International Comfort Product HMD Series, HMD-163, HMD-179, HMD-124, HMD-146 Installation Instructions And Homeowner's Manual

...

Models :

HMD

Save these instructions for future reference.

Printed in Canada

DNS

-

0450 Rev A

OIL FIRED HOT

WATER BOILER

Manufactured by :

International Comfort Product

Division of UTC Canada Corporation

3400, Industriel blvd, Sherbrooke, Qc, Canada

Caution : Do not tamper with

the unit or its controls.

Call a qualified service

technician.

2003/05/06 X40014 Rev. E

PART 1

INSTALLATION

WARNING

• This boiler has been designed to provide you with

comfort, savings and reliability for many years to

come. Its performances, however, depends on the

appliance being installed, brought on-line, and

maintained correctly in accordance with the

instructions provided in this manual.

• This boiler is equipped with a burner designed to

burn only No.2 fuel oil (furnace oil). Never attempt

to burn used motor oil or any oil containing

gasoline.

• Make sure that the boiler and system are filled

with water and that all air has been bled before

attempting to start the burner.

• Never operate the burner above the maximum

temperature indicated on the boiler nameplate.

• Never attempt to start the burner when the

combustion chamber contains excess oil, is

overheated, or when a strong smell of oil

permeates the appliance.

• Close oil valves if the boiler has not to be used for

extended period of time.

• Never store garbage or combustibles near the

boiler.

• Never burn garbage or paper in your boiler.

• DO NOT TAMPER WITH THE UNIT OR THE

CONTROLS.

We recommend that you have a qualified

technician install your boiler.

1) UNIT IDENTIFICATION

It is very important that you consult the figure 1 to

recognise the characteristics of the “HMD” serie.

HMD boiler with potable hot water stainless steel tankin-tank and with a flue-pipe of 7 inches diameter. The

models are identified HMD-124, HMD-135, HMD-146,

HMD-163 and HMD-179 and are available with Riello

burner.

2) DELIVERY

Check carefully your boiler upon delivery for any

evidence of damage that may have occurred during

shipping and handling. Any claims for damages or lost

parts must be made with the transport company.

3) INSTALLATION

Your unit must be installed according to regulations

set down by competent authorities. See CSA B139

installation code.

3.1) Location

Your boiler must be installed in a clean and dry area,

as close as possible to a chimney. These boilers are

not approved for installation on combustible floor.

3.2) Clearances

The following minimum clearances from combustible

surfaces must be observed.

Top : 24 inches

Flue-pipe : 9 inches

First side : 3 inches

Other side : 24 inches

Front (from the cabinet): 24 inches

Rear : 24 inches

4) WIRING

The boiler must be connected to a 15 amp. @ 120

Vac protected circuit. The installer must wire the boiler

according to the electrical diagram figure 2. All wiring

must be done in accordance with the “Canadian

Electrical Code CSA C22.1/ Part I”.

WARNING

The use of a triple action / relay aquastat is

necessary whit the « HMD » boiler.

If more than 1 circulator is used, we recommend the

use of a RC-02 circulator control.

3

5) OIL SUPPLY

The oil tank and lines must be installed in accordance

with local codes and regulations. The burner can be

hooked up with a one pipe system if the oil level in the

tank is always over the burner level. For an outside

aboveground fuel tank hook up, ideally use a one pipe

system with nominal dimension of 12 mm (1/2”)

diameter, and be sure to have the oil filter and at least

3 meters (10 ft) of piping installed inside, to allow the

fuel oil to warm up before reaching the burner in very

cold weather. The following configurations must be

respected regarding the oil pump by-pass plug. With

Riello burner, remove the by-pass plug for one pipe

system.

The installation must include an oil filter and shutoff

valve. Make sure the piping has no leaks or

stoppages. Oil lines shall include no couplings. Never

use compression fittings. For a 2 pipes system, use

the same diameter for both the suction and the return

lines and set them at the same depth in the oil tank.

Additional information can be found in the burner

installation brochure that came with your boiler.

6) CHIMNEY

6.1) Chimney draft

Chimney draft must be strong enough to ensure safe,

reliable operation of your unit.

6.2) Installation

The connecting flue pipe diameter should never

exceed that of the chimney and its horizontal runs

should have a minimum slope of 1/4” (6.4 mm) per

foot (300 mm) of run upward toward the chimney. The

use of a damper in the connecting flue pipe is strictly

prohibited. If more than one pipe are to be connected

to the same chimney, the sectional area of the

chimney must be equal to the total of individual

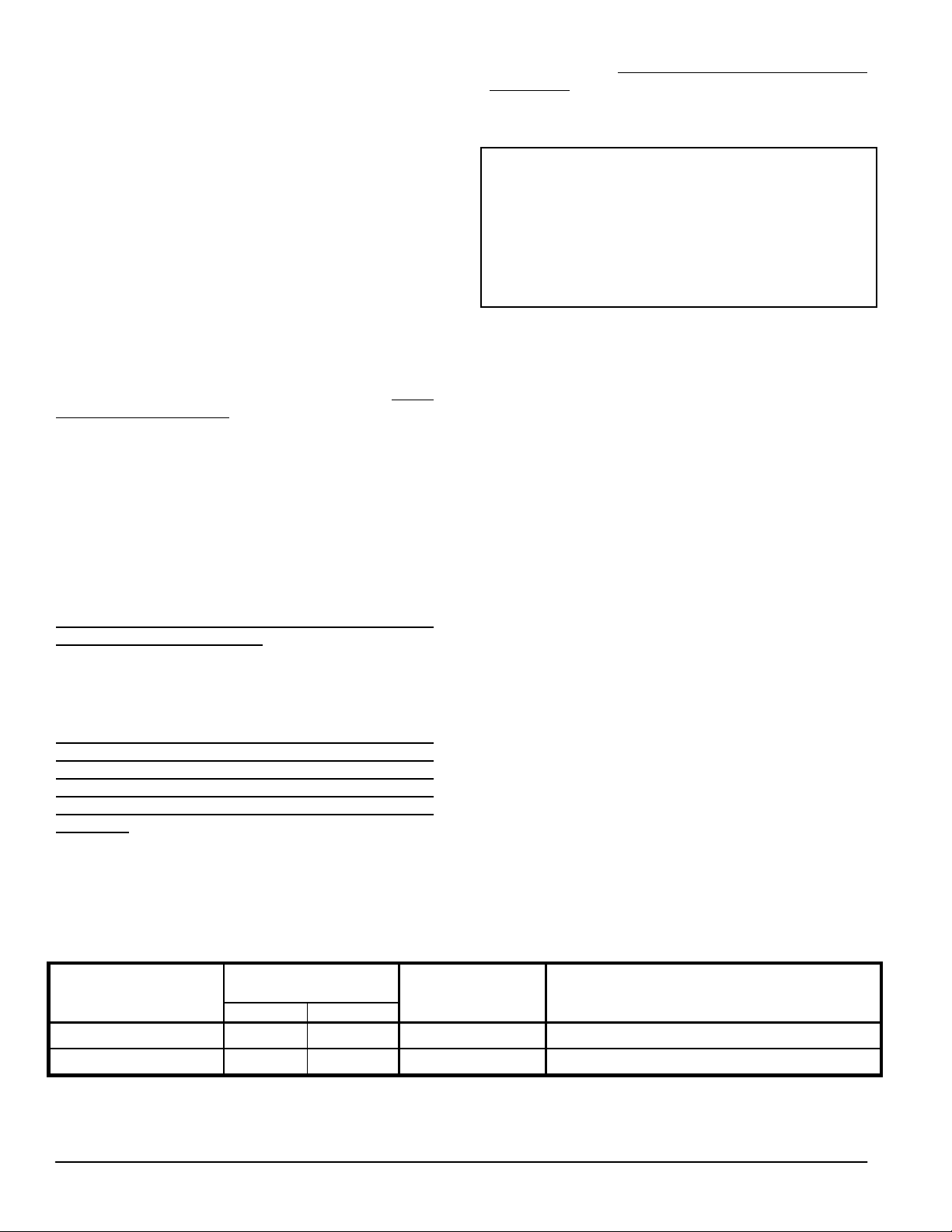

TABLE 1

Chimney draft

Chimney size

Models

Minimum Maximum

HMD-124 @ 146

HMD-163 @ 179

4

inches (mm)

5 (127) 6 (152) 7 (178) 0.035 (0.9)

6 (152) 8 (203) 7 (178) 0.05 (1.3)

Connecting pipe

inches (mm)

sectional areas. The usage of a draft control is

compulsory. His omission constitutes sufficient

grounds for voiding your warranty.

NOTICE

The formation of condensation on the three

outer sides of an outside chimney is a

possibility with efficient hot water boilers.

Should this happen, a chimney liner or a

“SMH” sidewall venting system should be

installed.

7) BURNER INFORMATIONS

The burner is shipped in a separate box from the

boiler and must be installed following the next steps :

1. Verify the model number on burner box to be

match with the one on the boiler nameplate;

2. Install the nozzle supplied and verify the

electrodes setting;

3. Install the burner on the boiler using supplied nuts

already on the studs. Do not forget the fireproof

gasket supplied with the burner. For the Riello

burners with an adjustable flange, make sure that

the end of the blast tube is flush with the inside

surface of the combustion chamber;

4. Connect the oil pipe(s) to the burner pump;

5. Perform electrical connections in accordance with

the appropriate diagram (See paragraph 4).

Recommended draft

inches (mm) W.C.

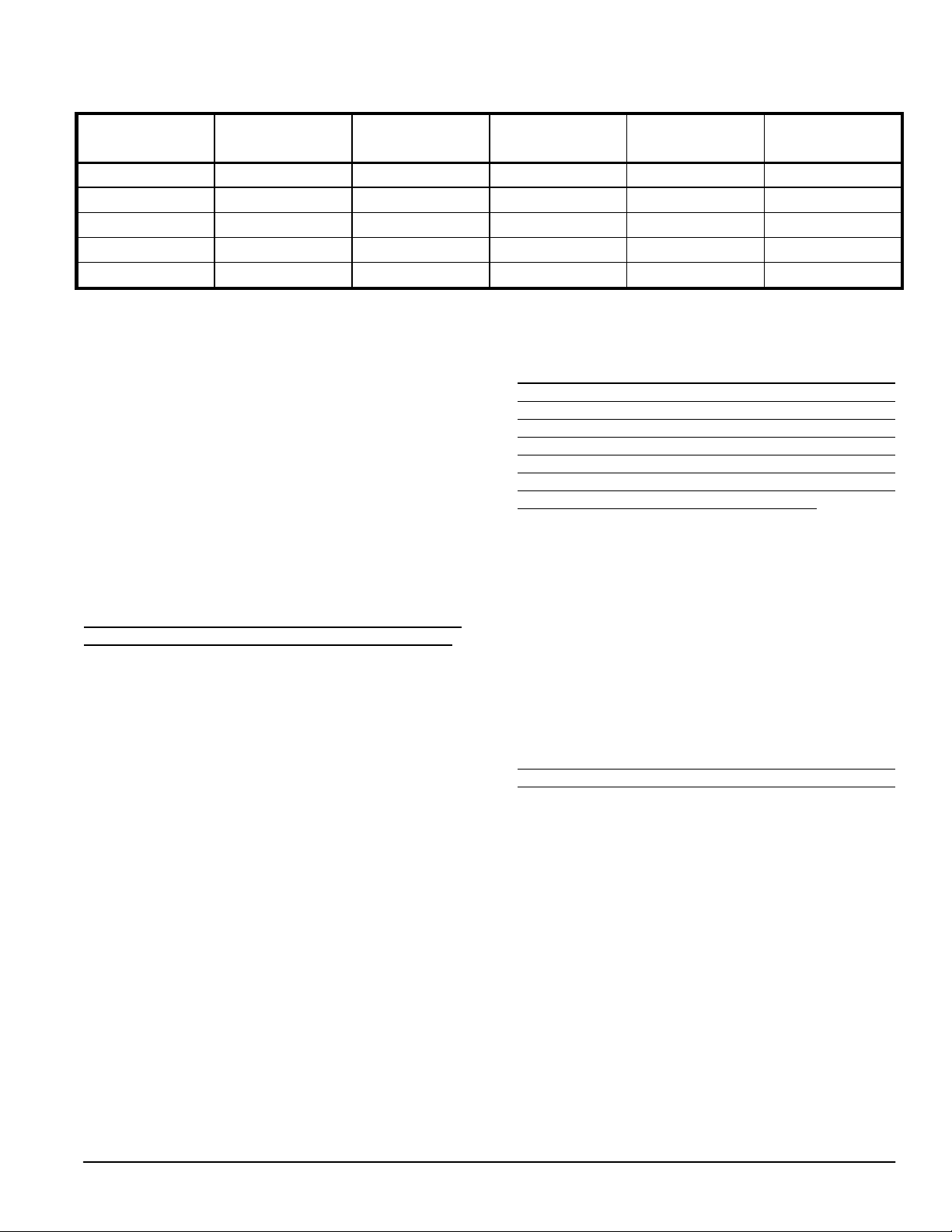

TABLE 2

Model

Capacity

Input

Burner

Nozzle

Pressure

HMD

-

124

124000

1.00 Riello F

-5

0.85-70B 140

HMD

-

135

135000

1.10 Riello F

-5

1.00-70B 125

HMD

-

146

146000

1.20 Riello F

-5

1.00-70B 145

HMD

-

163

163000

1.35 Riello F

-5

1.20-70B 130

HMD

-

179

179000

1.50 Riello F

-5

1.35-70B 125

Burner characteristics - “HMD” boilers

(Btu/hr) (USGPH)

8) COMBUSTION AIR SUPPLY

For a good and reliable operation, every oil heating

system must have an adequate and functional air

supply. If the boiler must be installed in a confined

area, 2 permanent air openings must be provided.

Both openings must be sized by allowing 1 ft2 per U.S.

gallon of oil to burn (240 cm2/l) per hour. One opening

should be located near the ceiling, the other near the

floor.

9) GENERAL PLUMBING

INFORMATIONS

Satisfying operation of your system greatly depend on

your plumbing arrangement. Refer to figures 3 and 4.

In all cases, your installation must include:

a. A pressure reducing valve, set at 12 psi (83 kPa),

installed in the boiler cold water supply;

b. An expansion tank pressurised to 12 psi (83 kPa),

present on the piping;

c. An automatic air vent, to eliminate trapped air in

the boiler;

d. A correctly sized water circulator, installed on the

heating loop;

e. Stop valves and threaded unions, installed on

return and supply boiler pipes.

Always use quality pipe sealant on all threaded

connections and make sure that these connections are

well tightened. Avoid flushing the system when this

boiler is a replacement for an existing one, to limit

oxygen to come in the system.

Delavan (psi)

10) POTABLE HOT WATER SUPPLY

Before attempting to proceed with the potable hot

water supply connections, always check the water

quality to avoid premature scaling, which quickly put

your installation inefficient. Refer to a specialist and

install a water softener if need. Locate the left tapping

to use as the potable cold water inlet. The use of the

thermostatic mixing valve (provided) is a necessity to

get safety and optimum of your installation.

11) THERMOSTAT

The thermostat must be mounted on an inside wall

approximately five feet high on the main floor. The

location should allow the thermostat to detect

temperature variations without exposing it to air

currents and sunrays.

12) DRAFT-REGULATOR

A barometric draft-regulator must be installed on the

connecting pipe between the chimney and the boiler.

It must be located in an easily serviceable location.

Please refer to the installation instructions supplied

with it.

5

Loading...

Loading...