Page 1

VE700 Series Vector Enhanced Motion Sensor

D

D

Installation Sheet

EN DA DE ES FR IT NL NO PL PT SV

1

2

3

4

C

AA

5

DIN 7996

(3.5 mm x 35 mm)

A

B

C

i

l

B

c

A

!

k

A

B

A

B

C

C

D

D

C

C

D

D

C

6

BB

C V

© 2012 UTC Fire & Security. All rights reserved 1 / 64 P/N 145797999-2 • REV B • ISS 19MAR12

D/N

WT

CP

NIGHT

DAY

ON

OFF

10

11

10

11

10

11

10

11

Page 2

7

V

5

V

(3)

(2)

(1)

E73

8

E736

-0V

+12V

ALARM

NC C

EOL

TAMPER

NC C

1234567891011

4K7

33R

4K7

9

DAY /

NIGHT

33R

WALK

TEST

ALARM

NC C

123456789 10

10

NO

33R

TAMPER

(1)

NC C

(2)

DAY /

NIGHT

33R

(3)

WALK

TEST

11

11

(5)

12

(1)

----

A

(4)

B

ON

J1

J2

(4)

J3

1

12 3 4

ON

(6)

ON

12 34

(1) (2)

(4)

A

B

12 34

----

(2)

(3)

(3)

(3)

(3)

13

(1) (2)

A

B

2 / 64 P/N 145797999-2 • REV B • ISS 19MAR12

Page 3

14

J1

20 m

86°

60 m (197 ft.)

UL639: 55 m (180 ft.)

15

J2

(1)

J1

J1

16

Dual Loop Zone

ALARM

34567

Panel

TAMPER

SPARE

33R

4K7

4K7

(3)

(1)

J2

(2)

3 s 3 s

(2)

17

Panel

Dual Loop Zone

ALARM

34567

TAMPER

SPARE

33R

4K7

4K7

ALARM

34567

TAMPER

SPARE

33R

4K7

4K7

ALARM

34567

TAMPER

SPARE

33R

4K7

4K7

P/N 145797999-2 • REV B • ISS 19MAR12 3 / 64

Page 4

18

)

1.8-3.0 m

(5.9-9.8 ft.)

20

1 m

(3.3 ft.)

60 m (197 ft.

19

(1)

(2)

(3) (4)

4 / 64 P/N 145797999-2 • REV B • ISS 19MAR12

Page 5

21

5

1

1

22

2.4 m

nom.

60 m (197 ft.) UL639: 55 m (180 ft.)

1234

5

6

8910

7

11

1234

5

6

8910

7

11

20 m (65.6 ft.)

11

10

1

2

9

8

7

5

3

4

23

10

9

8

7

6

3

4

1

2

(1)

2.3 m (7.5 ft.)

10 m

12 m

14 m

12 m

10 m

8m6m4m

Note: For UL compliant installations do not mount the motion

sensor below 8 ft mounting height

P/N 145797999-2 • REV B • ISS 19MAR12 5 / 64

0m2m4m6m8m

2m

14 m

Page 6

24

26

25

CP

ST400

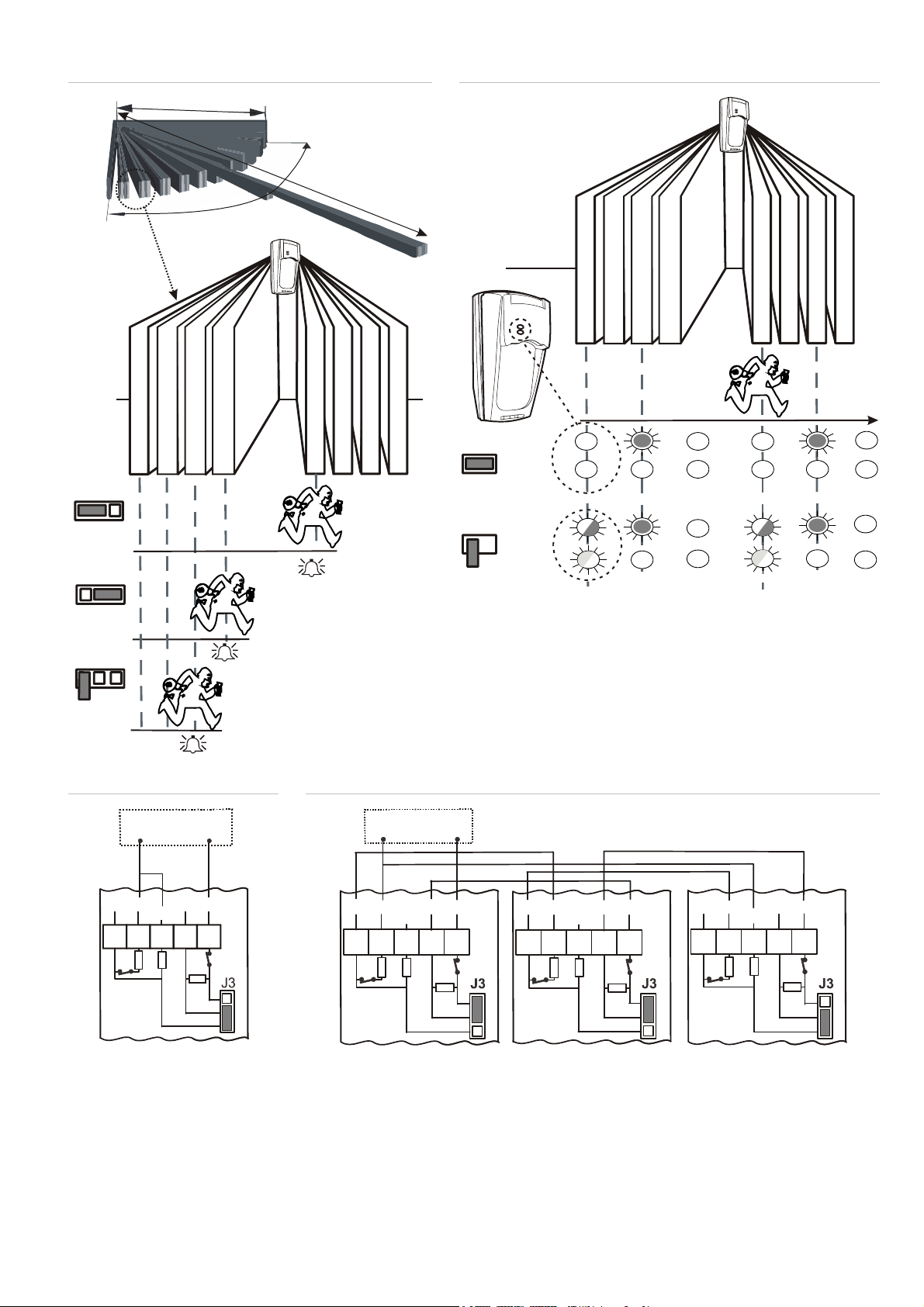

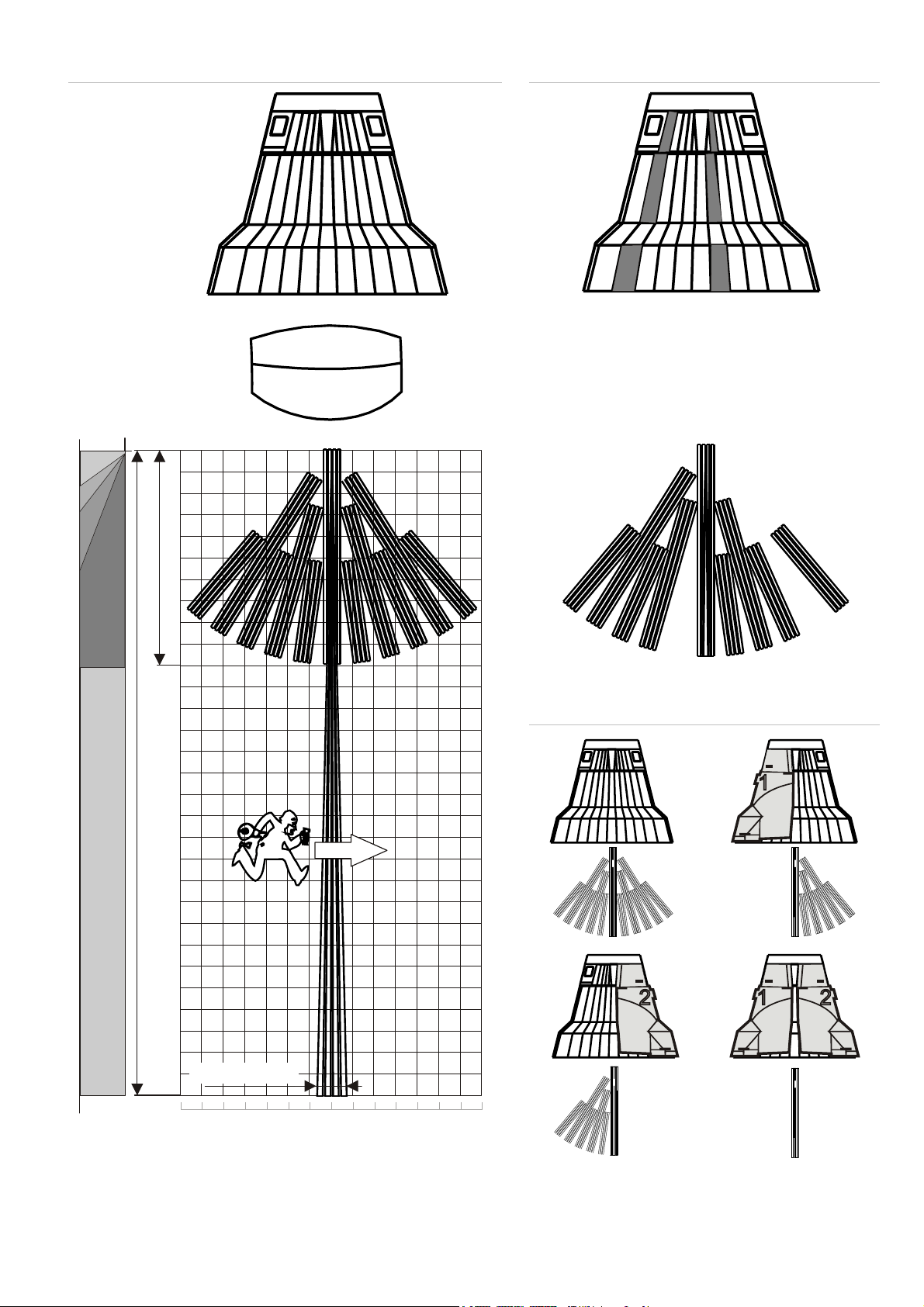

Install the detector so that the expected movement

of an intruder will be across the fields of view (see

example in Figure 21, item 1). This is the direction

best detected by PIR detectors.

SB01

EN: Installation Manual

Introduction

The VE735 and VE736 are PIR motion sensors.

They have a patented verified PIR technology.

Installation guidelines

The technology in this detector resists false alarm

hazards. Nevertheless avoid potential causes of

instability, such as:

Mounting the detector

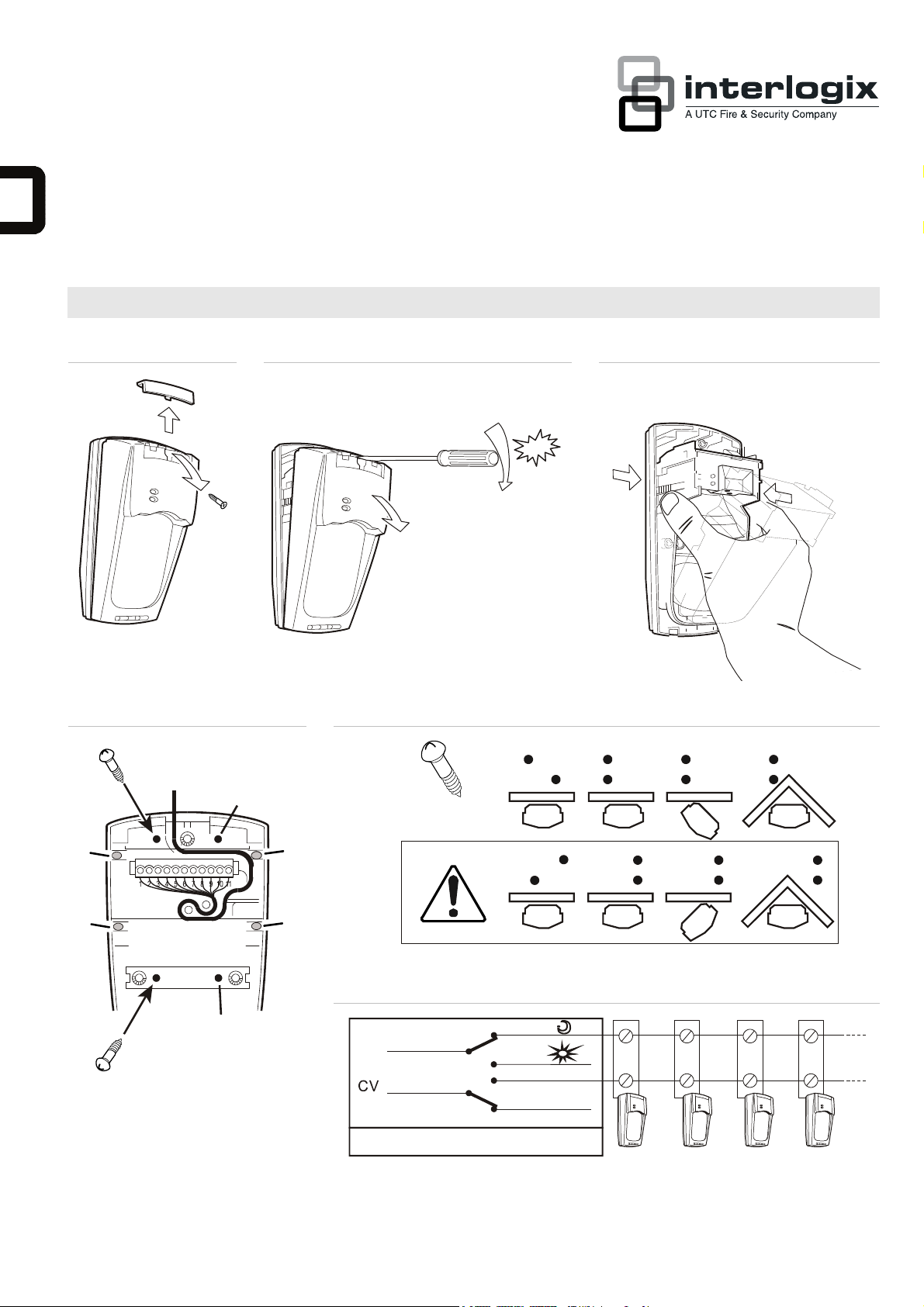

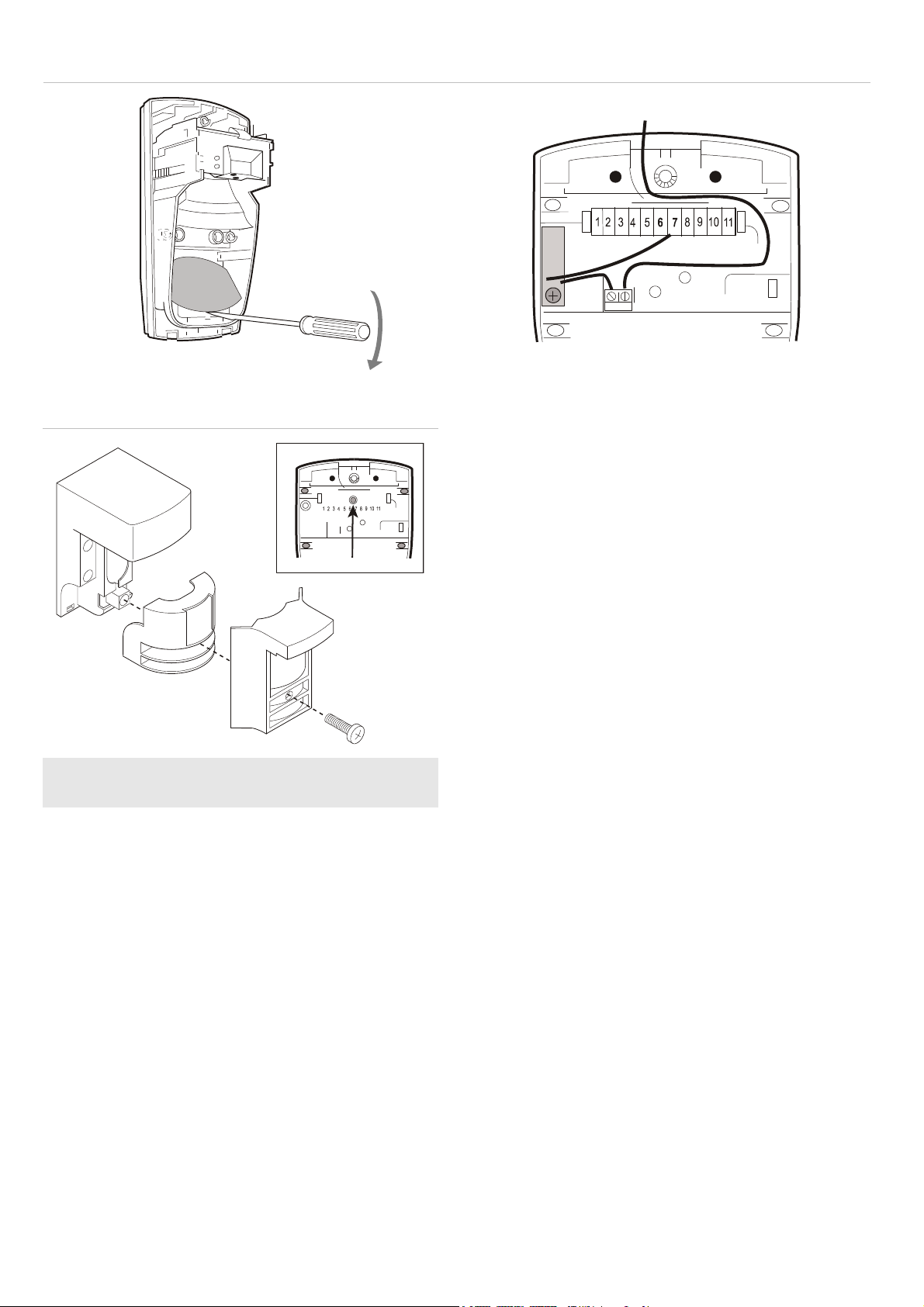

1. Lift off the custom insert and remove the

enclosed screw (Figure 1).

2. Using a screwdriver, carefully prise open the

detector (Figure 2).

3. Remove the interior part (Figure 3).

4. Fix the base to the wall between 1.8 m and 3.0

m (5.9 to 9.8 ft.) from the floor. For flat

mounting, use a minimum of two screws (DIN

7998), at least one in position A and one in

position B. For corner mounting, use screws in

positions C or D (see Figures 4 and 5).

Note: Not all screw positions have pry-off

tamper. Non pry-off positions are shown in the

warning box.

5. Wire the detector. See Figures 7 and 8.

Note: All wiring must be provided according to

National Electrical Code, NFPA 70 and CSA

C22.1, Canadian Electrical Code, Part I, Safety

Standard for Electrical Installations.

• Direct sunlight on the detector

• Heat sources within a field of view

• Strong draughts onto the detector

• Large animals in a field of view

• Obscuring the detector’s field of view with large

objects, such as furniture

6 / 64 P/N 145797999-2 • REV B • ISS 19MAR12

Figure 16 shows a single detector wiring,

Figure 17 — multiple devices connection.

6. Select the desired jumper and DIP switch

settings (see “Setting the detector” on page 7).

7.

Replace the interior part (Figure 9).

Page 7

8. Align the detector. See “Aligning the beam and

walk testing the detector” on page 8.

9.

Remove the blinders and add the stickers, if

required. See “Selecting the coverage pattern”

on page 9 and “Blocking the curtains” on page

10.

10.

Insert the insect-protection caps (Figure 10,

item 1).

11. Close the cover (item 2).

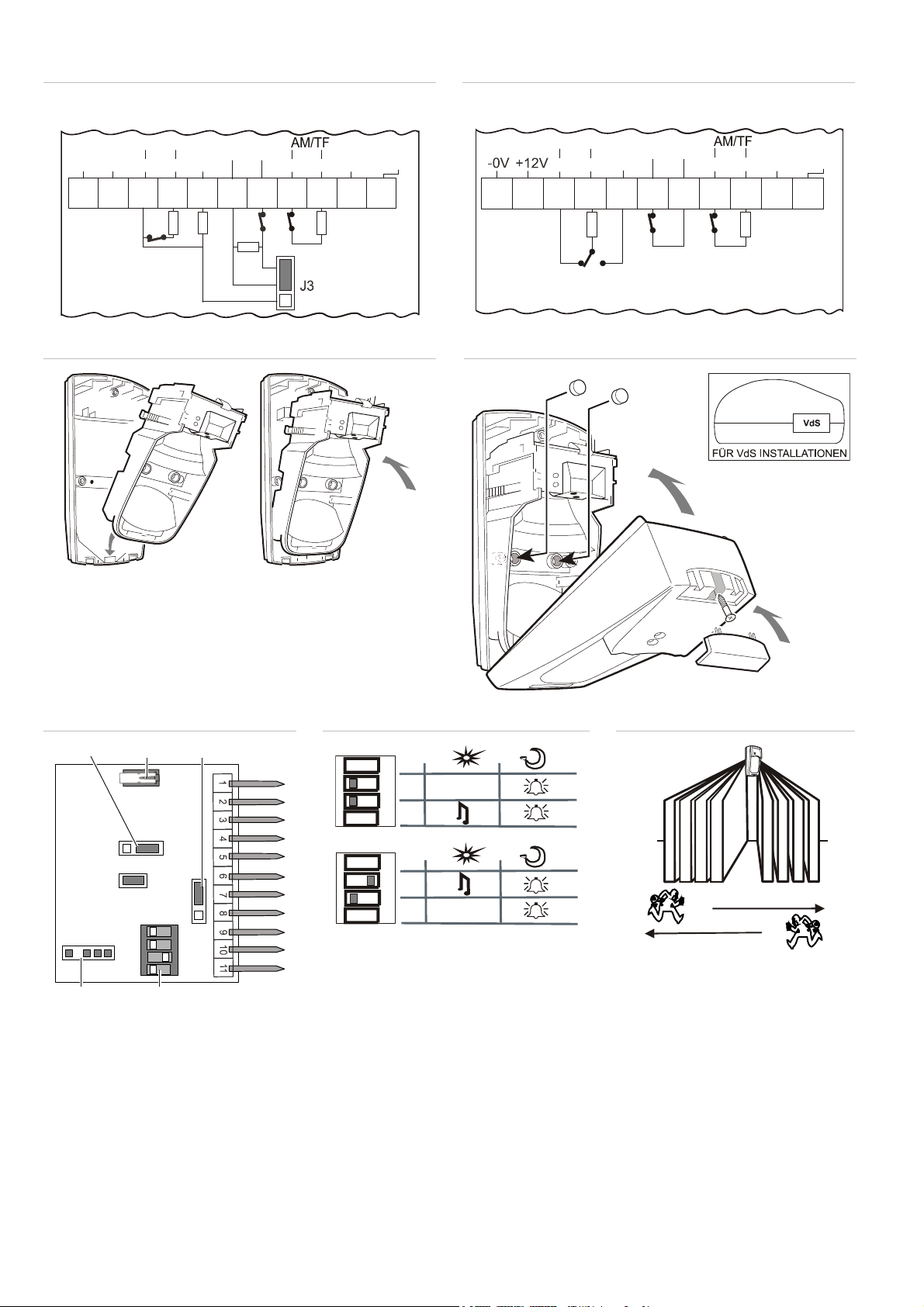

J2: Curtain location mode (CLM)

It allows you to identify where the edges of the

curtains are precisely located. When an intruder

enters a curtain, the red and yellow LEDs flash

alternatively.

See Figure 15.

J2 is also used for long-range alignment (see

“Aligning the beam and walk testing the detector”

on page 8).

12. Replace the custom insert (item 3).

Setting the detector

The detector must be restarted (repowered) after

changing the settings or detection pattern.

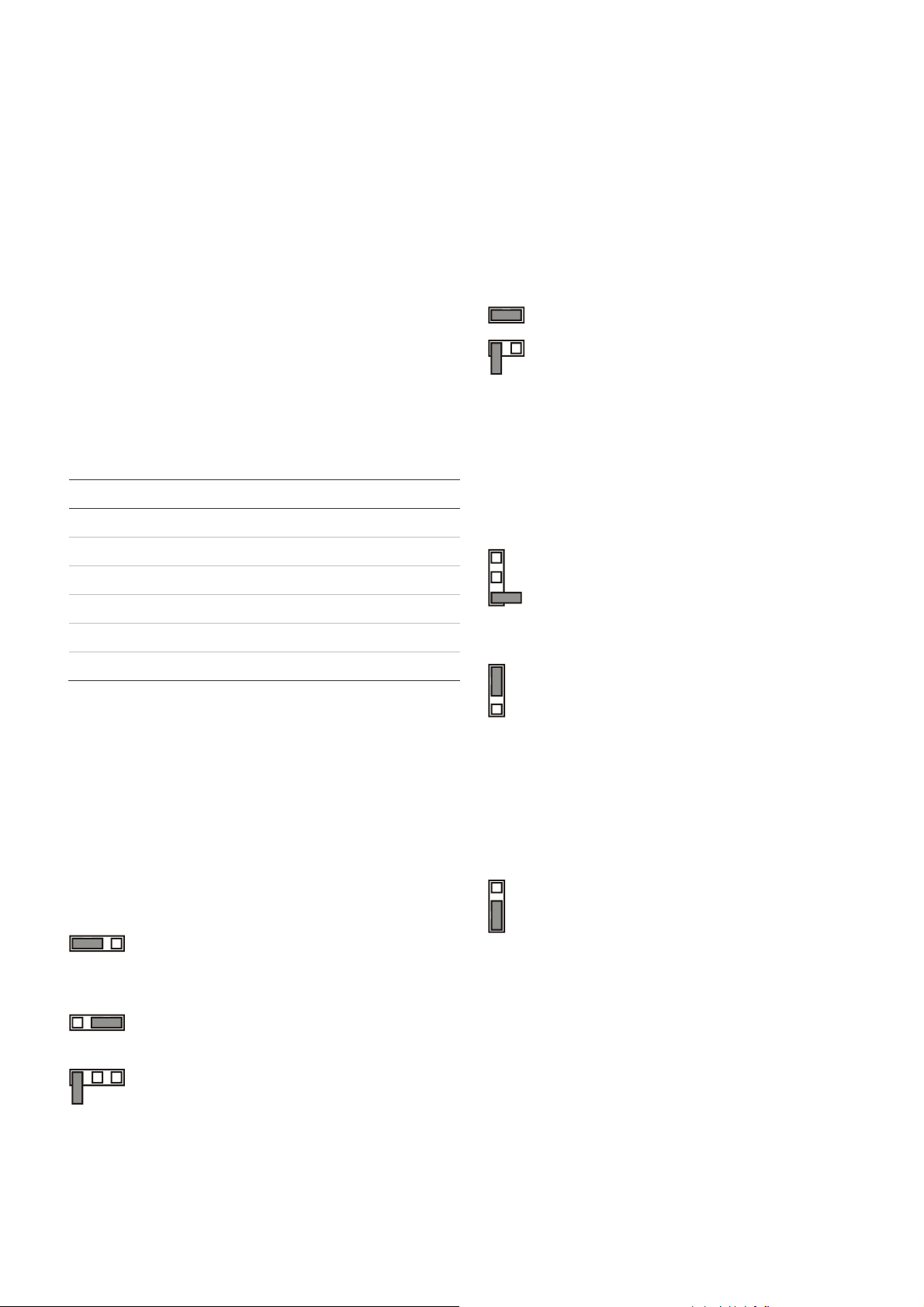

Figure 11 legend

Item Description

(1) J1: PIR sensitivity

(2) Tamper

(3) J3: Dual loop (only available on VE735)

(4) J2: CLM

(5) COM port

(6) PIR DIP switch

Jumpers

J1: PIR sensitivity

It changes the distance-to-alarm delay (the speed

of the decision algorithm); the higher the sensitivity,

the faster the sensor will react.

See Figure 14.

There are three different PIR sensitivities.

Low sensitivity: Use where there is a risk

of false alarms. Do not use in long-range

applications (>20 m / 65.6 ft.) (item 1).

Medium sensitivity: Most situations

(factory default) (item 2).

High sensitivity: Use for high-risk

situations. Recommended for use in

corridors (item 3).

Note: For UL/cUL installations, range of 65 ft and

180 ft requires maximum sensitivity setting (item 3).

Off (item 1).

On (item 2). See “Aligning without the

alignment tool” on page 8.

J3: Dual loop (onl

y available on VE735)

It is used to set the alarm and tamper relay. It

allows you to connect the detector to any control

panel.

See Figures 16 and 17.

EOL Loop (4.7 kΩ)

Terminals 4 and 5 of the alarm output must

be used when connecting to the control

panel.

Isolated Alarm and Tamper Loop

(factory default)

Tamper is isolated from the alarm relay.

The EOL resistor in the tamper circuit is

short-circuited.

Terminals 3 and 4 of the alarm output must

be used when connecting to the control

panel.

Dual Loop

Tamper and alarm loop can be monitored

over two wires.

In a normal situation (no alarm) the dual

loop impedance is 4.7 kΩ. For a detector

alarm, the alarm relay contact opens and

the impedance of the dual loop increases

to 9.4 kΩ, indicating an alarm. When the

detector housing is opened, the tamper

circuit opens and the dual loop is

interrupted, indicating a tamper alarm.

P/N 145797999-2 • REV B • ISS 19MAR12 7 / 64

Page 8

DIP switches

Table 1: PIR DIP switches

Function DIP switch On DIP switch Off

1. Polarity Active high* Active low

2. Chime Chime on Chime off*

3. Chime direction Left-to-right* Right-to-left

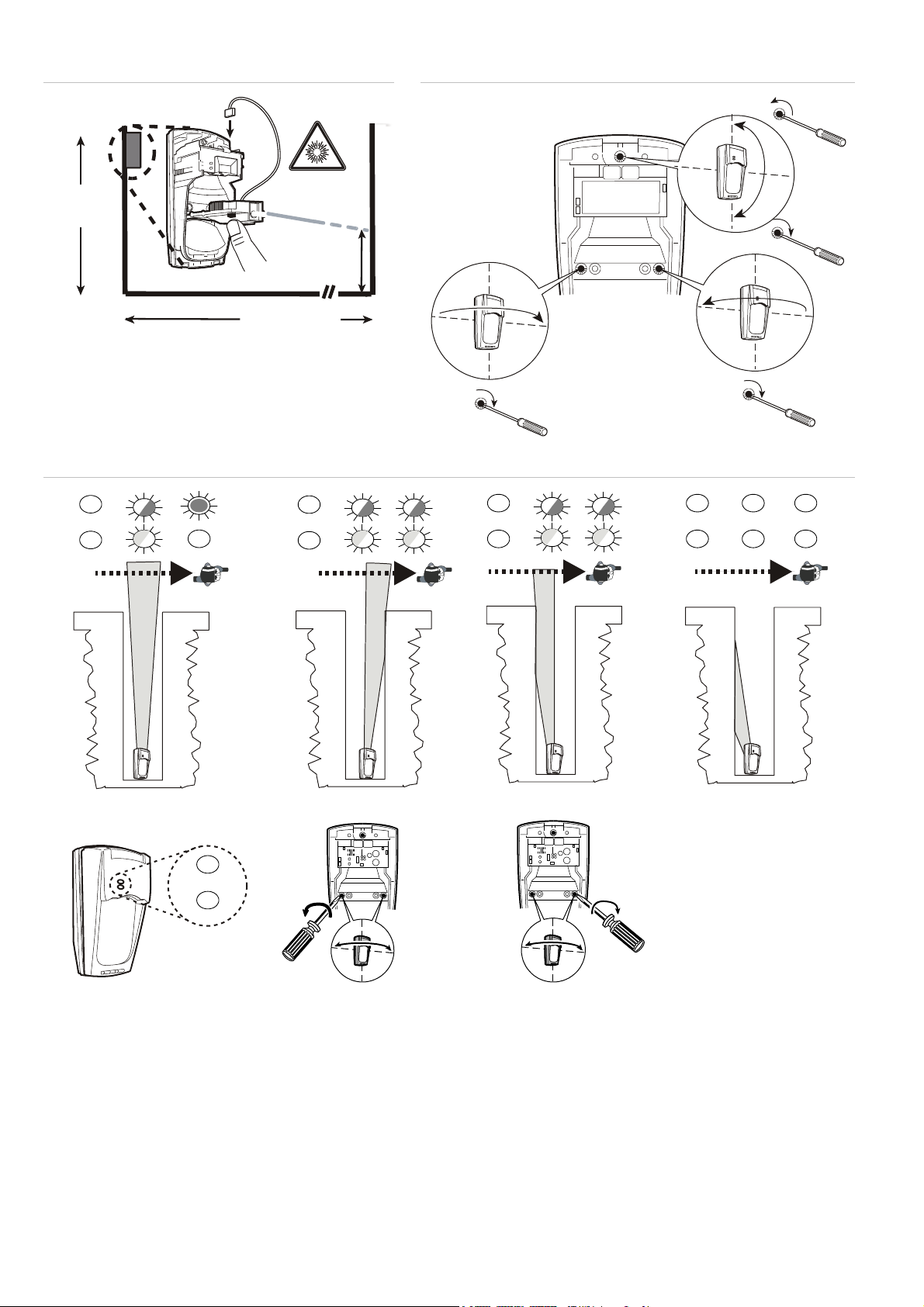

Aligning the beam and walk testing the detector

Aligning using VE710 alignment tool

Note: VE710 laser alignment tool has not been

evaluated by UL.

See Figures 18 and 19.

4. LEDs LEDs on* LEDs off

* Factory default

DIP switch 1: Polarity of control voltage (CV)

On: “Active high” provides the standard logic with

“Active high” logic to enable walk test and day/night

inputs.

Off: “Active low” provides “Active low” logic to

enable walk test and day/night inputs.

DIP switch 2: Chime

See Figure 12.

The detector can distinguish the direction of the

intruder during daytime. Disable this option by

setting the detector to chime OFF. When the chime

is ON, the detector will trigger an alarm when the

intruder moves right-to-left or left-to-right across the

curtains.

Note: If the day/night terminal is not used and the

chime is ON, the chime will be ON both during

disarm and arm (day/night) mode.

1. Insert the VE710 in the sub-frame with the

on/off switch facing the floor.

2. Connect it to the COM port.

3. Turn on the VE710.

WARNING: Do not look into the laser beam.

The output power is less than 1 mW.

Consequently the VE710 laser is classified by

IEC60825-1 as a Class 2 laser. The eye’s

blinking reflex is fast enough to prevent any

permanent damage to the eye.

4. The laser spot indicates the product alignment

(Figure 18). If this spot on the wall veers from

the centre of the desired detection area 1 m

(3.3 ft.) from the ground, then loosen the base

fixation screws (see Figure 4) and use the three

adjustment screws in the base to realign it to

the centre, as shown in Figure 19. When the

spot is correctly realigned, retighten the base

fixation screws.

5. Remove the alignment tool and replace the

cover.

DIP switch 3: Chime direction

See Figure 13.

On: Alarm when an intruder walks from left-to-right.

Off: Alarm when an intruder walks from right-to-left.

Stand with your back to the detector to determine

left and right directions.

DIP switch 4: LEDs

On: Enables both LEDs on the detector at all times.

Off: Puts both LEDs under the control of walk test

and armed/disarmed input.

6. Carry out walk test. Make sure that the red LED

is On after walk test.

Aligning without the alignment tool

See Figure 19.

1. Insert the mirror blinders in order to ensure that

the detector is in single-curtain mode.

2. Put J2 to On and wait until both LEDs are off.

3. Walk in front of the detector across the field of

view at normal speed (without pausing) and at

the maximum possible range. When you enter

the beam, both LEDs will start to blink

simultaneously.

After crossing the beam, if:

a. The red LED is On (Figure 20, item 1), the

alignment is OK.

8 / 64 P/N 145797999-2 • REV B • ISS 19MAR12

Page 9

b. The red and yellow LEDs are blinking

simultaneously then the field of view is

obstructed and is insufficient to verify an

alarm.

There are two options:

• If the blinking started near the end of the

detection area, you need to align the beam

to the left (Figure 20, item 2).

• If the blinking started near the start of the

detection area, you need to align the beam

to the right (Figure 20, item 3).

Loosen the base fixation screws (see Figure 4)

and use the three adjustment screws in the

base to realign the beam to the centre, as

shown in Figure 20. When the beam is correctly

realigned, retighten the base fixation screws.

4. If the LEDs do not blink, the curtain is outside of

the detection range (Figure 20, item 4). Walk

across the beam at a shorter distance to try to

detect it.

5. Redo walk test to confirm that the detector is

correctly aligned.

6. Put J2 to Off.

Notes

General information

Latching

When using multiple detectors in a single loop, wire

for day/night (D/N) and walk test (WT) inputs, as

shown in Figure 6.

Remotely enabling/disabling the walk test LED

See Figure 6.

Disconnect the CV to terminal 10 (D/N) and

connect it to terminal 11. The detector’s LED will

blink as the alarm relay opens and closes. The walk

test can now be carried out.

Note: Only enabling the walk test will not clear the

alarm memory. After disarming the system

following an alarm, switch the walk test to On.

When you switch walk test to Off, the indication of

memorised alarms will reappear. Only when CV is

re-applied to terminal 10 (i.e., the system is

rearmed) will the memory be cleared and the LEDs

turned off.

To enable the walk test LED without a remote CV

input, set DIP switch 4 to the On position. After

walk test, set DIP switch 4 to the Off position.

• If the CLM is on, the alarm output is activated.

• It is recommended to place the cover on the

detector during the CLM walk test.

Identifying detector status by the LEDs

Table 2: LED indication

Detector

status

Power On

Alarm

Trouble

High/Low

voltage

= On steady = Blinking (1 Hz)

Yellow

LED

Red

LED

Description

Blinks alternatively for

50 s

On during alarm period

— nominally for 3 s

Continuously on

On until correct voltage is

restored

We recommend that the detector is regularly walk

tested and the communication with the control

panel checked.

Setting the alarm memory

See Figure 6.

Note: First set the appropriate active polarity of the

control voltage (CV) using the PIR DIP switch 1.

Connect the CV to terminal 10 when the system is

armed. When the system is disarmed, disconnect

the CV. If an alarm occurs during the armed period,

a flashing red LED will indicate which the

detector(s) caused the alarm. Re-applying the CV

(re-arming the system) will reset the LED indication

and memory.

Selecting the coverage pattern

See Figures 21 and 22.

The coverage pattern can be changed to fit specific

requirements by using the mirror stickers

(enclosed), as shown. We recommend that you

blind unused curtains that are looking at objects

located very close to the detector.

P/N 145797999-2 • REV B • ISS 19MAR12 9 / 64

Page 10

Caution: Removing the stickers can damage the

mirror surface.

Blocking the curtains

See Figure 23.

The mirror blinders are fitted on the mirror by

default. To remove a blinder, first remove the

interior part of the detector. Then lift the lower part

of the blinder and wiggle the upper part to loosen it.

When long-range detection is not required (>20 m /

65.6 ft.), remove the long-range mirror (Figure 24).

Pry-off and cover tamper

The detector has both pry-off and cover tamper

(EN 50131-2-2 compliant).

It is important to use the screw indicated in Figure 4

in order to ensure pry-off tamper.

Self test. The detector itself monitors the sensor

and associated on-board signal processing

circuitry.

Technical fault (TF). The fault signal or message

that is generated on the trouble relay when the

detector suffers a fault.

Walk test. An operational test done by the installer

to see if the equipment will generate an alarm.

Specifications

Input power 9 to 15 V (12 V nominal)

For UL/cUL installations: 10 to

15 V (12 V nom.)

Peak-to-peak ripple 2 V (at 12 V)

Current consumption:

Normal operation

Alarm 9 mA

11 mA (for UL/cUL installations

0.132 W)

For corner-mount applications, the pry-off tamper

cannot be activated.

Pry-off tamper is not evaluated by UL.

SB01 swivel-mount bracket (optional)

When it is not possible to mount the detector on a

wall, use the SB01 to mount it on the ceiling.

See Figure 26.

SB01 swivel-mount bracket is not evaluated by UL.

Glossary

Alarm memory. A storage medium located on the

detector that can record signals generated by

the detector.

Curtains. A vertical continuous layer of detection

zones. The PIR detector can only detect motion

within the curtains and not in the spaces

between them.

Curtain Location Mode (CLM). A feature of the

detector that identifies precisely the edges of

the curtains.

Day mode (disarmed mode). The detector is not

required to generate an alarm signal or

message when activated by a person walking in

front of it.

Night mode (armed mode). The detector generates

an alarm signal or message when activated by

a person walking in front of it.

Maximum 15 mA

Mounting height 1.8 to 3.0 m (5.9 to 9.8 ft.)

Target speed range

Alarm output 80 mA at 30 V max., resistive

Tamper output 80 mA at 30 V max., resistive

Trouble output 80 mA at 30 V max., resistive

Alarm time 3 sec

Detector start-up time 50 sec

Operating temperature −10 to +55°C (14°F to 130°F)

Relative humidity

Dimensions

(H x W x D)

Weight 275 g (9.70 oz.)

Number of curtains

Viewing angle 86° at 20 m and 3° at 60 m

IP/IK rating IP30 IK02

20 cm/sec to 3 m/sec (7 in./sec

to 10 ft./sec)

For UL/cUL installations:

0 to 49°C (32 to 120°F)

95% max.

(UL/cUL installations)

175 x 93 x 66 mm

(6.88 x 3.66 x 2.60 in.)

11 at 20 m and 1 at 60 m

(11 at 65.6 ft. and 1 at 197 ft.)

UL639:

11 at 20 m and 1 at 55 m

(11 at 65.6 ft. and 1 at 180 ft.)

10 / 64 P/N 145797999-2 • REV B • ISS 19MAR12

Page 11

Regulatory information

Manufacturer

Certification

UL

compliance

UTC Fire & Security Americas

Corporation, Inc.

1275 Red Fox Rd., Arden Hills, MN

55112-6943, USA

Authorized EU manufacturing

representative:

UTC Fire & Security B.V.

Kelvinstraat 7, 6003 DH Weert,

Netherlands

The units are intended to be connected to

a Listed Burglar Alarm Control Unit or

Listed Burglar Alarm Power Supply, that

provides a minimum of 4 hours Standby

Power.

The installer should perform walktest at

least ones a year.

Use only a listed power-limited supply.

2002/96/EC (WEEE directive): Products

marked with this symbol cannot be

disposed of as unsorted municipal waste

in the European Union. For proper

recycling, return this product to your local

supplier upon the purchase of equivalent

new equipment, or dispose of it at

designated collection points. For more

information see: www.recyclethis.info.

Contact information

www.utcfireandsecurity.com or www.interlogix.com

Customer support: www.interlogix.com/customersupport

DA: Installationsvejledning

ICES-003

FCC

VE73x: This Class B digital apparatus

complies with Canadian ICES-003.

This equipment generates, uses and can

radiate radio frequency energy and, if not

installed and used in accordance with the

instructions, may cause harmful

interference to radio communications.

However, there is no guarantee that

interference will not occur in a particular

installation. If this equipment does cause

harmful interference to radio or television

reception, which can be determined by

turning the equipment off and on, the

user is encouraged to try to correct the

interference by one or more of the

following measures:

• Reorient or relocate the receiving

antenna.

• Increase the separation between the

equipment and receiver.

• Connect the equipment into an output

on a circuit different from that to

which the receiver is connected.

• Consult the dealer or an experienced

radio/TV technician for help.

Introduktion

VE735 og VE736 er PIR bevægelsesfølere. De har

en patenteret verificerede PIR teknologi.

Installationstip

Teknologien i denne detektor er modstandsdygtig

over for falske alarmer.

Alligevel skal du undgå mulige årsager til ustabilitet,

f.eks.:

• Direkte sollys på detektoren.

• Varmekilder inden for synsvidde.

• Kraftig træk på detektoren.

• Dyr inden for synsvidde.

• Afdækning af detektorens detekteringsfelt med

store genstande, såsom møbler

Monter detektoren således at en forventet

bevægelse af en indbrudstyv, vil være på tværs af

detektorens overvågningsfelt (se eksempel på

figur 21, punkt 1). Dette er retningen som best

detekteres af PIR detektoren.

Montering af detektoren

European

Union

directives

P/N 145797999-2 • REV B • ISS 19MAR12 11 / 64

1999/5/EC (R&TTE directive): Hereby,

UTC Fire & Security declares that this

device is in compliance with the essential

requirements and other relevant

provisions of Directive 1999/5/EC.

1. Løft dækpladen af (figur 1).

2. Åbn forsigtigt detektoren med en skruetrækker

(figur 2).

3. Udtag elektronikmodulet (figur 3).

Page 12

4. Fastgør basen (bagpladen) til væggen mellem

1,8 m og 3,0 m fra gulvet. Til overflade

montering, bruges minimum to skruer

(DIN 7998), mindst én i stilling A og én i stilling

B. Til hjørne montering, bruges skruer i stilling

C eller D (figur 4 og 5).

Punkt Beskrivelse

(4) J2: Gardintest

(5) COM

(6) DIP-switche

Note: Ikke alle skruepositioner har

vægsabotagebeskyttelse. Placering af

vægsabotagebeskyttelse er ikke vist i

advarselsboksen.

5. Tilslut ledningerne til detektoren. Se figur 7

og 8.

Note: Alle ledningstilslutninger skal udføres i

henhold til de nationale retningslinier gældende

for installationen.

Figur 16 viser en enkelt detektortilslutning.

Figur 17 — en tilslutning med flere enheder.

6. Vælg de ønskede indstillinger for jumpere og

DIP-switche (se “Indstilling af detektoren”

nedenfor).

Indsæt elektronikmodulet igen (figur 9).

7.

8. Juster detektoren som vist. Se “Justering af

dækningso

mråde og gangtest af detektoren” på

side 14.

Jumpere

J1: PIR-følsomhed

Den ændrer detektorens reaktionstid (antallet af

gardiner, der skal aktiveres før alarm). Jo højere

følsomhed, jo hurtigere reagerer sensoren.

Se figur 14.

Der er tre forskellige PIR-følsomheder.

Lav følsomhed: Bruges, hvor der er risiko

for falske alarmer. Må ikke bruges på

lange afstande (>20 m) (punkt 1).

Mellem følsomhed: De fleste situationer

(fabriksindstilling) (punkt 2).

Høj følsomhed: Bruges til situationer med

høj risiko. Anbefales til brug i korridorer

(punkt 3).

J2: Gardintest

Fjern spejlafdækninger, og monter

9.

afdækningslabels efter behov. Se “Valg af

dækningsmønstret” på side 15 og “Maskering af

gardinerne” på side 15.

10.

Indsæt insektbeskyttelsesdækslerne (figur 10,

punkt 1).

11. Luk dækslet (punkt 2).

12. Montér dækpladen (punkt 3).

Indstilling af detektoren

Detektoren skal genstartes efter ændring af

indstillingerne, eller hvis dækningsområdet er

ændret.

Figure 11 ikontekst

Punkt Beskrivelse

(1) J1: PIR-følsomhed

(2) Sabotagekontakt

(3)

J3: Valg af indbyggede endemodstande (kun

VE735)

Den giver dig mulighed for at identificere, hvor

gardinernes kanter præcist er placeret. Når man

rammer et gardin, blinker den røde og gule lysdiode

skiftevis.

Se figur 15.

J2 bruges også til kalibrering på lang afstand (se

“Justering af dækningsområde og gangtest af

detektoren” på side 14).

Fra (punkt 1).

Til (punkt 2). Se “Kalibrering uden

laserkalibrer

J3: Valg af indb

ingsværktøjet” på side 14.

yggede endemodstande (kun

VE735)

Giver mulighed for tilslutning til alle typer AIAcentraler, også med dobbelt balanceret sløjfe, uden

brug af løse endemodstande. De indbyggede

endemodstande er 4.7 kΩ.

Se figur 16 og 17.

12 / 64 P/N 145797999-2 • REV B • ISS 19MAR12

Page 13

EOL-sløjfe (4,7 kΩ)

Adskilt alarm og sabotage, enkeltbalanceret

med brug af de indbyggede endemodstande.

Sabotage og alarm er adskilt, hver med en

4,7 kΩ endemodstand i serie.

Alarmkredsen tilsluttes terminalerne 4 og 5,

og sabotagekredsen tilsluttes terminalerne 6

og 7.

Terminal 3 må ikke anvendes.

Isoleret sløjfe til alarm og

sabotagekontakt (fabriksstandard)

Adskilt alarm og sabotage uden brug af de

indbyggede endemodstande.

Alarmkredsen tilsluttes terminalerne 3 og 4,

og sabotagekredsen tilsluttes terminalerne 6

og 7.

DIP-switche

Tabel 1: DIP-switche

Funktion DIP-switch ON DIP-switch OFF

1. Polaritet Aktiv høj * Aktiv lav

2. Dørklokke Til Fra*

3. Dørklokkeretning Venstre til højre* Højre til venstre

4. Lysdioder Til* Fra

* Fabriksindstilling

DIP-switch 1: Kontrolspænding (CV)

ON: Standardlogik med “Aktiv høj”-logik til

aktivering af Gangtest og Dag/nat

(alarmhukommelse).

OFF: “Aktiv lav”-logik til aktivering af Gangtest og

Dag/nat (alarmhukommelse).

DIP-switch 2: Dørklokkefunktion

Terminal 5 må ikke anvendes.

Sabotagekontakten er isoleret fra

alarmrelæet. EOL-modstanden i

sabotagekontaktens kredsløb kortsluttes.

Dobbelt balanceret sløjfe med brug af de

indbyggede endemodstande.

Sløjfen til sabotagekontakten og alarmen kan

overvåges via to ledninger.

Under normale omstændigheder (ingen

alarm) er impedansen ved dobbelt balanceret

sløjfe på 4,7 kΩ. Ved alarm åbnes

alarmrelæets kontakt, og impedansen øges

til 9,4 kΩ, hvilket angiver en alarm. Når

alarmens kabinet åbnes, bliver

sabotagekontaktens kredsløb åbnet, og den

dobbelte sløjfe afbrydes, hvilket angiver en

sabotagealarm.

Tilslutning til AIA-centralen sker via

terminalerne 4 og 7.

Der skal etableres forbindelse mellem

terminalerne 4 og 5.

Terminalerne 3 og 6 må ikke benyttes

Se figur 12.

Detektoren kan bestemme en persons retning i

dagtiden. Deaktiveres ved at indstille detektoren

med dørklokkefunktion fra. Når dørklokkefunktion

er til, udløser detektoren en alarm, når en person

bevæger sig fra højre mod venstre eller fra venstre

mod højre på tværs af gardinerne.

Note: Hvis Dag/nat-terminalen ikke bruges, og

dørklokkefunktionen er til, vil den være aktiv både

under fra- og tilkoblet tilstand (Dag/nat).

DIP-switch 3: Dørklokkeretning

Se figur 13.

ON: Alarm, når en person går fra venstre mod

højre.

OFF: Alarm, når en person går fra højre mod

venstre.

Stil dig med ryggen mod detektoren for at

bestemme venstre og højre retning.

DIP-switch 4: Lysdioder

.

ON: Begge lysdioder på detektoren er altid aktive.

OFF: Begge lysdioder er kontrolleret af gangtest,

og tilkoblet/frakoblet input når systmet er frakoblet.

P/N 145797999-2 • REV B • ISS 19MAR12 13 / 64

Page 14

Justering af dækningsområde og gangtest af detektoren

Brug af VE710-laserkalibreringsværktøjet

Se figur 18 og 19.

1. Indsæt VE710 i underrammen, mens til/frakontakten peger mod gulvet.

2. Slut den til COM-porten.

3. Tænd for VE710.

ADVARSEL: Se ikke ind i laserstrålen.

Udgangseffekten er mindre end 1 mW. Derfor

er VE710-laseren klassificeret som en laser i

klasse 2 i henhold til IEC60825-1. Øjets

blinkerefleks er hurtig nok til at forhindre

eventuel permanent beskadigelse af øjet.

4. Laserprikken angiver detektorens kalibrering

(Figur 18). Hvis prikken på væggen afviger fra

centret af det ønskede dækningsområde, 1 m

over gulvet, løsnes bagpladens fikseringsskruer

(se figur 4), og de tre justeringsskruer i

bagpladen bruges til at rette den ind til centrum,

som vist i figur 19. Når prikken er rettet korrekt

ind, strammes bagpladens fikseringsskruer

igen.

5. Fjern laserkalibreringsværktøjet, og sæt

dækslet på igen.

b. Den røde og gule lysdiode blinker samtidigt,

er synsfeltet spærret og ikke tilstrækkeligt til

at verificere en alarm.

Der er to muligheder:

• Hvis de begyndte at blinke nær slutningen

af registreringsområdet, skal du justere

laserstrålen til venstre (Figur 20, punkt 2).

• Hvis de begyndte at blinke nær starten af

registreringsområdet, skal du justere

laserstrålen til højre (Figur 20, punkt 3).

Løsn bagpladens fikseringsskruer (se figur 4),

og brug de tre justeringsskruer i bagpladen til at

rette dækningsområdet ind til centrum, som vist

i figur 18. Når prikken er rettet korrekt ind,

strammes bagpladens fikseringsskruer igen.

4. Hvis lysdioderne ikke blinker, er gardinet uden

for registreringsområdet (figur 20, punkt 4). Gå

tværs gennem dækningsområdet i en kortere

afstand for at forsøge at detektere det.

5. Udfør gangtesten igen for at bekræfte, at

detektoren er korrekt justeret.

6. Stil J2 på OFF.

Noter

• Hvis Gardintest er aktiveret, bliver Fejludgang

aktiveret.

• Det anbefales at anbringe dækslet på

detektoren under Gardintest.

6. Udfør gangtesten. Kontroller, at den røde

lysdiode lyser efter gangtesten.

Kalibrering uden laserkalibreringsværktøjet

Se figur 19.

1. Indsæt spejlafskærmningerne for at sikre, at

detektoren kun aktiveres af et enkelt gardin.

2. Sæt J2 på Til, og vent, til begge lysdioder er

slukket.

3. Gå foran detektoren på tværs af synsfeltet med

normal hastighed (uden at stoppe) og i den

størst mulige afstand. Når du går ind i

dækningsområdet, begynder begge lysdioder at

blinke samtidigt.

Hvis:

a. Den røde lysdiode lyser efter at have

krydset lysstrålen (figur 20, punkt 1), er

kalibreringen OK.

Lysdiodevisninger

Tabel 2: Lysdiodevisninger

Detektorstatus

Ved

opstart

Alarm

Fejl

Høj / lav

spænding

= Tændt = Blinker (1 Hz)

Gul

lysdiode

Rød

lysdiode

Beskrivelse

Blinker skiftevis i 50 s

Tændt under

alarmperiode –

nominelt 3 s

Tændt konstant

Tændt, indtil korrekt

forsyningsspænding

er opnået

14 / 64 P/N 145797999-2 • REV B • ISS 19MAR12

Page 15

Generelle oplysninger

Alarmhukommelse (latch)

med), som vist. Det anbefales at afdække ubrugte

gardiner, der vender mod vægge eller vinduer, som

er placeret megettæt på detektoren.

Når der bruges flere detektorer i en enkelt sløjfe,

forbindes Dag/nat (D/N) og Gangtest (WT), som

vist i figur 6.

Ekstern aktivering/deaktivering af gangtest

lysdioden

Se figur 6.

Afbryd kontrolspændingen til terminal 10 (D/N), og

forbind den til terminal 11. Detektorens lysdiode

blinker, når alarmrelæet åbnes og lukkes.

Gangtesten kan nu udføres.

Note: Hvis gangtesten blot aktiveres, slettes

detektorens alarmhukommelse ikke. Ved frakobling

efter en alarm sættes gangtest til ON. Når man

sætter gangtest tilbage til OFF, vises den gemte

alarmindikation igen. Først når kontrolspændingen

forbindes til terminal 10 igen (dvs. systemet

tilkobles igen), slettes hukommelsen, og

lysdioderne slukkes.

Hvis du vil aktivere gangtest lysdioden uden

anvendelse af kontrolspænding, skal du indstille

DIP-switch 4 til ON. Efter gangtesten indstilles DIPswitch 4 til OFF.

Vi anbefaler, at detektoren gangtestes med jævne

mellemrum, og at kommunikationen med AIAcentralen kontrolleres.

Forsigtig: Fjernelse af spejlafdækningslabels kan

beskadige spejloverfladen.

Maskering af gardinerne

Se figur 23.

Spejlafskærmningerne er monteret fra fabrikken på

spejlet. Hvis du vil fjerne en afskærmning, skal du

først fjerne den indre del af detektoren. Derefter

skal du løfte den nederste del af afskærmningen og

vrikke den øverste del for at løsne den. Hvis

detektering på lang afstand ikke er påkrævet

(>20 m), fjernes spejlet til lange afstande (figur 24).

Vægsabotagekontakt og sabotagekontakt

Detektoren har både en væg- & sabotagekontakt.

Det er vigtigt at bruge skruen, der angives i figur 4

for at sikre vægsabotagekontakten.

Ved hjørnemontering kan vægsabotagekontakten

ikke aktiveres.

SB01-svingmonteringsbeslag (ekstra tilbehør)

Bruges til vægmonteringer, der kræver en 90°dækning.

Se figur 26.

Anvendelse af alarmhukommelsen

Se figur 6.

Note: Indstil først DIP-switch 1 til den anvendte

kontrolspænding (CV).

Forbind kontrolspændingen til terminal 10, når

systemet tilkobles. Når systemet frakobles,

afbrydes kontrolspændingen. Hvis der har været en

alarm under den tilkoblede periode, angiver en

blinkende rød lysdiode, hvilke detektor(er) der har

forårsaget alarmen. Når kontrolspændingen

tilsluttes igen (tilkobling af systemet), resettes

lysdioden og alarmhukommelsen.

Valg af dækningsmønstret

Se figur 21 og 22.

Dækningsmønstret kan ændres, så det passer til

specifikke krav, vha. spejlafdækningslabels (følger

Ordliste

Alarmhukommelse. Et lagringsmedie i detektoren,

der kan registrere signaler, der er genereret af

detektoren.

Dag mode (frakoblet tilstand). Detektoren skal ikke

udløse alarmsignal eller -meddelelse, når en

person går ind foran den.

Gangtest. En manuel test, der udføres af

installatøren, for at se, om udstyret vil udløse

en alarm.

Gardiner. Et lodret sammenhængende lag af

detekteringsområder. PIR-detektoren kan kun

detektere bevægelse inden for gardinerne og

ikke i mellemrummene mellem dem.

Gardintest. En funktion i detektoren, som

registrerer gardinernes hjørner præcist.

Nat mode (tilkoblet tilstand). Detektoren udløser

alarmsignal eller -meddelelse, når en person

går ind foran den.

P/N 145797999-2 • REV B • ISS 19MAR12 15 / 64

Page 16

Selvtest. Detektoren overvåger selv sensoren og

det tilknyttede interne

signalbehandlingskredsløb.

Teknisk fejl (TF). Fejlsignalet eller -meddelelsen,

der genereres af AM-relæet, når relæet

rammes af en defekt.

Specifikationer

Driftsspænding 9 til 15 V (12 V nominel)

Peak-to-peak

ripplespænding

Strømforbrug:

Normal drift 11 mA

Alarm 9 mA

Maks. 15 mA

Monteringshøjde 1.8 til 3.0 m

2 V (ved 12 V)

EU-direktiver

1999/5/EC (R&TTE): UTC Fire & Security

erklærer herved at dette produkt

overholder de væsentlige krav og andet

relevant i detektivet 1999/5/EC.

2002/96/EC (WEEE): Bortskaffelse af

elektrisk og elektronisk udstyr har til

formål at minimere den indvirkning, som

affald af elektrisk og elektronisk udstyr

har på miljøet og mennesker. I henhold til

direktivet må elektrisk udstyr, der er

mærket med dette symbol, ikke

bortskaffes sammen med almindeligt

husholdningsaffald i Europa. Europæiske

brugere af elektrisk udstyr skal aflevere

kasserede produkter til genbrug.

Yderligere oplysninger findes på

webstedet www.recyclethis.info.

PIR-følsomhed

(detekteringshastighed)

Alarmudgang 80 mA ved maks. 30 V

Sabotageudgang 80 mA ved maks. 30 V

Fejludgang 80 mA ved maks. 30 V

Alarmtid 3 s

Detektoropstartstid 50 s

Driftstemperatur −10 til +55°C

Relativ luftfugtighed Maks. 95%

Mål (H x B x D) 175 x 93 x 66 mm

Vægt 275 g

Antal gardiner 11 ved 20 m + 1 ved 60 m

Åbningsvinkel 86° ved 20 m + 3° ved 60 m

IP-/IK-klasse IP30 IK02

20 cm/s til 3 m/s

Certificering og overholdelse

Producent

Certificering

UTC Fire & Security Americas

Corporation, Inc.

1275 Red Fox Rd., Arden Hills, MN

55112-6943, USA

Europæisk repræsentant for producent:

UTC Fire & Security B.V.

Kelvinstraat 7, 6003 DH Weert,

Netherlands

Kontakt information

www.utcfireandsecurity.com, www.interlogix.com

Kundesupport: www.interlogix.com/customersupport

DE: Installations Handbuch

Einführung

VE735 und VE736 sind PIR-Bewegungsmelder. Sie

verfügen über eine geprüfte PIR-Technologie.

Installationsanleitungen

Die Technologie in diesem Melder dient zur

Vermeidung falscher Alarmmeldungen. Dennoch

sollten Sie potenzielle Instabilitätsfaktoren

vermeiden, darunter:

• Direkte Einstrahlung von Sonnenlicht auf den

Melder.

• Hitzequellen innerhalb des

Erfassungsbereiches.

• Starke Zugluft auf den Melder.

• Große Tiere innerhalb des Erfassungsbereichs.

• Verdecken des Sichtfeldes des Melders durch

große Objekte, wie z. B: Möbel.

Installieren Sie den Bewegungsmelder so, dass die

zu erwartende Eindringrichtung quer zum

Erfassungsbereich (siehe Beispiel in Abbildung 21,

16 / 64 P/N 145797999-2 • REV B • ISS 19MAR12

Page 17

Punkt 1) erfolgt. Diese Richtung kann durch PIRMelder am besten erfasst werden.

Montage des Melders

1. Nehmen Sie den individuellen Einsatz ab und

entfernen Sie die darin befindliche Schraube

(Abbildung 1).

2. Heben Sie mit einem Schraubendreher

vorsichtig den Melder ab (Abbildung 2).

3. Entnehmen Sie das Innenteil (Abbildung 3).

4. Befestigen Sie die Basis an der Wand.

Verwenden Sie für eine flache Montage

mindestens zwei Schrauben (DIN 7998),

mindestens eine in Position A und eine in

Position B. Verwenden Sie für eine

Eckmontage Schrauben in den Positionen C

oder D (Abbildung 4 und 5).

Einstellen des Melders

Nachdem die Einstellungen oder der

Erfassungsbereich geändert wurden, muss der

Melder neu gestartet werden.

Steckbrücken

Abbildung 11 Legende

Position Beschreibung

(1) J1: PIR-Empfindlichkeit

(2) Sabotagekontakt

(3)

(4) J2: CLM

(5) COM-Port

(6) PIR-DIP-Schalter

J3: Dual-MG Anschaltung (nur verfügbar

bei VE735)

Hinweis: Nicht alle Schraubenpositionen

verfügen über einen Abreißkontakt. Die

Positionen ohne Abreißkontakt sind in einem

Warnfeld in Abbildung 5 angegeben.

5. Verdrahten Sie den Melder. Siehe Abbildung 7

und 8.

6. Wählen Sie die gewünschten Steckbrückenund DIP-Schaltereinstellungen aus (sie

„Einstellen des Melders“ unten).

7.

Setzen Sie das Innenteil wieder ein (Abb. 9).

8. Richten Sie den Melder aus und beachten Sie

den Abschnitt „Ausrichten des

Erfassungsb

ereichs und Durchführung eines

Gehtests für den Melder“ auf Seite 19.

Entfernen Sie die Abdeckungen und bringen

9.

Sie bei Bedarf die Aufkleber an. Siehe

„Auswählen des Erfassungsbereichs“ auf Seite

20 und „Abdecken der Vorhänge“ auf Seite 21).

10.

Setzen Sie die Insektenschutzkappen ein

(Abbildung 10, Position 1).

11. Schließen Sie die Abdeckung (Position 2).

12. Setzen Sie den individuellen Einsatz wieder ein

(Position 3).

J1: PIR-Empfindlichkeit

Sie ändert die Entfernung-zu-Alarm-Verzögerung

(die Geschwindigkeit des

Entscheidungsalgorithmus). Je höher die

Empfindlichkeit ist, desto schneller reagiert der

Melder.

Siehe Abb. 14.

Es gibt drei unterschiedliche PIR-Empfindlichkeiten.

Geringe Empfindlichkeit: Verwenden Sie

diese Einstellung, wenn das Risiko von

Falschalarmen existiert. Verwenden Sie

die Einstellung nicht bei Anwendungen mit

großer Reichweite (>20 m) (Position 1).

Mittlere Empfindlichkeit: In den meisten

Fällen die richtige Einstellung

(Werkseinstellung) (Position 2).

Hohe Empfindlichkeit: Für Situationen mit

besonders hohem Risiko geeignet.

Empfohlen für die Verwendung in

Korridoren (Position 3).

J2: Vorhang-Lokalisierung-Modus (CLM)

Mit diesem Modus können Sie die genaue Position

der Vorhangskanten bestimmen. Wenn eine

eindringende Person einen Vorhangsbereich betritt,

blinkt die rote und gelbe LED abwechselnd.

Siehe Abb. 15.

P/N 145797999-2 • REV B • ISS 19MAR12 17 / 64

Page 18

J2 wird auch für die Ausrichtung bei hoher

Reichweite verwendet.

Aus (Position 1).

Ein (Position 2). Siehe „Ohne das

Ausrichtung

stool“, Seite 19.

J3: Dual-MG Anschaltung (nur verfügbar bei

VE735)

Dient zur Einstellung de

s Alarm- und

Sabotagerelais. Sie können damit den Melder an

eine beliebige Einbruchmeldezentrale anschließen.

Siehe Abb. 16 und 17.

Abschluss-Schleifenwiderstand (4.7 kΩ)

PIR-DIP-Schalter

Tabelle 1: PIR-DIP-Schalter

Funktion DIP-Schalter Ein DIP-Schalter Aus

1. Polarität Aktiv-High* Aktiv-Low

2. Türgong Gong ein

3. Gongrichtung

4. LEDs LEDs Ein* LEDs Aus

* Werkseinstellung

Links nach

rechts*

DIP-Schalter 1: Polarität der Steuerspannung

(CV):

Gongfunktion ist

aus*

Rechts nach links

Die Anschlüsse 4 und 5 des Alarmausgangs

müssen verwendet werden, wenn der

Anschluss an die Einbruchmeldezentrale

erfolgt.

Isolierte Alarm- und Sabotageschleife

(Werkseinstellung)

Die Sabotageschleife ist vom Alarmrelais

getrennt. Der Abschlusswiderstand in der

Sabotageschaltung ist kurzgeschlossen.

Die Anschlüsse 3 und 4 des Alarmausgangs

müssen verwendet werden, wenn der

Anschluss an die Einbruchmeldezentrale

erfolgt.

Dual-MG

Die Sabotage- und Alarmschleife können mit

zwei Adern angeschaltet werden.

In einer normalen Situation (kein Alarm)

beträgt die Dual-MG Impedanz 4.7 kΩ. Bei

einem Alarm öffnet sich der

Alarmrelaiskontakt und die Impedanz der

Dualschleife steigt auf 9.4 kΩ, was einen

Alarm auslöst. Wenn das Meldergehäuse

geöffnet wird, öffnet sich die

Sabotageschaltung und die Dualschleife wird

unterbrochen, was einen Sabotagealarm

auslöst.

Ein: „Aktiv-High“ stellt die standardmäßige

Steuerlogik mit Aktiv-High-Pegel zur Verfügung, um

die Eingänge für Gehtest und Scharf/Unscharf zu

steuern.

Aus: „Aktiv-Low“ stellt Aktiv-Low-Pegel zur

Verfügung, um die Eingänge für Gehtest und

Scharf/Unscharf zu steuern.

DIP-Schalter 2: Türgong

Siehe Abb. 12.

Der Melder kann die Gehrichtung von Personen

während der Tageszeit erkennen. Sie deaktivieren

diese Option durch Einstellen des Melders auf

„Gong aus“. Wenn der Türgong aktiviert ist, löst der

Melder einen Alarm aus, wenn eine Person sich

von rechts nach links oder von links nach rechts

durch die Erfassungvorhänge bewegt.

Hinweis: Wenn der Scharf/Unscharf-Anschluss

nicht verwendet wird und der Türgong aktiviert ist,

ist der Türgong sowohl während der Scharf- als

auch während der Unscharfschaltung (Tag/Nacht)

aktiviert.

DIP-Schalter 3: Gongrichtung

Siehe Abb. 13.

Ein: Alarm, wenn eine Person von links nach rechts

geht.

Aus: Alarm, wenn eine Person von rechts nach

links geht.

Die Ausrichtung (links oder rechts) legen Sie fest,

während Sie mit dem Rücken zum Melder stehen.

18 / 64 P/N 145797999-2 • REV B • ISS 19MAR12

Page 19

DIP-Schalter 4: LEDs

Ohne das Ausrichtungstool

Ein: Aktiviert ständig beide LEDs an dem Melder.

Aus: Beide LEDs werden durch den Eingang für

Gehtest und durch die Einstellung für

Scharf/Unscharf gesteuert.

Ausrichten des Erfassungsbereichs und Durchführung eines Gehtests für den Melder

Verwenden des VE710 Ausrichtungstools

Siehe Abb. 18 und 19.

1. Führen Sie das VE710 in den Unterrahmen ein,

wobei der Ein/Aus-Schalter in Richtung des

Bodens zeigt.

2. Schließen Sie es an den COM-Port an.

3. Schalten Sie das VE710 ein.

WARNUNG! Schauen Sie nicht in den

Laserstrahl.

Daher beträgt die Ausgabeleistung weniger als

1 mW. Der VE710-Laser ist durch IEC60825-1

als Klasse-2-Laser klassifiziert. Durch den

Augenschließreflex werden dauerhafte

Schäden am Auge vermieden.

4. Der Laserpunkt gibt die Produktausrichtung an

(Abbildung 18). Wenn dieser Punkt auf der

Wand vom Zentrum des gewünschten

Überwachungsbereichs 1 m über dem Boden

abweicht, lösen Sie die Befestigungsschrauben

des Gehäuseunterteils (Abbildung 4) und

verwenden die drei Einstellschrauben im

Unterteil, um ihn wieder am Zentrum

auszurichten, wie in Abbildung 19 gezeigt.

Wenn der Punkt richtig ausgerichtet ist, ziehen

Sie die Befestigungsschrauben des Unterteils

wieder an.

Siehe Abb. 19.

1. Setzen Sie die Spiegelabdeckungen ein, um

sicherzustellen, dass sich der Melder im EinVorhang-Modus befindet.

2. Stellen Sie J2 auf Ein und warten Sie, bis beide

LEDs erloschen sind.

3. Gehen Sie vor dem Melder mit normaler

Geschwindigkeit (ohne Pausen) und im

maximalen Abstand quer durch den

Erfassungsbereich. Wenn Sie in den

Vorhangbereich eintreten, beginnen beide

LEDs, gleichzeitig zu blinken.

Nachdem Sie den Vorhang durchquert haben,

gilt Folgendes:

a. Die rote LED ist EIN (Abb. 20, Position 1): in

diesem Fall ist die Ausrichtung OK.

b. Die roten und gelben LEDs blinken

gleichzeitig: in diesem Fall ist das Sichtfeld

eingeschränkt und nicht ausreichend, um

einen Alarm zu überprüfen.

Es gibt zwei Optionen:

• Wenn das Blinken in der Nähe des Endes

des Überwachungsbereichs begonnen hat,

müssen Sie den Erfassungsvorhang nach

links ausrichten (Abb. 20, Position 2).

• Wenn das Blinken in der Nähe des Anfangs

des Überwachungsbereichs begonnen hat,

müssen Sie den Erfassungsvorhang nach

rechts ausrichten (Abb. 20, Position 3).

Lösen Sie die Befestigungsschrauben des

Gehäuseunterteils (Abbildung 4) und

verwenden Sie die drei Einstellschrauben im

Unterteil, um den Vorhang wieder am Zentrum

auszurichten, wie in Abb. 20 gezeigt. Wenn der

Vorhang richtig ausgerichtet ist, ziehen Sie die

Befestigungsschrauben des Unterteils wieder

an.

5. Entfernen Sie das Ausrichtungswerkzeug und

setzen Sie die Abdeckung wieder ein.

6. Führen Sie den Gehtest durch. Stellen Sie

sicher, dass die rote LED nach dem Gehtest

eingeschaltet ist.

P/N 145797999-2 • REV B • ISS 19MAR12 19 / 64

4. Wenn die LEDs nicht blinken, befindet sich der

Vorhang außerhalb des Überwachungsbereichs

(Abb. 20, Position 4). Gehen Sie in kürzerem

Abstand quer durch den Strahl, um die

Erkennung nochmals zu testen.

5. Wiederholen Sie den Gehtest, um zu

bestätigen, dass der Melder richtig ausgerichtet

ist.

6. Stellen Sie J2 auf Aus.

Page 20

Hinweise

• Wenn CLM auf Ein eingestellt ist, ist der

Alarmausgang aktiviert.

• Es wird empfohlen, die Abdeckung während der

CLM-Gehtests auf den Melder aufzusetzen.

• Hinweise für VdS-Installationen: In VdSInstallationen muß ein Plombiersiegel über den

Deckel und Meldersockel geklebt werden

(Abbildung 10).

Die Plombiersiegel können unter der

Bestellnummer VS200 (50 Siegel pro Blatt)

bestellt werden.

Bestimmung des Melderstatus anhand der LEDs

Hinweis: Wenn Sie lediglich den Gehtest

aktivieren, wird dadurch der Alarmspeicher nicht

gelöscht. Wenn Sie das System nach einem Alarm

unscharfschalten, müssen Sie den Gehtest auf Ein

schalten. Wenn Sie den Gehtest auf Aus schalten,

wird eine Anzeige zu den gespeicherten Alarmen

erneut erscheinen. Nur wenn das Scharf/UnscharfSignal (CV) wieder an Anschluss 10 angelegt wird

(das heißt, wenn das System wieder

scharfgeschaltet wird), erfolgt ein Löschen des

Speichers, und die LEDs werden ausgeschaltet.

Um die Gehtest-LED ohne eine Steuerspannung zu

aktivieren, setzen Sie DIP-Schalter 4 in die Position

Ein. Setzen Sie nach dem Gehtest den DIPSchalter 4 in die Position Aus.

Tabelle 2: LED-Anzeige

Melderstatus

Spannung

angelegt

Alarm

Störung

Über-/

Unterspannung

= Ständig Ein = Normales Blinken (1 Hz)

Gelbe

LED

Rote

LED

Beschreibung

Blinkt abwechselnd 50

Sek. lang.

Während

Alarmzeitraum —

nominal 3 Sek.

Ständig ein.

Bis richtige Spannung

wiederhergestellt ist

Allgemeine Informationen

Alarmspeicher

Wenn mehrere Melder in einer einzelnen

Meldegruppe verwendet werden, verkabeln Sie die

Anschlussklemmen für Scharf/Unscharf und

Gehtest, wie in Abbildung 6 dargestellt.

Aktivieren/Deaktivieren der Gehtest-LED von

einem entfernten Standort (EMZ) aus

Siehe Abb. 6.

Trennen Sie die “CV-Steuerspannung” von

Anschluss 10 (Speicherung), und legen Sie sie

diese an den Anschluss 11 an. Die LED des

Melders blinkt, wenn sich das Alarmrelais öffnet

und schließt. Der Gehtest kann jetzt durchgeführt

werden.

Es wird empfohlen, in regelmäßigen Abständen

einen Gehtest für den Melder durchzuführen und

die Kommunikation mit der Einbruchmeldezentrale

zu überprüfen.

Einstellen des Alarmspeichers

Siehe Abb. 6.

Hinweis: Stellen Sie zuerst die geeignete aktive

Steuerspannung (Control Voltage, “CV”) mit dem

DIP-Schalter 1 ein.

Legen Sie die CV an Anschluss 10 an, wenn das

System scharfgeschaltet wird. Wenn das System

unscharfgeschaltet ist, trennen Sie die CV wieder.

Wenn während der Scharfschaltperiode ein Alarm

auftritt, weist eine blinkende rote LED auf die

Melder hin, die den Alarm ausgelöst haben. Wenn

Sie die CV erneut anlegen (das System erneut

scharfschalten), werden LED-Anzeige und

Speicher zurückgesetzt.

Auswählen des Erfassungsbereichs

Siehe Abb. 21 und 22.

Der Erfassungsbereich kann geändert werden, um

spezifischen Anforderungen Rechnung zu tragen.

Verwenden Sie hierzu wie gezeigt die (beigefügten)

Spiegelaufkleber. Nicht verwendete Vorhänge, die

in Richtung von Wänden oder Fenstern zeigen,

welche sich in der unmittelbaren Nähe des Melders

befinden, sollten abgedeckt werden.

Warnung: Wenn Sie die Aufkleber entfernen, kann

dadurch die Spiegeloberfläche beschädigt werden!

20 / 64 P/N 145797999-2 • REV B • ISS 19MAR12

Page 21

Abdecken der Vorhänge

Siehe Abb. 23.

Die Spiegelabdeckungen sind werkseitig auf dem

Spiegel angebracht. Um die Abdeckung zu

entfernen, entfernen Sie zunächst den inneren Teil

des Melders. Heben Sie dann den unteren Teil der

Abdeckung hoch und bewegen Sie den oberen Teil

hin und her, um ihn zu lockern. Wenn eine

Erfassung mit hoher Reichweite nicht erforderlich

ist (>20 m), entfernen Sie den Spiegel für hohe

Reichweite (Abb. 24).

Abreiß-und Deckelkontaktt

Der Melder verfügt sowohl über einen

Deckelkontakt für die Gehäuseöffnung als auch

über einen Abreißkontakt (erfüllt EN 50131-2-2).

Es ist wichtig, die Schraube in Abbildung 4 zu

verwenden, um den Abreißkontakt verwenden zu

können.

Bei der Eckmontage kann der Abreisskontakt nicht

aktiviert bzw. verwendet werden.

SB01 Dreh-Befestigungshalterung (optional)

Wenn es nicht möglich ist, den Melder auf eine

Wand zu montieren, verwenden Sie den SB01, um

ihn an der Decke zu befestigen.

Unscharf/Tagbetrieb. Der Melder löst kein

Alarmsignal und keine Meldung aus, wenn er

eine Person im Erfassungsbereich detektiert.

Vorhänge. Eine vertikale kontinuierliche Schicht

von Erfassungszonen. Der PIR-Melder kann

Bewegung nur innerhalb der Vorhänge

erkennen, nicht in den Räumen zwischen

ihnen.

Vorhang-Lokalisierung-Modus (CLM). Eine

Funktion des Melders, die die Kanten des

Vorhangs genau identifiziert.

Technische Daten

Versorgungsspannung

Spitze/SpitzeBrummspannung

Stromaufnahme:

Normalbetrieb 11 mA

Alarm 9 mA

maximal 15 mA

Montagehöhe 1,8 bis 3,0 m

Erfassungsgeschwindigkeitsbereich

Alarmausgang

9 bis 15 V Gleichspannung

(12 V nominal)

2 V (bei 12 V

Gleichspannung)

20 cm/Sek bis 3 m/Sek

80 mA bei 30 V

Gleichspannung max.

Siehe Abb. 26.

Glossar

Alarmspeicher. Ein Speichermedium innerhalb des

Melders, das vom Melder erzeugte Signale

aufzeichnen kann.

Gehtest. Eine vom Betreiber oder Errichter

vorgenommene Betriebsart, mit der überprüft

wird, ob der Melder innerhalb seines

Erfassungsbereichs Bewegungen korrekt

detektiert.

Scharf/Nachtbetrieb. Der Melder erzeugt ein

Alarmsignal oder eine Meldung, wenn er durch

die Bewegung einer Person im

Erfassungbereich ausgelöst wird .

Selbsttest. Der Detektor selbst überwacht den

Sensor und den dazugehörenden internen

Schaltkreis für die Signalverarbeitung.

Technischer Fehler (TF). Das Fehlersignal oder die

Fehlermeldung, die auf dem AM-Relais erzeugt

wird, wenn in dem Melder ein Fehler cvorliegt.

Sabotageausgang

Störungsausgang

Alarmdauer 3 Sek

Meldereinschaltzeit 50 Sek

Betriebstemperatur −10°C bis +55°C

Relative Luftfeuchtigkeit Max. 95%

Abmessungen (H x B x T) 175 x 93 x 66 mm

Gewicht 275 g

Anzahl der Vorhänge 11 bei 20 m 1 bei 60 m

Erfassungswinkel 86° bei 20 m 3° bei 60 m

IP/IK-Einstufung IP30 IK02

80 mA bei 30 V

Gleichspannung max.

80 mA bei 30 V

Gleichspannung max.

P/N 145797999-2 • REV B • ISS 19MAR12 21 / 64

Page 22

Rechtliche Hinweise

A

Hersteller

UTC Fire & Security Americas

Corporation, Inc.

1275 Red Fox Rd., Arden Hills, MN

55112-6943, USA

Autorisierter EUHerstellungsrepräsentant:

UTC Fire & Security B.V.

Kelvinstraat 7, 6003 DH Weert,

Niederlande

ES: Instrucciones de instalación

Introducción

Los VE735 y VE736 son detectores PIR de

movimiento. Ambos poseen una tecnología PIR

verificada y patentada.

Sugerencias de instalación

Zertifizierung

VdS VdS-Anerkennung: G 106026

Umweltklasse: Geprüft nach VdS

Umweltklasse 2

1999/5/EC (R&TTE): Hiermit erklärt UTC

Fire & Security, dass diese Vorrichtung

gemäß den wesentlichen Anforderungen

und anderen relevanten Bestimmungen

der Direktive 1999/5/EC entspricht.

2002/96/EC (WEEE): Produkte die mit

diesem Symbol gekennzeichnet sind,

dürfen nicht als unsortierter städtischer

bfall in der europäischen Union entsorgt

werden. Für die korrekte

Wiederverwertung bringen Sie dieses

Produkt zu Ihrem lokalen Lieferanten

nach dem Kauf der gleichwertigen neuen

Ausrüstung zurück, oder entsorgen Sie

das Produkt an den gekennzeichneten

Sammelstellen. Weitere Informationen

hierzu finden Sie auf der folgenden

Website: www.recyclethis.info.

La tecnología de este detector resiste riesgos de

falsas alarmas. Sin embargo, debe evitar

potenciales causas de inestabilidad, como:

• Luz solar directa en el detector

• Fuentes de calor dentro del campo de visión

• Corrientes de aire intensas en el detector

• Animales grandes en el campo de visión

• Oscurecer el campo de visión del detector con

objetos de gran tamaño, como por ejemplo

mobiliario

Instalar el detector de tal manera que el

movimiento del intruso cruce el campo de visión

(ver ejemplo en la figura 21, elemento 1). Esta es la

mejor dirección de detección de los detectores

infrarojos.

Montaje del detector

1. Levante la tapa de la carcasa (figura 1).

2. Usando un destornillador, abra el detector con

cuidado (figura 2).

3. Retire la pieza interior (figura 3).

Kontaktinformation

4. Fije la base al muro entre 1.8 y 3 m (5.9 y

www.utcfireandsecurity.com oder

www.interlogix.com

Kontaktinformationen für den Kundendienst finden

Sie auf www.interlogix.com/customer-support

22 / 64 P/N 145797999-2 • REV B • ISS 19MAR12

9.8 ft.) de altura. Para montaje en superficie,

utilice un mínimo de dos tornillos, al menos uno

en la posición A y otro en la posición B. Para

montaje en esquina, utilice tornillos en las

posiciones C ó D (figuras 4 y 5).

Nota: no todas las posiciones de los tornillos

tienen tamper de pared. No se muestra ninguna

posición de pared en el cuadro de advertencia.

5. Conecte los cables del detector. Consulte las

figuras 7 y 8.

Nota: todas las conexiones se deben realizar

de acuerdo con el National Electrical Code

(Código nacional de electricidad), NFPA 70

estadounidense y las normas de seguridad

Loading...

Loading...