International comfort products N8MPL050B12, N8MPL075B12, N8MPL075F16, N8MPL100F20, N8MPL100J22 Installation Instructions Manual

...

CARBON MONOXIDE POISONING AND FIRE

HAZARD

Failure to follow this warning could result in

personal injury, death, and/or property damage.

This furnace is not designed for use in mobile

homes, trailers or recreational vehicles.

!

ELECTRIC SHOCK HAZARD

Failure to follow this warning

could result in injury and/or

death.

Turn OFF all power, lockout and

tag with suitable warning label

before servicing.

!

International Comfort Products, LLC

Lewisburg, TN 37091 U.S.A.

See section 5 for Category I definition.

INSTALLER: Affix these instructions

on or adjacent to the furnace.

CONSUMER: Retain these

instructions for future reference.

Portions of the text and tables are reprinted from ANSI Z223.1/NFPA 54!2009, with permission of National Fire Protection Association, Quincy, MA 02269 and American Gas Association, Wash-

ington, DC 20001. This reprinted material is not the complete and official position of the NFPA or ANSI, on the referenced subject, which is represented only by the standard in its entirety.

WARNING

WARNING

WARNING

* Denotes Brands (C, H, T)

Printed in U.S.A. 441 01 2613 05 Sept. 2009

80+ SINGLE STAGE GAS FURNACE

Category I Furnace

N8MPN/N8MPL & *8MPN/*8MPL

Upflow/Downflow/Horizontal

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance, or use can cause explosion, fire, electrical shock, or other conditions

which may cause death, personal injury, or property damage. Consult a qualified installer, service agency, or your distributor or branch for

information or assistance. The qualified installer or agency must use factory!authorized kits or accessories when modifying this product.

Refer to the individual instructions packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing, and work gloves. Use quenching cloth for brazing operations. Have fire

extinguisher available. Read these instructions thoroughly and follow all warnings or cautions included in literature and attached to the unit.

Consult local building codes, the current editions of the National Fuel Gas Code (NFCG) NFPA 54/ANSI Z223.1, National Electrical Code

(NEC) NFPA 70.

In Canada refer to the current editions of the National standards of Canada CAN/CSA!B149.1 and .2 Natural Gas and Propane Installation

Codes, and Canadian Electrical Code CSA C22.1.

Recognize safety information. This is the safety!alert symbol

. When you see this symbol on the unit and in instructions or manuals, be

alert to the potential for personal injury. Understand these signal words; DANGER, WARNING, and CAUTION. These words are used with

the safety!alert symbol. DANGER identifies the most serious hazards which will result in severe personal injury or death. WARNING

signifies hazards which could result in personal injury or death. CAUTION is used to identify unsafe practices which may result in minor

personal injury or product and property damage. NOTE is used to highlight suggestions which will result in enhanced installation, reliability,

or operation.

Table of Contents

1. Safe Installation Requirements 3. . . . . . . . . . . . . . . .

2. Installation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Side Venting 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Combustion & Ventilation Air 9. . . . . . . . . . . . . . . . . .

5. Gas Vent Installation 12. . . . . . . . . . . . . . . . . . . . . . . .

6. Horizontal Venting 13. . . . . . . . . . . . . . . . . . . . . . . . .

7. Masonry Chimney Venting 15. . . . . . . . . . . . . . . . . . .

8. Gas Supply and Piping 18. . . . . . . . . . . . . . . . . . . . . .

9. Electrical Wiring 21. . . . . . . . . . . . . . . . . . . . . . . . . . .

10.Ductwork and Filter (Upflow/Horizontal) 22. . . . . . . .

11.Ductwork and Filter (Downflow) 25. . . . . . . . . . . . . . . .

12. Checks and Adjustments 27. . . . . . . . . . . . . . . . . . . . . .

13. Furnace Maintenance 32. . . . . . . . . . . . . . . . . . . . . . . .

14. Sequence of Operation & Diagnostics 33. . . . . . . . . . . .

15.Technical Support Manual 35. . . . . . . . . . . . . . . . . . . . .

16.Model Specificications 36. . . . . . . . . . . . . . . . . . . . . . . .

17.Circulation Data & Bellyband Placement 31. . . . . . . . . .

18.Wiring Diagram 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.Parts Information Guide 43. . . . . . . . . . . . . . . . . . . . . .

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.

2

441 01 2613 05

Specifications are subject to change without notice

START!UP CHECK SHEET

For 80+ Furnace

(This sheet is optional. Keep this page for future reference.)

Date of Start!Up:

Dealer Name:

Address:

City, State(Province), Zip or Postal Code:

Phone:

Owner Name:

Address:

City, State(Province), Zip or Postal Code:

Model Number:

Serial Number:

Setup Checks

Check the box when task is complete

Thermostat: Heat

Cooling Fan

Subbase level:

Anticipator Set: Setting of Anticipator ____

All Electrical Connections Tight:

Supply voltage: ____

Blower Motor H.P.: ____

Fan “Time ON” setting: ____ Fan “Time OFF” Setting ___

Manual Gas Shut!Off Upstream of Furnace/Drip!Leg?

Gas Valve turned ON?

Type of Gas: Natural: Propane:

Filter Type and Size:

Calculated Firing Rate:(See Checks and Adjustments

Section).

Heating Check

Measured Line Pressure when Firing Unit:

Measured Manifold Gas Pressure:

Temperature of Supply Air: (°)

Temperature of Return Air: (°)

Temperature Rise (supply!return temperature): (°)

In Rise (see furnace rating plate)? (°)

Static Pressure (Ducts): Supply Air Return

Blower speed tap used for heating

Limit Opens: (°) Limit Closes: (°)

Optional Check: CO ? CO2 ?

Cooling Check

Temperature of Supply Air: (°)

Temperature of Return Air: (°)

Temperature Difference: (°)

Static Pressure (Ducts) cooling: Supply Air Return

Blower Speed Tap used for cooling: _______

Dealer Comments:

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.

441 01 2613 05

3

Specifications are subject to change without notice

1. Safe Installation Requirements

FIRE, EXPLOSION, AND ASPHIXIATION HAZARD

Improper adjustment, alteration, service,

maintance or installation could cause personal

injury, death, and/or property damage.

Installation or repairs made by unqualified persons

could result in hazards to you and others.

Installation MUST conform with local codes or, in

the absence of local codes, with codes of all

governmental authorities having jurisdiction.

The information contained in this manual is

intended for use by a qualified service agency that

is experienced in such work, is familiar with all

precautions and safety procedures required in

such work, and is equipped with the proper tools

and test instruments.

!

WARNING

NOTE: This furnace is design!certified by the CSA International

(formerly AGA and CGA) for installation in the United States and

Canada. Refer to the appropriate codes, along with this manual,

for proper installation.

• Use only the Type of gas approved for this furnace (see

Rating Plate on unit). Overfiring will result in failure of heat

exchanger and cause dangerous operation. (Furnaces

can be converted to Propane gas with approved kit.)

• Install this furnace only in a location and position as

specified in “Installation” of these instructions.

• Provide adequate combustion and ventilation air to the

furnace as specified in “Combustion and Ventilation Air” of

these instructions.

• Combustion products must be discharged outdoors.

Connect this furnace to an approved vent system only, as

specified in “Gas Vent Installation, Horizontal Venting and

Masonry Chimney Venting” of these instructions.

• Never test for gas leaks with an open flame. Use a

commercially available soap solution made specifically for

the detection of leaks to check all connections, as

specified in “Gas Supply and Piping, Final Check” of these

instructions.

• Always install furnace to operate within the furnace’s

intended temperature!rise range with a duct system which

has an external static pressure within the allowable range,

as specified in “Technical Support Manual” of these

instructions. See furnace rating plate.

• When a furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside the space

containing the furnace, the return air shall also be handled

by a duct(s) sealed to the furnace casing and terminating

outside the space containing the furnace.

• A gas!fired furnace for installation in a residential garage

must be installed as specified in “Installation” of these

instructions.

• This furnace is not to be used for temporary heating of

buildings or structures under construction.

• This furnace is NOT approved for installation in

mobile homes, trailers or recreation vehicles.

• Seal around supply and return air ducts.

• Install correct filter type and size.

• Unit MUST be installed so electrical components are

protected from direct contact with water.

Safety Rules

Your unit is built to provide many years of safe and dependable

service providing it is properly installed and maintained. However,

abuse and/or improper use can shorten the life of the unit and

create hazards for you, the owner.

A. The U.S. Consumer Product Safety Commission encourages

installation of carbon monoxide alarms. There can be various

sources of carbon monoxide in a building or dwelling. The

sources could be gas!fired clothes dryers, gas cooking

stoves, water heaters, furnaces, gas!fired fireplaces, wood

fireplaces.

Carbon monoxide can cause serious bodily injury and/or

death. Carbon monoxide or “CO” is a colorless and odorless

gas produced when fuel is not burned completely or when the

flame does not receive sufficient oxygen.

Therefore, to help alert people of potentially dangerous carbon

monoxide levels, you should have a commercially available

carbon monoxide alarm that is listed by a nationally

recognized testing agency in accordance with Underwriters

Laboratories Inc. Standard for Single and Multiple Station

Carbon Monoxide Alarms, ANSI/UL 2034 or the CSA 6.19!01

Residential Carbon Alarming Devices installed and

maintained in the building or dwelling concurrently with the

gas!fired furnace installation (see Note below). The alarm

should be installed as recommended by the alarm

manufacturer’s installation instructions.

B. There can be numerous sources of fire or smoke in a building

or dwelling. Fire or smoke can cause serious bodily injury,

death, and/or property damage. Therefore, in order to alert

people of potentially dangerous fire or smoke, you should have

fire extinguisher and smoke alarms listed by Underwriters

Laboratories installed and maintained in the building or

dwelling (see Note below).

Note: The manufacturer of your furnace does not test any alarms

and makes no representations regarding any brand or type

of alarms.

C. To ensure safe and efficient operation of your unit, you should

do the following:

1. Thoroughly read this manual and labels on the unit. This

will help you understand how your unit operates and the

hazards involved with gas and electricity.

2. Do not use this unit if any part has been under water.

Immediately call a qualified service agency to inspect the unit

and to replace any part of the control system and any gas

control which has been under water.

3. Never obstruct the vent grilles, or any ducts that provide

air to the unit. Air must be provided for proper combustion and

ventilation of flue gases.

Frozen Water Pipe Hazard

WATER DAMAGE TO PROPERTY HAZARD

FaiIure to follow this warning could result in

property damage.

Do not leave your home unattended for long periods

during freezing weather without turning off water

supply and draining water pipes or otherwise

protecting against the risk of frozen pipes and

resultant damage.

!

WARNING

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.

4

441 01 2613 05

Specifications are subject to change without notice

Your furnace is designed solely to provide a safe and comfortable

living environment. The furnace is NOT designed to ensure that

water pipes will not freeze. It is equipped with several safety

devices that are designed to turn the furnace off and prevent it from

restarting in the event of various potentially unsafe conditions.

If your furnace remains off for an extended time, the pipes in your

home could freeze and burst, resulting in serious water damage.

If the structure will be unattended during cold weather you should

take these precautions.

1. Turn off the water supply to the structure and drain the water

lines if possible and add an antifreeze for potable water to

drain traps and toilet tanks. Open faucets in appropriate

areas.

!or!

2. Have someone check the structure frequently during cold

weather to make sure it is warm enough to prevent pipes

from freezing. Instruct them on a service agency to call to

provide service, if required.

!or!

3. Install a reliable remote sensing device that will notify

somebody of freezing conditions within the home.

2. Installation

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in

personal injury or death.

If this furnace is replacing a previously common-

vented furnace, it may be necessary to resize the

existing vent system to prevent oversizing

problems for the other remaining appliances(s).

See Venting and Combustion Air Check in the Gas

Vent Installation section of this instruction.

!

WARNING

Location and Clearances

If furnace is a replacement, it is usually best to install the furnace

where the old one was. Choose the location or evaluate the

existing location based upon the minimum clearance and furnace

dimensions (Figure 1 or Figure 2).

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in

personal injury or death.

Do NOT operate furnace in a corrosive

atmosphere containing chlorine, fluorine or any

other damaging chemicals which could harm the

furnace and vent system, and permit spillage of

combustion products into an occupied space.

Refer to Combustion & Ventilation Air section,

Contaminated Combustion Air for combustion air

evaluation and remedy.

!

WARNING

Installation Requirements

1. Install furnace level.

2. This furnace is NOT to be used for temporary heat of buildings

or structures under construction.

3. Install furnace as centralized as practical with respect to the

heat distribution system.

4. Install the vent pipes as short as practical. (See Gas Vent

Installation section).

5. Do NOT install furnace directly on carpeting, tile or other

combustible material other than wood flooring.

6. Maintain clearance for fire safety and servicing. A front

clearance of 24″ (609.6mm) required and 30″ (762mm) is

recommended for access to the burner, controls and filter. See

clearance requirements in Figure 1 or Figure 2.

7. Use a raised base if the floor is damp or wet at times.

8. Residential garage installations require:

• Burners and ignition sources installed at least 18″

(457.2mm) above the floor.

• Furnace must be located or physically protected from

possible damage by a vehicle.

9. If the furnace is to be suspended from the floor joists in a

basement or a crawl space or the rafters in an attic, it is

necessary to use steel pipe straps or an angle iron frame to

attach the furnace. These straps should be attached to the

furnace bottom side with sheet metal screws and to the rafters

or joists with bolts. The preferred method is to use an angle iron

frame bolted to the rafters or joists.

10. This furnace may be used for construction heat provided that:

• The furnace is permanently installed with all electrical

wiring, piping, venting and ducting installed according to

these installation instructions. A return air duct is

provided, sealed to the furnace casing, and terminated

outside the space containing the furnace. This prevents

a negative pressure condition as created by the

circulating air blower, causing a flame rollout and/or

drawing combustion products into the structure.

• The furnace is controlled by a thermostat. It may not be

“hot wired” to provide heat continuously to the structure

without thermostatic control.

• Clean outside air is provided for combustion. This is to

minimize the corrosive effects of adhesives, sealers and

other construction materials. It also prevents the

entrainment of drywall dust into combustion air, which

can cause fouling and plugging of furnace components.

• The temperature of the return air to the furnace is

maintained between 55° F (13° C) and 80° F (27° C) , with

no evening setback or shutdown. The use of the furnace

while the structure is under construction is deemed to be

intermittent operation per our installation instructions.

• The air temperature rise is within the rated rise range on

the furnace rating plate, and the firing rate has been set to

the rating plate value.

• The filters used to clean the circulating air during the

construction process must be either changed or

thoroughly cleaned prior to occupancy.

• The furnace, ductwork and filters are cleaned as

necessary to remove drywall dust and construction

debris from all HVAC system components after

construction is completed.

• Verify proper furnace operating conditions including

ignition, gas input rate, air temperature rise, and venting

according to these installation instructions.

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.

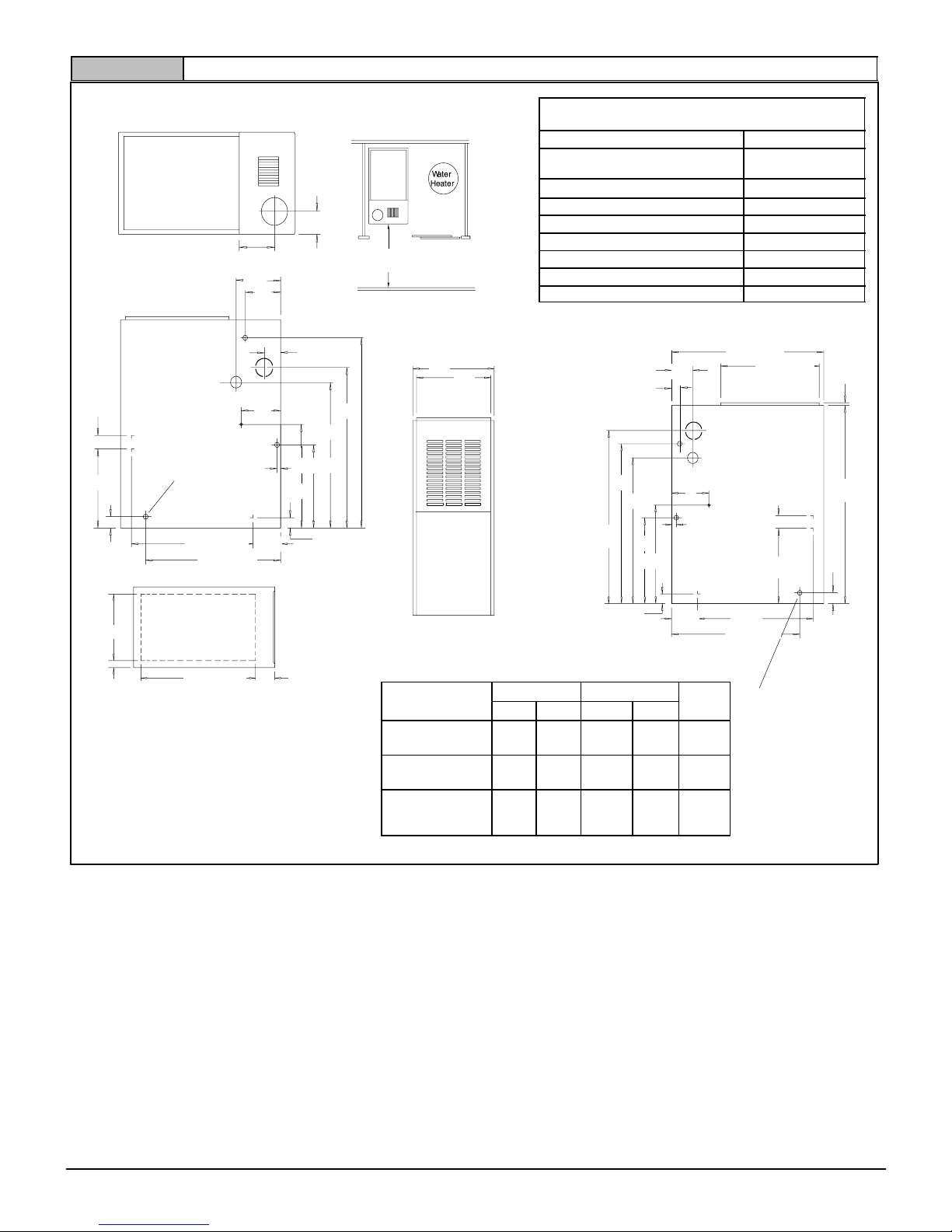

Drawing is representative, but some models may vary

NOTE: Evaporator “A” coil drain pan dimensions

may vary from furnace duct opening size. Always

consult evaporator specifications for duct size

requirements.

Unit is designed for bottom return or side return.

Return air through back of unit is NOT allowed.

131/

4

281/

2

33/

4

171/

3

21/

4

TOP

51/

3

31/

4

LEFT SIDE

61/

2

33/

4

5

271/

2

33

131/

4

241/

2

17/

8

213/

4

265/

8

131/

4

47/

8

11/

2

7

1

RIGHT SIDE

281/

2

181/

2

21/

4

131/

4

171/

3

3

/

4

2

7

1

35

32

213/

4

11/

2

253/

4

47/

8

265/

8

17/

8

FRONT

A

B

30″ Min.

BOTTOM

D

C

231/

8

41/

16

J

H

Plugged starting

hole to cut side

duct opening

Plugged starting

hole to cut side

duct opening

ALL DIMENSIONS in(mm)

1 in = 25.4 mm

(724)

(470)

(19)

(57)

(337)

(178)

(470)

(676)

(124)

(48)

(889)

(95)

(51)

(813)

(654)

(337)

(440)

(38)

(95)

(127)

(178)

(124)

(48)

(337)

(838)

(670)

(622)

(337)

(440)

(38)

(552)

(57)

(762)

(587)

(103)

(83)

(25)

(552)

(165)

(676)

(135)

441 01 2613 05

5

Specifications are subject to change without notice

Figure 1 Dimensions and Clearances N8MPN/L

MINIMUM CLEARANCES TO

COMBUSTIBLE MATERIALS FOR ALL UNITS

REAR 0

FRONT (combustion air openings

in furnace and in structure)

3″ (76 mm)

Required For Service

*30″ (762 mm)

ALL SIDES Of SUPPLY PLENUM 1″ (25 mm)

SIDES 0

VENT

Single Wall Vent 6″ (152 mm)

Type B!1 Double Wall Vent 1″ (25 mm)

TOP OF FURNACE 1″ (25 mm)

Horizontal position: Line contact is permissible only between lines

formed by intersections of top and two sides of furnace jacket, and

building joists, studs or framing.

DIMENSIONAL INFORMATION

Unit

Capacity

Cabinet Bottom

Duct

Size

A B C D

N8MPL050B12

N8MPL075B12

151/

2

(76)

14

(356)

13/

8

(1.4)

125/

8

(321)

H

N8MPL075F16

N8MPL100F20

191/

8

(486)

175/

8

(447)

21/

8

(54)

143/

4

(15)

J

N8MPL100J22

N8MPL125J20

N8MPL125J22

223/

4

(578)

211/

4

(540)

115/

16

(49)

183/

4

(476)

J

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.

331/

2

303/

4

291/

2

175/

16

33/

4

21/

4

13/

4

47/

8

21/

4

47/

8

271/

2

175/

16

321/

2

277/

8

NOTE: Evaporator “A” coil drain pan dimensions may vary from

furnace duct opening size. Always consult evaporator specifica

tions for duct size requirements.

Furnace is designed for bottom return or side return.

Return air through back of furnace is NOT allowed.

ALL DIMENSIONS - in(mm)

1 in = 25.4 mm

D

C

231/

8

41/

16

24″ (610) min.

51/

3

F

TOP

111/

16

1

5

38

7

265/

8

131/

4

217/

8

17/

8

33/

4

LEFT SIDE

A

B

FRONT

BOTTOM

RIGHT SIDE

7

1

37

2

40

181/

2

281/

2

131/

4

3

/

4

261/

2

215/

8

17/

8

Plugged starting hole

to cut side duct opening..

Plugged starting hole

to cut side duct opening..

J

H

Drawing is representative, but some models may vary

(135)

(127)

(95)

(365)

(826)

(708)

(699)

(440)

(43)

(124)

(556)

(676)

(587)

(48)

(337)

(57)

(178)

(103)

(25)

(57)

(470)

(724)

(19)

(51)

(95)

(178)

(25)

(940)

(781)

(851)

(749)

(440)

(45)

(124)

(542)

(673)

(337)

(48)

(1016)

6

441 01 2613 05

Specifications are subject to change without notice

Figure 2 Dimensions and Clearances *8MPN/L Models

MINIMUM CLEARANCES TO

COMBUSTIBLE MATERIALS FOR ALL UNITS

REAR 0

FRONT (combustion air openings in

furnace and in structure)

3″ (76 mm)

Required For Service

*24″ (610 mm)

ALL SIDES Of SUPPLY PLENUM 1″ (25 mm)

SIDES 0

VENT

Single Wall Vent 6″ (152 mm)

Type B!1 Double Wall Vent 1″ (25 mm)

TOP OF FURNACE 1″ (25 mm)

*30″ (762 mm) clearance recommended for furnace removal.

Horizontal position: Line contact is permissible only between lines

formed by intersections of top and two sides of furnace jacket, and

building joists, studs or framing.

Furnace

Capacity

Cabinet Top Bottom

Return

Air

Opening

A B F C D

*8MPL050B12

*8MPL075B12

151/

2

(394)

14

(356)6(152)

13/

8

(35)

125/

8

(321)

H

*8MPL075F16

*8MPL100F20

191/

8

(486)

171/

2

(445)

73/

4

(197)

21/

8

(54)

143/

4

(375)

J

*8MPL100J22

*8MPL125J20

223/

4

(578)

211/

4

(540)

91/

2

(241)

115/

16

(49)

183/

4

(476)

J

* Denotes Brand (C, H, T)

Installation Positions

This furnace can be installed in an upflow, horizontal (either left or

right) or downflow airflow position. DO NOT install this furnace on

its back. For the upflow position, the return air ductwork can be

attached to either the left or right side panel and/or the bottom. For

horizontal and downflow positions, the return air ductwork must be

attached to the bottom. The return air ductwork must never be

attached to the back of the furnace.

Furnace Installation

Inspect the rating plate to be certain the model number begins with

“N8MP” or “*8MP”. This identifies the unit as a multi!position

furnace and can be Installed in a Upflow, Horizontal Right,

Horizontal Left or Downflow position.

* Dentoes Brand (C, H, T)

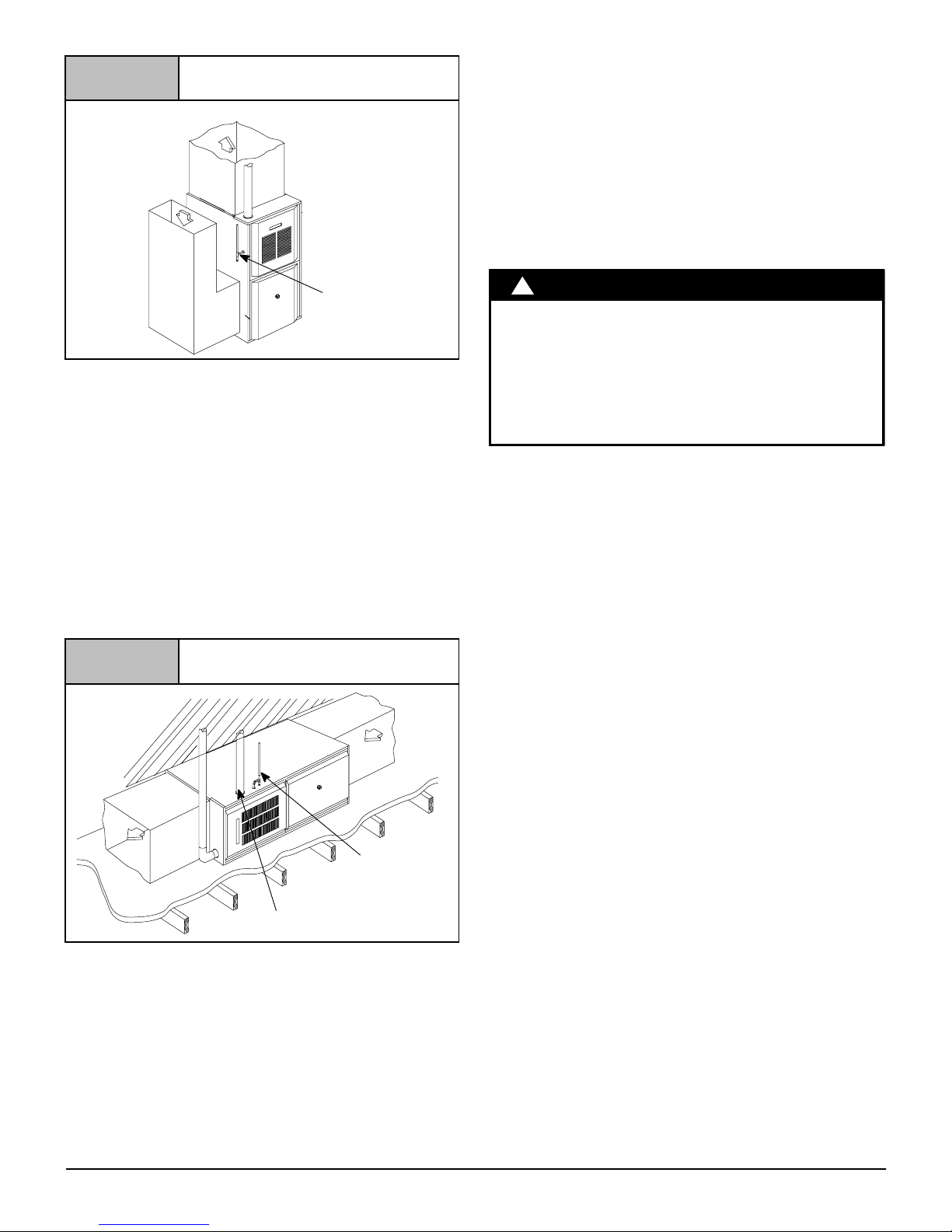

Upflow

No modifications are required for upflow installation. (See

Figure 3)

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.

441 01 2613 05

7

Specifications are subject to change without notice

Typical Upflow Installation

Figure 3

25!23!17

VENT

SUPPLY

AIR

GAS SUPPLY

RETURN

AIR

Horizontal

If you purchased a multi!position furnace, it can be installed

horizontally in an attic, basement, crawl space, alcove, or

suspended from a ceiling in a basement or utility room in either a

right or left airflow position. (see Figure 4)

Horizontally installed furnaces may be vented out the top of the

unit or out the side facing up. See “Side venting” for instructions to

rotate the vent to the side.

The minimum clearances to combustibles MUST be maintained

between the furnace and adjacent construction, as shown in

Figure 1 and Figure 2. ONLY the corner of the cabinet is allowed

to contact the rafters as shown in Figure 4. All other clearances

MUST be observed as shown in Figure 1 and Figure 2.

Typical Horizontal Installation

Figure 4

VENT

VENT

GAS SUPPLY

SUPPLY

AIR

RETURN

AIR

25-23-18a

OPTIONAL

VENT LOCATION

If the furnace is to be suspended from the floor joists in a basement

or crawl space or the rafters in an attic, it is necessary to use steel

pipe straps or an angle iron frame to attach the furnace. These

straps should be attached to the furnace bottom side with sheet

metal screws and to the rafters or joists with bolts. The preferred

method is to use an angle iron frame bolted to the rafters or joists.

If the furnace is to be installed at ground level in a crawl space,

consult local codes. A concrete pad 1″ to 2″ (25.4 to 50.8mm) thick

is recommended.

24″ (609.6mm) is required between the front of the furnace and

adjacent construction or other appliances. This should be

maintained for service clearance.

Keep all insulating materials clear from louvered door. Insulating

materials may be combustible.

The horizontal furnaces may be installed directly on combustible

wood flooring or supports, however, it is recommended for further

fire protection cement board or sheet metal is placed between the

furnace and the combustible wood floor and extend 12″

(304.8mm) beyond the front of the furnace louver door. (This is a

recommendation only, not a requirement).

This furnace MUST NOT be installed directly on carpeting, tile or

other combustible material other than wood flooring or supports.

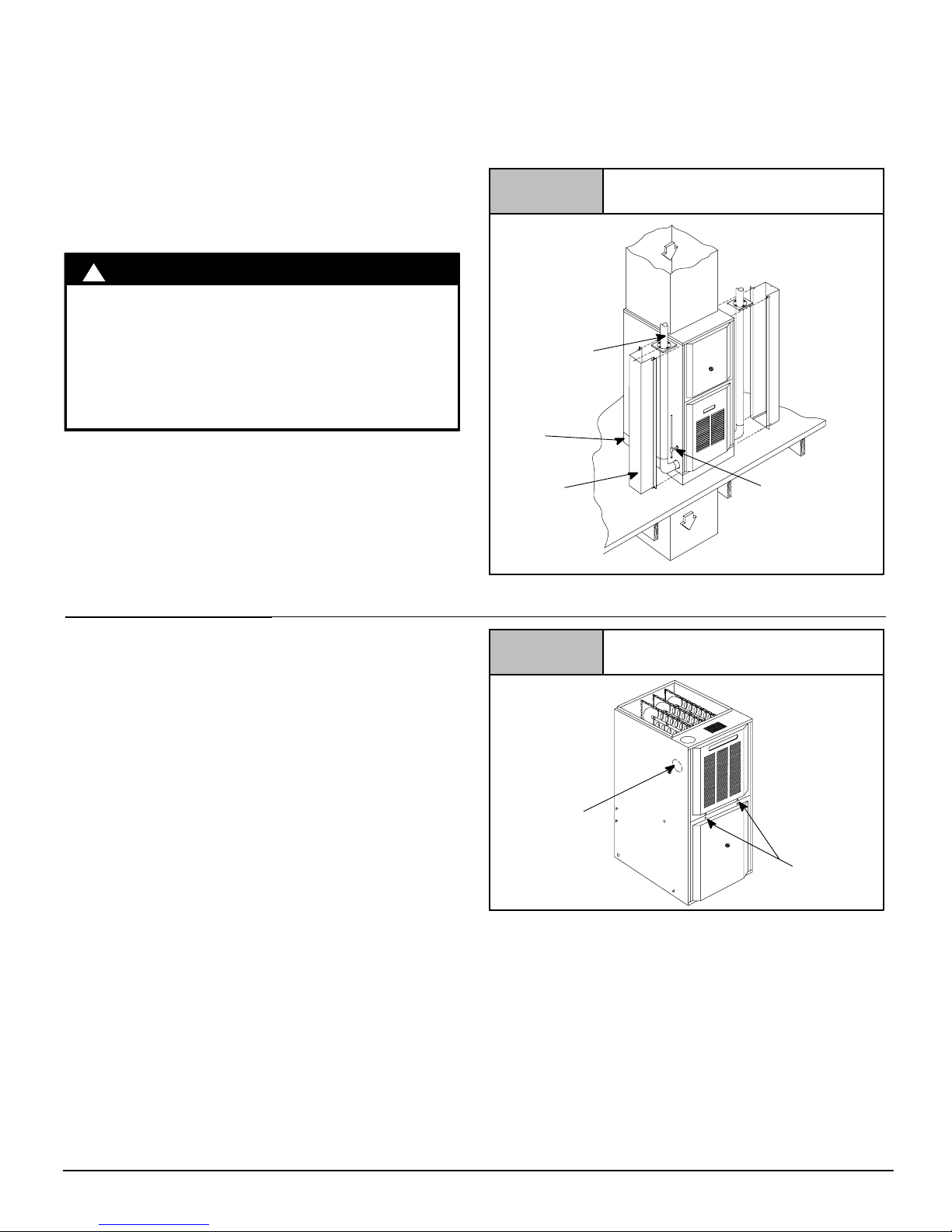

Downflow

FIRE HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Place furnace on noncombustible subbase on

downflow applications, unless installing on

noncombustible flooring.

!

WARNING

If you purchased a Multi!position furnace (N8MP or *8MP) it may

be installed in a downflow configuration, (see Figure 5). The

minimum clearances to combustible material MUST be

maintained between the furnace and adjacent construction, as

shown in Figure 1 and Figure 2.

In addition to clearances in Figure 1 and Figure 2, clearance for

the vent pipe must be considered.

A subbase for combustible floors MUST be used when the furnace

is installed as a downflow on combustible material. See “Ductwork

and Filter” (Downflow Section). The outlet flange must be bent flat

for downflow installation.

When installing a four!position furnace in the downflow position

(not the *8DNL furnace), the logo is to be repositioned so that it is

rightside!up as follows:

T8MPN/L

1. Find the door hardware kit that is stored in the furnace and

save it.

2. Carefully remove logo from the outside of burner compartment

door and save it.

3. Carefully remove two small plug buttons from outside of

blower compartment door and save them.

4. Remove two thumbscrews from blower compartment door .

5. Install two thumbscrews in holes at other end of blower

compartment door from where thumbscrews were removed.

6. Install new strip of rubber gasket on inside of blower

compartment door on edge that does not already have a

gasket.

7. Install logo retainer pins into holes in blower compartment door

from which plug buttons were removed.

8. Install plug buttons into holes in burner compartment door from

which logo was removed.

9. Install blower compartment door on furnace with bevel edge

and logo at top.

10. Install burner compartment door on furnace with bevel edge at

bottom.

N8MPN/L, C8MPN/L, H8MPN/L

1. Carefully remove logo from burner compartment door and

save it.

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.

8

441 01 2613 05

Specifications are subject to change without notice

2. Turn the logo rightside!up, and install the logo retainer pins

into holes in burner compartment door.

3. New labels for rightside!up application on outside of blower

compartment door may be purchased in a kit from your

distributor to cover upside!down labels.

Downflow Venting: The combustion venter MUST be rotated to

vent out the side for all downflow installations, (see Figure 5).

Bottom venting is not permitted. See “Side venting” for

instructions to rotate the vent to the side. In addition to rotating the

vent to the side a Vent Pipe Shield (NAHA002VC) is required to

shield the hot vent pipe.

!

BURN HAZARD

Failure to follow this warning could result in

personal injury and/or property damage.

Vent pipe is HOT and could cause personal injury.

Hot vent pipe is in reach of small children when

installed in downflow position.

Install vent pipe shield NAHA002VC.

WARNING

Pressure Switch Relocation

If the furnace is installed in the upflow position, the pressure switch

will remain in the same position as installed by the factory unless

the inducer is rotated. If the furnace is installed in an orientation

that places the pressure switch below the pressure tap on the

inducer housing, then the switch MUST be relocated. In order to

relocate the switch, locate 2 mounting holes or drill above the

inducer pressure tap. When drilling the 2 holes make sure to keep

the switch and tubing far enough away from the burners or hot

surfaces as to not melt the hose, switch, or wires. To prevent

possible kinking of the pressure switch hose, trim the hose to

remove excess length.

Note: When drilling new holes make sure metal shavings do not fall

on or in components, as this can shorten the life of the furnace.

See side venting

for venter rotation

Typical Downflow Installation

Figure 5

VENT

GAS SUPPLY

MUST BE OPPOSITE

VENT DISCHARGE

SIDE

SUPPLY

AIR

RETURN

AIR

OPTIONAL VENT

25!23!19

Combustible floor

base outlet flange

adapter

Vent Shield

Kit

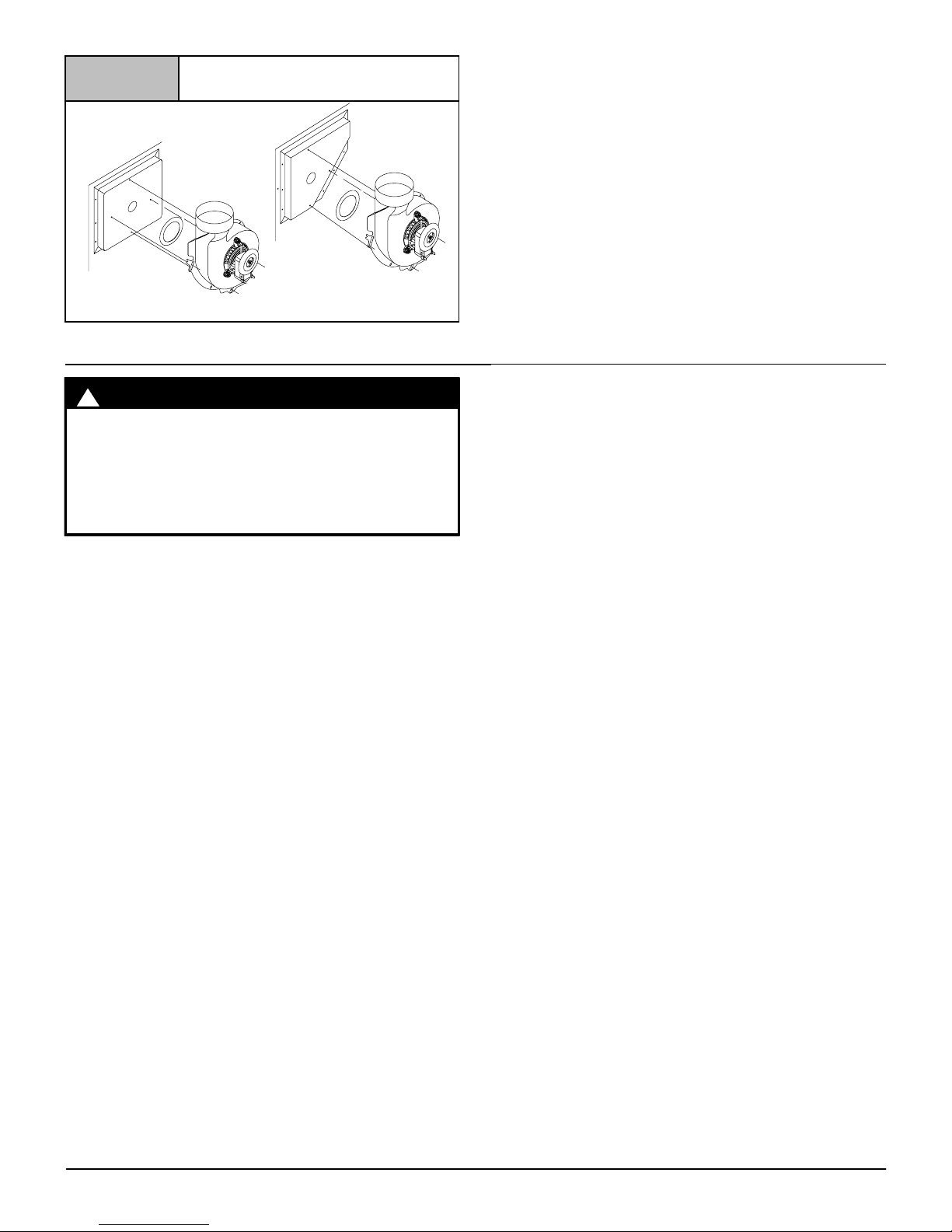

3. Side Venting

This furnace is shipped from the factory with the venter assembly

in an upflow configurations (top vent). The venter assembly can

easily be rotated to a side vent configuration for use in upflow,

horizontal!flow, or downflow application.

When using a side vent configuration (side outlet instead of top

outlet), it may be necessary to relocate the pressure switch to the

alternate position on the opposite side of the top panel. Two screw

holes are provided at the alternate position. Route the pressure

switch tubing so the tubing is not kinked and not touching the hot

collector box, venter housing, or motor. It may be necessary to

shorten the length of the tubing to properly route the tubing and

eliminate kinks.

Rotating the Venter Assembly

1. If gas and electrical power have already been connected to

unit shut off gas and remove power from unit. Unscrew screws

on burner compartment door and remove burner compartment

door. (see Figure 6).

2. Disconnect power leads to the venter motor and hose to

pressure switch. Remove three (3) or four (4) screws which

secure the venter to the collector box, (see Figure 7).

3. Cut webbing with a pair of snips holding the vent plate to the

cabinet on either the left or right side of unit depending on right

or left venting as desired. Discard vent plate, (see Figure 6).

4. Replace venter gasket (part # 1013540, if needed) to venter

assembly with adhesive in the same location as the old one.

5. Clip the wire tie for the venter wires, if needed.

6. Rotate venter assembly 90° right or left from original location

depending on venting configurations.

Figure 6

25!23!45

Screws (2)

Furnace with Screws

Vent Plate

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.

441 01 2613 05

9

Specifications are subject to change without notice

Figure 7

Venter Gasket

25-23-52b

Entry

25-23-52c

Main Line

7. Tighten the three (3) or four (4) screws that secure the venter

assembly to the collector box. Do tighten screws enough to

compress venter gasket.

8. Replace power leads to venter motor and reconnect hose to

pressure switch.

NOTE: Unused open vent hole must be covered. A Vent Cover is

supplied with Vent Pipe Shield Kit NAHA002VC. A 5

5

/16″ (135mm)

diameter Vent Cover is available separately from your distributor,

or one can be fabricated with sheet metal for all side vent

installations.

4. Combustion & Ventilation Air

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in

personal injury or death.

Use methods described here to provide

combustion and ventilation air.

!

WARNING

Furnaces require ventilation openings to provide sufficient air for

proper combustion and ventilation of flue gases. All duct or

openings for supplying combustion and ventilation air must

comply with the gas codes, or in the absence of local codes, the

applicable national codes.

Combustion and ventilation air must be supplied in accordance

with one of the following:

Note: The Combustion & Ventilation Air Section, in this document,

uses tables and information from the ANSI Z223.1/NFPA

54!2009. For use in Canada, use CSA B149.1 for this

information.

1. Section 9.3, Air for Combustion and Ventilation, of the National

Fuel Gas Code, (NFGC), ANSI Z223.1/NFPA 54!2009 in the

U.S.,

2. Sections 8.2, 8.3, 8.5, 8.6, 8.7, and 8.8 of National Standard of

Canada, Natural Gas and Propane Installation Code

(NSCNGPIC), CSA B149.1!05 in Canada,

3. Applicable provisions of the local building code.

When the installation is complete, check that all appliances have

adequate combustion air and are venting properly. See Venting

And Combustion Air Check in “Gas Vent Installation” Section in

this manual.

Contaminated Combustion Air

Installations in certain areas or types of structures could cause

excessive exposure to contaminated air having chemicals or

halogens that will result in safety and performance related

problems and may harm the furnace. These instances must use

only outdoor air for combustion.

The following areas or types of structures may contain or have

exposure to the substances listed below. The installation must be

evaluated carefully as it may be necessary to provide outdoor air

for combustion.

• Commercial buildings.

• Buildings with indoor pools.

• Furnaces installed in laundry rooms.

• Furnaces installed in hobby or craft rooms.

• Furnaces installed near chemical storage areas.

• Permanent wave solutions for hair.

• Chlorinated waxes and cleaners.

• Chlorine based swimming pool chemicals.

• Water softening chemicals.

• De!icing salts or chemicals.

• Carbon tetrachloride.

• Halogen type refrigerants.

• Cleaning solvents (such as perchloroethylene).

• Printing inks, paint removers, varnishes, etc.

• Hydrochloric acid.

• Sulfuric Acid.

• Solvent cements and glues.

• Antistatic fabric softeners for clothes dryers.

• Masonry acid washing materials.

Outdoor Combustion Air Method

A space having less than 50 cubic feet per 1,000 BTUH (4.8 cubic

meters per kW) input rating for all gas appliances installed in the

space requires outdoor air for combustion and ventilation.

Air Openings and Connecting Ducts

1. Total input rating for all gas appliances in the space MUST be

considered when determining free area of openings.

2. Connect ducts or openings directly to the outdoors.

3. When screens are used to cover openings, the openings

MUST be no smaller than

1

/4″ (6.4mm) mesh.

4. The minimum dimension of air ducts MUST NOT be less than

3″(76.2mm).

5. When sizing a grille, louver or screen use the free area of

opening. If free area is NOT stamped or marked on grill or

louver, assume a 20% free area for wood and 60% for metal.

Screens shall have a mesh size not smaller than

1

/4″(6.4mm).

Requirements

1. Provide the space with sufficient air for proper combustion and

ventilation of flue gases using horizontal or vertical ducts or

openings.

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.

10

441 01 2613 05

Specifications are subject to change without notice

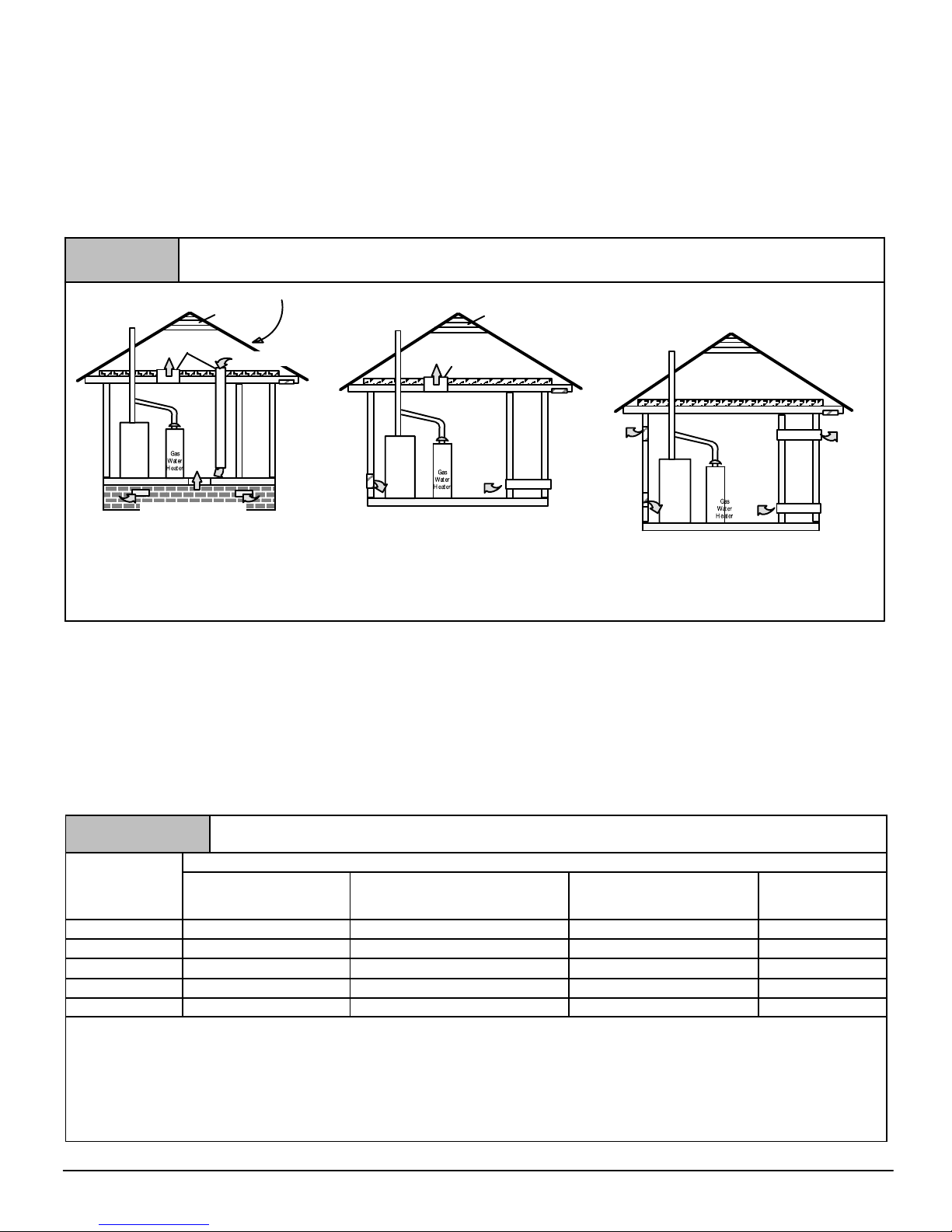

2. Figure 8 illustrates how to provide combustion and ventilation

air when two permanent openings, one inlet and one outlet, are

used.

a. One opening MUST commence within 12″ (304.8mm) of

the floor and the second opening MUST commence

within 12″ (304.8mm) of the ceiling.

b. Size openings and ducts per Table 1.

c. Horizontal duct openings require 1 square inch of free

area per 2,000 BTUH (11 cm

2

/kW) of combined input for

all gas appliances in the space (see Table 1).

d. Vertical duct openings or openings directly

communicating with the outdoors require 1 square inch

of free area per 4,000 BTUH (5.5 cm

2

/kW) for combined

input of all gas appliances in the space (see Table 1).

3. When one permanent outdoor opening is used, the opening

requires:

a. 1 sq. in of free area per 3,000 BTUH (7 cm

2

/kW) for

combined input of all gas appliances in the space (see

Table 1) and

b. Not less than the sum of the areas of all vent connectors

in the space.

Figure 8

Furnace

Furnace

Minimum One Inlet and One Outlet Air Supply is Required

May be in and Combination Shown

Inlet Air Opening Must be Within12″(304.8 mm) of floor

Outlet Air Opening Must be Within12″(304.8 mm) of ceiling

(1) 1 Square Inch per 4000 BTUH

(2) 1 Square Inch per 2000 BTUH

Outside Air (This is ONLY a guide. Subject to codes of country having jurisdiction.)

This installation NOT approved in Canada

Gas Vent

Gas Vent

Gas Vent

Gable Vent

Gable Vent

Outlet

Air (1)

Outlet Air (1)

Outlet Air (1)

Furnace

Outlet

Air (2)

Optional Inlet Air (1)

Ventilated Attic

Ventilated Attic

Ventilated Crawl Space

Inlet

Air (1)

Inlet

Air (1)

Inlet

Air (1)

Inlet

Air (2)

Inlet

Air (2)

Top Above Insulation

Top Above Insulation

Soffit Vent

Soffit Vent

The opening shall commence within 12″ (304.8mm) of the top of

the enclosure. Appliances shall have clearances of at least 1″

(25.4mm) from the sides and back and 6″ (152.4mm) from the

front. The opening shall directly communicate with the outdoors or

shall communicate through a vertical or horizontal duct to the

outdoors or spaces (crawl or attic) that freely communicate with

the outdoors.

4. Combination of Indoor and Outdoor Air shall have:

a. Indoor openings that comply with the Indoor

Combustion Air Method below and

b. Outdoor openings located as required in the Outdoor

Combustion Air Method above and

c. Outdoor openings sized as follows.

1) Calculate the Ratio of all Indoor Space volume

divided by required volume for Indoor Combustion Air

Method. Outdoor openings sized as follows.

2) Outdoor opening size reduction Factor is 1 minus the

Ratio in 1) above.

3) Minimum size of Outdoor openings shall be the size

required in Outdoor Combustion Air Method above

multiplied by reduction Factor.

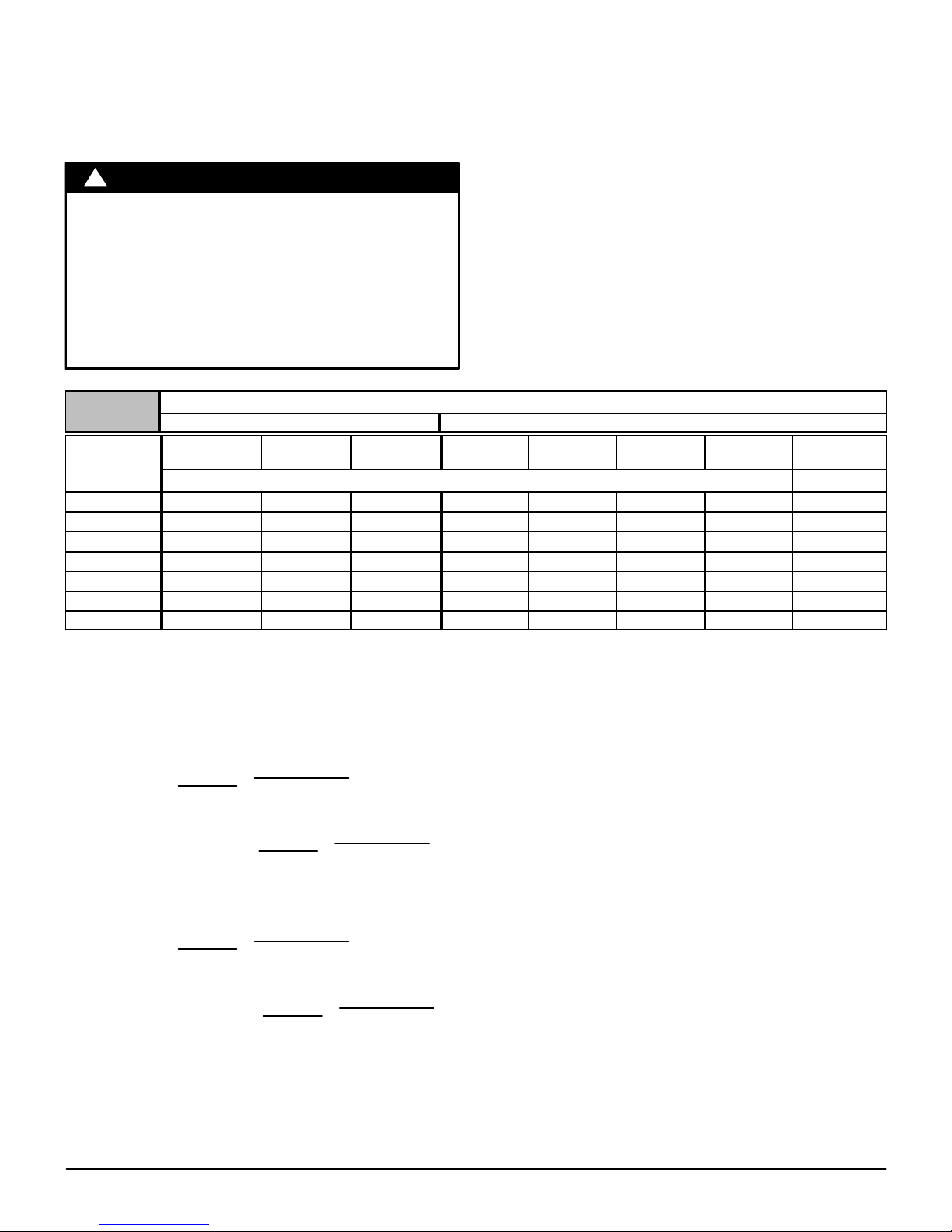

Table 1

Free Area

BTUH (kW)

Input

Rating

Minimum Free Area Required for Each Opening or Duct to Outdoors

Two Horizontal Ducts

BTUH (kW)

sq. in./2,000(1 cm

2

/.09)

Single Opening

BTUH (kW)

sq. in./3,000 (1 cm

2

/.135)

Two Vertical Ducts or Openings

BTUH (kW)

sq. in./4,000(1 cm

2

/.18)

Round Duct

BTUH (kW)

sq. in./4,000(6.5cm

2

/.18)

50,000 (14.65) 25 sq. in. (161 cm2) 16.7 sq. in. (108 cm2) 12.5 sq. in. (81 cm2) 4″ (101.6mm)

75,000 (21.98) 37.5 sq. in. (242 cm2) 25 sq. in. (161 cm2) 18.75 sq. in. (121 cm2) 5″ (127mm)

100,000 (29.31) 50 sq. in. (322 cm2) 33.3 sq. in. (215 cm2) 25 sq. in. (161 cm2) 6″ (152.4mm)

125,000 (36.63) 62.50 sq. in. (403 cm2) 41.7 sq. in. (269 cm2) 31.25 sq. in. (202 cm2) 7″ (177.8mm)

150,000 (43.95) 75 sq. in. (484 cm2) 50 sq. in. (322 cm2) 37.5 sq. in. (242 cm2) 7″ (177.8mm)

EXAMPLE: Determining Free Area

Furnace

100,000

29.31

Furnace

100,000

29.31

+

+

Water Heater

30,000

8.8

Water Heater

30,000

8.8

=

=

Total Input

(130,000 ÷ 4,000)

(38.11 ÷ .18)

Total Input

(130,000 ÷ 2,000)

(38.11 ÷ .09)

= 32.5 Sq. In. Vertical

= 210 c

m

2

Vertical

= 65 Sq. In. Horizontal

= 423

cm

2

Horizontal

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.

441 01 2613 05

11

Specifications are subject to change without notice

Indoor Combustion Air

Standard and Known-Air-Infiltration Rate Methods

NFPA & AGA

Indoor air is permitted for combustion and ventilation, if the

Standard or Known!Air!Infiltration Rate Method is used.

!

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in

personal injury or death.

Most homes will require additional air from outdoors

for combustion and ventilation. A space with at least

50 cubic feet per 1,000 BTUH (1.4 cubic meters per

.293 kW/h) input rating or homes with tight

construction may need outdoor air to supplement air

infiltration for proper combustion and ventilation of

flue gases.

WARNING

The Standard Method may be used, if the space has no less

volume than 50 cubic feet per 1,000 BTUH (4.8 cubic meters per

kW) of the maximum input ratings for all gas appliances installed in

the space. The standard method permits indoor air to be used for

combustion and ventilation air.

The Known Air Infiltration Rate Method shall be used if the

infiltration rate is known to be less than 0.40 air changes per hour

(ACH) and equal to or greater than 0.10 ACH. Infiltration rates

greater than 0.60 ACH shall not be used. The minimum required

volume of the space varies with the number of ACH and shall be

determined per Table 2 or Equations 1 and 2. Determine the

minimum required volume for each appliance in the space, and

add the volumes together to get the total minimum required

volume for the space.

Table 2

MINIMUM SPACE VOLUME FOR 100% COMBUSTION AND VENTILATION AIR FROM INDOORS

Other Than Fan-Assisted Total Fan-assisted Total

ACH

30,000 BTU

(8.79 kW)

40,000 BTU

(11.72 kW)

50,000 BTU

(14.65 kW)

50,000 BTU

(14.65 kW)

75,000

(21.98 kW)

100,000 BTU

(29.30 kW)

125,000 BTU

(36.63 kW)

150,000 BTU

(43.95 kW)

ft

3

(m3)

0.60 1,050 (29.7) 1,400 (39.2) 1,750 (49) 1,250 (35) 1,875 (52.5) 2,500 (70) 3,125 (87.5) 3,750 (105)

0.50 1,260 (35.3) 1,680 (47.04) 2,100 (58.8) 1,500 (42) 2,250 (63) 3,000 (84) 3,750 (105) 4,500 (126)

0.40 1,575 (44.1) 2,100 (58.8) 2,625 (73.5) 1,875 (52.5) 2,813 (78.8) 3,750 (105) 4,688 (131.3) 5,625 (158)

0.30 2,100 (58.8) 2,800 (78.4) 3,500 (98) 2,500 (70) 3,750 (105) 5,000 (140) 6,250 (175) 7,500 (210.6)

0.20 3,150 (88.2) 4,200 (117.6) 5,250 (147) 3,750 (105) 5,625 (157.5) 7,500 (210) 9,375 (262.5) 11,250 (316)

0.10 6,300 (176.4) 8,400 (235.2) 10,500 (294) 7,500 (210) 11,250 (315) 15,000 (420) 18,750 (525) 22,500 (632)

0.00 NP NP NP NP NP NP NP NP

NP = Not Permitted

Table 2 Minimum Space Volumes were determined by using the

following equations from the National Fuel Gas Code ANSI

Z223.1/NFPA 54!2009, 9.3.2.2:

1. For other than fan!assisted appliances such as a draft

hood!equipped water heater,

1000 Btu / hr

21 ft

3

(

I

other

)

Volume

other

=

ACH

.293 kW / hr

59 m

3

(

I

other

)

Required Volume

other

!

ACH

2. For fan!assisted appliances such as this furnace,

1000 Btu / hr

15 ft

3

(

I

fan

)

Volume

fan

=

ACH

.293 kW / hr

.42 m

3

(

I

fan

)

Required Volume

fan

!

ACH

If:

I

other

= combined input of all other than fan!assisted

appliances in Btu/hr

I

fan

= combined input of all fan!assisted appliances in Btu/hr

ACH = air changes per hour (ACH shall not exceed 0.60.)

The following requirements apply to the Standard Method and to

the Known Air Infiltration Rate Method.

• Adjoining rooms can be considered part of a space, if there

are no closable doors between rooms.

• An attic or crawl space may be considered a space that freely

communicates with the outdoors provided there are adequate

ventilation openings directly to outdoors. Openings MUST

remain open and NOT have any means of being closed off.

Ventilation openings to outdoors MUST be at least 1 square

inch of free area per 4,000 BTUH (5.5 cm

2

/kW) of total input

rating for all gas appliances in the space.

• In spaces that use the Indoor Combustion Air Method,

infiltration should be adequate to provide air for combustion,

ventilation and dilution of flue gases. However, in buildings

with unusually tight construction, additional air MUST be

provided using the methods described in section titled

Outdoor Combustion Air Method:

• Unusually tight construction is defined as Construction with:

1. Walls and ceilings exposed to the outdoors have a

continuous, sealed vapor barrier. Openings are gasketed

or sealed and

2. Doors and openable windows are weather stripped and

3. Other openings are caulked or sealed. These include

joints around window and door frames, between sole

plates and floors, between wall!ceiling joints, between

wall panels, at penetrations for plumbing, electrical and

gas lines, etc.

Ventilation Air

Some provincial codes and local municipalities require ventilation

or make!up air be brought into the conditioned space as

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.

12

441 01 2613 05

Specifications are subject to change without notice

replacement air. Whichever method is used, the mixed return air

temperature across the heat exchanger MUST not fall below 60°

F(16° C) continuously, or 55° F(13° C) on an intermittent basis so

that flue gases will not condense excessively in the heat

exchanger. Excessive condensation will shorten the life of the heat

exchanger and possibly void your warranty.

5. Gas Vent Installation

CARBON MONOXIDE POISONING, FIRE AND

EXPLOSION HAZARD

Failure to follow this warning could result in

personal injury, death, and/or property damage.

Read and follow all instructions in this section.

!

WARNING

Install the vent in compliance with codes of the country having

jurisdiction, local codes or ordinances and these instructions.

This Category I furnace is fan!assisted.

Category I furnace definition: A central furnace which operates

with a non!positive vent static pressure and with a flue loss not

less than 17 percent. These furnaces are approved for

common!venting and multi!story venting with other fan!assisted

or draft hood!equipped appliances in accordance with the NFGC

or NSCNGPIC

Category I Safe Venting Requirements

Category I furnace vent installations shall be in accordance with

Parts 12 and 13 of the National Fuel Gas Code (NFGC), ANSI

Z223.1/NFPA 54!2009; and/or Section 8 and Appendix C of the

CSA B149.1!05, National Standard of Canada, Natural Gas and

Propane Installation Code; the local building codes; furnace and

vent manufacturer’s instructions.

NOTE: The following instructions comply with the ANSI

Z223.1/NFPA 54!2009 National Fuel Gas Code and CSA B149.1

Natural Gas and Propane Installation code, based on the input

rate on the furnace rating plate.

1. If a Category I vent passes through an attic, any concealed

space or floor, use ONLY Type B or Type L double wall vent

pipe. If vent pipe passes through interior wall, use Type B vent

pipe with ventilated thimble ONLY.

2. Do NOT vent furnace into any chimney serving an open

fireplace or solid fuel burning appliance.

3. Use the same diameter Category I connector or pipe as

permitted by:

• the National Fuel Gas Code Code ANSI Z223.1/ NFPA

54!2009 Sections 12 and 13 venting requirements in the

United States

or

• the National Standard of Canada Natural Gas and

Propane Installation Code (NSCNGPIC) CSA

B149.1!05 Section 8 and appendix C venting

requirements in Canada.

4. Push the vent connector onto the furnace flue collar of the

venter assembly until it touches the bead [at least

5

/8″

(15.9mm) overlap] and fasten with at least two field!supplied,

corrosion!resistant, sheet metal screws located at least 140°

apart.

5. Keep vertical Category I vent pipe or vent connector runs as

short and direct as possible.

6. Vertical outdoor runs of Type!B or ANY single wall vent pipe

below the roof line are NOT permitted.

7. Slope all horizontal runs up from furnace to the vent terminal a

minimum of

1

/4″ per foot (10mm/m).

8. Rigidly support all horizontal portions of the venting system

every 6′ or less using proper clamps and metal straps to

prevent sagging and ensure there is no movement after

installation.

9. Check existing gas vent or chimney to ensure they meet

clearances and local codes. See Figure 1

10. The furnace MUST be connected to a factory built chimney or

vent complying with a recognized standard, or a masonry or

concrete chimney lined with a lining material acceptable to the

authority having jurisdiction. Venting into an unlined

masonry chimney or concrete chimney is prohibited. See

the 6. Masonry Chimney Venting section in these

instructions.

11. Fan!assisted combustion system Category I furnaces shall

not be vented into single!wall metal vents.

12. Category I furnaces must be vented vertically or nearly

vertically, unless equipped with a listed mechanical venter.

13. Vent connectors serving Category I furnaces shall not be

connected into any portion of mechanical draft systems

operating under positive pressure.

Venting and Combustion Air Check

NOTE: When an existing Category I furnace is removed or

replaced, the original venting system may no longer be sized to

properly vent the attached appliances, and to make sure there is

adequate combustion air for all appliances, MAKE THE

FOLLOWING CHECK.

Vent Check

Draft HoodVent Pipe

Match

Typical Gas

Water Heater

Figure 9

NOTE: If flame pulls towards draft hood, this indicates

sufficient infiltration air.

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.

441 01 2613 05

13

Specifications are subject to change without notice

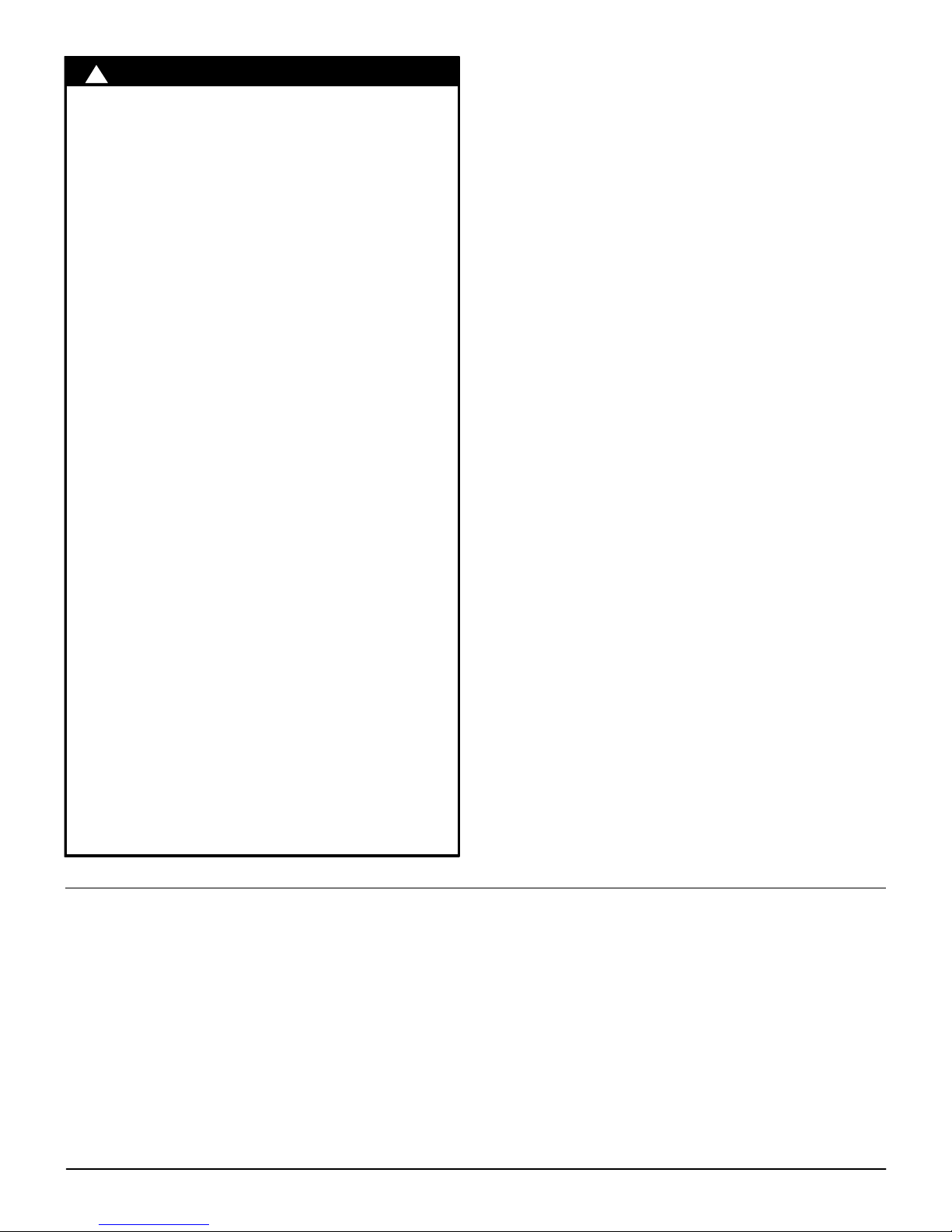

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each

appliance connected to the venting system being placed

into operation, could result in carbon monoxide

poisoning or death:

The following steps shall be followed for each appliance

connected to the venting system being placed into

operation, while all other appliances connected to the

venting system are not in operation:

1.Seal any unused openings in the venting system.

2.Inspect the venting system for proper size and horizontal

pitch, as required in the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 or CSA B149.1, Natural Gas and

Propane Installation Code and these instructions. Deter-

mine that there is no blockage or restriction, leakage, corrosion and other deficiencies which could cause an unsafe

condition.

3.As far as practical, close all building doors and windows

and all doors between the space in which the appliance(s)

connected to the venting system are located and other

spaces of the building.

4.Close fireplace dampers.

5.Turn on clothes dryers and any appliance not connected to

the venting system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so they are

operating at maximum speed. Do not operate a summer

exhaust fan.

6.Follow the lighting instructions. Place the appliance being

inspected into operation. Adjust the thermostat so

appliance is operating continuously.

7.Test for spillage from draft hood equipped appliances at

the draft hood relief opening after 5 minutes of main burner

operation. Use the flame of a match or candle. (Figure 9)

8.If improper venting is observed, during any of the above

tests, the venting system must be corrected in accordance

with the National Fuel Gas Code, ANSI Z223.1/NFPA 54

and/or CSA B149.1, Natural Gas and Propane Installation

Code.

9.After it has been determined that each appliance connected to the venting system properly vents when tested

as outlined above, return doors, windows, exhaust fans,

fireplace dampers and any other gas!fired burning

appliance to their previous conditions of use.

!

WARNING

Venting to Existing Masonry Chimney

Dedicated venting of one fan assisted furnace into any

masonry chimney is restricted. A chimney must first be lined

with either Type B vent sized in accordance with

ANSIZ223.1/NFPA!2009 tables 13.1a or 13.1b or a listed metal

lining system. (See Masonry Chimney Venting of these

instructions.)

Listed, corrugated metallic chimney liner systems in masonry

chimneys shall be sized by using ANSIZ223.1/NFPA!2009

section 13.1.7 for dedicated venting and 13.2.20 for common

venting with the maximum capacity reduced by 20% (0.80 X

maximum capacity) and the minimum capacity as shown in the

applicable table. In Canada, use the CSA B149.1!05 Natural Gas

and Propane Installation Code, appendix C, Section 10.

Corrugated metal vent systems installed with bends or offsets

require additional reduction of 5% of the vent capacity for each

bend up to 45° and 10% of the vent capacity for each bend from 45°

up to 90°.

NOTE: Two (2) 45° elbows are equivalent to one (1) 90° elbow.

Combined Venting into a Masonry Chimney

Venting into a masonry or concrete chimney is only permitted

as outlined in the NFGC or NSCNGPIC venting tables. Follow

all safe venting requirements.

Note: See section “Masonry Chimney Venting”.

6. Horizontal Venting

Category I Furnaces With External Power

Venters

In order to maintain a Category I classification of fan!assisted

furnaces when vented horizontally with sidewall termination, a

power venter is REQUIRED to maintain a negative pressure in the

venting system.

In the U.S.: Per the NFGC, a listed power venter may be used,

when approved by the authority having jurisdiction.

In Canada: Only power venters approved by the power venter

manufacturer and where allowed by the authority having

jurisdiction may be used.

Please consult the Fields Controls Co. or Tjernlund Products, Inc.

for power venters certified for use with our furnaces.

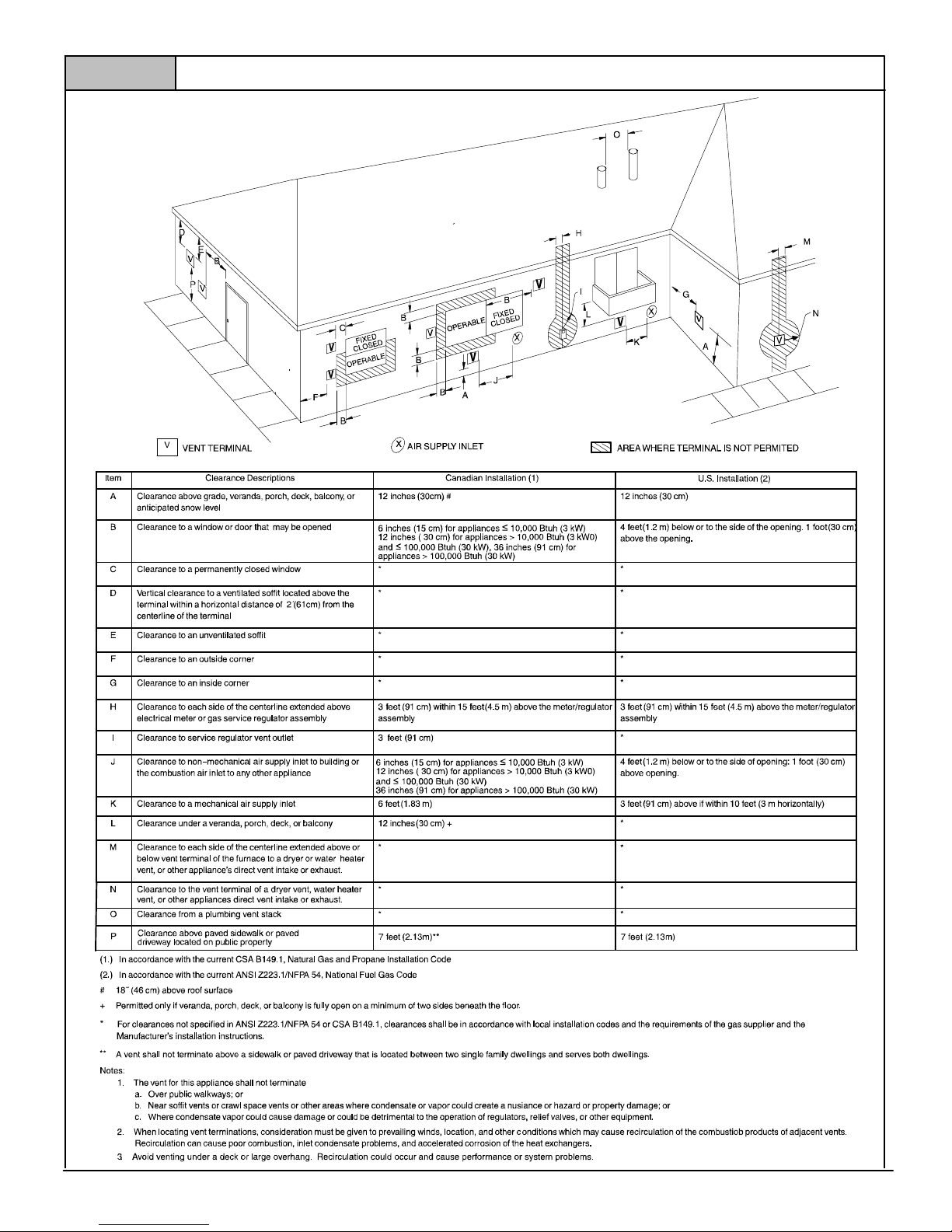

Vent Termination

Venting Through a Non-Combustible and

Combustible Wall

Consult External Power Venter manufacturer instructions.

Select the power venter to match the Btuh input of the furnace

being vented. Follow all of the Power Venter manufacturer’s

installation requirements included with the power venter for:

• venting installation,

• vent terminal location,

• preventing blockage by snow,

• protecting building materials from degradation by flue gases,

• see Figure 10 for required vent termination.

NOTE: It is the responsibility of the installer to properly terminate

the vent and provide adequate shielding. This is essential in order

to avoid water/ice damage to building, shrubs and walkways.

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.

Other than Direct Vent Termination Clearance

Figure 10

A05013

V

V

14

441 01 2613 05

Specifications are subject to change without notice

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.

441 01 2613 05

15

Specifications are subject to change without notice

7. Masonry Chimney Venting

Chimney Inspection

All masonry chimney construction must conform to Standard

ANSI/NFPA 211!2006 and to any state or local codes applicable.

The chimney must be in good condition and a complete chimney

inspection must be conducted prior to furnace installation. If the

inspection reveals damage or abnormal conditions, make

necessary repairs or seek expert help. See Figure 11 “The

Chimney Inspection Chart”. Measure inside area of tile!liner and

exact height of chimney from the top of the chimney to the highest

appliance flue collar or drafthood outlet.

Connector Type

To reduce flue gas heat loss and the chance of condensate

problems, the vent connector must be double!wall Type B vent.

Venting Restrictions for Chimney Types

Interior Chimney ! has no sides exposed to the outdoors below

the roofline. All installations can be single furnace or common

vented with another draft hood equipped Category I appliance.

Exterior Chimney ! has one or more sides exposed to the

outdoors below the roof line. All installations with a 99% Winter

Design Temperature* below 17°F(!8°C) must be common vented

only with a draft hood equipped Category I appliance.

* The 99% Winter Design Dry!Bulb (db) temperatures are

found in the 2005 ASHRAE Fundamentals Handbook CD

and Chapter 28.

CARBON MONOXIDE POISONING, FIRE AND

EXPLOSION HAZARD

Failure to follow this warning could result in

personal injury, death, and/or property damage.

These furnaces are CSA (formerly AGA and CGA)

design!certified for venting into exterior clay

tile!lined masonry chimneys with a factory

accessory Chimney Adapter Kit. Refer to the

furnace rating plate for correct kit usage. The

Chimney Adapter Kits are for use with ONLY

furnaces having a Chimney Adapter Kit number

marked on the furnace rating plate.

!

WARNING

If a clay tile!lined masonry chimney is being used and it is exposed

to the outdoors below the roof line, relining might be required.

Chimneys shall conform to the Standard for Chimneys,

Fireplaces, Vents, and Solid Fuel Burning Appliances ANSI/NFPA

211!2006 in the United States and to a Provincial or Territorial

Building Code in Canada (in its absence, the National Building

Code of Canada) and must be in good condition.

U.S.A.!Refer to Sections 13.1.9 or 13.2.22 of the ANSI

Z223.1/NFPA 54!2009 or the authority having jurisdiction to

determine whether relining is required. If relining is required, use a

properly sized listed metal liner, Type!B vent, or a listed alternative

venting design.

NOTE: See the ANSI Z223.1/NFPA 54!2009, 13.1.9 and 13.2.22

regarding alternative venting design and the exception, which

cover installations such as the Chimney Adapter Kits

NAHA001DH and NAHA002DH.

The Chimney Adapter Kits are listed alternative venting designs

for these furnaces. See the kit instructions for complete details.

Canada (and U.S.A.)!This furnace is permitted to be vented into a

clay tile!lined masonry chimney that is exposed to the outdoors

below the roof line, provided:

1. Vent connector is Type!B double!wall, and

2. This furnace is common vented with at least 1 draft

hood!equipped appliance, and

3. The combined appliance input rating is less than the

maximum capacity given in Table A, and

4. The input rating of each space!heating appliance is greater

than the minimum input rating given in Table B for Masonry

Chimneys for the local 99% Winter Design Temperature.

Chimneys having internal areas greater than 38 square

inches (245 sq. cm) require furnace input ratings greater

than the input ratings of these furnaces. See footnote at

bottom of Table B, and

5. The authority having jurisdiction approves.

If all of these conditions cannot be met, an alternative venting

design shall be used, such as the listed chimney adapter kit with a

furnace listed for use with the kit, a listed chimney!lining system,

or a Type!B vent.

These furnaces are CSA design!certified for use in exterior clay

tile!lined masonry chimneys with a factory accessory Chimney

Adapter Kit. Refer to the furnace rating plate for correct kit usage.

The Chimney Adapter Kits are listed alternative venting designs

and are for use with ONLY furnaces having a Chimney Adapter Kit

number marked on the furnace rating plate.

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.

16

441 01 2613 05

Specifications are subject to change without notice

Chimney is

acceptable for use

Crown

condition:

Missing mortar

or brick?

Rebuild

crown

Is

Chimney properly lined

with clay tile

liner?

Yes

Yes

No

No

Yes

Is

liner and top

seal in good

condition

No

Debris in

cleanout? Mortar, tile,

metal vent, fuel oil

residue?

Repair

liner or top seal

or reline chimney as

necessary.

Reline

Yes Repair

Yes

No

Yes

Clay

tile misalignment,

missing sections,

gaps?

No

Is Chimney

lined with properly

sized, listed liner or

Type-B vent?

Line chimney with properly

sized, listed flexible metal

liner or Type-B vent per NFGC or

NSCNGPIC Vent Sizing Tables

and liner or vent manufacturer's

installation instructions.

CHIMNEY INSPECTION CHART

For additional requirements refer to the National Fuel Gas Code ANSI Z223.1/NFPA 54-2009 and ANSI/NFPA 211-2006 Chimneys, Fireplaces, Vents, and Solid Fuel

Burning Appliances in the U.S.A. or to the Canadian Installation Code CSA B149.1-05 in Canada.

Yes

No

No

Mortar or

tile debris?

Yes

Remove mortar

and tile debris?

No

Remove metal vent or liner.

Consult

Part B of chimney

adapter venting

instructions for

application

suitability.

Chimney

exposed to outdoors

below roof line?

Is Chimney to

be dedicated to a

single furnace?

Yes

Install chimney

adapter per

instructions.

Not Suitable

Not Suitable

Suitable

No

Consult

Part C of chimney

adapter venting

instructions for

application

suitability.

Suitable

Install chimney

adapter per

instructions.

No

Condensate

drainage at bottom

of chimney?

Yes

Figure 11

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.

441 01 2613 05

17

Specifications are subject to change without notice

Exterior Masonry Chimney,

FAN+NAT Installations with

Type!B Double!Wall Vent Connectors

! NFPA & AGA

Table A-

Combined Appliance

Maximum Input Rating in

Thousands of Btu per Hr

VENT

HEIGHT

FT(m)

INTERNAL AREA OF CHIMNEY

SQ IN.(cm)

12(77.4) 19(122.6) 28(180.6) 38(245.2)

6(1.8) 74 119 178 257

8(2.4) 80 130 193 279

10(3) 84 138 207 299

15(4.6) NR 152 233 334

20(6.1) NR NR 250 368

30(9.1) NR NR NR 404

Table B-

Minimum Allowable Input Rating of

Space-Heating Appliance in

Thousands of Btu per Hr

VENT

HEIGHT

FT(m)

INTERNAL AREA OF CHIMNEY

sq. in(cm)

12(77.4) 19(122.6) 28(180.6) 38(245.2)

17 to 26"F (!8 to !3"C)

Local 99% Winter Design Temperature:

17 to 26°F (!8 to !3°C)*

6(1.8) 0 55 99 141

8(2.4) 52 74 111 154

10(3) NR 90 125 169

15(4.6) NR NR 167 212

20(6.11) NR NR 212 258

30(9.1) NR NR NR 362

5 t o 16"F (!15 to !9"C)

Local 99% Winter Design Temperature:

5 to 16°F (!15 to !9°C)*

6(1.8) NR 78 121 166

8(2.4) NR 94 135 182

10(3) NR 111 149 198

15(4.6) NR NR 193 247

20(6.11) NR NR NR 293

30(9.1) NR NR NR 377

!10 to 4"F (!23 to !16"C)

Local 99% Winter Design Temperature:

!10 to 4°F (!23 to !16°C)*

6(1.8) NR NR 145 196

8(2.4) NR NR 159 213

10(3) NR NR 175 231

15(4.6) NR NR NR 283

20(6.11) NR NR NR 333

30(9.1) NR NR NR NR

!11 °F

(!24°C)

or lower

Local 99% Winter Design Temperature:

!11°F (!24°C) or lower*

Not recommended for any vent configuration

* The 99% Winter Design Dry!Bulb (db) temperatures are

found in the 2005 ASHRAE Fundamentals Handbook CD

and Chapter 28.

Inspections before the sale and at the time of installation will

determine the acceptability of the chimney or the need for repair

and/or (re)lining. Refer to the Chimney Inspection Chart to

perform a chimney inspection.

If the inspection of a previously used tile!lined chimney:

a. Shows signs of vent gas condensation, the chimney should

be relined in accordance with local codes and the authority

having jurisdiction. The chimney should be relined with a

listed metal liner, Type!B vent, or a listed chimney adapter

kit to reduce condensation. If a condensate drain is required

by local code, refer to the ANSI Z223.1/NFPA 54!2009,

Section 12.10 for additional information on condensate

drains.

b. Indicates the chimney exceeds the maximum permissible

size in the tables, the chimney should be rebuilt or relined to

conform to the requirements of the equipment being

installed and the authority having jurisdiction.

A chimney without a clay tile liner, which is otherwise in good

condition, shall be rebuilt to conform to ANSI/NFPA 211!2006 or

be lined with a UL listed (ULC listed in Canada) metal liner or UL

listed Type!B vent. Relining with a listed metal liner or Type!B

vent is considered to be a vent!in!a!chase.

If a metal liner or Type!B vent is used to line a chimney, no other

appliance shall be vented into the annular space between the

chimney and the metal liner.

APPLIANCE APPLICATION REQUIREMENTS

Appliance operation has a significant impact on the performance

of the venting system. If the appliances are sized, installed,

adjusted, and operated properly, the venting system and/or the

appliances should not suffer from condensation and corrosion.

The venting system and all appliances shall be installed in

accordance with applicable listings, standards, and codes.

The furnace should be sized to provide 100 percent of the design

heating load requirement plus any margin that occurs because of

furnace model size capacity increments. Heating load estimates

can be made using approved methods available from Air

Conditioning Contractors of America (Manual J); American

Society of Heating, Refrigerating, and Air!Conditioning

Engineers; or other approved engineering methods. Excessive

oversizing of the furnace could cause the furnace and/or vent to

fail prematurely.

When a metal vent or metal liner is used, the vent or liner must be in

good condition and be installed in accordance with the vent or liner

manufacturer’s instructions.

To prevent condensation in the furnace and vent system, the

following precautions must be observed:

1. The return!air temperature must be at least 60°F(16°C) db

except for brief periods of time during warm!up from

setback at no lower than 55°F(13°C) db or during initial

start!up from a standby condition.

2. Adjust the gas input rate per the installation instructions.

Low gas input rate causes low vent gas temperatures,

causing condensation and corrosion in the furnace and/or

venting system. Derating is permitted only for altitudes

above 2000′ (610m).

3. Adjust the air temperature rise to the midpoint of the rise

range or slightly above. Low air temperature rise can cause

low vent gas temperature and potential for condensation

problems.

4. Set the thermostat heat anticipator or cycle rate to reduce

short cycling.

Air for combustion must not be contaminated by halogen

compounds which include chlorides, fluorides, bromides, and

iodides. These compounds are found in many common home

products such as detergent, paint, glue, aerosol spray, bleach,

cleaning solvent, salt, and air freshener, and can cause corrosion

of furnaces and vents. Avoid using such products in the

combustion!air supply. Furnace use during construction of the

building could cause the furnace to be exposed to halogen

compounds, causing premature failure of the furnace or venting

system due to corrosion.

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.

18

441 01 2613 05

Specifications are subject to change without notice

Vent dampers on any appliance connected to the common vent

can cause condensation and corrosion in the venting system. Do

not use vent dampers on appliances common vented with this

furnace.

8. Gas Supply and Piping

CARBON MONOXIDE POISONING, FIRE AND

EXPLOSION HAZARD

Failure to follow this warning could result in

personal injury, death, and/or property damage.

Models designated for Natural Gas are to be used

with Natural Gas ONLY, unless properly converted to

use with Propane gas.

!

WARNING

Gas Supply Requirements

• Use only the type of gas approved for this furnace. See rating

plate for approved gas type.

• Gas input must not exceed the rated input shown on the rating

plate. Overfiring will result in failure of heat exchanger and

cause dangerous operation.

• Do not allow minimum supply pressure to vary downward.

Doing so will decrease input to furnace. Refer to Table 3 for

gas supply. Refer to Table 6 and Table 7 for manifold

pressures.

Table 3 Gas Pressures

Gas Type

Supply Pressure

Recommended Max. Min.

Natural 7 in wc

(1744 Pa)

14 in wc

(3487 Pa)

4.5 in wc

1121 Pa)

Propane 11 in wc

(2740 Pa)

14 in wc

(3487 Pa)

11 in wc

(2740 Pa)

Gas Piping Requirements

NOTE: The gas supply line must be installed by a qualified service

technician in accordance with all building codes.

NOTE: In the state of Massachusetts.

a. Gas supply connections MUST be performed by a

licensed plumber or gas fitter.

b. When flexible connectors are used, the maximum length

shall not exceed 36″ (914.4mm).

c. When lever handle type manual equipment shutoff

valves are used, they shall be T!handle valves.

d. The use of copper tubing for gas piping is NOT approved.

1. Install gas piping in accordance with local codes, or in the

absence of local codes, the applicable national codes.

2. It is recommended that a manual equipment shutoff valve be

installed in the gas supply line outside the furnace. Locate