) 3/8 3/4

WLAM304AA 2−1/2 14*3/16 (360) 3/8 3/4

WLAM304BA 2−1/2 17*1/2 (445) 3/8 3/4

WLAM364BA 3 17*1/2 (445) 3/8 3/4

WLAM374BA 3 17*1/2 (445) 3/8 3/4

WLAM374CA 3 21 (533) 3/8 7/8

WLAM424CA 3−1/2 21 (533) 3/8 7/8

WLAM434CA 3−1/2 21 (533) 3/8 7/8

WLAM484CA 4 21 (533) 3/8 7/8

WLAM604CA 5 21 (533) 3/8 7/8

WLAM604DA 5 24*1/2 (622) 3/8 7/8

WLAM614DA 5 24*1/2 (622) 3/8 7/8

Figure 1 − Correct Orientation of Coil Support on Furnace

INSTALLATION OF EVAPORATOR COILS

A. Upflow coil installation.

The cased coil is designed to fit furnaces of the same width.

1. Set coil in place on upflow furnace discharge air opening.

2. Ensure coil is level for proper condensate drainage. Do not tip

coil toward condensate drain. Coil casing need not be

fastened or screwed to furnace.

2 484 01 3905 00

Specifications subject to change without notice.

3. When installing wider coil on narrow furnace, create field

fabricated adapter. (See Figure 2)

4. When installing narrow coil on wide furnace, create field

fabricated adapter. (See Figure 2)

NOTE: On upflow installations where the indoor coil is placed in

an unconditioned space, a 6” wide piece of insulation should be

applied and wrapped around the outside of coil casing and supply

duct contact point.

Loading...

Loading...