International Comfort Products DNPWREXH030A01, DNPWREXH022A01, DNPWREXH023A01 Installation Manual

Installation Instructions

ACCESSORY VERTICAL POWER EXHAUST, GAS HEATING/ELECTRIC COOLING,

ELECTRIC COOLING, AND HEAT PUMP UNITS

3 TO 121/2 TON

DNPWREXH030A01, DNPWREXH021A01, DNPWREXH022A01

DNPWREXH023A01, DNPWREXH080A00, DNPWREXH081A00

For Use With Vertical Economizer

TABLE OF CONTENTS

PACKAGE CONTENTS 1............................

UNIT CONFIGURATION TABLE 1....................

PACKAGE USAGE 1................................

SAFETY CONSIDERATIONS 1.......................

GENERAL 1........................................

INSTALLATION 2...................................

Power Exhaust Wiring with Economizer 3.............

Attaching Power Exhaust to the Unit 7................

Install Hinged Door Angle (Small and Large Cabinet) 8...

IMPORTANT: Read these instructions completely before

attempting to install the accessory power exhaust.

PACKAGE CONTENTS

QTY CONTENTS

1 Power Exhaust Hood/Fan Assembly

Low Voltage Wiring Harness with plug and 12 in (305mm)

1

gray jumper wire

1 High Voltage Wiring Harness with plug

8 No. 10 x 3/

1 Gasketing Roll

1 Sealing Angle

NOTES:

1. Both wiring harnesses are shipped attached to the power

exhaust assembly.

1

in. (19mm) Mounting Screws

4

1

1

UNIT CONFIGURATION TABLE

UNIT

CONFIGURATION

Small Cabinet 46 3/4” x 74 3/8”

Large Cabinet 58 1/2” x 88 1/8”

Extra Large Cabinet 63 3/8” x 115 7/8”

UNIT

FOOTPRINT SIZE

PACKAGE USAGE

UNIT

CONFIGURATION

Small Cabinet

Large Cabinet

Extra Large

Cabinet

NOTE: For 575−v installations, a field−supplied and installed transformer

(FAST part no. 1171494) must be used with 208/230 V power exhaust.

POWER EXHAUST

PART NUMBER

DNPWREXH030A01

DNPWREXH021A01

DNPWREXH022A01

DNPWREXH023A01

DNPWREXH080A00

DNPWREXH081A00

POWER EXHAUST

VOLTAGE

208/230 V,1 Ph

460 V, 3 Ph

208/230 V, 1 Ph

460 V, 3 Ph

208/230 V, 1 Ph

460 V, 3 Ph

SAFETY CONSIDERATIONS

Installation and servicing of air−conditioning equipment

can be hazardous due to system pressure and electrical

components. Only trained and qualified service personnel

should install, repair, or service air-conditioning equipment.

Untrained personnel can perform the basic maintenance

functions. All other operations should be performed by

trained service personnel. When working on

air-conditioning equipment, observe precautions in the

literature, tags and labels attached to the unit, and other

safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves.

Recognize safety information. This is the safety−alert

symbol . When you see this symbol on the unit and in

instructions or manuals, be alert to the potential for

personal injury.

Understand the signal words DANGER, WARNING, and

CAUTION. These words are used with the safety−alert

symbol. DANGER identifies the most serious hazards

which will result in severe personal injury or death.

WARNING signifies a hazard which could result in

personal injury or death. CAUTION is used to identify

unsafe practices which may result in minor personal injury

or product and property damage. NOTE is used to

highlight suggestions which will result in enhanced

installation, reliability, or operation.

GENERAL

The accessory vertical power exhaust is used in

conjunction with the vertical Economizer accessories. For

horizontal applications, this power exhaust accessory

cannot be used. The horizontal power exhaust accessory

must be used for horizontal applications.

See Table 1 for Economizer usage. See Fig. 1 for

dimensions.

Table 1 – Accessory Vertical Economizer Use

PART NO. DESCRIPTION

DNECOMZR020A02

DNECOMZR021A03

DNECOMZR062A00

Economizer with

W7212 controller.

509 06 2302 01

8/22/11

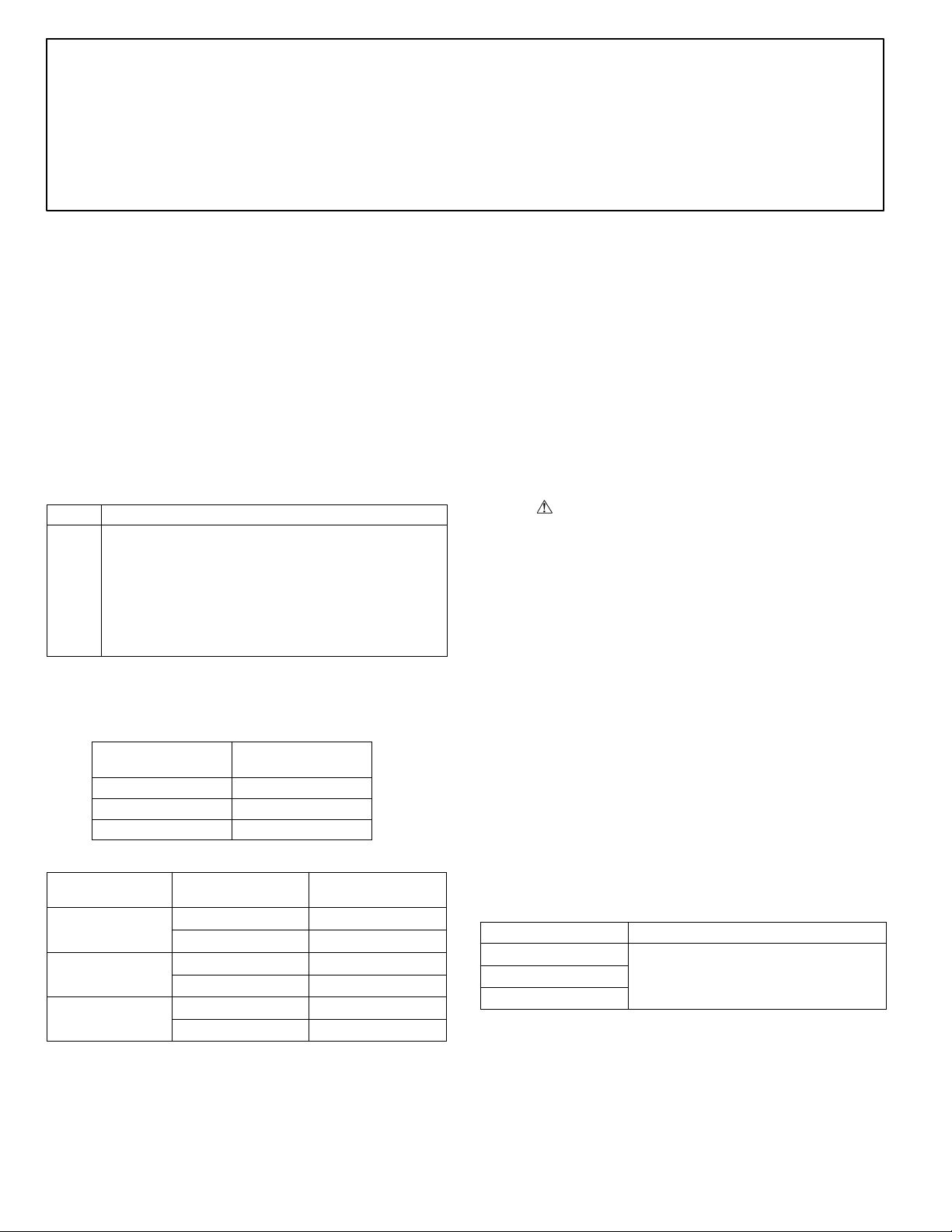

Fig. 1 − Dimensions, Economizer with Power Exhaust

X

ECONOMIZER

INLET

Y

POWER EXHAUST

OUTLET

Z

UNIT

CONFIGURATION

Small Cabinet

Large Cabinet

Extra-Large Cabinet

NOTE: Measurements are in inches (mm)

X

18.5 (470)

26 (660)

28.6 (725)

Y

19.25 (515)

25 (635)

37.75 (960)

Z

7

(11)

16

/

0 (0)

4.5 (115)

INSTALLATION

IMPORTANT: Follow all applicable local and national elec-

trical codes when installing this accessory.

Follow all local and NEC (National Electrical Code) codes.

If a single power source is to be used, size the wire to

include power exhaust MCA and MOCP. (See Table 2.)

Table 2 – Power Exhaust Electrical Data

POWER EXHAUST

PART NO.

DNPWREXH030A01

DNPWREXH021A01

DNPWREXH022A01

DNPWREXH080A00

DNPWREXH023A01

DNPWREXH081A00

LEGEND

MCA - Minimum Circuit Amps

MOCP- Maximum Overcurrent Protection

N/A - Not Applicable

MCA

(230 v)

N/A 0.9 N/A 15

N/A 1.8 N/A 15

MCA

(460 v)

1.5 N/A 0.64 15

3.3 N/A 1.32 15

MCA

(575 v)

NOTE: For R−410A units, refer to unit nameplate for MCA

and MOCP for installed power exhaust. For R−22 units,

use the calculations detailed below.

MOCP

(for separate

power source)

Check MCA and MOCP when power exhaust is powered

through the unit (must be in accordance with NEC and/or

local codes). Determine the new MCA including the power

exhaust using the following formula:

MCA New = MCA unit only + MCA of Power Exhaust

For example, using a R−22 gas heat, electric cooling,

6−ton unit with MCA = 28.9 and MOCP = 35, with

DNPWREXH030A01 power exhaust.

MCA New = 28.9 amps + 1.5 amps = 30.4 amps

If the new MCA does not exceed the published MOCP,

then MOCP would not change. The MOCP in this example

is 35 amps, the MCA New is below 35, therefore the

MOCP is acceptable. If “MCA New” is larger than the

published MOCP, raise the MOCP to the next larger size.

For separate power, the MOCP for the power exhaust will

be 15 amps per NEC.

NOTE: For 575−v installations, a field−supplied and

installed transformer (FAST part no. 1171494) must be

used with 208/230−v power exhaust. (See Fig. 6.)

The vertical power exhaust can be used with the following

type of economizer

S Economizer with controller W7212.

To install the vertical power exhaust, perform the

following procedure:

1. Turn off unit power supply and install lockout tag. For

gas units, turn off the gas supply.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal injury

and/or death.

Before beginning any modification, be certain the

main−line electrical disconnect switch is in the OFF

position. Close the main gas supply shutoff valve. Tag

disconnect switch and gas valve with suitable warning

labels.

NOTE: Before installing, ensure voltage of power exhaust

agrees with power supply to the equipment.

2. Remove the power exhaust knockout plugs located on

the lower left side of the Economizer. (See Fig. 2.)

Fig. 2 − Power Exhaust Knockout Location

509 06 2302 01

ECONOMIZER

POWER

EXHAUST

KNOCKOUTS

2

3. Remove the RTU unit filter panel to allow access to the

inside of the rooftop.

4. The panel covering the horizontal return opening on

the unit may also be removed for easier access and

installation. Be sure to replace this panel when installation is complete.

5. Install the vertical economizer per the instructions

provided with the economizer. Do not install the rainhood shipped with the Economizer. Set aside the aluminum air filter for use with the power exhaust.

6. Remove fan shield so power exhaust can lay flat

without bending the shield or damaging the roof.

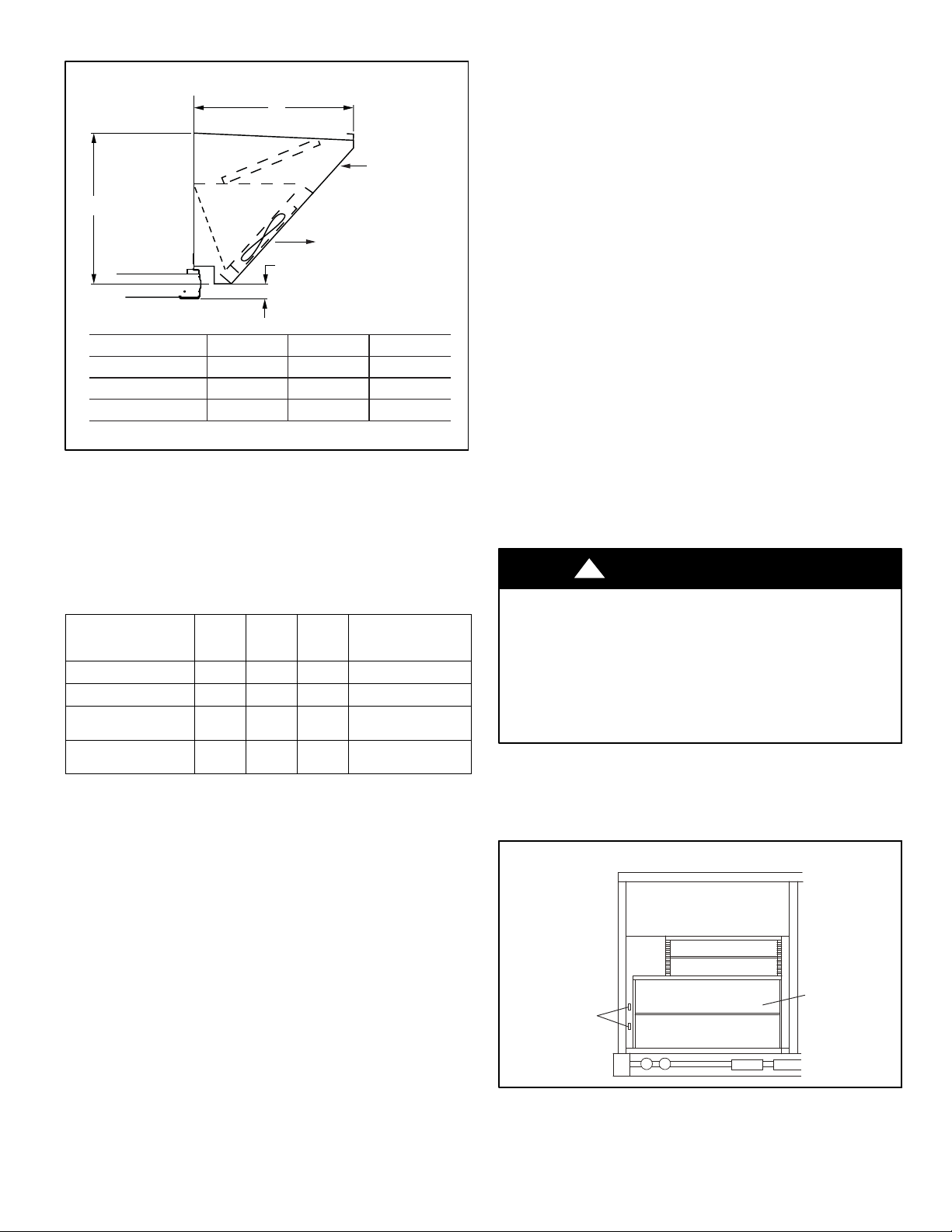

7. Remove the shipping blocks from the bottom of the accessory vertical power exhaust. (See Fig. 3.)

Fig. 3 − Shipping Block Removal

8. There may be a hinged door panel in place of the filter

panel. Open the hinged door, remove the screws and

hinges, remove the door and set it aside. Keep all

screws and hinges.

9. Place the power exhaust close to the Economizer to

allow for wiring harness connection.

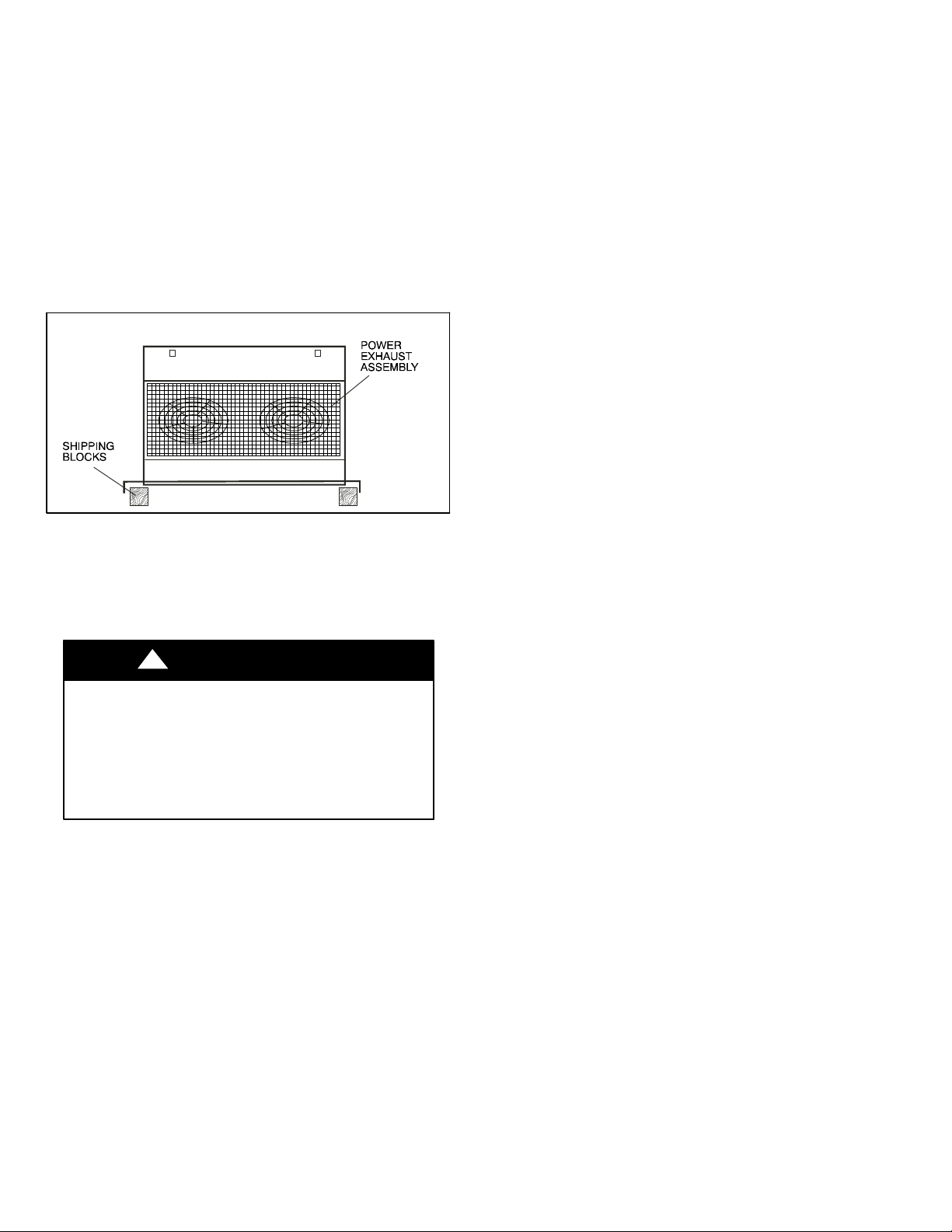

!

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in

equipment damage.

Be careful to route wires to avoid pinching or

cutting during assembly. It can be difficult to

protect the wires while attaching the power

exhaust to the unit.

10. Follow the wiring instructions specific to the Economizer. Be sure power exhaust wiring does not interfere

with damper operation.

Power Exhaust Wiring with Economizer

Use these instructions and diagrams if using the vertical

power exhaust with Economizer.

1. The 2−wire low voltage harness from the power ex-

haust and the 24 or 36 in (610 or 915 mm) low voltage

extension harness are plugged together for shipping.

Unplug these 2 harnesses for installation.

2. Insert the 2−wire low voltage harness plug from the

power exhaust into the top knockout on the economizer. (See Fig. 2.)

3. From the rear of the economizer, connect the 24 in

(610) long low voltage extension harness plug to the

power exhaust harness.

4. Route the other end of the low voltage extension harness to the economizer controller. (See Fig. 4.) The

harness is connected to the controller by connecting

the tan wire to the tan wire 24 VAC COM terminal on

the controller. The terminal on the gray wire is connected to terminal EF1 on the controller. See Fig. 5 and 6

for economizer wiring diagrams. Install the gray jumper

wire on the controller from the exhaust fan terminal

(EF), to the 24 VAC HOT terminals. The gray jumper is

shipped wire tied to the control harness.

5. The high voltage harness from the power exhaust and

the high voltage extension harness are plugged together

for shipping. Unplug these 2 harnesses for installation.

6. Insert the high voltage harness plug from the power

exhaust into the bottom knockout on the economizer.

(See Fig.2 and 4.)

R−410A Rooftop Models Only — For single point

wiring application, connect the power exhaust power

wire harness to the compressor contactor or indoor fan

contactor in the control box. Install the power exhaust

power wire harness into the pressure lugs on the

compressor contactor or indoor fan contactor, used for

the field power wiring also.

Proceed to steps 7 and 8 for details on completing

connection and routing.

7. From the rear of the economizer, connect the long high

voltage extension harness plug to the power exhaust

harness. (See Fig. 4.)

8. Route the other end of the long high voltage extension

harness through the HVAC unit to the control box.

(See Fig. 5.) The harness must be routed through the

grommets provided in the unit. Do not drill routing

holes. Be careful not to route the power exhaust

harness on top of the indoor coil. Wire the end of the

high voltage harness extension to the power exhaust

power source. (See Fig. 6 and 7.)

3

509 06 2302 01

Fig. 4 − Power Exhaust Harness Installation for Economizer with W7212 Controller

COIL

FILTERS

HVAC UNIT

W7212

CONTROLLER

24−IN (610mm)

LOW VOLTAGE

EXTENSION

HARNESS

ECONOMIZER

Cover panel

over

horizontal

return

2−WIRE

LO W

VOLTAGE

HARNESS

ECONOMIZER/POWER

EXHAUST

OUTDOOR AIR HOOD

134−IN. (3406mm)

OR 194−IN. (4928mm)

HIGH VOLTAGE

EXTENSION HARNESS

Fig. 5 − Power Line Harness Routing (Top View of Unit Shown)

MAIN POWER

Note 1

KNOCKOUTS

UNIT ROOF CURB

HIGH VOLTAGE

HARNESS

ROOF

HIGH & LOW VOLTAGE WIRING HARNESS

ECONOMIZER

Low Voltage Harness

note 1

FILTER

COIL

High Voltage

Harness

INDOOR

FAN

POWER EXHAUST

(INSTALLED POSITION)

509 06 2302 01

Field supplied

connectors

RTU CONTROL

BOX

note 1

Note: Ensure main power line, disconnect, and fuse/breaker are sized per National Electric Guide.

4

Fig. 6 − Power Exhaust Wiring for Economizer with Controller W7212 — 208/230 V and 575 V Units

FIELD

POWER

SUPPLY

BLK

YEL

BLU

GRN/YEL

To C11 for Small and Large Cabinet

To IFC−11 for Extra−Large Cabinet

To C13 for Small

and Large Cabinet

To IFC13 for

Extra−Large Cabinet

GRD.

POWER LINE

PLUG

3

1

2

4

OR

FIELD SUPPLIED

2 X 4 JUNCTION BOX

GROUND

FOR 575−V POWER SUPPLY

FOR 208/230−V SEPARATE

POWER SUPPLY

GREEN − YELLOW

C1

GREEN − YELLOW

BROWN

GRD.

13

4

79

AB

REL AY

NOTES:

1

2

3

4

BL ACK

BL ACK

GREEN

3

BL ACK

1

RED

2

4

3

1

2

4

TO 575V POWER

575V

PRIMARY

SECONDARY

220V

RED

EXH.

FA N #1

TRANSFORMER

No. 1171494

Field Supplied

AND INSTALLED)

BL ACK

BLUE

C2

BL ACK

BL ACK

6

BLUE

EXH.

FAN #2

TO ECONOMIZER

ACTUATOR

BROWN

END

SWITCH

PLUG

TA N

1

2

3

GRAY GRAY

4

TA N

TA N

1

2

3

4

3

Field Supplied Wiring

575 V transformer No. 1171494 is ordered

separately from power exhaust.

Economizer actuator and controller are shipped with

the Economizer − not with power exhaust.

Connections from End Switch plug to Economizer

controller are made by installer.

If a single power source is to be used, size wire to

include power exhaust MCA and MOCP.

For R−410A units, refer to unit nameplate for MCA

and MOCP for installed power exhaust.

WHITE

GRAY

BL ACK

RED

POWER

EXHAUST

ACCESSORY

2

ECONOMIZER

CONTROLLER

24 VAC

HOT

24 VAC

COM

+

EF 1

EF

2

For R−22 units, use the following calculations

Check MCA and MOCP when power exhaust is powered

through the unit. Determine the new MCA including the

FIELD

SUPPLIED

FUSED

DISCONNECT

power exhaust using the following formula:

MCA New = MCA unit only + MCA of Power Exhaust

For example, using an electric cooling, 6−ton

R−22 unit with MCA + 28.9 and MOCP = 35, with

DNPWREXH030A01 power exhaust.

MCA New = 28.9 amps + 1.5 amps = 30.4 amps

If the new MCA does not go over the MOCP published,

then MOCP would not change. The MOCP in this

example is 35 amps, the MCA New is below 35,

therefore the MOCP is OK. If “MCA New” is larger than

the published MOCP, raise the MOCP to the next

larger size. For separate power, the MOCP for the

power exhaust will be 15 amps per NEC.

C10426

5

509 06 2302 01

Fig. 7 − Power Exhaust Wiring for Economizer with Controller W7212 — 460 V Units

FIELD

POWER

SUPPLY

BLK

YEL

BLU

GRN/YEL

To C11 for Small and

Large Cabinet

To IFC−11 for

Extra−Large Cabinet

To C13 for Small

and Large Cabinet

To IFC13

for Extra−Large

Cabinet

EQUIP

GND

GREEN

GROUND

FIELD

SUPPLIED

FUSED

DISCONNECT

SEPARATE

POWER

SOURCE

BL ACK

RED

WHITE

POWER

FIELD SUPPLIED

2 x 4 JUNCTION BOX

BL ACK

LINE

PLUG

1

2

3

4

OR

GREEN − YELLOW

GRAY

GRAY

BLUE

BROWN

REL AY #1

3

23

5

6

9

8

B

WHITE

WHITE

GRD

BL ACK

FAN #2

BL ACK

112

4

7

A

4

7

A

1

2

3

4

EXH.

FAN #1

BL ACK

RED

GREEN

EXH.

BROWN

5

8

GRAY

GRAY

BLUE

REL AY #2

6

9

B

TA N

GRAY

POWER

EXHAUST

ACCESSORY

1

END

SWITCH

PLUG

1

4

TO ECONOMIZER

ACTUATOR

TA N

1

22

GRAY

33

GRAY

4

2

Field Supplied Wiring

1

2

3

4

NOTES:

Economizer actuator and controller are shipped with the Economizer

1

not with power exhaust.

Connections from End Switch Plug to the Economizer controller are made

2

by installer.

If a single power source is to be used, size wire to include power exhaust

3

MCA and MOCP.

For R−410A units, refer to the unit nameplate for MCA and MOCP for

installed power exhaust.

For R−22 units use the following calculations

Check MCA and MOCP when power exhaust is powered through the unit.

Determine the new MCA including the power exhaust using the following

formula:

MCA New = MCA unit only + MCA of Power Exhaust

For example, using an electric cooling, 6−ton R−22 unit with MCA = 28.9 and

MOCP = 35, with DNPWREXH030A01 power exhaust.

MCA New = 28.9 amps + 1.5 amps = 30.4 amps

If the new MCA does not go over the MOCP published,

then MOCP would

not change. The MOCP in this example is 35 amps, the MCA New is below

35, therefore the MOCP is OK. If “MCA NEW” is larger than the published

MOCP, raise the MOCP to the next larger size. For separate power, the

MOCP for the power exhaust will be 15 amps per NEC.

BL ACK

WHITE

TA N

ECONOMIZER

CONTROLLER

RED

24V

HOT

24V

COM

+

EF

1

EF 1

C10427

509 06 2302 01

6

Attaching Power Exhaust to the Unit

1. Make sure all power exhaust harnesses are connected

as indicated in the previous steps. See Fig. 6 and 7 for

Economizer.

2. Make sure all wiring is secure. Use field−supplied wire

ties if necessary. Be sure that wiring does not interfere

with operation of the HVAC unit, economizer, or power

exhaust.

3. For units with a standard filter panel (i.e., no hinged

door): Install the gasketing (provided) on the back of

power exhaust side mating flanges. (See Fig. 8)

NOTE: This step does not apply to units with a hinged

door.

Fig. 8 − Gasketing Location Detail

(Standard Filter Panel Only)

UNIT CORNER

POST

GASKETING

POWER

EXHAUST

4. Lift power exhaust and install over economizer using

the #10 x 3/4 in. long screws provided. Make sure wiring harnesses are properly secured. (See Fig. 9)

Fig. 9 − Power Exhaust Installed on Unit

ALUMINUM

CONTROLLER

FILTER

POWER

EXHAUST

5. Locate the aluminum filter shipped with the economizer. Open the filter clips under the top hood of the

power exhaust. Slide aluminum filter into the outside

air opening of the power exhaust. Filter will slide past

filter clips. Close filter clips, which will lock filter in

place.

6. Reinstall the fan shield.

7. Return power to unit and remove lockout tag.

8. Test power exhaust operation by setting the power exhaust set point on the economizer controller to 0%.

Power exhaust performance is shown in Fig. 10.

9. Adjust the power exhaust set point on the Economizer

controller to the desired activation point per unit

schematic.

10. For units with a standard filter access panel, reinstall

the unit filter access door.

For units with a hinged access door (Small & Large

Cabinet), install the hinged door seal angle included in

the power exhaust kit using the instructions in this

instruction. Do not proceed unless the sealing angle is

installed. Units with a hinged door that do not have a

sealing angle may not have a watertight seal.

Fig. 10 − Power Exhaust Performance

5000

4000

3000

EXHAUST

2000

AIRFLOW (cfm)

1000

0

0 0.1 0.2 0.3 0.4 0.5

RETURN DUCT STATIC PRESSURE (in wc)

Small Cabinet

Large and

Extra-Large

Cabinet

7

509 06 2302 01

Install the Hinged Door Angle

(Small and Large Cabinet)

Follow these instructions if the unit has a hinged panel

instead of a standard filter panel. Hinged Door Angle

DNPECONV003A00 is for 3 to 5 ton units and

DNPECONV004A00 is for 6 to 10 ton units.

1. Find the sealing angle and three screws provided in

the power exhaust kit.

2. Attach the sealing angle to the top of the power exhaust hood using the screws provided. Refer to Fig.

14. Note that the gasketing flange will be facing out.

3. If there are NO pre−drilled holes in the Power Exhaust

hood: Lay the hinged panel, insulation side up, on top

of the hood so that the hinge screw holes align with

the pre−drilled screw holes in the sealing angle. (For

hoods with pre−drilled holes, skip to Step 7.)

4. Check the alignment of the hinged door with the side

of the filter opening to be sure it will close properly.

5. Use a pencil to mark the hood where the screw holes

will be.

6. Remove the hinged door and drill four (4) 11/64 in.

holes where the marks are.

Fig. 11 − Power Exhaust Installation

Fig. 12 − Install Sealing Angle

SEE

NOTE

SEE

NOTE

GASKETED

FLANGE

SEALING

ANGLE

Fig. 13 − Re−Install the Hinged Door

SEALING ANGLE

POWER EXHAUST HOOD

SCREW ANGLE

TO HOOD (3)

HINGED DOOR

GASKET

LOCATION

(STANDARD

FILTER

PAN E L

ONLY)

POWER EXHAUST

SIDE FLANGES

GASKET LOCATION

NOTE: The sealing angle will be in place; use the holes in

it as a guide.

7. Place the door and hinges back on the unit. Screw

through the door hinges and sealing angle into the

flanged top of the hood using the 4 screws set aside

when the hinged door was removed. (See Fig. 13.)

8. Close the hinged door and adjust handles if necessary.

509 06 2302 01

8

Loading...

Loading...