International comfort products DLCBHR, DLFAHH, DLFBHB, DLFBHC, DLFBHF Installation Instructions Manual

...

DLCBHR / DLFAHH / DLFBHB / DLFBHC / DLFBHD / DLFBHF

Multi- Zone Ductless Split System

Size 18K, 24K, 30K, 36K, 42K, 48K and 56K

Installation Instructions

NOTE: Read the entire instruction manual before starting the installation.

TABLE OF CONTENTS

SAFETY CONSIDERATIONS 2.........................

PAGE

GENERAL 2.........................................

SYSTEM REQUIREMENTS 3- 4.........................

ELECTRICAL DATA 4................................

PARTS LIST 6........................................

DIMENSIONS 7- 14...................................

CLEARANCES 15- 17.................................

DIMENSIONS - BRANCH BOXES 18- 19.................

INSTALLATION GUIDE 20.............................

HIGH- WALL INDOOR UNIT INSTALLATION 20..........

DUCTED INDOOR UNITS INSTALLATION 21............

FLOOR CONSOLE INDOOR UNITS INSTALLATION 24....

INSTALLING THE INDOOR UNIT 26....................

CASSETTE TYPE INDOOR UNIT INSTALLATION 28......

OUTDOOR UNIT INSTALLATION 31....................

SYSTEM VACUUM AND CHARGE 35...................

START- UP 37........................................

TROUBLESHOOTING 38- 41...........................

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air- conditioning equipment

can be hazardous due to system pressures, electrical components,

and equipment location (roofs, elevated structures, etc.).

Only trained, qualified installers and service mechanics should

install, start-up, and service this equipment.

Untrained personnel can perform basic maintenance functions such

as cleaning coils. All other operations should be performed by

trained service personnel.

When working on the equipment, observe precautions in the

literature and on tags, stickers, and labels attached to the

equipment.

Follow all safety codes. Wear safety glasses and work gloves. Keep

quenching cloth and fire extinguisher nearby when brazing. Use

care in handling, rigging, and setting bulky equipment.

Read these instructions thoroughly and follow all warnings or

cautions included in literature and attached to the unit. Consult

local building codes and current editions of the National Electrical

Code ( NEC ) NFPA 70. In Canada, refer to current editions of the

Canadian electrical code CSA 22.1.

!

Recognize safety information. This is the safety- alert symbol

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury. Understand

these signal words: DANGER, WARNING, and CAUTION.

These words are used with the safety- alert symbol. DANGER

identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards which could

result in personal injury or death. CAUTION is used to identify

unsafe practices which may result in minor personal injury or

product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability, or

operation.

!

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF

position. There may be more than 1 disconnect switch.

Lock out and tag switch with a suitable warning label.

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Do not bury more than 36 in. (914 mm) of refrigerant pipe

in the ground. If any section of pipe is buried, there must be

.

a 6 in. (152 mm) vertical rise to the valve connections on

the outdoor units. If more than the recommended length is

buried, refrigerant may migrate to the cooler buried section

during extended periods of system shutdown. This causes

refrigerant slugging and could possibly damage the

compressor at start- up.

WARNING

CAUTION

GENERAL

These instructions cover the inst allati on, start-up and servic i ng of the

multi-zone outdoor unit connec t ed to up to nine indoor fan coil units .

For approved combinations, please refer to the Product Data.

2

SYSTEM REQUIREMENTS

Allow sufficient space for airflow and servicing unit. See Fig. 14 through 19 for minimum required clearances.

Piping

IMPORTANT: Both refrigerant lines must be insulated separately.

Minimum refrigerant line length between the indoor and outdoor units is 10 ft. (3 m). The following maximum lengths are allowed:

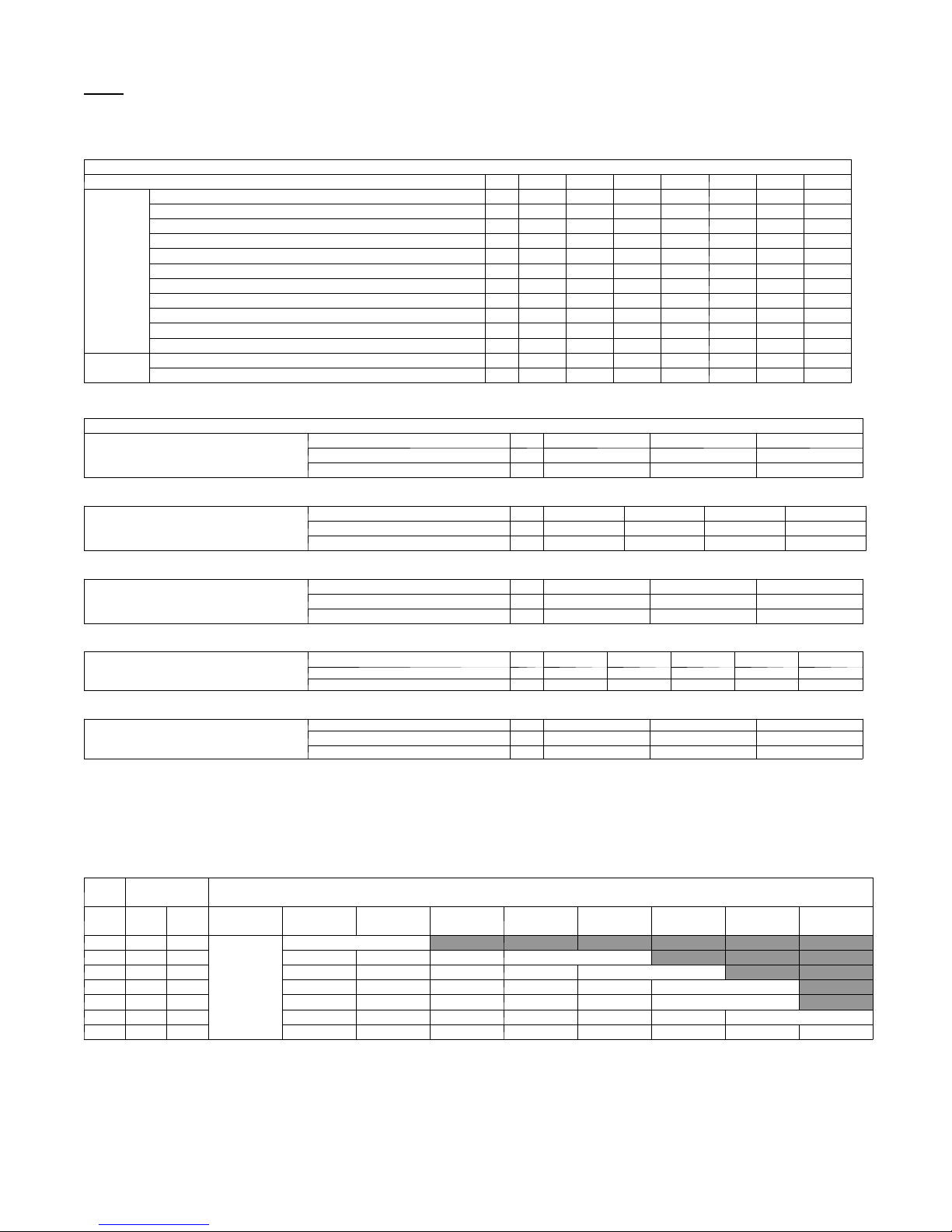

Table 1—Maximum Piping Lengths

System Size 18 24 30 36 42 48 56

Piping

Refrigerant

Min. Piping Length ft 10 10 10 10 10 10 10

Standard Piping Length ft 32 98 131.2 131.2 131.2 98.42 98.42

Max. outdoor-indoor height difference ft 33 33 49.2 49.2 49.2 98.42 98.42

Max. height distance between indoor and indoor ft 33 33 24.6 24.6 24.6 49.21 49.21

Max. height distance between indoor and outdoor and indoor ft 32 32 49.2 49.2 49.2 98.42 98.42

Max. height distance between indoor and outdoor and outdoor up ft 33 33 49.2 49.2 49.2 98.42 98.42

Max. equivalent piping outdoor to last indoor ft 33 65 82 82 82 229 229

Max. Piping Length with no additional refrigerant charge ft 32 98 131.2 131.2 131.2 98.42 98.42

Max. Piping Length ft 65 196 229.7 246 246 442.9 475.7

Gas Pipe (size - connection type) in 3/8 3/8 3/8 3/8 3/8 5/8 5/8

Liquid Pipe (size - connection type) in 1/4 1/4 1/4 1/4 1/4 3/8 3/8

Refrigerant Type R-410A R-410A R-410A R-410A R-410A R-410A R-410A

Heat Pump Models Charge Amount Lbs 3.53 4.85 6.17 8.05 8.05 10.91 10.91

NOTE: Tables 2 through 6 show the piping size specifications.

Indoor Unit Piping Connection Sizes

Indoor High Wall

(DLFAHH)

Indoor High Wall

(DLFBHB)

Indoor Cassette

Indoor Ducted

Size 9 12 18

Pipe Connection Size - Liquid In. 1/4" 1/4" 1/4"

Pipe Connection Size - Suction In. 1/2" 1/2" 5/8"

Size 9 12 18 24

Pipe Connection Size - Liquid In. 1/4" 1/4" 1/4" 1/4"

Pipe Connection Size - Suction In. 1/2" 1/2" 5/8" 5/8"

Size 12 18 24

Pipe Connection Size - Liquid In. 1/4" 1/4" 3/8"

Pipe Connection Size - Suction In. 3/8" 1/2" 5/8"

Size 9 12 18 21 24

Pipe Connection Size - Liquid In. 1/4" 1/4" 1/4" 3/8" 3/8"

Pipe Connection Size - Suction In. 3/8" 3/8" 1/2" 5/8" 5/8"

Table 6—Indoor Floor Console

Size 9 12 18

Indoor Floor Console

Pipe Connection Size - Liquid In. 1/4" 1/4" 1/4"

Pipe Connection Size - Suction In. 3/8" 3/8" 1/2"

Refrigerant Piping:

Line sets to be sized based on the connection size of the indoor unit. Each pipe to be insulated individually.

Conversion Joints:

The outdoor unit may include a package of conversion joints to facilitate installation of various sizes of fan coils. These joints are to be

connected to the outdoor unit as needed to match the line set size.

Table 7—Additional Refrigerant Charge

Total Line

Unit

Size

Length ft

Min Max

18 10 66

24 10 196 None None 0.20 / 0.20 0.20 / 0.20

30 10 230 None None None 0.24 / 0.58 0.24 / 0.58

36 10 246 None None None 0.24 / 0.58 0.24 / 0.58 0.24 / 0.58

42 10 246 None None None 0.24 / 0.58 0.24 / 0.58 0.24 / 0.58

48 10 443 None None 0.24 / 0.58 0.24 / 0.58 0.24 / 0.58 0.24 / 0.58 0.24 / 0.58

56 10 476 None None 0.24 / 0.58 0.24 / 0.58 0.24 / 0.58 0.24 / 0.58 0.24 / 0.58 0.24 / 0.58

10 - 32

(3 - 10)

None

>32 - 66

(10 - 20)

Additional Charge, 1/4” Liquid Line / 3/8” Liquid Line, oz/ft. ft (m)

>66 - 98

(20 - 30)

0.20 / 0.20

Outdoor Unit

Table 2—Indoor High Wall

Table 3—Indoor High Wall

Table 4—Indoor Cassette

Table 5—Indoor Ducted

>98 - 131.2

(30 - 40)

>131.2 - 196

(40 - 60)

>196 - 230

(60 - 70)

>230 - 246

(70 - 75)

>246 - 443

(75 - 135)

>443 - 476

(135 - 145)

Additional Refrigerant Calculation Sizes 30K, 36K and 42K:

Sum Total Liquid Pipe 1/4” (ft) x 0.24 + Sum Total Pipe 3/8” (ft) x 0.58 – 31 oz

Additional Refrigerant Calculation Sizes 48K and 56K:

Sum Total Liquid Pipe 1/4” (ft) x 0.24 + Sum Total Pipe 3/8” (ft) x 0.58 – 51.7 oz

NOTE: If the calculation results in a negative number no additional refrigerant is required.

NOTES:

EXV = Electronic Expansion Device

Electronic expansion valves in the outdoor unit are used as metering devices.

3

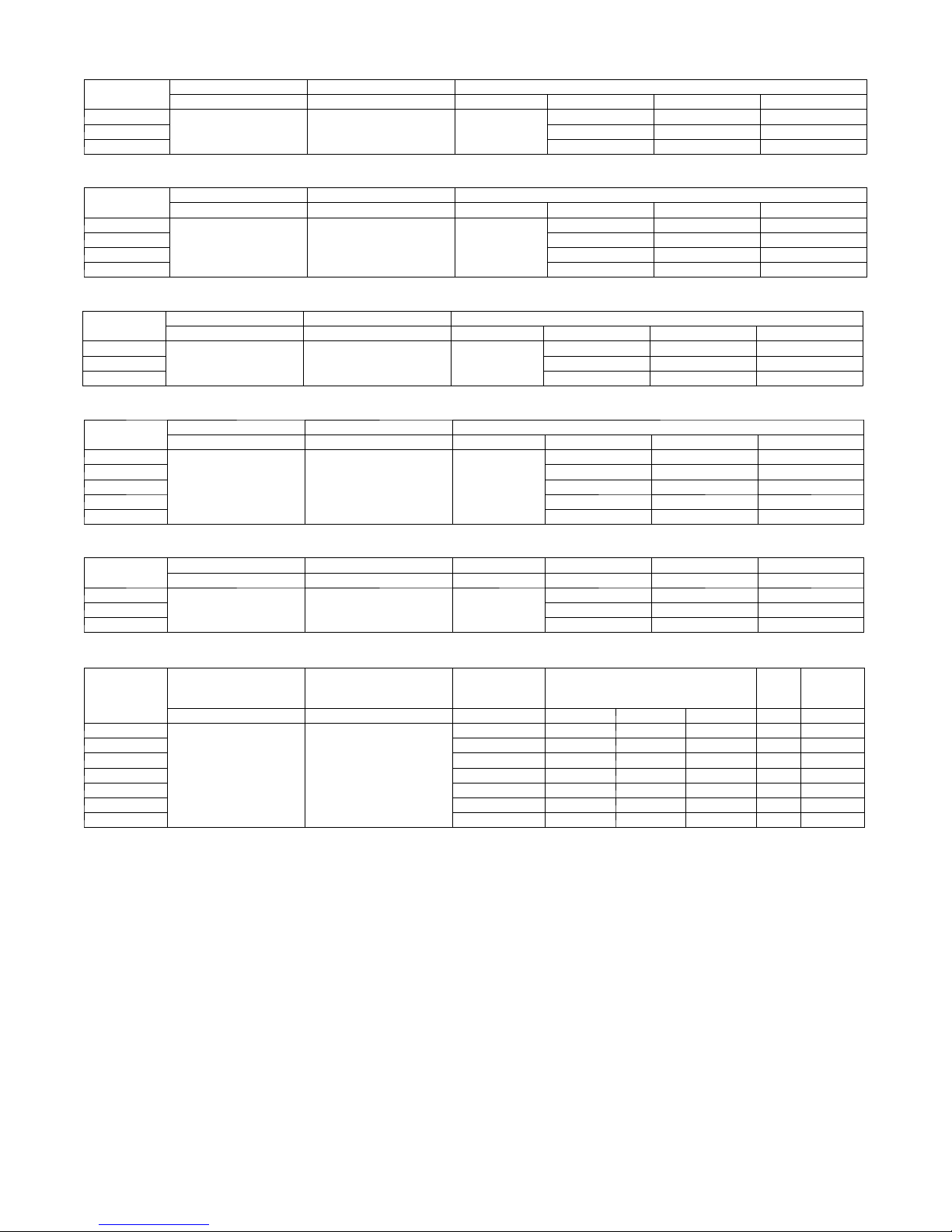

ELECTRICAL DATA

Table 8—High Wall DLFAHH

UNIT SIZE

9

12 0.1 0.0268 20

18 0.1 0.0268 20

UNIT SIZE

9

12 0.17 1/72 10

18 0.3 1/29 25

24 0.38 1/10 70

UNIT SIZE

12

18 0.18 1/72 46

24 0.43 1/20 46

UNIT SIZE

9

12 0.31 1/18 80

18 0.41 1/12 100

21 0.5 1/36' 124

24 0.5 1/36' 124

SYSTEM VOLTAGE OPERATINGVOLTAGE INDOORFAN

VOLT / PHASE / HZ MAX / MIN V-PH-HZ FLA HP W

0.1 0.0268 20

208-230/1/60 253 / 187 208-230/1/60

Table 9—High Wall DLFBHB

System Voltage OPERATING VOLTAGE INDOOR FAN

VOLT / PHASE / HZ MAX / MIN V-PH-HZ FLA HP W

0.17 1/72 10

208-230/1/60 253 / 187 208-230/1/60

Table 10—Cassette

System Voltage OPERATING VOLTAGE INDOORFAN

VOLT / PHASE / HZ MAX / MIN V-PH-HZ FLA HP W

0.18 1/72 46

208-230/1/60 253 / 187 208-230/1/60

Table 11—Ducted

System Voltage OPERATING VOLTAGE INDOORFAN

VOLT / PHASE / HZ MAX / MIN V-PH-HZ FLA HP W

0.28 1/24 80

208-230/1/60 253 / 187 208-230/1/60

Table 12—Floor Console

UNIT SIZE

9

12 0.14 1/24 30

18 0.14 1/24 30

System Voltage OPERATING VOLTAGE INDOOR FAN

VOLT / PHASE / HZ MAX / MIN V-PH-HZ FLA HP W

0.14 1/24 30

208-230/1/60 253 / 187 208-230/1/60

Table 13—Multi Zone Outdoor Unit

UNIT SIZE

18

24 11.5 0.59 1/8 90 21 35

30 13.9 0.68 1/6 150 19 30

36 15.6 0.82 2/9 240 21 35

42 17.8 0.82 2/9 240 24 40

48 23 1 1/6 150 30 50

56 23 1 1/6 150 30 50

*Permissible limits of the voltage range at which the unit will operate satisfactorily.

LEGEND

FLA - Full Load Amps

LRA - Locked Rotor Amps

MCA - Minimum Circuit Amps

RLA - Rated Load Amps

System Voltage OPERATING VOLTAGE COMPRESSOR OUTDOOR FAN MCA

VOLT / PHASE / HZ MAX / MIN RLA FLA HP W

7.2 0.62 1/12 60 15 25

208-230/1/60 253 / 187

MAX

FUSE/CB

AMP

4

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

S Wires should be sized based on NEC and local codes.

S Use copper conductors only with a minimum 300 volt .

rating and 2/64 inch thick insulation.

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage

or improper operation.

S Be sure to comply with local codes while running wire from

indoor unit to outdoor unit.

S Every wire must be connected firmly. Loose wiring may

cause terminal to overheat or result in unit malfunction. A

fire hazard may also exist. Therefore, be sure all wiring is

tightly connected.

S No wire should be allowed to touch refrigerant tubing,

compressor or any moving parts.

S Disconnecting means must be provided and shall be located

within sight and readily accessible from the air conditioner.

S Connecting cable with conduit shall be routed through hole

in the conduit panel.

All wires must be sized per NEC (National Electrical Code) or

CEC (Canadian Electrical Code) and local codes. Use Electrical

Data table MCA (minimum circuit amps) and MOCP (maximum

over current protection) to correctly size the wires and the

disconnect fuse or breakers respectively.

Per caution note, only copper conductors with a minimum 300

volt rating and 2/64- inch thick insulation must be used. The u se

of BX cable is not recommended.

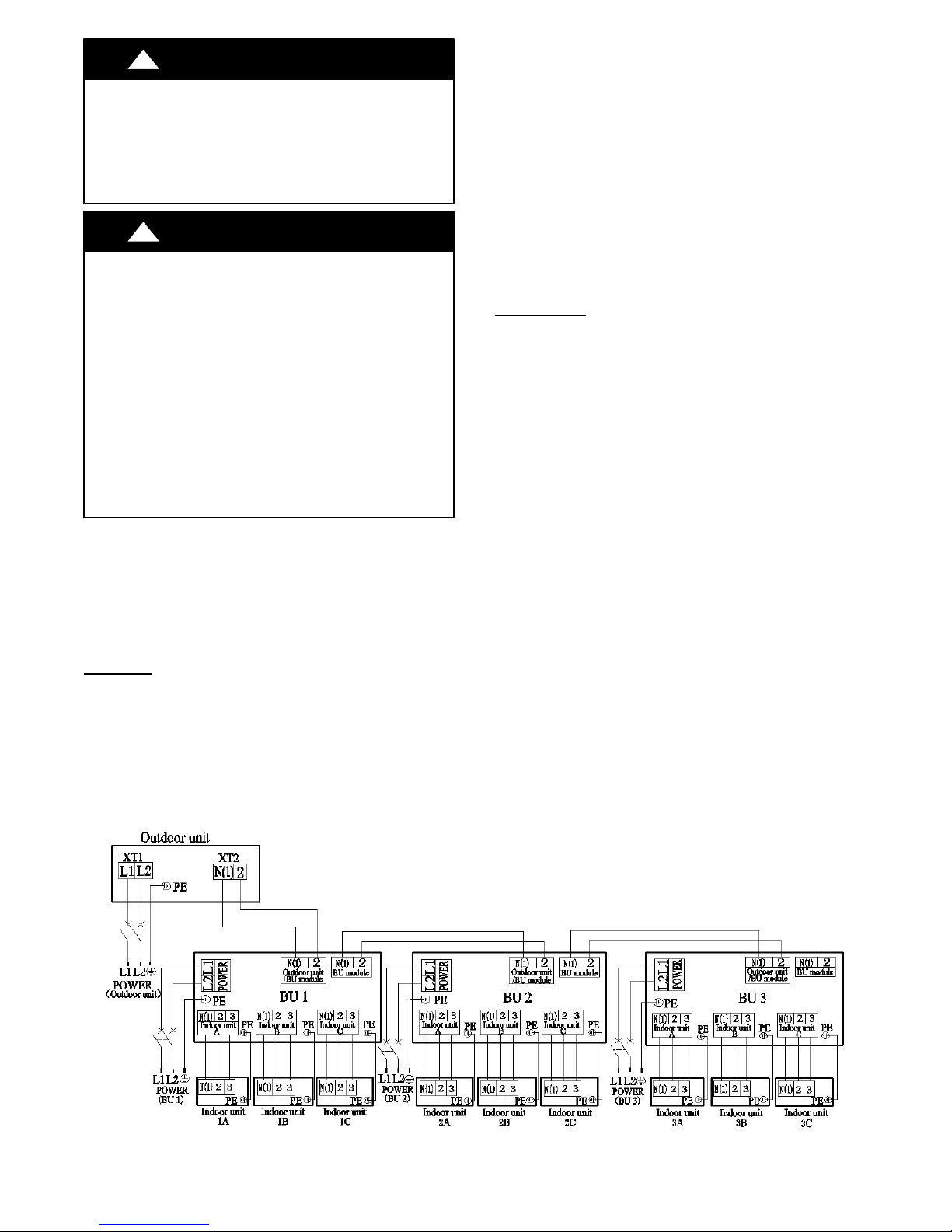

18- 42

Sizes

Recomme nde d Connection Method for Power and

Communication - Wi r ing - Power and Communication Wiri ng:

The main power is supplied to the outdoor unit. The field supplied

14/3 power/communication wiring from the outdoor unit to indoor

unit consists of four (4) wires and provides the power for the

indoor unit. Two wires are high voltage AC power; one is

communication wiring and the other is a ground wire.

CAUTION

CAUTION

Recomme nde d Connection Method for Power and

Communication Wiring (To minimize communication wiring

interference)

Power Wiring:

The main power is supplied to the outdoor unit. The fie l d supplied

power wiring from the outdoor unit to indoor unit consists of three (3)

wires and provides the power for the indoor unit. Two wires are high

voltage AC powe r and one is a ground wi re. To mini mize voltage

drop, the fac tory recommended wir e size is 14/2 stranded with a

ground.

Communication Wiring:

A separate shielded copper conductor only, with a minimum 300

volt rating and 2/64- inch thick insulation, must be used as the

communication wire from the outdoor unit to the indoor unit.

Please use a separate shielded 16GA stranded control wire.

For sizes

Recomme nde d Connection Method for Power and

Communication - Wi r ing - Power and Communication Wiri ng:

Power Wiri ng OUTDOOR UNIT& BRANCH BOXES:

Separate power s upplies ar e required for t he outdoor unit and the

Branch Boxes. The indoor units are powered from the Branch Boxes.

The field supplied 14/3 power wiring from the OUTDOOR UNIT

consists of three (3) wires. Two wires are high voltage AC power, one

is a ground wire.

The field supplied 14/3 power wiring from the BRANCH BOXES

consists of three (3) wires. Two wires are high voltage AC power, one

is a ground wire.

Up to three (3) Branch Boxes can be powered from the same 15 amp

breaker.

Communication Wiring:

A separate shiel ded copper conductor only, with a minimum 300 volt

rating and 2/64- inch thick insulati on, must be used as the

communication wire from the OUTDOOR UNIT to the BRANCH

BOX.

Please use a separate shielded 16GA stranded control wire.

Power and Communication Wiring BRANCH BOXES to

INDOOR UNITS:

The field supplied 14/3 power/communication wiring from the

BRANCH BOX to the INDOOR UNIT consists of f our (4) wires

and provides the power for the indoor unit. Two wires are high

voltage AC power, one is communicat i on wiring “2” and the other is

a ground wire “N(1)”

See diagr am below for detai ls on wiring for size s 48- 56.

48- 56

Fig. 1 - Wiring Connection

5

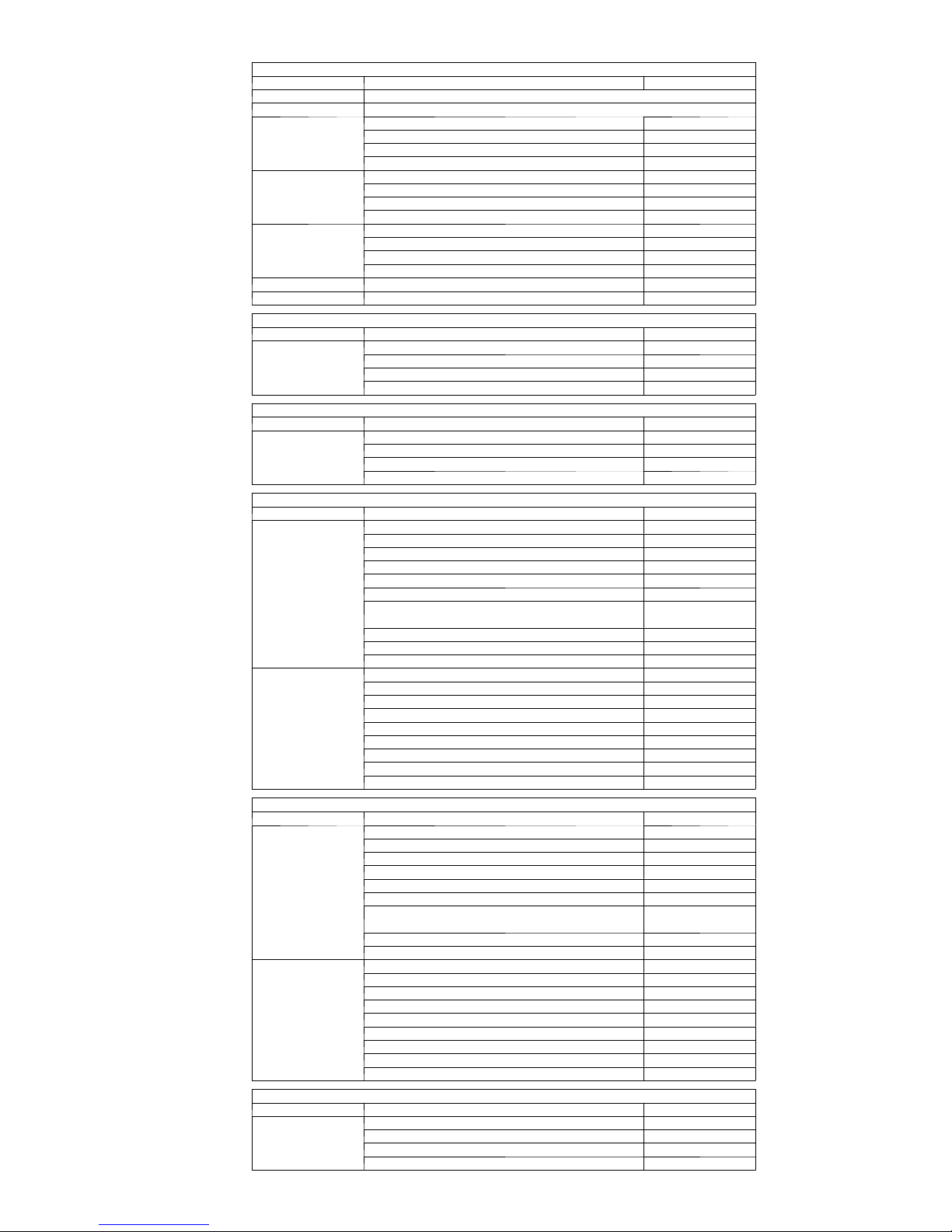

PARTS LIST

Size Name Qty

18 No parts included

24 No parts included

30

36

42

48 bellows φ16 1

56 bellows φ16 1

Size Name Qty

9,12,18

Size Name Qty

9,12,18,24

Size Name Qty

12,18

24

Size Name Qty

9,12,18

21,24

Size Name Qty

9,12,18

Outdoor Units

Conversion Joint 3/8 to 5/8 2

Conversion Joint 3/8 to 1/2 4

Conversion Joint 1/4 to 3/8 2

Screw M4X12 1

Conversion Joint 3/8 to 5/8 2

Conversion Joint 3/8 to 1/2 4

Conversion Joint 1/4 to 3/8 2

Screw M4X12 1

Conversion Joint 3/8 to 5/8 2

Conversion Joint 3/8 to 1/2 4

Conversion Joint 1/4 to 3/8 2

Screw M4X12 1

Indoor High Wall DLFAHH

Mounting Plate 1

Remote Control 1

Remote Control Holder 1

Battery (1.5V) 2

Indoor High Wall DLFBHB

Mounting Plate 1

Remote Control 1

Remote Control Holder 1

Battery (1.5V) 2

Indoor Cassette

Remote control 1

Battery (1.5V) 2

GasketM6Xφ18X1.4 4

GasketM10Xφ30X2.5 10

Screw ST4.8X13 HC 4

Screw M6X25 4

Nut of Connector Pipe(B)

Package

Pipe Connection Nut ("I" shape) 1

Connection wire of wired control 1

Wired controller 1

bellows φ16 1

Connection wire of wired control 1

Remote control 1

Battery (1.5V) 2

Gasket location board 1

Screw ST4.8X13 HC 4

Gasket 10 10

Nut of Connector Pipe(B) 1

Wired controller 1

Indoor Ducted

Remote control 1

Battery (1.5V) 2

Screw M10X8 4

Screw M10 4

Gasket 10GB93 4

Pipe Connection Nut ("I" shape) 1

Nut of Connector Pipe(B)

Package

Wired control 1

Connection wire of wired control 1

Remote control 1

Battery (1.5V) 2

Screw M10X8 4

Screw M10 4

Gasket 10GB93 4

Nut of Connector Pipe(B) 1

Wired controller 1

Connection wire of wired control 1

bellows φ16 1

Indoor Floor Console

Installation Panel 1

Remote Control 1

Remote Control Holder 1

Battery (1.5V) 2

1

1

6

DIMENSIONS - INDOOR

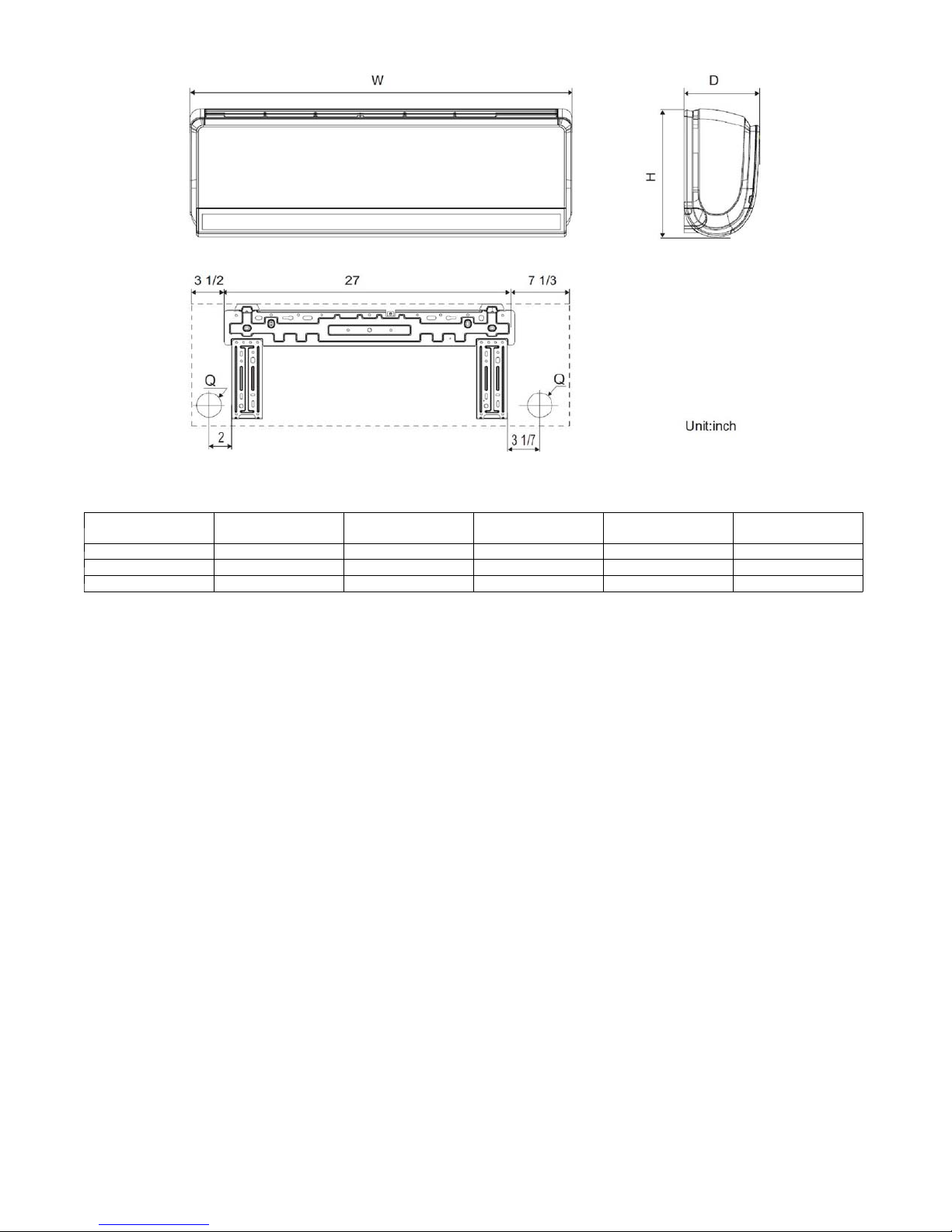

Fig. 2 - High Wall Dimensions

Table 14—High Wall DLFAHH Dimensions

Unit Size W In. (mm) D In. (mm) H In. (mm) Q In. (mm)

9k 37.8 (960)g 8.07 (205) 12.6 (320) 2.16 (55) 33.07 (15)

12k 37.8 (960) 8.07 (205) 12.6 (320) 2.16 (55) 33.07 (15)

18k 37.8 (960) 8.07 (205) 12.6 (320) 2.75 (70) 33.07 (15)

Operating Weight

Lbs. (kg)

7

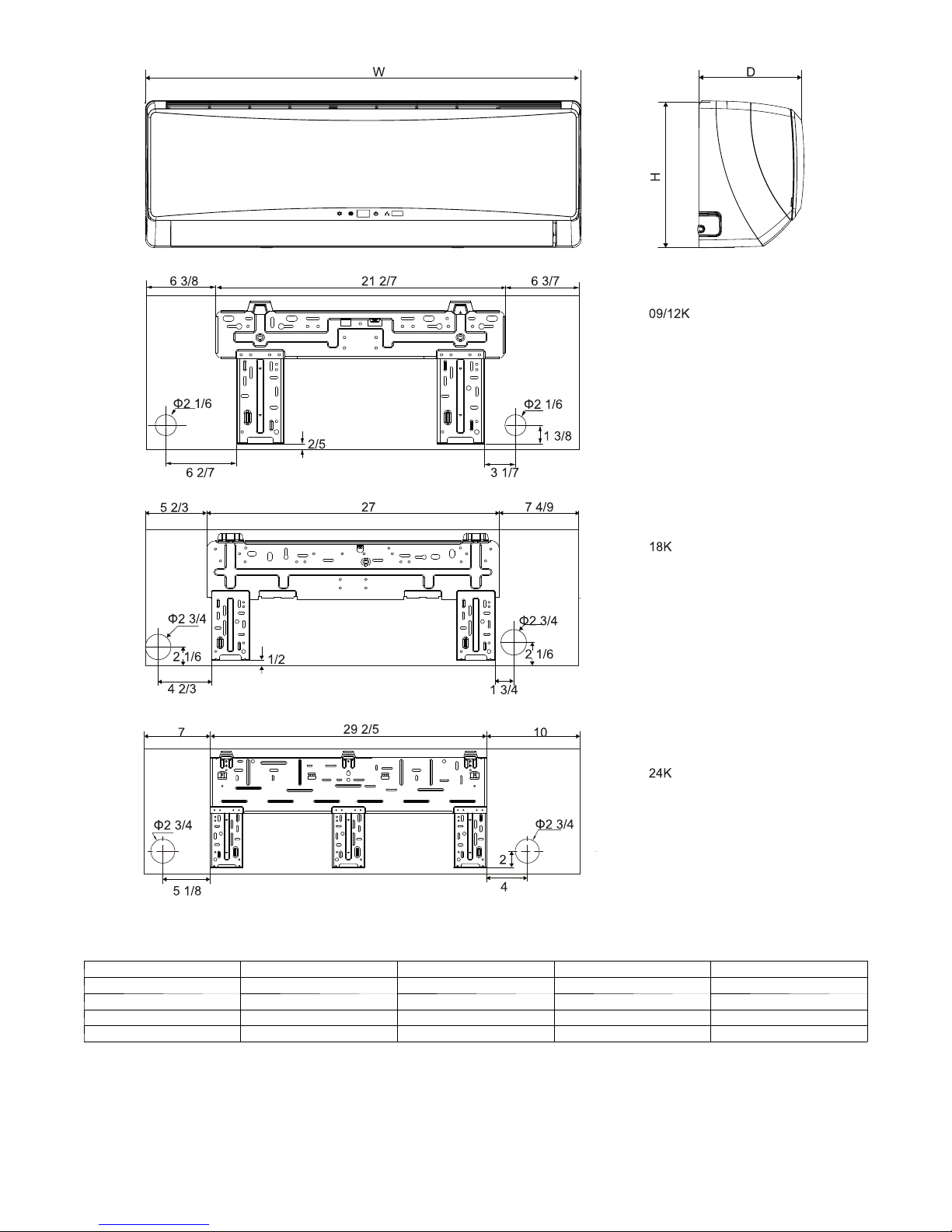

DIMENSIONS - INDOOR (CONTINUED)

Unit Size W In. (mm) D In (mm) H In. (mm) Operating Weight

9k 34.09 8.23 11.5 24.3

12k 34.09 8.23 11.5 24.3

18k 40.079 9.055 12.6 30.9

24 46.378 10.394 12.8 38.6

Fig. 3 - Wall Dimensions

Table 15—High Wall DLFBHB

8

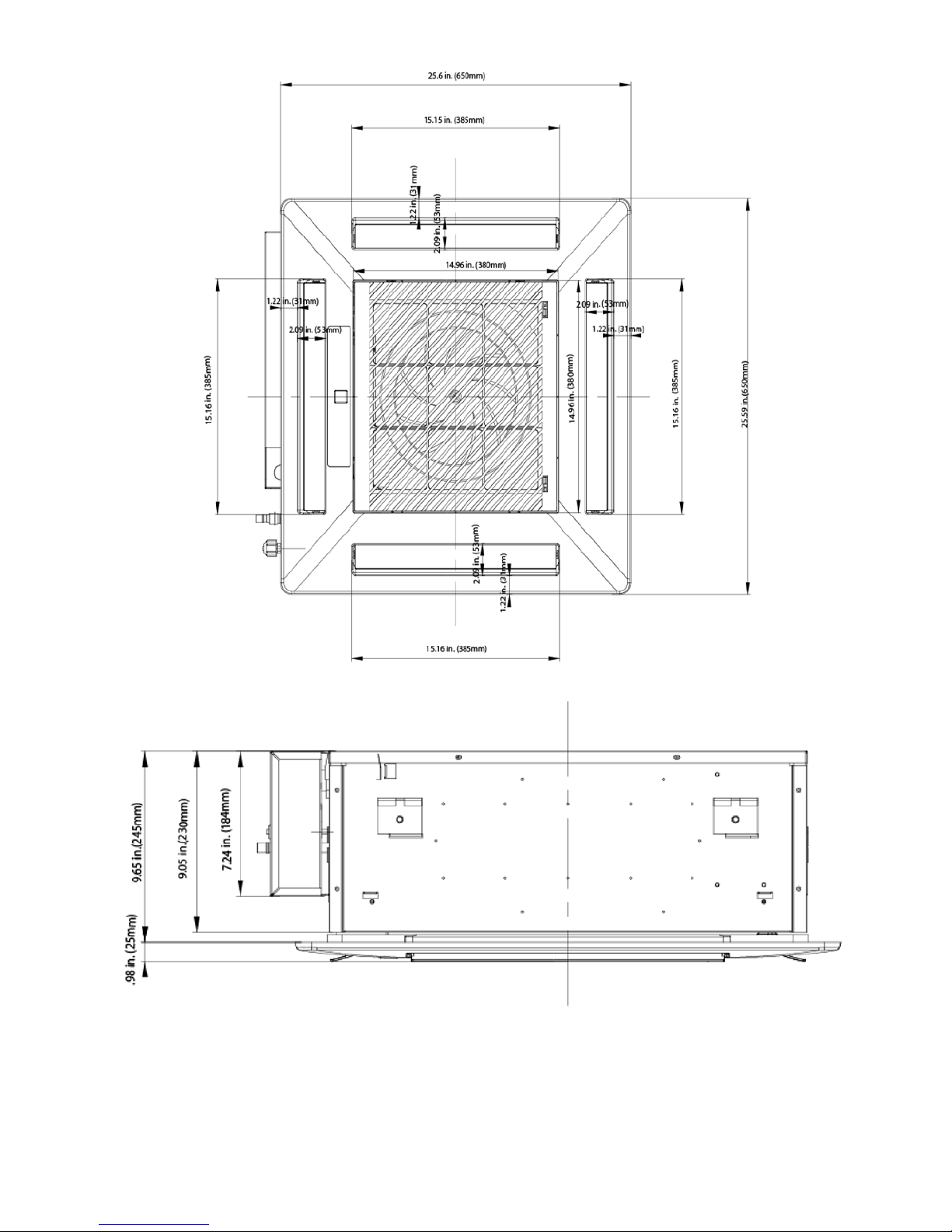

DIMENSIONS - INDOOR (CONTINUED)

Fig. 4 - Cassette Grill Dimensions

Fig. 5 - Cassette Side View Dimensions

9

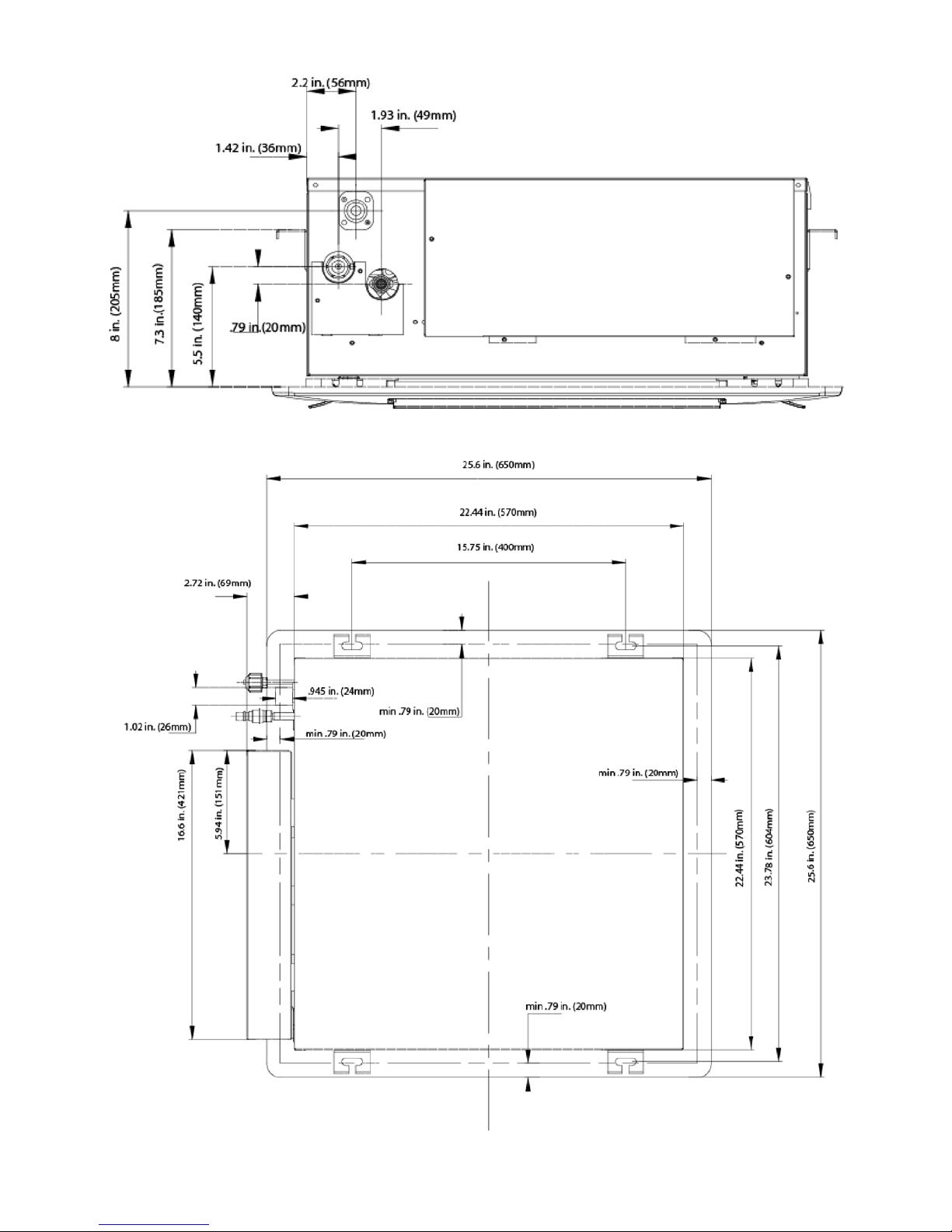

DIMENSIONS - INDOOR (CONTINUED)

Fig. 6 - Cassette Connection Side View Dimensions

Fig. 7 - Cassette Top View Dimensions

10

DIMENSIONS - INDOOR (CONTINUED)

Item

Size

09

12

18

21

24

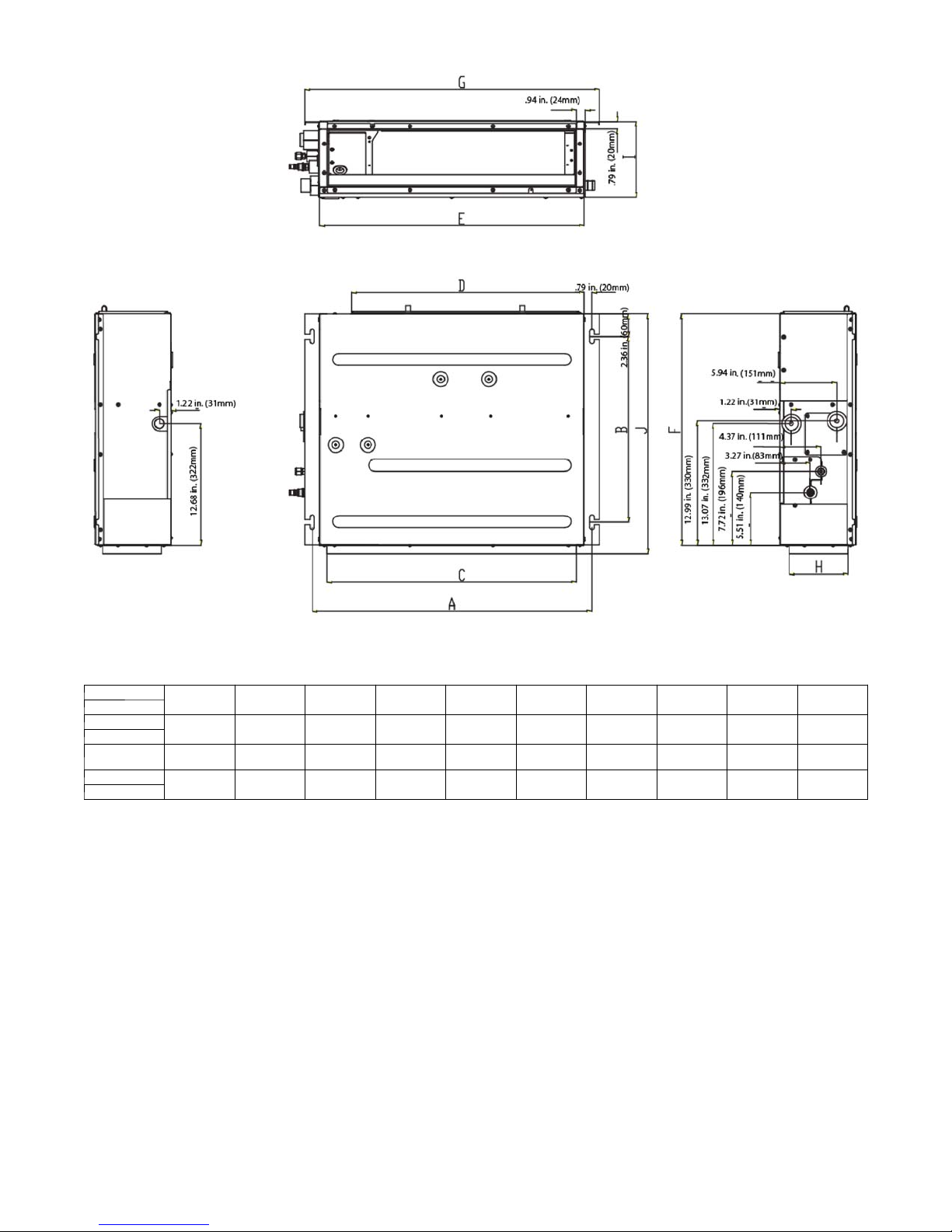

Fig. 8 - Ducted Dimensions

Table 16—Outline Dimensions

A B C D E F G H I J

29 1/5 in

(742 mm)

37 in

(942 mm)

45 in

(1142 mm)

19 1/3 in

(491 mm)

19 1/3 in

(491 mm)

19 1/3 in

(491 mm)

26 in

(662 mm)

34 in

(862 mm)

41 4/5 in

(1062 mm)

24 2/5 in

(620 mm)

32 2/7 in

(820 mm)

40 1/6 in

(1020 mm)

27 5/9 in

(700 mm)

35 3/7 in

(900 mm)

43 1/3 in

(1100 mm)

24 1/5 in

(615 mm)

24 1/5 in

(615 mm)

24 1/5 in

(615 mm)

30 4/5 in

(782 mm)

38 2/3 in

(982 mm)

46 1/2 in

(1182 mm)

6 1/7 in

(156 mm)

6 1/7 in

(156 mm)

6 1/7 in

(156 mm)

7 7/8 in

(200 mm)

7 7/8 in

(200 mm)

7 7/8 in

(200 mm)

25 in

(635 mm)

25 in

(635 mm)

25 in

(635 mm)

11

DIMENSIONS - INDOOR (CONTINUED)

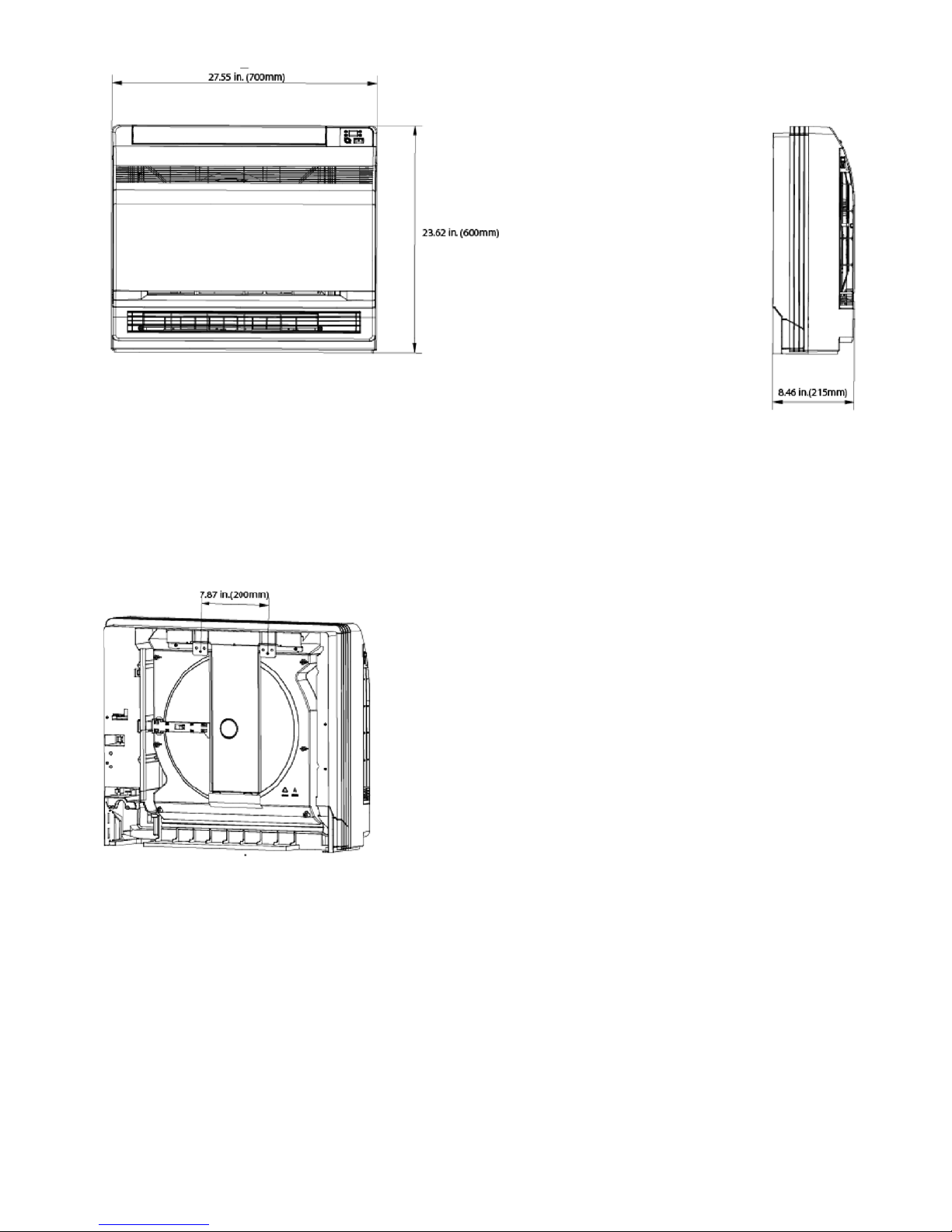

Fig. 9 - Floor Console Dimensions

12

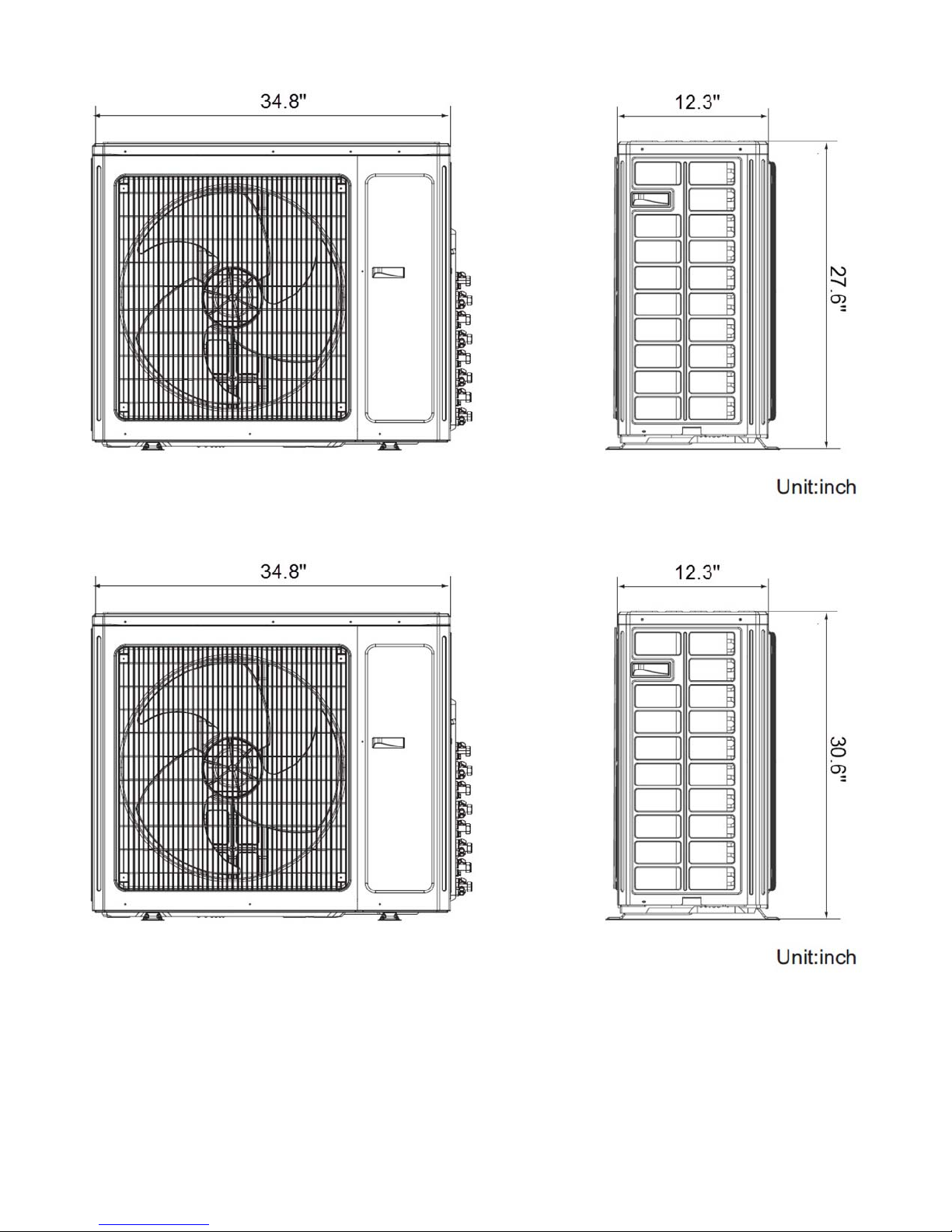

DIMENSIONS - OUTDOOR

Fig. 10 - Outdoor Dimensions Size 18

Fig. 11 - Outdoor Dimensions Size 24

13

DIMENSIONS - OUTDOOR (CONTINUED)

Fig. 12 - Outdoor Dimensions Size 30- 42

Fig. 13 - Outdoor Dimensions Size 48- 56

14

CLEARANCES - INDOOR

(0.13m)

min.

CEILING

6" (0.15m) min.

5

"

(1.8m)

6'

5

"

(0.13m)

min.

FLOOR

Fig. 14 - High Wall Clearance

Fig. 15 - Cassette Clearance

15

CLEARANCES - INDOOR (CONTINUED)

Fig. 16 - Ducted clearance

Fig. 17 - Floor console clearance

16

CLEARANCES - OUTDOOR (CONTINUED)

D

A

B

C

Air-outlet

Fig. 18 - Clearances Outdoor 18 - 42

Table 17—Clearances Outdoor

UNIT

A 24 (609)

B 24 (609)

C 24 (609)

D 4 (101)

E 4 (101)

Minimum Value

in. (mm)

Air-inlet

E

Fig. 19 - Clearances Outdoor 48- 56

17

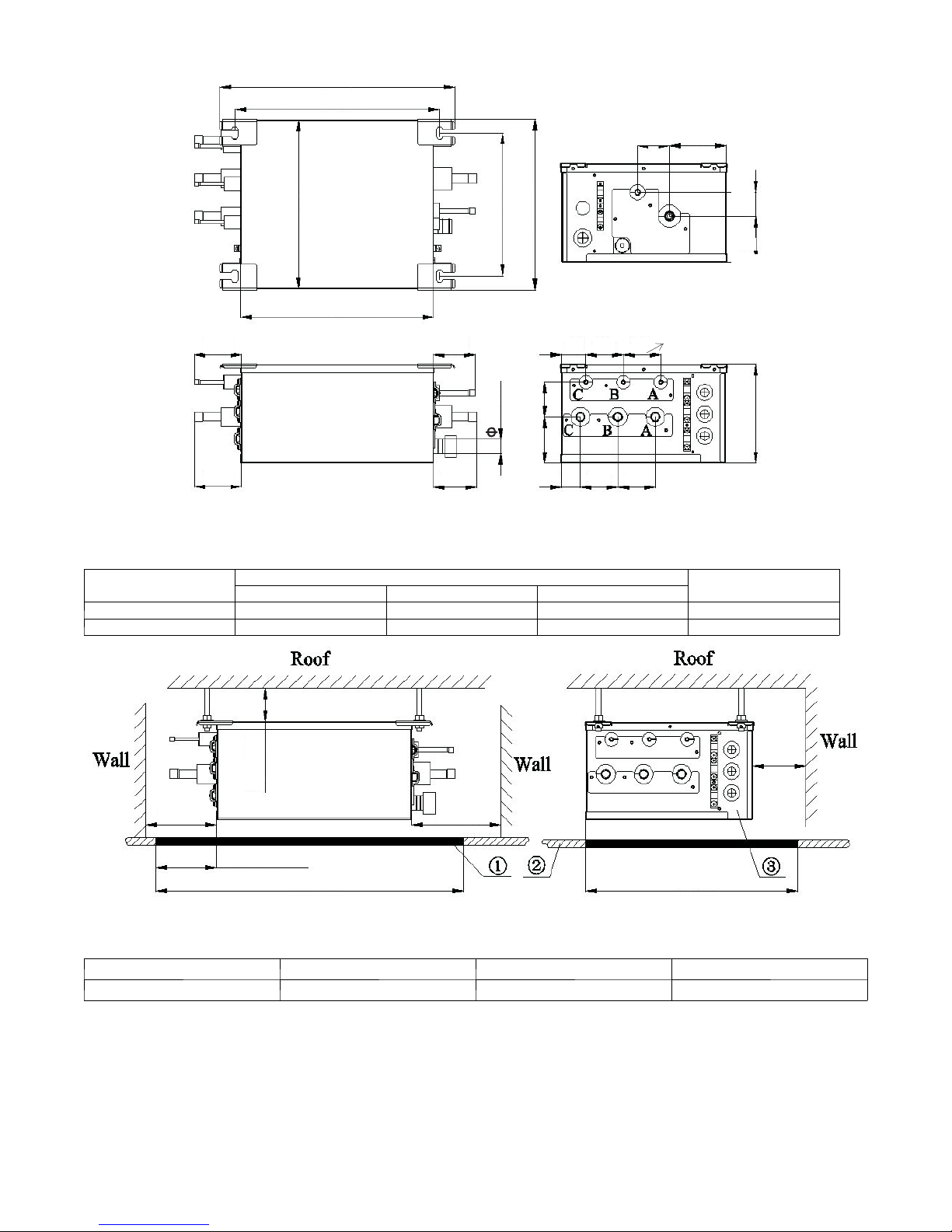

DIMENSIONS - BRANCH BOXES (REQUIRED ON SIZES 48 AND 56)

OUTLINE DIMENSION AND SERVICING SPACE OF KSAUI0201AAA

17 2/7 in (439 mm)

15 in (383 mm)

2 1/3 in (60 mm)

7 1/7 in (105 mm)

1 3/4 in (44 mm)

12 1/5 in (310 mm)

10 1/3 in (263 mm)

12 1/3 in (313 mm)

3 1/3 in (85 mm)

14 1/5 in (361 mm)

5 in (128 mm)

5 in (128 mm)

3 4/7 in (91 mm)

1 in (26 mm)

3 1/7 in (80 mm)

2 1/2 in (64 mm)

7 1/6 in (182 mm)

3 1/3 in (85 mm)

5 in (128 mm)

Sorts

Liquid Pipe

Gas Pipe

Port A Port B

5 1/5 in (132 mm)

Fig. 20 - Outline Dimensions

Table 18—Outline Dimensions

Indoor unit side (inch/mm)

2 2/5 in (61 mm)

3 1/2 in (88 mm)

Outdoor unit side (inch/mm)

17 5/7 in (450 mm)

≥

3/5 in (15 mm)~4/5 in (20 mm)

4 in (100 mm)~4 5/7 in (120 mm)

23 5/8 in (600 mm)

≥

No.

Name Service space Ceiling Electrical box side

17 5/7 in (450 mm)

≥

23 5/8 in (600 mm)

≥

Fig. 21 - Installation and Service Space

Table 19—Installation and Service Space

1 2 3

18

11 4/5 in (300 mm)

≥

OUTLINE DIMENSION AND SERVICING SPACE OF KSAUI0401AAA

17 2/7 in (439 mm)

15 in (383 mm)

2 1/3 in (60 mm)

7 1/7 in (105 mm)

1 3/4 in (44 mm)

12 1/5 in (310 mm)

10 1/3 in (263 mm)

12 1/3 in (313 mm)

3 1/3 in (85 mm)

14 1/5 in (361 mm)

5 in (128 mm)

5 in (128 mm)

1 4/5 in (35 mm)

2 3/4 in (70 mm)

2 3/4 in (70 mm)

2 1/2 in (64 mm)

1 in (26 mm)

7 1/6 in (182 mm)

3 1/3 in (85 mm)

5 in (128 mm)

Sorts

Liquid pipe

Gas liquid

Port A Port B Port C

5 1/5 in (132 mm)

Fig. 22 - Outline Dimensions

Table 20—Outline Dimensions

Indoor unit side (inch/mm)

1 3/8 in (35 mm)

2 3/4 in (70 mm)

2 3/4 in (70 mm)

Outdoor unit side (inch/

mm)

11 4/5 in (300 mm)

≥

19 2/3 in (500 mm)

≥

3/5 in (15 mm)~4/5 in (20 mm)

17 5/7 in (450 mm)

≥

4 in (100 mm)~4 5/7 in (120 mm)

23 5/8 in (600 mm)

≥

Fig. 23 - Installation and Service Space

Table 21—Installation and Service Space

No.

Name Servicing Space Ceiling Electrical box side

1 2 3

19

23 5/8 in (600 mm)

≥

INSTALLATION GUIDE

3

Up to nine fan coil units can be connected to one outdoor unit.

Refer to the Product Data for approved combinations.

Ideal installation locations include:

Each Indoor

Unit

S A location where there are no obstacles near inlet and outlet area.

S A location which can bear the weight of indoor unit.

S Do not install indoor units near a direct source of heat such as

direct sunlight or a heating appliance.

S A location with the appropriate clearances (see Fig. 14).

Outdoor

Unit

S A convenient location for the instal l ation that is not exposed to

strong wind. If unit is exposed to strong winds it is recomm ended

that a field- fabricated wind baffle be used (see Fig. 73).

S A location which can bear the weight of outdoor unit and where

the outdoor unit can be mounted in a level position.

S A location which provides appropriate clearances (see Fig. 17

and Fig. 18).

S Do not install the indoor or outdoor units in a location with

special environmental conditions. For those applications, contact

your Sales Representative.

HIGH- WALL INDOOR UNIT

INSTALLATION

INSTALL MOUNTING PLATE

For each fan coil:

1. Carefully remove the mounting plate, which is attached to

the back of the indoor unit.

2. The mounting plate should be located horizontally and level

on the wall.

3. If the wall is block, brick, concrete or similar material, drill .2”

(5 mm) diamete r holes and insert anchors for t he appropriat e

mounting screws.

4. Attach the mounting plate to the wall (see Fig. 2 and 3).

FOR EACH F AN COIL, DRILL HOLE IN WALL FOR

INTERCONNECTING PIPING, DRAIN AND WIRING

Refrigerant Line Routing

The refrigerant lines may be routed in any of the four directions

showninFig.24(a)and(b).

For maximum serviceability, it is recommended to have refrigerant

line flare connections and the drain connection on the outside of

the wall that the fan coil is mounted on.

If piping is going through the back:

1. Determine pipe hole position using the mounting plate as a

template. Drill pipe hole diameter per chart below. The

outside pipe hole is 1/2- in. (13 mm) min. lower than inside

pipe hole, so it slants slightly downward (see Fig. 25).

If piping is going to exit from the left rear, it is

recommended to field-fabricate piping extensions to get the

flare connections to the outside of the wall.

1/2 in. (13 mm)

Min.

INDOOR

OUTDOOR

Fig. 25 - Drill Holes

Table 22—Hole Diameter

Unit Size

9k, 12k, 18k and 24k 3.75 (95)

Hole Diameter

in. (mm)

If piping is going through the right or left side:

1. Use a small saw blade to carefully remove the

corresponding plastic covering on side panel and drill the

appropriate size hole where the pipe is going through the

wall (see Fig. 24 (c)).

2. Remove knockout 1 if you are running only the wiring.

Remove knockout 1 and 2 or knockout 1, 2 and 3 if you are

running both piping and wiring through the side of the unit.

!

CAUTION

DLFAHH Rear left condensate drain connection on

unit.

When piping out of the rear right, a field supplied joint

connection will need to be made behind the unit.

Please ensure that the connection is made properly to avoid

leaks.

A07371

As viewed from front

Left Exit

1

Right Exit

2

( a )

Right Rear Exit

( b )

3

Left Rear Exit

4

Fig. 24 - Refrigerant Line Routing

Knockout

Knockout 2

Knockout 1

( c )

A08281

20

DUCTED INDOOR UNITS INSTALLATION

A

INSTALLATION OF THE INDOOR DUCTED UNIT

Requirements on the Installation Location

1. Ensure the hanger is strong enough to withstand the weight

of the unit.

2. The drainage pipe is easy for connection.

3. No obstacle is in the inlet/outlet and the air circulation is in

good condition.

4. Ensure the installation space is left for access to

maintenance.

5. It should be far away from where there is a heat source,

leakage of any inflammable, explosive substances, or smog.

6. It is the ceiling type unit (concealed in the ceiling).

7. The power cords and connection lines of the indoor and

outdoor units must be at least 1m away from the TV set or

radio to avoid the image interference and noise (even if 1m

is kept, the noise may be produced due to the strong

electromagnetic wave).

Installation of the Indoor Ducted

1. Insert the M10 expansion bolt into the hole, and then knock

the nail into the bolt. Refer to the Outline Dimension

Drawings of the Indoor Unit for the distance between holes

and see Fig.26 for the installation of the expansion bolt.

Unit

!

CAUTION

S Prior to the inst allation, make a good preparation for all piping

(refrigerant pipe, drain pipe) and wiring (wires of the wired

controller, wires between the indoor and outdoor unit) of the

indoor unit to make the further installation much easi er.

S If there is an opening in the ceiling, its better to reinforce it

to keep it flat and prevent it from vibrating. Consult the user

and builder for more details.

S If the strength of the ceiling is not strong enough, a bea m

made of angle iron can be used and then sec ur e the unit on it.

S If the indoor unit is not installed in the air conditioning

area, please use sponge around the unit to prevent

condensing. The thickness of the sponge depends on the

actual installation environment.

HORIZONTAL CHECK OF THE INDOOR DUCTED

UNIT

After the installation of the indoor unit, its horizontality must be

checked to make sure the unit keeps a horizontal fore and aft and

maintains an inclination of 5

as shown in Fig.29.

_ toward the drain pipe right and left,

Fig. 26 - Expansion Bolt

2. Install the hanger on the indoor unit (see Fig.27).

Hanger bolt

nchor

Air conditioning unit

Fig. 27 - Hanger Bolt

3. Install the indoor unit on the ceiling, as shown in Fig.28.

48mm

Fig. 28 - Install the indoor unit

Horizontality Check Device

Fig. 29 - Horizontal check device

INSTALLATION OF THE AIR SUPPLY DUCT

1. Installation of the Rectangular Air Supply Duct

1

2

3

Return air

4 6 83 75

Fig. 30 - Installation of Air Duct Supply

No. Name No. Name

1 Hanger 5 Plenum Box

2 Return Air Duct 6 Filter Screen

3 Canvas Duct 7

4 Return Air Heat 8

Return air

Table 23—Air Duct

Supply air

Main Air

Supply Duct

Air Supply

Outlet

21

INSTALL THE ROUND AIR SUPPL Y DUCT

D

1

2

4

5 6 7

3

8 9

Fig. 31 - Air supply duct

Table 24—Air Duct

No. Name No. Name

1 Return Air Duct 6 Transition Duct

2 Canvas Duct 7 Air Supply Duct

3

4 Hanger 9 Diffuser Joint

5 Air Supply Duct

Return Air

Louver

8 Diffuser

INSTALLATION STEPS OF THE ROUND AIR

SUPPLY DUCT

1. Pre- install the outlet of the round duct on the transition duct

and then secure it with the tapping screw.

2. Place the transition duct to the air outlet of the unit and

secure it with a rivet.

3. Connect the outlet to the duct and then tighten them with

tape. Other installation details are not covered herein.

C

Fig. 33 - Return Air Inlet

Table 25—Dimensions of the Air Supply Outlet and Return

Air Inlet (unit: in/mm)

Item Air Supply Outlet Return Air Inlet

Size A B C D

09

12

18

21

24

6 1/7 in

(156 mm)

6 1/7 in

(156 mm)

6 1/7 in

(156 mm)

26 in (662

mm)

34 in (862

mm)

41 4/5 in

(1062

mm)

22 5/6 in

(580 mm)

30 5/7 in

(780 mm)

38 4/7 in

(980 mm)

22 5/6 in

(580 mm)

6 3/8 in

(162 mm)

6 3/8 in

(162 mm)

INSTALLATION OF THE RETURN AIR DUCT

1. The default installation location of the rectangular flange is

in the back and the return air cover plate in in the bottom as

shown in Fig.34.

Rectangular Flange

Backward Return Air

Downward Return Air

!

CAUTION

S The max. lengt h of the duct means the max. length of the air

supply duct plus the max. length of the ret urn air duct.

S The duct is either rectangular or round and connected with

the air inlet/outlet of the indoor unit. Among all air supply

outlets, at least one should remain open. As for the round

duct, it needs a transition duct of which the size should

match with the air supply of the unit. After the fitting of the

transition duct, it is best to keep the round duct 32ft (10m)

away from the corresponding diffuser.

DRAWINGS OF THE AIR SUPPLY OUTLET AND

RETURN AIR INLET

21

A

B

Fig. 32 - Air Supply Outlet

Return Air Cover Plate

Fig. 34 - Return Air Duct

2. If the downward return air is desired, just change the place

of the rectangular flange and the return air cover plate.

3. Connect one end of the return air duct to the return air outlet

of the unit by rivets and the other to the return air louver.

For the sake of the convenience to freely adjust the height, a

cutting of canvas duct will be helpful, which can be

reinforcedandfoldedby8#ironwire.

4. More noise is likely to be produced in the downward return

air mode than the backward return air mode. We suggest

installing a muffler and a plenum box to minimize the noise.

5. The instal l ation me t hod can be c hosen with consideri ng the

conditions of the building and maintenance etc. (see Fig. 35).

64

5

Wind supply

Back wind

Install the back wind pipe (a)

4

2

Wind supply

1

5

Install the back wind pipe(b)

Fig. 35 - Return Air Duct

Table 26—Air Duct

No. Name No. Name

1 Return Air Louver

(with the filter screen)

2 Canvas Duct 5 Air Supply Duct

3 Return Air Duct 6 Access Grille

4 Indoor Unit

3

1

Back wind

22

INSTALLATION OF THE CONDENSATE PIPE

1. The condensate pipe should keep a inclination angle of 5 ~

10”, to facilitate the drainage of the condensate water. And

the joints of the condensate pipe should be insulated by the

insulation material to prevent condensing (see Fig. 36).

Insulating Layer for the Condensate Pipe

5. Insert the drain hose into the drain hole and tighten it with

clamps.

6. Wrap the clamps with large amount of sponge for thermal

insulation.

7. The drain hose inside the room also should be insulated.

Clamp (accessory)

Sponge (accessory)

Clamp

(accessory)

Pipe Lid

Fig. 36 - Thermal Insulation of the Condensate Pipe

2. There is a condens ate outlet on both the left and right sides of

the unit. Once one i s confirmed for use, the other should be

clogged by a rubber plug, bundle d by the binding wire and

insulated by the insulation material to avoid water leakage.

3. The right outlet is defaulted to be clogged with a plug.

IMPORTANT: No water leakage is allowed on the joint of the

condensate pipe.

DESIGN OF THE DRAIN PIPE

1. The drain pipe should always be kept an inclination angle

(1/50~1/100) to avoid water from gathering.

2. During the connection of the drain pipe and devi ce, do not

impose excessive forc e on the pipe on one side of the device.

Additionally the pipe should be secured closely to the device.

3. The drain pipe can be the ordinary hard PVC pipe which

can be purchased locally. During the connection, inset the

end of the PVC pipe to the drain outlet, then tighten it with

the drain hose and binding wire. Never connect the drain

outlet and the drain hose with adhesive.

4. When the drain pipe is used for multiple devices, the public

section of the pipe should be 4 in (100 mm) lower than the

drain hole of each device and it is better to use the much

thicker pipe for such a purpose.

INSTALLATION OF THE DRAIN PIPE

1. The diameter of the drain pipe should be larger than or

equal to that of the refrigerant pipe (PVC pipe, outer

dimater: 1 in (25 mm), wall thickness

2. The drain pipe should be a short as possible and with at

least a 1/100 degree of slope to avoid forming air pockets.

3. If the proper degree of slope of the drain pipe is not

allowed, a lift pipe should be installed.

4. A distance of 3.28 ft~4.92 ft (1m~1.5 m) should be kept

betwe en the hangers to avoid the drain hose from making a

turn.

0.06 in (1.5 mm).

Sponge (gray) Drain Hose

Max. 4mm

Fig. 38 - Drain Hose Insulation

PRECAUTIONS FOR THE LIFT PIPE

The lift pipe install height should be less than 33 1/2 in (850 mm). We

recommend setting an inclination angle 1~ 2

the drainage direction. If the lift pipe and the unit form a right angle,

the height of the lift pipe must be less than 31 1/2 in (800 mm).

1~1.5m

Lift Pipe

850mm

1000mm

150mm

Drain Hose (accessory)

Hanger Bracket

11 4/5 in (300 mm)

Clamp (accessory)

1° 2°

Fig. 39 - Installation Height

NOTE:

1. The inclination height of the drain hose should be within 3

in. (75 mm) so that the outlet of the drain hose does not

suffer any external force.

2. If multiple drain pipes converge, follow the installation

steps below.

The specification of the joint of the drain pipe should be suitable to the running capacity of the unit

Drain Hose (accessory)

Max.75mm

Max.1000mm

_ for the lift pipe toward

Ceiling

3.28 ft~4.92 ft

(1m~1.5 m)

(Wrong)

Fig. 37 - Slope Degree

Fig. 40 - Multiple Line Convergence

23

FLOOR CONSOLE INDOOR UNITS

INSTALLATION

Follow these key steps when selecting a location for the unit.

S Select a placewhere cool air can be distributed throughout

the room.

S Select a place where condensation water is easily drained

away.

S Select a site that can handle the weight of the indoor unit.

S Select a place which has easy access for maintenance.

Indoor unit

The indoor unit should be sited in a place where:

1. The restrictions for the installation specified in the indoor

unit installation drawings are met.

2. Both the air intake and exhaust have clear paths.

3. The unit is not in the path of direct sunlight.

4. The unit is away from a heat or steam source.

5. There is no source of machine oil vapour (this may shorten

indoor unit life).

6. Cool (warm) air is circulated throughout the room.

7. The unit is away from electronic ignition type fluorescent

lamps (inverter or rapid stert type) as they may shorten the

remote controller range.

8. The unit is at least 3.28 ft (1 m) away from any television or

radio set (unit may cause interference with the picture or

sound).

CAUTIONS FOR INSTALLATION WHERE AIR

CONDITIONER TROUBLE IS LIABLE TO OCCUR

S Do not install in areas with or near an abundance of oil.

S Do not install in areas with an acid base area.

S Do not install in areas with an irregular electrical supply.

Mounting plate

Drawings

Half conceated

Concealed

Grid(field supply)

Indoor Unit Installation

The indoor unit may be mounted in any of the three styles shown

here.

Exposed

Molding

Floor lnstallation Wall Installation

Fig. 41 - Indoor Unit Installation Drawings

Location for securing the installation

7 7/8 in (200

4 5/7 in (120 mm

)

8 2/3 in (220 mm)

6 2/3 in (170 mm)

1 1/6 in (30 mm)

25 1/3 in (644 mm)

panel

27 5/9 in (700 m

mm)

1 1/6 in (30 m

m)

m)

)

m

m

021(

n

i

7

/

5

4

(570 mm)

)m

n

m

0

2

2(

23 5/8 in (600 mm)

22 4/9 i

n

i

3/

2 8

6 2/7 in (160 mm

Schematic drawing of hooks:

7 7/8 in (200 mm)

Fig. 42 - Schematic Drawing of Hooks

INSTALLATION

PAPER PLANK

Fig. 43 - Installation Paper Plank

REFRIGERANT PIPING

Use the following steps to connect the refrigerant pipe.

1. Drill a hole (2 1/6 in (55 mm) in diameter ) in the spot

indicated by the

2. The location of the hole is different depending on which

side of the pipe is taken out.

3. For piping, see Connecting the refrigerant pipe, under

Indoor Unit Installation (1).

4. Allow space around the pipe for a easier indoor unit pipe

connection.

symbol in the illustration as below.

(Unit : in/mm)

Wall

)

Left bottom piping

24

1 7/9 in (45 mm)

3 in (75 mm)

2 1/3 in (60 mm)

Right bottom piping

3 in (75 mm)

Fig. 44 - Piping

Left back piping Right back piping

3 in (75 mm)

1 7/9 in (45 mm)

3 in (75 mm)

1 7/9 in (45 mm)

Left/right piping

1 7/9 in (45 mm)

Fig. 45 - Back piping

!

CAUTION

The suggested shortest pipe length is 8.2 ft (2.5 m) to avoid

noise from the outdoor unit and vibration. (Mechanical

noise and vibration may occur depending on how the unit is

installed and the environment in which it is used.)

See the installation manual for the outdoor unit for the

maximum pipe length.

1 7/9 in (45 mm)

DRILLING A WALL HOLE AND INSTALLING

WALL EMBEDDED PIPE

S For walls containing metal frameormetal board ,be sureto

use a wall embedded pipe and wall cover in the

feed-through hole to prevent water leakage.

S Be sure to caulk the gaps around the pipes with caulking

material to prevent water leakage.

1. Bore a feed- through hole of 2 1/6 in (55 mm) in the wall so

it has a down slope toward the outside.

2. Insert a wall pipe into the hole.

3. Insert a wall cover into wall pipe.

Inside Outside

Wall embedded pipe

(field supply)

Wall hole cover

Caulking

2 1/6 in (55 mm)

Refrigerant pipe

Fig. 46 - Refrigerant Pipe

3 in (75 mm)

Fig. 47 - Refrigerant Pipe

wall

Floor

13 7/9 in (350 mm)

1 7/9 in (45 mm)

Wall embedded pipe

(field supply)

Fig. 48 - Wall Embedded Pipe

4. After completing refrigerant piping, wiring, and drain

piping, caulk pipe hole gap with putty.

DRAIN PIPING

1. Use commercial regid polyvinyl chloride pipe general VP

20 pipe, outer diameter 1 in (26 mm), inner diameter 4/5 in

(20 mm) for the drain pipe.

2. The drain hose (outer diameter 5/7 in (18 mm) at

connecting end, 8 2/3 in (220 mm) long)is supplied with the

indoor unit. Prepare the drain pipe picture below position.

3. The drain pipe should be inclined downward so that water

will flow smoothly without any accumulation. (Should not

beatrap.)

4. Insert the drain hose to this depth so it will not be pulled out

of the drain pipe.

5. Insulate the indoor drain pipe with 10mm or more of

insulation material to prevent condensation.

6. Remove the air filters and pour some water into the drain

pan to check the water flows smoothly.

6 in (150 mm)

Must be no trap

25

4 in (100 mm)

4 in (100 mm)

Drain hose

Reducer

Fig. 49 - Trap

2 in (50 mm)

or more

Vinyl chloride

drain pipe

Do not touch water

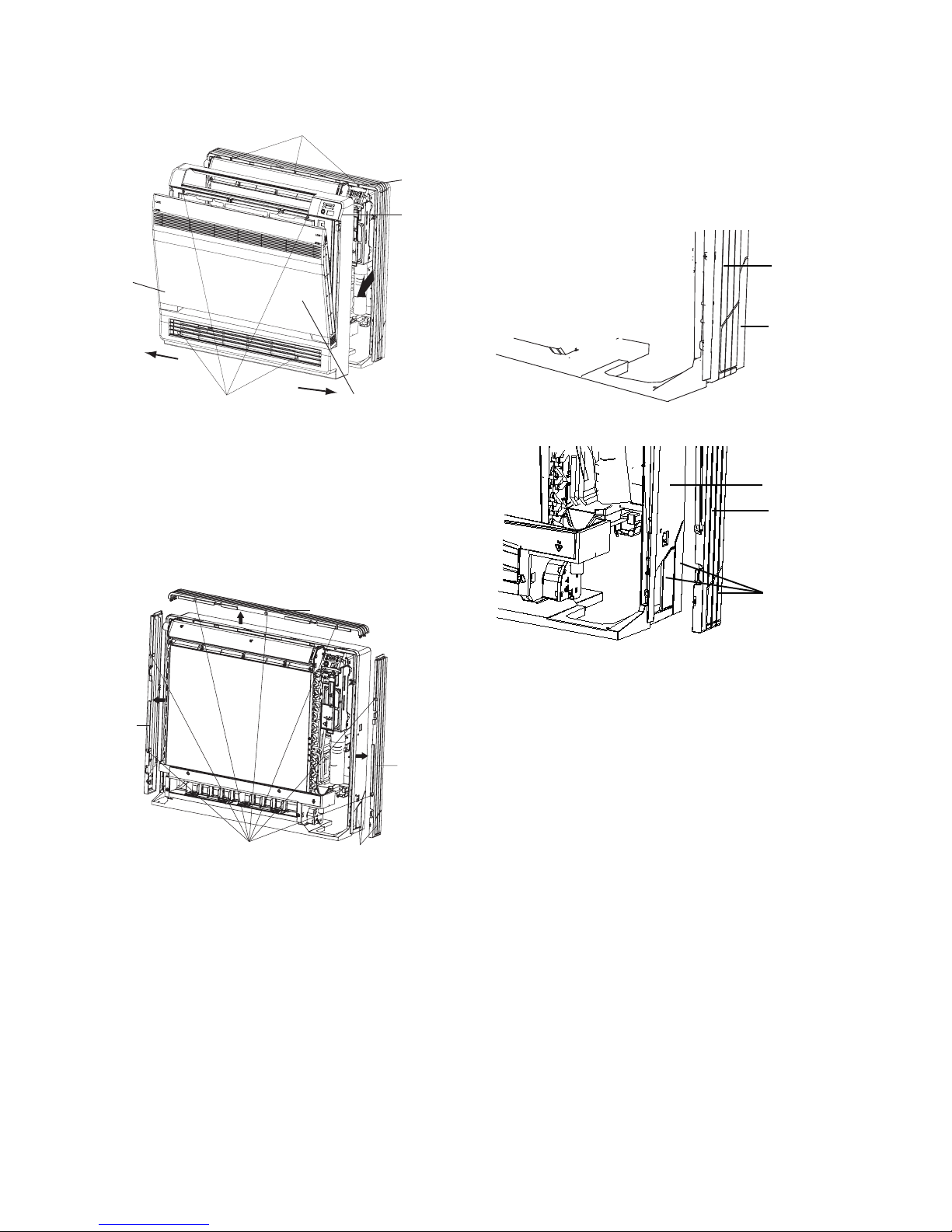

INSTALLING THE INDOOR UNIT

1. Preparation

S Open the front panel, remove the 4 screws and dismount

the front grille while pulling it forward.

3 tabs

Casing

Front

grille

For Side Piping

S Remove the pillars.

(1.) Remove the 7 screws.

(2.) Remove the upper casing (2 tabs).

(3.) Remove the left and right casings (2 tabs on each

side).

(4.) Remove the slit portions on the bottom frame and

casings using nippers.

(5.) Return by following the steps in reverse order

(3>2>1).

Front panel

Remove 4 screws

Open the front panel

Fig. 50 - Remove the screws

S Follow the arrows to disengagetheclasps on the front case

to remove it.

S Follow the procedure below when removing the slit

portions.

For Moldings

S Remove the pillars. Remove the slit portions on the bottom

frame using nippers.

2)Upper casing

3)Side

casings

Remove

front grille

3)Side

casings

Casing

Remove the pillar

Fig. 52 - Remove the pillar

Bottom frame

Casing

Remove the pillar

Fig. 53 - Remove the pillar

2. Installation

S Secure using 6 screws for floor installations. Do not forget

to secure to the rear wall.

S For wall installations, secure the mounting plate using 5

screws and the indoor unit using 4 screws.

Remove 7 screws

Fig. 51 - Remove the screws

Remove the pillar

26

The mounting plate should be installed on a wall which can

support the weight of the indoor unit.

(1.) Temporarily secure the mounting plate to the wall,

make sure that the panel is completely level, and

mark the boring points on the wall.

(2.) Secure the mounting plate to the wall with screws.

Casing

6screws

Fig. 54 - Floor Installation

7 7/8 in (200 mm)

Molding

6screws

Fig. 55 - Wall Installation

(3.) Once refrigerant piping and drain piping

connections are complete, fill in the gap of the

through hole with putty. A gap can lead to

condensation on the refrigerant pipe, and drain

pipe, and the entry of insects into the pipes.

(4.) Attach the front panel and front grille in their

original positions once all connections are

complete.

Flaring the Pipe

End

1. Cut the pipe end with a pipe cutter.

2. Remove burrs with the cut surface facing downward so that

the chips do not enter the pipe.

3. Fit the flare nut on the pipe.

4. Flare the pipe.

5. Check that the flaring is properly made.

Set exactly at the position shown below

Flare tool for R410A

Cut exactly

at right

angles

Renove

burrs

A

Die

Clutch-type

A

0~0.02 in (0~0.5 mm)

Flaring

Conventional flare tool

Clutch-type

(Rigid-type)

0.04~0.06 in

(1.0~1.5 mm)

Fig. 56 - Flaring

!

WARNING

(1.) DO not use mineral oil on flared part.

(2.) Prevent mineral oil from getting into the

system as this would reduce the lifetime of

the units.

(3.) Never use piping which had been used for

previous installations. Only use parts which

are delivered with the unit.

(4.) Do never install a drier to this R410A unit

in order to guarantee its lifetime.

(5.) The drying material may dissolve and

damage the system.

(6.) Incomplete flaring may cause refrigerant gas

leakage.

Flare’s inner

surface must

be scratch-free

Wing-nut type

(lmperial-type)

0.06~0.08 in

(1.5~2.0 mm)

The pipe end must

be evenly flared in

a perfect circle

Make sure that the

flare nut is fitted

27

CASSETTE TYPE INDOOR UNIT INSTALLATION

37 2/5 in ( 950 mm)

37 2/ 5 in (950 m m)

35 in(8 90 mm )

35 in(8

9

0

m

m

)

33 in(8 40 mm )

33 in(8 40 mm)

3

0 5

/

7 in (780

m

m

)

26 7/9 in (680 m m)

4/5 i n

59 in

(1500 mm)

(20 m m)

59 in

(1500 mm)

70 6/ 7

in/mm

in (1800 mm)

Fig. 57 - Schematic diagram of installation spaces

Select install location of the indoor unit

1. Obstructions should be removed from the indoor unit’s

intake or outlet vents so the air can flow throughout the

room.

2. Make sure the installation is in accordance with the

requirements of the required clearances on the schematic

diagram.

3. Select a location that can withstand 4 times the weight of

the indoor unit and would not increase the operating noise.

4. Ensure the unit is level.

5. Select a location where condensated coagulated water can

drain easy connect easy with the outdoor unit.

6. Ensure there is enough space for care and maintenance.

Ensure the weight between the indoor unit and ground is

above 70 6/7 in (1800 mm).

7. When installing the steeve bolt, check if the install place can

withstand a weight 4 times of the unit’s. If not, reinforce

before installation. Refer to the install cardboard and find

where the location should be reinforced.

NOTE: There will be lots of lampblack and dust stick on the

acentric, heat exchanger and water pump in the dining room and

kitchen, which would reduce the capacity of heat exchanger, lead

water leakage and abnormal operation of the water pump. The

following treatment should be taken under this circumstance:

(1.) Ensure the smoke trap above the cooker has

enough capacity to obviate lampblack to prevent

the indraft of the lampblack by the air conditioner.

(2.) Keep the air conditioner far from the kitchen so that

the lampblack does not indraft into the air

conditioner.

IMPORTANT: To guarantee the good performance, the unit must

be installed by professional personnel according with this

instruction.

12

18

24

25 3/5 in (650 mm)

22 4/9 in (570 mm)

15 3/4 in (400 mm)

Install dimension of mode

10 1/4 in

(260 mm)

)mm 075( n

)

mm

406(

n

i

i

9/

9/7

4

22

32

)mm

05

6( ni

5/

3 5

2

Fig. 58 - Dimension of ceiling opening and location of the

hoisting screw (M10)

IMPORTANT: The drilling of holes in the ceiling must be done

by the professional personnel.

Installation stands for main body of the unit

)mm 0

ni 7/2

Ceiling

6

6

1

(

Above 4/6 in (20 mm)

Fig. 59 - Drilling holes

NOTE: The dimension for the ceiling openings with * marks can

be as large as 35 5/6 in (910 mm). But the overlapping sections of

the ceiling and the decorated surface boards should be maintained

at no less than 4/6 in (20 mm).

28

Hoisting the main body of the air

conditioner

The primary step for installing the indoor unit.

S Whenattaching thehoisting standon the hoisting screw, do

use nut and gasket individually at the upper and lower of

the hoisting stand to secure it. The use of gasket anchor

board can prevent gasket break off.

Use install cardboard.

S Refer to the install cardboard about the dimension of

ceiling opening.

S The central mark of the ceiling opening is marked on the

install cardboard.

1. Install the install cardboard on the unit by bolt (3 pieces)

and fix the angle of the drainage pipe at the outlet vent by

bolt.

2. Adjust the unit to the suitable install place. Refer to Fig. 59.

3. Check if the unit is horizontal.

4. The inner drainage pump and bobber switch are included in

the indoor unit, check if the 4 angle of every unit are

horizontal by the water lever. If the unit is slanted toward

the opposite of the coagulate water flow, there may be a

malfunction of the bobber switch and lead water drop.)

5. Backout the gasket anchor board used to prevent gasket

break off and tighten the nut on it.

6. Backout the install cardboard.

Nut supplied at scene

DRAINAGE HOSE

1. Install the drain hose.

S The diameter of the drain hose should be equal or bigger

than the connection pipe’s. (The diameter of the polythene

pipe:Outer diameter1in(25mm) Surface thickness

in (1.5 mm).

S The drain hose should be short and the drooping gradient

should be less than 1/100 to prevent the formation of an air

bubble.Ifthe drain hose doesnothasenough of a drooping

gradient, a drain raising pipe should be added.

S To prevent a bend in the drain hose, the distance between

the hoisting stand should is 3.28 to 4.92 ft (1 to 1.5 m) (see

Fig.61).

3.28 to 4.92 ft (1 to 1.5 m)

3.28 to 4.92 ft (1 to 1.5 m)

Fig. 61 - Drain Hose

S Use the drainhoseand clampattached.Insert the drainhose

into the drain vent, and then tighten the clamp.

S Entwine the big sponge on the clamp of drain hose to

insulate heat.

S Heat insulation should be applied to the indoor drain hose.

0.06

Fig. 60 - Hoisting the main body

NOTE: Tighten the nuts and bolts to prevent the air conditioner

from breaking off.

CONNECTION OF THE REFRIGERANT PIPE

Connection of the Refrigerant Pipe

When connecting the pipe to the unit or backout from the unit, use

both a spanner and a torque wrench.

When connecting, smear both inside and outside of the flare nut

with freeze motor oil, screw it by hand and then tighten with a

spanner.

Refer to form 1 to check if the wrench had been tightened (too

tight would mangle the nut and lead leakage).

Examine the connection pipe to see if it had a gas leak, then take

the treatment of heat insulation. Only use a median sponge to

entwine the wiring interface of the gas pipe and heat preservation

sheath of the gas collection tube.

Sponge(attachment)

Drain hose

Clamp(attachment)

Below 1/6 in (4 mm)

Clamp

Sponge (gray)

Fig. 62 - Drain Hose

NOTE: Drain Setup pipe

S The install height of the drain raising pipe should lessthan

11 in. (280 mm).

S The drain raising pipe should form a right angle with the

unit, and distance to unit should not beyond 11.81 in.

(300mm).

11 4/5 in (300 mm)

Fig. 63 - Drain Setup Pipe

3.28-4.92

ft (1-1.5 m)

8 2/3 i n (220 mm )

11 in (2 80 mm)

3 (500 mm)

/

19 2

29

INSTRUCTION

The slant gradient of the attached drain hose should be within 3 in.

(75 mm) so that the drain hole does not have to endure unnecessary

outside force.

mm)

5

Fig. 64 - Slant gradient

7

in (

3

3 (500 mm)

/

2

19

The power cord reference power cord standard recommending

table.

1. Install the drain hose according to the following process if

several drain hoses join together.

Fig. 65 - Slant gradient

2. Check the smoothness of the drain after the installation.

3. Check the drain state by immitting 36 3/5 in3 (600 cc)

water slowly from the outlet vent or test hole.

4. Check the drain in the state of refrigerating after installing

the electric circuit.

4 in (100 mm)

Fig. 67 - Power cord

Install the

panel

1. Set the panel to the indoor unit body by matching the position of the panel’s swing flap motor to the panel’s piping

position to the indoor unit’s piping position (see Fig. 68).

2. Install the panel

(1.) Install the panel on the indoor unit temporarily.

When installing, hang the latch on the hook that is

located on the opposite side of the swing flap on

the panel of the indoor unit (two positions).

(2.) Hang the remaining 2 latches to the hooks on the

sides of the indoor unit. (Be careful not to let the

swing motor lead wire get caught in the sealing

material.)

(3.) Screw the 4 hexagon head screws under the latches

in about 3/5 in (15 mm). (The panel should rise)

(4.) Adjust the panel by turning it toward the direction

pointed by the arrow (see Fig. 68) so the adjust

board connects well to the ceiling.

(5.) Tighten the screws until the thickness of the sealing

material between the panel and the indoor unit is

reduced to 5- 8mm.

Fig. 66 - Drain

Electrical

wiring

NOTE: The power of the entire indoor unit must be connected in

the outdoor unit.

S About the electricalwiring,seethe circuit diagram attached

with the unit.

S All electrical wiring installation must be done by

professional personnel.

S Remove the earthing treatment.

Wiring method of connection unit and contr

Connection wiring (communication)

1. Open the electric box cover, drag the wiring

(communication) from rubber plug A, and impact them well

individually with an impact fastener.

2. Wire according to the indoor side circuit diagram.

(1.) Fix the impact fastener after the connection.

(2.) Entwine the small sponge on the electric wire

(entwine to prevent condensation).

(3.) Impact tightly with an impact fastener after

connection. Then fir on the electric box.

(4.) Connect the 3 cord rubber wire to the counter

terminal of the 3 way terminal board.

oller

1/5 in to 1/3 in (5 mm to 8 mm)

Fig. 68 - Panel Installation

30

NOTE:

(1.) Improper screwing of the screws may cause issues

Air leak from ceiling

as shown in Fig. 69.

Air leak

Water condensatation, water drop

Fig. 69 - Improper Screwing

OUTDOOR UNIT INSTALLATION

1. Use a rigid base to support unit in a level position.

2. Locate outdoor unit and connect piping and wiring.

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Excessive torque can break flare nut depending on

installation conditions.

CAUTION

(2.) If a gap still exists between the ceiling and

decoration panel after tightening the screws,

readjust the height of the indoor unit (see Fig. 70).

If the raising lever and drain hose are

not affect, can adjust the height of

indoor unit by the hole on the corner

of panel.

Gaps are not allowed

Fig. 70 - Improper Screwing

IMPORTANT: After securing, ensure there is no gap between the

ceiling and the panel.

(3.) Wiring of the decoration panel (Fig.71). Connect

the joints for the swing flap motor lead wire (at 2

places) onto the panel.

At body At pane

At body At pane

Fig. 71 - Connect joints

Piping Connections to Outdoor

Unit

IMPORTANT: Use refrigeration grade tubing ONLY. No other

type of tubing may be used. Use of other types of tubing will

void manufacturer’s warranty.

Make sure there is enough piping to cover the required length

between the outdoor and indoor unit.

Only use piping suitable for high side pressure for both high

side and low side connections.

Piping Guide:

S Do not open service valves or remove protective caps from

tubing ends until all the connections are made.

S Bend tubing with bending tools to avoid kinks and flat spots.

S Keep the tubing free of dirt, sand, moisture, and other

contaminants to avoid damaging the refrigerant system.

S Avoid sags in the suction line to prevent the formation of oil traps.

Insulate each tube with minimum 3/8- in. (10 mm) wall thermal

pipe insul ation. Inserting the tubing into the insulation before

making the connections will save time and improve installation

quality.

1. The unit is equipped with multiple pairs of service valves

(Except sizes 48 and 56). Each pair is clearly marked (color

and letter) to ide nt ify the indoor unit cir cuits. In the outdoor

unit wiring area, each indoor unit interconnecting termina l

block is marked (letter) the sam e as the corresponding pair of

service valves. The indoor units must be piped and wired in

matched sets (A to A; B to B, etc).

2. It is not required to use all of the available fan coil

connections if the application does not require them at the

current time. The system can be expanded at any time.

3. Conversion joints are supplied with the outdoor unit. They

are required for certain fan coil combinations. These joints

are to be connected to the outdoor unit as needed to match

the line set size.

4. Cut tubing with tubing cutter.

5. Install correct size flare nut onto tubing and make flare

connection.

6. Apply a small amount of refrigerant oil to the flare

connection on the tubing.

7. Properly align tubing in with service valve (conversion

joint).

8. Tighten flare nut and finish installation using two wrenches

as shown in Fig. 72.

A07354

Fig. 72 - Tighten Flare Nut

31

INSTALL ALL POWER AND INTERCONNECTING

WIRING TO OUTDOOR UNIT*

!

NOTE

Strong

wind

Fig. 73 - High Wind Installation

Outdoor Unit Wiring

1. Mount outdoor power disconnect.

2. Run power wiring from main box to disconnect per NEC

and local codes.

3. Remove field wiring cover (if available) from unit by

loosening screws.

4. Remove knockouts..

5. Connect conduit to conduit panel (see Fig. 75).

6. Properly connect both power supply and control lines to

terminal block per the connection diagram.

7. Ground unit in accordance with NEC and local electrical

codes.

8. Use lock nuts to secure conduit.

9. Reinstall field wiring cover.

Connections

A07350

*Branch Boxes required on sizes 48 and 56.

Separate power connection is required for the Outdoor unit

and the Branch Boxes.

Refer to Branch Box installation instructions.

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

S Be sure to comply with local codes while running wire

from indoor unit to outdoor unit.

S Every wire must be connected firmly. Loose wiring may

cause terminal to overheat or result in unit malfunction.

A fire hazard may also exist. Therefore, be sure all wiring

is tightly connected.

S No wire should be allowed to touch refrigerant tubing,

compressor or any moving parts.

S Disconnecting mea ns must be provided and shall be located

within sight and readily accessible from the air conditioner.

S Connecting cable with conduit shall be routed through

hole in the conduit panel.

CAUTION

32

OUTDOOR UNIT INSTALLATION SIZES 48 AND 56

For sizes 48 and 56, one outdoor unit can drive up to three Branch Box (BU) modules and nine different types of indoor units (high wall,

cassette, ducted and floor console). At least one Branch Box (KSAUI0201AAA up to 2 indoor units or KSAUI0401AAA up to 3 indoor

units) is required on these sizes. If two or more Branch Boxes are installed the Y-type Branch tube (KSAUI0501AAA) is required.

Fig. 74 - Connection Flow

33

CONNECTION DIAGRAMS

18-42

Fig. 75 - Connection Diagram Sizes 18- 42

48-56

Fig. 76 - Connection Diagram Sizes 48- 56

Connection Diagram

Fig. 77 - Connection Diagram Branch Box

34

INSTALL ALL POWER, INTERCONNECTING

t

WIRING, AND PIPING TO INDOOR UNIT .

1. Run interconnecting piping and wiring from outdoor unit to

each indoor unit (in matched pairs) (except sizes 48 and 56

refer to Branch Box installation instructions).

2. Pass interconnecting cable through hole in wall (outside to

inside).

3. Lift indoor unit into position and route piping and drain

through hole in wall (inside to outside). Fit the

interconnecting wiring into back side of indoor unit.

4. Hang indoor unit on upper hooks of wall mounting plate

(see Fig. 78).

A08283

Fig. 78 - Hanging Indoor Unit

5. Open front cover of indoor unit and remove field wiring

terminal block cover (see Fig. 79)

Field Wiring

Cover

Interconnecting

Cable

A08279

Fig. 79 - Field Wiring Cover

6. Pull interconnecting wire up from back of indoor unit and

position in close to the terminal block on indoor unit.

7. Push bottom of indoor unit onto mounting plate to

complete wall mount.

8. Connect wiring from outdoor unit per connection diagram

(see Fig. 75).

NOTE: Polarity of power wires must match original

connection on outdoor unit.

9. Replace field wiring cover and close front cover of indoor

unit.

10. Connect refrigerant piping and drain line outside of indoor

unit. Refer to Piping Connections to Outdoor Unit section

and Fig. 72 for proper installation of flare connections.

Complete pipe insulation at flare connection then fasten

piping and wiring to the wall as required. Completely seal

the hole in the wall.

11. Repeat steps 1 through 10 for each indoor unit.

SYSTEM VACUUM AND CHARGE

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Never use the system compressor as a vacuum pump.

Refrigerant tubes and indoor coil should be evacuated using the

recommended deep vacuum method of 500 microns. The alternate

triple evacuation method may be used if the procedure outlined

below is followed. Always break a vacuum with dry nitrogen.

Using Vacuum

1. Completely tighten flare nuts A, B, C, D, (for all fan coils).

Connect gage charge hose to one circuit or all circuits (if

using a multiple connection manifold) at the low side

service valve charge port(s) (see Fig. 80.).

2. Connect charge hose to vacuum pump.

3. Fully open the low side of manifold gage (see Fig. 81).

4. Start vacuum pump.

5. Evacuate using either deep vacuum or triple evacuation

method.

6. After evacuation is complete, fully close the low side of

manifold gage and stop operation of vacuum pump.

7. If multiple connection manifold is not used, repeat the

procedure (1 through 6) until all indoor units and piping are

completely vacuumed.

8. The factory charge contained in the outdoor unit is suitable

for max pipe length. If an additional charge is required, it

should be added to the system as liquid at this time.

9. Disconnect charge hose from charge connection of the low

side service valve.

10. Fully open all service valves.

11. Securely tighten caps of service valves.

Outdoor Unit

500 microns

Low side valve

Charge hose

CAUTION

Pump

Refrigerant

Low Side

A

High Side

B

Service Valve

Fig. 80 - Service Valve

Manifold Gage

Indoor Uni

C

D

A07360

High side valve

Charge hose

Vacuum pump

Low side valve

A07361

Fig. 81 - Manifold

35

Deep Vacuum

Method

The deep vacuum method requires a vacuum pump capable of

pulling a vacuum of 500 microns and a vacuum gage capable of

accurately measuring this vacuum depth. The deep vacuum method

is the most positive way of assuring a system is free of air and

liquid water (see Fig. 82).

5000

4500

4000

3500

3000

2500

2000

MICRONS

1500

1000

500

01234567

MINUTES

LEAK IN

SYSTEM

VACUUM TIGHT

TOO WET

TIGHT

DRY SYSTEM

A95424

Fig. 82 - Deep Vacuum Graph

Triple Evacuation

Method

The triple evacuation method should only be used when vacuum

pump is only capable of pumping down to 28 in. of mercury

vacuum and system does not contain any liquid water.

Refer to Fig. 83 and proceed as follows:

1. Pump system down to 28 in. of mercury and allow pump to

continue operating for an additional 15 minutes.

2. Close service valves and shut off vacuum pump.

3. Connect a nitrogen cylinder and regulator to system and

open until system pressure is 2 psig.

4. Close service valve and allow system to stand for 1 hr.

During this time, dry nitrogen will be able to diffuse

throughout the system absorbing moisture.

5. Repeat this procedure as indicated in Fig. 83. System will

then be free of any contaminants and water vapor.

EVACUATE

BREAK VACUUM WITH DRY NITROGEN

WAIT

EVACUATE

BREAK VACUUM WITH DRY NITROGEN

WAIT

EVACUATE

CHECK FOR TIGHT, DRY SYSTEM

(IF IT HOLDS DEEP VACUUM)

RELEASE CHARGE INTO SYSTEM

A95425

Fig. 83 - Triple Evacuation Method

Final Tubing

Check

IMPORTANT: Check to be certain factory tubing on both indoor

and outdoor unit has not shifted during shipment. Ensure tubes are

not rubbing against each other or any sheet metal. Pay close

attention to feeder tubes, making sure wire ties on feeder tubes are

secure and tight.

36

START- UP

Tes t Operation

Perform test operation after completing gas leak and electrical

safety check.

1. Push the “ON/OFF” button on Remote Control to begin

testing.

NOTE: A protection feature prevents the air conditioner from

being activated for approximately 3 minutes.

2. Push MODE button, select COOLING, HEATING, FAN

mode to check if all functions work correctly.

SYSTEM CHECKS

1. Conceal the tubing where possible.

2. Make sure that the drain tube slopes downward along its

entire length.

3. Ensure all tubing and connections are properly insulated.

4. Fasten tubes to the outside wall, when possible.

5. Seal the hole through which the cables and tubing pass.

INDOOR UNIT

1. Do all Remote Control buttons function properly?

2. Do the display panel lights work properly?

3. Does the air deflection louver function properly?

4. Does the drain work?

OUTDOOR UNIT

1. Are there unusual noises or vibrations during operation?

Explain The Following Items To Customer With The Aid Of

The Owner’s Manual:

1. How to turn air conditioner on and off; selecting

COOLING, HEA TING and other operating modes; setting

a desired temperature; setting the timer to automatically start

and stop air conditioner operation; and all other features of

the Remote Control and display panel.

2. How to remove and clean the air filter.

3. How to set air deflection louver.

4. Explain care and maintenance.

5. Present the Owner’s Manual and installation instructions to

customer.

37

TROUBLESHOOTING

This unit has on- board diagnostics. Error codes are displayed on the wired remote controller and the outdoor unit microprocessor board with

colored LED lights. The table below explains the error codes on both.

SIZES 18 & 24

Table 27—Malfunction Status Table

Malfunction name Malfunction type

Zero cross detection circuit malfunction(for indoor unit) Hardware malfunction U8

Malfunction protection of jumper cap(for indoor unit) Hardware malfunction C5

Feedback of without I DU motor(for indoor unit) Hardware malfunction H6

Indoor ambient temperature sensor is open/short circuited Hardware malfunction F1

Indoor evaporator temperature sensor is open/short circuited Hardware malfunction F2

Liquid valve temperature sensor is open/short circuited Hardware malfunction b5

Gas valve temperature sensor is open/short circuited Hardware malfunction b7

Modular temperature sensor is open/short circuited Hardware malfunction P7

Outdoor ambient temperature sensor is open/short circuited Hardware malfunction F3

Outdoor condenser middle pipe temperature sensor is open/short

circuited

Hardware malfunction F4

Outdoor discharge temperature sensor is open/short circuited Hardware malfunction F5

Communication malfunction Hardware malfunction E6

Malfunction o f phase current detection circuit for compressor Hardware malfunction U1

Module high temperature protection

Refrigerant lacking or blockage protection of system (not

available for residential ODU)

Viewing malfunction code through remote controller within 200s;

displayed directly on nixie tube after 200s

Charging malfunction of capacitor Hardware malfunction

High pressure protection of system

Hardware malfunction E1

Low pressure protection of system (reserved) Hardware malfunction E3

Compressor overload protection

Indoor unit and outdoor unit do not match Hardware malfunction LP

Malfunction of memory chip Hardware malfunction EE

Wrong connection of communication wire or malfunction of

electronic expansion valve

Malfunction protection of outdoor fan 1 Hardware malfunction L3

Detection status of wrong connection of communication wire or

malfunction of electronic expansion valve

Mode conflict Operation status E7

Refrigerant recycling mode Operation status Fo

X-fan Operation status AL

Defrosting or oil return i n heating mode Operation status H1

Start failure of compressor

High discharge temperature protection of compressor E4

Overload protection E8

Whole unit over- current protection E5

Compressor phase current protection P5

Compressor de- synchronizing H7

Compressor phase- lacking/phase- inverse protection Ld

IPM modular protection H5

DC bus-bar low voltage protection PL

DC bus-bar high voltage protection PH

PFC protection HC

The four - way valve is abnormal U7

Viewing malfunction code through remote controller within 200s;

displayed directly on nixie tube after 200s

Hardware malfunction dn

Operation status dd

Viewing malfunction code through remote controller within 200s;

displayed directly on nixie tube after 200s

Nixie

tube

P8

F0

PU

H3

Lc

38

TROUBLESHOOTING

This unit has on - board diagnostics. Error codes are displayed on the wired remote controller and the outdoor unit microprocessor board with

colored LED lights. The table below explains the error codes on both.

SIZES 30, 36 & 42

Table 28—Malfunction Status Table

Name of malfunction

Compressor runs Flash once

Defrost Flash twice H1

Anti- freezing protection Flash 3 times E2

IPM protection Flash 4 times H5

AC over-current protection Flash 5 times E5

Over- burden protection Flash 6 times H4

Compressor exhaust high temperature protection Flash 7 times E4

Compressor overload protection Flash 8 times H3

Power protection Flash 9 times L9

EEPROM reads and write protection Flash 11 times

Low PN voltage protection Flash 12 times PL

Over voltage protection for PN Flash 13 times PH

PFC protection Flash 14 times HC

PFC module temperature protection Flash 15 times oE

Low pressure protection Flash 17 times E3

High pressure protection Flash 18 times E1

Limit/decline frequency(electric current) Flash 1 times

Frequency limit(exhaust) Flash 2 times

Frequency limit(Over-burden) Flash 3 times

Outdoor ambient sensor malfunction Flash 6 times F3

Outdoor tube sensor malfunction Flash 5 times F4

Exhaust sensor malfunction Flash 7 times F5

Attain the temperature of switch on Flash 8 times

Frequency limit(power) Flash 13 times

Outdoor fan malfunction Flash 14 times

Frequency limit(PFC module temperature) Flash 15 times

PFC module sensor malfunction Flash 16 times oE

Liquid pipe temperature sensor malfunction of A Flash 17 times

Gas pipe temperature sensor malfunction of A Flash 18 times

Liquid pipe temperature sensor malfunction of B Flash 19 times

Gas pipe temperature sensor malfunction of B Flash 20 times

Liquid pipe temperature sensor malfunction of C Flash 21 times

Gas pipe temperature sensor malfunction of C Flash 22 times

Liquid pipe temperature sensor malfunction of D Flash 23 times

Gas pipe temperature sensor malfunction of D Flash 24 times

Liquid pipe temperature sensor malfunction of E Flash 25 times

Gas pipe temperature

sensor malfunction of E Flash 26 times

Exit of the condenser tube sensor malfunction Flash 27 times

Correspondence is normal Flash 7

Communication failure between indoor unit and outdoor unit Often brigh t

Yellow light Red light Green light

The indicator display

Indoor display

times(n = indoor unit

number)

(indoor unit all Communication failure)

Indoor ambient sensor malfunction F1

Indoor evaporate sensor malfunction F2

Mode conflict E7

Accept fluorine mode Fo

Jumper cap malfunction protection C5

39

TROUBLESHOOTING

This unit has on - board diagnostics. Error codes are displayed on the wired remote controller and the outdoor unit microprocessor board with

colored LED lights. The table below explains the error codes on both.

SIZES 48 - 56

Table 29—Malfunction Status Table

Errors of definition