International comfort products DLCBHR, DLFAHH, DLFBHB, DLFBHC, DLFBHF Installation Instructions Manual

...

DLCBHR / DLFAHH / DLFBHB / DLFBHC / DLFBHD / DLFBHF

Multi- Zone Ductless Split System

Size 18K, 24K, 30K, 36K, 42K, 48K and 56K

Installation Instructions

NOTE: Read the entire instruction manual before starting the installation.

TABLE OF CONTENTS

SAFETY CONSIDERATIONS 2.........................

PAGE

GENERAL 2.........................................

SYSTEM REQUIREMENTS 3- 4.........................

ELECTRICAL DATA 4................................

PARTS LIST 6........................................

DIMENSIONS 7- 14...................................

CLEARANCES 15- 17.................................

DIMENSIONS - BRANCH BOXES 18- 19.................

INSTALLATION GUIDE 20.............................

HIGH- WALL INDOOR UNIT INSTALLATION 20..........

DUCTED INDOOR UNITS INSTALLATION 21............

FLOOR CONSOLE INDOOR UNITS INSTALLATION 24....

INSTALLING THE INDOOR UNIT 26....................

CASSETTE TYPE INDOOR UNIT INSTALLATION 28......

OUTDOOR UNIT INSTALLATION 31....................

SYSTEM VACUUM AND CHARGE 35...................

START- UP 37........................................

TROUBLESHOOTING 38- 41...........................

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air- conditioning equipment

can be hazardous due to system pressures, electrical components,

and equipment location (roofs, elevated structures, etc.).

Only trained, qualified installers and service mechanics should

install, start-up, and service this equipment.

Untrained personnel can perform basic maintenance functions such

as cleaning coils. All other operations should be performed by

trained service personnel.

When working on the equipment, observe precautions in the

literature and on tags, stickers, and labels attached to the

equipment.

Follow all safety codes. Wear safety glasses and work gloves. Keep

quenching cloth and fire extinguisher nearby when brazing. Use

care in handling, rigging, and setting bulky equipment.

Read these instructions thoroughly and follow all warnings or

cautions included in literature and attached to the unit. Consult

local building codes and current editions of the National Electrical

Code ( NEC ) NFPA 70. In Canada, refer to current editions of the

Canadian electrical code CSA 22.1.

!

Recognize safety information. This is the safety- alert symbol

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury. Understand

these signal words: DANGER, WARNING, and CAUTION.

These words are used with the safety- alert symbol. DANGER

identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards which could

result in personal injury or death. CAUTION is used to identify

unsafe practices which may result in minor personal injury or

product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability, or

operation.

!

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF

position. There may be more than 1 disconnect switch.

Lock out and tag switch with a suitable warning label.

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Do not bury more than 36 in. (914 mm) of refrigerant pipe

in the ground. If any section of pipe is buried, there must be

.

a 6 in. (152 mm) vertical rise to the valve connections on

the outdoor units. If more than the recommended length is

buried, refrigerant may migrate to the cooler buried section

during extended periods of system shutdown. This causes

refrigerant slugging and could possibly damage the

compressor at start- up.

WARNING

CAUTION

GENERAL

These instructions cover the inst allati on, start-up and servic i ng of the

multi-zone outdoor unit connec t ed to up to nine indoor fan coil units .

For approved combinations, please refer to the Product Data.

2

SYSTEM REQUIREMENTS

Allow sufficient space for airflow and servicing unit. See Fig. 14 through 19 for minimum required clearances.

Piping

IMPORTANT: Both refrigerant lines must be insulated separately.

Minimum refrigerant line length between the indoor and outdoor units is 10 ft. (3 m). The following maximum lengths are allowed:

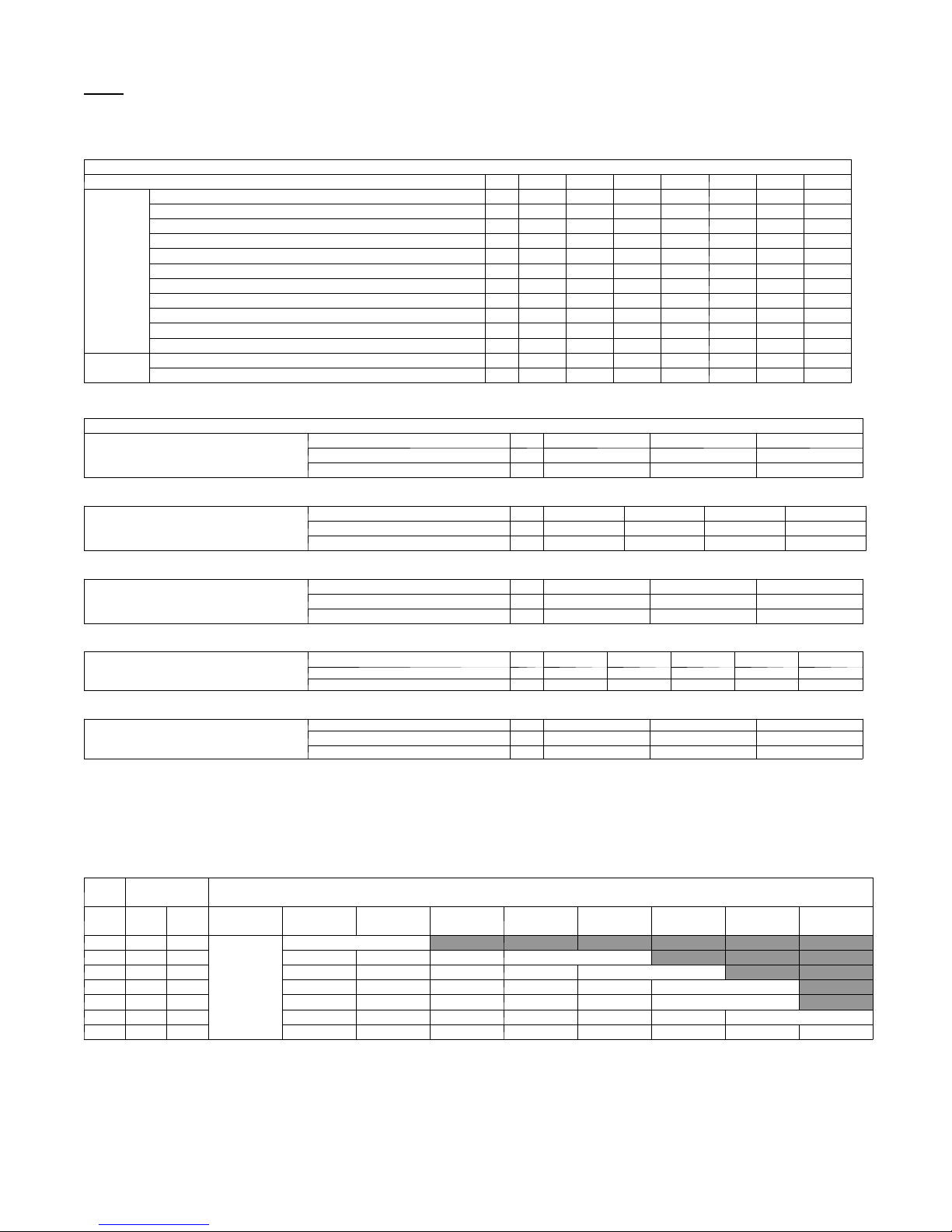

Table 1—Maximum Piping Lengths

System Size 18 24 30 36 42 48 56

Piping

Refrigerant

Min. Piping Length ft 10 10 10 10 10 10 10

Standard Piping Length ft 32 98 131.2 131.2 131.2 98.42 98.42

Max. outdoor-indoor height difference ft 33 33 49.2 49.2 49.2 98.42 98.42

Max. height distance between indoor and indoor ft 33 33 24.6 24.6 24.6 49.21 49.21

Max. height distance between indoor and outdoor and indoor ft 32 32 49.2 49.2 49.2 98.42 98.42

Max. height distance between indoor and outdoor and outdoor up ft 33 33 49.2 49.2 49.2 98.42 98.42

Max. equivalent piping outdoor to last indoor ft 33 65 82 82 82 229 229

Max. Piping Length with no additional refrigerant charge ft 32 98 131.2 131.2 131.2 98.42 98.42

Max. Piping Length ft 65 196 229.7 246 246 442.9 475.7

Gas Pipe (size - connection type) in 3/8 3/8 3/8 3/8 3/8 5/8 5/8

Liquid Pipe (size - connection type) in 1/4 1/4 1/4 1/4 1/4 3/8 3/8

Refrigerant Type R-410A R-410A R-410A R-410A R-410A R-410A R-410A

Heat Pump Models Charge Amount Lbs 3.53 4.85 6.17 8.05 8.05 10.91 10.91

NOTE: Tables 2 through 6 show the piping size specifications.

Indoor Unit Piping Connection Sizes

Indoor High Wall

(DLFAHH)

Indoor High Wall

(DLFBHB)

Indoor Cassette

Indoor Ducted

Size 9 12 18

Pipe Connection Size - Liquid In. 1/4" 1/4" 1/4"

Pipe Connection Size - Suction In. 1/2" 1/2" 5/8"

Size 9 12 18 24

Pipe Connection Size - Liquid In. 1/4" 1/4" 1/4" 1/4"

Pipe Connection Size - Suction In. 1/2" 1/2" 5/8" 5/8"

Size 12 18 24

Pipe Connection Size - Liquid In. 1/4" 1/4" 3/8"

Pipe Connection Size - Suction In. 3/8" 1/2" 5/8"

Size 9 12 18 21 24

Pipe Connection Size - Liquid In. 1/4" 1/4" 1/4" 3/8" 3/8"

Pipe Connection Size - Suction In. 3/8" 3/8" 1/2" 5/8" 5/8"

Table 6—Indoor Floor Console

Size 9 12 18

Indoor Floor Console

Pipe Connection Size - Liquid In. 1/4" 1/4" 1/4"

Pipe Connection Size - Suction In. 3/8" 3/8" 1/2"

Refrigerant Piping:

Line sets to be sized based on the connection size of the indoor unit. Each pipe to be insulated individually.

Conversion Joints:

The outdoor unit may include a package of conversion joints to facilitate installation of various sizes of fan coils. These joints are to be

connected to the outdoor unit as needed to match the line set size.

Table 7—Additional Refrigerant Charge

Total Line

Unit

Size

Length ft

Min Max

18 10 66

24 10 196 None None 0.20 / 0.20 0.20 / 0.20

30 10 230 None None None 0.24 / 0.58 0.24 / 0.58

36 10 246 None None None 0.24 / 0.58 0.24 / 0.58 0.24 / 0.58

42 10 246 None None None 0.24 / 0.58 0.24 / 0.58 0.24 / 0.58

48 10 443 None None 0.24 / 0.58 0.24 / 0.58 0.24 / 0.58 0.24 / 0.58 0.24 / 0.58

56 10 476 None None 0.24 / 0.58 0.24 / 0.58 0.24 / 0.58 0.24 / 0.58 0.24 / 0.58 0.24 / 0.58

10 - 32

(3 - 10)

None

>32 - 66

(10 - 20)

Additional Charge, 1/4” Liquid Line / 3/8” Liquid Line, oz/ft. ft (m)

>66 - 98

(20 - 30)

0.20 / 0.20

Outdoor Unit

Table 2—Indoor High Wall

Table 3—Indoor High Wall

Table 4—Indoor Cassette

Table 5—Indoor Ducted

>98 - 131.2

(30 - 40)

>131.2 - 196

(40 - 60)

>196 - 230

(60 - 70)

>230 - 246

(70 - 75)

>246 - 443

(75 - 135)

>443 - 476

(135 - 145)

Additional Refrigerant Calculation Sizes 30K, 36K and 42K:

Sum Total Liquid Pipe 1/4” (ft) x 0.24 + Sum Total Pipe 3/8” (ft) x 0.58 – 31 oz

Additional Refrigerant Calculation Sizes 48K and 56K:

Sum Total Liquid Pipe 1/4” (ft) x 0.24 + Sum Total Pipe 3/8” (ft) x 0.58 – 51.7 oz

NOTE: If the calculation results in a negative number no additional refrigerant is required.

NOTES:

EXV = Electronic Expansion Device

Electronic expansion valves in the outdoor unit are used as metering devices.

3

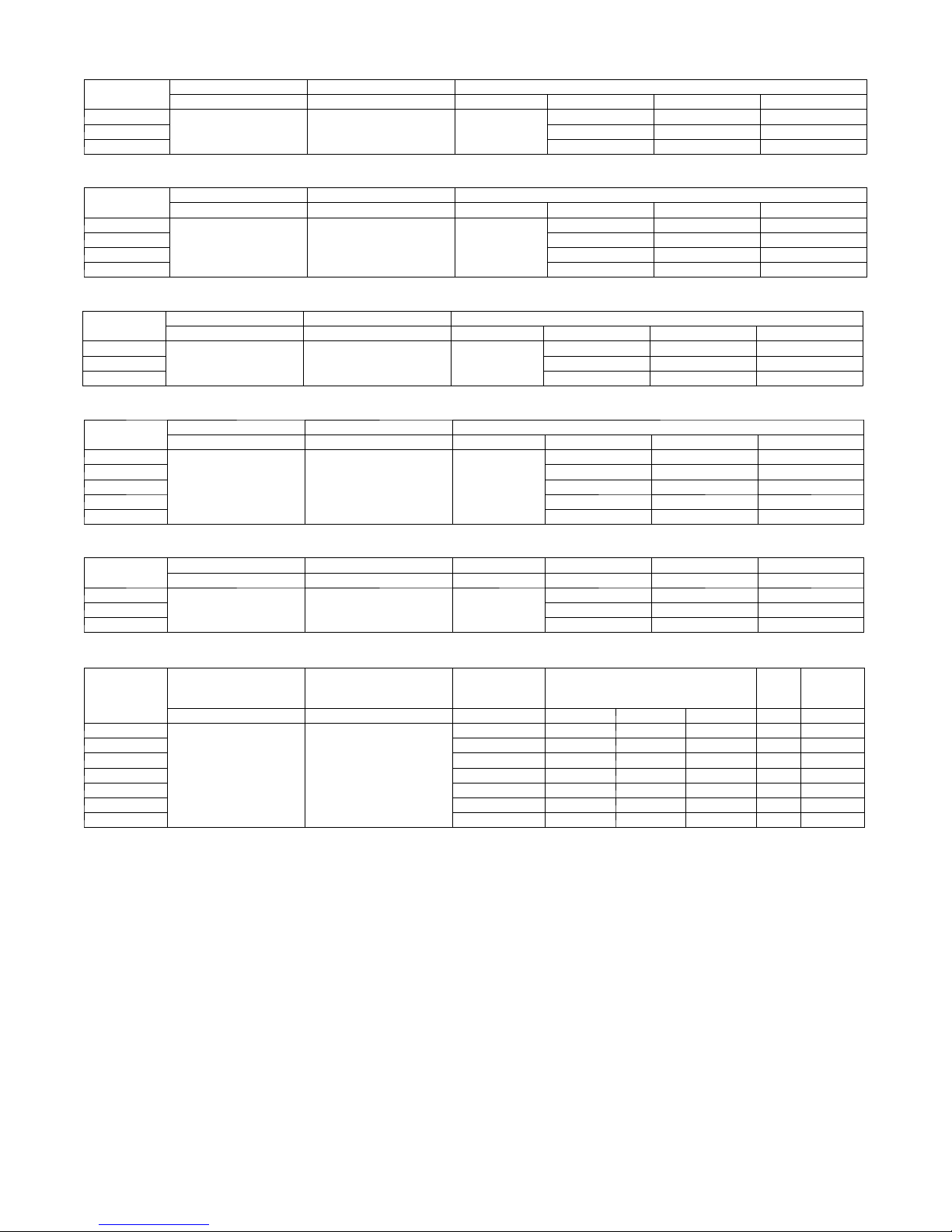

ELECTRICAL DATA

Table 8—High Wall DLFAHH

UNIT SIZE

9

12 0.1 0.0268 20

18 0.1 0.0268 20

UNIT SIZE

9

12 0.17 1/72 10

18 0.3 1/29 25

24 0.38 1/10 70

UNIT SIZE

12

18 0.18 1/72 46

24 0.43 1/20 46

UNIT SIZE

9

12 0.31 1/18 80

18 0.41 1/12 100

21 0.5 1/36' 124

24 0.5 1/36' 124

SYSTEM VOLTAGE OPERATINGVOLTAGE INDOORFAN

VOLT / PHASE / HZ MAX / MIN V-PH-HZ FLA HP W

0.1 0.0268 20

208-230/1/60 253 / 187 208-230/1/60

Table 9—High Wall DLFBHB

System Voltage OPERATING VOLTAGE INDOOR FAN

VOLT / PHASE / HZ MAX / MIN V-PH-HZ FLA HP W

0.17 1/72 10

208-230/1/60 253 / 187 208-230/1/60

Table 10—Cassette

System Voltage OPERATING VOLTAGE INDOORFAN

VOLT / PHASE / HZ MAX / MIN V-PH-HZ FLA HP W

0.18 1/72 46

208-230/1/60 253 / 187 208-230/1/60

Table 11—Ducted

System Voltage OPERATING VOLTAGE INDOORFAN

VOLT / PHASE / HZ MAX / MIN V-PH-HZ FLA HP W

0.28 1/24 80

208-230/1/60 253 / 187 208-230/1/60

Table 12—Floor Console

UNIT SIZE

9

12 0.14 1/24 30

18 0.14 1/24 30

System Voltage OPERATING VOLTAGE INDOOR FAN

VOLT / PHASE / HZ MAX / MIN V-PH-HZ FLA HP W

0.14 1/24 30

208-230/1/60 253 / 187 208-230/1/60

Table 13—Multi Zone Outdoor Unit

UNIT SIZE

18

24 11.5 0.59 1/8 90 21 35

30 13.9 0.68 1/6 150 19 30

36 15.6 0.82 2/9 240 21 35

42 17.8 0.82 2/9 240 24 40

48 23 1 1/6 150 30 50

56 23 1 1/6 150 30 50

*Permissible limits of the voltage range at which the unit will operate satisfactorily.

LEGEND

FLA - Full Load Amps

LRA - Locked Rotor Amps

MCA - Minimum Circuit Amps

RLA - Rated Load Amps

System Voltage OPERATING VOLTAGE COMPRESSOR OUTDOOR FAN MCA

VOLT / PHASE / HZ MAX / MIN RLA FLA HP W

7.2 0.62 1/12 60 15 25

208-230/1/60 253 / 187

MAX

FUSE/CB

AMP

4

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

S Wires should be sized based on NEC and local codes.

S Use copper conductors only with a minimum 300 volt .

rating and 2/64 inch thick insulation.

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage

or improper operation.

S Be sure to comply with local codes while running wire from

indoor unit to outdoor unit.

S Every wire must be connected firmly. Loose wiring may

cause terminal to overheat or result in unit malfunction. A

fire hazard may also exist. Therefore, be sure all wiring is

tightly connected.

S No wire should be allowed to touch refrigerant tubing,

compressor or any moving parts.

S Disconnecting means must be provided and shall be located

within sight and readily accessible from the air conditioner.

S Connecting cable with conduit shall be routed through hole

in the conduit panel.

All wires must be sized per NEC (National Electrical Code) or

CEC (Canadian Electrical Code) and local codes. Use Electrical

Data table MCA (minimum circuit amps) and MOCP (maximum

over current protection) to correctly size the wires and the

disconnect fuse or breakers respectively.

Per caution note, only copper conductors with a minimum 300

volt rating and 2/64- inch thick insulation must be used. The u se

of BX cable is not recommended.

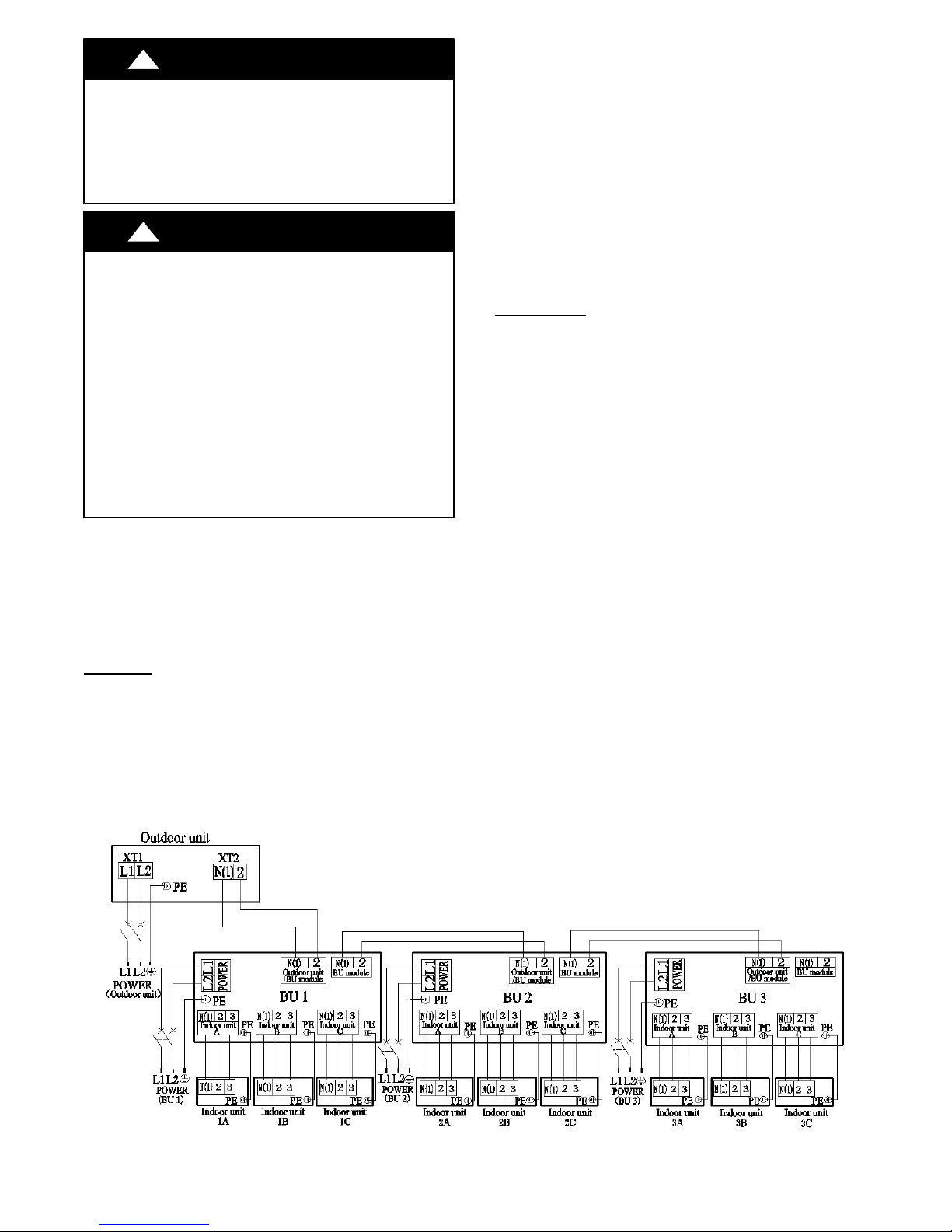

18- 42

Sizes

Recomme nde d Connection Method for Power and

Communication - Wi r ing - Power and Communication Wiri ng:

The main power is supplied to the outdoor unit. The field supplied

14/3 power/communication wiring from the outdoor unit to indoor

unit consists of four (4) wires and provides the power for the

indoor unit. Two wires are high voltage AC power; one is

communication wiring and the other is a ground wire.

CAUTION

CAUTION

Recomme nde d Connection Method for Power and

Communication Wiring (To minimize communication wiring

interference)

Power Wiring:

The main power is supplied to the outdoor unit. The fie l d supplied

power wiring from the outdoor unit to indoor unit consists of three (3)

wires and provides the power for the indoor unit. Two wires are high

voltage AC powe r and one is a ground wi re. To mini mize voltage

drop, the fac tory recommended wir e size is 14/2 stranded with a

ground.

Communication Wiring:

A separate shielded copper conductor only, with a minimum 300

volt rating and 2/64- inch thick insulation, must be used as the

communication wire from the outdoor unit to the indoor unit.

Please use a separate shielded 16GA stranded control wire.

For sizes

Recomme nde d Connection Method for Power and

Communication - Wi r ing - Power and Communication Wiri ng:

Power Wiri ng OUTDOOR UNIT& BRANCH BOXES:

Separate power s upplies ar e required for t he outdoor unit and the

Branch Boxes. The indoor units are powered from the Branch Boxes.

The field supplied 14/3 power wiring from the OUTDOOR UNIT

consists of three (3) wires. Two wires are high voltage AC power, one

is a ground wire.

The field supplied 14/3 power wiring from the BRANCH BOXES

consists of three (3) wires. Two wires are high voltage AC power, one

is a ground wire.

Up to three (3) Branch Boxes can be powered from the same 15 amp

breaker.

Communication Wiring:

A separate shiel ded copper conductor only, with a minimum 300 volt

rating and 2/64- inch thick insulati on, must be used as the

communication wire from the OUTDOOR UNIT to the BRANCH

BOX.

Please use a separate shielded 16GA stranded control wire.

Power and Communication Wiring BRANCH BOXES to

INDOOR UNITS:

The field supplied 14/3 power/communication wiring from the

BRANCH BOX to the INDOOR UNIT consists of f our (4) wires

and provides the power for the indoor unit. Two wires are high

voltage AC power, one is communicat i on wiring “2” and the other is

a ground wire “N(1)”

See diagr am below for detai ls on wiring for size s 48- 56.

48- 56

Fig. 1 - Wiring Connection

5

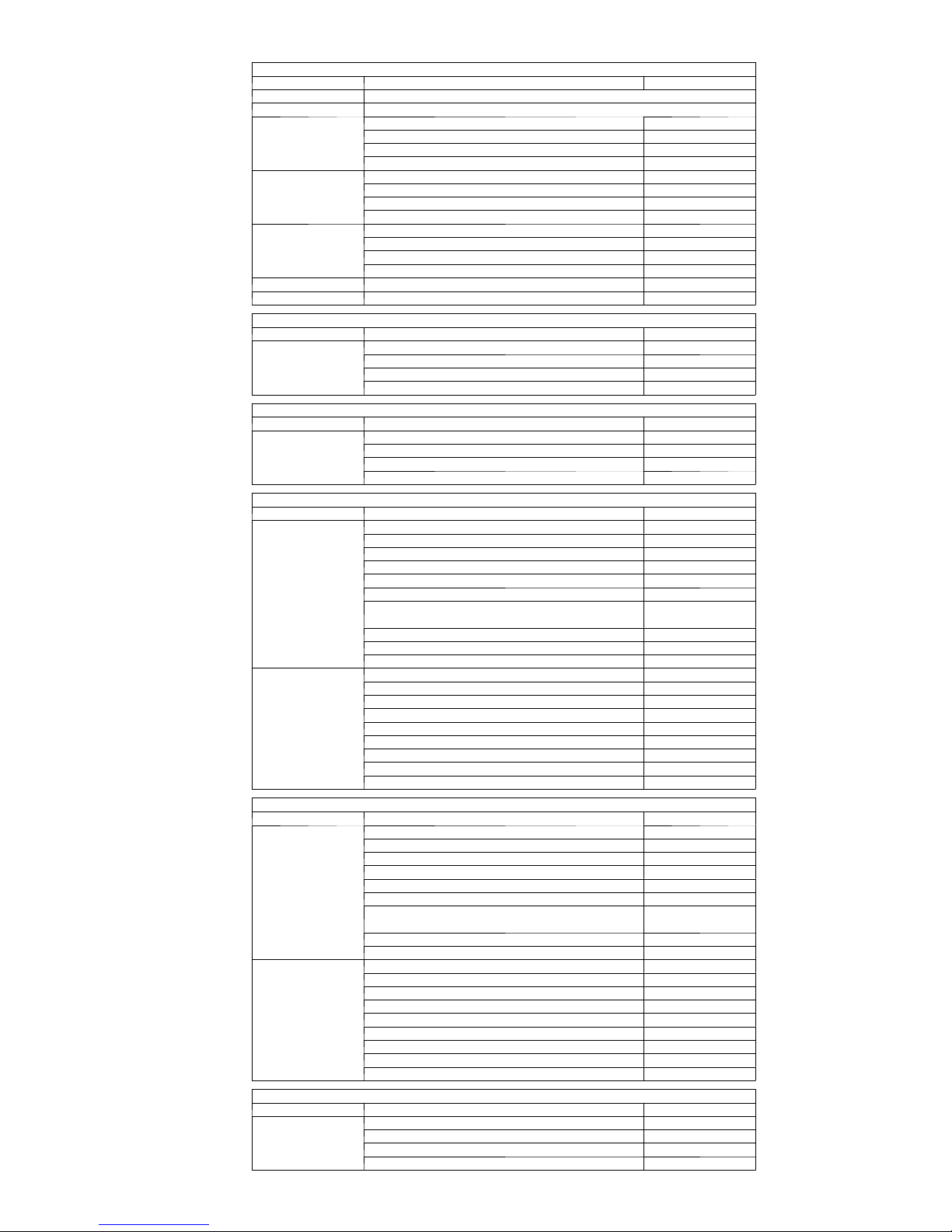

PARTS LIST

Size Name Qty

18 No parts included

24 No parts included

30

36

42

48 bellows φ16 1

56 bellows φ16 1

Size Name Qty

9,12,18

Size Name Qty

9,12,18,24

Size Name Qty

12,18

24

Size Name Qty

9,12,18

21,24

Size Name Qty

9,12,18

Outdoor Units

Conversion Joint 3/8 to 5/8 2

Conversion Joint 3/8 to 1/2 4

Conversion Joint 1/4 to 3/8 2

Screw M4X12 1

Conversion Joint 3/8 to 5/8 2

Conversion Joint 3/8 to 1/2 4

Conversion Joint 1/4 to 3/8 2

Screw M4X12 1

Conversion Joint 3/8 to 5/8 2

Conversion Joint 3/8 to 1/2 4

Conversion Joint 1/4 to 3/8 2

Screw M4X12 1

Indoor High Wall DLFAHH

Mounting Plate 1

Remote Control 1

Remote Control Holder 1

Battery (1.5V) 2

Indoor High Wall DLFBHB

Mounting Plate 1

Remote Control 1

Remote Control Holder 1

Battery (1.5V) 2

Indoor Cassette

Remote control 1

Battery (1.5V) 2

GasketM6Xφ18X1.4 4

GasketM10Xφ30X2.5 10

Screw ST4.8X13 HC 4

Screw M6X25 4

Nut of Connector Pipe(B)

Package

Pipe Connection Nut ("I" shape) 1

Connection wire of wired control 1

Wired controller 1

bellows φ16 1

Connection wire of wired control 1

Remote control 1

Battery (1.5V) 2

Gasket location board 1

Screw ST4.8X13 HC 4

Gasket 10 10

Nut of Connector Pipe(B) 1

Wired controller 1

Indoor Ducted

Remote control 1

Battery (1.5V) 2

Screw M10X8 4

Screw M10 4

Gasket 10GB93 4

Pipe Connection Nut ("I" shape) 1

Nut of Connector Pipe(B)

Package

Wired control 1

Connection wire of wired control 1

Remote control 1

Battery (1.5V) 2

Screw M10X8 4

Screw M10 4

Gasket 10GB93 4

Nut of Connector Pipe(B) 1

Wired controller 1

Connection wire of wired control 1

bellows φ16 1

Indoor Floor Console

Installation Panel 1

Remote Control 1

Remote Control Holder 1

Battery (1.5V) 2

1

1

6

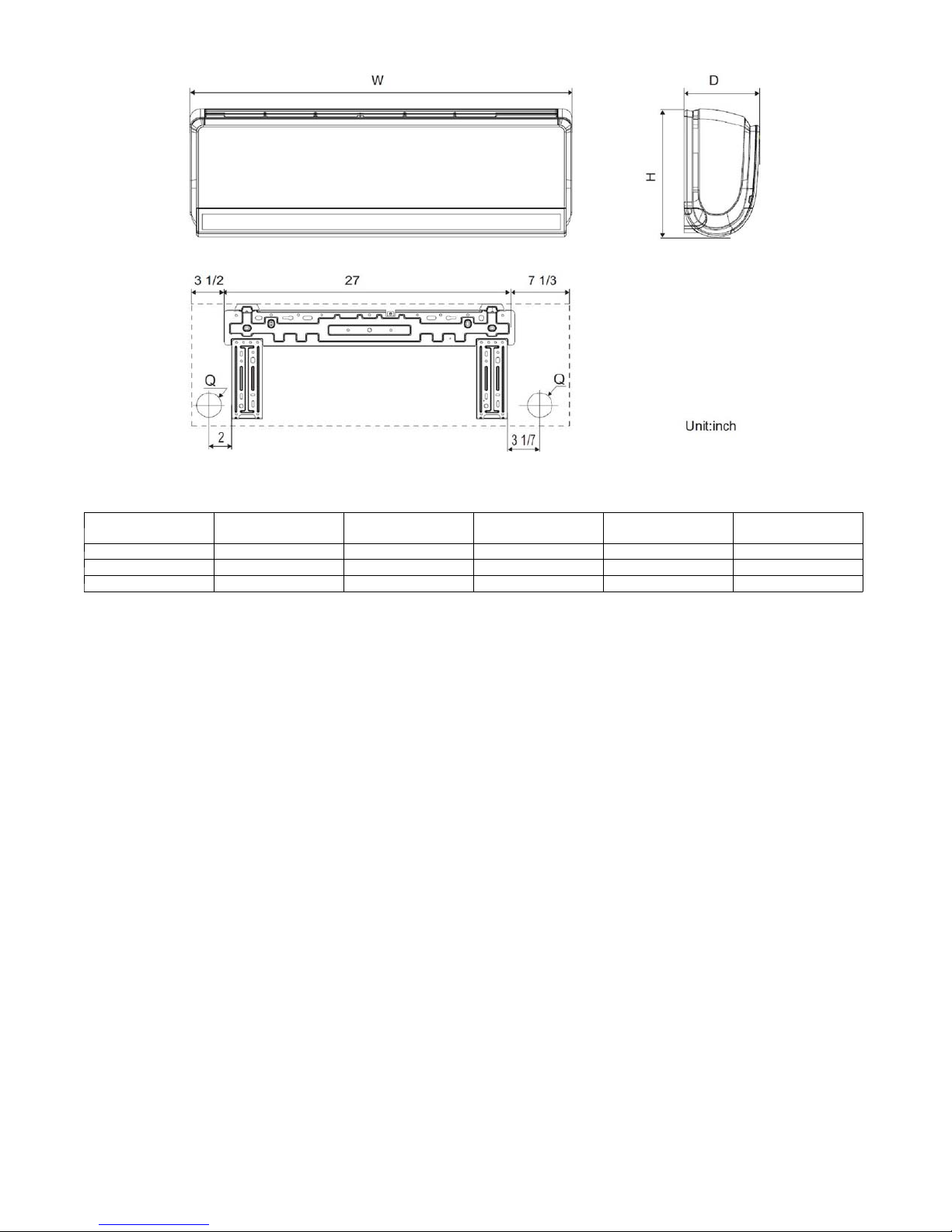

DIMENSIONS - INDOOR

Fig. 2 - High Wall Dimensions

Table 14—High Wall DLFAHH Dimensions

Unit Size W In. (mm) D In. (mm) H In. (mm) Q In. (mm)

9k 37.8 (960)g 8.07 (205) 12.6 (320) 2.16 (55) 33.07 (15)

12k 37.8 (960) 8.07 (205) 12.6 (320) 2.16 (55) 33.07 (15)

18k 37.8 (960) 8.07 (205) 12.6 (320) 2.75 (70) 33.07 (15)

Operating Weight

Lbs. (kg)

7

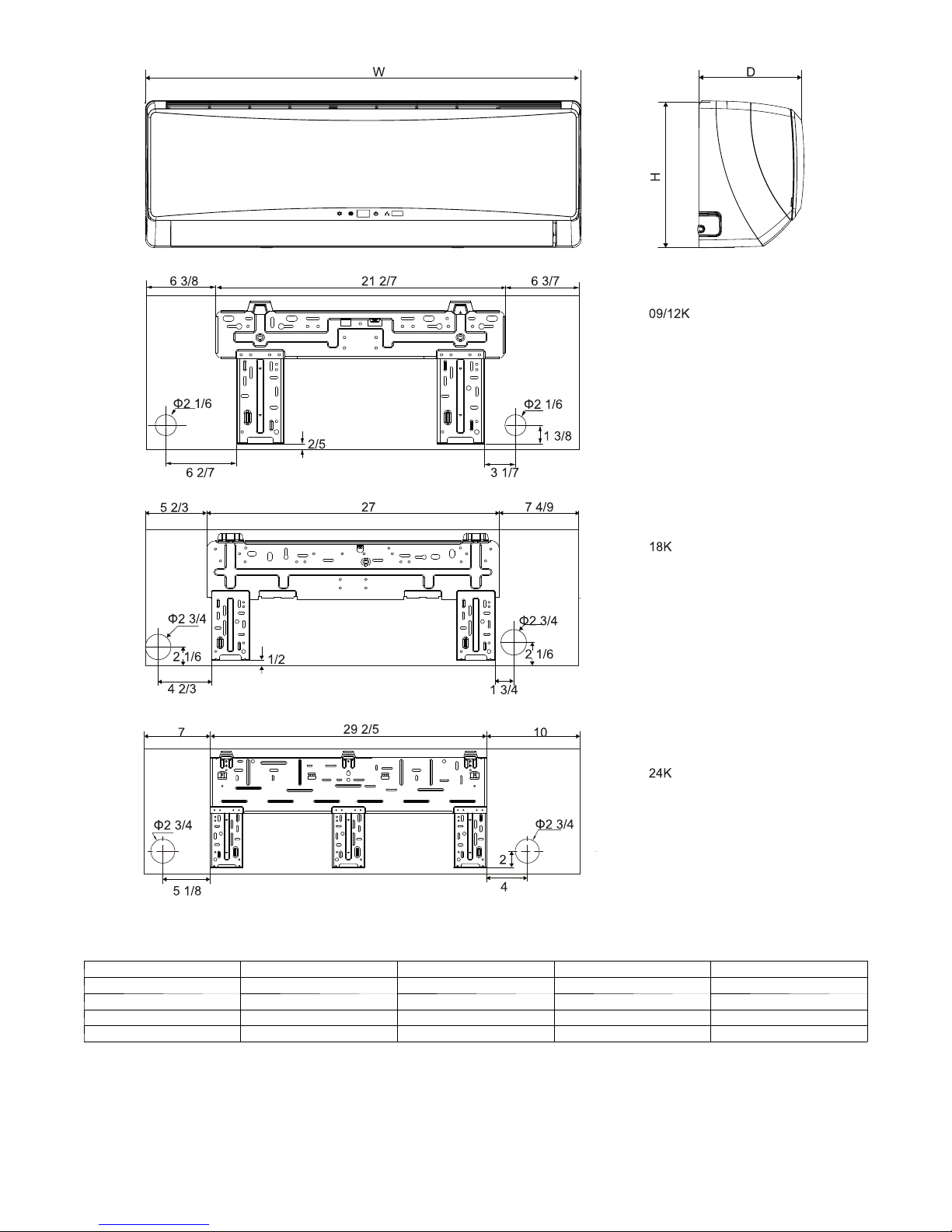

DIMENSIONS - INDOOR (CONTINUED)

Unit Size W In. (mm) D In (mm) H In. (mm) Operating Weight

9k 34.09 8.23 11.5 24.3

12k 34.09 8.23 11.5 24.3

18k 40.079 9.055 12.6 30.9

24 46.378 10.394 12.8 38.6

Fig. 3 - Wall Dimensions

Table 15—High Wall DLFBHB

8

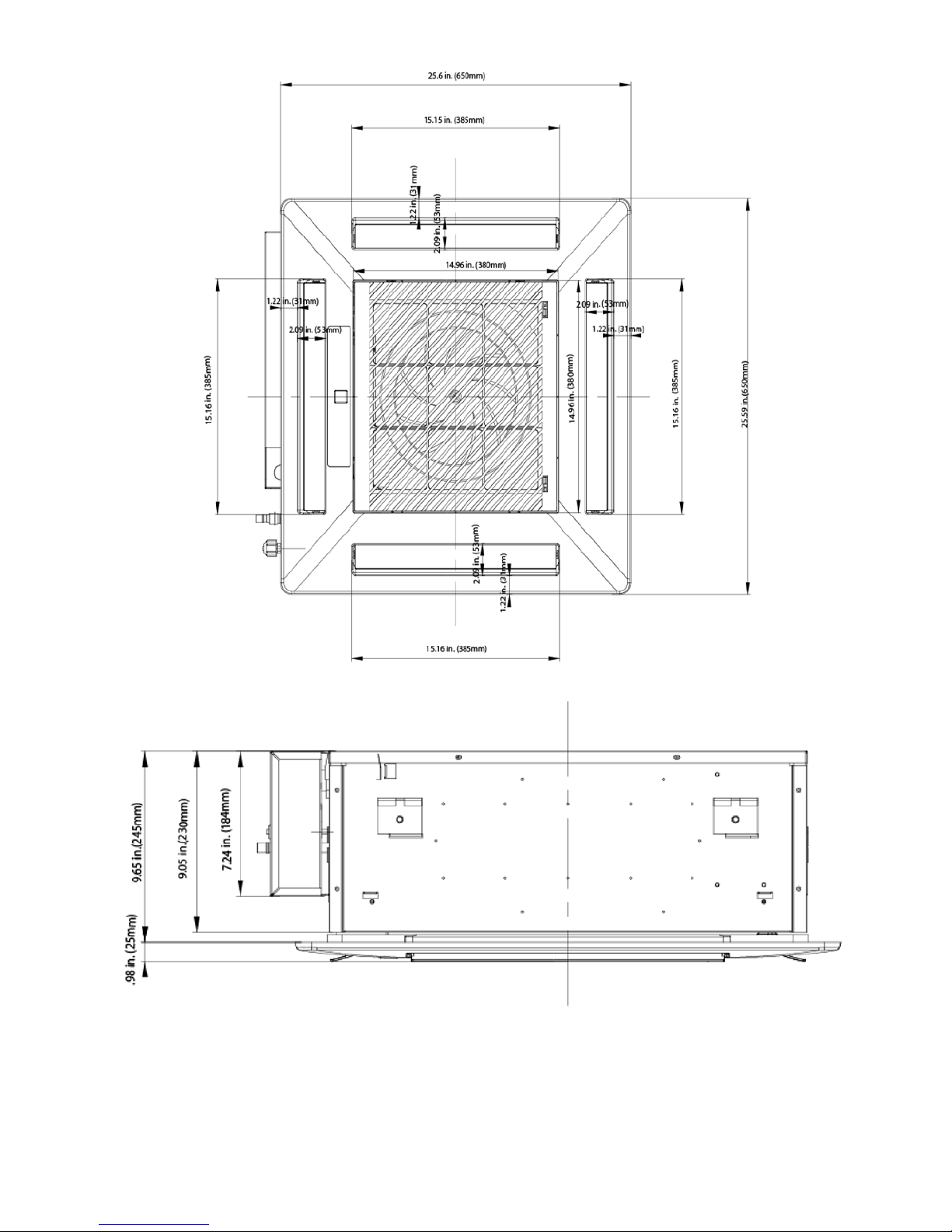

DIMENSIONS - INDOOR (CONTINUED)

Fig. 4 - Cassette Grill Dimensions

Fig. 5 - Cassette Side View Dimensions

9

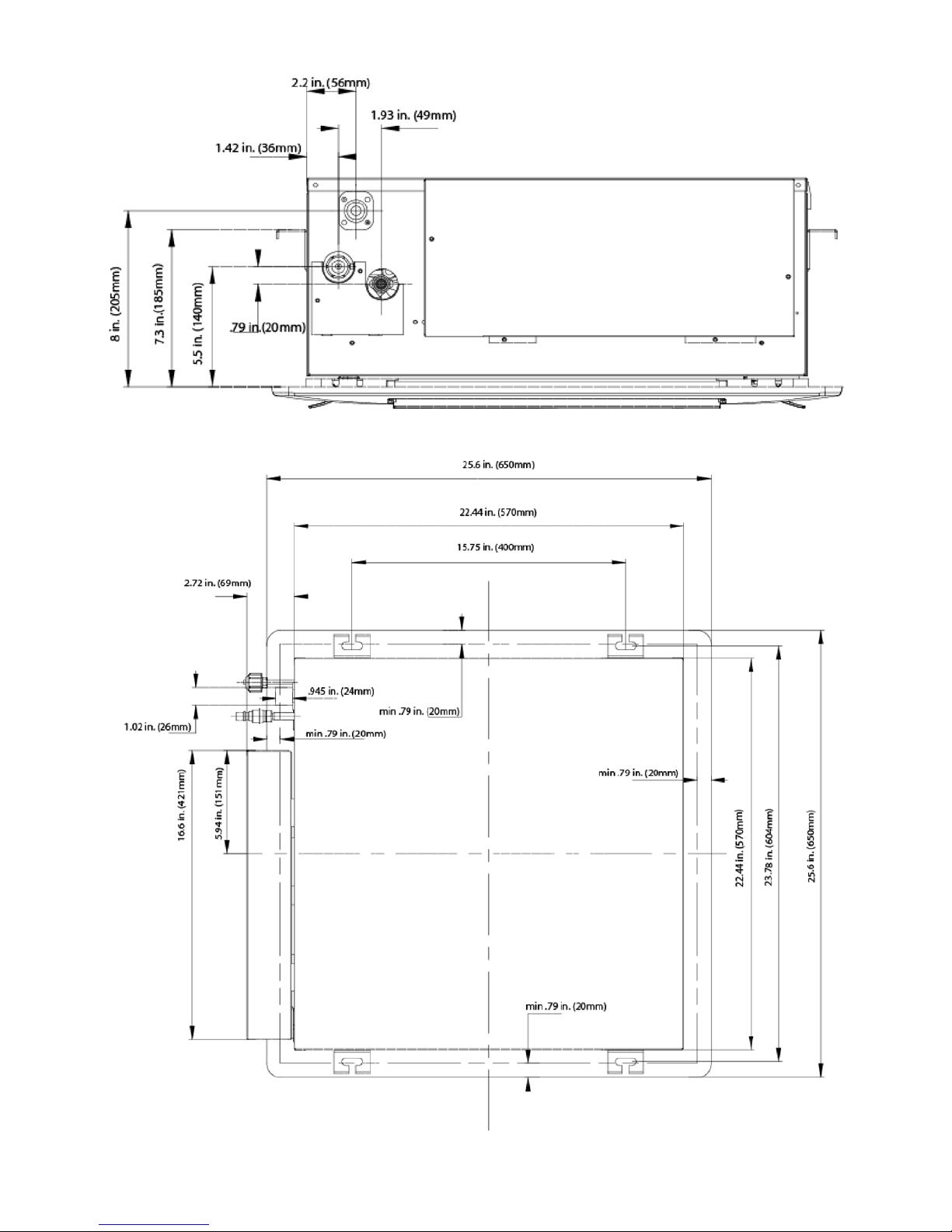

DIMENSIONS - INDOOR (CONTINUED)

Fig. 6 - Cassette Connection Side View Dimensions

Fig. 7 - Cassette Top View Dimensions

10

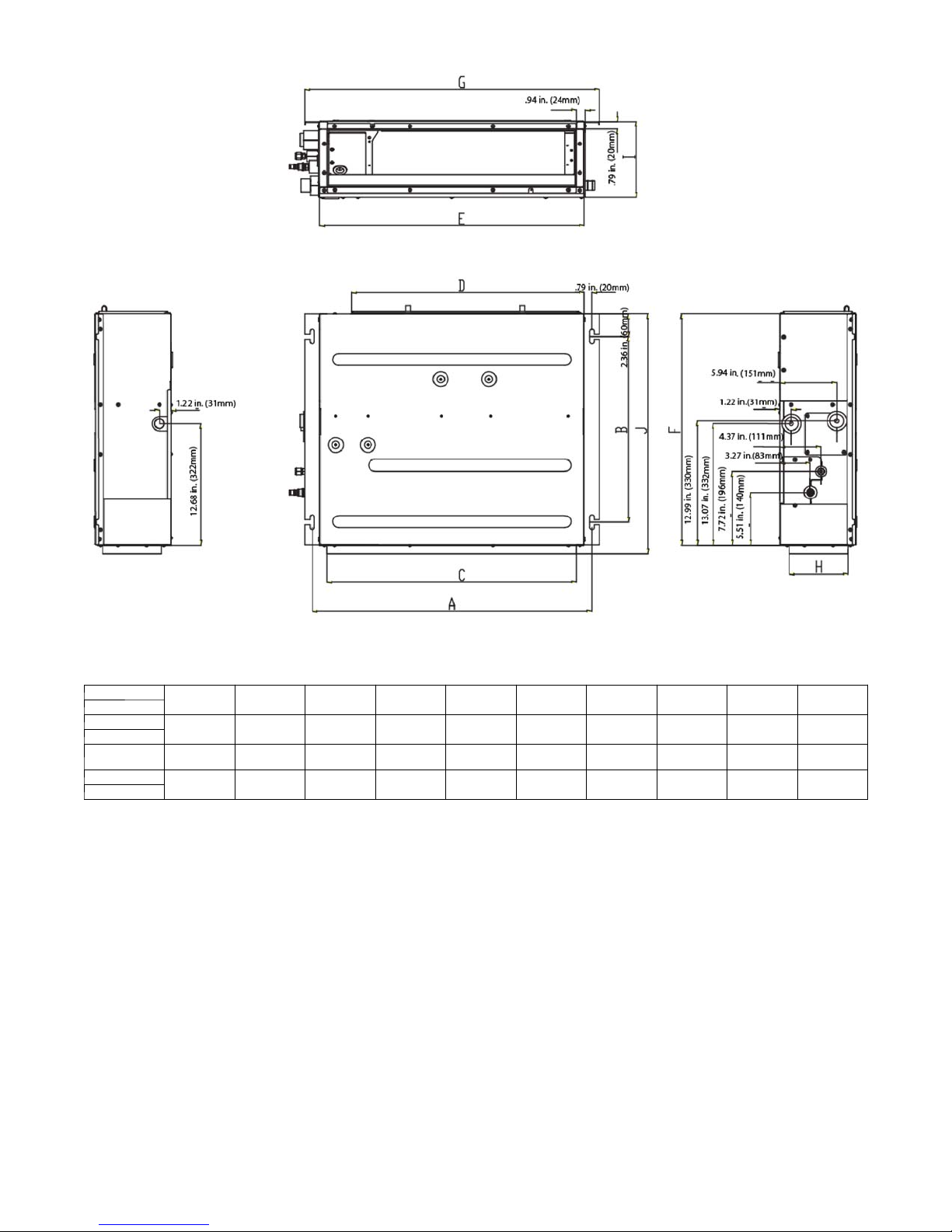

DIMENSIONS - INDOOR (CONTINUED)

Item

Size

09

12

18

21

24

Fig. 8 - Ducted Dimensions

Table 16—Outline Dimensions

A B C D E F G H I J

29 1/5 in

(742 mm)

37 in

(942 mm)

45 in

(1142 mm)

19 1/3 in

(491 mm)

19 1/3 in

(491 mm)

19 1/3 in

(491 mm)

26 in

(662 mm)

34 in

(862 mm)

41 4/5 in

(1062 mm)

24 2/5 in

(620 mm)

32 2/7 in

(820 mm)

40 1/6 in

(1020 mm)

27 5/9 in

(700 mm)

35 3/7 in

(900 mm)

43 1/3 in

(1100 mm)

24 1/5 in

(615 mm)

24 1/5 in

(615 mm)

24 1/5 in

(615 mm)

30 4/5 in

(782 mm)

38 2/3 in

(982 mm)

46 1/2 in

(1182 mm)

6 1/7 in

(156 mm)

6 1/7 in

(156 mm)

6 1/7 in

(156 mm)

7 7/8 in

(200 mm)

7 7/8 in

(200 mm)

7 7/8 in

(200 mm)

25 in

(635 mm)

25 in

(635 mm)

25 in

(635 mm)

11

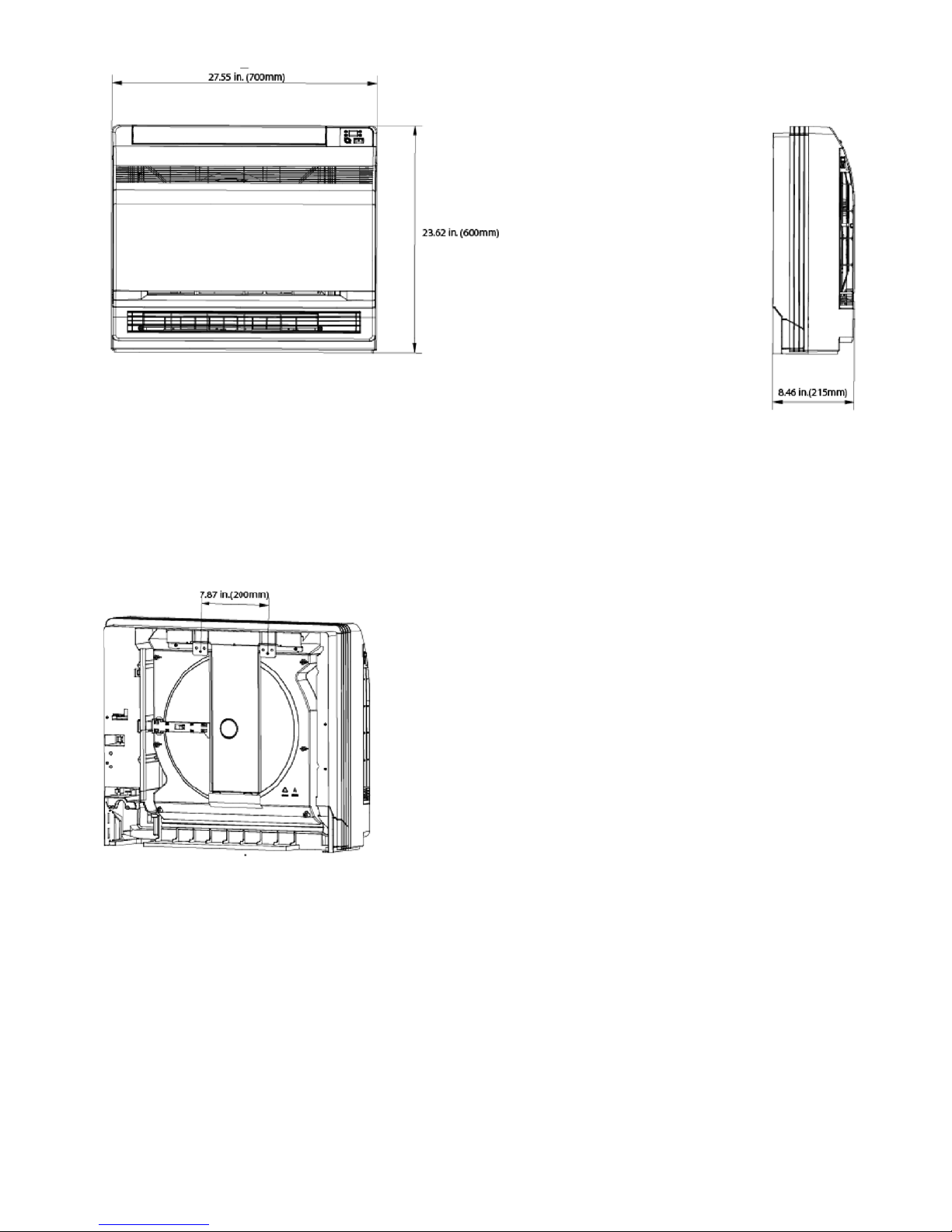

DIMENSIONS - INDOOR (CONTINUED)

Fig. 9 - Floor Console Dimensions

12

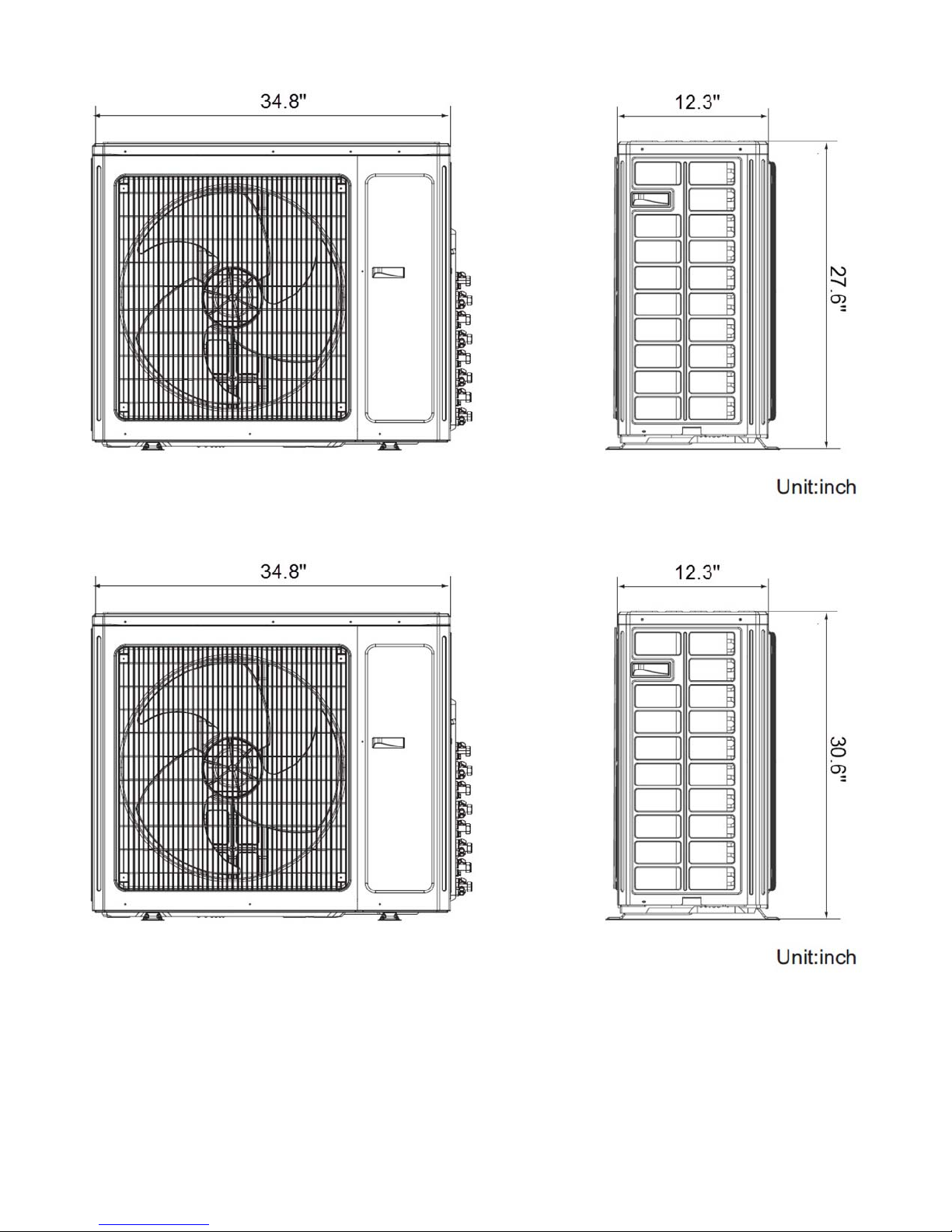

DIMENSIONS - OUTDOOR

Fig. 10 - Outdoor Dimensions Size 18

Fig. 11 - Outdoor Dimensions Size 24

13

Loading...

Loading...