International Comfort Products CRECOMZR077A00, CRECOMZR079A00, CRECOMZR081A00 Installation Manual

CRECOMZR077A00

CRECOMZR079A00

CRECOMZR081A00

Small Rooftop Products

3 to 12 ½ Tons

Horizontal EconoMi$er X Accessory

Installation Instructions

Read these instructions completely before attempting to install the

Horizontal EconoMi$er X Accessory.

CONTENTS

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . 1

GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

ACCESSORIES LIST. . . . . . . . . . . . . . . . . . . . . 2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . 2-5

Sensor Usage. . . . . . . . . . . . . . . . . . . . . . . . . . 2

Accessories List. . . . . . . . . . . . . . . . . . . . . . . .2

Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . .6

Controller Setup and Menu Structure. . . . 7-10

Setup and Conguration. . . . . . . . . . . . . .11-14

Troubleshooting. . . . . . . . . . . . . . . . . . . . 14-15

Barometric Relief Chart. . . . . . . . . . . . . . . . . 15

Return Air Pressure Loss. . . . . . . . . . . . . . . 15

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can be

hazardous due to system pressure and electrical components. Only

trained and qualied service personnel should install, repair, or service

air-conditioning equipment.

Untrained personnel can perform the basic maintenance functions of

replacing lters. All other operations should be performed by trained

service personnel. When working on air-conditioning equipment, observe

precautions in the literature, tags, and labels attached to the unit, and

other safety precautions that may apply. Follow all safety codes. Wear

safety glasses and work gloves.

Recognize safety information. This is the safety-alert symbol . When

you see this symbol on the unit and in instructions or manuals, be alert to

the potential for personal injury.

Understand the signal words DANGER, WARNING, and CAUTION.

These words are used with the safety-alert symbol. DANGER identies

the most serious hazards which will result in severe personal injury or

death. WARNING signies a hazard which could result in personal

injury or death. CAUTION is used to identify unsafe practices which may

result in minor personal injury or product and property damage. NOTE is

used to highlight suggestions which will result in enhanced installation,

reliability, or operation.

WARNING

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal injury or death.

Before performing service or maintenance operations on the unit,

always turn off main power switch(es) to unit and install lockout

tag(s). Unit may have more than one power switch.

!

CAUTION

!

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and wear

appropriate protective clothing, safety glasses and gloves when

handling parts and servicing roof top units.

GENERAL

The EconoMi$er X system utilizes the latest technology available

for integrating the use of free cooling with mechanical cooling for

packaged rooftop units. The solid-state control system optimizes energy

consumption, zone comfort, and equipment cycling by operating the

compressors when the outdoor-air temperature is too warm, integrating

the compressor with outdoor air when free cooling is available, and

locking out the compressor when outdoor-air temperature is too cold.

Demand control ventilation is supported.

Units displaying 17th position of the model number to indicate that the

unit is equipped with the factory-installed VFD (Variable Frequency

Drive) option for 2-speed indoor fan control. The VFD option is required

for units equipped with EconoMi$er X. For detailed information on the

VFD see the Variable Frequency Drive (VFD) Installation, Setup and

Troubleshooting Supplement.

The EconoMi$er X system utilizes gear-drive technology with a directmount spring return actuator that will close upon loss of power. The

EconoMi$er X system comes standard with an outdoor air temperature

sensor, supply air temperature sensor, and low temperature compressor

lockout switch. Outdoor enthalpy, indoor enthalpy, and CO2 sensors are

available for eld installation. See Table 3 for sensor usage.

Standard barometric relief dampers provide natural building pressurization

control. An optional power exhaust system is available for applications

requiring even greater exhaust capabilities. The power exhaust set point

is adjustable at the EconoMi$er X controller.

See Table 1 for package usage. See Table 2 for package contents. See

Table 3 for sensor usage and table for accessories.

Table 1 - Package Usage

UNIT SIZE PART NUMBER

Small Cabinet,

Footprint Size: 46 3/4” x 74 3/8”

Large Cabinet,

Footprint Size: 58 1/2” x 88 1/8”

Extra-large Cabinet,

Footprint Size: 63 3/8” x 115 7/8”

CRECOMZR077A00

CRECOMZR079A00

CRECOMZR081A00

1

Table 2 - Package Contents

PACKAGE NO. QTY CONTENTS

1

Hood Assembly

1

Filter Access Door

1

Aluminum Filter

CRECOMZR077A00

CRECOMZR079A00

CRECOMZR081A00

18

Screws

1

EconoMi$er X Assembly

1

Front Blank Off Panel

1

Supply Air Temperature Sensor

1

Hood Assembly

1

Filter Access Door

1

Aluminum Filter

18

Screws

1

EconoMi$er X Assembly

1

Supply Air Temperature Sensor

1

Front Blank Off Panel

1

Horizontal Blank Off Panel

1

Hood Assembly

1

Filter Access Door

1

Aluminum Filter

1

Hardware Bag

1

EconoMi$er X Assembly

1

Front Blank-Off Panel

1

Horizontal Blank-Off Panel

1

Supply Air Temperature Sensor

Table 4 - EconoMi$er X Field-Installed

Accessories

DESCRIPTION PART NUMBER

Small & Large Cabinet Power Exhaust

208-230 v 1 Ph

Small & Large Cabinet Power Exhaust

460 v 3Ph

Extra Large Cabinet Power Exhaust

208-230 v 1Ph

Extra Large Cabinet Power Exhaust

460 v 3Ph

Enthalpy Sensor HH57AC081

CO2 Sensor and Aspirator Box CRCBDIOX005A00

Return Air CO2 Sensor (4 to 20 mA) CRCBDIOX002A00

CO2 Room Sensor (4 to 20 mA)

Aspirator Box for Duct Mount

CO2 Sensor (4 to 20 mA)

CRPWREXH028A01

CRPWREXH029A01

CRPWREXH082A00

CRPWREXH083A00

33ZCSENCO2 or

CGCDXSEN004A00

33ZCASPCO2 or

CGCDXASP001A00

INSTALLATION

WARNING

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury and/or

death.

Disconnect power supply and install lockout tag before attempting to

install accessory.

Table 3 - EconoMi$er X Sensor Usage

ECONOMI$ER X WITH OUTDOOR AIR

APPLICATION

Outdoor Air

Dry Bulb

Single

Enthalpy

Differential

Enthalpy

CO2 for

DCV Control

Using a

Wall-Mounted

CO2 Sensor

CO2 for

DCV Control

Using a

Duct-Mounted

CO2 Sensor

†33ZCSENCO2 and CGCDXSEN004A00 are accessory CO2 sensors.

**33ZCASPCO2 and CGCDXASP00100 are accessory aspirator boxes required for duct-mounted

applications.

††CRCBDIOX005A00 is an accessory that contains both 33ZCSENCO2 and 33ZCASPCO2

accessories.

33ZCSENCO2 or

CGCDXSEN004A00†

and

33ZCASPCO2 or

CGCDXASP00100**

DRY BULB SENSOR

Accessories Required

None. The outdoor air dry bulb sensor

is factory installed

HH57AC081

HH57AC081

33ZCSENCO2

or

CGCDXSEN004A00

CRCBDIOX005A00††

OR

ACCESSORIES LIST

The EconoMi$er X has several eld-installed accessories available to

optimize performance. Refer to Table 4 for authorized parts and power

exhaust descriptions

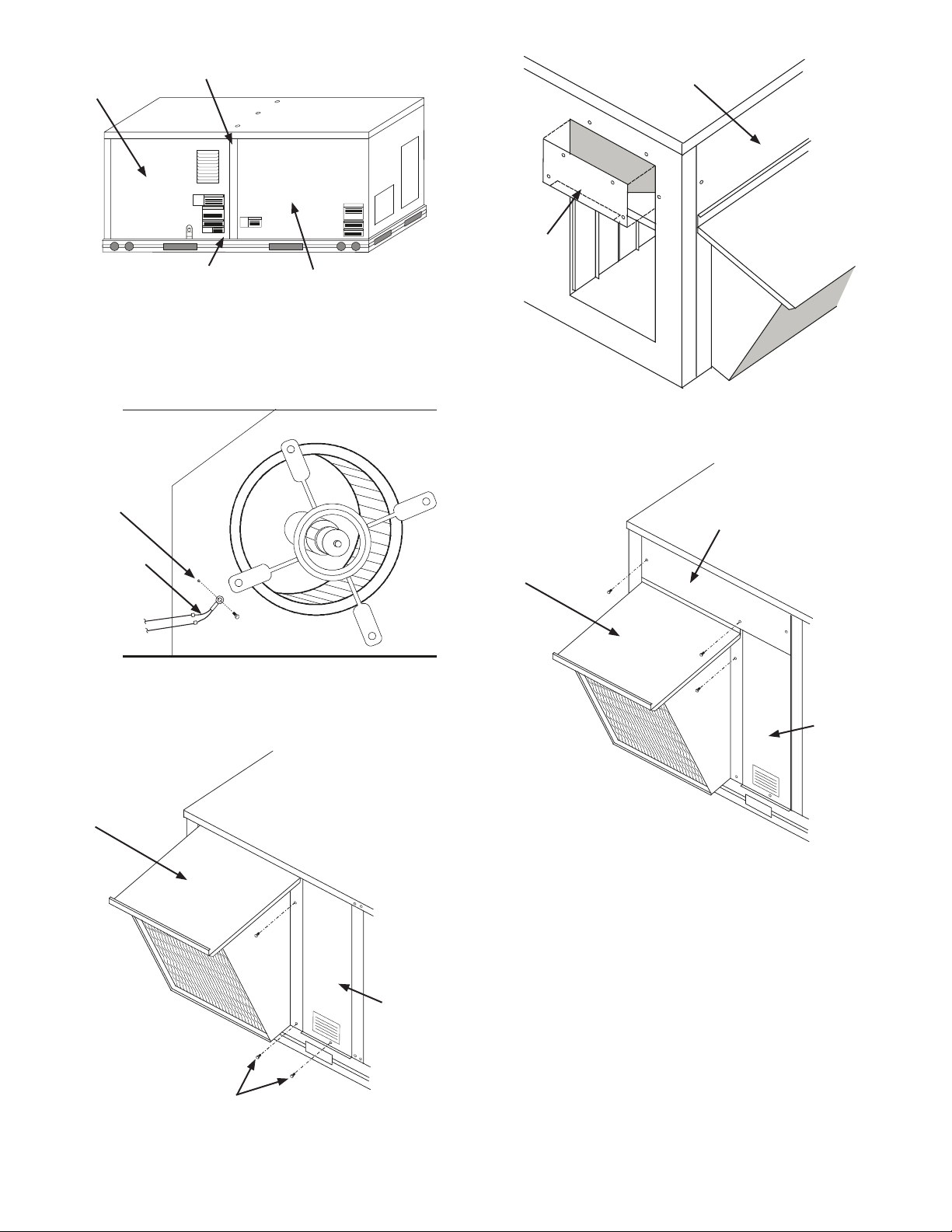

1. Turn off unit power supply(s) and install lockout tag.

2. Remove the existing unit lter access panel. Raise the panel and

swing the bottom outward. The panel is now disengaged from the

track and can be removed and discarded. (See Fig. 2.)

NOTE: Unit with hinged panels will require a hinged door seal angle

kit. Use part no. CRHNGPNL001A00 for small cabinet units. Use part

no. CRHNGPNL002A00 for large cabinet units. Refer to the separate

accessory installation instructions for details on installing the seal angle

kit.

3. Remove the indoor coil access panel and discard. (See Fig. 2.)

4. The EconoMi$er X hood assembly is shipped assembled. Aluminum

lter must be installed on some models. See step 13.

5. Set the EconoMi$er X upright. (See Fig. 4.)

6. If EconoMi$er X will be operating under enthalpy control, replace

the factory installed outdoor dry bulb temperature sensor with

accessory enthalpy sensor HH57AC081. (See Fig. 1.)

7. Insert the EconoMi$er X assembly into the rooftop unit, positioning

the EconoMi$er X to the far left side of the opening. (See Fig. 5.)

8. Slide the EconoMi$er X all the way back into the unit until it locks

into the horizontal opening of the HVAC (heating, ventilation and

air conditioning) unit.

9. Secure the EconoMi$er X mounting anges to the HVAC unit with

the screws provided. (See Fig. 6.)

10. Install a screw through the pre-punched hole in the EconoMi$er X

into the ange on the horizontal duct opening. (See Fig. 7.)

11. Remove the tape securing the relief dampers in place.

12. Remove and save the 12-pin jumper plug from the unit wiring

harness (located in the upper left corner of the unit). Insert the

EconoMi$er X plug into the unit wiring harness. Refer to Fig. 14

for wiring diagram.

NOTE: The 12-pin jumper plug should be saved for future use, in the

event that the EconoMi$er X is removed from the unit. The jumper plug

is not needed as long as the EconoMi$er X is installed.

2

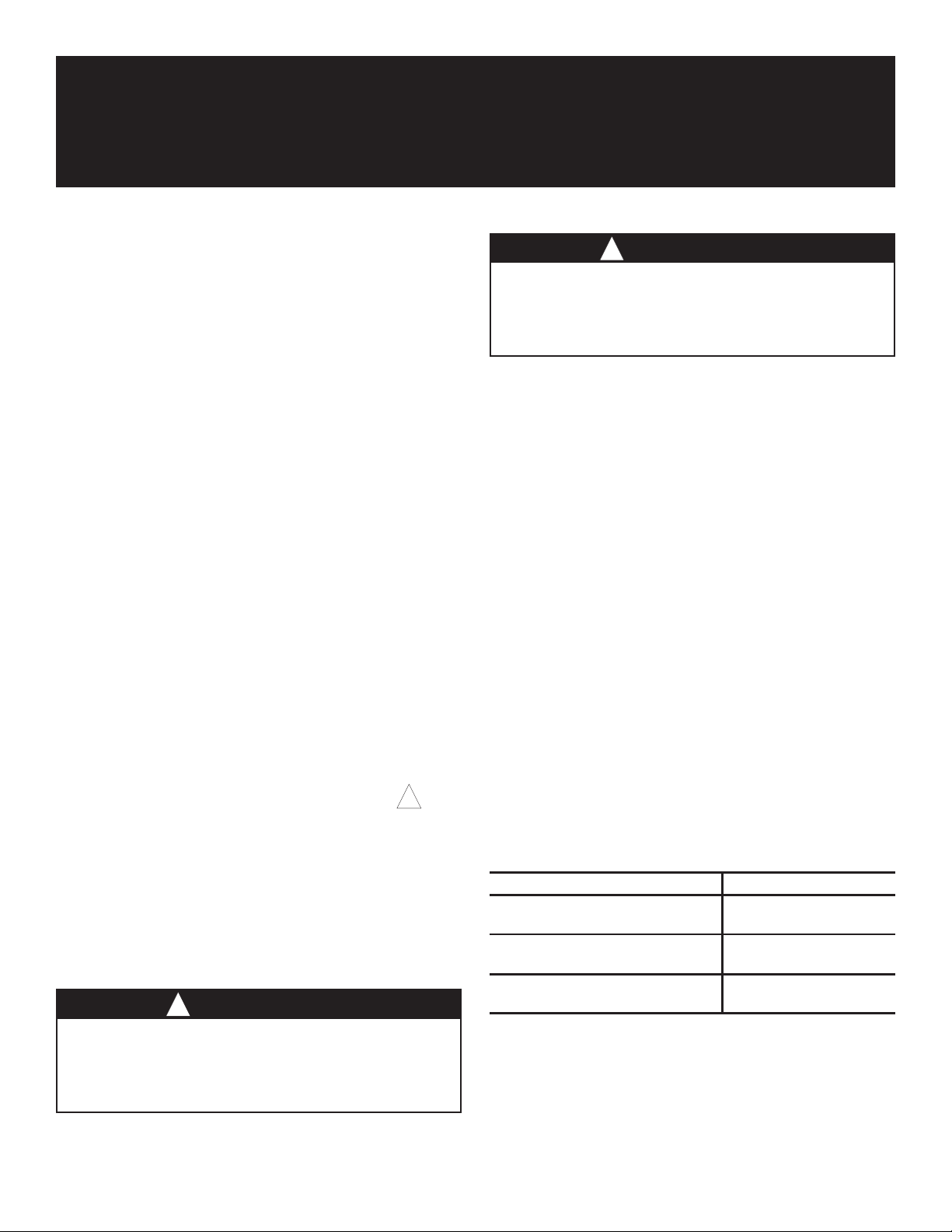

Wiring Harness

Outside Air

Temperature Sensor

Fig. 1 - EconoMi$er X Component Locations

Filter Access Panel

Fig. 4 - EconoMi$er X Positioned

for Installation in Unit

Compressor

Access Panel

Outdoor-Air Opening and

Indoor Coil Access Panel

Fig. 2 - Typical Outdoor Air Section

Access Panel Locations

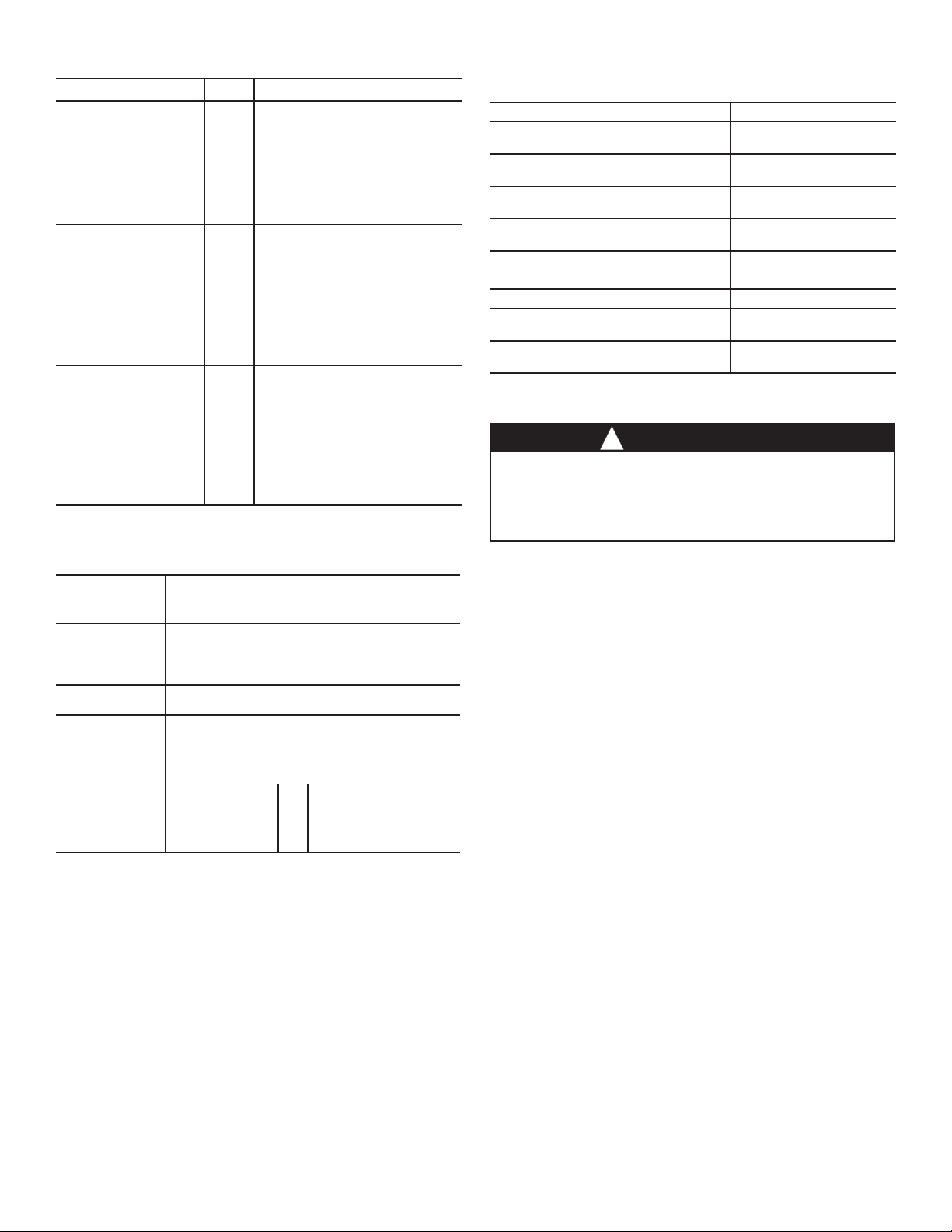

A

HOOD

ALUMINUM

FILTER

FILTER

B

OUTSIDE AIR

RELIEF AIR

ECONOMIZER P/N A B SHIP WT.

CRECOMZR077A00 27.09” 29.19” 95 lb

CRECOMZR079A00 29.21” 37.25” 150 lb

CRECOMZR081A00 24.81” 53.36 245lb

CLEANABLE

ALUMINUM

FILTER

CLIP

Fig. 3 - EconoMi$er X Hood Detail

Fig. 5 - Top View of EconoMi$er X Installation

Barometric

Relief Dampers

Mounting

Screws

Outdoor

Air Damper

Outside Air

Temperature

Sensor

Fig. 6 - EconoMi$er X Installed in Unit

3

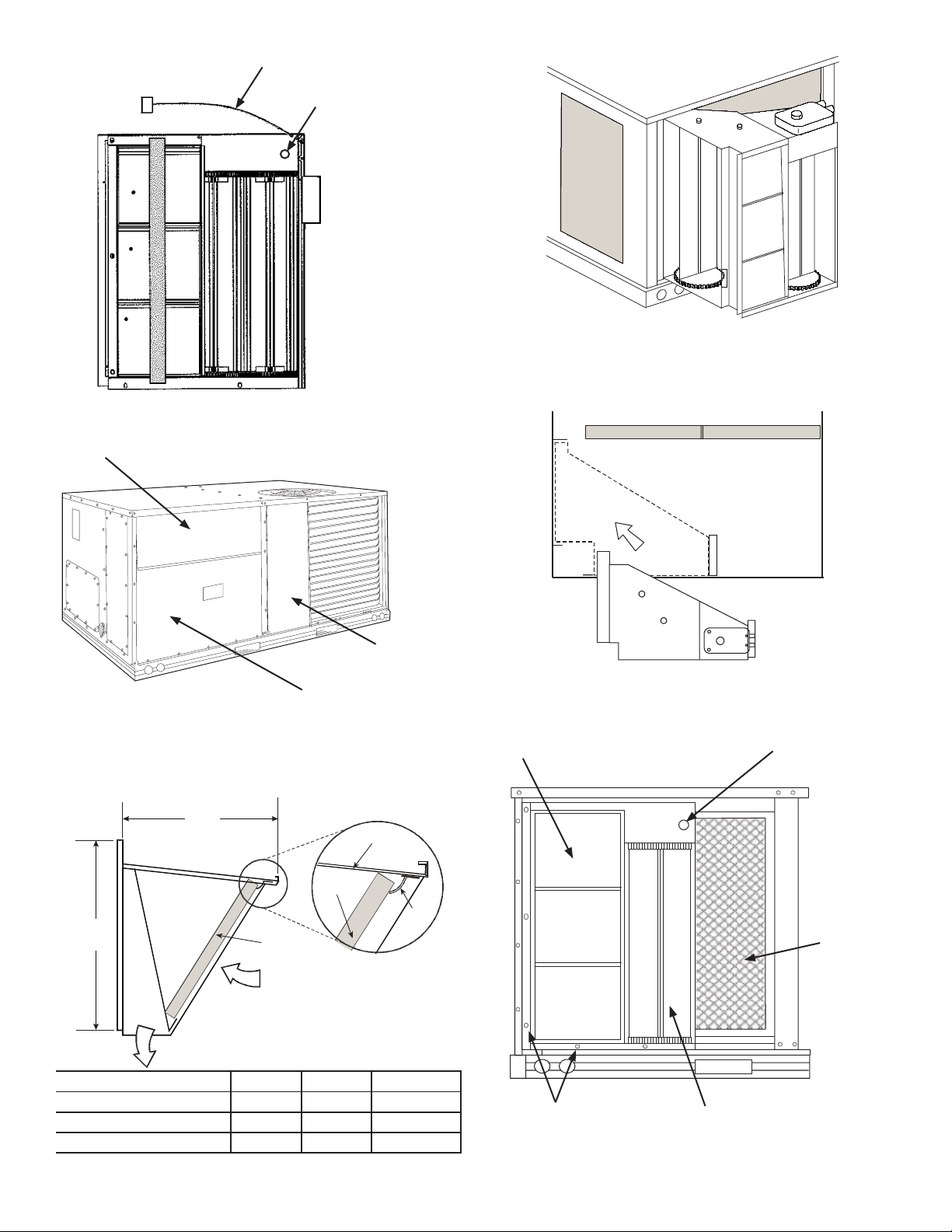

HVAC

Filters

Filters

Screw

EconoMi$er X

Plug

Wiring

Harness

EconoMi$er X

Actuator

Fig. 7 - Top View of EconoMi$er X

Installed in Unit

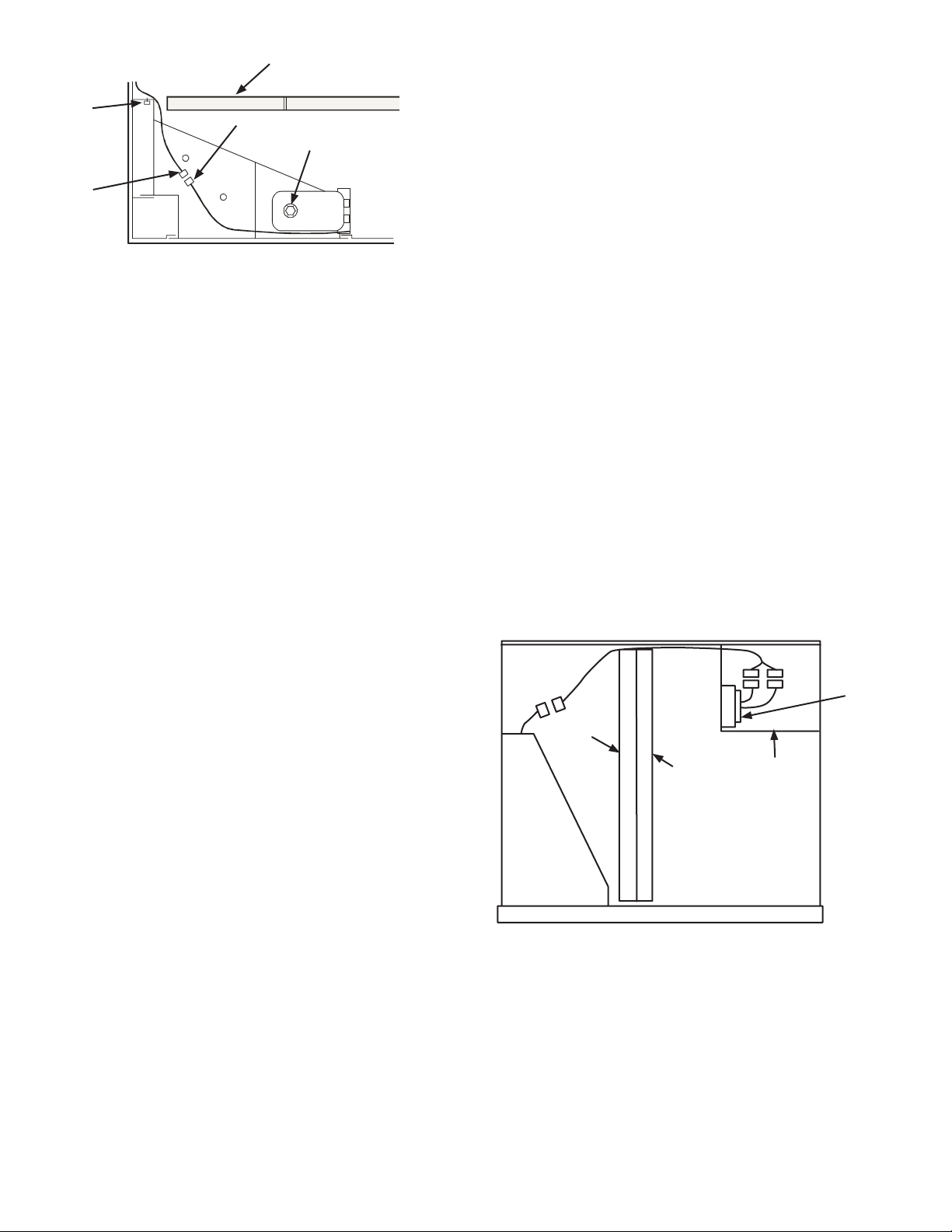

13. Remove the indoor fan motor access panel. (See Fig. 9.)

14. The supply air temperature sensor looks like an eyelet terminal with

wires running to it. The sensor is located on the “crimp end” and

is sealed from moisture. Mount the supply air temperature sensor

(provided) to the lower left section of the indoor fan blower housing.

(See Fig. 10.) Use the screw provided and use existing hole. Connect

the violet and pink wires to the corresponding connections on the

supply air temperature sensor. (See Fig. 14.) Reinstall the indoor

fan motor access panel.

15. While everything is open install and wire any other accessories

and/or sensors as applicable and convenient, per their installation

instructions and/or the Conguration section of this instruction.

Some accessories require that unit ducting already be installed.

16. On some units the EconoMi$er X and hood does not reach to the

top of the unit. In this case a front blank-off panel must be installed.

Install provided front blank-off panel above hood. Screw in place.

(See Fig. 13.)

NOTE: The front blank-off panel must be installed before the hood

because the top of the hood ts into a channel in the bottom of the

panel.

17. Install the EconoMi$er X hood over the EconoMi$er X. Use screws

provided. (See Fig. 11 and 13.) Insert screw through right side ange

of hood into EconoMi$er X ange.

18. On some units the return damper does not reach to the top of the

horizontal return opening in the unit. In this case a horizontal blankoff must be installed. Install the horizontal blank-off at the top of

the horizontal return opening. (See Fig. 12.) Screw in place thru

pre-punched holes.

19. The W7220 EconoMi$er X controller is shipped mounted to a

bracket. Install the controller / bracket in the top left corner of the

unit control box as shown in wiring diagram, Fig. 14. Screw in

place through pre-punched holes.

20. Connect the plugs coming from the controller as shown in wiring

diagram, Fig. 7, 8 and 14.

21. Adjust controller settings (minimum position, outside air, etc.) per

instructions detailed later in this instruction.

22. Follow all local and other applicable codes.

23. Check all wiring for safety then reapply power to the unit.

Verify correct operation and setting of the accessory(s) per the

Conguration and Operations sections of the instruction.

24. Install access door next to hood. Screw bottom of door to HVAC

unit. (See Fig. 11 and 13.) For the economizer for the extra large

cabinet, install plastic inserts on right-hand vertical post and install

long gasketed screws along the vertical edge. Use standard serrated

screws along the bottom of the panel for all units.

25. Replace the indoor fan motor access panel.

26. Install the lter by opening the lter clips which are located

underneath the hood top. Insert the aluminum lter into the bottom

lter rack (hood divider). Push the lter into position past the open

lter clips. Close the lter clips to lock the lter into place. (See Fig.

3.)

Filter

Economizer

Coil

Control

Box

Fig. 8 - Harness Detail

W7220

Controller

4

Thermostat

Connection

Access Panel

Center Post

Front Blank-Off Panel

Heating Access

Panel

Indoor Fan Motor

Access Panel

Fig. 9 - Typical Indoor Fan Motor

Access Panel Locations

Supply Air

Temperature

Sensor

Mounting

Location

Supply Air

Temperature

Sensor

To Unit

Control Box

Fig. 10 - Mixed Air Sensor Placement

Horizontal

Blank-Off

EconoMi$er X

Hood

Fig. 12 - Horizontal Return Opening Blank-Off Panel

Front Blank-Off Panel

EconoMi$er X

Hood

EconoMi$er X

Hood

Fig. 11 - EconoMi$er2 Hood Installation

Access Door

to Filters

Fig. 13 - Front Blank-Off Panel Installation Panel

Access Door

to Filters

Screws

5

Loading...

Loading...