Page 1

Installation &

Paragon Precision

TIME INITIATED, TIME TERMINATED

Grasslin

Operating Instructions

DTAV40 Series Time Initiated, Temperature, Pressure or

Time Terminated Auto-Voltage 40A Defrost Timers

WARNING

• Disconnect power at the circuit breaker(s) or disconnect switch(es) before installing or servicing.

• More than one circuit breaker or disconnect switch may be required to de-energize the equipment before

servicing.

• Installation and/or wiring must be in accordance with national and local electrical code requirements.

• For 40 amp loads, use #8 AWG wire, rated 90° C min.

• Bonding between conduit connections is not automatic and must be provided as part of the installation.

• When replacing a timer with a metal bracket, replace the bracket with a non-metallic bracket. (Intermatic

Model DT-B is recommended).

• For outdoor locations, raintight, or wet location, conduit hubs that comply with requirements of UL514B

(standard for fittings for conduit and outlet boxes) are to be used.

NOTICE

• Rotate timer dial clockwise only.

• Do not move the clock hands on the timer. Moving the clock hands can damage the timer.

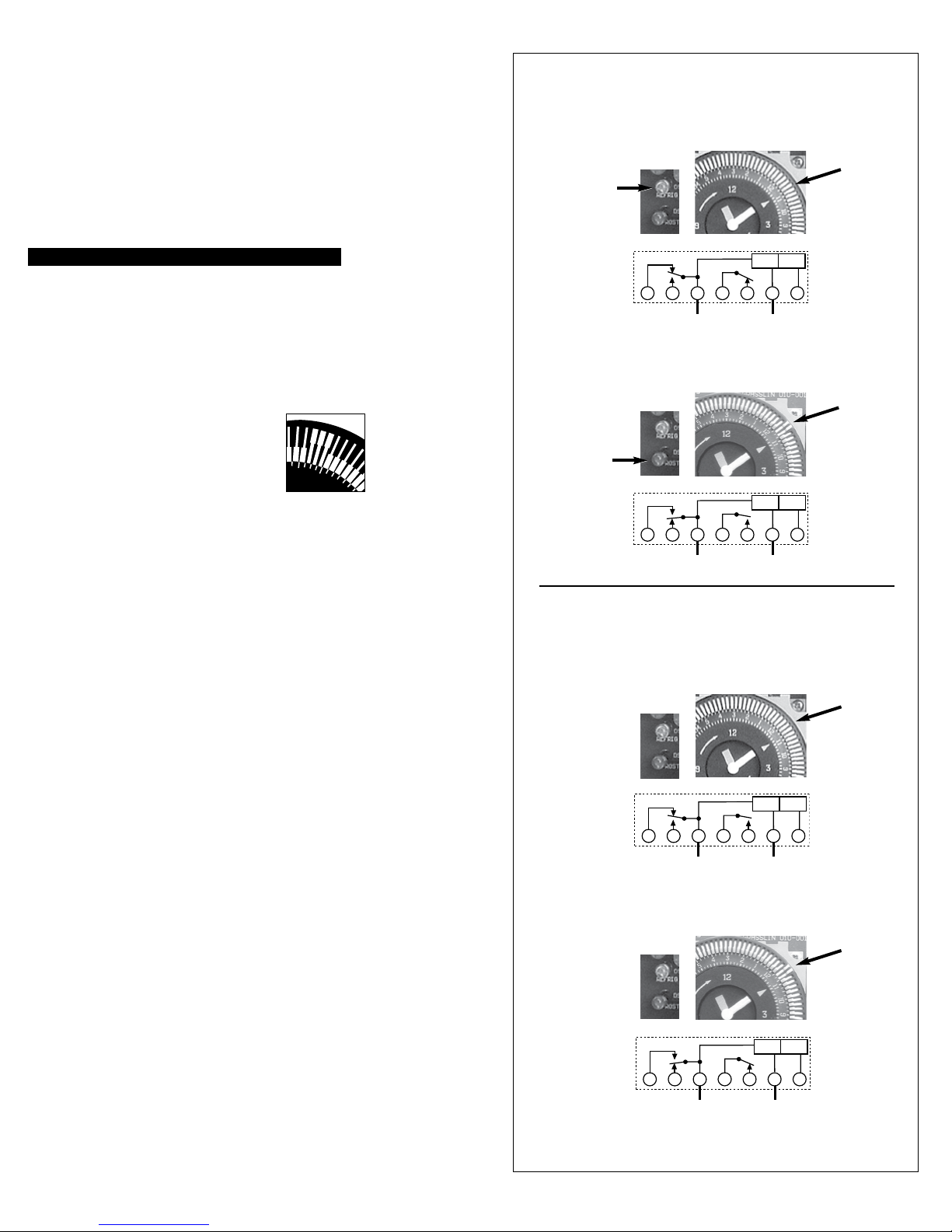

Mode Selection Switch (S1)

UL TYPE 3R ENCLOSURE

Risk of Fire or Electric Shock

Risk of Damage to Timer

UL TYPE 1 ENCLOSURE

BRACKET MOUNT

(Saleable item DT-B)

SEE SEPARATE BRACKET

REPLACEMENT NOTICE

IN PACKAGE

Set Mode Selection (See S1 DIP Switch, table and instructions below).

MODE SELECTION (S1 DIP SWITCH):

First determine what model is being replaced (Grasslin or Competitors).

The mode selector DIP switch (located at lower right side of the board)

determines the configuration of terminals 2 & 4. In position “A”, the terminals are normally closed, and will open during a defrost. In position “B”,

terminals 2 & 4 are normally open, and will close during a defrost. Select

proper position from table below and wiring diagrams indicated.

To select mode simply slide the switch as follows:

Mode A - position switch up;

Mode B - position switch down;

Note: When Mode “B” is selected the

DTAV40 will operate as follows:

Refrigeration Mode - Red & Green LEDs

will turn OFF (1 & 3 and 2 & 4 break while

1 & F make)

Defrost Mode - RED & GREEN LEDs will turn

ON (1 & 3 and 2 & 4 make while 1 & F break)

SPECIFICATIONS:

Maximum Contact Switch Rating:

40A Resistive @ 120-240VAC

2HP @ 240VAC; 1HP @ 120VAC

WIRING CONNECTIONS:

Screw box lug terminals. Up to one #8AWG Wire

ENVIRONMENTAL RATINGS:

Operating Temperature Range: -40˚F to 104˚F

(-40˚C to 40˚C)

Operating Humidity: 0 - 95% RH,

non-condensing

ELECTRICAL LIFE:

50,000 Operations at Full Load

DIMENSIONS:

8.795" x 6.631" x 2.935" (H x W x D)

SHIPPING WEIGHT: 3 lbs.

AGENCY APPROVALS: UL LISTED

INSTALLATION

1. Open door and then remove interior protective cover by releasing

spring latch on bottom (Figure 1). Cover flexes out easily on Type 1

metallic case (Figure 4).

2. Apply corresponding Terminal Identification and Door labels-see

retrofit kit instructions.

3. Remove timer mechanism by releasing PCB Latch on bottom

(Figure 1). Timer Mechanism comes detached in TYPE-1 Metallic

Enclosure (Figure 4).

4. Select knockouts to be used. Remove inner 1/2" knockout by

inserting a screwdriver in the slot and carefully punch knockout

loose. Remove slug. If 3/4" knockout is required, remove the outer

ring with pliers after removing the 1/2" knockout. Smooth edges

with knife if necessary, on plastic enclosure only.

5. Place enclosure in desired mounting location and mark the three

mounting holes (refer to Figure 2 for Type 3R and Figure 3 for

Type 1 below). Start by installing top screw into mounting surface

and hanging enclosure on screw head through keyhole; then screw

in remaining two screws in bottom holes.

6. Grounding: Terminate all ground wires to ground lug on bottom of

enclosure.

7. Re-install timer in enclosure.

8. Replace interior protective cover.

Interior

Protective

Cover

Timer Mechanism

6-1/8"

2-1/2"

Mode Selection Wiring Diag.

TIME INITIATED, REMOTE TEMPERATURE OR

PRESSURE TERMINATED

TIME INITIATED, PRESSURE TERMINATED

(Separate Pressure Switch Required (see instructions)

Cross Ref.

DTAV replaces over 40 models.

4-1/16"

Spring Latch

2-1/2"

Type 1 Enclosure

Figure 3

PCB Latch

Type 3R Enclosure

5"

Figure 1

7 ¾"

PCB Latch

Interior

Protective Cover

Ground Lug

Type 3R Enclosure

Figure 2

TImer Mechanism

Type 1 Enclosure

Figure 4

Page 2

L1 L2/N

M

PROGRAMMING SYNCHRONOUS AND QUARTZ

MODELS

Follow the instructions in the sections below to program the

DTAV40 Timer.

DTAV40 TROUBLESHOOTING GUIDE

DTAV40 TRIPPERS

M ODE A

MODE A

Setting the Time of Day:

Rotate the timer dial clockwise to align the triangle on the

inner dial with the desired time. The triangle represents the

current time on the timer.

NOTE: The AM and PM locations on the wheel represent 6

AM and 6 PM. For example, if the triangle points to the 7

after PM, then the current time is 7 PM. If the triangle

points to the 5 before PM, then the current time is 5 AM.

DO NOT ROTATE MINUTE HAND COUNTER-CLOCKWISE

Setting Defrost Times:

Follow this procedure to configure defrost times.

1. On the timer wheel, choose a defrost starting time.

2. Slide the tripper upward that is directly above the desired

time. The timer will initiate a 15 minute defrost at the

configured time.

3. To increase the duration of the defrost,

slide up the trippers that are adjacent to the

starting time.

8

7

A

NOTE: Each tripper on the time wheel

represents 15 minutes. For example, to set a 45-minute

defrost, slide the two trippers adjacent to the starting time.

NOTE: The AM and PM locations on the wheel represent 6

AM and 6 PM.

“Green” LED ON

“1 & F” Make

“1 & 3” Break

“Red” LED ON

“1 & F” Break

“1 & 3” Make

In Refrigeration Mode

Arrow on timer points to current time.

CONTROL

TERMINATE

POWER

INPUT

1 2

3

F

L1 L2/N

4XN

In Defrost Mode

Arrow on timer points to current time.

CONTROL

TERMINATE

POWER

INPUT

1 2

3

F

L1 L2/N

4XN

Trippers are “IN”

Indicates

Refrigeration

“2 & 4” Make

Trippers are “OUT”

Indicates

Defrost

“2 & 4” Break

4. Repeat steps 1 through 3 as necessary to configure

multiple defrost times for a given day.

APPLICATION

The DTAV40 Defrost Timer is equivalent in function, terminal identification

(with appropriate terminal block label attached), and wiring to the Paragon

8140 and Precision 6140 series Defrost Timers. The DTAV40 may also be

used to replace Paragon 8040 and Precision 6040 series time terminated

defrost timers. With the addition of a remote pressure switch, the DTAV40 can

replace the Paragon 8240 series pressure terminated defrost timers.

Defrosts will be initiated by programming the timer, which will accept from 1

to over 24 defrost initiation settings per day at 15 minute intervals (8:00 AM,

8:15 AM, 8:30 AM, etc)

Defrost duration is settable in 15 minute intervals from a minimum of 15

minutes up to several hours. The defrost duration determines the termination

time. In standard configuration, the contacts between terminals 1 and 3 are

normally open and closed during a defrost to energize defrost heaters; the

contacts between terminals 2 and 4 are normally closed with S1 in “A”

position and open during a defrost to de-energize refrigeration and fans.

DTAV40 Time Initiated, Remote Temperature,

Pressure or Time Terminated:

Used in electric or hot gas defrost applications where the defrost is

terminated when the coil is frost free, as sensed by a temperature or

pressure switch, even though the defrost programmed termination time

has not been reached. The time termination functions as a fail-safe and will

terminate the defrost if the temperature or pressure switch fails to do so. The

temperature or pressure switch on the refrigeration coil has contacts which

close on a temperature or pressure rise above freezing, indicating

that frost and ice have melted from the coil. Typically a wide differential

SPDT temperature switch is used with it’s normally closed contacts wired to

the fans thereby delaying the fans from coming on until the coil temperature

has dropped back to below freezing. In most applications, the contacts at

terminals 2 and 4 are normally closed with S1 in “A” position and control the

fans and refrigeration equipment or compressor. For hot gas defrost, or for

double pole switching, contacts 2 and 4 may be configured as normally open

by selecting mode “B”. Refer to wiring diagrams 1 thru 10 for

additional detail.

DTAV40 TRIPPERS

DTAV40 TROUBLESHOOTING GUIDE

MODE B

MODE B

In Refrigeration Mode

Arrow on timer points to current time.

Trippers are “IN”

Indicates

Refrigeration

Both LED’s OFF

CONTROL

TERMINATE

POWER

“1 & F” Make

“1 & 3” Break

1 2

3

F

L1 L2/N

INPUT

“2 & 4” Break

4XN

In Defrost Mode

Arrow on timer points to current time.

Both LED’s ON

“1 & F” Break

“1 & 3” Make

Trippers are “OUT”

CONTROL

TERMINATE

POWER

INPUT

1 2

3

F

4XN

Indicates

Defrost

“2 & 4” Make

Note: It is necessary to apply power across terminals 1&N

in order to perform electrical test.

Page 3

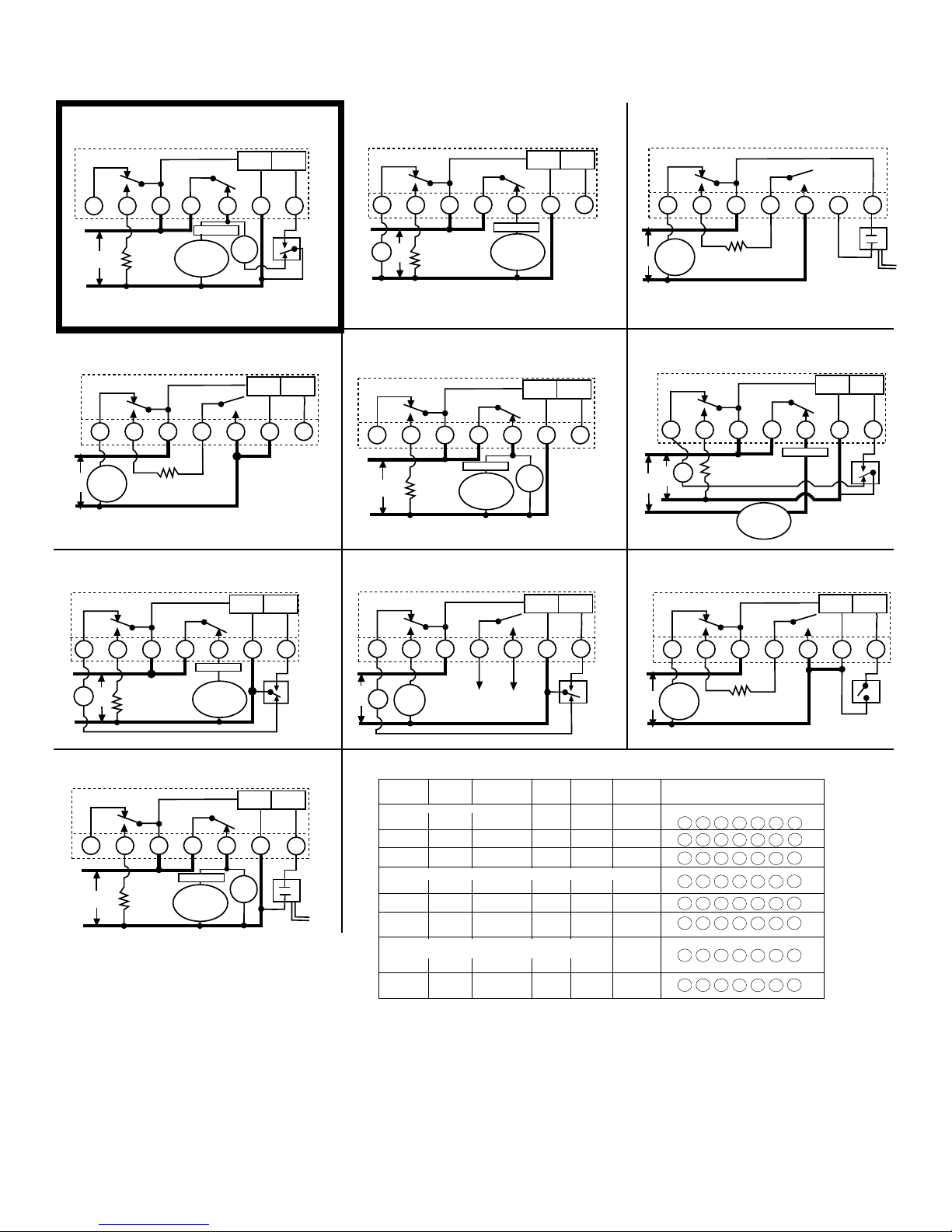

All switch positions are shown in refrigeration cycle operation, and change position upon initiation of a defrost.

WIRING LEGENDS

DTAV40 - TYPICAL WIRING DIAGRAMS

8145 Replacement

1

Mode A - No Label Required

2

1

3

F

L1

DEFROST

LINE

HEATER

THERMOSTAT

COMPRESSOR

OR

SOLENOID VALVE

OR

CONTACTOR COIL

4

FAN

MOTOR

L2

DEFAULT (Out of the Box)

8047 Replacement–Double Pole Switching

4

Mode B with 8047

N

L1

SOLENOID

VALVE

OR

LINE

CONTACTOR

L2

8141 Replacement

7

Mode A with 8141

1

Terminal Block Label Applied

3

DEFROST

HEATER

2

4

Terminal Block Label Applied

CONTROL

POWER

CONTROL

POWER

CONTROL

POWER

N

TERMINATE

INPUT

TERMINATE

INPUT

2

TERMINATE

INPUT

X

TERMINATION

THERMOSTAT

W/FAN DELAY

8047

LABEL

8041 Replacement

2

Mode A with 8041

N

L1

FAN

LINE

L2

8045 Replacement

5

Mode A with 8045

3

F

L1

LINE

L2

8143 Replacement

8

Mode B with 8143

1

DEFROST

DEFROST

HEATER

Terminal Block Label Applied

2

3

THERMOSTAT

COMPRESSOR

SOLENOID VALVE

HEATER

1-N

CONTACT

Terminal Block Label Applied

2

4 X

THERMOSTAT

COMPRESSOR

OR

SOLENOID VALVE

OR

CONTACTOR COIL

Terminal Block Label Applied

CONTROL

POWER

4 X

OR

OR

OR COIL

CONTROL

POWER

FAN

MOTOR

CONTROL

POWER

TERMINATE

INPUT

TERMINATE

INPUT

TERMINATE

INPUT

8041

LABEL

8045

LABEL

8247 Replacement–Double Pole Switching

3

Mode B with 8247 Terminal Block Label Applied

3

N

1

2

L1

SOLENOID

LINE

CONTACTOR

VALVE

OR

DEFROST

HEATER

L2

120V Fan & Defrost Heater; 240V Compressor

6

Mode A - No Label Required

3

F

2

1

L1

DEFROST

FAN

HEATER

120V

240V

N

L2

8143 Replacement–Double Pole Switching

9

Mode B with 8143 Terminal Block Label Applied

COMPRESSOR

OR

SOLENOID VALVE

OR

CONTACT

OR COIL

4

4

THERMOSTAT

CONTROL

POWER

CONTROL

POWER

Xp

PRESSURE

SWITCH

N

TERMINATE

INPUT

TERMINATE

INPUT

p

X

TERMINATION

THERMOSTAT

8247

LABEL

W/FAN

DELAY

8143

LABEL

L1

TERMINATION

THERMOSTAT

W/FAN DELAY

L2

Terminal Typical

5

2

4

1, 6

7

8, 9

See Note 1

10

3

SOLENOID

LINE

CONTACTOR

1

VALVE

3

N

OR

DEFROST

HEATER

F

3

1-N

2

4

N

1

3

2

4

N

1

3

4

2

F

3

1

2

4

N

1

3

2

4

1

N

3

4

2

F

3

1-N

2

4

N

1

3

2

4

2

4

X

TERMINATION

THERMOSTAT

X

X

2

X

N

X

X

p

Xp

p

Xp

L1

L2

10

L1

L2

N

1

FAN

LINE

8245 Replacement

Mode A with 8245

F

LINE

DEFROST

HEATER

3

DEFROST

HEATER

2

3

1-N

4

THERMOSTAT

COMPRESSOR

OR

SOLENOID VALVE

OR

CONTACT

Terminal Block Label Applied

2

THERMOSTAT

COMPRESSOR

OR

SOLENOID VALVE

OR

CONTACTOR COIL

OR COIL

4

FAN

MOTOR

X

CONTROL

POWER

Xp

TERMINATE

INPUT

8141

LABEL

TERMINATION

THERMOSTAT

W/FAN DELAY

8245

p

LABEL

PRESSURE

SWITCH

1

3

N

2

4

X

L1

HOT

GAS

FAN

LINE

VALVE

L2

Paragon Precision GRASSLIN S1 Mode Ident. Wiring Terminal Layout

Model Model Model Selector Label Diagram

TIME INITIATED, TIME TERMINATED

8045 6045 DTAV40 A 8045

8041 6041 DTAV40 A 8041

8047 6047 DTAV40 B 8047

TIME INITIATED, REMOTE TEMPERATURE OR PRESSURE TERMINATED

8145 6145 DTAV40 A None

8141 6141 DTAV40 A 8141

8143 --- DTAV40 B 8143

TIME INITIATED, PRESSURE TERMINATED

(Separate Pressure Switch Required - see instructions)

8245 --- DTAV40 A 8245

8247 --- DTAV40 B 8247

CONNECT ACROSS

COMPRESSOR

THERMOSTA

T

REPLACING EXISTING DEFROST TIMERS

The DTAV40 will replace all models of Paragon 8040, 8140,8240 Series or Precision 6040, 6140 Series and all prior Grasslin Defrost Timer models.

TERMINAL IDENTIFICATION:

The standard DTAV40 terminal identification is identical to the Paragon 8145 with the addition of the “F” terminal. Terminal identification labels are provided for the other models to be

placed over the printed numbers on the printed circuit board. From the table above, select the proper label, apply to printed circuit board and wire per the original wiring or the wiring

diagrams indicated.

“F” TERMINAL:

The DTAV40 contains a normally closed contact between terminals 1 and F. This terminal may be used to switch the fans off during a defrost rather than terminals 2 and 4. For hot gas

defrost applications, with the mode switch set to position “B”, the fans may be connected to terminal “F”.

8143 Replacement: When replacing a Paragon 8143, wire the termination thermostat to terminal X of the DTAV40 (with the 8143 label attached), and the adjacent blank terminal. The

Paragon timers are wired to terminal X and the blank terminal. If the termination thermostat is wired to terminal N of the DTAV40 temperature termination will not occur and may result

in burnout of the DTAV40. See wiring diagrams 8 & 9.

8240 SERIES REPLACEMENT: The DTAV40 may be used to replace the Paragon 8240 series defrost timers with integral pressure termination by the addition of a remote pressure

switch wired to terminals Xp and p of the DTAV40 (with an 8240 series terminal label applied). There must be no external voltage connected to the pressure switch. Set pressure

switch cut-in to the same value as set on the Paragon defrost timer being replaced. Set cut-out 6 to 14 psi below cut-in. See wiring diagrams 10 and 3.

8143

LABEL

Page 4

Instrucciones de

Paragon Precision

INICIADO POR HORA, FINALIZADO POR HORA

Grasslin

instalación y operación

Temporizadores de descongelación de 40 A y voltaje automático, iniciados por hora y

finalizados por temperatura, hora o presión de la serie DTAV40

ADVERTENCIA

Riesgo de incendio o descarga eléctrica

• Desconecte la energía desde los disyuntores o desconecte los interruptores antes de realizar la instalación o el

mantenimiento.

• Es posible que requiera más de un disyuntor o interruptor de desconexión para desenergizar el equipo antes de

realizar mantenimiento.

• La instalación y el cableado se deben realizar de acuerdo con los requisitos del Código Eléctrico Nacional y Local.

• Para cargas de 40 A, use cable AWG n.º 8, clasificado para 90 °C mín.

• La unión entre las conexiones de los conductos no es automática y se debe proporcionar como parte de la

instalación.

• Cuando reemplace un temporizador que tenga un soporte de metal, reemplace el soporte por uno no metálico. (Se

recomienda el modelo DT-B de Intermatic).

• Se deben usar ejes de conducto pluvífugos o para ubicaciones húmedas que cumplan los requisitos de la norma

UL514B (estándar para piezas para conductos y cajas de distribución) en ubicaciones al aire libre.

AVISO

Riesgo de daños al temporizador

• Gire el disco del temporizador sólo en la dirección de las agujas del reloj.

• No mueva las agujas del reloj del temporizador. Hacerlo puede dañar el temporizador.

Interruptor de selección de modo (S1)

INSTALACIÓN

1. Abra la puerta y retire la cubierta interior de protección liberando el

pestillo de resorte del fondo (Figura 1). La cubierta se saca fácilmente

en la caja metálica tipo 1 (Figura 4).

2. Aplique la identificación de terminal y etiquetas de puerta

correspondiente. Consulte las instrucciones del kit de conversión.

3. Retire el mecanismo temporizador liberando el pestillo del circuito del

MONTAJE DE SOPORTE

(elemento comercializable DT-B)

CONSULTE EL AVISO DE

REEMPLAZO DE SOPORTE

CAJA TIPO 3R UL

Ajuste de la selección de modo (consulte Interruptor PLD S1, la tabla y las instrucciones a continuación).

CAJA TIPO 1 UL

SEPARADO EN EL EMPAQUE

SELECCIÓN DE MODO (INTERRUPTOR PLD S1):

Primero determine cuál modelo será reemplazado (Grasslin o sus

competidores). El interruptor PLD de selección de modo (que se

encuentra en el lado inferior derecho de la placa) determina la configuración de los terminales 2 y 4. En la posición “A”, los terminales

normalmente están cerrados y se abren durante la descongelación. En

la posición “B” los terminales 2 y 4 normalmente están abiertos y se cierran

durante la descongelación. Seleccione la posición adecuada de la tabla

que se encuentra a continuación y los diagramas de cableado que se

indican. Para seleccionar un modo, simplemente deslice el interruptor del

siguiente modo:

Modo A - posición del interruptor hacia arriba;

fondo (Figura 1). El mecanismo temporizador viene separado en la caja

metálica tipo 1 (Figura 4).

4. Seleccione los orificios ciegos que desee usar. Inserte un destornillador

en la ranura para retirar el orificio ciego interior de 1/2pulg. y presione

cuidadosamente para soltar el orificio ciego. Retire la tapa. Si se necesita

un orificio ciego de 3/4pulg., retire el anillo exterior con un alicate luego

de retirar el orificio ciego de 1/2pulg. Alise los bordes con un cuchillo si

fuera necesario, solo en la caja de plástico.

5. Coloque la caja en la ubicación de montaje que desee y marque los tres

orificios de montaje (consulte la Figura 2, para obtener más información

sobre el tipo 3R y la Figura 3, para obtener más información sobre el tipo

1 que se muestra a continuación). Primero instale el tornillo superior

en la superficie de montaje y la caja colgante en la cabeza del tornillo a

través del ojo de la cerradura; luego atornille los dos tornillos restantes

en los orificios del fondo.

6. Conexión a tierra: Termine todos los cables a tierra en el terminal de

tierra en la parte inferior de la caja.

7. Vuelva a instalar el temporizador en la caja.

8. Reemplace la cubierta interior de protección.

Modo B - posición del interruptor hacia abajo;

Nota: Cuando esté seleccionado el modo “B”

DTAV40 funcionará del siguiente modo:

Modo de refrigeración - Las luces LED ROJOS y

VERDES se APAGARÁN (1 y 3, y 2 y 4 se

Cubierta

interior de

protección

desconectan, mientras 1 y F se conectan)

Modo de descongelación - Los LED ROJOS

Y VERDES se ENCIENDEN (1 y 3, y 2 y 4 se

conectan, mientras 1 y F se desconectan)

Selección

de modo

INICIADO POR HORA, SEÑAL REMOTA DE FINALIZACIÓN

POR TEMPERATURA O PRESIÓN

INICIADO POR HORA, FINALIZADO POR PRESIÓN

[Se necesita un presostato separado (consulte las instrucciones)]

Diagrama

de cableado

10,32 cm

(4-1/16 pulg.)

Pestillo de resorte

Pestillo del circuito impreso (PCB)

ESPECIFICACIONES:

Clasificación máxima de contacto de interruptor:

Resistivo de 40 amperios de 120 a 240 V CA

2HP a 240 V CA; 1 HP a 120 V CA

CONEXIONES DE CABLEADO:

Terminales del cárter de tornillo, A un cable AWG n˚8

CLASIFICACIONES AMBIENTALES:

Rango de temperatura de funcionamiento:

-40˚C hasta 40˚C (-40˚F hasta 104˚F)

Humedad de funcionamiento: 0 a 95% HR, no

condensante

VIDA ELÉCTRICA:

50.000 Operaciones a carga completa

DIMENSIONES:

22,3 x 16,8 x 7,4 cm (8,795 x 6,631 x 2,935 pulg.)

(Altura x Ancho x Profundidad)

PESO DE EMBARQUE: 1,36 kg (3 libras)

APROBACIONES DE AGENCIAS: INCLUIDA EN LISTA DE UL

Mecanismo temporizador

6,35 cm

(2-1/2 pulg.)

Caja tipo 3R

Figura 1

19,69 cm

(7-3/4 pulg.)

7 ¾"

Pestillo del circuito

impreso (PCB)

15,56 cm

(6-1/8 pulg.)

6,35 cm

(2-1/2 pulg.)

Terminal de tierra

Caja tipo 3R

Figura 2

Mecanismo temporizador

Referencia

DTAV40 Substituye sobre 40 modelos

12,7 cm (5 pulg.)

5"

Caja tipo 1

Figura 3

Cubierta

interior de

protección

Caja tipo 1

Figura 4

Page 5

M

PROGRAMACIÓN DE MODELOS SINCRÓNICOS Y

L1 L2/N

DE CUARZO

Siga las instrucciones descritas en las secciones que se presentan a

continuación para programar el temporizador DTAV40.

Ajuste de la hora del día:

Gire el disco del temporizador en la dirección de las agujas del reloj

para alinear el triángulo del disco interno con la hora deseada. El

triángulo representa la hora actual del temporizador.

NOTA: Las ubicaciones a.m. y p.m. de la rueda representan las

6:00 a.m. y las 6:00 p.m. Por ejemplo, si el triángulo apunta hacia

el número 7, después de p.m., la hora actual es 7:00 p.m. Si el

triángulo apunta hacia el número 5, antes de p.m., la hora actual es

5:00 a.m.

NO GIRE EL MINUTERO EN EL SENTIDO CONTRARIO AL DE LAS AGUJAS DEL RELOJ

Ajuste de las horas de descongelación:

Siga este procedimiento para configurar las horas de descongelación.

1. En la rueda del temporizador, elija una hora de inicio de la

descongelación.

2. Deslice el disparador hacia arriba de forma que quede

directamente sobre la hora deseada. El temporizador

iniciará una descongelación de 15 minutos a

la hora configurada.

3. Para aumentar la duración del la descongelación,

deslice hacia arriba los disparadores adyacentes

a la hora de inicio.

NOTA: Cada disparador en la rueda de tiempo

representa 15 minutos. Por ejemplo, para configurar una

8

7

A

descongelación de 45 minutos, deslice los dos disparadores

adyacentes a la hora de inicio.

NOTA: Las ubicaciones a.m. y p.m. de la rueda representan las 6:00

a.m. y las 6:00 p.m.

4. Repita los pasos del 1 al 3, según sea necesario, para configurar

múltiples horas de descongelación para un determinado día.

APLICACIÓN

El temporizador de descongelación DTAV40 es equivalente a las series de

temporizadores Paragon 8140 y Precision 6140 en términos de función,

identificación de terminal (con una etiqueta adecuada de bloque de terminal

adjunta) y cableado. El DTAV40 también se puede utilizar para reemplazar la

serie de temporizadores de descongelación finalizados por hora Paragon 8040

y Precision 6040. Con la adición de un presostato remoto, el DTAV40 puede

reemplazar la serie de temporizadores de descongelación finalizados por

presión Paragon 8240. Las descongelaciones serán iniciadas al programar el

temporizador, el cual aceptá de 1 a más de 24 configuraciones de iniciación

de descongelación por día en intervalos de 15 minutos (8:00a.m., 8:15a.m.,

8:30 a.m., etc.). La Duración de descongelación se puede ajustar en intervalos

de 15 minutos, a partir de un mínimo de 15 minutos hasta varias horas. La

duración de descongelación determina la hora de término. Normalmente, en

una configuración estándar, los contactos entre los terminales 1 y 3 se abren

y cierran durante una descongelación para energizar los calefactores de

descongelación; los contactos entre los terminales 2 y 4 se cierran con S1 en

la posición “A” y se abren durante una descongelación para desenergizar la

refrigeración y los ventiladores.

DTAV40 iniciado por tiempo, señal remota de finalización por

temperatura, presión u hora:

Se usa en aplicaciones de descongelación eléctrica o a gas caliente donde se

finaliza la descongelación en el momento en que la bobina se encuentre libre

de escarcha, lo cual se detecta mediante un presostato o termostato, incluso

si no se ha cumplido la hora de término programada de la descongelación.

La hora de término funciona como un modo a prueba de fallos y finalizará la

descongelación en el caso de que el termostato o el presostato no funcionen.

El termostato o el presostato en la bobina de refrigeración tienen contactos que

se cierran cuando una temperatura o presión superan a la de congelación, lo

que indica que la escarcha y el hielo se derritieron de la bobina. Típicamente, se

utiliza un termostato de amplio diferencial unipolar de doble tiro (SPDT), en el

cual sus contactos se encuentran normalmente conectados a los ventiladores,

lo cual retrasa el comienzo de los ventiladores hasta que la temperatura de la

bobina haya caído a temperaturas bajo el nivel de congelación. En la mayoría

de las aplicaciones, los contactos en los terminales 2 y 4 se encuentran

normalmente cerrados con S1 en la posición “A” y controlan los ventiladores

y el equipo de refrigeración o el compresor. En el caso de la descongelación

con gas caliente o de una conmutación bipolar, los contactos 2 y 4 se pueden

configurar como normalmente abiertos mediante la selección del modo “B”.

Consulte los diagramas de cableado 1 al 10 para conocer detalles adicionales.

GUÍA DE SOLUCIÓN DE

DISPARADORES DEL DTAV40

PROBLEMAS DEL DTAV40

MODO

A

MODO A

En modo de refrigeración

El puntero en el temporizador apunta a la hora actual.

LED “Verde”

encendido

Conexión

de “1 y F”

Desconexión

de “1 y 3”

POTENCIA

TERMINAL

DE CONTROL

DE ENTRADA

1 2

3

F

L1 L2/N

4XN

Los disparadores

están “Adentro”,

lo que indica

refrigeración

Conexión

de “2 y 4”

En modo de descongelación

El puntero en el temporizador apunta a la hora actual.

LED “Rojo”

Encendido

Desconexión

de “1 y F”

Conexión

de “1 y 3”

F

GUÍA DE SOLUCIÓN DE

DISPARADORES DEL DTAV40

PROBLEMAS DE DTAV40

1 2

3

L1 L2/N

MODO

4XN

B

POTENCIA

DE CONTROL

TERMINAL

DE ENTRADA

Los disparadores

están “Afuera”,

lo que indica

descongelación

Desconexión

de “2 y 4”

MODO B

En modo de refrigeración

El puntero en el temporizador apunta a la hora actual

Los disparadores

están “Adentro”,

lo que indica

Ambos LED

apagados

TERMINAL

Conexión

de “1 y F”

Desconexión

de “1 y 3”

1 2

3

F

L1 L2/N

POTENCIA

DE CONTROL

4XN

DE ENTRADA

En modo de descongelación

El puntero en el temporizador apunta a la hora actual.

Ambos

LED ENCENDIDOS

POTENCIA

Desconexión

de “1 y F”

Conexión

de “1 y 3”

1 2

3

F

DE CONTROL

4XN

TERMINAL

DE ENTRADA

Nota: Es necesario aplicar potencia entre los terminales

1 y N para realizar una prueba eléctrica.

refrigeración

Desconexión

de “2 y 4”

Los disparadores

están “Afuera”,

lo que indica

descongelación

Conexión

de “2 y 4”

Page 6

DTAV40 - DIAGRAMAS TÍPICOS DE CABLEADO

TERMOSTATO

COMPRESOR

O VÁLVULA DE

SOLENOIDE

O CONTACTOR

DE BOBINA

CALEFACTOR DE

DESCONGELACIÓN

L1

L2

1

2

4 X

Reemplazo de 8141

Modo A con etiqueta aplicada del bloque

de terminales 8141

2

8041

ETIQUETA

3

LÍNEA

VENTILADOR

N

L1

L2

L1

L2

4

Reemplazo 8247, conmutación bipolar

Modo B con etiqueta aplicada del bloque de

terminales 8247

8247

ETIQUETA

3

CALEFACTOR DE

DESCONGELACIÓN

LÍNEA

VÁLVULA

DE SOLENOIDE

O CONTACTOR

N

2

1

p

PRESOSTATO

Xp

LEYENDAS DE CABLEADO

Se muestran todas las posiciones de interruptores en la operación de ciclo de refrigeración y

cambian su posición al momento de iniciar una descongelación.

Reemplazo

Modo A: No necesita etiqueta

1

F

L1

LÍNEA

L2

8145

3

CALEFACTOR DE

DESCONGELACIÓN

POTENCIA

DE CONTROL

2

1

TERMOSTATO

COMPRESOR

O VÁLVULA DE

SOLENOIDE

O CONTACTOR

DE BOBINA

4

MOTOR

DEL

VENTILADOR

N

CONFIGURACION DE FABRICA

(Fuera de la caja)

Reemplazo 8047, conmutación bipolar

4

Modo B con etiqueta aplicada del bloque

de terminales 8047

3

1

N

VÁLVULA

DE SOLENOIDE

LÍNEA

O CONTACTOR

CALEFACTOR DE

DESCONGELACIÓN

POTENCIA

DE CONTROL

2

4

2

TERMINAL

DE ENTRADA

X

TERMINAL

DE ENTRADA

TERMINAL DE

TERMOSTATO

CON RELÉ DE

VENTILADOR

ETIQUETA

8047

POTENCIA

DE CONTROL

Reemplazo de 8045

5

Modo A con etiqueta aplicada del bloque de

terminales 8045

POTENCIA

DE CONTROL

1-N

2

TERMOSTATO

COMPRESOR

O VÁLVULA DE

SOLENOIDE

O CONTACTOR

DE BOBINA

4 X

MOTOR

DEL

VENTILADOR

L1

L2

F

LÍNEA

3

CALEFACTOR DE

DESCONGELACIÓN

TERMINAL

DE ENTRADA

TERMINAL

DE ENTRADA

ETIQUETA

8045

3

Ventilador y calefactor de descongelación de

6

120 V; compresor de 240 V

Modo A: No necesita etiqueta

3

F

2

1

L1

CALEFACTOR DE

VENTI-

LADOR

DESCONGELACIÓN

120V

240V

N

L2

COMPRESOR

O VÁLVULA DE

SOLENOIDE

O CONTACTOR

DE BOBINA

4

TERMOSTATO

POTENCIA

DE CONTROL

N

TERMINAL

DE ENTRADA

X

TERMINAL DE

TERMOSTATO

CON RELÉ DE

VENTILADOR

Reemplazo 8141

7

Modo A con etiqueta aplicada del bloque de

terminales 8141

POTENCIA

TERMINAL

DE CONTROL

DE ENTRADA

ETIQUETA

8141

TERMINAL DE

TERMOSTATO

CON RELÉ DE

VENTILADOR

N

1

L1

VENTILADOR

CALEFACTOR DE

LÍNEA

DESCONGELACIÓN

2

3

TERMOSTATO

COMPRESOR

O VÁLVULA DE

SOLENOIDE

O CONTACTOR

L2

Reemplazo 8245

10

Modo A con etiqueta aplicada del bloque de

4

DE BOBINA

X

terminales 8245

POTENCIA

TERMINAL

DE CONTROL

DE ENTRADA

ETIQUETA

p

1-N

2

TERMOSTATO

COMPRESOR

O VÁLVULA DE

SOLENOIDE

O CONTACTOR

DE BOBINA

3

F

L1

LÍNEA

CALEFACTOR

DE DESCONGELACIÓN

L2

REEMPLAZO DE TEMPORIZADORES DE DESCONGELACIÓN EXISTENTES

El DTAV40 reemplazará todos los modelos de serie Paragon 8040, 8140, la serie 8240 o la serie Precision 6040, 6140 y todos los modelos de temporizador de descongelación Grasslin

anteriores.

IDENTIFICACIÓN DE TERMINAL: La identificación de terminal estánder del DTAV40 es idéntica a la del Paragon 8145, con la adición del terminal “F”. Se entregan otras etiquetas de identificación

de terminales para los otros modelos a ser ubicados sobre los números impresos en el tablero de circuitos impresos. En la tabla superior, seleccione la etiqueta adecuada, aplíquela al tablero de

4

MOTOR

DEL

VENTILADOR

Xp

8245

PRESOSTATO

Reemplazo de 8143

8

Modo B con etiqueta aplicada del bloque de

terminales 8143

3

1

N

4

L1

VÁLVULA

L2

VENTI-

DE GAS

LADOR

LÍNEA

CALIENTE

Modelo

Paragon

INICIADO POR HORA, FINALIZADO POR HORA

INICIADO POR HORA, SEÑAL REMOTA DE FINALIZACIÓN

POR TEMPERATURA O PRESIÓN

INICIADO POR HORA, FINALIZADO POR PRESIÓN

[Se necesita un presostato separado (consulte las instrucciones)]

8247 --- DTAV40 B 8247

CONECTE A LO

LARGODEL TERMOSTATO

DEL COMPRESOR

Modelo

Precision

8045 6045 DTAV40 A 8045

8041 6041 DTAV40 A 8041

8047 6047 DTAV40 B 8047

8145 6145 DTAV4 A Ninguna

8141 6141 DTAV40 A 8141

8143 --- DTAV40 B 8143

8245 --- DTAV40 A 8245

GRASSLIN

POTENCIA

TERMINAL

DE CONTROL

DE ENTRADA

ETIQUETA

modo S1

8143

TERMINAL DE

TERMOSTATO

CON RELÉ DE

VENTILADOR

Etiqueta de

identificación

de terminal

2

X

LEYENDAS DE CABLEADO

Modelo

Selector de

Reemplazo de 8143, conmutación bipolar

9

Modo B con etiqueta aplicada del bloque de

terminales 8143

3

1

N

4

L1

SOLENOID

LÍNEA

L2

Diagrama de

cableado típico

5

2

4

1, 6

7

8, 9

Consulta la Nota 1

10

3

VALVE

OR

CONTACTOR

*See Note 1

Esquema de terminal

F

3

N

1

N

1

F

3

N

1

1

N

F

3

N

1

CALEFACTOR DE

DESCONGELACIÓN

1-N

2

4

3

2

4

3

4

2

1

2

4

3

2

4

3

4

2

1-N

2

4

3

2

4

X

X

2

N

X

X

Xp

Xp

POTENCIA

TERMINAL

DE CONTROL

DE ENTRADA

2

X

X

p

p

circuitos impresos y conéctela a través del cableado original o los diagramas de cableado indicados.

TERMINAL “F”: El DTAV40 contiene un contacto normalmente cerrado entre los terminales 1 y F. Este terminal puede ser utilizado para apagar los ventiladores durante una descongelación en

vez de los terminales 2 y 4. Para aplicaciones de descongelación a gas caliente, con el modo de cambio en posiciôn “B”, los ventiladores pueden ser conectados al terminal “F”.

Reemplazo de 8143: Al remplazar una unidad Paragon 8143, cablee el termostato de término al terminal X del DTAV40 (con la etiqueta de 8143 adjunta) y al terminal vacío adyacente. Los

temporizadores Paragon se cablean al terminal X y al terminal vacío. Si el termostato de término está cableado al terminal N del DTAV40, no ocurrirá la terminación de la temperatura y puede

causar que el DTAV40 se queme. Consulte los diagramas de cableado 8 y 9.

REEMPLAZO DE LA SERIE 8240: El DTAV40 se puede usar para reemplazar temporizadores de descongelación con término de presión integral de la serie 8240 de Paragon agregando un

presostato remoto cableado en las terminales Xp y p del DTAV40 (con una etiqueta de terminal de la serie 8240 aplicada). El presostato no debe tener conectado voltaje externo. Configure el conjuntor del presostato en el mismo valor que está configurado en el temporizador de descongelación Paragon que esté reemplazando. Configure el disyuntor y 6 a 14 psi bajo el valor del conjuntor.

Consulte los diagramas de cableado 10 y 3.

ETIQUETA

8143

TERMINAL DE

TERMOSTATO

Page 7

Instructions d’installation

Paragon Precision

DÉCLENCHEMENT PAR HORLOGE, INTERRUPTION PAR HORLOGE

Grasslin

et d’utilisation

Série DTAV40 Minuterie de dégivrage 40A à tension automatique,

à déclenchement par horloge et interruption par température, pression ou horloge

AVERTISSEMENT

Risque d’incendie ou de choc électrique

• Débrancher l’alimentation au niveau des disjoncteurs ou des sectionneurs avant de procéder à l’installation

ou à l’entretien.

• Il peut être nécessaire d’ouvrir plusieurs disjoncteurs ou sectionneurs pour mettre le matériel hors tension

avant d’y travailler.

• L’installation et/ou le câblage doivent être conformes aux exigences du code de l’électricité en vigueur.

• Pour les charges de 40 A, utiliser du fil n°8 AWG classé 90°C min.

• La liaison entre les raccordements de conduits n’est pas automatique et doit être prévue dans le cadre de

l’installation.

• Lors du remplacement d’une minuterie à support métallique, remplacer ce support par un support non

métallique (de préférence par le modèle DT-B d’Intermatic).

• Pour les emplacements extérieurs, étanches à la pluie ou les emplacements mouillés, des entrées de conduit

qui sont conformes aux exigences de UL514B (norme pour les pièces de fixation pour conduit et boîtes de

sortie) doivent être utilisées.

AVIS

Risque de dommage à la minuterie

• Toujours tourner le cadran dans le sens horaire.

• Ne pas déplacer les aiguilles de l’horloge sur la minuterie. Déplacer les aiguilles de l’horloge peut endommager la minuterie.

Sélecteur de mode (S1)

INSTALLATION

1. Ouvrir la porte puis enlever le revêtement protecteur intérieur en dégageant

2. Apposer les étiquettes d’identification de borne et de porte correspondantes -

3. Enlever le mécanisme de la minuterie en dégageant le loquet PCB dans le bas

MONTAGE SUR SUPPORT

COFFRET UL DE TYPE 3R

COFFRET UL DE TYPE 1

(Article DT-B vendable)

VOIR L’AVIS SÉPARÉ DE

REMPLACEMENT DU SUPPORT

DANS L’EMBALLAGE

4. Sélectionner les alvéoles défonçables qui seront utilisées. Enlever l’intérieur

Régler la sélection de mode (Voir Interrupteur DIP S1, le tableau et les instructions ci-dessous).

SÉLECTION DE MODE (COMMUTATEUR DIP S1):

5. Placer le coffret dans l’emplacement de montage désiré et marquer les trois

Déterminer d’abord quel modèle doit être remplacé (Grasslin ou autre marque).

Le commutateur DIP de sélection de mode (sur le côté droit du circuit)

détermine la configuration du contact entre les bornes 2 et 4. En position A, ce

contact est normalement fermé (contact repos) et s’ouvre durant un dégivrage.

En position B, le contact 2-4 est normalement ouvert (contact travail) et se

ferme durant un dégivrage. Sélectionner la position qui convient depuis le

tableau ci-dessous et les schémas de câblage indiqués. Pour sélectionner le

mode, il suffit de coulisser le commutateur comme suit:

6. Mise à la terre : Terminer tous les fils de mise à la terre à la cosse de mise à

7 Réinstaller la minuterie dans le coffret.

8. Remettre le revêtement protecteur intérieur.

Mode A - commutateur en position haute;

Mode B - commutateur en position basse;

Remarque: Si le mode B est sélectionné, la

minuterie DTAV40 fonctionne comme suit:

Mode réfrigération - Voyants rouge et vert

éteints (contacts 1-3 et 2-4 ouverts, 1-F fermé)

Mode dégivrage - Voyants rouge et vert

allumés (contacts 1-3 et 2-4 fermés, 1-F ouvert)

DONNÉES TECHNIQUES :

Intensité maximale du commutateur à contact :

40 A résistifs sous 120 à 240 V c.a.

2 HP sous 240 V c.a. ; 1 HP sous 120 V c.a.

RACCORDEMENTS DE CÂBLES :

Bornes de connexion à vis. Conducteur jusqu’à n˚ 8 AWG

DONNÉES ENVIRONNEMENTALES :

Plage de température d’exploitation :

-40˚C à 40˚C (-40˚F à 104˚F)

Humidité d’exploitation : 0 à 95 % d’H.R. sans

condensation

DURABILITÉ ÉLECTRIQUE :

50 000 actionnements à pleine charge

DIMENSIONES :

223,4 x 168,4 x 74,5 mm (H x L x P)

POIDS D’EXPÉDITION : 1 360 g

HOMOLOGATION : LISTÉ UL

le loquet à ressort dans le bas (Figure 1). Le revêtement fléchit facilement sur

un boîtier métallique de Type 1 (Figure 4).

voir les instructions pour la trousse de modification.

(Figure 1). Le mécanisme de la minuterie se détache du coffret métallique de

Type 1 (Figure 4).

de 1/2 po de l’alvéole défonçable en insérant un tournevis dans la fente et

en défonçant soigneusement l’alvéole défonçable. Enlever la pastille. Si une

alvéole défonçable de 3/4 po est requise, enlever la bague extérieure avec des

pinces après avoir enlevé l’alvéole défonçable de 1/2 po. Adoucir les bords

avec un couteau si nécessaire, sur coffret en plastique seulement.

trous de montage (consulter la Figure 2 pour le Type 3R et la Figure 3 pour

le Type 1 ci-dessous). Commencer par installer la vis supérieure dans la

surface de montage et par suspendre le coffret sur la tête de vis à travers la

boutonnière; puis visser les deux vis restantes dans les trous du bas.

la terre au bas du coffret.

Mécanisme de minuterie

Capot

protecteur

intérieur

15,56 cm

(6-1/8 po)

6,35 cm

(2-1/2 po)

Sélection de mode Schéma câbl.

DÉCLENCHEMENT PAR HORLOGE, INTERRUPTION PAR

THERMO- OU MANOCONTACTEUR EXTERNE

DÉCLENCHEMENT PAR HORLOGE, INTERRUPTION PAR MANOCONTACTEUR

(nécessite un manocontacteur séparé - voir les instructions)

Correspondance

DTAV40 substitue plus de 40 modèles.

10,32 cm

(4-1/16 po)

Loquet à ressort

6,35 cm

(2-1/2 po)

12,7 cm (5 po)

5"

Coffret de Type 1

Figure 3

Loquet PCB

Coffret de Type 3R

Figure 1

19,69 cm

(7-3/4 po)

7 ¾"

Loquet PCB

Capot

protecteur

intérieur

Cose de terre

Coffret de Type 3R

Figure 2

Mécanisme de minuterie

Coffret de Type 1

Figure 4

Page 8

M

PROGRAMMER LES MODÈLES SYNCHRONE ET

L1 L2/N

QUARTZ

Suivre les instructions dans les sections ci-dessous pour programmer

la minuterie DTAV40.

Régler l’heure du jour :

Tourner le cadran de la minuterie dans le sens horaire pour aligner

le triangle sur le cadran intérieur avec l’heure désirée. Le triangle

représente l’heure actuelle sur la minuterie.

REMARQUE : Les emplacements AM et PM sur la roue représentent

6 AM et 6 PM. Par exemple, si le triangle pointe sur le 7 après PM,

alors l’heure actuelle est 7 PM. Si le triangle pointe sur le 5 avant

PM, alors l’heure actuelle est 5 AM.

NE PAS TOURNER L’AIGUILLE DES MINUTES DANS LE SENS ANTIHORAIRE

Régler les temps de dégivrage :

Suivre cette procédure pour configurer les temps de dégivrage.

1. Sur la roue de la minuterie, choisir l’heure de début du dégivrage.

2. Glisser le déclencheur vers le haut directement au dessus de

l’heure désirée. La minuterie initiera un dégivrage de 15 minutes à

l’heure configurée.

3. Pour augmenter la durée de dégivrage, glisser

vers le haut les déclencheurs qui sont adjacents

à l’heure de début.

REMARQUE : Chaque déclencheur sur la roue

représente 15 minutes. Par exemple, pour

régler un dégivrage de 45 minutes, glisser les

deux déclencheurs adjacents à l’heure de début.

REMARQUE : Les emplacements AM et PM sur la roue représentent

6 AM et 6 PM.

4. Répéter les étapes 1 à 3 pour configurer plusieurs temps de

dégivrage pour un jour donné.

8

7

A

GUIDE DE DÉPANNAGE DTAV40

Voyant vert

allumé

1-F fermé

1-3 ouvert

Voyant rouge

allumé

1-F ouvert

1-3 fermé

MODE A

En mode Réfrigération

Flèche de minuterie pointée sur l’heure courante.

ALIMENTATION

ENTRÉE

DE COMMANDE

D’INTERRUPTION

1 2

3

F

L1 L2/N

En mode Dégivrage

Flèche de minuterie pointée sur l’heure courante.

1 2

3

F

L1 L2/N

4XN

ALIMENTATION

DE COMMANDE

4XN

ENTRÉE

D’INTERRUPTION

Déclencheur

« rentré »

pour la

réfrigération

2-4 fermé

Déclencheur

« sorti »

pour le

dégivrage

2-4 ouvert

UTILISATION

La minuterie de dégivrage DTAV40 est équivalente par ses fonctions, par

l’identification des bornes (avec l’étiquette de bornier appropriée) et par son

câblage aux minuteries de dégivrage Paragon série 8140 et Precision série

6140. La DTAV40 peut également s’utiliser pour remplacer les minuteries de

dégivrage à interruption par horloge Paragon série 8040 et Precision série

6040. Avec l’ajout d’un manocontacteur externe, la DTAV40 peut remplacer

les minuteries de dégivrage à interruption manométrique Paragon série

8240. Les dégivrages sont déclenchés par la programmation de l’horloge,

qui accepte 1 à plus de 24 déclenchements de dégivrage par jour par

intervalles de 15 minutes (8h00, 8h15, 8h30, etc.). La durée de dégivrage est

réglable par intervalles de 15 minutes, depuis un minimum de 15 minutes

jusqu’à plusieurs heures. La durée du dégivrge détermint l’heure de fin du

dégivrage. En configuration standard, les contacts entre les bornes 1 et 3

sont normalement ouverts et se ferment durant un dégivrage pour activer

les réchauffeurs de dégivrage; les contacts entre les bornes 2 et 4 sont

normalement fermés si S1 est en position A et ouverts durant un dégivrage

pour désactiver la réfrigération et les ventilateurs.

DTAV40 à déclenchement par horloge et interruption par horloge,

thermostat ou manocontacteur externe :

Utilisé dans les applications de dégivrage électrique ou par gaz chaud où le

dégivrage s’arrêtte une fois que le serpentin est exempt de givre, ce qui est

détecté par un thermo-ou un manocontacteur, même si la durée de dégivrage

programmée n’est pas écoulée. L’interruption par horloge est une fonction de

sécurité intégrée qui met fin au dégivrage si cela n’est pas commandé par

le thermo-ou le manocontacteur. Le thermocontacteur ou manocontacteur

de serpentin de réfrigération comporte des contacts qui se ferment pour une

élévation de température ou de pression au-dessus du gel, indiquant que le

givre et la glace ont entièrement fondu du serpentin.

Généralement, un thermocontacteur SPDT (unipolaire bidirectionnel) à large

différentiel est utilisé, avec ses contacts normalement fermés raccordés

aux ventilateurs, ce qui retarde l’activation des ventilateurs jusqu’à ce que

la température du serpentin soit redescendu jusqu’en dessous du gel. Dans

lamajorité des cas, les contacts entre les bornes 2 et 4 sont normalement

fermés avec S1 en position A et ils commandent les ventilateurs et

l’équipement de réfrigération ou le compresseur. Pour le dégivrage par gaz

chaud ou pour la commutation bipolaire, les contacts entre 2 et 4 peuvent

être configurés pour être normalement ouverts en sélectionnant le mode B.

Voir les détails supplémentaires dans les schémas de câblage 1 à 10.

GUIDE DE DÉPANNAGE DTAV40

MODE B

En mode Réfrigération

Flèche de minuterie pointée sur l’heure courante.

Déclencheur

« rentré »

pour la

Les deux

voyants éteints

ALIMENTATION

ENTRÉE

DE COMMANDE

1-F ouvert

1-3 fermé

1 2

3

F

L1 L2/N

D’INTERRUPTION

4XN

En mode Dégivrage

Flèche de minuterie pointée sur l’heure courante.

Les deux

voyants allumés

ALIMENTATION

ENTRÉE

DE COMMANDE

1-F ouvert

1-3 fermé

1 2

3

F

D’INTERRUPTION

4XN

Remarque : Il est nécessaire d’appliquer une tension entre

les bornes 1et N pour effectuer le contrôle.

réfrigération

2-4 ouvert

Déclencheur

« sorti »

pour le

dégivrage

2-4 fermé

Page 9

Remplacement de 8047 - Commutation bipolaire

4

DTAV40 - SCHÉMAS DE CÂBLAGE TYPIQUES

LÉGENDES DE CÂBLAGE

Tous les commutateurs sont représentés en position de réfrigération et

changent de position lors du déclenchement d’un dégivrage.

Remplacement de 8145 Remplacement de 8041

1

L1

L2

- Aucune étiquette requise

Mode A

1

3

F

SECTEUR

CHAUFFAGE

DE DÉGIVRAGE

2

THERMOSTAT

COMPRESSEUR

OU

ÉLECTROVANNE

OU

BOBINE DE

CONTACTEUR

ALIMENTATION

ENTRÉE

DE COMMANDE

D’INTERRUPTION

4

N

X

MOTEUR

DE

VENTI-

LATEUR

THERMOSTAT

D’INTERRUPTION

À DÉLAI DE

VENTILATION

Mode A avec étiquette de bornier 8041 apposée

2

N

1

L1

VENTI-

LATEUR

SECTEUR

L2

DÉFAUT (configuration usine)

Remplacement de 8045

5

Mode B avec étiquette de bornier 8047 apposée

3

1

N

2

4

L1

ÉLECTROVANNE

CONTACTEUR

SECTEUR

OU

CHAUFFAGE

DE DÉGIVRAGE

L2

Remplacement de 8141

Mode A avec étiquette de bornier 8141 apposée

7

ALIMENTATION

DE COMMANDE

ALIMENTATION

DE COMMANDE

ENTRÉE

D’INTERRUPTION

2

ENTRÉE

D’INTERRUPTION

ÉTIQUETTE

8047

Mode A avec étiquette de bornier 8045 apposée

3

F

L1

SECTEUR

CHAUFFAGE

DE DÉGIVRAGE

L2

Remplacement de 8143

8

Mode B avec étiquette de bornier 8143 apposée

3

CHAUFFAGE

DE DÉGIVRAGE

1-N

2

2

THERMOSTAT

COMPRESSEUR

OU

ÉLECTROVANNE

OU

BOBINE DE

CONTACTEUR

4 X

THERMOSTAT

COMPRESSEUR

OU

ÉLECTROVANNE

OU

BOBINE DE

CONTACTEUR

4 X

MOTEUR

DE VENTI-

LATEUR

ALIMENTATION

DE COMMANDE

ALIMENTATION

DE COMMANDE

ALIMENTATION

DE COMMANDE

ENTRÉE

D’INTERRUPTION

ENTRÉE

D’INTERRUPTION

ENTRÉE

D’INTERRUPTION

ÉTIQUETTE

8041

ÉTIQUETTE

8045

Remplacement de 8247 - Commutation bipolaire

Mode B avec étiquette de bornier 8247 apposée

3

N

1

3

4

2

L1

ÉLECTROVANNE

SECTEUR

CONTACTEUR

OU

CHAUFFAGE

DE DÉGIVRAGE

L2

Ventilateur et chauffage de dégivrage 120 V;

6

compresseur 240 V

Mode A - Aucune étiquette requise

2

OU

OU

4

THERMOSTAT

3

F

L1

VENTI-

LATEUR

120 V

240 V

N

L2

Remplacement de 8143 - Commutation bipolaire

9

Mode B avec étiquette de bornier 8143 apposée

1

CHAUFFAGE

DE DÉGIVRAGE

COMPRESSEUR

ÉLECTROVANNE

BOBINE DE

CONTACTEUR

Xp

ALIMENTATION

DE COMMANDE

N

ALIMENTATION

DE COMMANDE

MANOCONTACTEUR

ENTRÉE

D’INTERRUPTION

ENTRÉE

D’INTERRUPTION

p

X

ÉTIQUETTE

8247

THERMOSTAT

D’INTERRUPTION

À DÉLAI DE

VENTILATION

Sélecteur

de mode

S1

ÉTIQUETTE

8143

THERMOSTAT

D’INTERRUPTION

À DÉLAI DE

VENTILATION

Étiquette

d’ident.

de bornes

L1

L2

Schéma de

câblage

Voir Note 1

ÉLECTROVANNE

SECTEUR

CONTACTEUR

typique

5

2

4

1, 6

7

8, 9

10

3

1

OU

3

N

CHAUFFAGE

DE DÉGIVRAGE

Configuration des bornes

F

3

1-N

N

1

3

N

1

3

F

3

1

N

1

3

1

N

3

F

3

1-N

N

1

3

2

4

2

4

2

4

4

2

2

4

2

4

4

2

2

4

2

4

Xp

Xp

X

THERMOSTAT

D’INTERRUPTION

X

X

2

X

N

X

X

p

p

1-N

2

THERMOSTAT

2

THERMOSTAT

COMPRESSEUR

OU

ÉLECTROVANNE

OU

BOBINE DE

CONTACTEUR

4

COMPRESSEUR

OU

ÉLECTROVANNE

OU

BOBINE DE

CONTACTEUR

4

N

1

L1

VENTILATEUR

10

CHAUFFAGE

DE DÉGIVRAGE

SECTEUR

Remplacement de 8245

Mode A avec étiquette de bornier 8245 apposée

3

F

L1

SECTEUR

CHAUFFAGE

DE DÉGIVRAGE

L2

ALIMENTATION

DE COMMANDE

MOTEUR

DE

VENTI-

LATEUR

X3

Xp

ENTRÉE

D’INTERRUPTION

ÉTIQUETTE

THERMOSTAT

D’INTERRUPTION

À DÉLAI DE

VENTILATION

p

MANOCONTACTEUR

8141

ÉTIQUETTE

8245

1

3

N

2

4

X

L1

VANNE

VENTILATEUR

SECTEUR

DE GAZ

CHAUD

RACCORDER AUX BORNES DU

THERMOSTAT DE COMPRESSEUR

L2

Modèle

Paragon

DÉCLENCHEMENT PAR HORLOGE, INTERRUPTION PAR HORLOGE

DÉCLENCHEMENT PAR HORLOGE, INTERRUPTION PAR THERMO- OU MANOCONTACTEUR EXTERNE

DÉCLENCHEMENT PAR HORLOGE, INTERRUPTION PAR MANOCONTACTEUR

(Nécessite un manocontacteur séparé - voir les instructions)

Modèle

Precision

8045 6045 DTAV40 A 8045

8041 6041 DTAV40 A 8041

8047 6047 DTAV40 B 8047

8145 6145 DTAV40 A Néant

8141 6141 DTAV40 A 8141

8143 --- DTAV40 B 8143

8245 --- DTAV40 A 8245

8247 --- DTAV40 B 8247

Modèle

GRASSLIN

REMPLACEMENT D’HORLOGES DE DÉGIVRATE EXISTANTES

La DTAV40 peut remplacer tous les modèles Paragon des séries 8040, 8140 et 8240 ou Precision des séries 6040 et 6140, ainsi que tous les modèles de minuteries de dégivrage

Grasslin antérieurs.

IDENTIFICATION DES BORNES : L’identification des bornes DTAV40 standard est identique à celle de la minuterie Paragon 8145 avec la borne F en plus. Des étiquettes d’identification des bornes

sont fournies pour les autres modèles, à placer sur les nombres imprimés sur le circuit imprimé. Dans le tableau ci-dessous, sélectionner l’étiquette qui convient, l’apposer sur le circuit imprimé

et câbler de façon identique au câbleag d’origine ou conformément au schéma de câblege.

BORNE F : La minuterie DTAV40 comporte un contact normalement fermé entre les bornea 1 et F. Cette borne peur être utilisée pour couper les ventilateurs durant un dégivrage, au lieu des

bornes 2 et 4. Pour les applications de dégivrage par gaz chaud, avec le sélecteur de mode en position B, les ventilateurs peuvent être raccordés à la borne F.

REMPLACEMENT DE 8143 : Lors du remplacement d’un Paragon 8143, raccorder le thermostat d’interruption à la X de la DTAV40 (apposer l’étiquette 8143) et à la borne non marquée voisine.

Les minuteries Paragon se raccordent à la borne X et à la borne non marquée. Si le thermostat d’interruption est raccordé à la borne N de la DTAV40, l’interruption thermique ne se produit pas et

la DTAV40 peut griller. voir les schémas de câblage 8 et 9.

REMPLACEMENT DE LA SÉRIE 8240 : La minuterie DTAV40 peut êtreutilsée pour remplacer les minuteries de dégivrage Paragon de série 8240 à interruption manométrique intégrale par l’ajout

d’un manocontacteur extene rccordé aux bornes Xp et p de la DTAV40 (apposer une étiquetter de bornes série 8240). Il nedoit y avoir aucune source de tension externe rccordée au manocontacteur. Régler la pression d’enclenchement du manocontacteur sur la même valeur que celle de la minuterie de dégivrage Paragon remplacée. Régler la pression de coupure sur 6 à 14 psi en

dessous de l’enclenchement. Voir les schémas de câblage 10 et 3.

ÉTIQUETTE

8143

Page 10

DTAV40 Series

Time Initiated, Temperature, Pressure or Time

Terminated Auto-Voltage 40 A Defrost Timers

SPECIFIERS GUIDE

Furnish and install a Grasslin DTAV40 defrost control which

automatically adjusts for 120-240V operation and shall have defrost

initiation times settable to the quarter hour via captive trippers at 15

minute intervals. The defrost timer shall be housed in a UL TYPE 3R

indoor/outdoor plastic enclosure. The relay output will be rated for

40A Resistive, 2HP @ 240VAC. Defrost termination to be by time (and

by a remote temperature or pressure switch).

FEATURES

• Auto-Voltage automatically adjusts for 120-240VAC

• Mounts in existing enclosures, no tools required

• Box lug terminals

• Defrost times settable on quarter hour with captive trippers

• UL TYPE 3R outdoor enclosure

• 40 Amp, 2HP Rating

• Moisture resistant conformal coated board

• LED indications for defrost and refrigeration cycles

• Defrost cycles are programmed independently

• “Real-time” clock for quick, easy and accurate setting

• Min ON/OFF time: 15 minutes

• Max ON/OFF time: 23 hours 45 minutes

NO TOOLS

REQUIRED!

Our “GUTS” simply snap

into existing enclosures

Moisture Resistant

Conformal Coated Board

Ground Lug Termination

Red and Green LED

Lights Indicate

Defrost or Run Cycle

Large Screw

Terminals for Easy Wiring

Up to one #8 AWG wire

40 Amp Rated

Contacts

Captive Trippers

Can’t Be Lost

Independently

Adjustable Trippers

Allow For Full or

Partial Defrost Cycles

on 15 Minute Intervals

True Clock Face

New Compact

UL TYPE 3R

Outdoor Enclosure

Replaces All Metal

Enclosures

• DTAV40 replaces over 40 competitive models

Serie DTAV40

Temporizadores de descongelación iniciados por hora, temperatura,

nalizados por hora o presión con autovoltaje 40 A

Los disparadores

imperdibles no se

deben extraviar

Los disparadores

ajustables de forma

independiente permiten

ciclos de descongelación

completos o parciales en

intervalos de 15 minutos

La nueva caja de

exterior compacta

UL TIPO 3R

reemplaza todas

las cajas de metal

Las luces LED roja y

verde indican

descongelación o

ejecución de ciclo

Terminales de tornillo

grandes para una fácil

conexión eléctrica a

un cable AWG n° 8

Apariencia verdadera

del reloj

¡NO SE NECESITAN

HERRAMIENTAS!

Nuestros “INTERIORES”

simplemente encajan a

presión en cajas existentes

Contactos de

40 amperios

Placa revestida de

conformación resistente

a la humedad

Terminal de tierra

CARACTERÍSTICAS

• El DTAV40 reemplaza a más de 40 modelos de la competencia

• El autovoltaje se ajusta automáticamente a la norma de 120 a 240 V CA

• Se instala en cajas existentes sin la necesidad de herramientas

• Terminales del cárter

• Horas de descongelación ajustables a cuarto de hora con los

disparadores imperdibles

• Caja de exterior UL TIPO 3R

• 40 amperios, clasificación 2HP

• Placa revestida de conformación resistente a la humedad

• Indicaciones con luces LED de ciclos de descongelación y refrigeración

• Los ciclos de descongelación se programan de forma independiente

• Reloj de “Hoja real” para un ajuste rápido, fácil y preciso.

• Tiempo mínimo de ENCENDIDO/APAGADO 15 minutos

• Tiempo máximo de ENCENDIDO/APAGADO 23 horas y 45 minutos

GUÍA DEL ESPECIFICADOR

Equipe e instale un control de descongelación Grasslin DTAV40, que se

ajustará automáticamente para operar de 120 a 240 V y deberá tener

horarios de comienzo de descongelación ajustables a cuartos de hora

mediante los disparadores imperdibles en intervalos de 15 minutos. El

temporizador de descongelación se deberá instalar en una caja de

plástico para exteriores/interiores UL TIPO 3R La corriente de salida del

relé será clasicada para una resistencia de 40 amperios, 2HP a 240 V CA.

El término de descongelación será por hora (y por un termostato o

presostato remoto).

Page 11

Série DTAV40

Minuterie de dégivrage 40 A à tension automatique, à déclenchement par horloge et

interruption par température, pression ou horloge

Les déclencheurs

captifs ne peuvent

pas se perdre

Les déclencheurs à

réglage indépendant

permettent des cycles

de dégivrage complets

ou partiels par intervalles

de 15 minutes

Façade d’horloge réelle

CARACTÉRISTIQUES

• La DTAV40 remplace plus de 40 modèles concurrents

• Réglage automatique de la tension de 120 à 240 V c.a.

• Se monte sur les boîtiers existants sans outillage

• Bornes de connexion à vis

• Heures de dégivrage réglables par quarts d’heure au moyen de

déclencheurs captifs

• Boîtier pour extérieur UL de TYPE 3R

• Classée 40 A, 2HP

• Circuit à revêtement conforme résistant à l’humidité

• Voyants indicateurs des cycles de dégivrage et de réfrigération

• Programmation indépendante des cycles de dégivrage

• Horloge « temps réel » assurant un réglage rapide, facile et précis

• Durée marche/arrêt min. : 15 minutes

• Durée marche/arrêt max. : 23 heures 45 minutes

Le nouveau boîtier

compact extérieur

UL de TYPE 3R

remplace tous les

boîtiers métalliques

Les voyants rouge

et vert indiquent les

cycles de dégivrage

et de marche

Grosses bornes à vis

acceptant des

conducteurs jusqu’au

calibre n° 8 AWG

AUCUN OUTIL

NÉCESSAIRE!

Nos mécanismes

s’encliquètent simplement

dans les boîtiers existants

Contacts classés 40 A

Circuit à revêtement

conforme résistant

à l’humidité

Cosse de terre

Notes / Notas / Notes

GUIDE DE SPÉCIFICATION

Fournir et installer une commande de dégivrage Grasslin DTAV40 qui

s’ajuste automatiquement sur la tension d’alimentation de 120 à 240 V

et comporte des heures de déclenchement de dégivrage réglables au

quart d’heure près au moyen de déclencheurs captifs placés à des

intervalles de 15 minutes. La minuterie de dégivrage doit être contenue

dans un boîtier en plastique pour intérieur/extérieur UL de TYPE 3R.

La sortie de relais doit être classée 40 A résistifs, 2 HP sous 240 V c.a.

L’arrêt du dégivrage doit être commandée par minuterie (et par un

thermocontacteur ou manocontacteur externe).

Page 12

LIMITED ONE-YEAR WARRANTY

If within the warranty period specified, this product fails due to a defect in material or workmanship, Intermatic Incorporated will repair or replace it, at its sole option, free of charge. This warranty is extended to the original

household purchaser only and is not transferable. This warranty does not apply to: (a) damage to units caused by accident, dropping or abuse in handling, acts of God or any negligent use; (b) units which have been subject to

unauthorized repair, opened, taken apart or otherwise modified; (c) units not used in accordance with instructions; (d) damages exceeding the cost of the product; (e) sealed lamps and/or lamp bulbs, LED’s and batteries; (f) the

finish on any portion of the product, such as surface and/or weathering, as this is considered normal wear and tear; (g) transit damage, initial installation costs, removal costs, or reinstallation costs.

INTERMATIC INCORPORATED WILL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES,

SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU. THIS WARRANTY IS IN LIEU OF ALL OTHER EXPRESS OR IMPLIED WARRANTIES. ALL IMPLIED WARRANTIES, INCLUDING THE WARRANTY OF

MERCHANTABILITY AND THE WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE, ARE HEREBY MODIFIED TO EXIST ONLY AS CONTAINED IN THIS LIMITED WARRANTY, AND SHALL BE OF THE SAME DURATION AS

THE WARRANTY PERIOD STATED ABOVE. SOME STATES DO NOT ALLOW LIMITATIONS ON THE DURATION OF AN IMPLIED WARRANTY, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

This warranty service is available by either (a) returning the product to the dealer from whom the unit was purchased or (b) completing a warranty claim online at www.intermatic.com. This warranty is made by:

Intermatic Incorporated, Customer Service 7777 Winn Rd., Spring Grove, Illinois 60081-9698. For warranty service go to: http://www.Intermatic.com or call 815-675-7000.

Si dentro del período de garantía especificado este producto falla debido a un defecto de material o de mano de obra, Intermatic Incorporated lo reparará o reemplazará, a su entera discreción, sin cargo alguno. Esta

garantía sólo se otorga al comprador original y no es transferible. Esta garantía no se aplica en los siguientes casos: (a) daños en las unidades causados por accidentes, caídas o manejo indebido, causas de fuerza

mayor o uso neglige nte; (b) unid ades que hay an sido some tidas a una r eparación no autorizada, abiertas, desmontadas o modificadas de alguna manera; c) unidades no utilizadas de acuerdo con las instrucciones; (d) daños

que excedan el costo del producto; (e) lámparas y/o bombillas de lámparas selladas, diodos emisores de luz (LED) y baterías; (f) el acabado de cualquier parte del producto, como su superficie y/o por exposición a la intemperie,

ya que esto se considera un desgaste y uso normal; g) daños durante el transporte, costos de instalación inicial, costos de remoción o costos de reinstalación.

INTERMATIC INCORPORATED NO ASUME RESPONSABILIDAD ALGUNA POR DAÑOS INCIDENTALES O CONSECUENCIALES. ALGUNOS ESTADOS NO PERMITEN EXCLUIR O LIMITAR LOS DAÑOS INCIDENTALES O

CONSECUENCIALES, POR LO QUE LA LIMITACIÓN O EXCLUSIÓN ANTERIOR PUDIERA NO SER VÁLIDA EN SU CASO. ESTA GARANTÍA SUSTITUYE A CUALQUIER OTRA GARANTÍA EXPRESA O IMPLÍCITA. TODAS LAS

GARANTÍAS IMPLÍCITAS, INCLUIDA LA GARANTÍA DE IDONEIDAD COMERCIAL O DE IDONEIDAD PARA UN DETERMINADO FIN, SE MODIFICAN PARA QUEDAR INCLUIDAS ÚNICAMENTE EN LA PRESENTE GARANTÍA

LIMITADA, Y TENDRÁN LA MISMA DURACIÓN QUE EL PERIODO DE GARANTÍA MENCIONADO ANTES. ALGUNOS ESTADOS NO PERMITEN LIMITAR LA DURACIÓN DE UNA GARANTÍA IMPLÍCITA, POR LO QUE LA

LIMITACIÓN ANTERIOR PUDIERA NO SER APLICABLE EN SU CASO.

Este servicio de garantía está disponible (a) devolviendo el producto al distribuidor donde se compró la unidad o (b) completando un reclamo de garantía en Internet en www.intermatic.com. Esta garantía es concedida

por: Intermatic Incorporated Customer Service/7777 Winn Rd., Spring Grove, Illinois 60081-9698/815-675-7000 http://www.intermatic.com.

Si, dans la période de garantie spécifiée, ce produit tombait en panne dû à un vice de matériau ou de fabrication, Intermatic Incorporated le réparera ou le changera, à sa seule discrétion, et ce gratuitement.

La présente garantie s’étend à l’acheteur final initial uniquement et n’est pas transférable. Cette garantie ne s’applique pas : (a) aux dommages au dispositif causés par un accident, une chute ou une mauvaise

manipulation, une catastrophe naturelle ou une utilisation négligente; (b) aux dispositifs soumis à des réparations non autorisées, qui ont été ouverts, démontés ou modifiés de quelconque manière; (c) aux

dispositifs qui n’ont pas été utilisés conformément aux instructions; (d) aux dommages dépassant le coût du produit; (e) aux lampes scellées et/ou aux ampoules, aux DEL et aux piles; (f) à la finition de l’une des

parties du dispositif, telle que la surface ou les caractéristiques de résistance aux intempéries, ce qui est considéré comme de l’usure normale; (g) aux dommages causés par le transport, aux coûts d’installation

initiale, aux coûts de démontage ou de remontage.

INTERMATIC INCORPORATED NE POURRA ÊTRE TENUE RESPONSABLE DE DOMMAGES INDIRECTS OU CONSÉCUTIFS. CERTAINES JURIDICTIONS N’AUTORISENT PAS L’EXCLUSION OU LA LIMITATION DES

DOMMAGES INDIRECTS OU CONSÉCUTIFS. DANS CE CAS, LES LIMITES CI-DESSUS NE S’APPLIQUENT PAS. LA PRÉSENTE GARANTIE REMPLACE TOUTES LES AUTRES GARANTIES EXPRESSES OU IMPLICITES.

TOUTES LES GARANTIES IMPLICITES, NOTAMMENT GARANTIE DE QUALITÉ MARCHANDE ET GARANTIE D’ADAPTATION À UNE FIN PARTICULIÈRE, SONT MODIFIÉES AUX PRÉSENTES POUR EXISTER

UNIQUEMENT TELLES QUE COMPRISES DANS LA GARANTIE LIMITÉE, ET AURONT LA MÊME DURÉE QUE LA PÉRIODE DE GARANTIE INDIQUÉE CI-DESSUS. CERTAINES JURIDICTIONS N’AUTORISENT PAS LES

LIMITES DE DURÉE D’UNE GARANTIE IMPLICITE. DANS CE CAS, LES LIMITES CI-DESSUS NE S’APPLIQUENT PAS.

Le recours à la présente garantie se fait soit (a) par renvoi du produit au vendeur auprès duquel il a été acheté, soit (b) en remplissant le formulaire de réclamation sur le site Web www.intermatic.com. La

présente garantie est offerte par : Intermatic Incorporated, Customer Service 7777 Winn Rd., Spring Grove, Illinois 60081-9698. Pour recourir à la garantie, aller à : http://www.Intermatic.com ou composer le 815-

675-7000.

GARANTÍA LIMITADA DE UN AÑO

GARANTIE LIMITÉE UN AN

158--01607

Loading...

Loading...