Page 1

11”

158WP12465

8.5”

MODEL: WP1000RC

Pg.1

2. Leave Junction Box to be positioned in brickwork with opening set back 1/8”

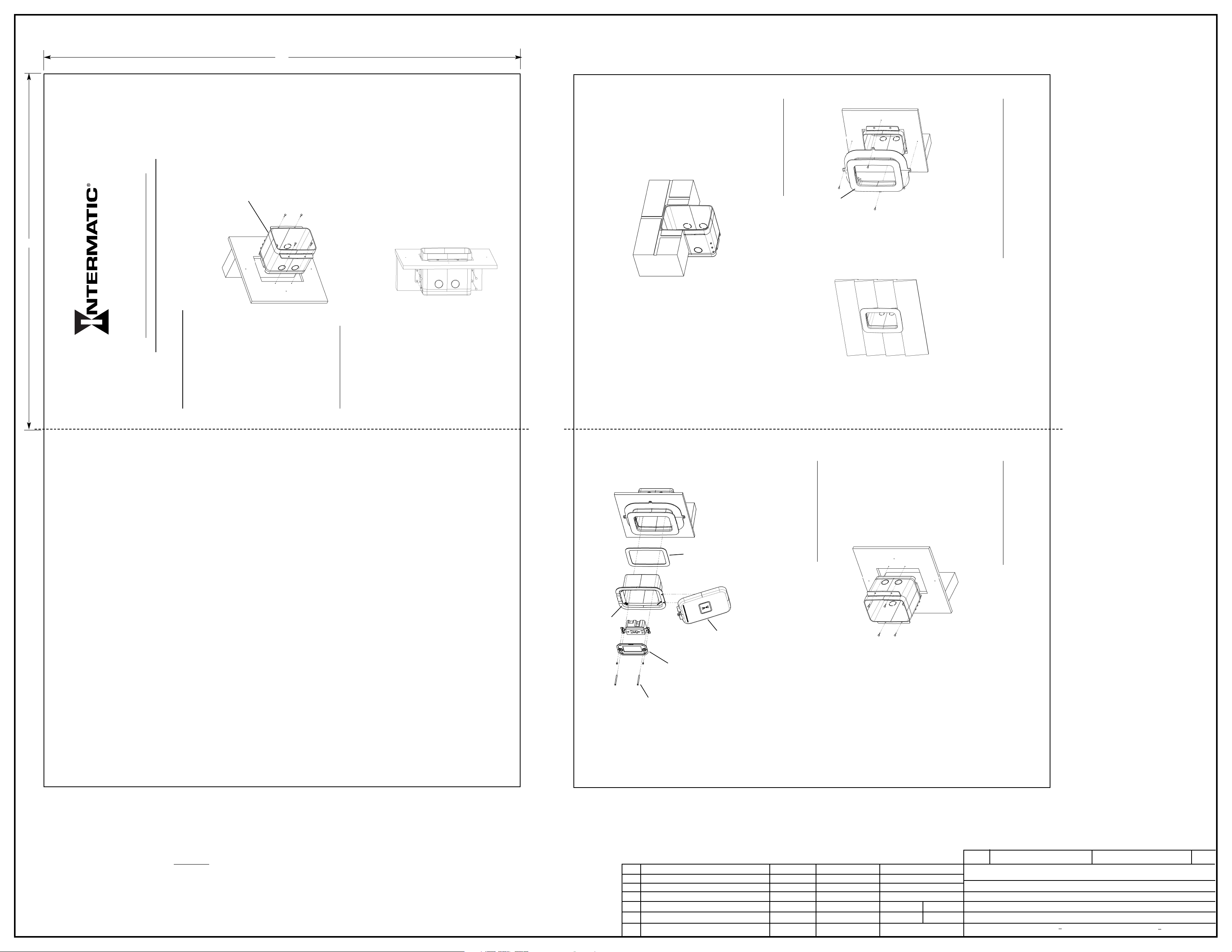

Brick Mounting (figure 5)

1. Cut off Stud Brackets and Plywood Brackets.

or more inside brick.

Fig. 3

Junction Box

Fig. 5

Fig. 1

Fig. 2

BACK

Siding Flange

2. Siding and other materials may be installed using flange as a channel to

using nails or screws (not provided).

provide a clean finish.

Mounting Siding Flange (figures 3 and 4)

1. Position Siding Flange over Junction Box opening and mount to plywood

FRONT

Fig. 4

MOUNTING INSTRUCTIONS FOR

FLUSH MOUNT WHILE-IN-USE COVER

foam board, siding, etc.

past front of stud and mount with nails or screws (not provided). Note: the

screws (not included).

First, determine the method to mount the Junction Box (plywood or stud).

Plywood Mount (figure 1)

1. Use Junction Box opening as template to cut hole in plywood.

2. Cut off two stud mounting brackets.

3. Slide Junction Box through plywood opening and mount using nails or

This

This warranty does

ABILITY AND THE

AL OR CONSEQUENTIAL

ATION OF INCIDENTAL OR

Stud Mount (figure 2)

depths may vary depending upon expected finish material - plywood, wrap,

Pg 2

1. Position Junction Box along stud with opening extending between 1/2” and 1”

2. Cut off two plywood mounting brackets if necessary (or use as a guide)

FOLD LINE

6. Slide Recessed Sleeve into Junction Box as far back as necessary for gasket.

8.

7. Secure Sleeve to Junction Box using screws provided.

5. Wire device according to device manufacturers instructions.

4. Snap Insert with device into Recessed Sleeve.

Pg.4

3. Mount device to insert using screws provided.

Snap hinged Cover into place.

Gasket

Finish Mounting (figure 7)

1.

2. Remove any mounting screws provided with the device.

Select insert for appropriate device to be installed.

3. Secure Junction box using plywood brackets and screws or nails (not provided).

2. Cut hole in plywood or block (if block construction).

Stucco Mounting (figure 6)

1. Cut off Stud Brackets.

.intermatic.com Please be sure to

OF MERCHANT

ARRANTY

YEAR W

LIMITED 1

(e) sealed lamps and/or lamp bulbs, LED’s and batteries; (f) the finish on any portion of the product, such

modified; (c) units not used in accordance with instructions; (d) damages exceeding the cost of the product;

negligent use; (b) units which have been subject to unauthorized repair, opened, taken apart or otherwise

workmanship, Intermatic Incorporated will repair or replace it, at its sole option, free of charge.

warranty is extended to the original household purchaser only and is not transferable.

not apply to: (a) damage to units caused by accident, dropping or abuse in handling, acts of God or any

If within one (1) year from the date of purchase, this product fails due to a defect in material or

TION OR EXCLUSION MAY NOT APPLY TO

A

ARRANTY

AND SHALL BE OF THE SAME DURATION AS THE

,

OTHER EXPRESS OR IMPLIED WARRANTIES. ALL

ALL

ABOVE LIMIT

NOT BE LIABLE FOR INCIDENT

ALLOW THE EXCLUSION OR LIMIT

TED WILL

TES DO NOT

A

TIC INCORPORA

as surface and/or weathering, as this is considered normal wear and tear; (g) transit damage, initial

installation costs, removal costs, or reinstallation costs.

DAMAGES. SOME ST

INTERMA

ARRANTY

PARTICULAR PURPOSE, ARE HEREBY MODIFIED TO EXIST ONLY

A

ARRANTY, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

This warranty is made by: Intermatic Incorporated/After Sales Service/7777

ATED ABOVE. SOME STATES DO NOT ALLOW LIMITATIONS ON THE

IS IN LIEU OF

DAMAGES, SO THE

ARRANTY

PERIOD ST

OF FITNESS FOR

ARRANTIES, INCLUDING THE W

AINED IN THIS LIMITED W

ARRANTY

ARRANTY

W

AS CONT

W

CONSEQUENTIAL

IMPLIED W

YOU. THIS W

.

AN IMPLIED W

TION OF

DURA

inn Rd., Spring Grove, Illinois 60081-9698/815-675-7000 http://www

purchased, or (b) mailing the product, along with proof of purchase, postage prepaid to the authorized

service center listed below

This warranty service is available by either (a) returning the product to the dealer from whom the unit was

W

wrap the product securely to avoid shipping damage.

158WP12465

Fig. 7

Fig. 6

Recessed Sleeve

Cover

Insert

Screws to Secure

Sleeve

Pg.3

NOTES:

ALL PRINTING TO BE AS PER INTERMATIC

APPROVED ARTWORK.

DR.: SRB 9/8/2005

CHKD.: TS 9/8/2005

SCALE:

APPROVED MATL.:

TD 9/8/2005

1 RELEASED TO ELEC. DATA

LET. REVISION SIGN. MODEL SUPERSEDES:

SEE B/M FOR ALL PART NUMBERS & QUANTITIES

. NO.

ITEM

PT

INTERMA

NAME:

HEAT TREAT:

INST SHT - INST

WHITE PAPER STOCK

FINISH:

DIM

TOL

TIC INCORPORATED

ALL, WP1000RC

BLACK PRINTING INK

FRACTIONS + .010 . DECIMALS

:

ALL DIMENSIONS MUST BE MET BEFORE PLATING.

DESC. QUAN.

AS SPECIFIED -

ANGLES + 1/2˚

Loading...

Loading...