Intermatic I-Wave PE45343RC, I-Wave PE45343RCT1, I-Wave PE45343RCT3, I-Wave PE5 Series Installation And User Manual

Page 1

PE45343RC

PE45343RCT1

PE45343RCT3

Installation and User Guide

Wave PE5 Series

Pool/Spa Combination Systems

Pool Systems

Spa Systems

Version 4-13-06

Page 2

2 I-Wave PE5 Installation Guide

Important Safety Instructions

All electrical work must be performed by a licensed electrician and conform to all national, state,

and local codes. When installing and using this electrical equipment, basic safety precautions

should always be followed, including the following:

DANGER: To reduce the risk of injury, do not remove the suction ttings of your spa or hot tub.

Never operate a spa or hot tub if the suction ttings are broken or missing. Never replace a

suction tting with one rated less than the ow rate marked on the equipment assembly.

WARNING: Prolonged immersion in hot water may induce hyperthermia. Hyperthermia occurs

when the internal temperature of the body reaches a level several degrees above the normal

body temperature of 98.6°F. The symptoms of hyperthermia include dizziness, fainting,

drowsiness, lethargy, and an increase in the internal temperature of the body. The effects of

hyperthermia include: 1) unawareness of impending danger; 2) failure to perceive heat; 3) failure

to recognize the need to exit spa; 4) physical inability to exit spa; 5) fetal damage in pregnant

women; 6) unconsciousness resulting in a danger of drowning.

WARNING: To Reduce the Risk of Injury —

The water in a spa should never exceed 104°F (40°C). Water temperatures between 100°F

•

(38°C) and 104°F (40°C) are considered safe for a healthy adult. Lower water temperatures are

recommended for young children and when spa use exceeds 10 minutes.

Since excessive water temperatures have a high potential for causing fetal damage during

•

the early months of pregnancy, pregnant or possibly pregnant women should limit spa water

temperatures to 100°F (38°C).

Before entering a spa or hot tub, the user should measure the water temperature with an

•

accurate thermometer since the tolerance of water temperature-regulating devices varies.

The use of alcohol, drugs, or medication before or during spa or hot tub use may lad to

•

unconsciousness with the possibility of drowning.

Obese persons and person with history of heart disease, low or high blood pressure,

•

circulatory system problems, or diabetes should consult a physician before using a spa.

Persons using medication should consult a physician before using a spa or hot tub since

•

some medication may induce drowsiness while other medication may affect heart rate, blood

pressure, and circulation.

WARNING: Risk of electric shock – Install the control center at least ve (5) feet (152.4cm) from

the inside wall of the pool and/or hot tub using non-metallic plumbing. Canadian installations

must be at least three (3) meters from the water.

Copyright © 2006 Intermatic, Inc.

Page 3

Children should not use spas or hot tubs without adult supervision.

•

Do not use spas or hot tubs unless all suction guards are installed to prevent body and hair

•

entrapment.

People using medications and/or having an adverse medical history should consult a

•

physician before using a spa or hot tub.

People with infectious diseases should not use a spa or hot tub.

•

To avoid injury, exercise care when entering or exiting the spa or hot tub.

•

Do not use drugs or alcohol before or during the use of a spa or hot tub to avoid

•

unconsciousness and possible drowning

Pregnant or possibly pregnant women should consult a physician before using a spa or hot

•

tub.

Water temperature in excess of 100°F (38°C) may be injurious to your health.

•

Before entering a spa or hot tub measure the water temperature with an accurate

•

thermometer.

Do nut use a spa or hot tub immediately following strenuous exercise.

•

Prolonged immersion in a spa or hot tub may be injurious to your health.

•

Safety 3

Do not permit any electric appliance (such as a light, telephone, radio, or television) within 5

•

feet (1.5m) of a spa or hot tub.

The use of alcohol, drugs or medication can greatly increase the risk of fatal hyperthermia in

•

hot tubs and spas.

Water temperature in excess of 100°F (38°C) may be hazardous to your health.

•

WARNING: A terminal bar marked “GROUND” is provided with the control center. To reduce

the risk of electrical shock, connect this terminal bar to the grounding terminal of your electric

service or supply panel with a continuous copper conductor having green insulation and one

that is equivalent in size to the circuit conductors supplying this equipment, nut no smaller than

no. 12 AWG (3.3mm). In addition, a second wire connector should be bonded with a no. 8

AWG (4.115mm) copper wire to any metal ladders, water pipes, or other metal within ve (5)

feet (1.52m) of the tub.

WARNING: A ground-fault circuit-interrupter must be provided if this device is used to control

underwater lighting xtures. The conductors on the load side of the ground-fault circuitinterrupter shall not occupy conduit, boxes or enclosures containing other conductors unless

the additional conductors are also protected by a ground-fault circuit-interrupter. Refer to local

codes for complete details.

Providing a brighter solution.™

Page 4

4 I-Wave PE5 Installation Guide

Contents

Section 1: System Overview .............................................................................................................6

Additional Detail on Key Components .........................................................................................7

Three-Circuit Clock (P1353ME) ...............................................................................................7

Valve/Pump Switch (P4243ME) ............................................................................................... 8

24-Volt Valve Actuator (PE24VA) .............................................................................................8

Panel-Mounted Transceiver (PE650) Includes Antenna (PA118) ..............................................8

Wireless Hand-Held Transceiver (PE950) ................................................................................9

35-ft. Antenna Extension Cable Assembly (PA121) .................................................................. 9

OMRON Relay Assembly (143T145A) ....................................................................................9

Water Temperature Sensor (PA122) .........................................................................................9

Steel Outdoor Enclosure Includes PE45300 (PE45300) ........................................................10

Optional — Transceiver Repeater Module (HA04C) .............................................................10

Optional — Three-Button Wired Remote Control (133PE1484A) ..........................................10

Optional — Freeze (Air Temperature) Sensor (178PA28A) ....................................................10

Section 2: Plumbing Examples ........................................................................................................ 11

For Pool and Spa Combo Installations ........................................................................................11

For Booster Pump Pool Cleaner Installations...............................................................................11

For Non-Booster Pump Pool Cleaner Installations.......................................................................12

Section 3: Control Center Installation ............................................................................................13

Mounting the Control Center ......................................................................................................13

Wiring the System Power ...........................................................................................................13

Bonding the Control Center ........................................................................................................14

Wiring the Individual Equipment ................................................................................................14

If Wiring 120-Volt Loads: .......................................................................................................15

If Wiring 240-Volt Loads: .......................................................................................................16

If Wiring Combination 120- and 240-Volt Loads: ..................................................................17

Wiring Underwater Lights ..........................................................................................................18

High-Voltage Underwater Lights ............................................................................................ 18

Low-Voltage Underwater Lights ............................................................................................. 19

Low-Voltage Wiring ...................................................................................................................20

Water Temperature Sensor .....................................................................................................20

Freeze Sensor ........................................................................................................................20

Motorized Valve Actuator Connection and Synchronizing .....................................................21

Fireman Switch Connection .......................................................................................................22

Connection to the Three-Circuit Clock ...................................................................................22

Connection for Teledyne Laars Heater ...................................................................................22

Connection for Raypak Heaters .............................................................................................22

Connection for Hayward Heaters .......................................................................................... 23

Connection for Pentair Heater ...............................................................................................23

Connection for Sta-Rite Heaters .............................................................................................24

Section 4: Programming the Three-Circuit Clock Mechanism .........................................................25

Overview of Three Circuit Clock Control Panel...........................................................................25

Copyright © 2006 Intermatic, Inc.

Page 5

Safety 5

Identifying Connections and Selecting Proper Input Voltage .......................................................26

Connection Detail .................................................................................................................26

Circuit Ratings ............................................................................................................................27

Mode Selection/Denition .........................................................................................................27

Mode 1 — (Aux1, Aux2, Aux3) ..............................................................................................27

Mode 2 — (Pump High, Pump Low, Aux3) ............................................................................ 28

Mode 3 — (Pump, Aux2, Cleaner Pump) ...............................................................................28

Mode 4 — (Pump High, Pump Low, Cleaner Pump) ..............................................................29

Mode 5 — (Pump, Pump, Aux3) ............................................................................................29

Mode 6 — (Aux1, Aux2, Aux3) ..............................................................................................30

Setting Mode ..............................................................................................................................30

Setting Time of Day ....................................................................................................................31

Setting the On/Off Times for Each Circuit ...................................................................................31

Setting the Heater’s Cool Down Time (optional) .........................................................................34

Setting Freeze Temperature (optional) .........................................................................................35

Section 5: Programming the Valve/Pump Switch Mechanism .........................................................36

Overview of the Valve/Pump Switch Control Panel .....................................................................36

Installing the Three-Button Wired Remote Control ......................................................................38

Installing Other Wired Remote Connections (Master Switch) ......................................................38

Connecting the Heater Switch to Control Temperatures ..............................................................39

If Connecting an External Timer: .................................................................................................40

Section 6: Programming the Hand-Held Remote Transceiver .........................................................41

Overview ...................................................................................................................................41

Synchronizing the Hand-Held Remote Transceiver with the Panel-Mounted Receiver .................41

Deleting Any Existing Programming ....................................................................................... 41

Linking the Hand-Held Remote to the Receiver ..................................................................... 42

Testing I-Wave Reception ...........................................................................................................43

Installing the 35-ft. Antenna Extension Cable (PA121) ........................................................... 44

Installing and Conguring Optional Repeaters .......................................................................44

Everyday Use of the Hand-Held Remote Transceiver .................................................................. 46

Changing between Pool and Spa ...........................................................................................46

Setting Pool and Spa Temperatures.........................................................................................46

Operating Programmed Functions .........................................................................................47

Changing Batteries ................................................................................................................47

Manually Turning Equipment On and Off .............................................................................. 47

Advanced Features .....................................................................................................................48

Conguring Two or More Hand-Held Remote Transceivers ....................................................48

Programming to Protect a Pool Cleaner Pump .......................................................................49

Using Two Hand-Held Controllers to Operate the System ......................................................49

Section 7: Checking Out and Troubleshooting the System ..............................................................50

Section 9: Warranty ........................................................................................................................62

Providing a brighter solution.™

Page 6

6 I-Wave PE5 Installation Guide

Section 1:

System Overview

The Intermatic I-Wave Pool/Spa PE5 Wireless Control System brings wireless control to a new

level of simplicity and affordability. What makes the system distinctive is that it is:

Easy to Use — with simple, push button controls and a clear, easy-to-read display panel

•

Everything You Need — providing, in its standard conguration, the functionality and

•

control called for in nearly every installation.

Modular — components snap in and out of the enclosure as needed to simplify installation

•

and repair, and to make customization simple for the installer. No need for the technician

to spend hours troubleshooting a circuit board…just snap in a replacement.

Dependable — with Z-Wave® technology that lets you plug inexpensive repeaters into an

•

electrical outlet to relay signals in any part of the site with dead spots. Z-Wave® technology

eliminates intermittent signal problems experienced with many other systems.

Cost Efciency — a superior system, easier to install and maintain, with better

•

dependability, and at a cost that’s competitive with any other system available.

The standard conguration for the I-Wave Pool/Spa PE5 Wireless Control System conguration is

shown in Figure 1-1. You can order individual components for a custom conguration or system

as indicated.

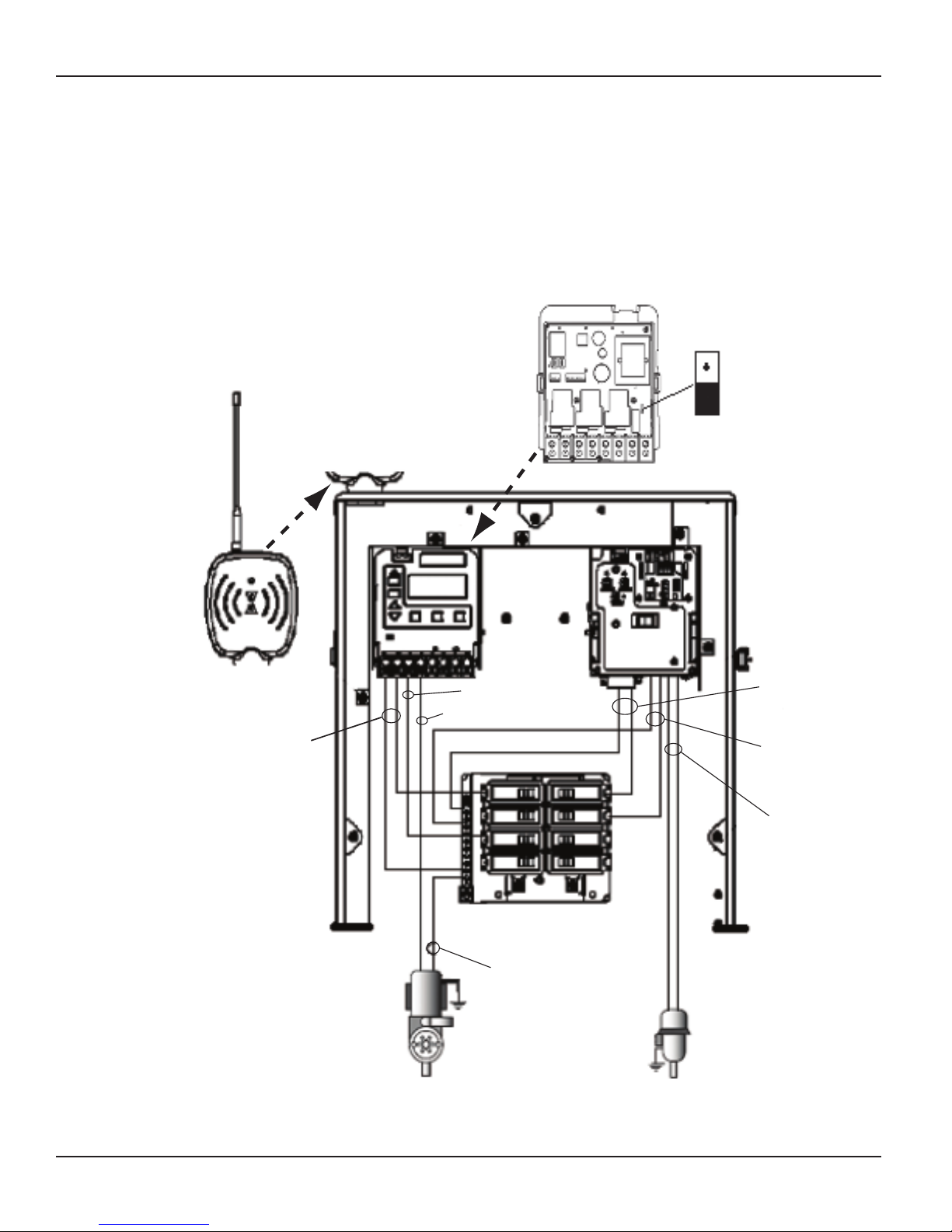

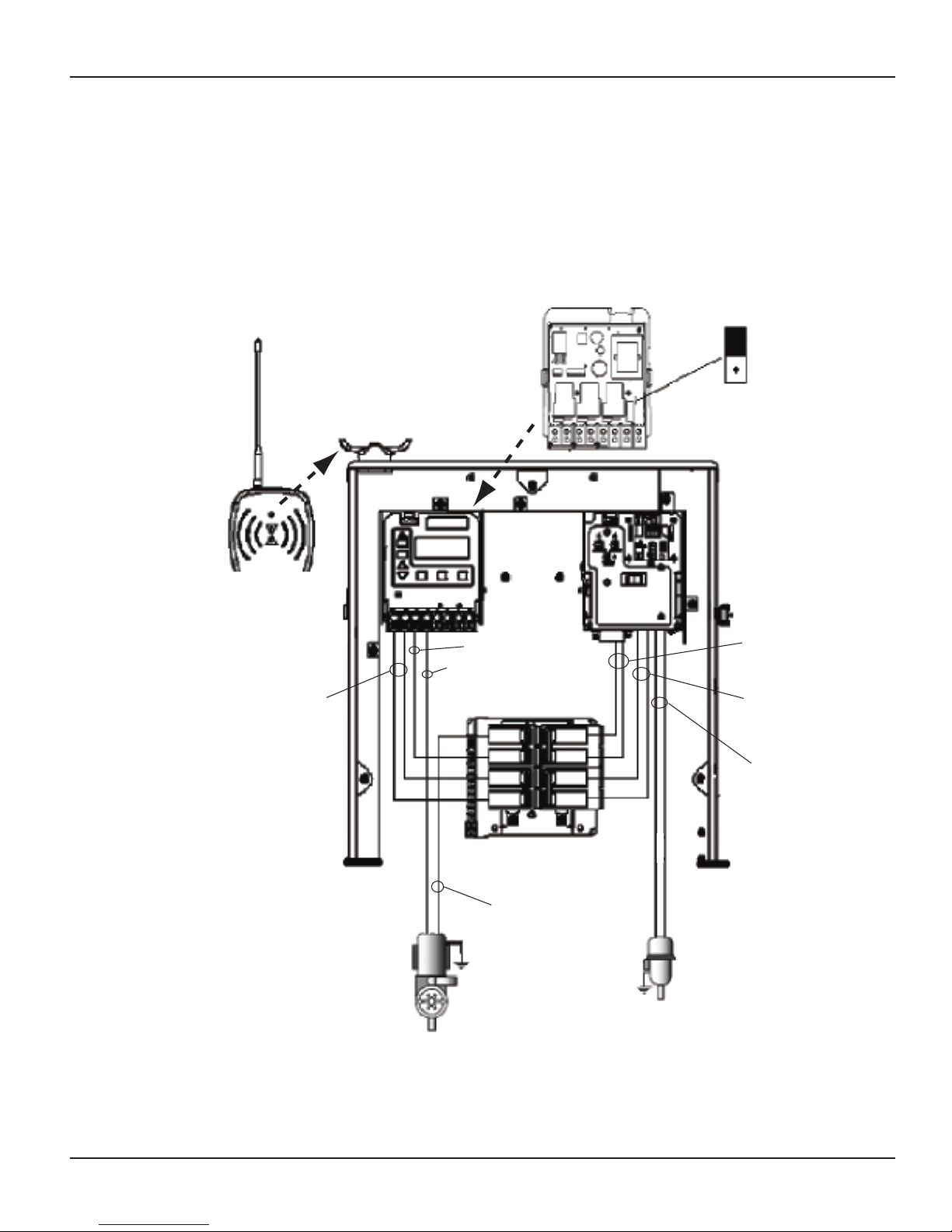

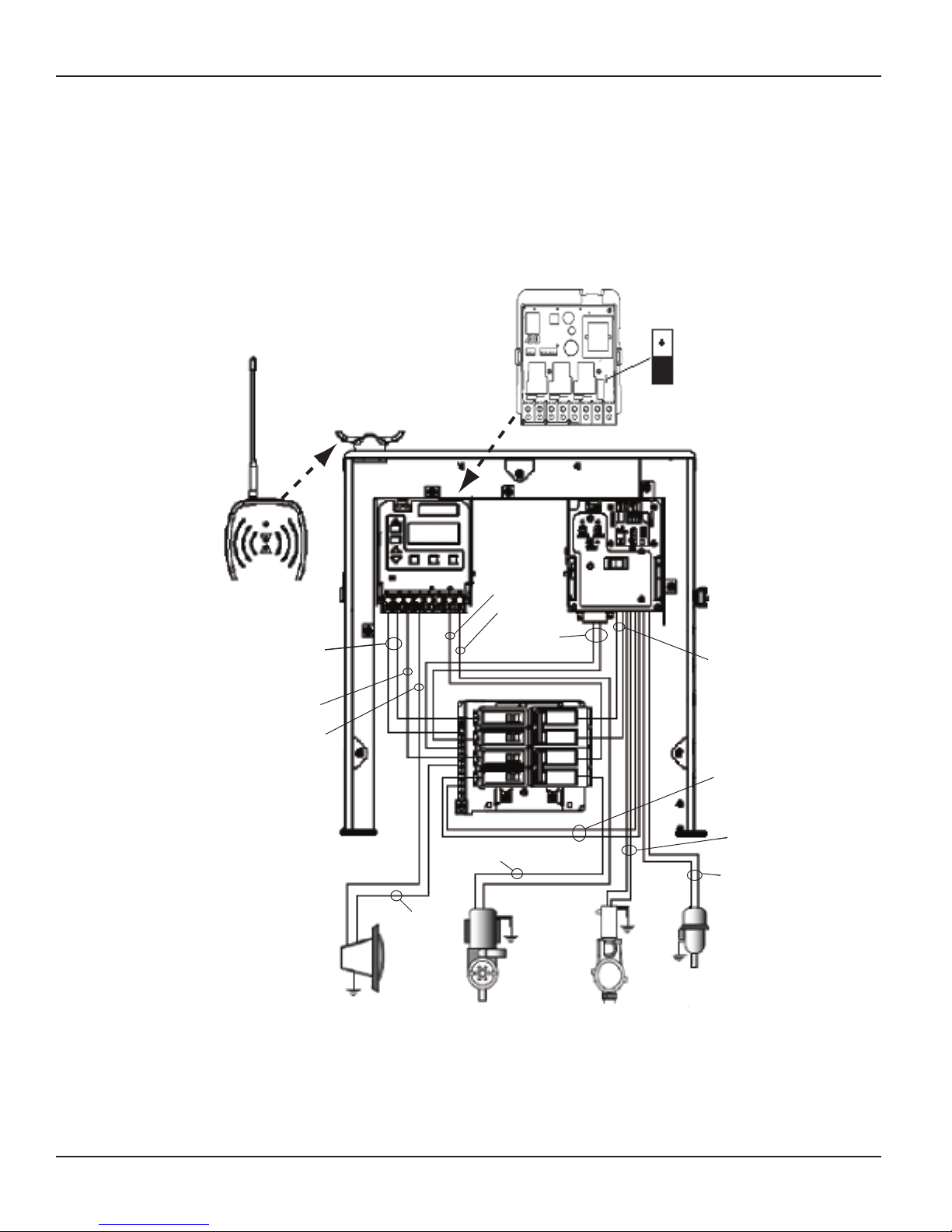

Removable antenna (PA118)

Removable antenna (PA118)

can be ordered separately

can be ordered separately

Panel-Mounted Transceiver (PE650).

Panel-Mounted Transceiver (PE650).

Includes Antenna (PA118).

Includes Antenna (PA118).

Three-Circuit Clock (P1353ME)

Three-Circuit Clock (P1353ME)

offers timer capability and can

offers timer capability and can

control up to 3 pool/spa circuits.

control up to 3 pool/spa circuits.

Offers five pre-programmed

Offers five pre-programmed

configuration modes.

configuration modes.

Hand-Held Transceiver (PE950).

Hand-Held Transceiver (PE950).

Up to 5 units can be used with an

Up to 5 units can be used with an

I-Wave system. Additional units

I-Wave system. Additional units

can be ordered separately.

can be ordered separately.

Valve/Pump Switch (P4243ME), can control

Valve/Pump Switch (P4243ME), can control

up to 2 different pool/spa circuits and up

up to 2 different pool/spa circuits and up

to 3 valve actuators. Can also be ordered

to 3 valve actuators. Can also be ordered

separately.

separately.

I-Wave Steel Outdoor Enclosure

I-Wave Steel Outdoor Enclosure

(PE40000), weatherproof, and with

(PE40000), weatherproof, and with

plenty of room to add additional

plenty of room to add additional

switch mechanisms if desirable.

switch mechanisms if desirable.

Can also be ordered separately

Can also be ordered separately

by installers who want to create

by installers who want to create

a non-standard system from

a non-standard system from

individual components.

individual components.

24-volt Valve Actuators (PE24VA)

24-volt Valve Actuators (PE24VA)

provide reliable control of 2-way

provide reliable control of 2-way

and 3-way diverter valves. (Two are

and 3-way diverter valves. (Two are

included, additional units can be

included, additional units can be

ordered)

ordered)

Figure 1-1Figure 1-1

Copyright © 2006 Intermatic, Inc.

Page 7

The standard system is shipped with snap-in mechanisms in place inside the enclosure, the

panel-mounted transceiver attached to the top of the enclosure, with antenna to be attached.

Components are already interconnected and are ready for wiring. System model numbers are

designed to make sure the installation meets local code as follows:

PE45343RC — the basic radio-controlled system.

•

PE45343RCT1 — a special version with a 100 watt transformer for 12-Volt underwater

•

lighting, where required by local code. The 100-watt transformer (PA117) can also be

ordered separately for installation into standard model PE45343RC.

PE45343RCT3 — a special version with a 300 watt transformer for 12-Volt underwater

•

lighting, where required by local code. The 300-watt transformer (PA116) can also be

ordered separately for installation into standard model PE45343RC.

You can order most system components individually to assemble a custom I-Wave system as

desired.

Additional Detail on Key Components

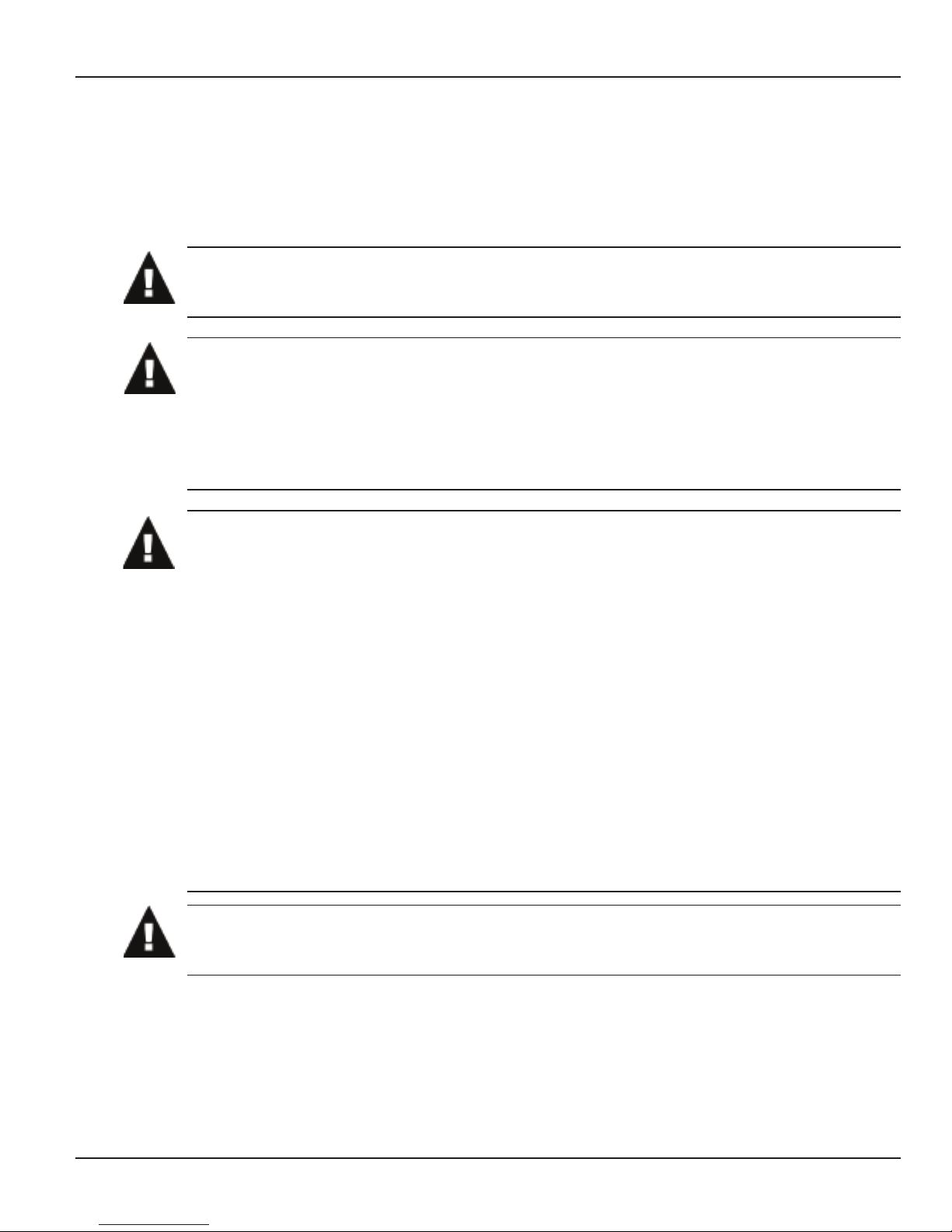

Three-Circuit Clock (P1353ME)

Designed for aftermarket and retrot applications, the P1353ME has the

ability to program up to three different circuits. Choose between six preprogrammed modes of operation, which include single speed pump or

2-speed pump/cleaner pump combinations. In addition, programmed

modes that include auxiliaries can control pumps up to 3 HP as well as

underwater, garden, and/or fountain lighting. Countdown and Override

features allow cycle interruptions when pool/spa service is required.

All timing and protection, associated with lter pump/cleaner pump

combinations and two-speed pumps, has already been integrated into

the software. This mechanism can also be installed into almost any

Intermatic enclosure.

One: System Overview 7

120 or 208-240 Volt Input Voltage

•

Memory Back-Up

•

Heater Protection (Fireman Switch)

•

LCD Readout

•

Shipping Weight — 3 lbs. (1.4 kg)

•

Agency Approval — CSA/C-US

•

CONTACT RATINGS – EACH CIRCUIT, ALL MODES

20A Resistive, 120/240 VAC., 50/60 Hz

•

20A FLA@120 VAC, 96A LRA@120 VAC, 50/60 Hz

•

17A FLA@240 VAC, 80A LRA@120 VAC, 50/60 Hz

•

5 Amps Tungsten, 120/240 VAC, 50/60 Hz

•

5 Amps Ballast, 120/240 VAC, 50/60 Hz

•

Providing a brighter solution.™

Page 8

8 I-Wave PE5 Installation Guide

Valve/Pump Switch (P4243ME)

120 or 208-240 Volt Input Voltage

•

Controls up to three valve actuators

•

Switches heater thermostat

•

Remote control capabilities

•

Shipping Weight — 3 lbs. (1.4 kg)

•

Agency Approval — CSA/C-US

•

Designed for aftermarket and retrot applications, the P4243ME is most

suited for controlling up to two different circuits associated with pool/

spa combinations but can also be used to control all the equipment

typically needed in connection with water features, water gardening,

solar heating, and other similar applications. This unit snaps into almost

any Intermatic enclosure and features two 3HP double pole relays,

one of which can be controlled by an external timer, 24 volt supply for

up to three valve actuators, automatic HIGH/LOW water temperature

selector, heater connection circuit, and push button control for each

load with indicator lights on the face of the control. In addition, the unit

has connections for a hard-wired or wireless remote and a master switch

controller.

CONTACT RATINGS – EACH CIRCUIT

17A Resistive, 120/240 VAC., 50/60 Hz

•

1.5 HP @ 120 VAC., 50/60 Hz

•

3.0 HP @ 240 VAC., 50/60 Hz

•

10 Amp Tungsten, 120/240 VAC, 50/60 Hz

•

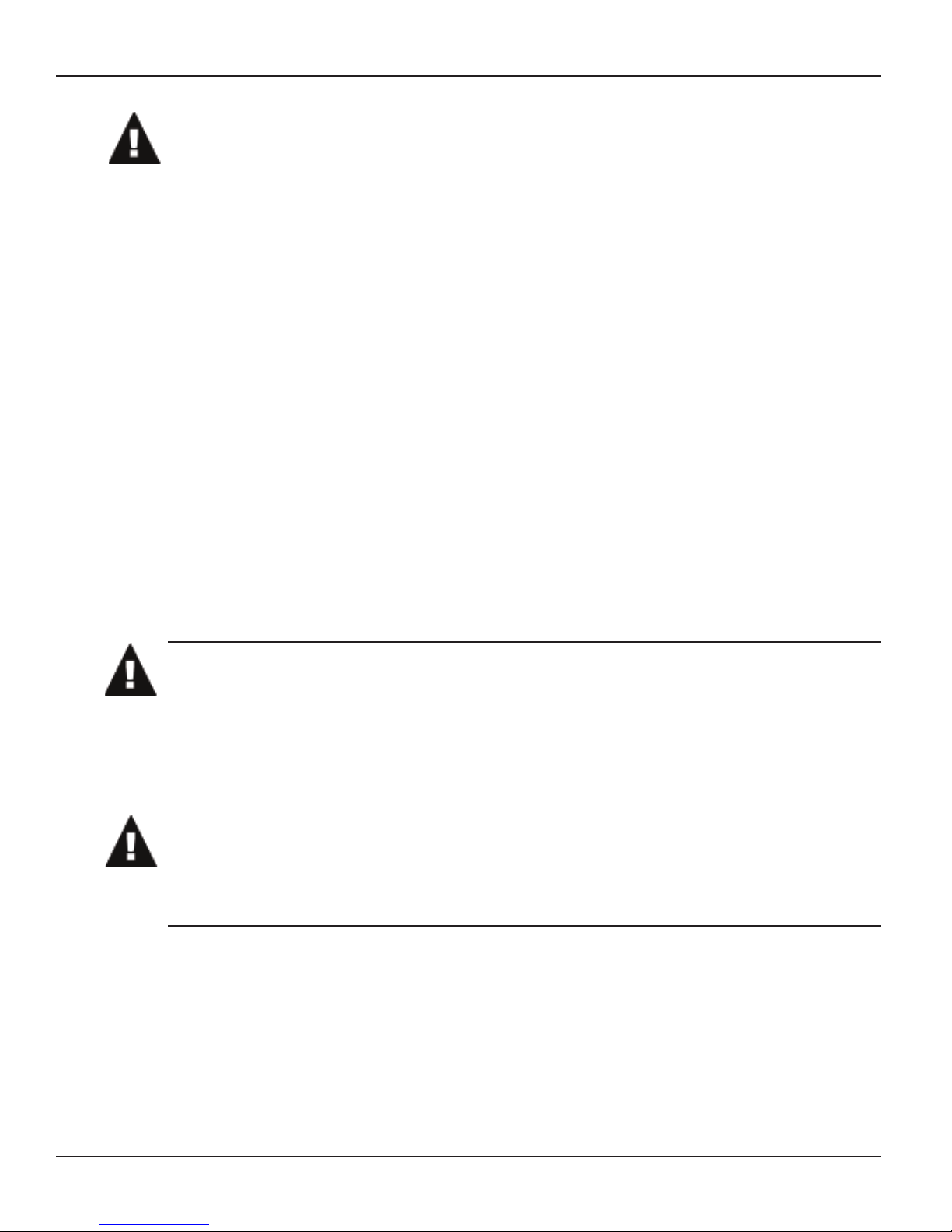

24-Volt Valve Actuator (PE24VA)

Designed with quality in mind, Intermatic’s 24-volt valve actuators

provide reliable control of 2-way and 3-way diverter valves for pool/

spa combinations and water features. The water ow can be altered

for specic applications through the adjustable cam, which rotates

diverter valves to multiple degree settings. The cam settings can be

easily adjusted by simply removing the lid. These valve actuators are

compatible with all pool/spa valves currently offered in the industry and

will retrot into all pool/spa control systems.

24VAC Input Voltage

•

Automates compatible diverter valves for

•

pool/spa combos

Adjustable cam rotates diverter valves to

•

multiple degree settings

Designed to operate most 2-way and 3-way diverter valves

•

Shipping Weight - 3 lbs. (1.4 kg)

•

Agency Approval - CSA/C-US

•

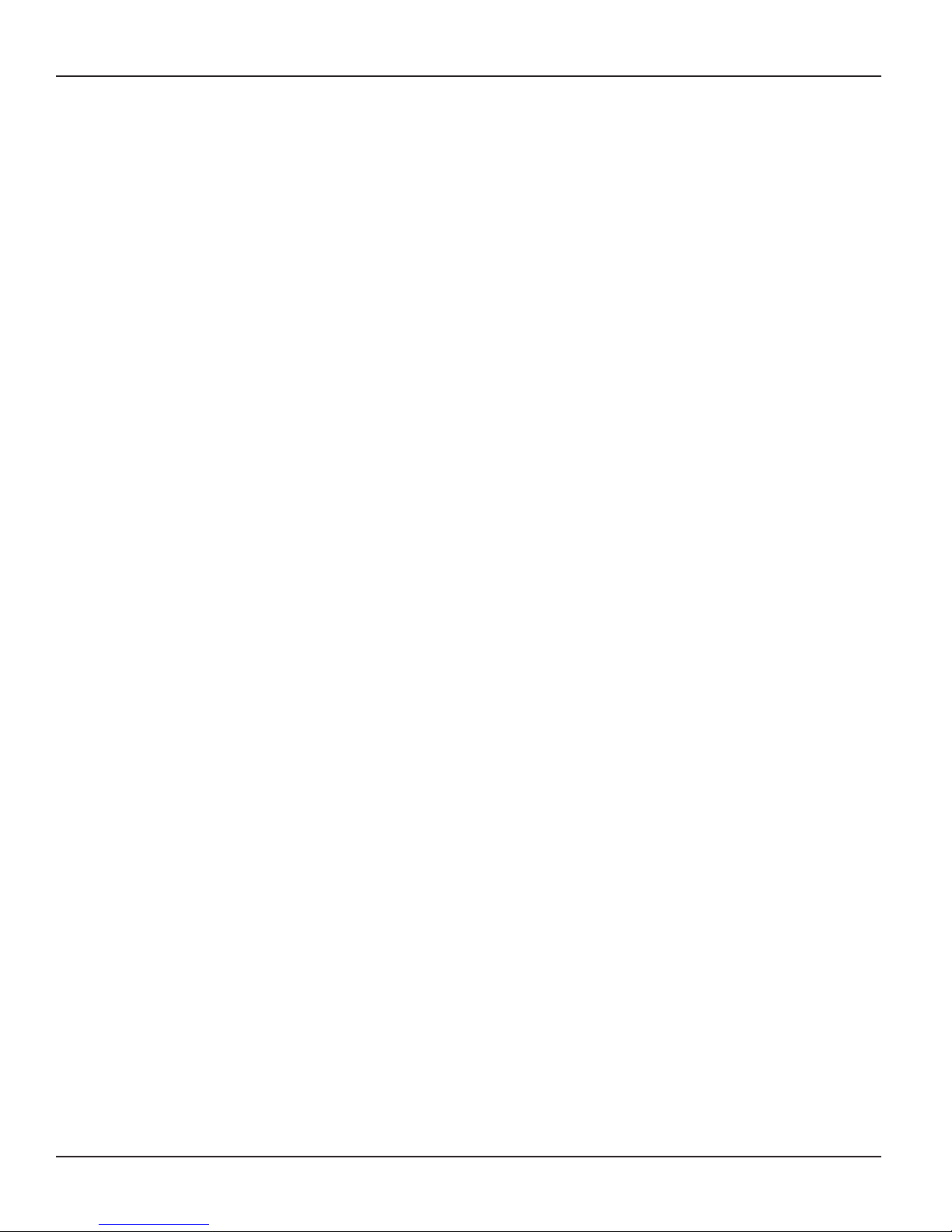

Panel-Mounted Transceiver (PE650) Includes Antenna (PA118)

The main function of the Panel-Mounted Transceiver is to take commands

from the Wireless Hand-Held Transceiver (PE950) and hand them off to two

mechanisms (P1353ME and/or P4243ME) in the I-Wave Enclosure box. This unit

can control:

One P1353ME unit and one P4243ME unit

•

•

•

In cases where the two devices are too far apart for direct communication, a

Transceiver Repeater Module (HA04C) will relay commands between the two

devices. Shown here with its removable antenna (PA118).

One or two P1353ME units

One or two P4243ME units

Copyright © 2006 Intermatic, Inc.

Page 9

One: System Overview 9

Wireless Hand-Held Transceiver (PE950)

The main function of the Wireless Hand-Held Transceiver is to transmit user

commands to the Panel-Mounted Transceiver (PE650) and display the status

of the equipment. The device can control up to ve loads, typically:

The three loads in the Three-Circuit Clock

•

The two relays in the Valve/Pump Switch, usually water temperature

•

controls for pool/spa

The actuators that switch between pool and spa

•

The unit oats if thrown in the pool or spa, is water-submersible, shock

resistant, and requires three (3) AA batteries. Expected battery life is about

one year in typical use.

The Wireless Hand-Held Transceiver (PE950) can only communicate with the Panel-Mounted

Transceiver (PE650) and Transceiver Repeater Module (HA04C), and is compatible with no

other hardware. In addition, when the components of a specic system are linked together into a

network, communication with another neighboring system cannot occur. Up to ve PE950 units

can be used in a single installation.

35-ft. Antenna Extension Cable Assembly (PA121)

When a structure impedes transmission between the Panel-Mounted Transceiver and Handheld Transceiver(s), you can use the 35-ft. Antenna Extension Cable Assembly (PA121) to

relocate the antenna from the Panel-Mounted Transceiver to the area of operation, ensuring that

communication between the Hand-Held unit and the control center is successful.

OMRON Relay Assembly (143T145A)

There are two OMRON Relay Assemblies (143T145A) in the Valve/Pump

Switch Mechanism (P4243ME) which switch either 120V or 240V loads.

These relays are replaceable and can be ordered separately.

CONTACT RATINGS – EACH CIRCUIT

CONTACT RATINGS – EACH CIRCUIT

17A Resistive, 120/240 VAC., 50/60 Hz

•

17A Resistive, 120/240 VAC., 50/60 Hz

•

1.5 HP @ 120 VAC., 50/60 Hz

•

1.5 HP @ 120 VAC., 50/60 Hz

•

3.0 HP @ 240 VAC., 50/60 Hz

•

3.0 HP @ 240 VAC., 50/60 Hz

•

10 Amp Tungsten, 120/240 VAC, 50/60 Hz

•

10 Amp Tungsten, 120/240 VAC, 50/60 Hz

•

Water Temperature Sensor (PA122)

The Intermatic Water Sensor (PA122) monitors both pool and spa water

temperature, depending on the position of the diverter valves. Installation

is necessary for the thermostatic control to work. The sensor can be

ordered separately.

Providing a brighter solution.™

Page 10

10 I-Wave PE5 Installation Guide

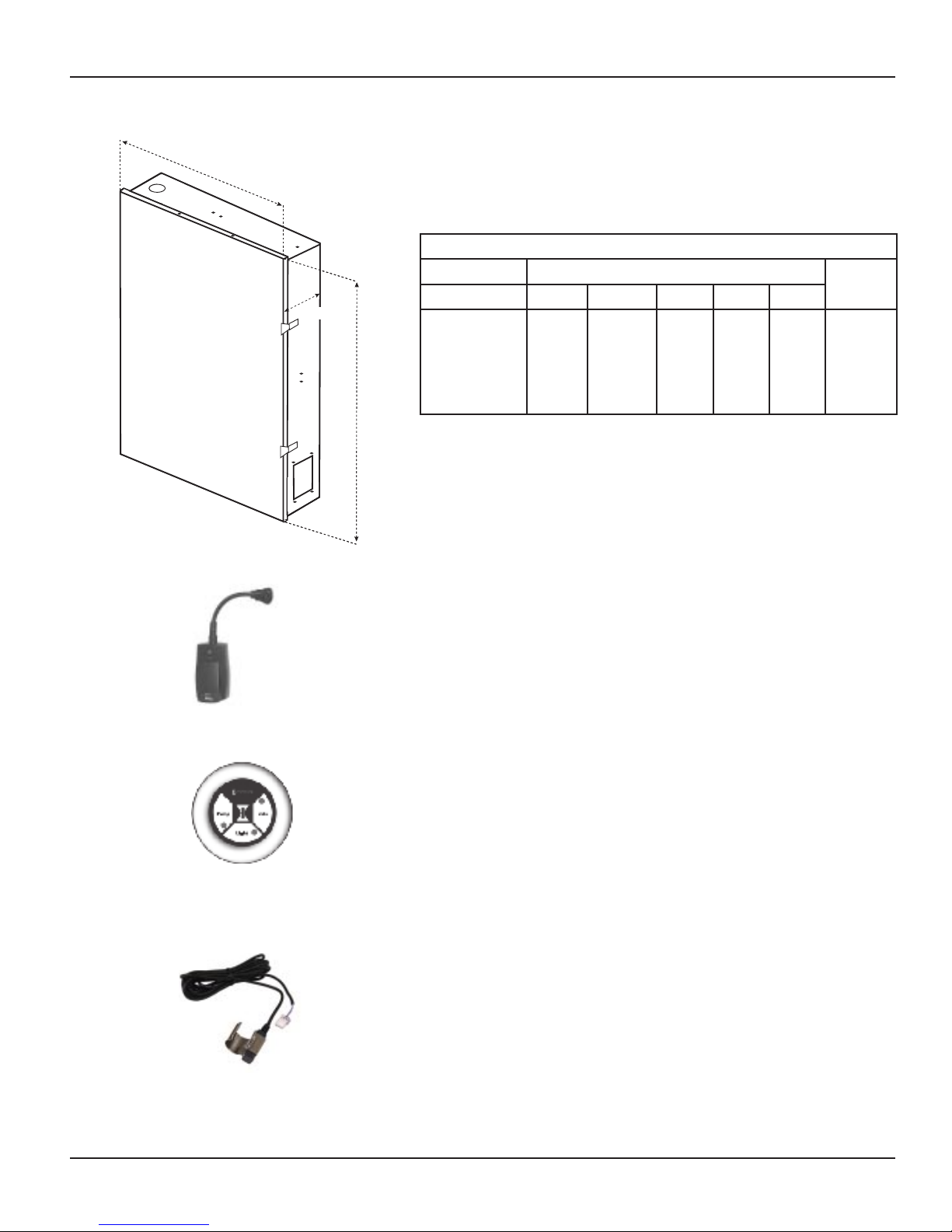

19”

26 3/4”

5 1/2”

19”

26 3/4”

5 1/2”

Steel Outdoor Enclosure Includes P1353ME (PE45300)

Suitable listed breakers (purchase locally)

CIRCUIT BREAKER FILLER

MFR SINGLE DOUBLE TWIN QUAD GFCB

Cutler-Hammer

Murray

Siemens

Square-D

Thomas & Betts

BR

MP-T

QP

HOM

TB

BR

MP-T

QP

HOM

TB

BRD

MH-T

QT

HOMT

TBBD

BRD

MH-T

QT

HOMT

TBBD

GFCB

MP-GT

QPF

HOMT

GFB

PLATE

BRFP

LX100FP

QF3

HOMFP

FP-1C-TB

Optional — Transceiver Repeater Module (HA04C)

The Transceiver Repeater Modules (HA04C) ensure that no problems in reception

occur between the Hand-Held Controller(s) (PE950) and the Panel-Mounted

Transceiver (PE650). Reception is affected by distance (about 100 feet, direct line

of sight) and by physical obstacles (like brick walls or structures). However, by

plugging in a Transceiver Repeater Module where necessary, long distances or

physical obstructions can be overcome.

Optional — Three-Button Wired Remote Control (133PE1484A)

The Three-Button Wired Remote Control (133PE1484A) plugs into either the

Three-Circuit Clock (P1353ME) or Valve/Pump Switch (P4243ME).

When installed as part of a system, it replaces the wireless method of controlling

the three circuits within the mechanism. For more information, refer to Installing

box, since the Wireless Hand-Held Transceiver (PE950) can only control two mechanisms.

Optional — Freeze (Air Temperature) Sensor (178PA28A)

a Wired Remote Connection in Section 4. The Three-Button Wired Remote

Control must be installed where a third mechanism is needed in the enclosure

Add the Intermatic Freeze or Air Temperature Sensor (178PA28A) to installations

where below-freezing outdoor temperatures are a concern. Programming

information to incorporate the sensor is provided on page 35.

Copyright © 2006 Intermatic, Inc.

Page 11

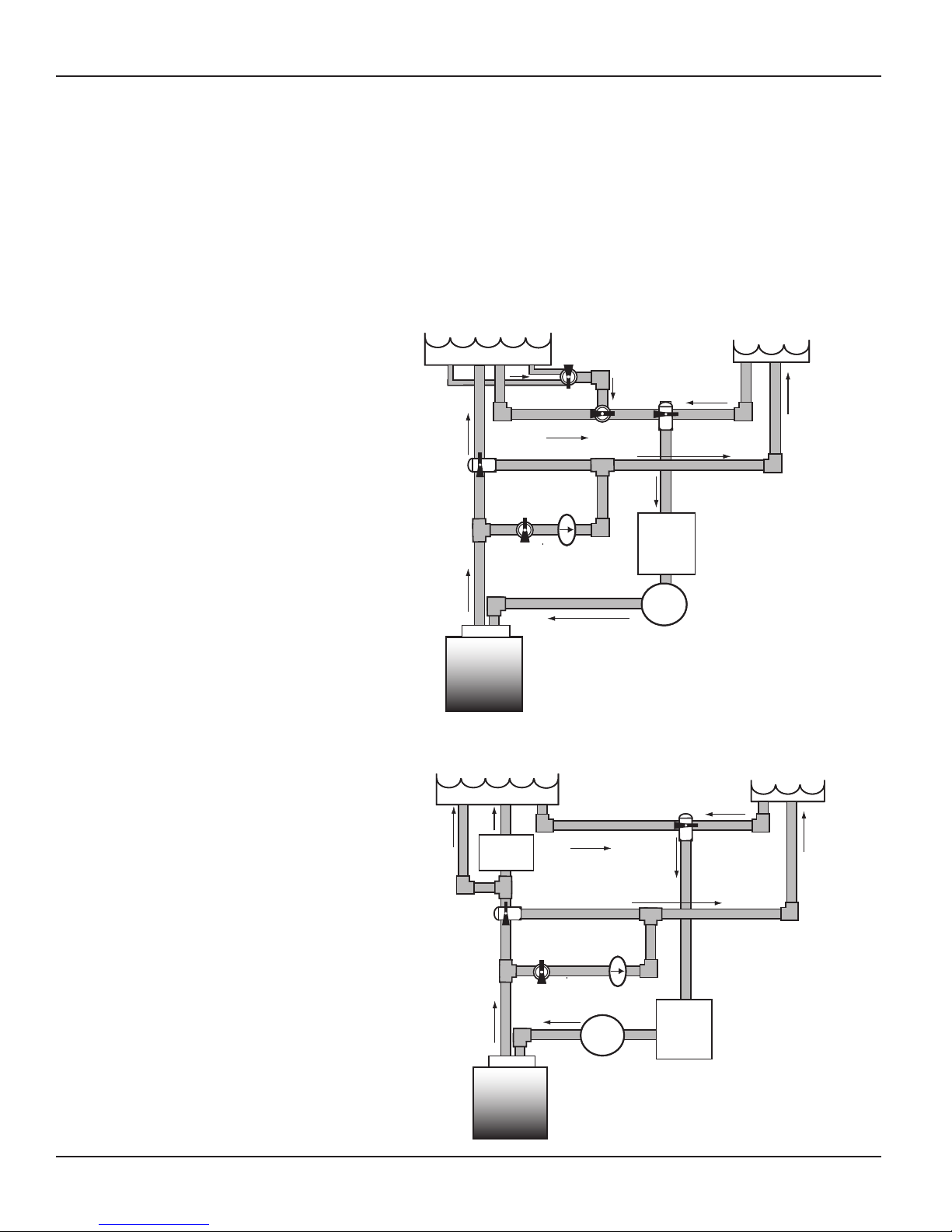

Section 2:

Pool

Spa

Filter

Check

Valve

Spa

Make-up

Filter

Pump

Intake

Return

Return

Intake

Skimmers

Heater

Pool

Spa

Filter

Check

Valve

Spa

Make-up

Filter

Pump

Intake

Return

Return

Intake

Skimmers

Heater

Pool

Spa

Filter

Check

Valve

Spa Make-up

Filter

Pump

Intake

Return

Return

Intake

Heater

Booster

Pump

Pool

Spa

Filter

Check

Valve

Spa Make-up

Filter

Pump

Intake

Return

Return

Intake

Heater

Booster

Pump

Plumbing Examples

The following diagrams show several plumbing and wiring examples of installations for pool and

spa that share a single lter pump, lter, and heater. If you are installing a pool only or spa only,

these diagrams will not apply.

For Pool and Spa

Combo Installations

Two: Plumbing and Wiring Examples 11

For Booster Pump Pool

Cleaner Installations

Providing a brighter solution.™

Page 12

12 I-Wave PE5 Installation Guide

Pool

Spa

Filter

Check

Valve

Spa

Make-up

Filter

Pump

Intake

Return

Return

Intake

Heater

Energy

Filter

Pool

Spa

Filter

Check

Valve

Spa

Make-up

Filter

Pump

Intake

Return

Return

Intake

Heater

Energy

Filter

For Non-Booster Pump

Pool Cleaner Installations

Copyright © 2006 Intermatic, Inc.

Page 13

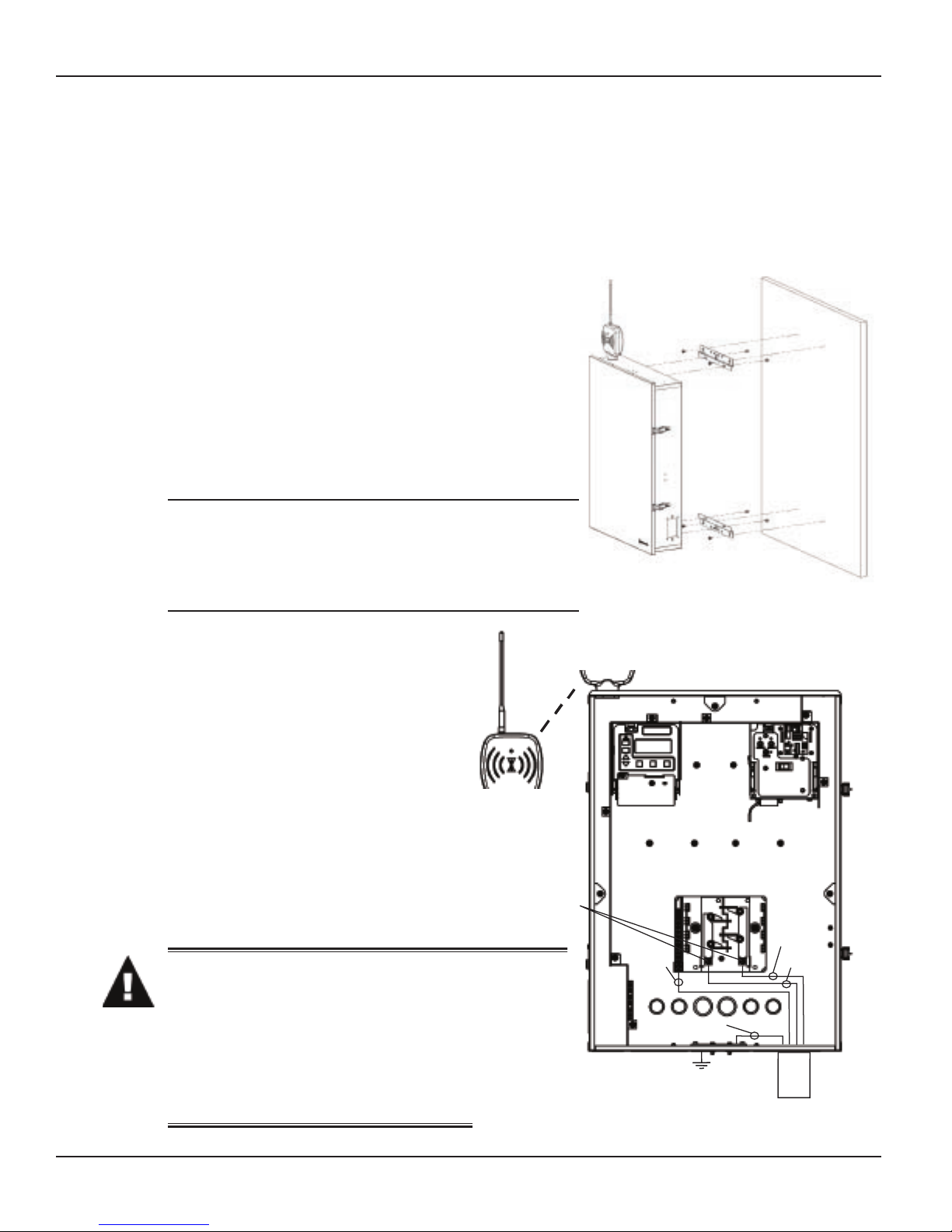

Section 3:

Earth Ground

From Main

Power

White

(neu)

Black

Red

Ground

Buss

Earth Ground

From Main

Power

White

(neu)

Black

Red

Ground

Buss

Control Center Installation

Mounting the Control Center

Special code requirements apply to your I-Wave

Control System. To ensure safe installation, please

follow all applicable national state, and local codes

when installing the Control Center.

Locate your Control Center near the pool/spa

equipment pad at least ve feet or more away from

either the pool or spa equipment and at least ve feet

off the ground.

Mounting brackets have been provided to assist you in

your installation.

NOTE: The Control Center is not to be considered

as suitable for use as Service Equipment. Therefore,

it is required to have the appropriate means of

disconnection, circuit isolation, and/or branch circuit

protection installed at the Main Power Panel.

Three: Control Center Installation 13

Figure 3-1Figure 3-1

Wiring the System Power

Run wire from the Main Power Panel

to your Control Center and connect the

leads to the Control Center Breaker Base.

See detail in Figure 3-2 at the right.

The breaker base of your Control Center

is capable of handling up to 125 amps.

You must comply with the applicable

local codes and use the proper gauge

wiring from your Main Power panel to

your control center breaker base. The

proper gauge wire will be determined by

the length of wire required and the 125

Max Amp rating.

WARNING: Potentially high voltages

in the Control Center can create

dangerous electrical hazards,

possibly causing death, serious

injury, or property damage. Turn

off the Main Power to the Control

Center to disconnect or service the

I-Wave Control Center.

Figure 3-2Figure 3-2

Providing a brighter solution.™

Page 14

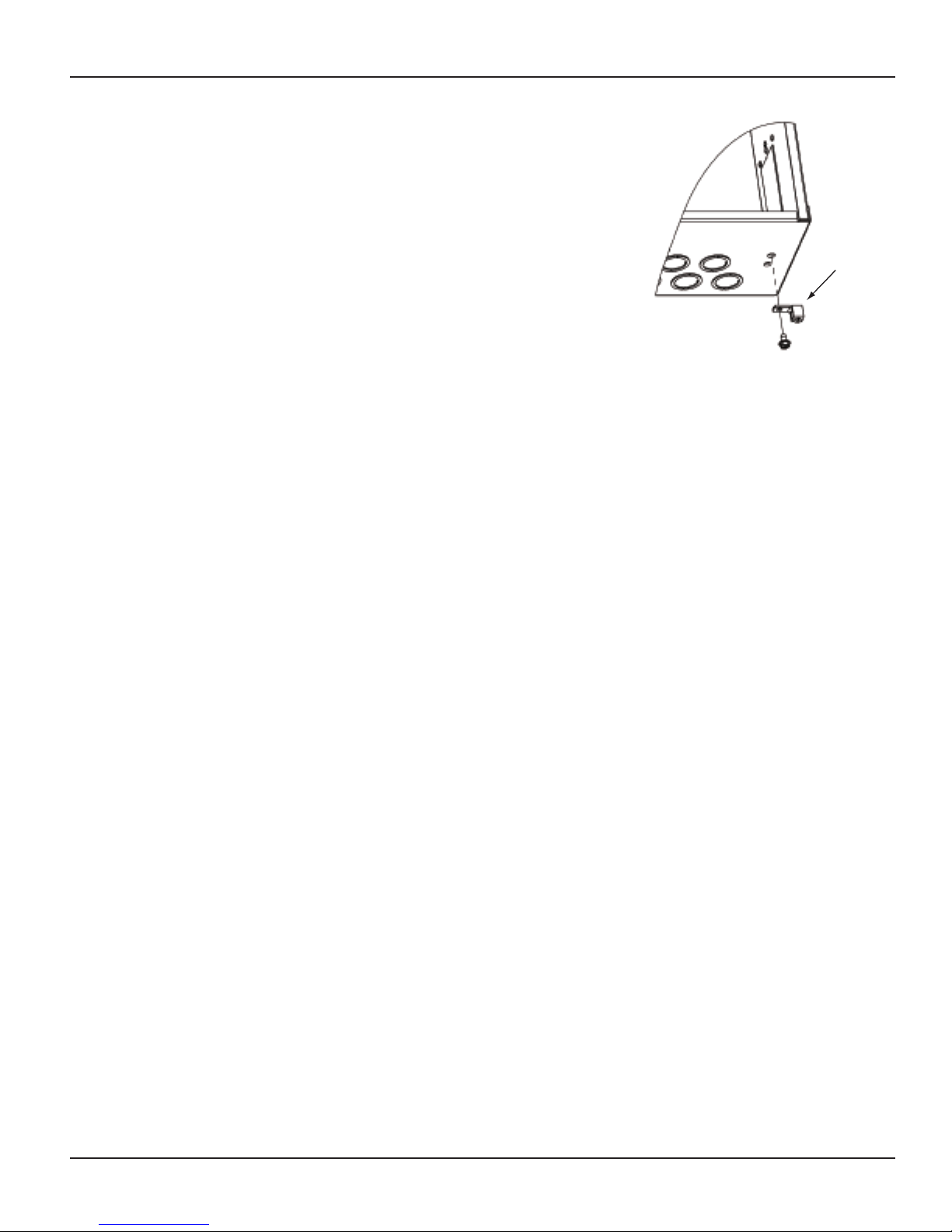

14 I-Wave PE5 Installation Guide

Part Number

156T11047A

Part Number

156T11047A

Bonding the Control Center

Some state local codes require bonding the control center

to the bonding grid. If this is required, install a bonding lug

(156T11047A) to the Control Center enclosure and connect a

#8 solid copper core wire, to an approved earth ground, (i.e.

approved ground stake, or conducting metal water pipe buried

to a sufcient depth, etc.). See detail in Figure 3-3 at the right.

Wiring the Individual Equipment

Each piece of pool or spa equipment requires its own high voltage relay and associated circuit

breaker branch protection. Each circuit breaker should be sized according to your load and the

appropriate local codes.

The I-Wave Control System consists of two Intermatic snap-in mechanisms:

P1353ME — with three timed circuits each comprised of three SPST relays

•

P4243ME — with two on-demand circuits comprised of two DPST relays

•

Even though the three circuit clock can easily handle on-demand circuits, any equipment that

requires programmed ON/OFF times should be wired to the three-circuit P1353ME mechanism

(i.e., lter pumps, booster pumps, etc.). On-demand equipment (i.e., blowers, lights, etc.) should

be wired to the P4243ME valve-controller mechanism. This practice will maximize your control

capabilities.

All circuits are independent contacts. Therefore you can mix and match 120-Volt and 240-Volt

loads within each mechanism. Refer to the following illustrations for sample wiring diagrams.

Figure 3-3Figure 3-3

Copyright © 2006 Intermatic, Inc.

Page 15

If Wiring 120-Volt Loads:

If using 120V source voltage,

set voltage selector jumper

on back of P1353ME clock

mechanism to 120V

Breaker

Panel

Filter Pump

(120 VAC)

Neutral

Blower

(120 VAC)

Blk/Wht

120 VAC

Blk/Red

Line

Blu/Yel

Load

Blk/Wht

120 VAC

120V

240V

Blk (line)

Blk (load)

(P1353ME)

If using 120V source voltage,

set voltage selector jumper

on back of P1353ME clock

mechanism to 120V

Breaker

Panel

Filter Pump

(120 VAC)

Neutral

Blower

(120 VAC)

Blk/Wht

120 VAC

Blk/Red

Line

Blu/Yel

Load

Blk/Wht

120 VAC

120V

240V

Blk (line)

Blk (load)

(P1353ME)

For safety purposes, the factory default setting for the source voltage of a P1353ME

•

mechanism is for 240 Volts.

For 120-Volt installations, be sure you set the Source Voltage Selection Jumper on the back of

•

the Three-Circuit Clock mechanism (P1353ME) for 120 Volts before you begin wiring.

For more information, see Identifying Connections and Selecting Proper Input Voltage on

•

page 26.

Three: Control Center Installation 15

Figure 3-4Figure 3-4

Providing a brighter solution.™

Page 16

16 I-Wave PE5 Installation Guide

If using 240V source voltage,

set voltage selector jumper

on back of P1353ME clock

mechanism to 240V

Breaker

Panel

Filter Pump

(240 VAC)

Red

Blower

(240 VAC)

Blk/Org

240 VAC

Blk/Red

Line

Blu/Yel

Load

Blk/Red

240 VAC

120V

240V

Blk (line)

Blk (load)

(P1353ME)

If using 240V source voltage,

set voltage selector jumper

on back of P1353ME clock

mechanism to 240V

Breaker

Panel

Filter Pump

(240 VAC)

Red

Blower

(240 VAC)

Blk/Org

240 VAC

Blk/Red

Line

Blu/Yel

Load

Blk/Red

240 VAC

120V

240V

Blk (line)

Blk (load)

(P1353ME)

If Wiring 240-Volt Loads:

For safety purposes, the factory default setting for the source voltage of a P1353ME

•

mechanism is for 240 Volts.

The Source Voltage Selection Jumper on the back of the Three-Circuit Clock mechanism

•

(P1353ME) will already be correctly set, ready for you to begin wiring.

For more information, see Identifying Connections and Selecting Proper Input Voltage on

•

page 26.

Figure 3-5Figure 3-5

Copyright © 2006 Intermatic, Inc.

Page 17

If Wiring Combination 120- and 240-Volt Loads:

For combo 120- 240V loads,

set source voltage selector

jumper on back of P1353ME

clock mechanism to 120V

Filter Pump

(120 VAC)

Neu

Blower

(120 VAC)

Blk/Wht

120 VAC

Blk/Red

Line

Blu/Yel

Load

Blk/Wht

120 VAC

120V

240V

Blk (line)

Blk (load)

(P1353ME)

Blk (load)

Blk (line)

Vio/Org

Line

Blu/Gry

Load

Jet Pump

(240 VAC)

Light

(120 VAC)

Red

For combo 120- 240V loads,

set source voltage selector

jumper on back of P1353ME

clock mechanism to 120V

Filter Pump

(120 VAC)

Neu

Blower

(120 VAC)

Blk/Wht

120 VAC

Blk/Red

Line

Blu/Yel

Load

Blk/Wht

120 VAC

120V

240V

Blk (line)

Blk (load)

(P1353ME)

Blk (load)

Blk (line)

Vio/Org

Line

Blu/Gry

Load

Jet Pump

(240 VAC)

Light

(120 VAC)

Red

For combination 120- and 240-Volt loads, change the factory default setting of the Source

•

Voltage Selection Jumper on the back of the Three-Circuit Clock mechanism (P1353ME) from

its factory default setting to 120 Volts.

For more information, see Identifying Connections and Selecting Proper Input Voltage on

•

page 26.

Three: Control Center Installation 17

Figure 3-6Figure 3-6

Providing a brighter solution.™

Page 18

18 I-Wave PE5 Installation Guide

(WP1000C

)

(WP1000C

)

Wiring Underwater Lights

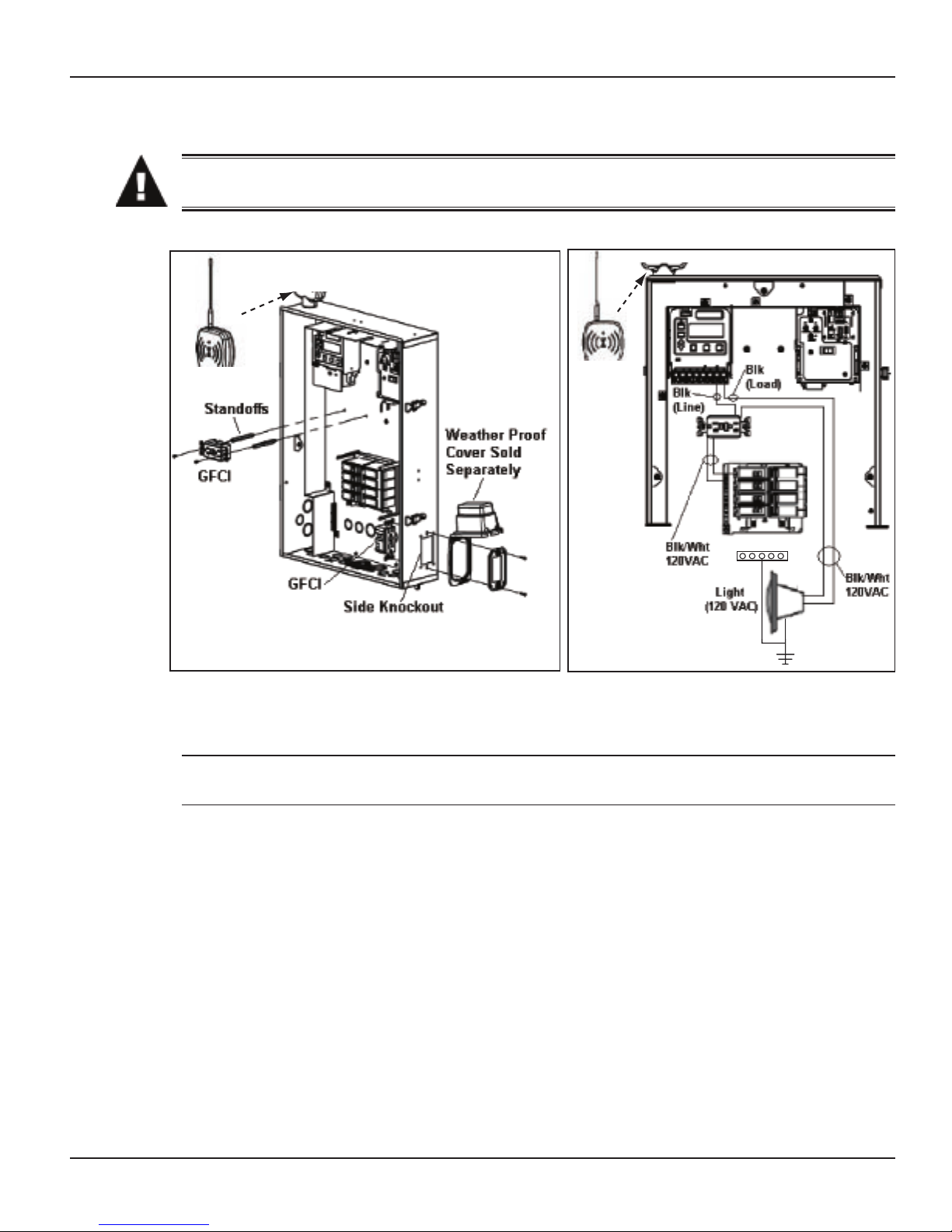

CAUTION: A Ground Fault Circuit Interrupter (GFCI) must be provided for high voltage

pool/spa lights. Do not use a GFCI circuit breaker.

High-Voltage Underwater Lights

Figure 3-7 Figure 3-8 Figure 3-7 Figure 3-8

The I-Wave PE5 Control Center comes equipped with two décor knockouts on the dead front

and one side knockout for installation of GFCI receptacles. (See Figure 3-7).

NOTE: If using the décor knockouts to install a GFCI, you must use the standoffs provided with

the Control Center to mount your GFCI.

Install a GFCI receptacle and connect the neutral and hot wire, from the circuit breaker, to the

1.

LINE side of the GFCI. (See Figure 3-8).

Connect the neutral (white) from the light to the GFCI.

2.

Connect the hot (black) as follows:

3.

From the LOAD side of the GFCI to the line side of the clock,

a.

From the light to the LOAD side of the clock. (See Figure 3-8.)

b.

Connect the ground (green) from the light to the grounding bar inside the Control Center.

4.

Copyright © 2006 Intermatic, Inc.

Page 19

Three: Control Center Installation 19

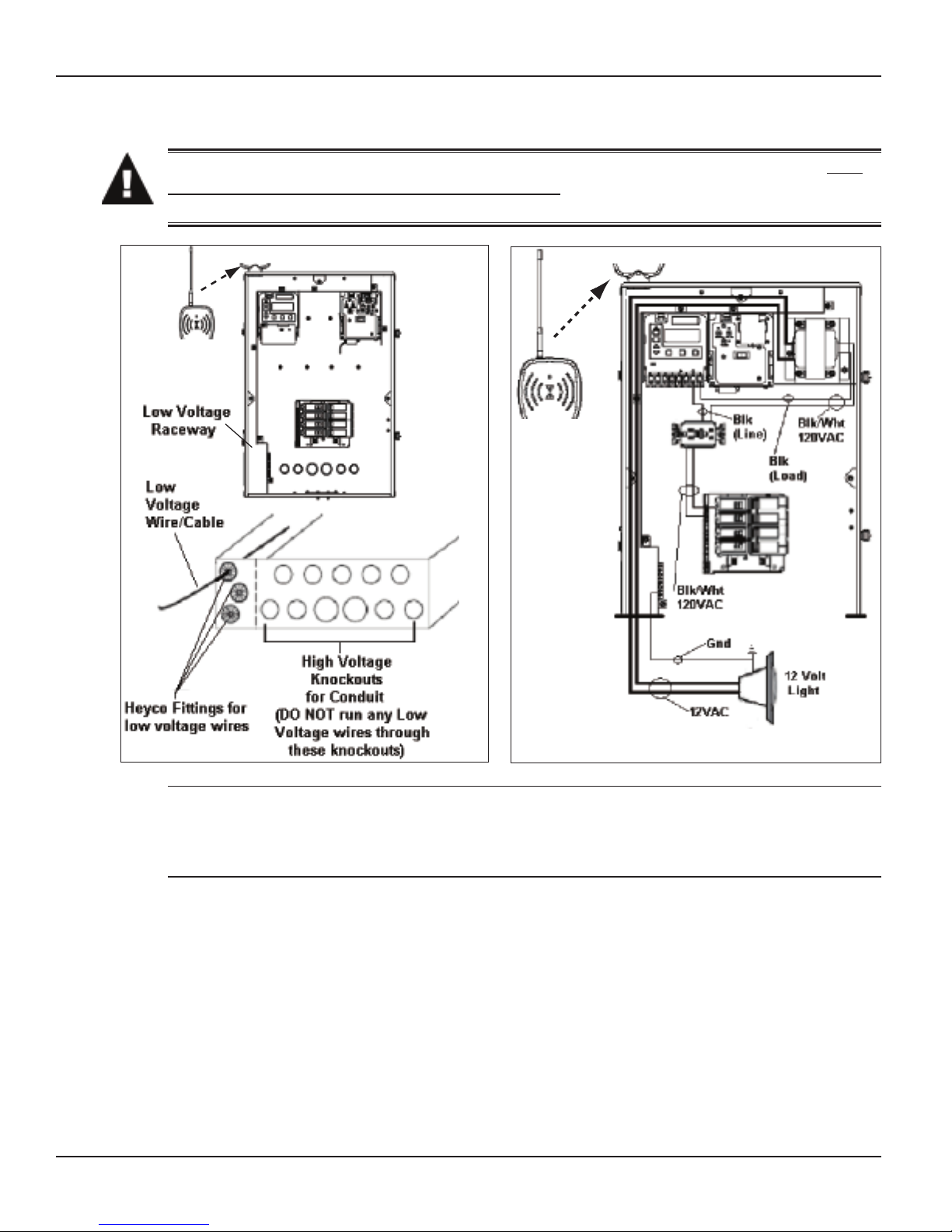

Low-Voltage Underwater Lights

CAUTION: Your I-Wave Control Center is equipped with a Low Voltage Raceway. You

must use this raceway for all low voltage wiring. You cannot mix high and low voltages

in the high voltage compartment.

Figure 3-9 Figure 3-10 Figure 3-9 Figure 3-10

NOTE: If you require a low voltage transformer, you should order system model PE45343RCT1

(with a 100 watt transformer) or PE45343RCT3 (with a 300-watt transformer). Alternatively, you

can order a 300-watt PA124 or 100-watt PA123 12V transformer kit to mount in the standard

system model PE45343RC. (See Figure 3-10.)

If required by local code, install a GFCI receptacle and connect the neutral and hot wire, from

1.

the circuit breaker, to the LINE side of the GFCI. (See Figure 3-10.)

Connect the light to the secondary side of the transformer.

2.

Connect the neutral (white) on the primary side of the transformer to the load side of the

3.

GFCI.

Connect the hot (black) as follows:

4.

To the LOAD side of clock,

a.

Then out the LINE side of the clock to the LOAD side of the GFCI. (See Figure 3-10.)

b.

Connect the ground (green) from the light to the grounding bar inside the Control Center.

5.

Providing a brighter solution.™

Page 20

20 I-Wave PE5 Installation Guide

Fireman’s Switch Wires

(Brown/Brown)

Water Temp Wires

(Black/White)

Make connection

with connectors

provided

Cable to

P1353ME

Cable to

P4232ME

Wires from

Water Temp Sensor

(Black/White)

(178PE4)

Fireman’s Switch Wires

(Brown/Brown)

Water Temp Wires

(Black/White)

Make connection

with connectors

provided

Cable to

P1353ME

Cable to

P4232ME

Wires from

Water Temp Sensor

(Black/White)

(178PE4)

Remove clock and connect

Freeze (Air Temp) Sensor

(178PA28A) here

Freeze Sensor

(178PA28A)

Remove clock and connect

Freeze (Air Temp) Sensor

(178PA28A) here

Freeze Sensor

(178PA28A)

Low-Voltage Wiring

CAUTION: Your I-Wave Control Center is equipped with a Low Voltage Raceway. You

must use this raceway for all low voltage wiring, including the 12 Volt wires from the

transformer. You cannot mix high and low voltages in the high voltage compartment.

Water Temperature Sensor

The I-Wave Control System comes equipped

with a Water Temperature Sensor. This

sensor is needed to monitor and maintain

both the pool and spa water temperature

depending on the position of the diverter

valves. It needs to be installed in order for

the thermostat control to work. Power needs

to be disconnected when connecting the

temp sensor. Only an Intermatic Sensor

will work with this controller. Follow the

directions below to install and mount your

water temperature sensor. Refer to page 46

for programming instructions.

Drill a 3/8” hole in the pipe between the

1.

lter pump and lter and install the Water

Temperature Sensor with hose clamp (not

provided). Ensure the O-ring is in place.

Run the wire to the Control Center, through the low voltage raceway. Connect both wires to

2.

Figure 3-11Figure 3-11

the Panel-Mounted Receiver. (See Figure 3-11.)

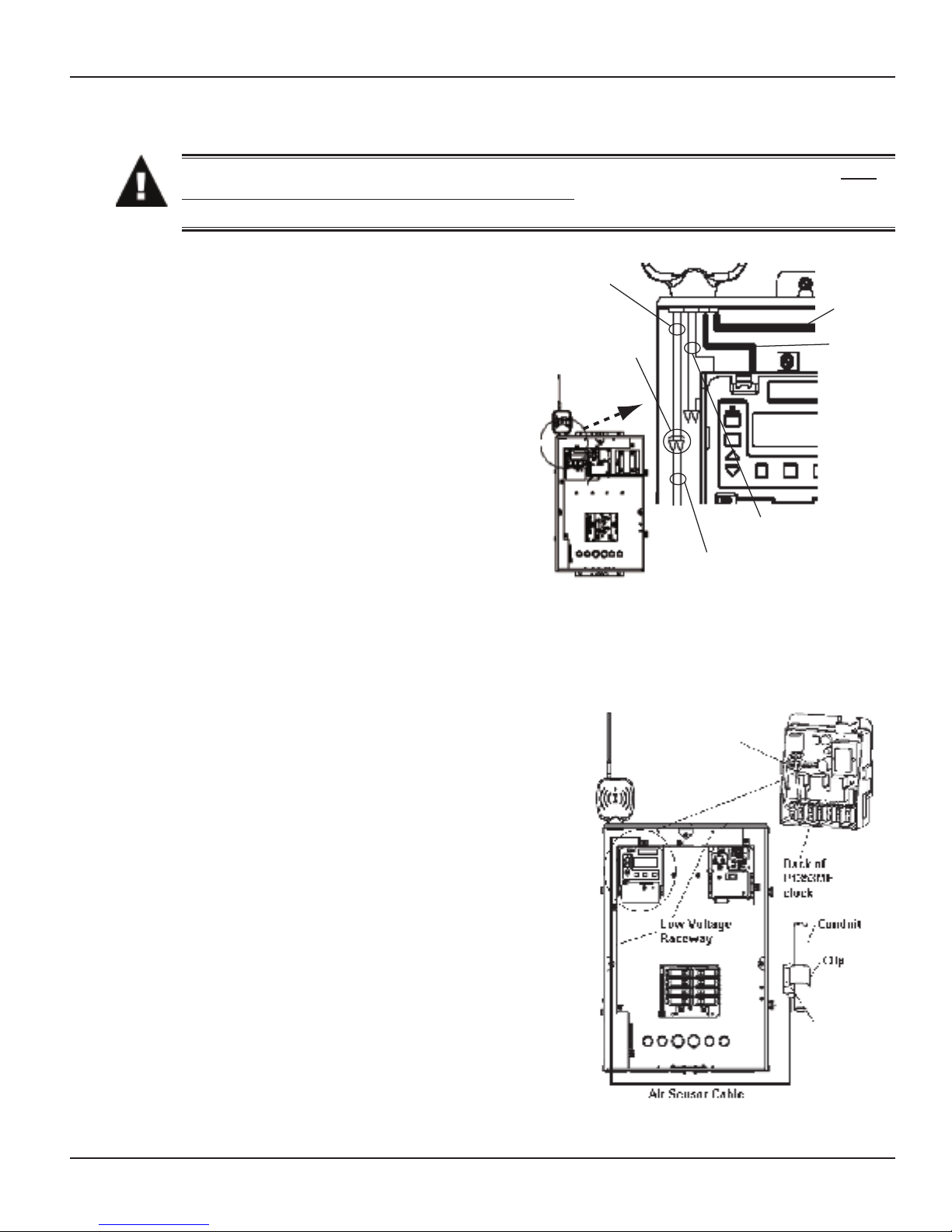

Freeze Sensor

The I-Wave Control System uses an optional Freeze

Sensor (178PA28A) for measuring air temperature and

implementing the Freeze Protection Circuit—necessary

for the freeze protection circuit and programming to

work. Power must be disconnected when connecting

the Freeze Sensor. Only an Intermatic Freeze Sensor

will work with this controller. Refer to page 35 for

programming information, and page 10 for ordering

information.

Install the Freeze Sensor outside the Control Center,

1.

preferably onto a piece of conduit at or near your

equipment pad. Use the clip provided with the

sensor. Do not install in direct sunlight or around

motors or other heat sources.

Run the wire to the Control Center through the low

2.

voltage raceway. Connect Freeze Sensor directly

to the back of the three-circuit clock mechanism.

(See Figure 3-12.) Refer to page 26 for connection

information.

Figure 3-12Figure 3-12

Copyright © 2006 Intermatic, Inc.

Page 21

Three: Control Center Installation 21

Motorized Valve Actuator Connection and Synchronizing

The I-Wave Control System is capable of controlling up to three Motorized Valve Actuators. Two

Intermatic Motorized Valve Actuators (PE24VA) are included with your I-Wave system. Refer to

page 8 for information to order additional actuators.

The actuators must be installed to automatically rotate your valves between pool and spa

plumbing. Power must be disconnected when connecting the actuator connectors to your I-Wave

Control Center. Refer to the directions below prior to installing your PE24VA actuators. Refer to

Figure 3-13 for detail.

Figure 3-13Figure 3-13

Remove power from the I-Wave control center.

1.

Attach the valve actuators (PE24VA) to the water valves. (See instructions included.)

2.

Run the actuator cable to the Control Center, and through the low voltage raceway.

3.

Remove the access door to the Pump/Valve Switch mechanism.

4.

Insert the three-pin connector of the motorized valve actuator to any of the three available

5.

connectors on the Pump/Valve Switch mechanism circuit board.

Apply power to the I-Wave Control Center and synchronize the actuators as follows:

6.

Use the Valve button located on your Pump/Valve switch to illuminate the green light

a.

above the Valve button. This indicates that the switch is in SPA mode.

Use the switch located on your motorized valve actuator to ensure the valves are in the

b.

SPA position.

If either of the Actuators is positioned backwards, ip the switch on the back to reverse

c.

position.

Verify that the Actuators are correctly synchronized with your installation.

d.

Providing a brighter solution.™

Page 22

22 I-Wave PE5 Installation Guide

Fireman

Switch

Wires

(Brown/Brown)

Fireman

Switch

Wires

(Brown/Brown)

Fireman Switch Connection

The I-Wave Control System is capable of controlling most heaters or heat pumps, using

thermostatic circuitry of 24 VAC @ 2A or less, in the market today. Locate your heater in the

following pages and follow the instructions for proper installation with your I-Wave Control

Center.

Connection to the Three-Circuit Clock

Connect the Fireman switch to the Intermatic Fireman Switch

wires (tagged), located in the low-voltage raceway of the

Intermatic panel. (See Figure 3-14.)

Connection for Teledyne Laars Heater

Connect two #14 gauge wires, designed for

1.

Figure 3-14Figure 3-14

use in hot environments, to the two black

wires, marked heater connection, on the

panel-mounted receiver.

Connect the other ends of the #14 gauge

2.

wires from Step 1 to the Fireman’s Switch

terminal bar in place of the factory installed

wire loop.

Do not disconnect high limit or pressure

3.

switches.

Turn the heater thermostat(s) to maximum

4.

setting.

Turn the heater switch to the ON position.

5.

For dual thermostat heaters turn switch to Spa position.

Figure 3-15Figure 3-15

Connection for Raypak Heaters

The following connection procedure is for the two wire-one function conguration Raypak

heater.

Connect two #14 gauge wires, designed for

1.

use in hot environments, to the two black

wires on the panel-mounted receiver.

Connect one end of either #14 gauge wires

2.

from Step 1 to both the orange/black and

black/orange wires on the Raypak heater.

Connect the remaining #14 gauge wire

3.

from Step 1 to the yellow/black wire on the

Raypak heater.

Figure 3-16Figure 3-16

Copyright © 2006 Intermatic, Inc.

Page 23

Three: Control Center Installation 23

rs

Connection for Hayward Heaters

Remove heater service door on your Hayward

1.

Heater.

Remove factory-installed wire connector between

2.

two (2) red wires labeled “CONNECTION FOR

FIELD INSTALLED CONTROL SWITCH.” (See

Figure 3-17.)

Connect two #14 gauge wires, designed for use

3.

in hot environments, to the two red wires. (See

Figure 3-18.)

Wire the other end to the two black wires, marked

4.

Figure 3-17 — Wiring Before ModificationFigure 3-17 — Wiring Before Modification

heater connection, on the panel-mounted receiver

in your I-Wave Control Center.

Do not disconnect high limit or pressure switches.

5.

Turn the heater thermostat(s) to maximum setting.

6.

Turn the thermostat selector switch to the ON,

7.

HIGH, or SPA position.

Connection for Pentair Heater

Remove heater service door on your Pentair

1.

Heater.

Separate the black wires (common) from each

2.

other. (See Figure 3-19.)

Connect two #14 gauge wires, designed for use in

3.

hot environments, to the two black wires, marked

heater connection, on the panel-mounted receiver

in the I-Wave Control Center and attach the other

end to the two black wires on the heater. (See

Figure 3-20.)

Do not disconnect high limit or pressure switches.

4.

Turn the heater thermostat(s) to maximum setting.

5.

Turn the heater toggle switch on.

6.

Figure 3-18 — Wiring with [what??]Figure 3-18 — Wiring with [what??]

Figure 3-19 — Wiring Before ModificationFigure 3-19 — Wiring Before Modification

Figure 3-20 — Wiring with AquaLink RSFigure 3-20 — Wiring with AquaLink RS

Providing a brighter solution.™

Page 24

24 I-Wave PE5 Installation Guide

Connection for Sta-Rite Heaters

Figure 3-21 Figure 3-22 Figure 3-21 Figure 3-22

Turn off power to heater at main circuit breaker panel.

1.

Unbolt and remove the upper jacket

2.

halves (Refer to heater owners

manual).

3.

Open control box cover. (See

Figure 3-21.)

4.

Remove the factory-installed jumper

between the Fireman’s Switch

terminals. (See Figure 3-22. )

5.

Connect two #14 gauge

wires, designed for use in hot

environments, to the two black

wires, marked heater connection,

on the panel-mounted receiver

in the I-Wave Control Center and

attach the other end to the two

spade terminals at the heater. You

can also cut the yellow jumper wire

and wire connect the black wires to

each yellow wire. (See Figure 3-23.)

6.

Route the wires out through the

knockout on the bottom of the

Control Box.

7.

Do not disconnect high limit or

pressure switches.

8.

Turn the heater on and maximize

the temperature setting.

Figure 3-23Figure 3-23

Copyright © 2006 Intermatic, Inc.

Page 25

Four: Programming the Three-Circult Clock Mechanism 25

Section 4:

Programming the Three-Circuit Clock

Mechanism

Overview of Three Circuit Clock Control Panel

The Intermatic Three-Circuit Clock Control Panel is easy to program and capable of automatically

switching loads on three circuits according to a preset 24-hour daily schedule, and providing

control over a variety of different applications. Figure 4-1 shows the front of the mechanism.

MODE BUTTON—With a small tool, press and hold this button down

for 5 seconds. Using the Up and Down arrow keys, you can select the

appropriate preprogrammed mode that matches your particular pool or spa

equipment pad configuration. Hit the ENTER key when finished.

PROGRAM BUTTON—used to

enter programming mode and

access different programming

features.

ENTER BUTTON—used to

save programming changes

to memory and exit

programming mode.

ARROW BUTTONS—used

to increase or decrease

programming parameters

when in programming mode.

DISPLAY—Indicates time

of day and programming

settings during

programming mode.

ON/OFF BUTTONS—Turn

on and off circuit

functions.

Figure 4-1

TIMER POWER—the two terminals where you wire

120V or 240V to power the multipurpose control. Be

sure the jumper on the back, matches the source

voltage. See page 26.

CIRCUITS 1, 2, & 3—These six terminals are where you wire the equipment

source voltage and equipment load lines. You can have different source

voltages for each circuit, depending on your equipment requirements.

NOTE: The three-circuit clock breaks only one leg to the load. Wire the

other leg directly from the line to the load. (Refer to the illustration on the

clock, above the terminals.)

Providing a brighter solution.™

Page 26

26 I-Wave PE5 Installation Guide

Identifying Connections and Selecting Proper Input Voltage

Figure 4-2 below shows the reverse side of the Three-Circuit Clock Control Panel. Detailed

connection information is provided below the diagram.

CAUTION: If the Source Voltage Selector Jumper is in the wrong position, the F1 fuse

will blow and you may damage the circuit board, voiding the warranty.

Before making any connections: Set the Source Voltage Selector Jumper.

1.

The factory default position for this jumper is the 240 Volt position.

If the input voltage for the clock is 120 Volts, change this jumper to the

2.

120 Volt position.

Fireman Switch

Connection

Freeze Sensor

Connection

Source Voltage

Wired or Wireless

Remote Control

Connection

Figure 4-2

Selection Jumper

Fuse

Connection Detail

Freeze Sensor Connection — For the Intermatic Freeze Sensor (178PA28A), which is

•

necessary for the freeze protection circuit and programming to work. Disconnect power when

connecting the freeze sensor. Only an Intermatic sensor can be used. Refer to page 35 for

programming information.

Firemen Switch Connection — For the remen switch wires that connect to the Pool/Spa

•

heater. If installing with a Wireless Remote Control, use the two brown wires coming from the

panel-mounted receiver to create the circuit between this switch and the heater. Connectors

should be ¼” female spade connectors crimped to insulated-type wire. This connection is a

simple SPST contact, and switches the supplied heater voltage. It does not supply voltage to

the heater thermostat. In non-wireless installations, clip the “loop” supplied, then connect

with wire nut connectors. Refer to page 34 for programming information.

Remote Control Connection — Connects the Intermatic Remote Control (133PE1484A),

•

which allows you to remotely turn ON or OFF all three available circuits. It also has status

lights that indicate when a load is ON, OFF or delayed. If using the Three-Button Wired

Remote Control (133PE1484A), it connects here as well. Refer to page 38 for additional

information.

Copyright © 2006 Intermatic, Inc.

Page 27

Circuit Ratings

CLOCK SOURCE VOLTAGE — 120/240VAC, 50/60 Hz

POWER CONSUMPTION — 6.0 Watts Max

CIRCUIT CONTACT CONFIGURATION — SPST

CIRCUIT SWITCH RATINGS ALL MODES:

20A Resistive, 120/240 VAC, 50/60 Hz

•

20A FLA@120 VAC, 96A LRA@120 VAC, 50/60 Hz

•

17A FLA@240 VAC, 80A LRA@240 VAC, 50/60 Hz

•

5 Amps Tungsten, 120/240 VAC, 50/60 Hz

•

5 Amps Ballast, 120/240 VAC, 50/60 Hz

•

EVENTS PER CIRCUIT — 3 On/Off Events Per Circuit

INTERNAL BATTERY POWER:

40-year retention for all programmed settings

•

Up to 24 hours

•

Four: Programming the Three-Circult Clock Mechanism 27

Mode Selection/Definition

IMPORTANT NOTE—There are six modes to choose from, depending on your pool

or spa equipment pad configuration. Each mode has specific programming, timing,

and lockout features that are designed to work with specific types of pool or spa

equipment. Mode setting is generally done only once and usually during the initial

installation. It is purposely difficult to enter the mode-changing program and should

only be done by a Qualified Installer. Be sure you fully understand each mode

definitions and installation, prior to selecting the proper mode.

Mode 1 — (Aux1, Aux2, Aux3)

Each of the three single pole circuits are dened

generically, and can control any load within each

of its individual circuit ratings. All three circuits act

independent of each other.

NOTE: This drawing illustrates

NOTE: This drawing illustrates

that only one leg is broken, with

that only one leg is broken, with

the other leg going directly to

the other leg going directly to

load, whether 120V or 240V.

load, whether 120V or 240V.

Figure 4-3Figure 4-3

Providing a brighter solution.™

Page 28

28 I-Wave PE5 Installation Guide

Mode 2 — (Pump High, Pump Low, Aux3)

Circuit one and two are dedicated single pole

outputs for a two-speed pump load. Circuits one and

two will never be ON at the same time, consistent

with a two-speed pump application. Circuit

three is single pole circuit for a generic load, and

independent of circuits one and two.

NOTE: This drawing illustrates

NOTE: This drawing illustrates

that only one leg is broken, with

that only one leg is broken, with

the other leg going directly to

the other leg going directly to

load, whether 120V or 240V.

load, whether 120V or 240V.

Mode 3 — (Pump, Aux2, Cleaner Pump)

Circuit one and three are dedicated single pole

outputs for a single speed pump working with a

pressure side cleaner pump. Circuit three will never

come on unless circuit one is on for at least one

minute, consistent with a pressure side cleaner

pump. Circuit two is a single pole circuit for a

generic load, independent of circuits one and three.

NOTE: This drawing illustrates

NOTE: This drawing illustrates

that only one leg is broken, with

that only one leg is broken, with

the other leg going directly to

the other leg going directly to

load, whether 120V or 240V.

load, whether 120V or 240V.

Figure 4-4Figure 4-4

Figure 4-5Figure 4-5

Copyright © 2006 Intermatic, Inc.

Page 29

Four: Programming the Three-Circult Clock Mechanism 29

Mode 4 — (Pump High, Pump Low, Cleaner Pump)

Circuit one and two are dedicated single pole

outputs for a two-speed pump load. Circuits one and

two will never be ON at the same time, consistent

with a two-speed pump application. Circuit three

is also a dedicated single pole output for a pressure

side cleaner pump. Circuit three will never come

on unless circuit one is on for at least one minute,

consistent with a pressure side cleaner pump.

NOTE: This drawing illustrates

NOTE: This drawing illustrates

that only one leg is broken, with

that only one leg is broken, with

the other leg going directly to

the other leg going directly to

load, whether 120V or 240V.

load, whether 120V or 240V.

Figure 4-6Figure 4-6

Mode 5 — (Pump, Pump, Aux3)

Circuit one and two are now coupled together

making up one circuit capable of switching the

power source to one pump. The On/Off button for

circuit one now controls both circuit one and two

simultaneously. The On/Off button for circuit two is

disabled. Circuit three remains a single pole circuit

for a generic load, and is independent of circuits one

and two.

NOTE: This drawing illustrates

NOTE: This drawing illustrates

that only one leg is broken, with

that only one leg is broken, with

the other leg going directly to

the other leg going directly to

load, whether 120V or 240V.

load, whether 120V or 240V.

Figure 4-7Figure 4-7

Providing a brighter solution.™

Page 30

30 I-Wave PE5 Installation Guide

<Mode> button

<ENTER> button

“SET MODE”

<Arrow>

buttons

Circuit outputs will

be defined

Mode

Number

blinks

<Mode> button

<ENTER> button

“SET MODE”

<Arrow>

buttons

Circuit outputs will

be defined

Mode

Number

blinks

Mode 6 — (Aux1, Aux2, Aux3)

Identical to Mode 1, in which each of the three single

pole circuits are dened generically and can control any

load within each of its individual circuit ratings, with all

three circuits act independent of each other.

However, with Mode 6, the reman switch closes only

when Circuit 1 (the lter pump) is manually turned on

— not when the clock turns it on. This mode is useful

when you have Circuit 1 connected to a circulation

pump in the spa. When the spa is not in use, the clock

circulates the water to lter it, but does not turn on the

heater. When the spa is in use, the heat is also turned on

by manually switching Circuit 1.

NOTE: This drawing illustrates

NOTE: This drawing illustrates

that only one leg is broken, with

that only one leg is broken, with

the other leg going directly to

the other leg going directly to

load, whether 120V or 240V.

load, whether 120V or 240V.

Setting Mode

Figure 4-8Figure 4-8

Overview

Determine the mode that would be best for your installation, then select it using the instructions

provided below.

Procedure

NOTE: If you don’t press a button within 60 seconds

while setting Mode, the control will save current

settings and return to normal operating mode.

With a small pointed tool (i.e., pen, pencil,

1.

screwdriver, etc.), press and hold the <MODE>

button for about 5 seconds until the display

shows SET MODE and the Mode Number

blinks.

Use the <Arrow> buttons to cycle through all

2.

ve available modes. Each circuit output will

be dened on the display as you cycle through

the available modes.

Once the desired mode number is displayed,

3.

press and release the <ENTER> button. This

saves the mode number to memory and exits

SET MODE programming.

Copyright © 2006 Intermatic, Inc.

Page 31

Setting Time of Day

<PROGRAM>

button

Program Menu

Displayed Time

<Arrow>

buttons

AM/PM Indicator

<PROGRAM>

button

Program Menu

Displayed Time

<Arrow>

buttons

AM/PM Indicator

NO EVENT 1 Not definedNO EVENT 1 Not defined

Overview

This procedure makes sure that timer-controlled actions will occur at the right time.

Procedure

NOTE: If you don’t press a button within 60 seconds

while setting Time of Day, the control will save

current settings and return to normal operating mode.

Press and release the <PROGRAM> button. The

1.

displayed time will start to blink, and the program

menu will display Set Clock.

Use the <Arrow> buttons to change the time.

2.

NOTE: Check the AM and PM indicator to make

sure your setting is correct.

When the time is set, you have two choices:

3.

Four: Programming the Three-Circult Clock Mechanism 31

Press and release the <ENTER> button to save and exit programming.

•

Press and release the <PROGRAM> button to save and go on to the next programming

•

feature.

Setting the On/Off Times for Each Circuit

Overview

You can set up to three separate ON/OFF times per load or circuit, and you can set specic times

for them to turn on and off, i.e., you want the lter pump to run from noon till 4:00 P.M., or you

want lights on from 7:00 P.M., off at 11:00 P.M., then on again at 6:00 A.M. and off at 8:00 A.M.

Procedure

PROGRAMMING TIP: You can use the <ENTER> button to review all the events for each circuit.

You can use the <PROGRAM> button to advance through each circuit and on to the next

programming feature.

If you pressed and released the program key from

1.

the previous procedure, the screen display should

look like the illustration at the right. [If not, press and

release the <PROGRAM> button twice.]

Note that the display indicates that the rst event of

circuit one has not been dened (NO EVENT1).

Providing a brighter solution.™

Page 32

32 I-Wave PE5 Installation Guide

First Event

(EVENT1)

Start Time

First Event

(EVENT1)

Start Time

Stop Time

First Event

(EVENT1)

Stop Time

First Event

(EVENT1)

NO EVENT 2NO EVENT 2

Use the <Arrow> buttons to dene the Start time for

2.

the rst event (EVENT1) for circuit one. The screen

displays:

Once you are satised with the start time, press and

3.

release the <ENTER> button, saving the start time. The

display will prompt for the Stop time for the rst event

(EVENT1) for circuit one. The screen displays:

Use the <Arrow> buttons to dene the Stop time

4.

for the rst event (EVENT1) for circuit one. Press

and release the <ENTER> button when complete.

The program will now advance to the second event

(EVENT2) for circuit one, as shown below. Note that

the display indicates that the second event of circuit

one has not been dened (NO EVENT2).

Repeat Steps 2 thru 4 to set a second event for circuit

5.

#1, and for subsequent events you wish to set up.

Notes on Setting ON/OFF Times for Each Mode

General Note

The ON/OFF buttons were provided for service operations, and for circumstances where

•

instantaneous response is required. If the intent is to turn equipment on and off everyday at

the same time, programming individual events will make sure these functions take place.

All circuits will respond to a programmed off time. Therefore, when a circuit is turned on with

•

the ON/OFF button, it automatically turns itself off at the end of the next programmed event.

If there are no events programmed, the circuit stays on until the ON/OFF button is pressed

•

again.

If the ON/OFF button is pressed while the corresponding circuit is on, it turns the circuit

•

off and supersedes any program in progress. The priority is always given to the last manual

operation.

Copyright © 2006 Intermatic, Inc.

Page 33

Four: Programming the Three-Circult Clock Mechanism 33

Notes on Setting ON/OFF Times for Each Mode (cont’d)

Mode 1 — (Aux1, Aux2, Aux3)

All three of the available circuits act independently, and up to three individual on/off times can

be set for each circuit independently.

Mode 2 — (Pump High, Pump Low, Aux 3)

In this mode circuits 1 & 2 are connect to a two speed pump, and Aux 3 is connected

independent of circuits 1 & 2. In the event that you program high and low speed to be on at the

same time or if their independent ON times overlap, high speed will always take precedence.

Example: Low speed is programmed to come ON at noon and run until 6 PM. High speed is

programmed to come on at 2 PM and turn off at 4 PM. In this case the pump will come ON

at noon in low speed, go to high speed at 2 PM, and back to low speed at 4 PM, and shut off

at 6 PM.

All manual ON operations for circuits 1 & 2 override all programmed ON times. Therefore, any

desired low and high-speed run combinations need to be programmed as separate events and

cannot controlled by combining the manual ON/OFF button with a scheduled event. The last

speed started manually has priority over all prior automatic and manual operations.

Example: You would like to run the pump in high speed for 6 hours and low speed for the

remainder of the time. Program a 6-hour event for high speed, and an 18-hour event for low

speed. Do not turn the low speed on manually, and program a 6-hour event for high speed.

The high speed will not occur.

Mode 3 — (Filter Pump, Aux2, Cleaner Pump)

The cleaner pump cannot turn on unless the lter pump has been on for at least 30 seconds.

Therefore, for any ON/OFF time programmed for the cleaner pump, the lter pump will come on

rst, followed 30 seconds later by the cleaner pump. Both the cleaner and lter pump will turn

off according to the programmed off time. When programming an event for the cleaner pump, it

is not necessary to program a separate event for the lter pump, as it will automatically turn on

when the cleaner pump turns on at its next scheduled on time.

Mode 4 – (Pump High, Pump Low, Cleaner Pump)

Mode 4 is a combination of Modes 2 and 3, so refer above to Modes 2 and 3 for programming

specics. Note that if the cleaner pump is programmed to come ON, the control will turn ON

the lter pump to high speed 30 seconds prior to turning the cleaner pump ON, even if the lter

pump is currently on in low speed.

Mode 5 – (Aux1, Aux3)

Both of the available circuits act independently, similar to Mode 1. Therefore you can set up to

three individual ON/OFF times for each circuit and they will act independently.

Mode 6 — (Aux1, Aux2, Aux3)

All three of the available circuits act independently, and up to three individual on/off times can

be set for each circuit independently. When the clock turns ON Circuit #1 due to a scheduled

ON time, the heater will not come on. The heater will come ON only when Circuit #1 is turned

ON manually.

Providing a brighter solution.™

Page 34

34 I-Wave PE5 Installation Guide

COOL DOWN

<PROGRAM> button

<ARROW> buttons

COOL DOWN

<PROGRAM> button

<ARROW> buttons

Counting Down

Minutes and Seconds

AUX1 Indicator

Blinking

Counting Down

Minutes and Seconds

AUX1 Indicator

Blinking

Setting the Heater’s Cool Down Time (optional)

Overview

The heater’s cool down time is a time dened by the programmer. This time is dened as the

additional time the pump will run, over and beyond the desired pump OFF time, to make sure

the heater is cooled down before shutting off.

If the heater were to stay on after the pump had shut off, the water in the pipe could

boil, damaging the system. Refer to heater manufacturer for specific time.

If a cool down time is programmed, the cool down cycle will occur in all cases, even if the user

turns off the pump. To override the cool down time, press and release the ON/OFF key a second

time during the cool down cycle. The cool down feature only applies to Circuit #1, in all modes.

Procedure

Use the <PROGRAM> button to advance to the COOL

1.

DOWN setting, as shown. The default cool down time

is zero.

Use the <ARROW> buttons to modify the cool down

2.

time. The programming range is from zero to fteen

minutes and no seconds.

When you’ve set the cool down time, press the

3.

<ENTER> button to save and exit, or the <PROGRAM>

button to save and advance to the next programming feature.

The display will look like the example shown at the right

when the Heater’s Cool Down Time feature is activated. In

this example, the cool down time was set for 5 minutes,

and is in the process of counting down to zero, showing

minutes and seconds.

The AUX1 indicator is blinking, indicating that the Cool

Down feature is activated for Circuit #1. The Cool Down

feature only affects Circuit #1. When the countdown

display reaches zero, Circuit #1 will open and the time

display will change back to the time of day.

NOTE: You can override the Cool Down feature during countdown by pressing and releasing the

ON/OFF button associated with Circuit #1. This will end the cool down cycle and immediately

power off Circuit #1.

Copyright © 2006 Intermatic, Inc.

Page 35

Four: Programming the Three-Circult Clock Mechanism 35

32°F

Freeze Temp

1st Circuit

32°F

Freeze Temp

1st Circuit

Aux #1 and #3

Freeze

Aux #1 and #3

Freeze

Setting Freeze Temperature (optional)

Overview

Freeze temperature programming will not appear unless the optional Intermatic Freeze Sensor

(178PA28A) has been installed. This is the only freeze sensor that will work with the P1353ME

Mechanism.

Power must be disconnected when connecting the 178PA28A sensor.

If Intermatic Freeze Sensor (178PA28A) has been installed, use the following procedure to

program freeze temperature.

Procedure

Use the <PROGRAM> button to advance to the

1.

Freeze Temp setting, as shown. The 1st Circuit and

32°F are the factory default settings.

Use the <ARROW> buttons to modify the desired

2.

freeze temperature trip point. The programming range

is 32° through 44°F.

After you have set the desired trip temperature, push

3.

and release the desired ON/OFF button to indicate

which circuits should come ON when the trip temperature is reached.

When programming is complete, , press the <ENTER> button to save and exit, or the

4.

<PROGRAM> button to save and advance to the next programming feature.

The display will look like the example shown at the

right when the Freeze Control feature is activated. In

this example, the freeze sensor was connected, enabling

the Freeze Control feature. Circuits #1 and #3 were

programmed to come on during a Freeze condition.

AUX1 and AUX3 will blink, indicating that the control

has activated these two circuits due to a freeze condition.

NOTE: You can override the circuits during a freeze condition by pressing and releasing the

corresponding ON/OFF buttons. This will turn the devices OFF. The override will only last one

hour, so if the freeze condition still exists after one hour, Circuits #1 and #3 will come back on.

NOTE: Freeze protection stays enabled until the outside air temperature exceeds the

programmed freeze temperature for more than one minute.

Providing a brighter solution.™

Page 36

36 I-Wave PE5 Installation Guide

Section 5:

Programming the Valve/Pump Switch

Mechanism

Overview of the Valve/Pump Switch Control Panel

Front View

HEATER THERMOSTAT CONNECTOR — supports the three

ACTUATOR CONNECTION —

The Valve/Pump Switch

mechanism supports up to

three 24V valve actuators.

SERVICE BUTTONS —

allow you to operate the

mechanism at the panel.

wires from the heaters thermostat. The wires should be

marked Pool, Common, and Spa. The mechanism will