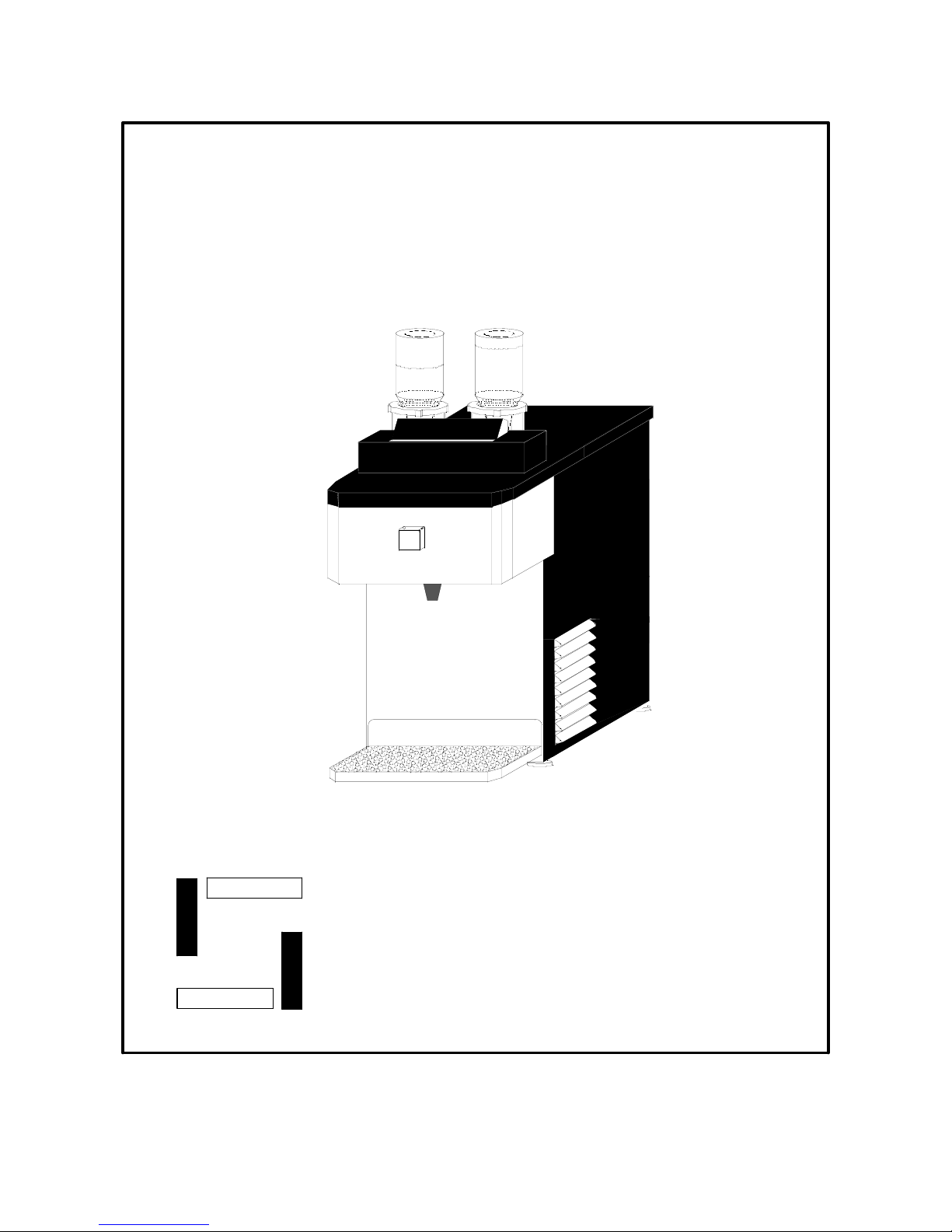

INTERNATIONAL CARBONIC TUACA Installation And Service Manual

TUACA

PUSH

HERE

Installation and Service Manual

INTERNATIONAL CARBONIC INC.

C

I

16630 Koala Rd.

Adelanto, California 92301

800 854-1177

3/22/05

IMPORTANT: This manual is a guide for installing,

operating, servicing and maintaining this equipment. Refer

to Table of Contents for page location of detailed

information to answer questions that arise during

installation, operating, service and maintenance, or

installation of this equipment.

TABLE OF CONTENTS

PAGE

PREFACE ........................................................................................... 1

CHAPTER 1

GENERAL DESCRIPTION.................................................................. 2

SYSTEM DESCRIPTION .................................................................... 2

DESIGN DATA.................................................................................... 2

THEORY OF OPERATION.................................................................. 3

EXPLODED VIEW............................................................................... 4

EXPLODED VIEW DESCRIPTION ..................................................... 5

ELECTRIC SCHEMATIC..................................................................... 7

CHAPTER II

UNPACKING AND INSPECTION........................................................ 8

SELECTING LOCATION..................................................................... 8

LOCATION RECOMMENDATIONS.................................................... 8

ELECTRICAL REQUIREMENTS......................................................... 8

TUACA UNIT INSTALLATION INSTRUCTIONS................................. 9

FLOW PLAN BOTTLE MOUNT........................................................... 11

CHAPTER III

OPERATORS INSTRUCTIONS.......................................................... 12

DAILY PRE-OPERATION CHECK...................................................... 12

COOLING UNIT MAINTENANCE........................................................ 12

CLEANING NOZZLE........................................................................... 12

CLEANING CONDENSER COIL......................................................... 13

CLEANING AND SANITIZING............................................................. 13

FREQUENTLY ASKED QUESTION.................................................... 14

CHANGING PERISTALTIC PUMP TUBING ....................................... 14

TROUBLE SHOOTING ....................................................................... 15

NOTES................................................................................................ 17

PREFACE

INTERNATIONAL CARBONIC INC. has enjoyed

over 53 years of manufacturing excellence in the

field of carbonation and in the beverage related

industry. We have been located in the Southern

California area since 1952 and have a long and

proud history with quality as our standard and

innovation as our goal. Originally started just

after World War II in Canfield Ohio as Carbonic

Dispensers we enjoyed patents on the first

Sodajet type carbonator. This method of

carbonation instantaneously carbonated the

water to 100% saturation. We developed the

first patented dispensing valve to dispense bulk

beverage with carbonation equal to or in excess

of bottled beverages. A valve with three flavors

and soda was another first. We were the first to

incorporate the total post-mix package; i.e.,

carbonation, refrigeration & the ability to

dispense from one self contained unit. We have

pioneered many such firsts and will continue to

develop advance systems for the future, such as

electronic interrogatable portion controls to

electronic liquid level controls.

We hope you enjoy this product that has been

produced to give many years of trouble free

service. We thank you for your purchase and

hope we may serve you in the future.

1

TUACA CHAPTER I

GENERAL DESCRIPTION

This chapter gives the description, theory of operation, and design data for the TUACA unit.

SYSTEM DESCRIPTION

The TUACA unit is a complete self-contained liquor dispenser which when supplied with TUACA will

dispense a delicious chilled TUACA drink. The unit consists of a cabinet, refrigeration system, modular

peristaltic pumps, and lighted merchandising. The cabinet is housed in an attractive black vinyl and then

decaled with vibrant TUACA Decals. The front plate and drain are formed from attractive grained

stainless steel. The TUACA unit has been designed to fit in the smallest possible space while dispensing

a maximum amount of highly chilled 1oz, servings of TUACA and lime.

Essentially the TUACA unit is designed to plug and play. For proper function the TUACA unit must have

120 volt electrical supply and proper space around unit to allow the refrigeration to breath during

operation. The TUACA unit is designed with a unique lift off drain pan that can be emptied at any

convenient drain outlet.

DESIGN DATA

TUACA

Cabinet:

Height .. ............................................................................................................17 ½

Overall Height w/Merchandiser .........................................................................22 ½

Width ..............................................................................................................11 ¾

Depth ............................................................................................................. 14 7/8

Depth w/Switch Housing....................................................................................17 ¾

Weights:

Shipping.............................................................................................................75 LBS.

Operational weight.............................................................................................69 LBS.

Refrigerant requirement (R-134a)...............................................3.18 ounces

90 grams

Ambient operating temperature.........................................................................40 F to 100 F

Electrical Requirements:

The cooling unit requires a 120 VAC, single phase, 60 Hertz power circuit.

Circuit Ampacity.................................................................................................3.1 Amps

Condensing Unit................................................................................................2.1 Amps

Peristaltic Pump Assembly................................................................................ 1. Amp

REFRIGERATION 1/9 H.P. capillary air-cooled.

2

THEORY OF OPERATION

The TUACA unit was designed to cool and dispense a chilled serving of alcohol

based TUACA. After initial connection to an electrical outlet and installing the

TUACA bottles into the bottle reservoir’s. The unit’s push switch must be

activated until a small portion of TUACA is dispensed. In approximately 15

minutes from the time the unit is electrically activated the unit will dispense a

chilled shot below 32 degrees.

When the Push Switch is pushed the incoming TUACA is routed to a peristaltic

pump, and then through a cooling coil that is positioned next to the refrigeration

evaporator coil. The temperature of the incoming TUACA is at ambient

temperature as it enters the cooling coil. As the incoming TUACA passes

through the cooling coil the heat is removed from the TUACA and chilled to a

temperature acceptable for a quality drink, normally a temperature 7 to 16

degrees is reached. The TUACA is now directed to a dispensing nozzle where

the TUACA is dispensed.

3

Loading...

Loading...