Page 1

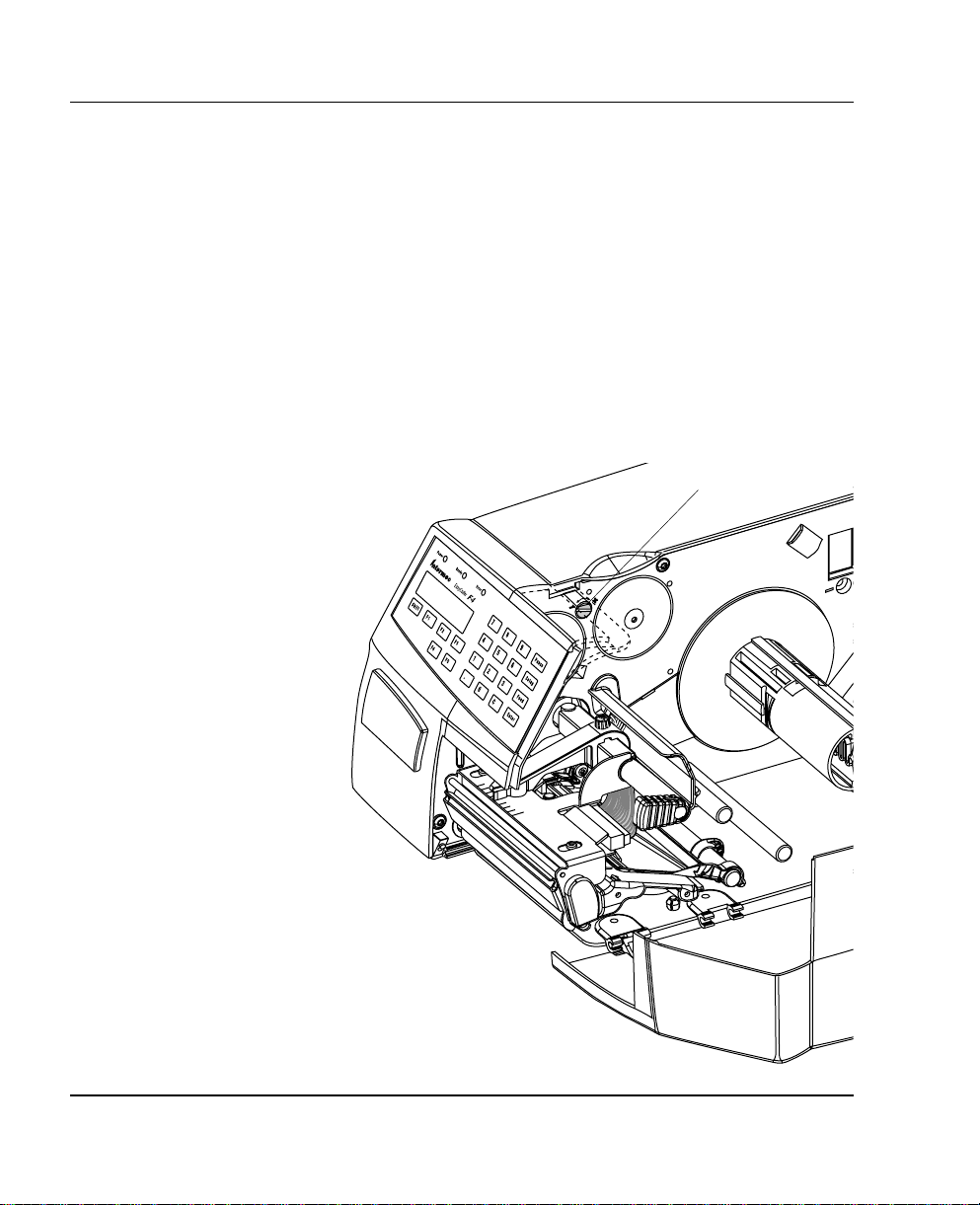

Chapter 11 Maintenance

Printhead Cleaning, cont'd.

87

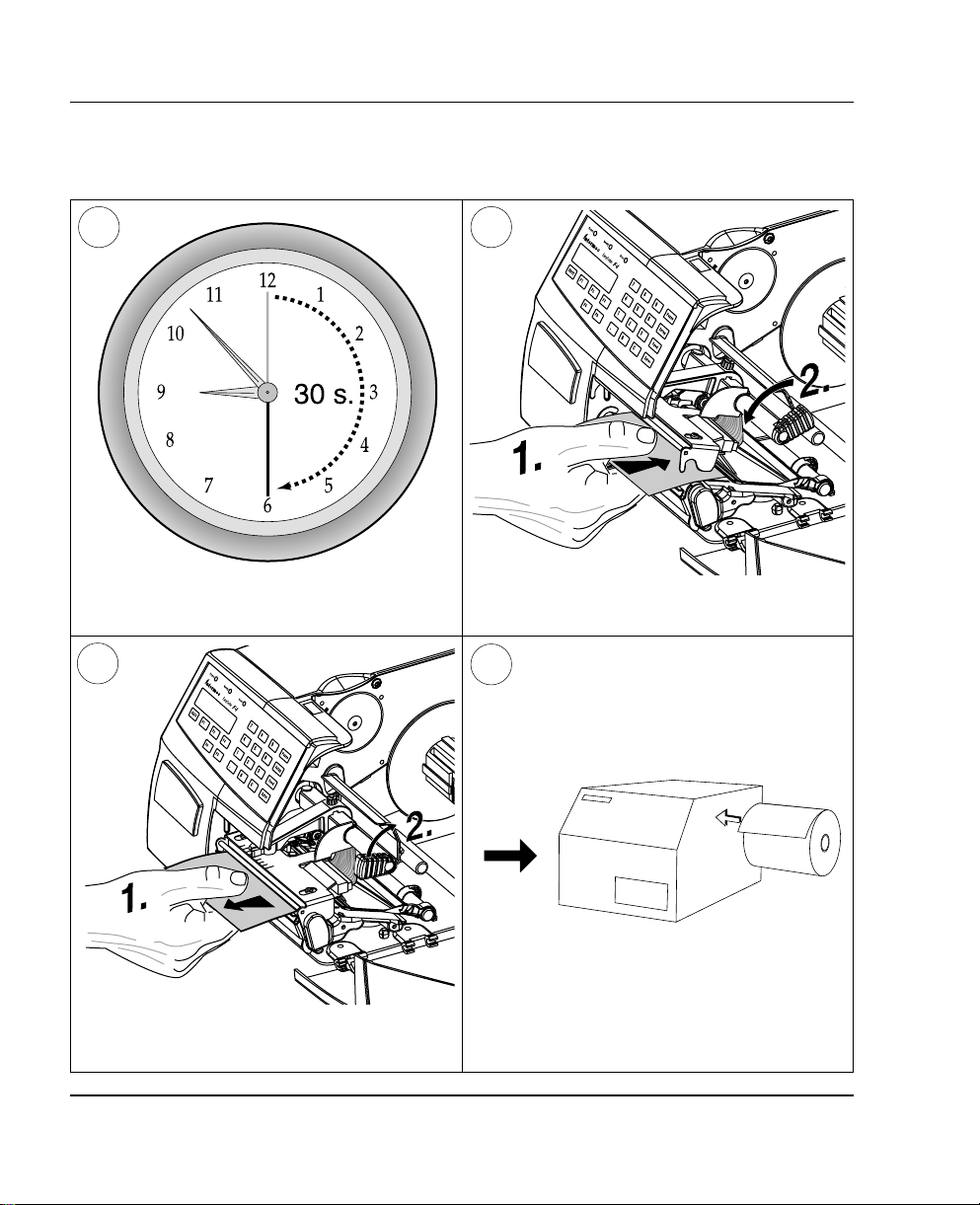

Wait for approx. 30 seconds to allow the

cleaning fl uid to dissolve the residue.

9

Pull out the cleaning card. If necessary, repeat

the process with a new cleaning card.

Insert most of the cleaning card under the

printhead (1). Close the printhead (2).

10

Allow the cleaned parts to dry before loading

any paper.

Intermec EasyCoder F4 – Installation & Operation Ed. 278

Page 2

External Cleaning

Chapter 11 Maintenance

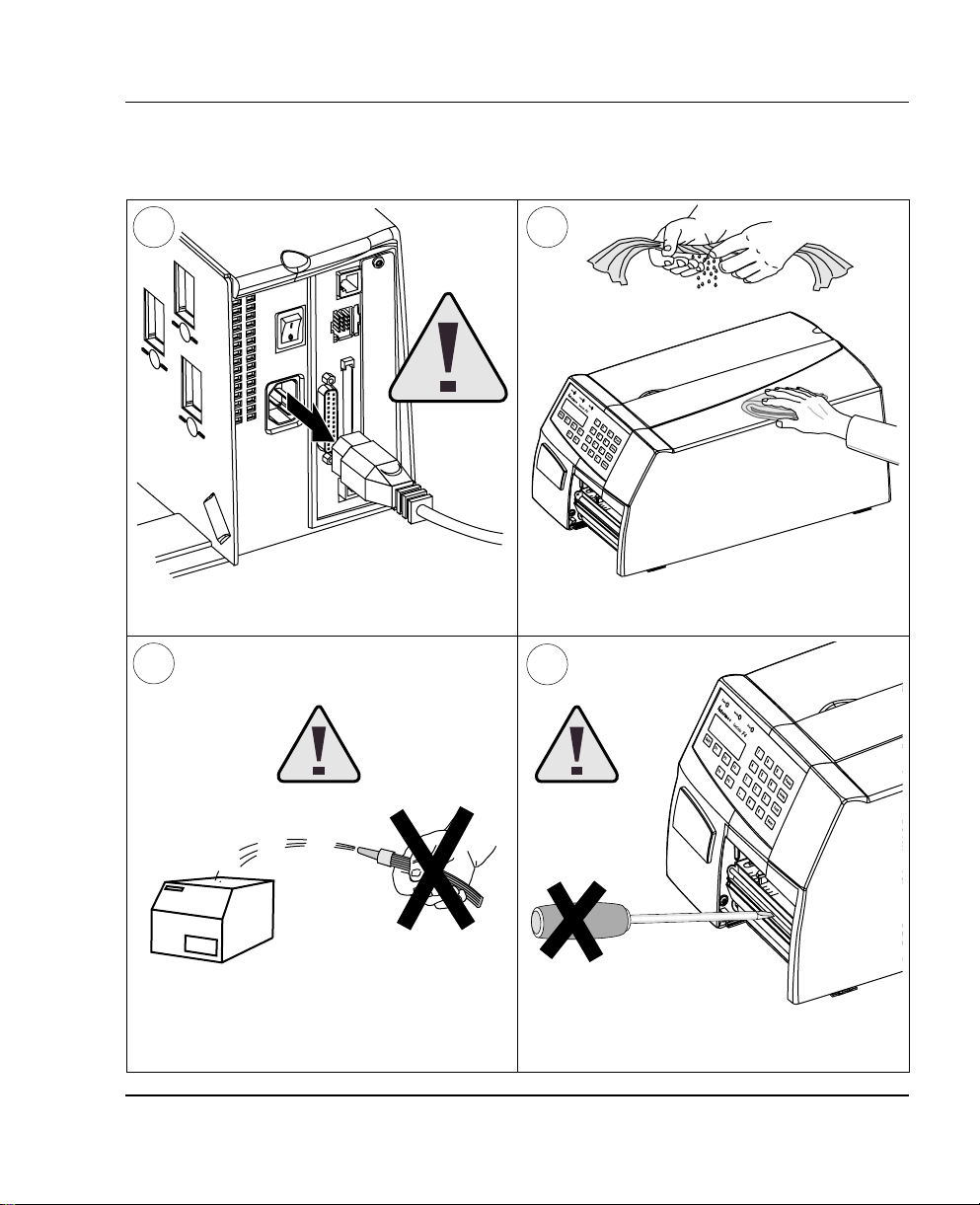

1

Always remove the power cord

before cleaning!

3

2

Wipe external surfaces with a soft cloth slightly

moistened with water or a mild detergent.

4

Never spray the printer. Protect it from water

when cleaning the premises.

Intermec EasyCoder F4 – Installation & Operation Ed. 2 79

Never use any sharp tools for removing stuck

labels. The printhead and rollers are delicate.

Page 3

Chapter 11 Maintenance

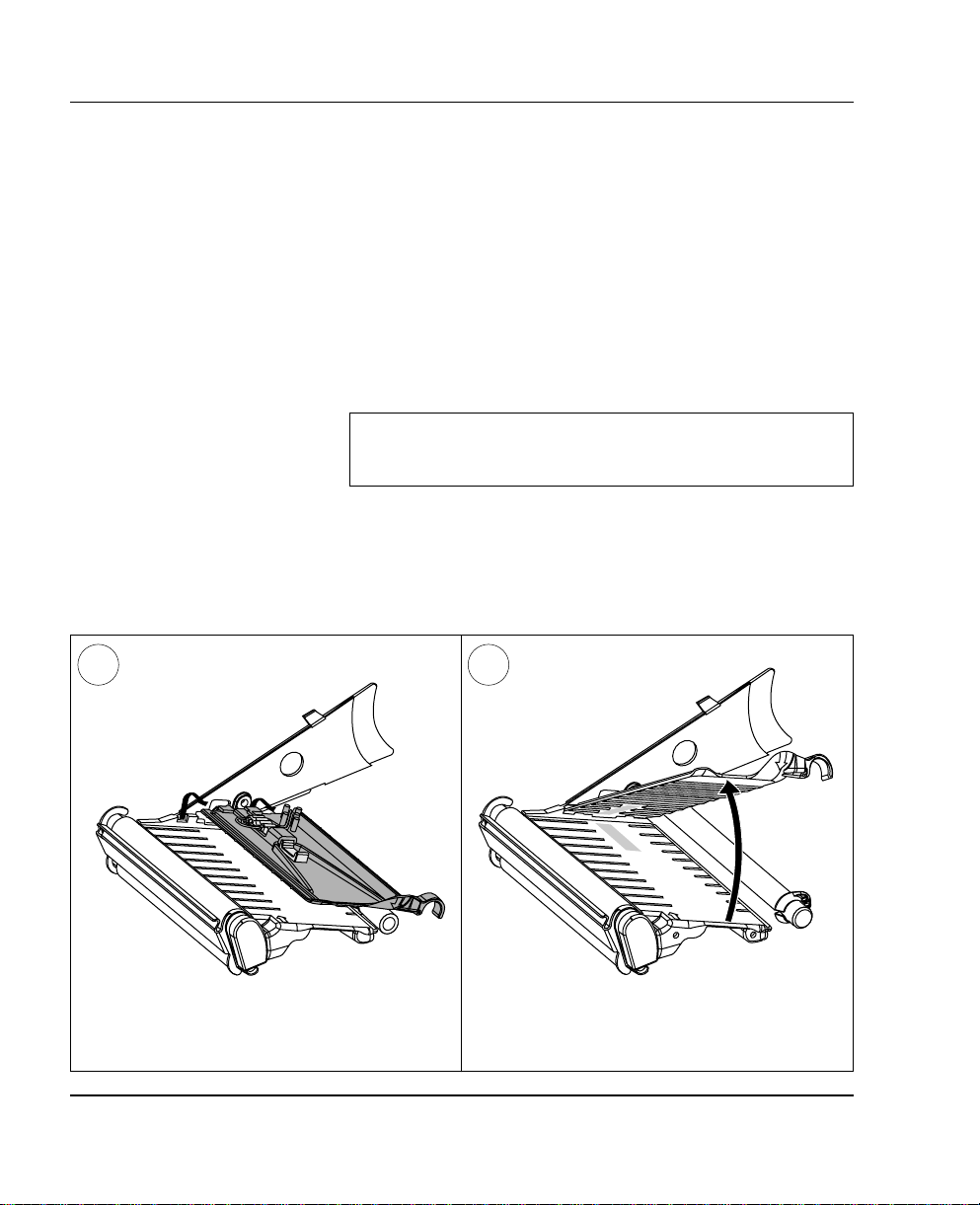

Cleaning the

Paper Guides

Both parts of the label stop sensor, which controls the paper feed, are

covered by plastic guides. The guides are provided with seemi ngly

non-t ranspa rent area s, thr ough which the l ight betwee n the two

part s of the lab el stop sensor is tra n sm itte d. T hese areas (indicated

by a shade of gre y in illustration #2 belo w) mus t be kep t c l ean from

dust, stuck labels, and adhesive residue.

If the printer starts to feeed our labels in an unexpected way. lift the

upper guide – as described be lo w – and c h eck f or an ythin g th at m a y

block the beam of light (dust, stuck labels, adhesive residue etc.).

If necessa ry, clean the guides using a cleaning card or a soft cloth

soaked with isopropyl alcohol. Do not use any other the of chemical.

Be careful not to scratch the guides.

Caution!

Isopropyl alco hol [(CH

fl ammable, moderately toxic and mildly irritating substance.

1 2

CHO H; CA S 67- 63- 0] is a h ighly

3)2

Lift the inner part of the upper guide and

pull it outwards,disengaging it from the lower

guide. Take care not to damage the cable.

Tilt the upper guide upwards and clean the

areas marked with grey. After cleaning, reas-

semble in reverse order.

Intermec EasyCoder F4 – Installation & Operation Ed. 280

Page 4

Chapter 11 Maintenance

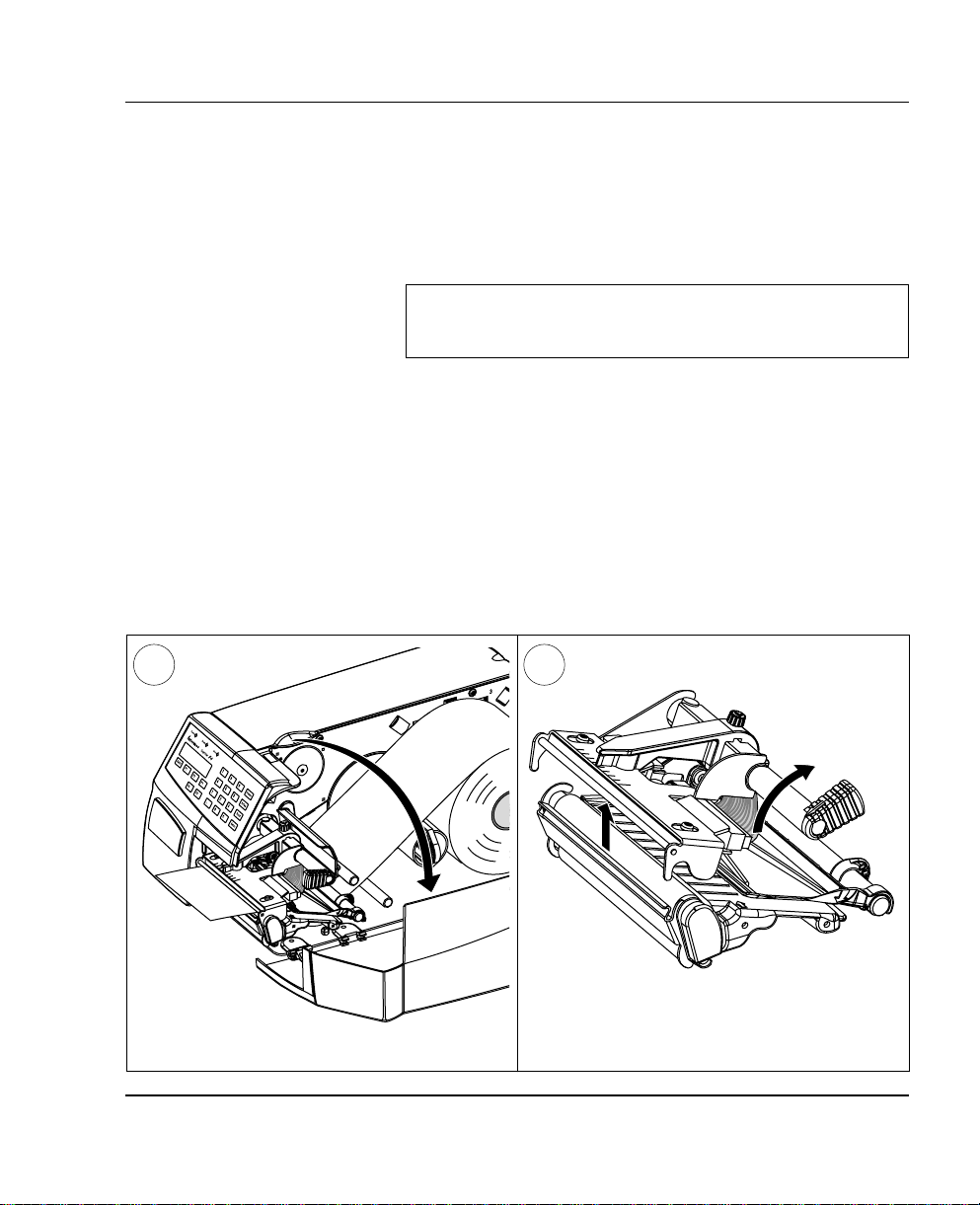

Printhead

Replacement

The printhead is subject to wear both from the direct thermal paper

and from the rapid heating and cooling process during printing. Thus,

the printhead will require periodical replacement.

Time between printhead replacements depends on the print images,

the type of paper in use, the amount of energy to the printhead,

and several other factors.

Note!

Whi le repla cing the pr inth ead, t he power sh ould b e switch ed

off.

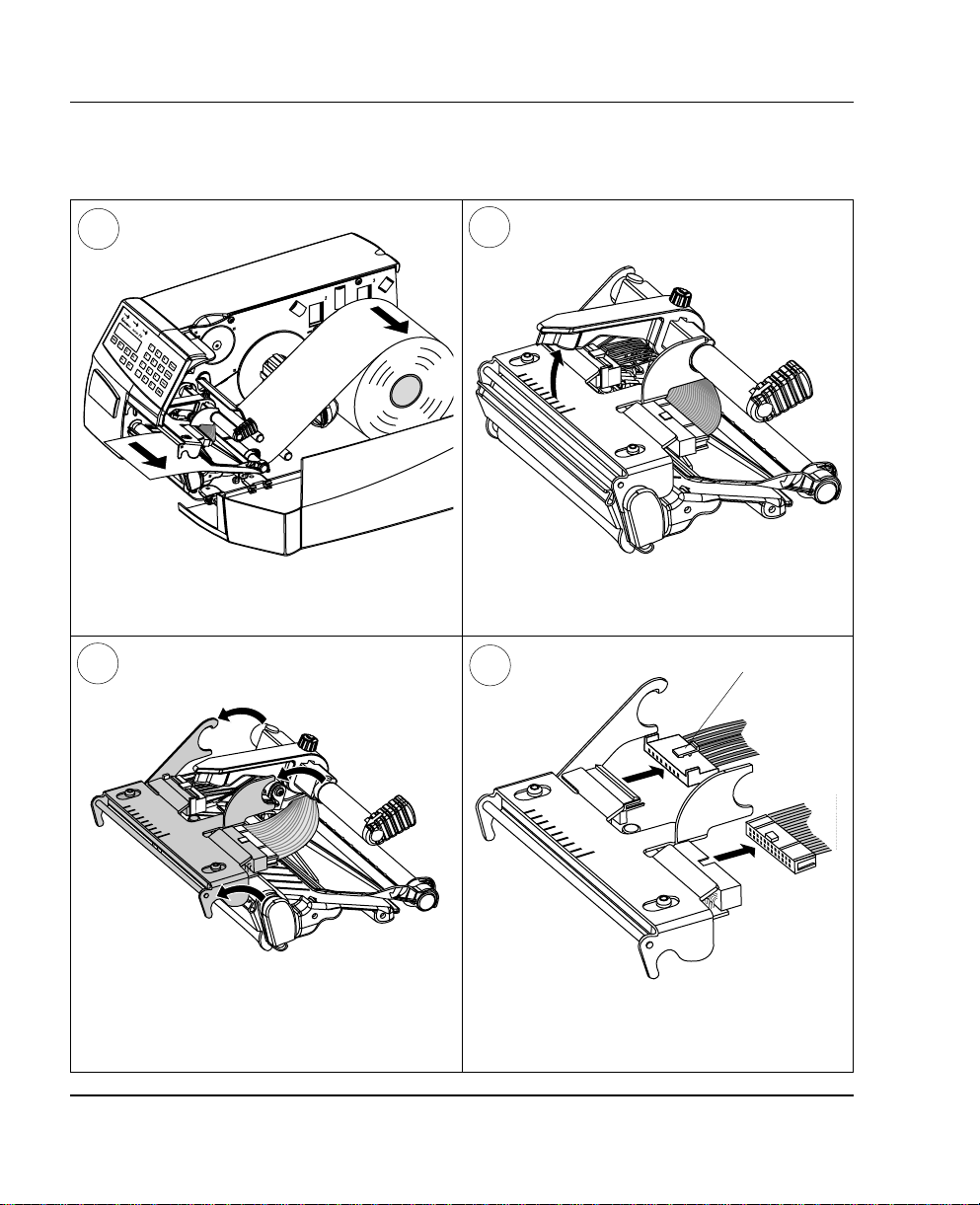

1 2

Turn the printhead lift knob clockwise to lift

Open the side door.

Intermec EasyCoder F4 – Installation & Operation Ed. 2 81

the printhead.

Page 5

Chapter 11 Maintenance

Printhead Replacement, cont'd.

3

Remove the paper, if any.

5

4

Pull the printhead bracket away from the

magnet in the pressure arm.

6

Snap-lock

Disconnect the printhead bracket from the print

mechanism – as indicated by the arrows – and

pull out the printhead as far as the cables allow.

Disconnect the cables from the printhead. Note

the snap-lock on the inner connector. Pull at the

connectors – not the cables!

Intermec EasyCoder F4 – Installation & Operation Ed. 282

Page 6

Printhead Replacement, cont'd.

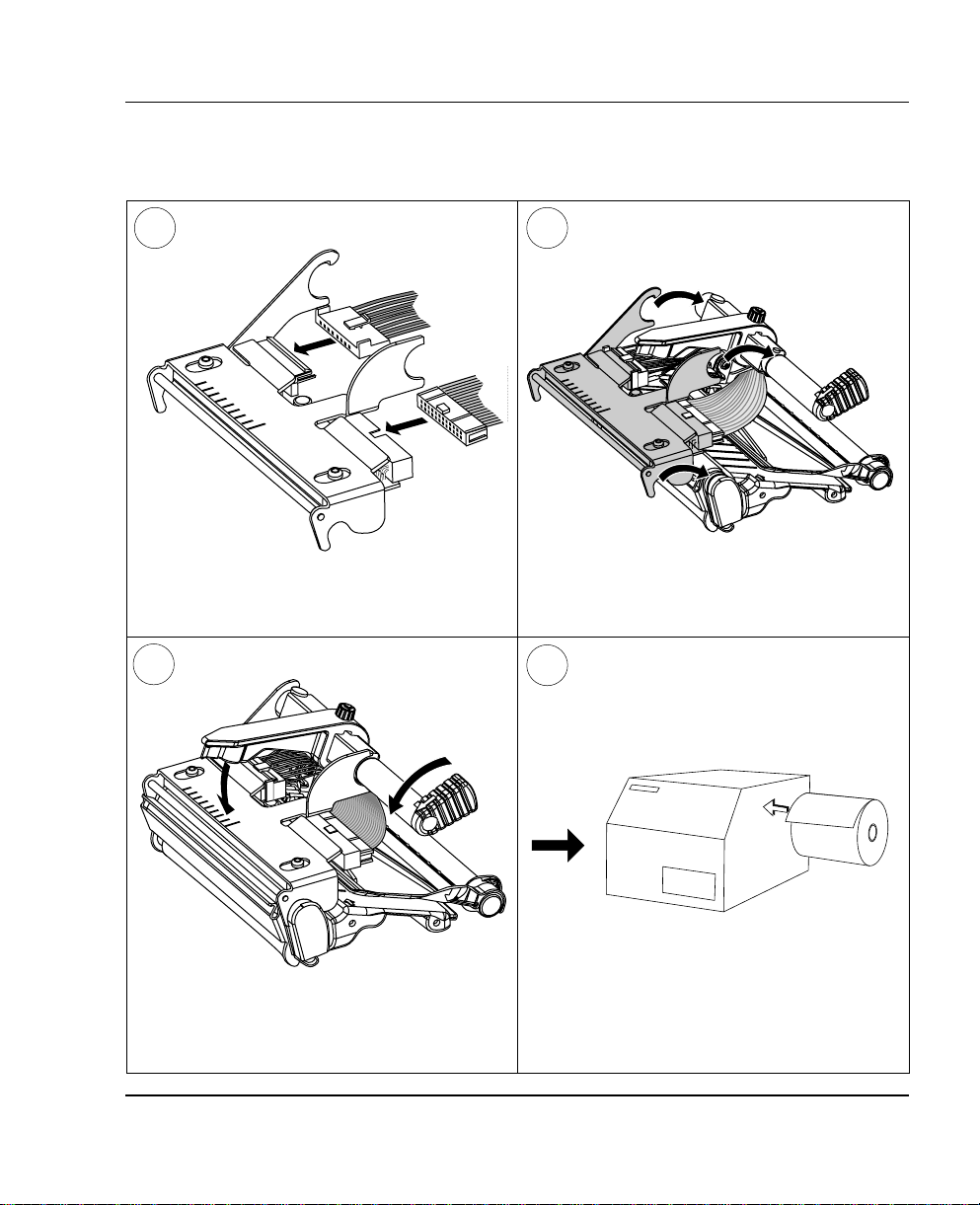

87

Chapter 11 Maintenance

Connect the two cables to the replacement

printhead.

9

Close the printhead so the magnet engages the

printhead bracket.

Intermec EasyCoder F4 – Installation & Operation Ed. 2 83

Put back the printhead in reserse order and

check that the printhead cables run freely.

10

Load a new supply of paper as described ear-

lier in this manual.

Page 7

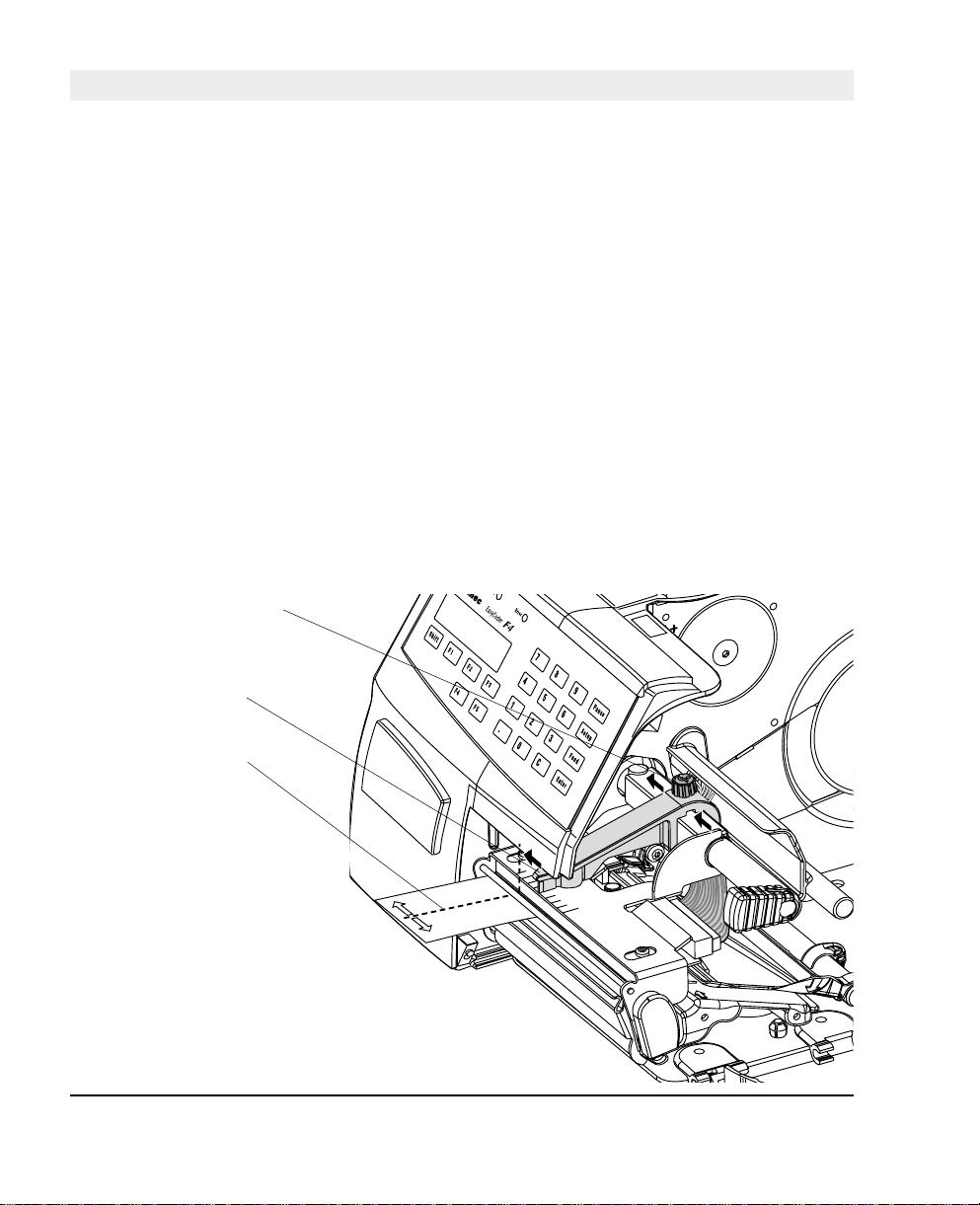

Chapter 12

Adjustments

Narrow Labels

Adjustment

Nut

Pressure Arm

Centre of Paper

The printer is factory-adjusted for full size paper width. When using

paper less than full width, it is recommended to adjust the pressure

arm so it becomes cent red on t he pap er. Thereby, an even pressure

across the paper is obtained.

A poorly adjusted pressure arm may be detected by a weaker printout

on the inner pa rt of a less than f ull width paper. Similarly, when

reverting to a wider paper, the arm should be adjusted, or the printout

on the outer part of the paper could be weak.

T o ad just the pressure arm, proceed as follo ws:

• Loosen the nut that holds the pressure arm. Move the arm inwards

or outwards until the arrow on the tip of the arm becomes

centre-aligned with the paper web.

While moving the arm, push at the part where the nut is situated,

not at the tip. If the arm is hard to move, lift the printhead and pull

the printhead bracket free from the magnet in the arm.

• After having centred the arm, lock it by tightening the nut.

Intermec EasyCoder F4 – Installation & Operation Ed. 284

Page 8

Chapter 12 Adjustments

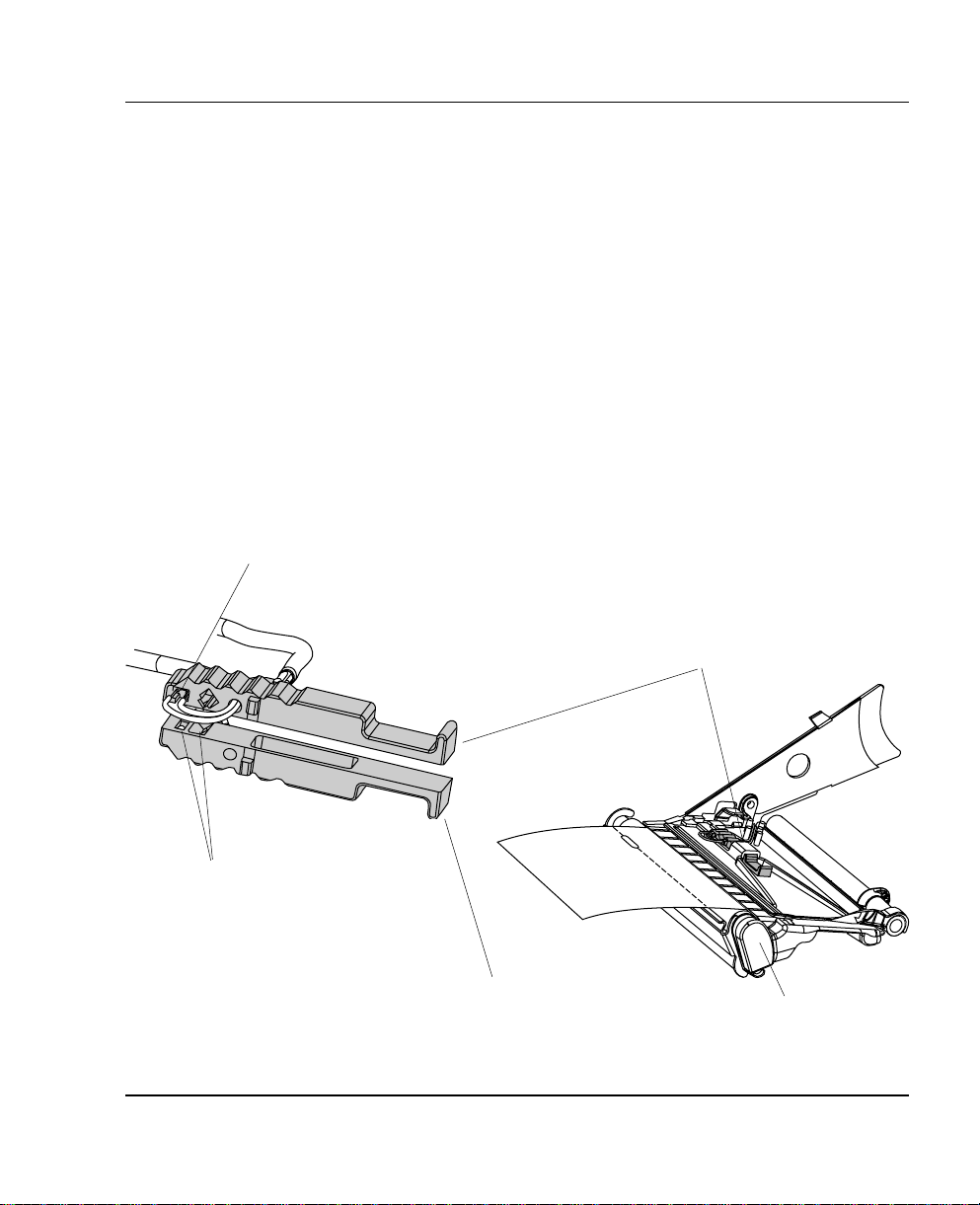

Label Stop Sensor

Position

One Sensor

The label stop/black mark sensor (LSS) is a photoelectric sensor that

controls the printer's paper feed by detect ing gaps between labels,

slots in paper strip, or black marks, depending on the printer's setup

in regard of media typ e (see chapter 6 “Setting Up the Pri nter”).

A prerequisite is obviously that the LSS is aligned with the slots

or black marks.

Thus, the LSS can b e moved laterally between 5 fi xed po sit ions.

There is one sensor on top of the upper paper guide and underneath

the bottom of the print unit. These two guides must be set individually

to th e same pos ition. Pu sh them inwa rds as fa r as they go a nd

then pull them out – one at the time – while counting the clicks

from the snap-locks.

The various dete ction points of the sensor in relation to the inner

edge of the paper are as follows:

One click out 3 mm .118"

Two c licks out 8 mm .3 1 5 "

Three clicks out 12 mm .47 2"

Four clicks out 16 mm .639"

Five c licks out 20 mm .787"

If usi ng irr egula rly shape d labels, a lign t he LSS with t he fron t

tips of the labels

Upper part of LSS

One Diode + One Sensor

Lower part of LSS

(printhead and headlift shaft omitted for

Intermec EasyCoder F4 – Installation & Operation Ed. 2 85

Print Unit

improved visibility)

Page 9

Chapter 12 Adjustments

Printhead

Pressure

The pressure of the thermal printhead against the paper is factory

adjusted. However, the use of thicker or thin ner pap er t ha n nor ma l

could require the printhead pressure to be readjusted.

Using a fl at-tipped screwdriver, turn the adjustment screw clockwise

for increased pressure (+), or counter-cl ockwise for less press ure (-).

Print a few labels, preferably test labels (see chapter 6 “Setting Up

the Printer”), and check the printout. Increa sed pressure general ly

gives a da rker pri ntout and v ice versa. Repe at until t he desir ed

result is obtained.

T o return to the factory setting, tighten the screw (+) as far as it goes

and then loosen it (-) six (6) full turns.

Note!

Do not use a higher prin thead pressure than necessary, because it

may increase the wear of the printhead and thus shorten its life.

Adjustment Screw

Intermec EasyCoder F4 – Installation & Operation Ed. 286

Page 10

Appendix 1

Technical Data

Printing

Print T echnique Direct Thermal

Printhead Resolution 8 dots/mm (203.2 dpi)

Print Speed (variable) 100 – 200 mm/sec. (≈ 4 – 8"/sec.)

Print Width (max) 104 mm (4.095") = 832 dots

Print Length (max) 32767 dots = 409.5 cm1

Media Width (min/max) 25 – 114.3 mm ( 1 –4.5") Standard paper guide

Media Width (min/max) 40 – 114.3 mm ( 1 .57 – 4.5") Quick-Load guides

Paper Roll Diameter (max) 213 mm (8.38") Short door/no rewind

Paper Roll Core Diameter 38 – 40 mm ( 1 .5") or 76 mm (3")

Print Directions 4

Modes of Operation

T ear Off Yes

Peel Off Optional Requires Rewind Unit

Firmware

Operating System Intermec Fingerprint 7.3 1 Incl. Direct Protocol

Smooth Fonts T rueDoc and T rue Type fonts

Built-in scalable fonts (std) 15 Unicode fonts

Built-in bar code symbologies (std) 36

Startup Program (std) Intermec Shell 4.4

Physical Measures

Dimensions (W x L x H) 244 x 397 x 178 mm (9.6 1 x 15 .63 x 7.00") w. Long side door

Weight (excluding media) ≈ 7 kgs ( 1 5.5 lbs) Depending on model

Ambient Operating Temperature +5°C – +40 ° C (+41 °F – +104° F)

Humidity 20 –80% non-condensin g

Electronics

Microprocessor 32 bit RISC

On-board Flash SIMMs 1 – 2 Std. 1 x 2 Mbytes

On-board DRAM SIMM 1 Std. 4 Mbytes

Real-Time Clock Option 10+ years life

Power Supply

Mains Voltage >90 – <264 V AC, 45 – 65 Hz

PFC Regulation IEC 61000-3-2

Maximum Power Consumption Continuous 1 40 W; Peek 300W

2

Intermec EasyCoder F4 – Installation & Operation Ed. 2 87

Page 11

Appendix 1 Technical Data

Technical Data, cont’d.

Sensors

Label Gap/Black Mark/Out of Paper Yes 5 fixed positions

Printhead Lifted Yes

Controls

Control Lamps 3

Display 2 x 16 character LCD w. background light

Keyboard 22 keys membrane switch type

Print Button 1

Beeper Yes

Data Interfaces

Serial 1 x RS 232C + 1 x USB

Bar Code Wand Yes

Electronic Keys 2 For setup

Connection for Optional Interface Boards

Memory Card Adapter 1

Accessories and Options Flash or SRAM cards

RFID Module Option

Rewind Unit Option For peel-off operation

Paper Supply Spool Option Replaces hanger

3” Adapter for Paper Supply Spool Option

Short Side Door Option

Long Side Door Option

Label Taken Sensor Option

Real-Time Clock Option 10+ years life

Quick-Load Guides Standard

RS 232C Cable Option

EasySet Bar Code Wand Option For quick setup

Parallel Interface Board Option IEEE 1284

Double Serial Interface Board Option

Industrial Interface Board Option

EasyLAN 100I Interface Board Option Ethernet

External Alphanumeric Keyboard Option

Flash Memory Cards Option

Electronic Keys Option

1. The max. print length is also restricted by the amount of free DRAM memory.

2. Latin, Greek, and Cyrillic fonts according to Unicode standard are included.

3. Depending on model, the printer may be delivered with either a long or a short side door.

1 Future option

3

3

Fitted in some models

= 64 Mbit (8 MB)

88 Intermec EasyCoder F4 – Installation & Operation Ed.2

Page 12

Media Specifi cations

Appendix 2

Direct Thermal

Labels

Interme c offers t wo quality grades of dire ct t hermal paper for the

EasyCoder range of printers:

• Premium Quality: Top-coated papers with high demands on

printout qual ity a nd resistance against moisture, plasticisers and

vegetable o ils. Examples. . .

- T op Board - Duratherm II,

- Premium - Duratherm II Tag

- Duratherm Ltg.

- Duratherm IR

• Economy Quality: Non top-coated papers with less resistance to

moisture, plasticisers and vegetable oils. In all other respects, it is

equal to Pr emium Quality . Examples...

- Economy

- Eco Board

Intermec EasyCoder F4 – Installation & Operation Ed. 2 89

Page 13

Appendix 2 Media Specifi cations

Paper Roll Size

Core

Diameters: 38 – 40 mm (1 .5 ") or 76 .2 mm (3")

Width: Must not protrude outside the web.

The web must be wound up on the core i n such a way that the

printer can pull the end of the web free.

Roll

Max. diameter (internal supply only):

- Position 1 152 mm (6.00")

- Position 2 213 mm (8.38")

- Position 3 203 mm (8.00")

Max. width: 1 14.3 mm (4.50")

Min. width (standard): 25 mm (1. 00")

Min. width (Quick -Load): 40 mm (1.5 7")

Max. web thickness: 17 5 µm (0.007")

The max imum recommended web thickness is 175µm. A thicker

web may be used, but print quality wi ll be reduce d. Web stiffness

is also impor tant and must be bala nced against web thickness to

maintain print q uali ty.

Pap er rol ls fitte d insi de the p rin ter sho uld be wo und wit h the

printable side facing outwards.

The paper supply must not be exposed to dust, sand, grit, etc. Any

hard particles, howe v er s mall, can damage the printhead.

Intermec EasyCoder F4 – Installation & Operation Ed. 290

Page 14

Paper

Appendix 2 Media Specifi cations

Non-Adhesive Strip

⇐ a ⇒ Web Width:

Maximum: 114.3 mm (4.50")

Minimum (standard): 25.0 mm (1 . 00")

Minimum (Quick-Load): 40.0 mm (1.5 7")

Media T ype Setup:

• Fix length strip

• Var length strip

Intermec EasyCoder F4 – Installation & Operation Ed. 2 91

Page 15

Appendix 2 Media Specifi cations

Paper, cont'd.

Self-Adhesive Strip

⇐ a ⇒ Web Width (including backing paper):

Maximum: 114.3 mm (4.50")

Minimum (standard): 25.0 mm (1 . 00")

Minimum (Quick-Load): 40.0 mm (1.5 7")

⇐ b ⇒ Backing Paper

The backi ng paper must not extend more than a tot al of 1.6 mm

(0.0 6") out side th e paper a nd shou ld prot rude e qual ly on bot h

sides.

⇐ c ⇒ Paper Width (e xc l uding backing paper):

Maximum: 112.74 mm (4.43")

Minimum: 23.8 mm (0.94")

Media T ype Setup:

• Fix length strip

• Var length strip

Intermec EasyCoder F4 – Installation & Operation Ed. 292

Page 16

Paper, cont'd.

Appendix 2 Media Specifi cations

Self-Adhesive Labels

⇐ a ⇒ Web Width (including backing paper):

Maximum: 114.3 mm (4.50")

Minimum (standard): 25.0 mm (1 . 00")

Minimum (Quick-Load): 40.0 mm (1.5 7")

⇐ b ⇒ Backing Paper

The backing pap er must not extend more than a tota l of 1.6 mm

(0.06") outside the paper and should protrude equally on bot h side.

Recommended min. transparency: 40% (DIN 53147).

⇐ c ⇒ Label Wid th (excluding backing paper):

Maximum: 112.7 mm (4.43")

Minimum: 23.8 mm (0.94")

⇐ d ⇒ Label Length:

Minimum: 8.0 mm (0.32")

Max label length: depends on DRAM size

Under favourable circumstances, a mini m um label length down to

4 mm (0 .16") could be used . It requires the s um of the label length

(d) and the label gap (e) to be lar ger than 7 mm (0.28"), that batch

printing is used , a nd th at no pull b ack of t he paper is per forme d.

Intermec does not guarantee that such short labels will work, but it

is up to the user to test this in his unique application.

⇐ e ⇒ Label Ga p:

Maximum: 21.3 mm (0.83")

Recommended: 3.0 mm (0.12")

Minimum: 1.2 mm (0.05")

The Lab el Stop Sensor must be able to det ect the extreme f ront

edges of the labels. It can be moved between 5 fi xed positions at the

following distances from the inner edge of the paper.

3 mm (.118")

8 mm (.3 1 5 ")

12 mm (.47 2")

16 mm (.63 9")

20 mm (.7 87")

Media T ype Setup:

• Label (w ga ps)

Intermec EasyCoder F4 – Installation & Operation Ed. 2 93

Page 17

Appendix 2 Media Specifi cations

Paper, cont'd.

Tickets with Gap

⇐ a ⇒ Web Width:

Maximum: 114.3 mm (4.50")

Minimum (standard): 25.0 mm (1 . 00")

Minimum (Quick-Load): 40.0 mm (1.5 7")

⇐ b ⇒ Cop y Length:

Min. length between slots: 8.0 mm (0.32")

Max. length between slots: depends on DRAM size

Under favoura ble circumsta nces, a minim um ticket le ngth down

to 4 mm ( 0.16") could b e used . It requires the s um of the c opy

length (b) a nd the d etec tion s lit heig ht (e) to be lar ger tha n 7

mm (0.28"), that batch printing is used, and that no pull back of

the pa per is per formed . Inter mec does n ot guaran tee that s uch

short l abels will work , but it is up to th e user to test this i n his

unique app l ic at io n.

⇐ c ⇒ LSS Detection Position:

Five fi xed positions (distance from inner edge of paper):

3 mm (.118")

8 mm (.3 1 5 ")

12 mm (.47 2")

16 mm (.63 9")

20 mm (.7 87")

⇐ d ⇒ Detection Slit Length:

The length of the detection slit (excluding corner radii) must be

mi nim um 2.5 m m (0.10" ) on eith er side of t he LSS d etec tion

positio n ( e).

⇐ e ⇒ Detection Slit Height:

Maximum: 21.3 mm (0.83")

Recommended: 1.6 mm (0.06")

Minimum: 1.2 mm (0.05")

Media T ype Setup:

• Ticket (w gaps)

Do not allow any per foratio n to break th e edge of the web, as this

may cause the web to split, resulting in a paper jam.

Intermec EasyCoder F4 – Installation & Operation Ed. 294

Page 18

Paper, cont'd.

Appendix 2 Media Specifi cations

Tickets with Black Mark

⇐ a ⇒ Web Width:

Maximum: 114.3 mm (4.50")

Minimum (standard): 25.0 mm (1 . 00")

Minimum (Quick-Load): 40.0 mm (1.5 7")

⇐ b ⇒ Cop y Length:

Minimum: 20.0 mm (0.8")

Maximum: depends on DRAM size

⇐ c ⇒ LSS Detection Position:

Five fi xed positions (distance from inner edge of paper):

3 mm (.118")

8 mm (.3 1 5 ")

12 mm (.47 2")

16 mm (.63 9")

20 mm (.7 87")

⇐ d ⇒ Black Mark Width:

The detectable width of the black mark should preferabl y be at least

5.0 mm (0.2") on either side of the LSS detection point.

⇐ e ⇒ Black Mark Length:

Maximum: 21.3 mm (0.83")

Common: 12.5 mm (0.5")

Minimum: 5.0 mm (0.2")

⇐ f ⇒ Black Mark Y-Position:

It is recom mended to place t he black mark as close to t he front

ed ge of th e ticke t as po ssible a nd us e a negat ive Sto p Adjust

valu e to cont rol the p aper fe ed, so t he ticke ts can b e prop erly

torn or cut off.

Media T ype Setup:

• Ticket (w mark)

Impor tant ! Preprint tha t may inter fere with the detec tion of the

black mark sh ould be avoid ed on th e bac k of the p aper. However,

th e LBL COND s tate men t allow s the se nsor to be tem porar ily

disabled during a specifi ed amount of paper feed in order to avoid

unintentional detection, see Intermec Fingerprint manuals.

The black mark should be non-refl ective carbon black on a whitish

backgr o und.

Do not allow any perforations to break the edge of the web, as this

may cause the web to split, resulting in a paper jam.

Intermec EasyCoder F4 – Installation & Operation Ed. 2 95

Page 19

Appendix 3

Interfaces

RS 232C Interface

The EasyCoder F4 has – as standard – two serial communication

interfaces: RS 232C on "uart1:" and US B (see next pag e).

Protocol

Defaul t se tup:

Baudrate: 9600

Char. length 8 bits

Parity: None

Stop bits: 1

RTS/CTS Disabled

ENQ/ACK: Disabled

XON/XOFF: Disabled (both ways)

New Line: CR/LF

To chang e the se ria l inte rfac e sett ings , see ch apter 6 “Setting

Up the Printer”.

Interface Cable

Computer end: DB-9 or DB- 25 female connector (PC)

Printer end: DB-25 male connector

Host EasyCoder F4 Host

Signal DB-9 DB-25 Signal DB-25 DB-25 Signal

1 1 1 1 shield

RXD 2 2 TXD 2 3 RXD

TXD 3 3 RXD 3 2 TXD

CTS 8 4 RTS 4 5 CTS

RTS 7 5 CTS 5 4 RTS

6 DSR 6 20 DTR

GND 5 7 Signal GND 7 7 GND

16 + 5V1 16

DSR 6 20 DTR 20 6 DSR

22 RI 22

"uart1:"

1

/. The external +5V is limited to 200 mA and is automatically turned

off at overload. It is intended to drive e.g. an external alphanumeric

keyboard connected to the RS 232C port.

Intermec EasyCoder F4 – Installation & Operation Ed. 296

Page 20

Appendix 3 Interfaces

USB Interface

USB = Uni ve r sal Serial Bus

The EasyCoder F4 has – as standard – one USB communication

port. To use the USB interface for printing from a PC, you need a

special USB printer driver installed in your PC.

Using an USB Class A - B cable , connect the Class A end to your PC

or hub and the Class B end to your EasyCoder F4 printer.

USB Class A connector.

Connect to PC or hub.

USB

Intermec EasyCoder F4 – Installation & Operation Ed. 2 97

Connect to USB receptacle on the printer's rear plate.

Note:

Th e USB in terf ace is pre sent ly not su ppor ted by t he Int erme c

Fingerprint fi rmware (v. 7.31 ).

USB Class B connector.

Page 21

Appendix 3 Interfaces

Double Serial

Interface Board

"uart2:"

1

/. Intermec Shell either automatically sets the correct std IN

and OUT port when an application is selected, e .g. a Windows

driver, or prompts you to select

one, see chapter 8.

The Easy Coder F4 can optional ly be fi tted with an extra double

seria l interface boa rd, which provides the pr inter with two more

serial por ts; "uart 2:" and "uart 3:". T hese ports can be con fi gured

for various types of serial communication in combination according

to the customer's request. Use the Intermec Fingerpr int inst r uction

SETSTDIO to select standard IN and OUT ports (by default "uart1:"

is both std IN and OUT port)

1

.

"uart2:" "uart3:"

RS 232C RS 232C

RS 422 Non-iso lated RS 422 Non- isolated

RS 422 Isolated 20 mA Current Loop

RS 485

"uart2:" Serial Port

The communication ports "uart2:" uses a female DB 25 connector.

Pin Signal Name Description

1 Not connected

2 TxD RS 232 T ransmitter

3 RxD RS 232 Receiver

4 RTS RS 232 Request To Send

5 CTS RS 232 Clear To Send

6 DSR RS 232 Data Set Ready

7 GND Ground

8–14 Not connected

1 5 +RS4 2 2 I +RS 4 22 R ec ei v e

16 +5V 5 Volt for external use (max. 200 mA)

1

1 7 -RS422I -RS 422 Receive

18 Not connected

19 +RS422O/+RS485 +RS 422 Transmit/+RS 485

20 DTR RS 232 Data Terminal Ready

21 -RS4 22O/-RS485 -RS 422 Transmit/-RS 485

22 RI R S 232 Ring Indicato r

23 Shield Optional shield for RS 422 and RS 485

24–25 Not connected

1

/. The external 5V is automatically turned off at overload.

Intermec EasyCoder F4 – Installation & Operation Ed. 298

Page 22

Appendix 3 Interfaces

Double Serial

Interface Board,

cont'd.

"uart3:"

"uart3:" Serial Port

The communication ports "uart3:" uses a male DB 25 connector.

Pin Signal Name Description

1 Not connected

2 TxD RS 232 Transmitter

3 RxD RS 232 Receiver

4 RTS RS 232 Request T o Send

5 CTS RS 232 Clear T o Send

6 DSR RS 232 Data Set Ready

7 GND Ground

8 Not connected

9 +20M1 +20 mA current loop

10 -20M1 -20 mA current loop

1 1 +TXD +TXD 20 mA current loop

12 - TXD - TXD 20 mA current loop

13 +20M2 +20 mA current loop

(prin te r act ive rece iv er )

14 -20M2 -20 mA current loop

(prin te r act ive rece iv er )

1 5 +RS4 2 2 I +RS 4 2 2 R e ce i v e

16 +5V 5 Volt for external use (max. 200 mA)

1 7 -RS422I -RS 422 Re ceive

18 +RxD +TXD 20 mA current loop

19 +RS422O/+RS485 +RS 422 Transmit/+RS 485

20 DTR RS 232 Data Terminal Ready

21 -RS4 22O/-RS485 -RS 422 T ran smit/-RS 485

22 RI RS 232 Ring Indica tor

23 Shield Optional shield for RS 422 and RS 485

24 Not connected

25 -RxD -TXD 20 mA current loop

1

/. The external 5V is automatically turned off at overload.

1

Intermec EasyCoder F4 – Installation & Operation Ed. 2 99

Page 23

Appendix 3 Interfaces

IEEE 1284

Parallel Interface

Board

"centronics:"

The EasyCoder F4 ca n optionally be fi t ted with an IEEE 1284-I

compatible parallel interface board1. The para llel por t is add ressed

in Intermec Fin g e rprint as d evice "centronics:". Select "centronics:"

as stand ard IN por t by means of the instr uction SETSTDIO (by

default, "uart1:" in std IN port)

Interface Cable Connectors

Computer end: Depends on type of host computer.

Printer end: 36 pin female IEEE 1284B Centron

Pin Signal Name

1 DStrobe

2–9 Data 0–7

10 Ack

11 Busy

12 PE

13 Select

14 AF

15 Not connected

16 Ground

17 Screen

18 +5V Ext

19–30 GND

31 Init

32 Error

33-35 Not connected

36 Selectin

2

.

1

/. Nibble, byte, E CP and EPP

from printer to host are presently

not supported.

2

/. Intermec Shell either automatically sets the correct std IN

and OUT p ort w hen an app lica tion is selected , e.g. a Windows

driver, or prompts you to select

one, see chapter 8.

Intermec EasyCoder F4 – Installation & Operation Ed. 2100

Page 24

Appendix 3 Interfaces

Industrial

Interface Board

The EasyCoder F4 can optionally be fitted with an Industrial

Int erfa ce Boar d, that p rovides t he pri nter w ith one ext ra ser ial

communicat ion port ("uar t2:"), which ca n be confi g ured for one

of the following alternatives

RS 232C

RS 422 Non-iso lated

RS 422 Isolated

RS 485

This port is identical to "uart2:" on the double serial interface

board.

The Industr ia l I nter face Boa rd a lso has a female DB- 4 4 con ne ctor

with...

8 digital IN ports with optocouplers

8 digital OUT ports with optocouplers

4 OUT ports with relays.

Refer to th e insta llation i nstr uctions for t he Indust rial I nterfa ce

Board for further information.

Industrial Interface

"uart2:"

Intermec EasyCoder F4 – Installation & Operation Ed. 2 101

Page 25

Appendix 3 Interfaces

EasyLAN 100i

Interface Board

The I nterme c EasyLAN 100 i Ether net inter face boa rd provides

the printer with a 10BaseT Ethernet or 100BaseTX Fast Ethernet

network c onnect ion. You c an commu nicate w ith the pr inter via

a LAN (L ocal Area Network) or provide the printer with its own

home page, so you can reach the printer via inter net on the world

wide web ( www ).

EasyLAN 100i supports most major computer systems and environments. You ca n assign passwords to restrict both login a nd pri nter

access. The inter nal EasyLAN 100i web pages allow you to continuously monitor printer status and to upgrade the fl ash memo ry of

the printer when new fi rmware becomes available.

EasyLAN 100i supports SNMP for remote monitoring.

When an EasyLAN 100i interface board is fi tted in the printer , s ome

extra menus will be added to the Setup Mode (see chapter 7 “Setup

Mode”). The Ethernet port is addressed in Intermec Fingerprint 7.3

or later as device "net1 :" (co mmunication channel 5).

RJ-45

connector

Intermec EasyCoder F4 – Installation & Operation Ed. 2102

Page 26

Appendix 4

EasySet Bar Code Wand Setup

Connection and Operation

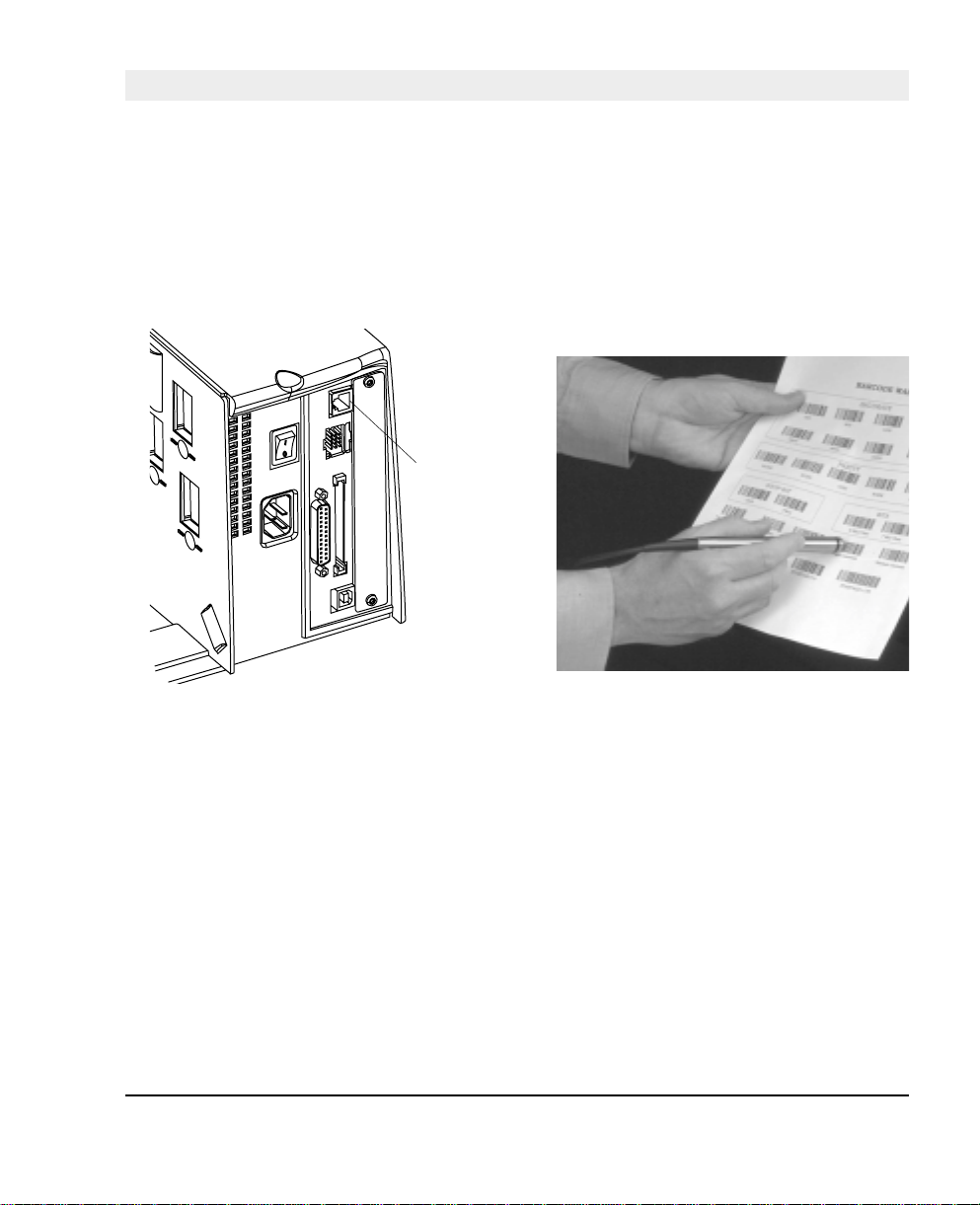

1. Connect the optional EasySet bar code wand to

the receptacle on the printer’s rear plate.

Connect

here!

3. When the bar code has been accepted, the printer

emits a short be ep and t he Ready control la mp

on the printer’s front blinks briefl y.

2. Read the appropriate bar code to set up the

printer. Hold the wand like a pencil and move it

rather swiftly across the bar code.

4. This manua l only conta ins a selection of setup

options. For information on how to produce your

own setup bar codes, please refer to the Intermec

Fingerprint 7 .31 Reference Manual.

Intermec EasyCoder F4 – Installation & Operation Ed. 2 103

Page 27

Appendix 4 EasySet Bar Code Wand Setup

Serial Communication on "uart1:"

Baudrate

Char. Length

Parity

Intermec EasyCoder F4 – Installation & Operation Ed. 2104

Page 28

Serial Communication on "uart1:", cont'd.

Appendix 4 EasySet Bar Code Wand Setup

No. of Stop Bits

RTS/CTS

ENQ/ACK

Reset comm. to default

XON/XOFF, Data to Host

Intermec EasyCoder F4 – Installation & Operation Ed. 2 105

Page 29

Appendix 4 EasySet Bar Code Wand Setup

Serial Communication on ”uart1:”, cont’d.

XON/XOFF, Data from Host

New Line

Start- and Stopadjust

Tear Off

Peel Off

Default

Intermec EasyCoder F4 – Installation & Operation Ed. 2106

Page 30

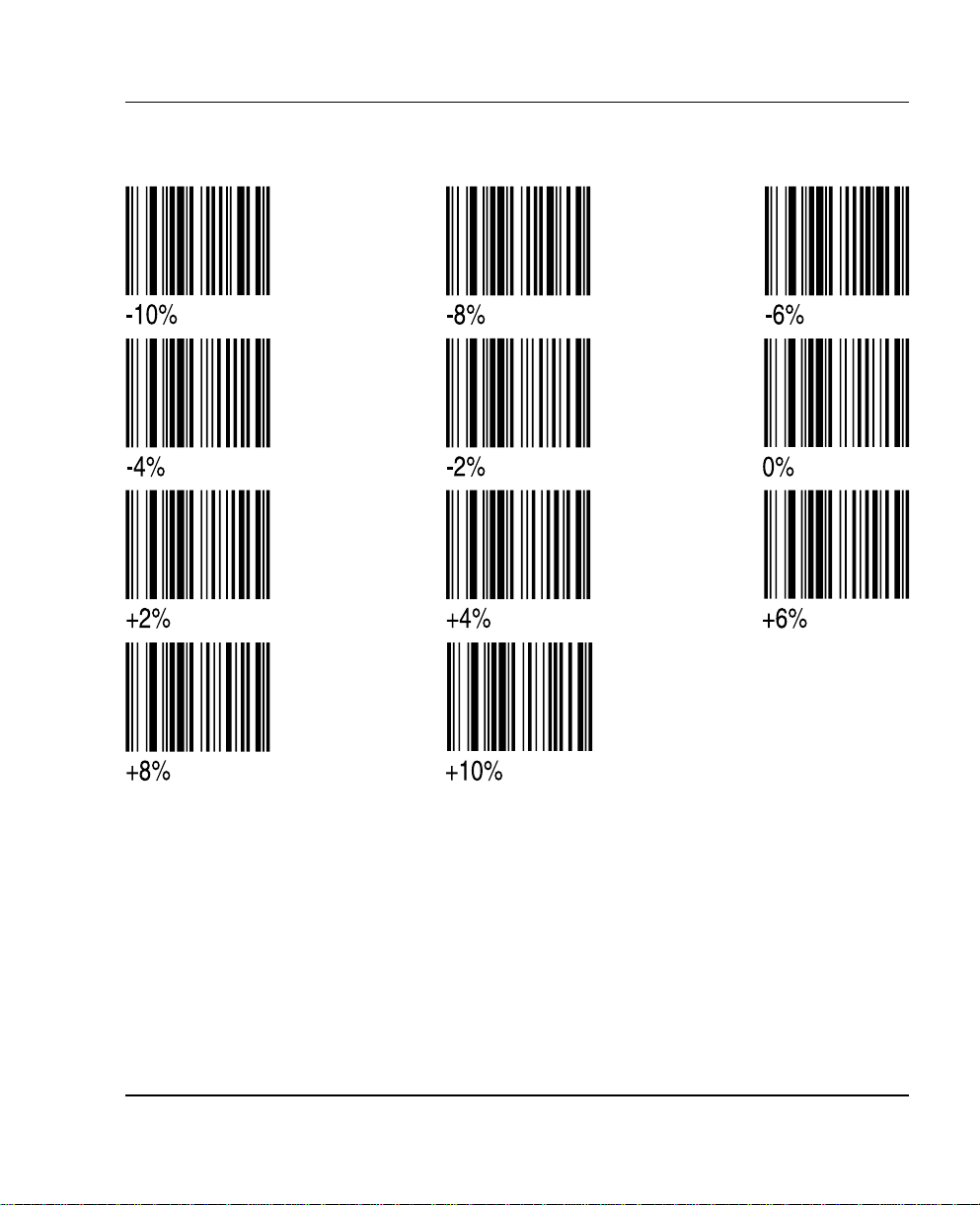

Contrast

Appendix 4 EasySet Bar Code Wand Setup

Intermec EasyCoder F4 – Installation & Operation Ed. 2 107

Page 31

Appendix 4 EasySet Bar Code Wand Setup

Test Labels

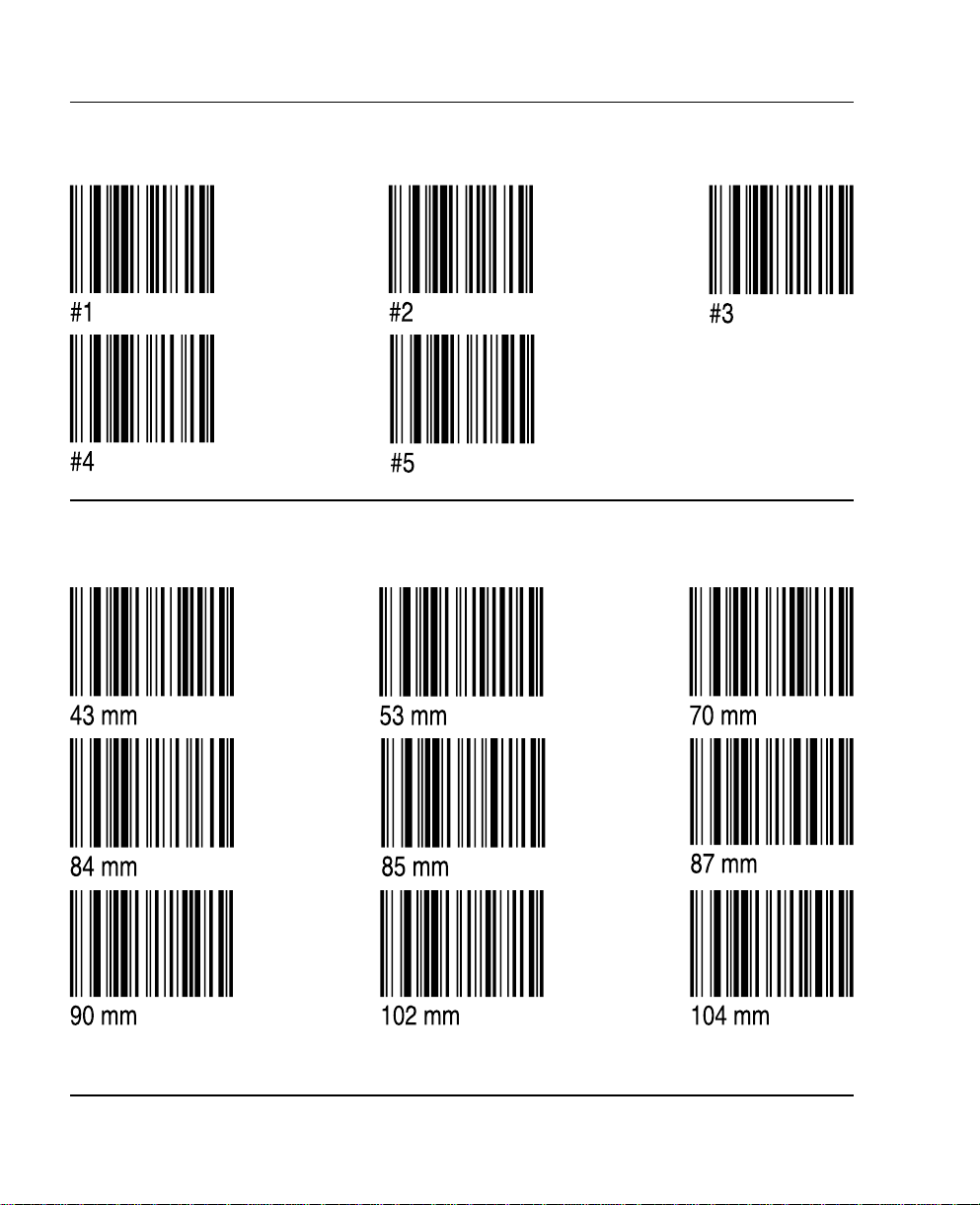

Media Width

Intermec EasyCoder F4 – Installation & Operation Ed. 2108

Page 32

Media Length

Appendix 4 EasySet Bar Code Wand Setup

Intermec EasyCoder F4 – Installation & Operation Ed. 2 109

Page 33

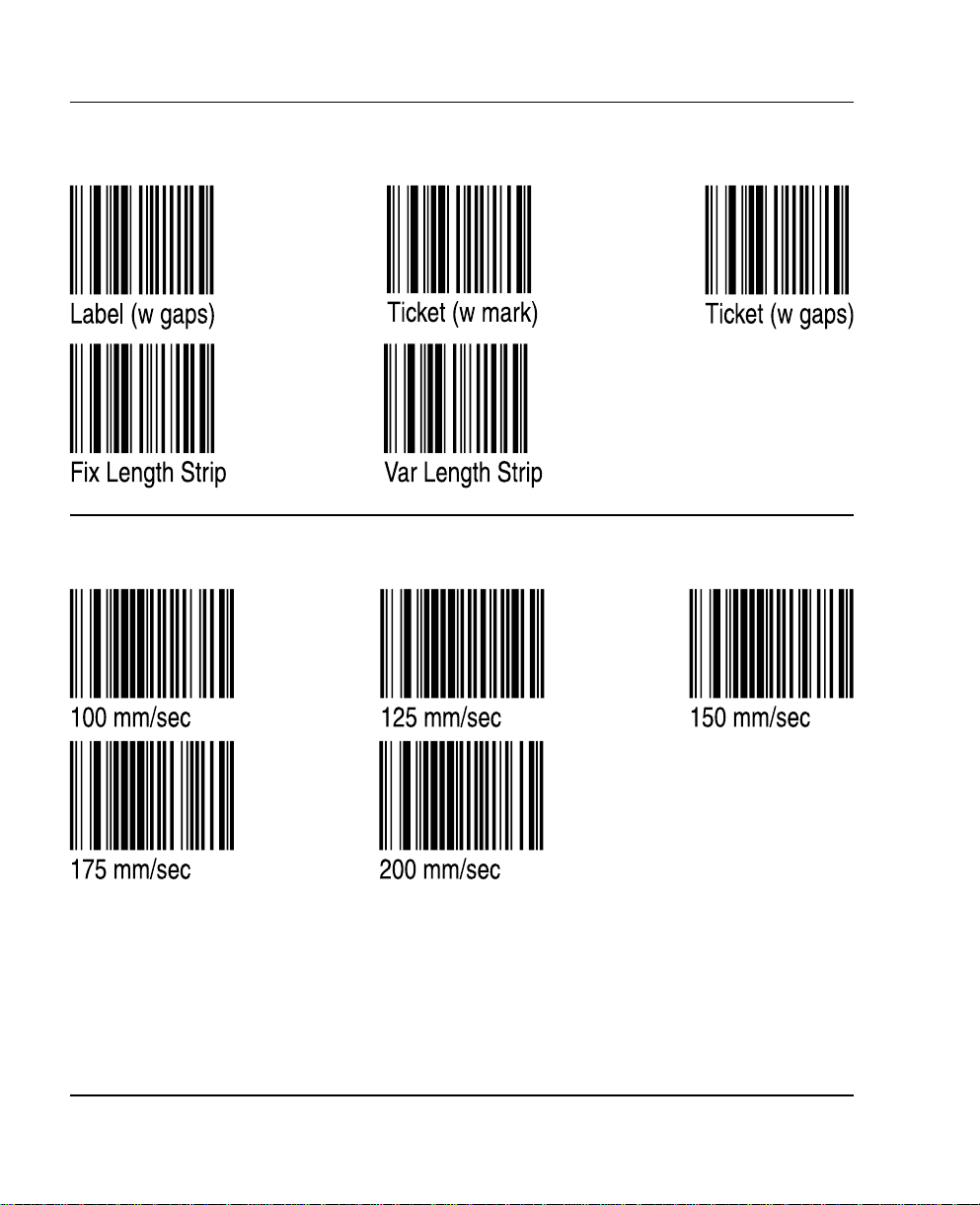

Appendix 4 EasySet Bar Code Wand Setup

Media Type

Print Speed

Intermec EasyCoder F4 – Installation & Operation Ed. 2110

Page 34

Paper Type

Direct Thermal Printing (Europe)

Appendix 4 EasySet Bar Code Wand Setup

Direct Thermal Printing (USA)

Intermec EasyCoder F4 – Installation & Operation Ed. 2 111

Page 35

RFID Module

The EasyCoder F4 can optionally be fitted with an Intellitag® 500 RFID (radio

frequency identification) board that provides the printer with the means to preprogram Intellitag

printed.

The RFID board is addressed in Intermec Fingerprint 7.3 or later as device “uart2:”

The RFID board does not require connection to any device external to the printer.

The RFID module is fitted in the printer in the space allocated for optional interface

boards and therefore cannot be used in conjuction with, or in addition to, any of the

optional interface boards.

Refer to the installation instructions for the RFID Option Board for further

information.

Appendix 5 RFID Module

®

500 RFID SmartLabels when the bar code portion of the label is

112

Chassis location for RFID module

Intermec EasyCoder F4 – Installation & Operation Ed. 2

Page 36

Notes

113Intermec EasyCoder F4 – Installation & Operation Ed. 2

Loading...

Loading...