CPLOWAMB001A00

ELECTRIC COOLING AND HEAT PUMP UNITS

Installation Instructions

IMPORTANT: Read these instructions completely before

attempting to install this accessory.

PACKAGE CONTENTS

ITEM QTY CONTENTS

AL56AU216 4 Screws 10B--- 16 x ½ LG

50DK402769 1 Conductive Grease

AU27AS131 2 Lockwashers, #10

50HS500288 1 Bracket

I I K --- C P LO WA M B --- 0 6 1 Instructions

SMALL ROOFTOP UNITS

GAS HEAT/ELECTRIC COOLING,

ACCESSORY MOTORMASTERR II

HEAD PRESSURE CONTROLLER 60Hz

3to12---1/2tons

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal

injury or death.

Before performing service or maintenance

operations on unit, turn off main power switch to

unit and install lockout tag. Ensure electrical service

to rooftop unit agrees with voltage and amperage

listed on the unit rating plate.

SAFETY CONSIDERATIONS

Installation, start--up and servicing of this equipment can

be hazardous due to system pressures, electrical

components and equipment location (roofs, elevated

structures, etc.)

Untrained personnel can perform the basic maintenance

functions. All other operations should be performed by

trained service personnel. When working on

air--conditioning equipment, observe precautions in the

literature, tags and labels attached to the unit, and other

safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves.

Recognize safety information. This is the safety--alert

symbol

instructions or manuals, be alert to the potential for

personal injury.

Understand the signal words DANGER, WARNING, and

CAUTION. These words are used with the safety--alert

symbol. DANGER identifies the most serious hazards

which will result in severe personal injury or death.

WARNING signifies a hazard which could result in

personal injury or death. CAUTION is used to identify

unsafe practices which may result in minor personal

injury or product and property damage. NOTE is used to

highlight suggestions which will result in enhanced

installation, reliability, or operation.

. When you see this symbol on the unit and in

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Open all remote disconnects and install lockout tag(s)

before servicing this equipment.

INTRODUCTION

The Motormaster II head pressure controller is a cycle

control device activated by a temperature sensor mounted

on a header tube of the outdoor coil. (See Fig. 1.) It is

designed to cycle the outdoor-fan motors on or off to

maintain the saturated condensing temperature within

normal operating limits of approximately 130_ to 110_F

high, 70_ to 50_F low. The controller maintains working

head pressure at low ambient temperatures down to 0_F.

The controller is activated by a temperature sensor and is

for use with 60 Hz units only. The controller can be used

with both single-phase and 3-phase units.

NOTE: This accessory requires Winter Start package.

Copyright 2011 CAC / BDP D 7310 W. Morris St. D Indianapolis, IN 46231 Printed in U.S.A. Edition Date: 12/11

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

Catalog No:IIK --- CPLOWAMB --- 06

R e p la ce s : I I K --- C P LO W A MB --- 0 4

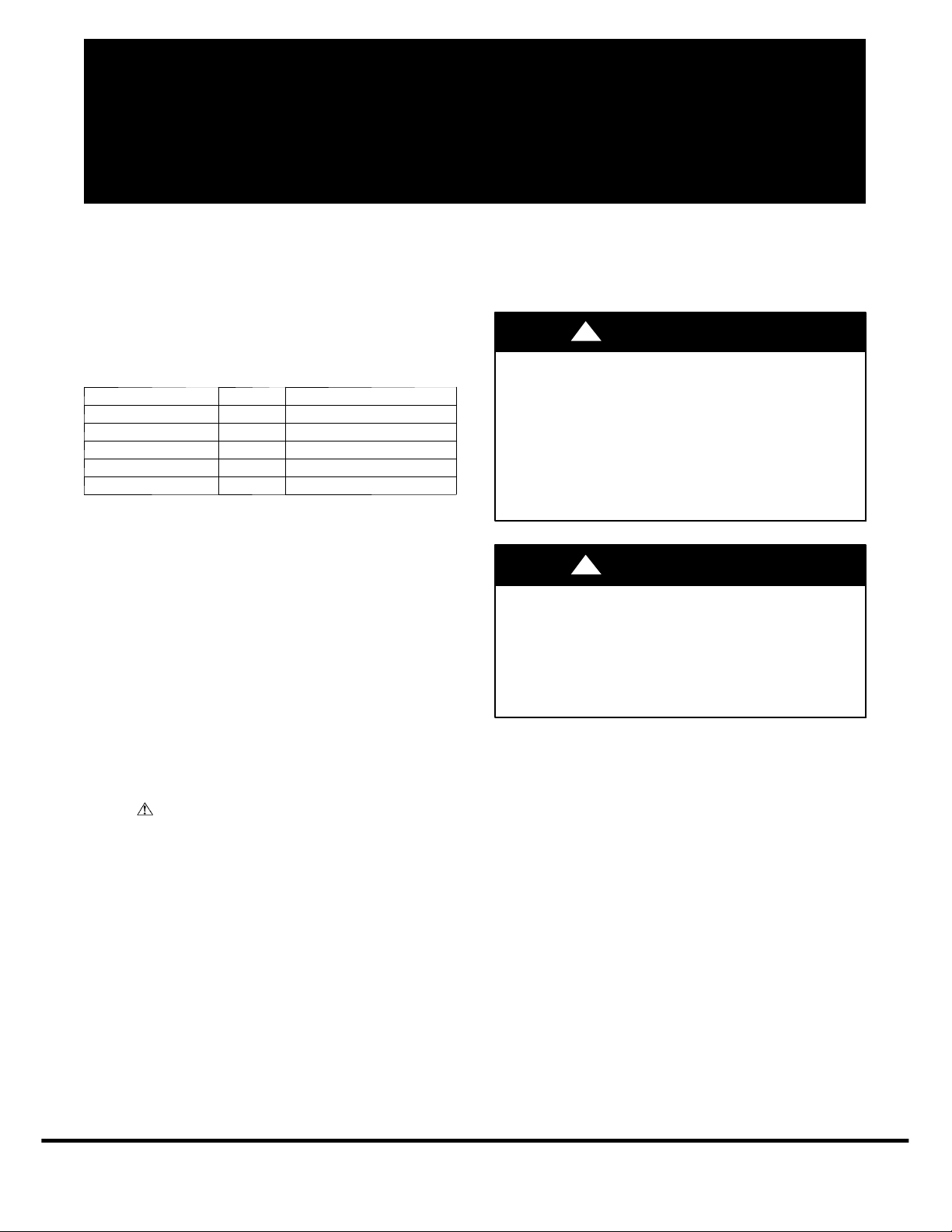

C08282

Fig. 1 -- Motormaster II Controller

1. Disconnect power to unit, install lockout tag.

2. Disconnect outdoor-fan motor (OFM) wires at the

contactor.

3. Remove OFM wires from unit control box.

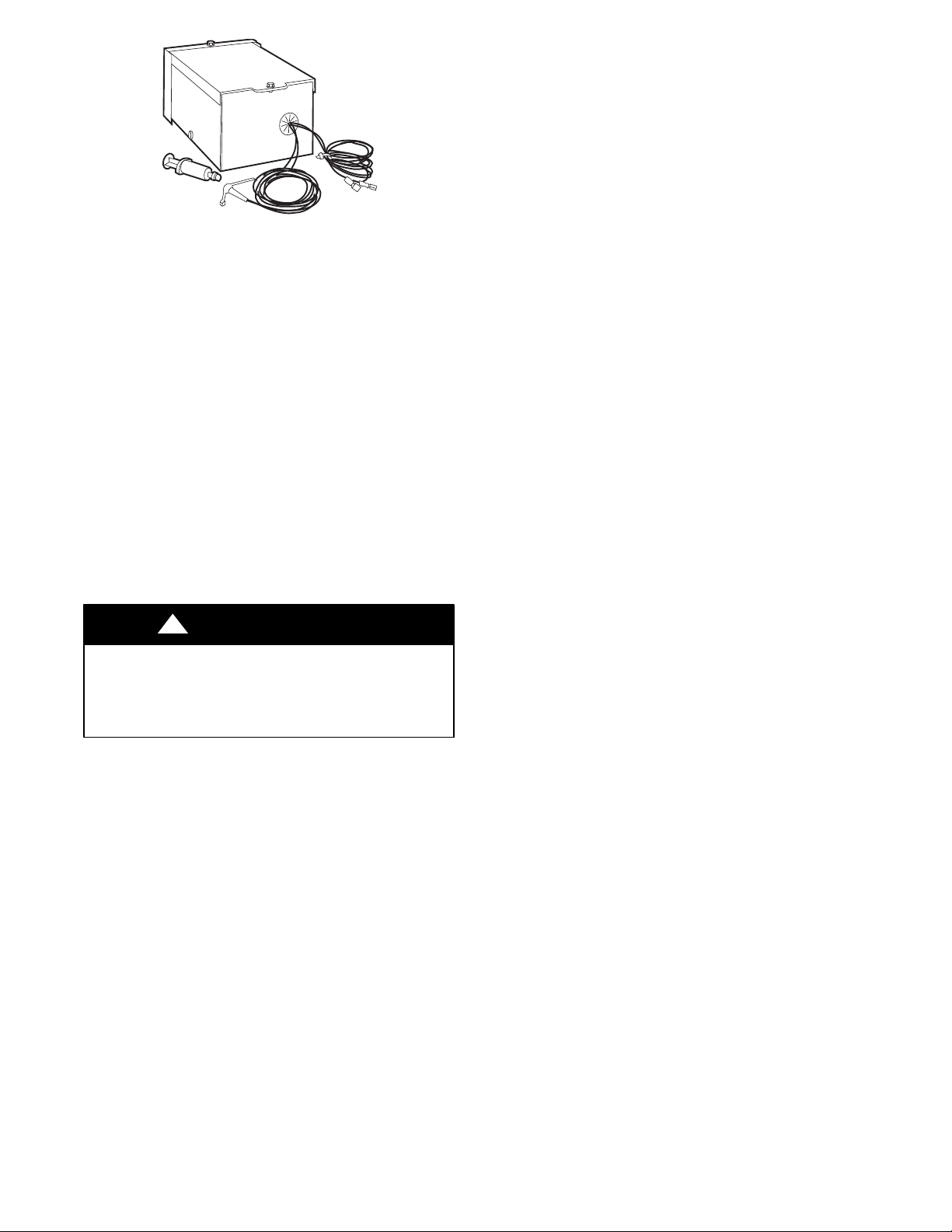

4. Mount Motormaster II controller on unit. Refer to

Fig. 2.

NOTE: The controller must be mounted vertically with

the leads at the bottom.

Using the template supplied on the last page in this book,

drill mounting holes. To ensure electrical ground, insert

star washers (supplied with the controller) under the heads

of mounting screws.

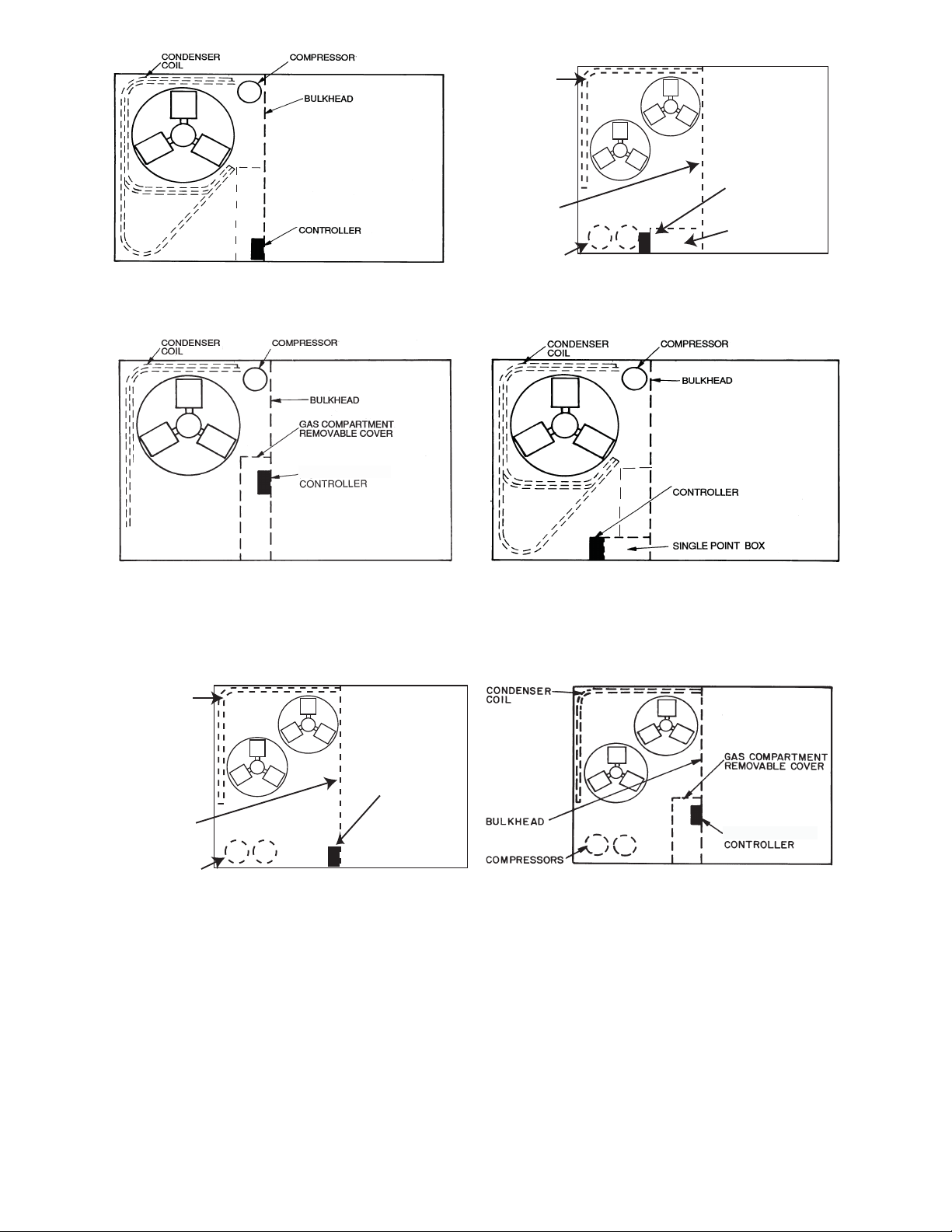

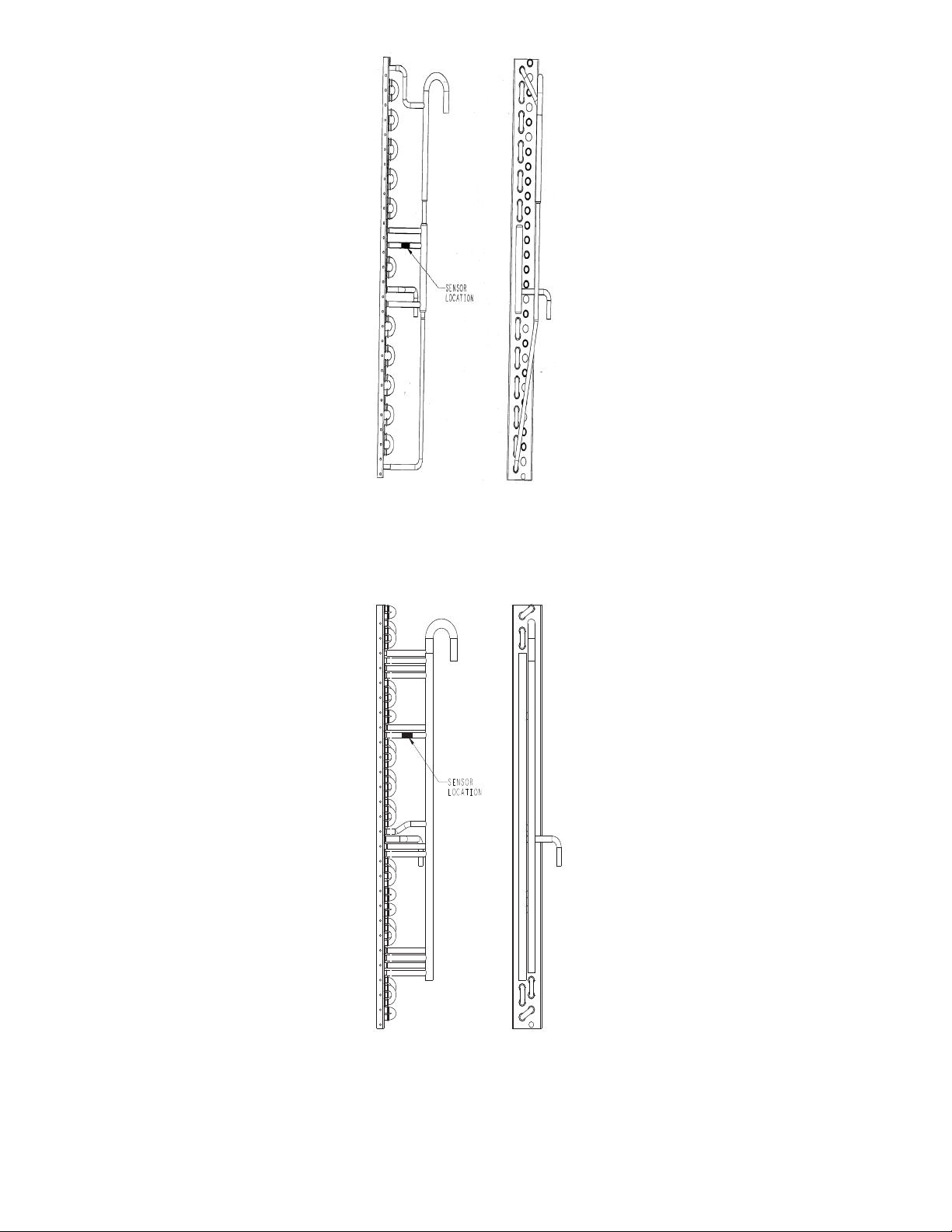

5. Determine sensor location by referring to Fig. 3-12.

Route sensor wire through bottom of Motormaster II

controller (Fig. 13) to sensor location specified. Prior to installation, apply conductive grease supplied

with accessory to contact surface of sensor.

!

CAUTION

6. Attach sensor to top half of header tube as shown in

Fig. 14. Installed sensor must be left uninsulated.

7. Power wiring must comply with all local and National Electrical Code (NEC) requirements. Refer to

Fig. 15-18 for power wiring connections. Coil up all

excess wire and secure it next to the controller.

8. The transformer is factory wired for 460-v operation. It must be rewired for 208/230-v use. Remove

the black wire from L2 to 460-v black and connect

red wire (208 v) or orange wire (230 v) to L2 for

desired operation. Install wire nuts over wires not in

use.

NOTE: Refer to Fig. 19 for thermistor resistance vs

temperature.

9. Wind baffles are required to prevent wind crosscurrents from causing abnormally low condensing temperatures. Wind baffle fabrication details are described in Fig. 20 and 21.

10. Reconnect power to the unit.

The Motormaster II head pressure controller is equipped

with an alternate operating mode. When this mode is

selected, the controller shifts the fan cycle sequence to

effectively raise the average condensing temperature

approximately 20_F higher than the standard operating

mode. In this alternate mode, the outdoor fan begins

cycling at higher outdoor ambient temperatures. This

mode should only be used if the evaporator coil shows

signs of frosting at low outdoor ambient temperatures.

To select the alternate operating mode, move the jumper

wire on the Motormaster II control board from terminal

T1 to terminal T2.

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in damage to

equipment.

Sensor assembly is delicate. Handle with care.

2

MOTORMASTER II

50TC04--07; RAS036--072; 558J04--07

UNITS WITHOUT SINGLE POINT BOX

MOTORMASTER II

MOTORMASTER II

C10715

CONDENSER

OIL

BULKHEAD

COMPRESSORS

50TC08--12; RAS090--121; 558J08--12

UNITS WITH SINGLE POINT BOX

MOTORMASTER III

CONTROLLER

SINGLE POINT

BOX

C10716

MOTORMASTER II

48TC04--07; RGS036--072; 580J04--07

UNITS WITHOUT SINGLE POINT BOX

CONDENSER

OIL

BULKHEAD

COMPRESSORS

50TC08--12; RAS090--121; 558J08--12

UNITS WITHOUT SINGLE POINT BOX

C10718

50TC04--07; RAS036--072; 558J04--07

UNITS WITH SINGLE POINT BOX

MOTORMASTER II

CONTROLLER

C10719

48TC08--12; RGS090--121; 580J08--12

UNITS WITH SINGLE POINT BOX

Fig. 2 -- Motormaster II Controller Location

C10717

MOTORMASTER II

C10720

3

48/50TC04;

C08615

RGS/RAS036;

580J/558J04

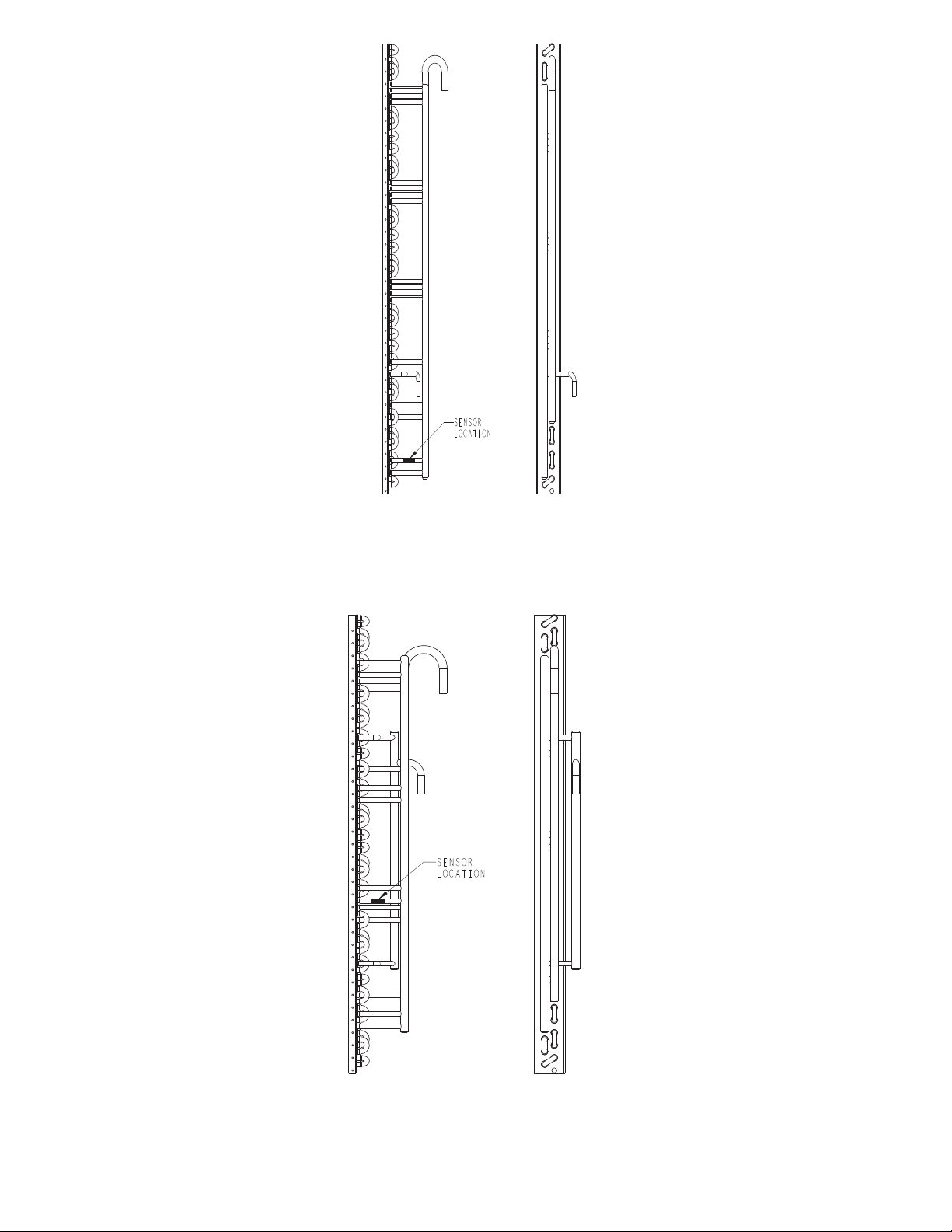

Fig. 3 -- MotormasterR II Sensor Locations -- 3 Ton Cooling Units

48/50TC05 and 06;

C08260

RGS/RAS048 and 060;

580J/558J05 and 06

Fig. 4 -- MotormasterR II Sensor Locations -- 4 and 5 Ton Cooling Units

4

48/50TC07;

C08261

RGS/RAS072;

580J/558J07

Fig. 5 -- MotormasterR II Sensor Locations -- 6 Ton Cooling Units

48/50TC08;

C08616

RGS/RAS090, 091;

580J/558J08

Fig. 6 -- MotormasterR II Sensor Locations -- 7--1/2 Ton Cooling Units

5

Loading...

Loading...