Part Number:

CPECOMZR010A00

SMALL PACKAGED PRODUCT (2-3 TON UNITS)

HORIZONTAL ECONOMIZER ACCESSORY

EXCLUDING 3 TON 14 SEER HP AND DUAL FUEL MODELS

Installation Instructions

Read these instructions completely before attempting to install the

Vertical Economizer Accessory.

CONTENTS

SAFETY CONSIDERATIONS.............................1

GENERAL...........................................................1,2

ACCESSORIES LIST............................................2

INSTALLATION.................................................2-6

CONFIGURATION..........................................6-10

ECONOMIZER CONTROL MODES............6

OPERATION ........................................................10

SEQUENCE OF OPERATION......................10

PERFORMANCE DATA.....................................11

TROUBLESHOOTING..................................11-12

WIRING DIAGRAMS ..................................13-18

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can be

hazardous due to system pressure and electrical components. Only

trained and qualied service personnel should install, repair, or service

air-conditioning equipment.

Untrained personnel can perform the basic maintenance functions of

replacing lters. All other operations should be performed by trained

service personnel. When working on air-conditioning equipment,

observe precautions in the literature, tags, and labels attached to the

unit, and other safety precautions that may apply.

Recognize safety information. This is the safety-alert symbol .

When you see this symbol on the unit and in instructions or manuals,

be alert to the potential for personal injury. Understand these signal

words; DANGER, WARNING, and CAUTION. These words are

used with the safety-alert symbol. DANGER identies the most

serious hazards which will result in severe personal injury or death.

WARNING signies hazards which could result in personal injury

or death. CAUTION is used to identify unsafe practices which may

result in minor personal injury or product and property damage.

NOTE is used to highlight suggestions which will result in enhanced

installation, reliability, or operation.

Follow all safety codes. Wear safety glasses, protective clothing, and

work gloves. Use quenching cloth for brazing operations. Have a re

extinguisher available. Read these instructions thoroughly and follow

all warnings or cautions included in literature and attached to the

unit. Consult local building codes and current editions of the National

Electrical Code (NEC) NFPA 70. In Canada, refer to current editions

of the Canadian electrical code CSA 22.1.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or

death.

Before installing, modifying, or servicing system, main electrical

disconnect switch must be in the OFF position and install a lockout

tag. There may be more than 1 disconnect switch. Lock out and

tag switch with suitable warning label.

!

CAUTION

!

UNIT PERFORMANCE AND COMPONENT HAZARD

Failure to follow this caution may result in unit damage.

For cooling operation, the recommended airow is 350 to 450

cfm for each 12,000 Btuh of rated cooling capacity. For heating

operation, the airow must produce a temperature rise that falls

within the range stamped on the unit rating plate.

GENERAL

Economizers are recommended for use with only commercial

packaged products that have ECM motors. The Economizer system

utilizes the latest technology available for integrating the use of free

cooling with mechanical cooling for rooftop units. The solid state

control system optimizes energy consumption, zone comfort, and

equipment cycling by operating the compressors when the outdoor-air

temperature is too warm, integrating the compressor with outdoor air

when free cooling is available, and locking out the compressor when

outdoor-air temperature is too cold. Demand ventilation is supported.

The Economizer system utilizes gear-drive technology with a directmount spring return actuator that will close upon loss of power. The

Economizer system comes standard with an outdoor air temperature

sensor, a supply air temperature sensor, and low temperature

compressor lockout switch. Indoor enthalpy sensor, outdoor enthalpy

sensors and CO2 sensors are available for eld installation.

See Table 1 for package contents. See Table 3 for sensor usage.

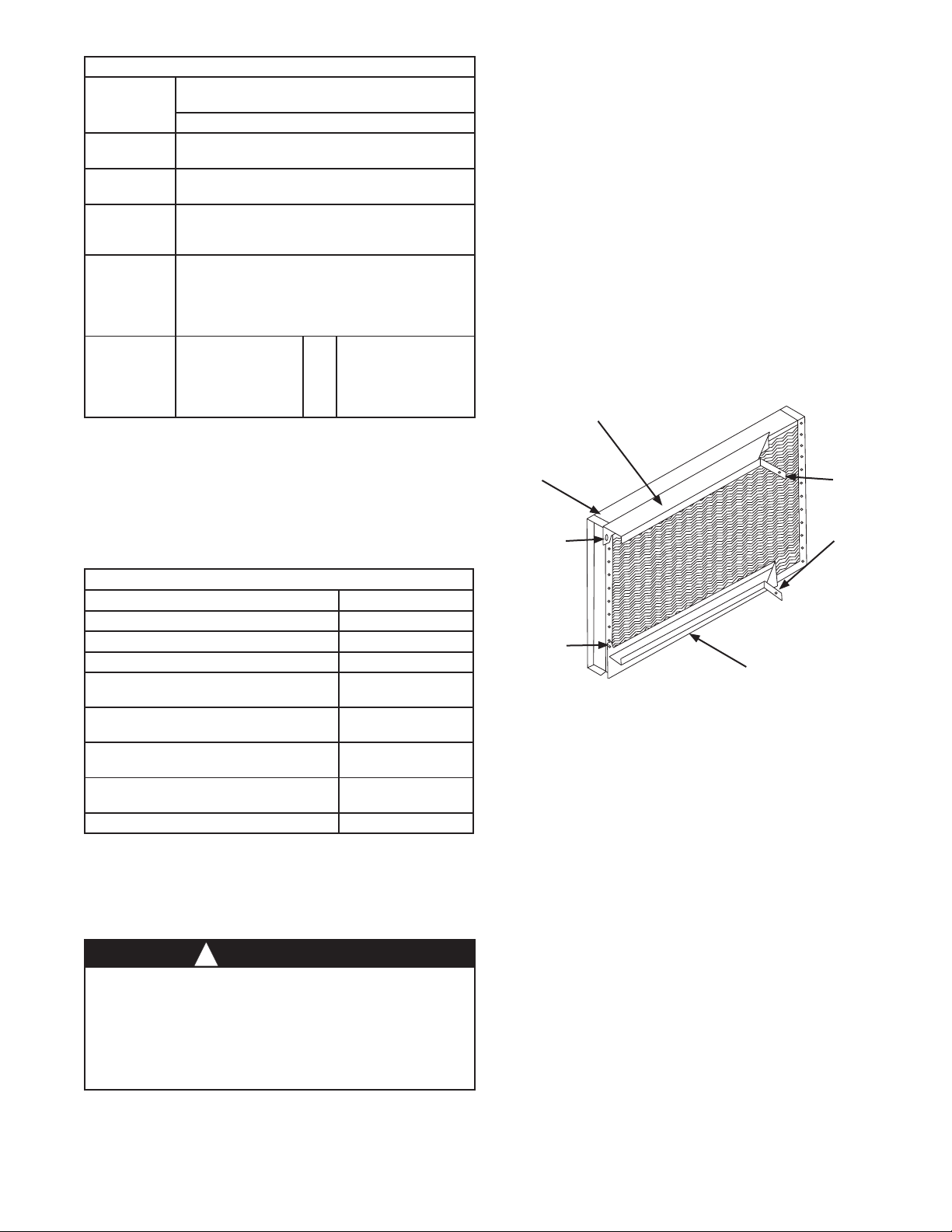

Table 1 - Package Contents

PART NUMBER QTY DESCRIPTIONS

1 Hood Top and Sides

1 Aluminum Filter

11 #10 Self-Drilling Screw and Washers

4 #10 x 1/2” Blunt End Screws

3 #10 x 1” Self-Drilling Screws

1 Economizer Assembly

1

CPECOMZR010A00

2 1” 12 x 20 Filter*

1 Top Filter Rack

1 Bottom Filter Rack

1 Replacement Return Chamber Panel

1 Compressor Cover Panel

1 Extension Harness w/ Plug

2 Wiring Diagram Labels

1 Installation Instruction

Table 2 - Filter Sizes

Part No. 1-IN. Filter Size 2-IN. Filter Size

CPECOMZR010A00 2 - 12 X 20 (304.8 X 508MM)

*Unscrew two brackets on the top lter rack to t 2-in. (50.8mm) lters.

Supply Air Temperature Sensor

with Bracket

1 - 10 X 20 (254 X 508MM)

1 - 12 X 20 (304.8 X 508MM)

1

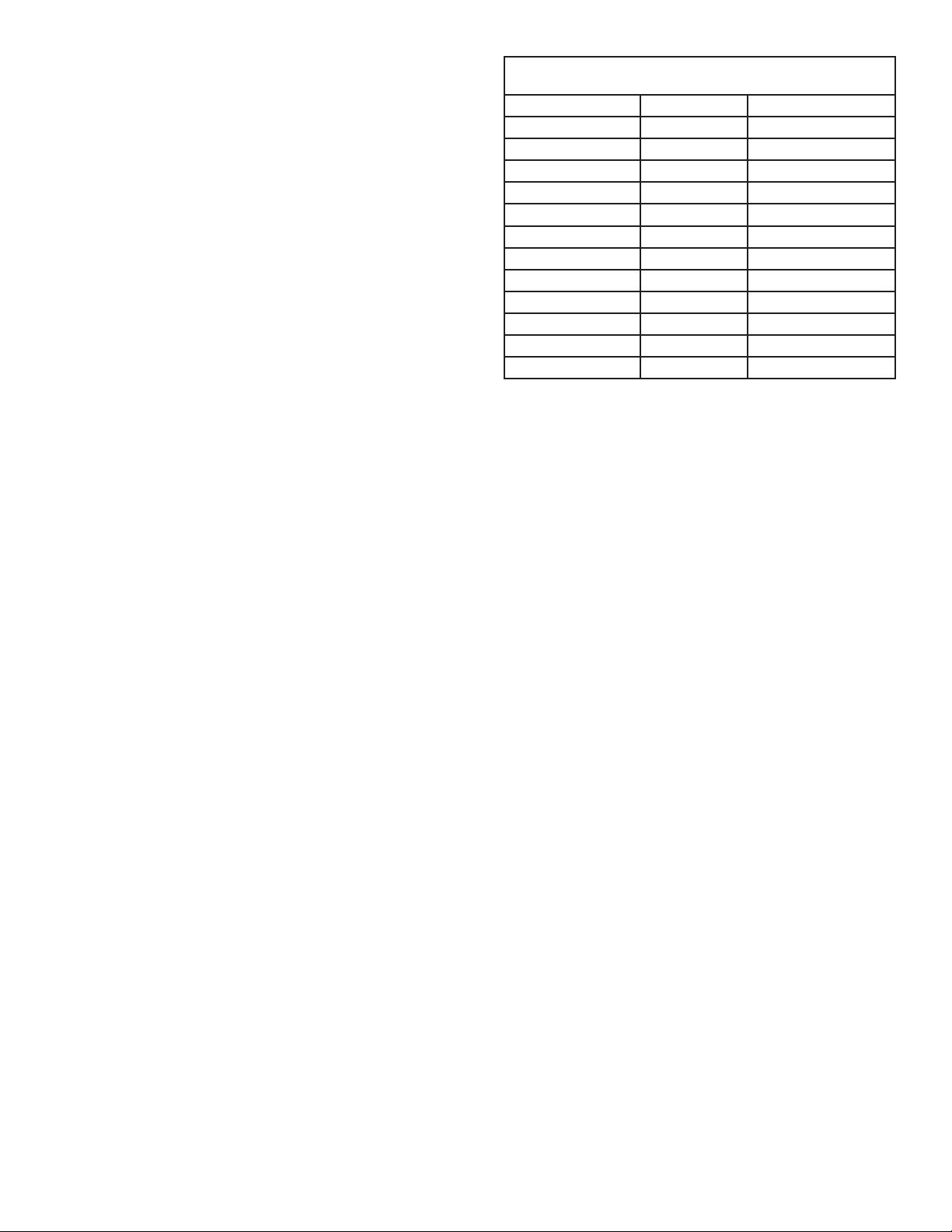

Table 3 - Economizer Sensor Usage

ECONOMIZER WITH OUTDOOR AIR

APPLICATION

Outdoor Air

Dry Bulb

Single

Enthalpy

Differential

Enthalpy

CO2 for

DCV Control

Using a

Wall-Mounted

CO2 Sensor

CO2 for

DCV Control

Using a

Duct-Mounted

CO2 Sensor

*CRENTDIF004A00 accessory is used on many different base units. As such, these kits may

contain parts that will not be needed for installation.

†33ZCSENCO2 and CGCDXSEN004A00 are accessory CO2 sensors.

**33ZCASPCO2 and CGCDXASP00100 are accessory aspirator boxes required for ductmounted applications.

††CRCBDIOX005A00 is an accessory that contains both 33ZCSENCO2 and 33ZVASPCO2

accessories.

33ZCSENCO2 or

CGCDXASP00100†

33ZCASPCO2 or

CGCDXASP00100**

DRY BULB SENSOR

Accessories Required

None. The outdoor air dry bulb sensor

is factory installed

HH57AC078

HH57AC078

CRENTDIF004A00*

33ZCSENCO2

CGCDXSEN004A00

and

and

or

CRCBDIOX005A00††

OR

ACCESSORIES LIST

The economizer has several eld-installed accessories available to

optimize performance. Refer to Table 4 for authorized parts.

Table 4 - Economizer Field-Installed Accessories

DESCRIPTION PART NUMBER

Outdoor Air Enthalpy Sensor HH57AC078

Indoor Air Enthalpy Sensor CRENTDIF004A00

Return Air CO2 Sensor (4-20mA) CRCBDIOX005A00

CO2 Room Sensor (4-20mA)

Aspirator Box for Duct Mount

CO2 Sensor (4-20mA)

Space Temperature and CO2 Room Sensor

with Override (4-20mA)

Space Temperature and CO2 Room Sensor

with Override and Set Point (4-20mA)

Heat Pump Relay Package CPRLYKIT001A00

33ZCSENXO2 or

CGCDXSEN004A00

33ZCASPCO2 or

CGCDXASP001A00

33ZTCT56CO2

33ZCT56CO2

INSTALLATION

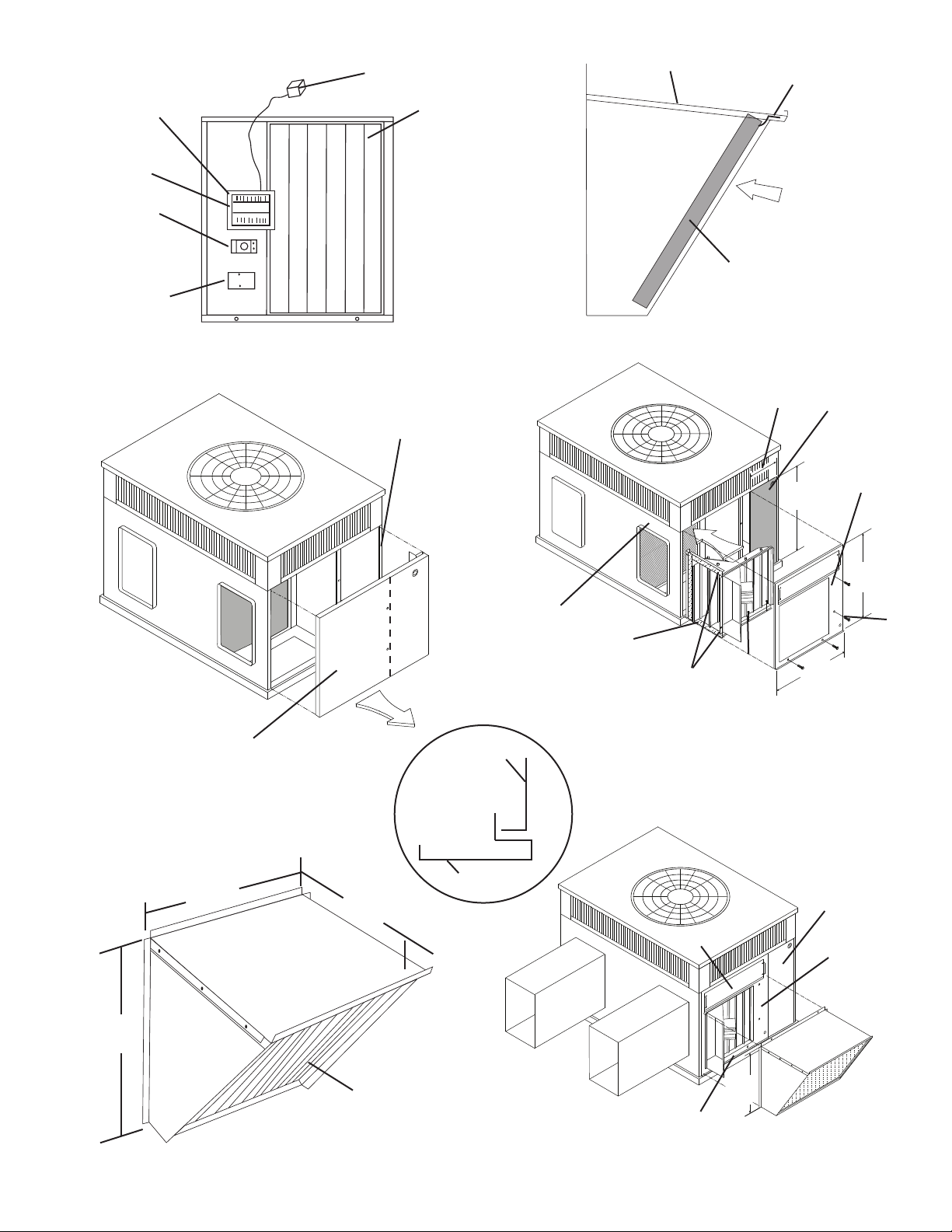

Economizer - See Fig. 2 for Economizer component locations. To

install the vertical Economizer perform the following procedure:

1. Turn off unit power supply and install lockout tag.

WARNING

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or

death.

Before installing or servicing system, always turn off main power

to system and tag. There may be more than one disconnect switch.

Turn off accessory heater power switch if applicable.

2. Remove the compressor access panel and unit side panel. See Fig.

3.

3. Remove the return air duct cover to aid in the installation.

4. Install the top lter rack in the HVAC unit next to the indoor coil.

Bend ange by hand at 90 degrees - Fig.1. Screw left side of rack in

to 4th hole down on coil frame. Use only 1/2” (12.7mm) long blunt

end screws. Make sure the bracket is level ant the right side of lter

bracket is pushed back against the coil then screw bent ange to unit

side panel using 1” long self-drilling screw provided. If using 2”

(50.8mm) lter the lter spacer must be removed.

NOTE: The lters are accessible through the access panel above the

hood.

Install the bottom lter rack. Bend ange 90 degrees - Fig.1. Screw

left side of rack to the coil frame. Use only 1/2” (12.7mm) long blunt

end screws. Make sure the bracket is level ant the right side of the

lter bracket is pushed back against the coil then screw bent ange

to unit side panel using 1” long self drilling screw.

Top lter rack

Evaporator

Coil

Screw rack

to coil frame

here

Screw rack

to coil frame

here

Bottom rack

Bend ange

at 900 and

screw to

divider with

1” long screw

Fig. 1 - Filter Rack

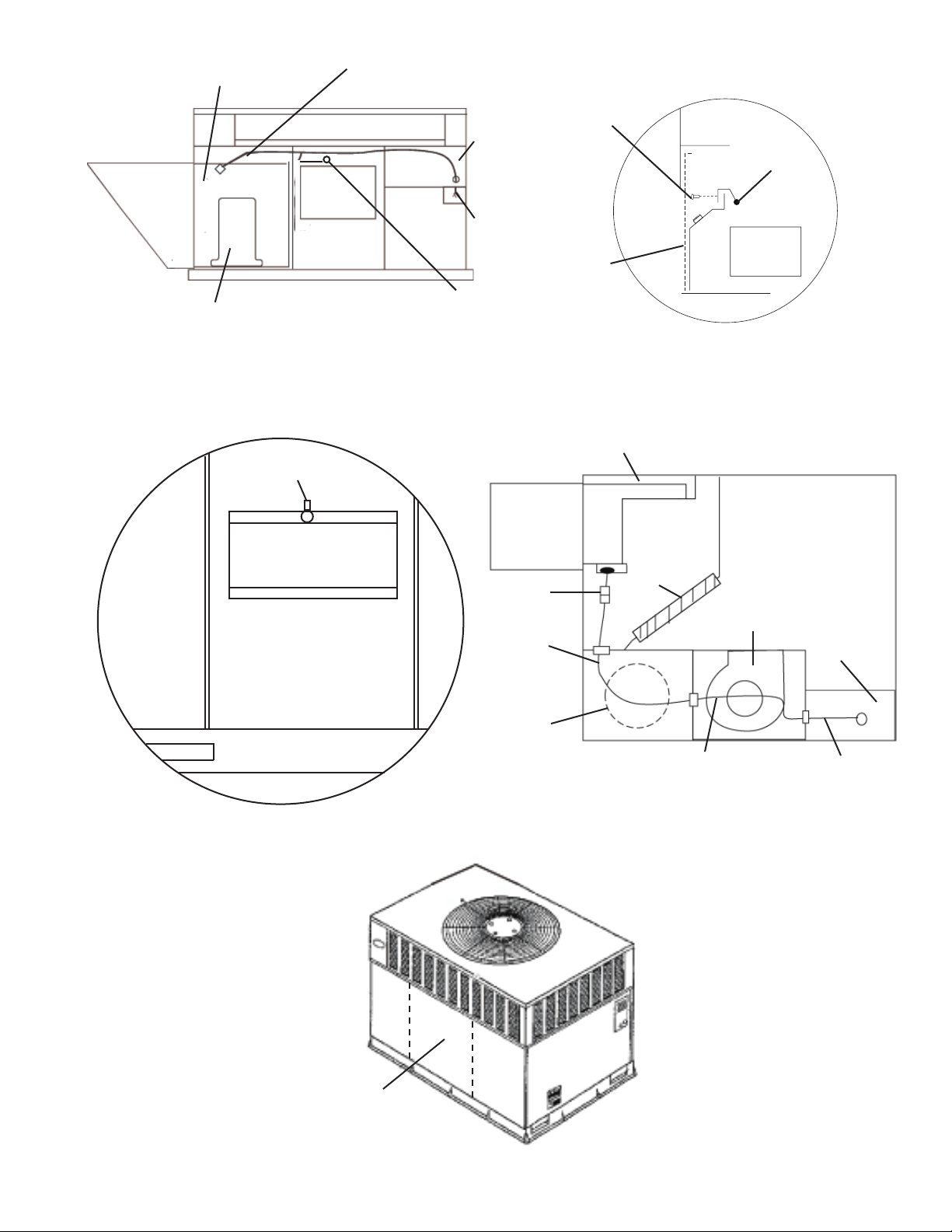

5. Most new 3 Phase HVAC units will have an economizer plug in

the return air chamber which runs back to the control box. If the unit

has the economizer harness/plug, rst remove the jumper plug from

the end of the harness to allow the plug from the economizer to be

connected.

NOTE: The jumper plug should be saved for future use in the event

that the economizer is removed from the unit. The jumper plug is not

needed as long as the economizer is installed.

In the event that your HVAC unit does not have a factory installed

harness for the economizer, the extension harness shipped with the

economizer must be installed in the unit. Route the extension harness

through the HVAC unit as shown in Fig. 8 & 10. Connect extension

harness per wiring diagrams in this booklet. The plug end of the harness

extension will connect to the economizer plug in the return chamber

and the other end will be routed to and connect in the control box.

2

HH63AW001

Economizer

Controller

Economizer

Actuator

HH18HA286

Low ambient

Compressor

Lockout switch

(HH57AC080)

Adjustable Dry

Bulb Outside

Air Sensor

Economizer Plug

Fig. 2 - Component Locations

Compressor

Compartment

Outside Air

Damper

Hood Top

Cleanable

Aluminum Filter

Fig. 5 - Filter Installation

7 15/16”

(202mm)

21 9/16”

(548mm)

Divider in

HVAC Unit

Filter Clip

Outside Air

Replacement

Panel Shipped

with Economizer

Economizer

Cover Panel

Side Panel shipped with HVAC

unit. Remove and Discard

NOTE: Units with base rails will

have a 2 piece panel. Discard the

panel covering the return air

chamber and reuse the panel

covering the compressor section.

Fig. 3 - Panel Removal

17 1/2”

(445mm)

21”

(533mm)

1/2 in. (38.1mm)

above the

top of the left side

of the return duct

opening use 1” self

drilling to screw

thru unit back panel

and into the top

rear corner of

economizer

assembly

Indoor

Blower

Panel

Compressor

Panel

Fig. 6A

Gasketing

4 Sides

Caulk these corners

after economizer

is installed

Screw

into base

(572mm)

Fig. 6 - Economizer Installation

HVAC Unit

Filter Door

21 9/16”

(548mm)

Screw

22 1/2”

Replacement

Panel

Economizer

Panel

16 1/4”

(413mm)

Aluminum

Filter

Remove Screw from base pan. Install

economizer then re-insert screw through

slot in economizer into basepan.

16 1/4”

(413mm)

Fig. 4 - Hood Assembly Fig. 7 - Economizer Installed in HVAC Unit

3

Economizer

Economizer Harness from

Actuator and controller

Economizer

Rainhood

Indoor

Blower

Compressor

Fig. 8 - Routing Harness Extension and

Mounting SAT Sensor

Supply Air Temperature

Sensor (SAT)

Indoor

Blower

Main 24V

Splice Box

Economizer

Harness

Supply Air Temperature

(See Fig. 8A)

Economizer

Hood

Economizer

Plug

Economizer

Harness

Self-Drilling

Screw

SAT Sensor

on Bracket

Indoor

Blower

Panel

Indoor

Blower

Fig. 8A - SAT Mounting for Units with

Upper Block Off Panel

Economizer

Filter

Indoor Fan

Control

Box

Fig. 9 - SAT Location for Units without

Block Off Panel

Indoor

Blower Panel

Fig. 11 - Indoor Blower Panel

Compressor

4

To SAT Sensor

Fig. 10 - Routing Harness (Top View)

Economizer

Harness

6. Remove the panel on the HVAC unit covering the indoor blower.

See Fig. 11. The (provided) Supply Air Temperature (SAT) sensor,

which looks like and eyelet terminal, must be installed in the blower

section. Attach the (2) pink wires from the economizer harness (or

extension harness) to the SAT.

The SAT sensor is shipped attached to a small bracket. If the HVAC

unit has an upper block off panel, attach the sensor / bracket as shown

in Fig. 8A using a #10 x 5/8” self-drilling screw. If the unit does not

have an upper block off panel, remove the bracket from the SAT and

screw the SAT to the side of the indoor blower, using a #10 x 5/8”selfdrilling screw, as shown in Fig. 9.

7. Replace the panel covering the indoor blower.

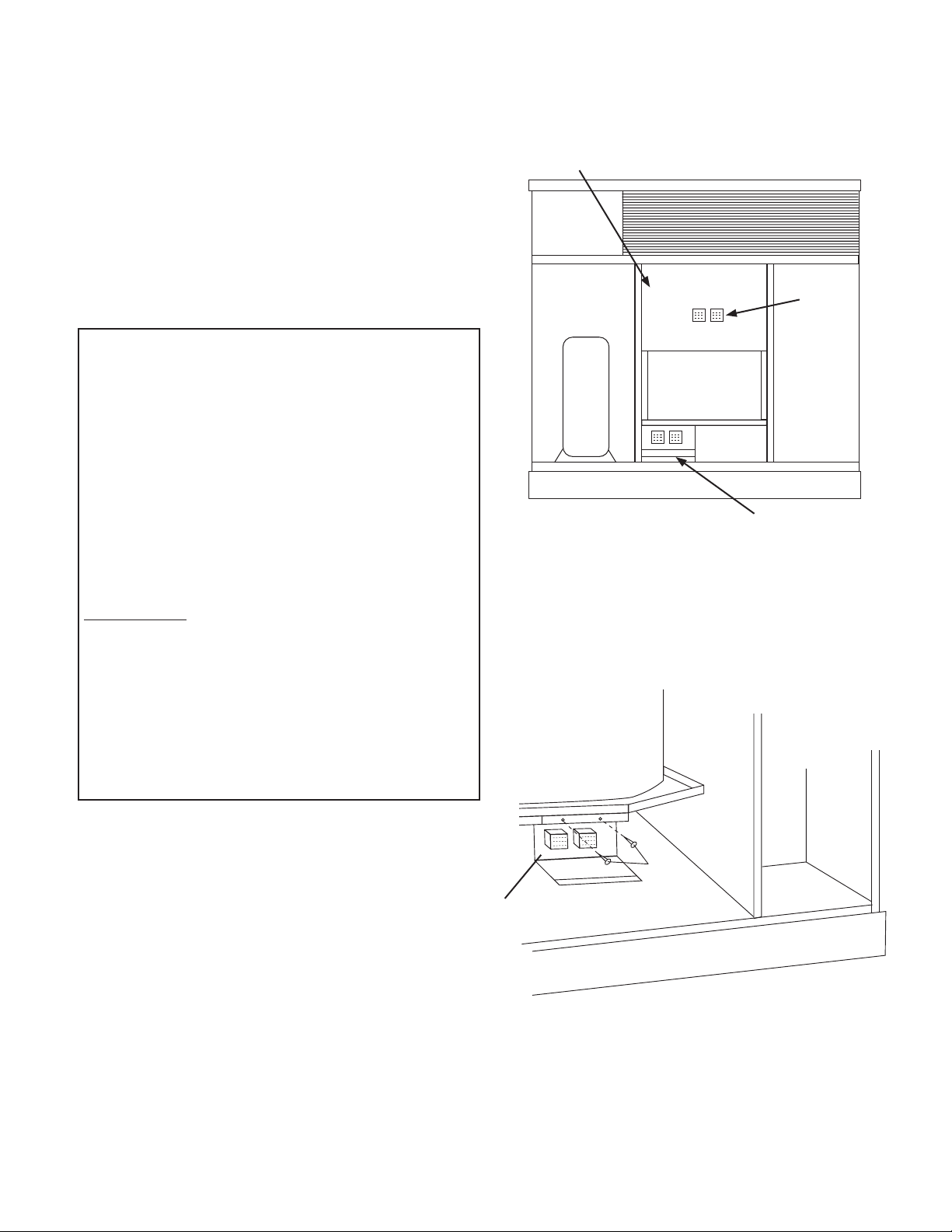

NOTE: For heat pump units, an additional relay package, factory kit

part number CPRLYKIT001A00, or eld provided relays must be

installed in the blower section. See heat pump diagram for details.

Installation of Heat Pump Relays

When this economizer is used on heat pump HVAC units, relays must

be added for proper operation.

The relays, which are shown on the attached diagrams, can be eld

supplied, or relay kit CPRLYKIT001A00 can be ordered. Field

provided relays must be:

•SPDT, one pole normally open and one normally closed. Same

polarity.

•Minimum 124 VA inrush.

Acceptable relays include:

•Honeywell: R8222B117

•Honeywell: R422B1124

•White Rodgers: 91-103001-13002

•White Rodgers: 91-102006-13302

Relay Installation:

A. If the optional relay kit CPRLYKIT001A00 is used, it will mount

underneath the indoor blower as shown in Fig. 12 & 13. Follow

instructions sent with the package.

B. If relays are eld provided and installed, they can be mounted

above the upper block off panel, as shown in Fig. 12. Use caution to

ensure screws do not interfere with blower operation, Blunt end screws

are recommended.

C. If no upper block off panel is present mount relays on compressor

partition below indoor blower on left as shown in Fig. 12.

D. Wire the relays per diagram in this instruction.

Upper Block-off

panel (some units)

COMPRESSOR

NOTE 1: Field provided

relays can be mounted

on upper block off

panel, if applicable

Fig. 12 - Relay Kit Location

INDOOR

BLOWER

INDOOR

BLOWER

SEE

NOTE 1

CONTROL

SECTION

Location for heat

pump relay package

number

CPRLYKIT001A00

8. This step applies to units without base rails only. If the unit does

not have a wrap around compressor access panel install the supplied

replacement panel (Fig. 7).

9. Install the 5/8” gasketing on the duct side anges of the economizer,

see Fig. 6. Remove the right of the two screws on the lip of the basepan

(Fig. 7). Turn the economizer on its side (Fig. 6.) Slide economizer

into cabinet and as far to the left as possible. The economizer will set

against the left side of the HVAC unit. Use the screw just removed

from the basepan to screw through the slot in the bottom ange of the

economizer into the basepan where the screw was removed. Caulk as

required.

10. Remove lter access panel. Install the replacement return chamber

panel over the economizer assembly and underneath the drip ange on

the HVAC unit. Line up the bottom left hole on the panel with the hole

in the bottom left of the economizer and the mating hole in the base of

the HVAC unit. Insert screw, which will hold all parts in place. Insert

screws on bottom right of panel as well. Install lters and then reinstall

the lter access panel. See Fig. 6.

11. At a location 1/2 in. (12.7mm) above the top of the left side of the

return duct opening use 1” self drilling to screw thru unit back panel

and into the top rear corner of economizer assembly (Fig. 6).

Screw

CPRLYKIT001A00

relay kit

Fig. 13 - Relay Kit Installation

5

12. Caulk or gasket the back side of the hood mating anges. Install

assembled hood over the economizer opening in the replacement return

chamber panel. Screw in place through pre-punched holes. Make sure

all seams are watertight.

13. Open the lter clips on the inside of the hood top. Insert the

aluminum lter into the hood and close the clips to hold in place. See

Fig. 5.

14. Remove the lter access panel and install disposable lters in lter

rack. Reinstall the lter access panel. Fig. 1. See Table 2 for lter

sizes.

15. Through the lter access door (horizontal return panel), adjust

the settings on the economizer controller. Review the settings in the

Operation section:

1. The standard economizer controller has a factory setting

of 63OF (17OC) for the outdoor air temperature changeover

and 55O F (13OC) for the supply air (mixed air) temperature

sensor. The outdoor air temperature changeover setting is

adjusted on the sensor by setting the dip switches on the

sensor. See Fig. 15. The ABCD potentiometer on the

economizer controller should be set to the “D” position.

2. The low ambient compressor lockout switch setting

is xed at 42O F (6O C).

3. The minimum position for the outdoor air damper can be

congured at the controller. When not using a CO2 sensor,

the DCV Max potentiometer must be completely closed

(CCW) for the Minimum Position potentiometer to

function correctly.

4. Settings for the optional outdoor enthalpy sensor, indoor

enthalpy sensor, and CO2 sensor can also be congured at

the controller.

16. Replace the lter access panel. Screw in place.

17. Install all economizer accessories then power HVAC unit and test

cycle economizer.

CONFIGURATION

Economizer Standard Sensors

OUTDOOR AIR TEMPERATURE (OAT) SENSOR— The outdoor

air temperature sensor (HH57AC080) is a 10 to 20mA device used to

measure the outdoor-air temperature. The outdoor-air temperature is

used to determine when the Economizer can be used for free cooling.

The operating range of temperature measurement is 40O to 100O F

(4O to 38O C). The sensor has 8 selectable temperature changeover

setpoints. The temperature changeover is set using the 3 dip switches

on the sensor. The ABCD potentiometer on the controller should be

set to the “D” position. See Fig. 15.

SUPPLY AIR TEMPERATURE (SAT) SENSOR—The supply air

temperature sensor is a 3 KΩ thermistor located at the inlet of the

indoor fan. See Fig. 8 and 9. This sensor is eld installed. The operating

range of temperature measurement is 0°(-18O C) to 158O F (70O C). See

Table 5 for sensor temperature/resistance values.

The temperature sensor looks like an eyelet terminal with wires

running to it. The sensor is located in the “crimp end” and is sealed

from moisture.

LOW TEMPERATURE COMPRESSOR LOCKOUT

SWITCH—The Economizer is equipped with a low ambient

temperature lockout switch located in the outdoor airstream which

is used to lock out the compressors below a 42O F (6O C) ambient

temperature. See Fig. 2.

Table 5 - Supply Air Sensor Temperature /

Resistance Values

TEMPERATURE (F) CELSIUS (C) RESISTANCE (ohms)

-22 -30 53,010

-4 -20 29,091

14 -10 16,590

32 0 9,795

50 10 5,970

68 20 3,747

77 25 3,000

86 30 2,416

104 40 1,597

122 50 1,080

140 60 746

158 70 525

Economizer Control Modes — Determine the Economizer control

mode before set up of the control. Some modes of operation may require

different sensors. Refer to Table 2. The Economizer is supplied from

the factory with a supply air temperature sensor, a low temperature

compressor lockout switch, and an outdoor air temperature sensor.

This allows for operation of the Economizer with outdoor air dry bulb

changeover control. Additional accessories can be added to allow for

different types of changeover control and operation of the Economizer

and unit.

OUTDOOR DRY BULB CHANGEOVER— The standard controller

is shipped from the factory congured for outdoor dry bulb changeover

control. The outdoor air and supply air temperature sensors are

included as standard.

For this control mode, the outdoor temperature is compared to

a selectable setpoint on the sensor. See Fig. 15. If the outdoorair temperature is above the set point, the Economizer will adjust

the outdoor air dampers to minimum position. If the outdoor-air

temperature is below the set point, the position of the outdoor-air

dampers will be controlled to provide free cooling using outdoor

air. When in this mode, the LED next to the free cooling set point

potentiometer will be on. The changeover temperature set point is set

using the switches on the sensor. See Fig. 15 for the corresponding

temperature changeover values.

OUTDOOR ENTHALPY CHANGEOVER—For enthalpy control,

accessory enthalpy sensor (part number HH57AC078) is required.

Replace the standard outdoor dry bulb temperature sensor with the

accessory enthalpy sensor in the same mounting location.

6