Page 1

TruVision

Camera Installation

Guide

P/N 1073188-EN • REV F • ISS 19OCT17

Series 3 IP

Page 2

Copyright

Trademarks and

patents

Manufacturer

Certification

© 2017 United Technologies Corporat ion.

Interlogix is part of UTC Climate, Controls & Sec urity, a

unit of United Technologies Corporati on. All rights

reserved.

Trade names used in this document may be trademarks or

registered trademarks of the manufactur ers or vendors of

the respective products.

Interlogix

2955 Red Hill Avenue, Costa Mesa, CA 92626-5923, USA

Authorized EU manufacturing representat ive:

UTC Fire & Security B.V.

Kelvinstraat 7, 6003 DH Weert, The Net herlands

FCC compliance

FCC conditions

ACMA compliance

Canada

Class A: This equipment has been tested and found to

comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC Rules. These limi ts are designed to

provide reasonable protection against harmf ul interference

when the equipment is operated in a comme rcial

environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not i nstalled and

used in accordance with the instruction m anual, may cause

harmful interference to radio communi cations. Operation of

this equipment in a residential area is likely to cause

harmful interference in which case the user will be requi red

to correct the interference at his own expense.

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditi ons:

(1) This device may not cause harmful interfer ence.

(2) This Device must accept any int erference received,

including interferenc e that may cause undesired operation.

Notice! This is a Class A product. In a domestic

environment this product may cause radio interference in

which case the user may be required to take adequate

measures.

This Class A digital apparatus complies with CAN I CES003 (A)/NMB-3 (A).

Cet appareil numérique de la classe A est conform e à la

norme CAN ICES-003 (A)/NMB-3 (A).

Page 3

European Union

directives

This product and - if applicable - the supplied accessories

too are marked with "CE" and comply therefore with t he

applicable harmonized European standards l isted under

the EMC Directive 2014/30/EU, the RoHS Directive

2011/65/EU.

2012/19/EU (WEEE directi ve): Products marked with this

symbol cannot be disposed of as unsorted munici pal waste

in the European Union. For proper recycling, return this

product to your local supplier upon the purchase of

equivalent new equipment, or dispose of it at designat ed

collection points. For more informati on see:

www.recyclethis.info

2013/56/EU and 2006/66/EC (battery directi ve): This

product contains a battery that cannot be disposed of as

unsorted municipal waste in the European Union. See the

product documentation f or specific battery information. The

battery is marked wit h this symbol, which may include

lettering to indicate cadmi um (Cd), lead (Pb), or mercury

(Hg). For proper recycling, r eturn the battery to your

supplier or to a designated collection poi nt. For more

information see: www.recyclethi s.info.

Page 4

Product warnings and

disclaimers

THESE PRODUCTS ARE INTENDED FOR SALE TO,

AND INSTALLATION BY, AN EXPERIENCED SECURITY

PROFESSIONAL. UTC FIRE & SECURITY CANNOT

PROVIDE ANY ASSURANCE THAT ANY PERSON OR

ENTITY BUYING ITS PRODUCTS, INCLUDING ANY

“AUTHORIZED DEALER”, IS PROPERLY TRAINED OR

EXPERIENCED TO CORRECTLY INSTALL SECURITY

RELATED PRODUCTS.

For more information on warranty disclaimer s and product

safety information, please check

www.firesecurityproducts.com or scan the following code:

Contact information

and manuals

For contact information go to: www.interl ogix.com or

www.firesecurityproducts.com

To get translations for this and other product manual s go

to: www.firesecurityproducts.c om

Page 5

Content

Introduction 3

Product overview 3

Installation 5

Installation environment 5

Package contents 6

Cable requirements 22

Camera description 22

Setting up the camera 30

Accessing the SD card 30

Mounting the IP fixed lens bullet camera 31

Mounting the IP VF lens bullet camera and the IP motorized

lens bullet camera (without the supplied back box) 32

Mounting the IP VF lens dome camera and IP motorized lens

dome camera 38

Mounting the IP fixed lens dome camera 43

Mounting the IP wedge dome camera 47

Mounting the IP turret camera 50

Using the camera with a recorder 55

Using the camera with TruVision Navigator 55

Specifications 56

TruVision IP fixed lens bullet cameras 56

TruVision IP VF lens bullet cameras 56

TruVision IP motorized lens bullet cameras 57

TruVision IP VF lens dome cameras 57

TruVision IP motorized lens dome cameras 58

Installation Guide 1

Page 6

TruVision IP fixed lens dome 59

TruVision IP wedge cameras 59

TruVision IP turret cameras 60

Pin definitions 61

2 Installation Guide

Page 7

Introduction

Product overview

This is the installation guide for TruVision Series 3 IP camera

models:

IP fixed lens bullet camera:

TVB-5301 (2MPX Bullet, 4 mm lens)

TVB-5302 (4MPX Bullet, 4 mm lens)

IP VF lens bullet camera:

TVB-5303 (2MPX Bullet, 2.8 to 12 mm VF lens)

TVB-5304 (4MPX Bullet, 2.8 to 12 mm VF lens)

IP motorized lens bullet camera:

TVB-5305 (2MPX Bullet, 2.8-12 mm VF motorized lens)

TVB-5306 (4MPX Bullet, 2.8-12 mm VF motorized lens)

IP fixed lens dome camera:

TVD-5301 (2MPX Plastic Dome, 2.8 mm lens)

TVD-5302 (4MPX Plastic Dome, 2.8 mm lens)

IP VF lens dome camera:

TVD-5303 (2MPX VF Dome)

TVD-5304 (4MPX VF Dome)

Installation Guide 3

Page 8

IP motorized lens dome camera:

TVD-5305 (2MPX Dome, 2.8-12 mm VF Motorized lens)

TVD-5306 (4MPX Dome, 2.8-12 mm VF Motorized lens)

IP wedge camera:

TVW-5301 (2MPX W edge, 2.0 mm lens, Gray)

TVW-5302 (2MPX Wedge, 2.8 mm lens, Gray)

TVW-5303 (2MPX W edge, 2.8 mm lens, Whi te)

TVW-5304 (2MPX W edge, 2.8 mm lens, Black)

TVW-5305 (4MPX W edge, 2.8 mm lens, Gray)

IP turret camera:

TVT-5301 (2MPX Turret, 2.8 mm lens, Gray)

TVT-5302 (2MPX Turret, 2.8 mm lens, White)

TVT-5303 (2MPX Turret, 2.8 mm lens, Black)

TVT-5304 (4MPX Turret, 2.8 mm lens, Gray)

TVT-5305 (4MPX Turret, 2.8 mm lens, Whi te)

TVT-5306 (4MPX Turret, 2.8 mm lens, Black)

TVT-5307 (4MPX Turret, 4.0 mm lens, Whi te)

4 Installation Guide

Page 9

Installation

This section provides information on how to install the

cameras.

Installation environment

When installing your product, consider these factors:

• Electrical: Install electrical wiring carefully. It should be

done by qualified service personnel. Always use a proper

PoE switch or a 12 VDC UL listed Class 2 or CE certified

power supply to power the camera. Do not overl oad the

power cord or adapter.

• Ventilation: Ensure that the location planned for the

installation of the camera is well ventilated.

• Temperature: Do not operate the camera beyond the

specified temperature, humidity or power source ratings.

The operating temperature of the camera is between -30

to +60°C (-22 to 140°F). Humidity is below 90%.

• Moisture: Do not expose the camera to rain or moisture,

or try to operate it in wet areas. Turn the power off

immediately if the camera is wet and ask a qualified

service person for servicing. Moisture can damage the

camera and also create the danger of electri c shock.

• Servicing: Do not attempt to service this camera

yourself. Any attempt to dismantle this product will

invalidate the warranty and may also result in serious

injury. Refer all servicing to qualified service personnel.

• Cleaning: Do not touch the sensor modules with fingers.

If cleaning is necessary, use a clean cloth with some

ethanol and wipe the camera gently. If the camera will not

Installation Guide 5

Page 10

be used for an extended period of time, put on the lens

Drill Template

Screw hole All: for integrative bracket

cap to protect the sensors from dirt.

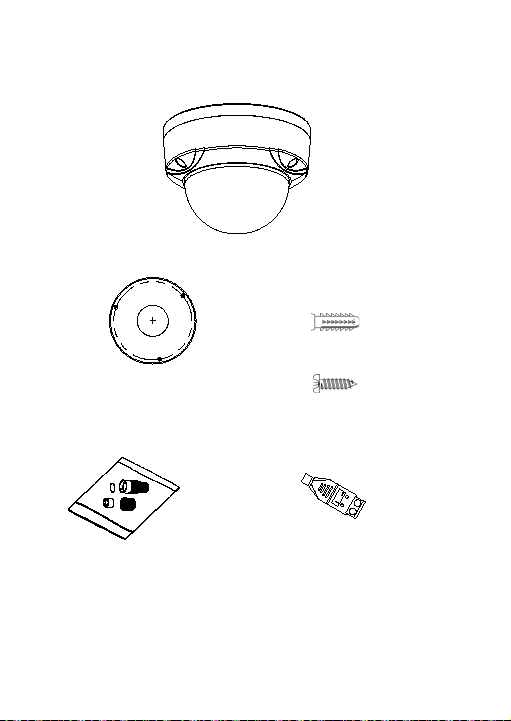

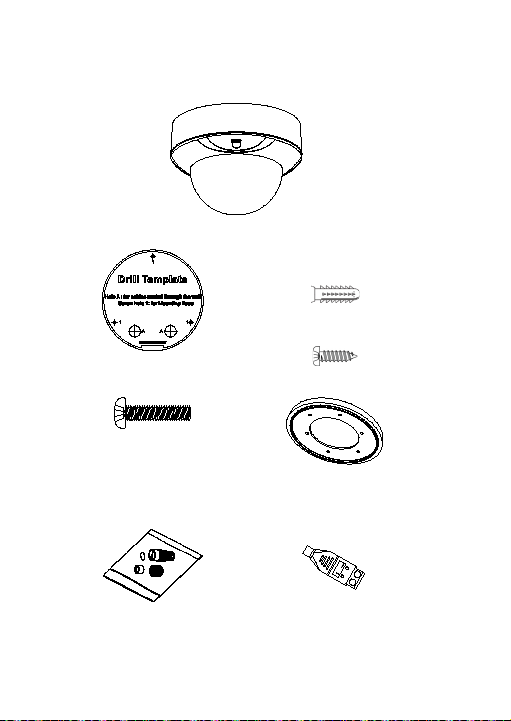

Package contents

Check the package and contents for visible damage. If any

components are damaged or missing, do not attempt to use

the unit; contact the supplier immediately. If the unit is

returned, it must be shipped back in its original packaging.

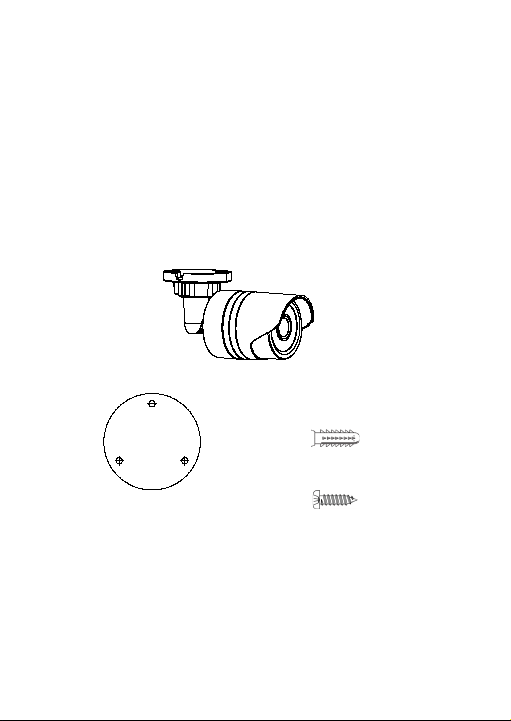

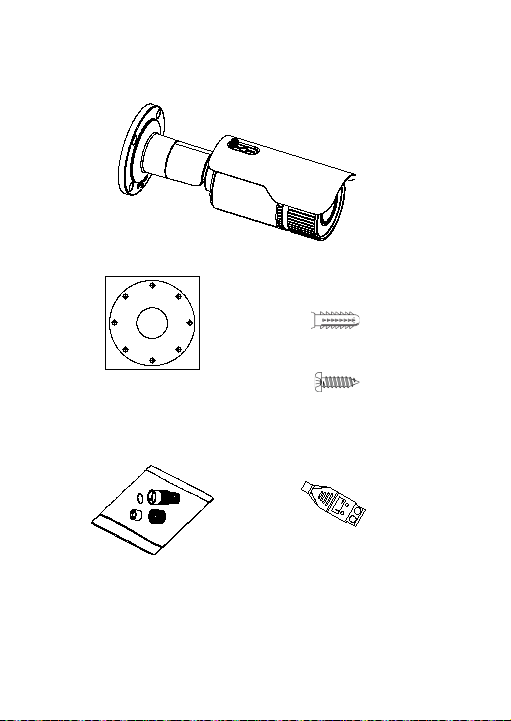

IP fixed lens bullet camera

Camera:

Drill template:

Screws:

Drywall anchor

7.5 × 24.5 mm (3 pcs)

Screw

M4 × 25 mm (3 pcs)

6 Installation Guide

Page 11

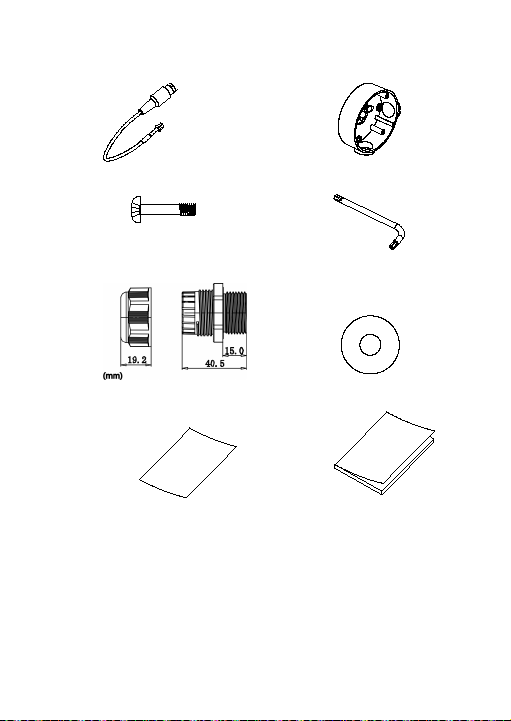

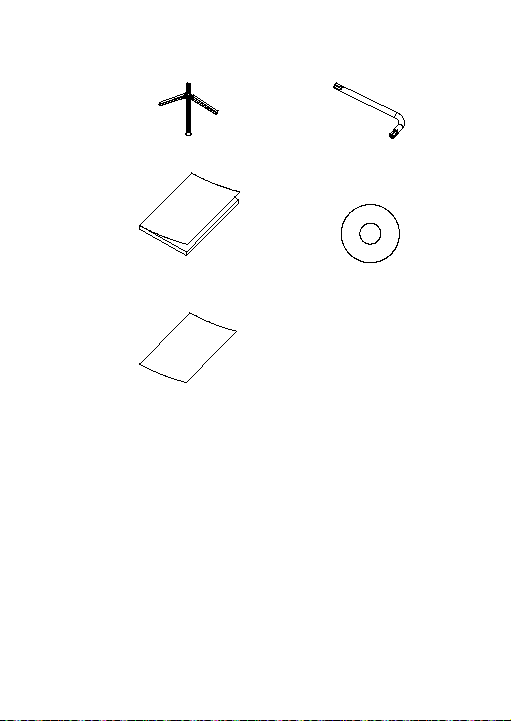

Water joint: Provides water

resistance to network cable

connector.

12 VDC connector:

Two terminal connector

with positive and

negative indicators.

Installation manual:

Equipment and Battery

Disposal sheets:

CD with manuals and

TruVision Device

Manager:

Installation Guide 7

Page 12

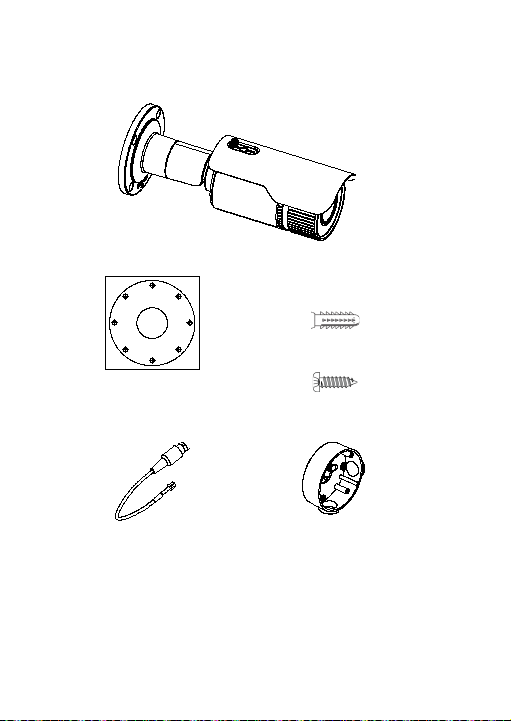

IP VF lens bullet camera

Hole A: for cables routed through the wall

A

Drill Template

1

1

1

2

2

2

2

Screw hole 1: for integrative bracket

Screw hole 2: for conduit back box

Camera:

Drill template:

Screws:

Drywall anchor

7.5 × 24.5 mm (4 pcs)

Screw

Water joint: Provides water

resistance to network cable

connector.

M4 × 25 mm (4 pcs)

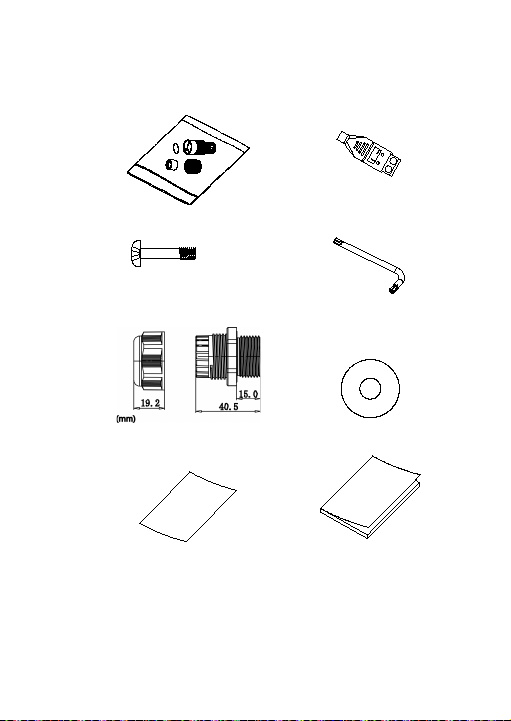

12 VDC connector:

Two terminal connector

with positive and

negative indicators.

8 Installation Guide

Page 13

Video test cable:

Screws: M4.8 × 8 (4 pcs)

Back box:

Torx wrench:

Plastic G3/4 cable adapter CD with manuals and

TruVision Device

Manager:

Equipment and Battery

Disposal sheets:

Installation Guide 9

Installation manual:

Page 14

IP motorized lens bullet camera

Hole A: for cables routed through the wall

A

Drill Template

1

1

1

2

2

2

2

Screw hole 1: for integrative bracket

Screw hole 2: for conduit back box

Camera:

Drill template:

Screws:

Drywall anchor

7.5 × 24.5 mm (4 pcs)

Screw

Video test cable:

M4 × 25 mm (4 pcs)

Back box:

10 Installation Guide

Page 15

Water joint: Provides water

resistance to network cable

connector.

12 VDC connector:

Two terminal connector

with positive and

negative indicators.

Screws: M4.8 × 8 (4 pcs)

Torx wrench:

Plastic G3/4 cable adapter CD with manuals and

TruVision Device

Manager:

Equipment and Battery

Disposal sheets:

Installation Guide 11

Installation manual:

Page 16

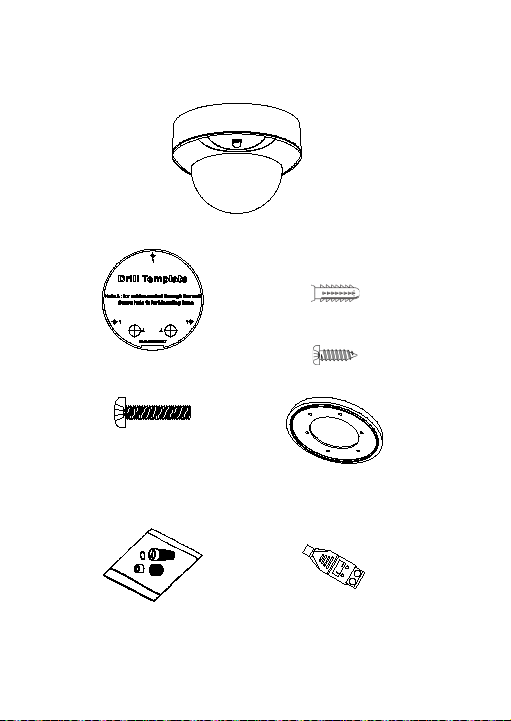

IP fixed lens dome camera

Drill Template

Hole A: for cables routed through the ceiling

screw hole 1: for Mounting Base

1

1

1

A

Camera:

Template:

Water joint: Provides water

resistance to network cable

connector.

Screws:

Drywall anchor

7.5 × 24.5 mm (3 pcs)

Screw

M4 × 25 mm (3 pcs)

12 VDC connector:

Two terminal connector

with positive and

negative indicators.

12 Installation Guide

Page 17

Screws: 4 × 75 mm (3 pcs)

Torx wrench:

Installation manual:

CD with manuals and

TruVision Device

Manager:

Equipment and Battery

Disposal sheets:

Installation Guide 13

Page 18

IP VF lens dome camera

Camera:

Drill template:

Screws: M4 × 9 (3 pcs)

Water joint: Provides water

resistance to network cable

connector.

Screws:

Drywall anchor

7.5 × 24.5 mm (4 pcs)

Screw

M4 × 25 mm (4 pcs)

Mounting adaptor plate:

12 VDC connector:

Two terminal connector

with positive and

negative indicators.

14 Installation Guide

Page 19

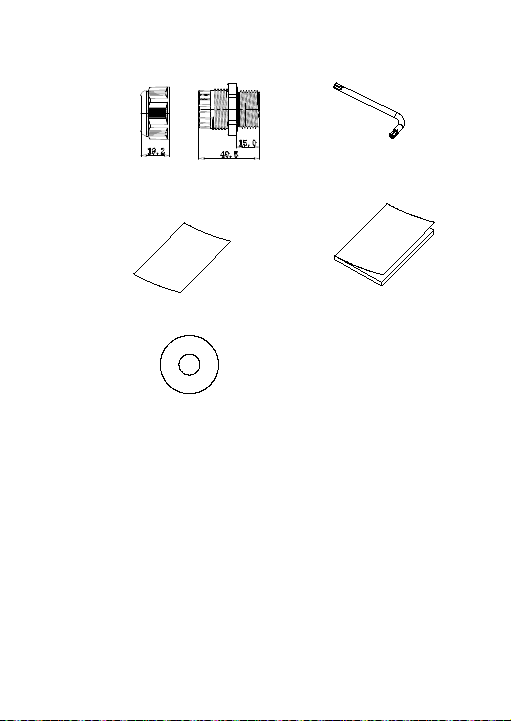

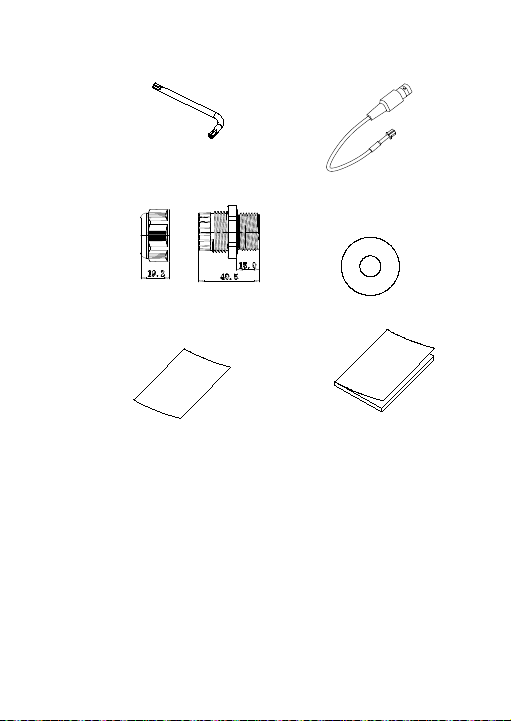

Plastic G3/4 cable adapter:

(mm)

Equipment and Battery

Disposal sheets:

CD with manuals and

TruVision Device Manager:

Torx wrench:

Installation manual:

Installation Guide 15

Page 20

IP motorized lens dome camera

Camera:

Drill template:

Screws:

Screws: M4 × 9 (3 pcs)

Mounting adaptor plate:

Water joint: Provides water

resistance to network cable

connector.

12 VDC connector:

Two terminal connector

with positive and

negative indicators.

Drywall anchor

7.5 × 24.5 mm (4 pcs)

Screw

M4 × 25 mm (4 pcs)

16 Installation Guide

Page 21

Torx wrench:

(mm)

Plastic G3/4 cable adapter:

Video test cable:

CD with manuals and

TruVision Device

Manager:

Equipment and Battery

Disposal sheets:

Installation manual:

Installation Guide 17

Page 22

IP wedge camera

Camera:

Camera drill template:

Adapter plate drill

template:

Water joint: Provides water

resistance to network cable

connector.

12 VDC connector:

Two terminal connector

with positive and negative

indicators.

Lens adjustment tool:

Adapter plate:

18 Installation Guide

Page 23

Screws: M4 × 8 (2 pcs)

Screws:

Drywall anchor

7.5 × 24.5 mm (3 pcs)

Screw

M4 × 25 mm (3 pcs)

CD with Configuration

manual and TruVision Device

Finder:

Torx wrench:

Installation manual:

Equipment and Battery

Disposal sheets:

Installation Guide 19

Page 24

IP turret camera

Camera:

Water joint: Provides water

resistance to network cable

connector.

Camera drill template:

Screws:

Drywall anchor

7.5 × 24.5 mm (3 pcs)

Screw

M4 × 25 mm (3 pcs)

20 Installation Guide

12 VDC connector: 2terminal connector

with positive and

negative indicators.

Adapter plate:

Screw PM6-32 × 10

(4 pcs, used to attach the

turret camera to a 2

Gang electrical box):

Page 25

Screw KM4 × 8 (4 pcs, used

to attach the adapter to the

brackets)

CD with Configuration

manual and TruVision Device

Finder:

Screw PM4 × 8 (3pcs):

Installation manual:

Equipment and Battery

Disposal sheets:

CAUTION: Use direct plug-in UL listed power supplies marked

Class 2/CE certified or LPS (limited power source) of the

required output rating as listed on the unit.

CAUTION: Risk of explosion if the battery is replaced by an

incorrect type. Dispose of used batteries according to the

instructions.

Installation Guide 21

Page 26

Cable requirements

Su

Ethernet RJ45 PoE port

For proper operation, adhere to the following cable and power

requirements for the cameras. Category 5 cabling or better is

recommended. All network cabling must be installed according

to applicable codes and regulations.

Camera description

Figure 1: IP fixed lens bullet camera

Adjustable

bracket

nshield

Housing

Grounding screw

22 Installation Guide

12 VDC power

Reset button

Page 27

Figure 2: IP VF bullet camera

8. SD/SDHC/SDXC slot

1. Sunshield

2. Front cover

3. Lens adjustment

4. IR LEDs

5. Lens

6. Waterproof film

7. Base

9. Reset button

10. Audio I/O

11. Alarm I/O

12. 12 VDC power

13. Ethernet RJ45 PoE port

14. Aux power output

(12 VDC, 50 mA)

15. Back box

Installation Guide 23

Page 28

Figure 3: IP motorized lens bullet camera

8. SD/SDHC/SDXC slot

1. Sunshield

2. Front cover

3. Lens adjustment

4. IR LEDs

5. Lens

6. Waterproof film

7. Base

9. Reset button

10. Audio I/O

11. Alarm I/O

12. 12 VDC power

13. Ethernet RJ45 PoE port

14. Back box

24 Installation Guide

Page 29

Figure 4: IP VF lens dome c amera

(BNC)

1. Housing cover

2. Dome liner

3. Lens

4. Mounting plate adapter

5. Reset button

6. SD/SDHC/SDXC slot

7. Aux power output

(12 VDC, 50 mA)

8. Ethernet RJ45 PoE port

9. 12 VDC power

10. Audio I/O

11. Alarm I/O

12. Analog video output

Installation Guide 25

Page 30

Figure 5: IP motorized lens dome camera

6. SD/SDHC/SDXC slot

1. Housing cover

2. Dome liner

3. Lens

4. Mounting plate adapter

5. Reset button

7. Video test cable

connection

8. Ethernet RJ45 PoE port

9. 12 VDC power

10. Audio I/O

11. Alarm I/O

26 Installation Guide

Page 31

Figure 6: IP fixed lens dome camera

13. 12 VDC power

1. Base

2. IR LEDs

3. Lens

4. Dome liner

5. Housing cover

6. SD/SDHC/SDXC slot

7. Reset button

8. Analog video output

(BNC)

9. Ethernet RJ45 PoE port

10. Alarm I/O

11. Audio I/O

12. Aux power output

(12 VDC, 50 mA)

Installation Guide 27

Page 32

Figure 7: IP wedge camera

5. 12 VDC power

1. Housing cover

2. Lens

3. SD/SDHC/SDXC slot

4. Ethernet RJ45 PoE port

6. Audio output and alarm

I/O

7. Reset button

8. Microphone

9. Adapter plate

28 Installation Guide

Page 33

Figure 8: IP turret camera

3. Base

6. Ethernet RJ45 PoE port

6

5

4

1. Trim ring

2. Housing

Installation Guide 29

4. Lens assembly

5. 12 VDC power

Page 34

Setting up the camera

Note: If the light source where the camera is installed

experiences rapid, wide variations in lighting, the camera may

not operate as intended.

To quickly put the cam era into operation:

1. Prepare the mounting surface.

2. Mount the camera on the mounting surface using the

appropriate hardware.

3. Set up the camera’s network and streaming parameters

so that the camera can be controlled over the network.

For further information, please refer to the “TruVision IP

Series 3 IP Camera Configuration Manual”.

4. Program the camera to suit its location. For further

information, please refer to the “TruVision IP Series 3 IP

Camera Configuration Manual”.

Accessing the SD card

Insert a Micro SD card with up to 128GB capacity for l ocal

storage as a backup in case, for example, the network fails

(see Figure 2 on page 23). The SD car d is not supplied with

the camera.

For the IP VF lens dome and IP motorized dome cameras,

point the lens vertically upwards to access the SD card slot.

For the IP VF bullet and IP motorized bullet cameras, remove

the sunshield and open the front cover to access the SD card

slot.

Video and log files stored on the Micro SD card can only be

accessed via the web browser.

30 Installation Guide

Page 35

Note: There is no Micro SD card slot in the mini fixed lens

Drill Template

Screw hole All: for integrative bracket

bullet and turret cameras.

Mounting the IP fixed lens bullet camera

Mount the camera on a ceiling or wall.

To mount the IP fixed lens bullet camera:

1. Use the supplied template to mark out the mounti ng area.

If you need to route the cables from the camera base, cut

out a cable access hole in the mounting surface.

2. Secure the mounting base to the ceiling or wall using the

three mounti ng screws and drywall anchors.

Installation Guide 31

Page 36

3. Loosen the large nut at the base of the mounting bracket

0°~360°

0°~90°

0°~360°

to adjust the camera’s viewing angle.

Pan direction: 0 to 360° adjustable

Tilt direction: 0 to 90° adjustable

Rotate direction: 0 to 360° adjustable

4. Adjust the lens to the desired surveillance angle. Tighten

the adjustable nuts to complete the installation.

Mounting the IP VF lens bullet camera and the IP motorized lens bullet camera (without the supplied back box)

To mount the IP VF lens bullet camera to a surface:

1. Use the supplied template to mark out the mounting area.

Drill mounti ng holes in the surface using the holes

labelled number “1” on the drill template.

32 Installation Guide

Page 37

2. To route the cable harness through the mounti ng surface,

cut a cable access hole in the mounting surface,

referencing the letter “A” on the drill template. Skip this

step if you want to route the cables on the surface.

3. Secure the camera to the surface with the four mounting

screws and drywall anchors.

Installation Guide 33

Page 38

To install the SD card:

1. Rotate the screw that secures the sunshield

counterclockwise to loosen it. Slide the sun shield so that

the hole in the sunshield lines up with the screw head.

2. Remove the sun shield. Remove the lens cover by

rotating it counterclockwise.

34 Installation Guide

Page 39

3. Insert the SD card in the SD card slot.

4. Reinstall the lens cover by rotating the assembly

clockwise. Reinstall the sunshield.

Installation Guide 35

Page 40

5. Rotate the sunshield screw clockwise to tighten it.

6. To ensure that the camera maintains its IP66 rating,

when rotating the lens cover clockwise align the red bar

on the label of the lens cover with red bar on the l abel

that is located on the camera housing.

36 Installation Guide

Page 41

To mount the IP VF lens bullet camera and the IP

Motorized lens bullet camera with a back box:

1. Use the supplied template to mark out the mounting area.

Drill mounting holes in the surface using the holes

labeled number “2” on the drill template.

2. To route the cable harness through the mounti ng surface,

cut a cable access hole in the mounting surface,

referencing the letter “A” on the drill template. Skip this

step if you want to route the cables on the surface.

3. Secure the back box to the wall using the mounti ng

hardware provided.

4. Route the cables of the camera.

5. Hook the camera to the back box using the safety

lanyard.

6. Secure the camera to the back box with the four M4 x 9

screws.

Installation Guide 37

Page 42

Mounting the IP VF lens dome camera and IP motorized lens dome camera

Note: For planning purposes, there are several cable routing

options available:

Route the interconnect cables through the mounting

surface, straight out the back of the dome.

– Or –

Route the interconnect cables through the side access

hole of the dome camera housing. A G3/4 cable adapter

is provided

– Or –

Use the mounting adapter plate to mount the dome on a

single or double gang electrical box.

38 Installation Guide

Page 43

To mount the IP VF lens dome camera and the IP

motorized lens dome camera on a surface:

1. Loosen the three Torx screws at the edge of the dome

housing using the supplied Torx wrench.

Torx screw

2. Remove the dome housi ng and then remove the black

plastic inner l iner.

3. Use the supplied template to mark out the mounting area

of the dome camera. Depending on how you want to

route the interconnect cables, route them out of t he side

of the dome housing or through the mounting surface.

Installation Guide 39

Page 44

Drill the three screw holes on the ceiling in the mounting

surface using with the supplied drill template. Use

number “1” as reference.

4. To route the cable harness through the mounti ng surface,

cut a cable access hole in the mounting surface,

referencing the letter “A” on the drill template. Skip this

step if you want to route the cables on the surface.

5. Attach the camera to the mounting surface. Sec ure the

camera with the supplied screws and anchors, as show n

below.

40 Installation Guide

Page 45

6. Connect the appropriate cables.

To mount the IP VF lens dome camera and the IP

Motorized lens dome camera on a single or double

gang electrical box:

1. Follow steps 1 to 3 in the section above, “To mount the IP

VF lens dome camera and the IP motorized l ens dome

camera on a sur face”.

2. Install the mounting plate adapter to a singl e gang

electrical box referencing number “2” on the adapter

plate, or to a double gang box referencing number “1” on

the adapter plate.

Installation Guide 41

Page 46

3. Route the cables through the center of the adapter plate

and connect the appropriate cables inside the electrical

box.

4. Attach the dome to the adapter plate.

5. Connect the video output connector to the monitor.

Connect the power connector to the power supply.

6. Adjust the image and focus.

a) Three-axis adjustment.

View the camera image using the monitor. Rotate

the lens assembly (see image below) to adjust the

panning position of the camera. Move the assembly

up and down to adjust the tilt position of the camera.

Rotate the inner lens assembly to obtain the desired

surveillance angle.

b) Zoom and focus adjustment.

Loosen the zoom lever and move the lever between

T(Tele) and W(Wide) to obtain the appropriate angle

of view.

c) Tighten the zoom lever.

Loosen the focus lever and move the lever between

F(Far) and N(Near) to obtain the optimum focus.

Tighten the focus lever.

42 Installation Guide

Page 47

Tilting Rotation

Rotation

Mounting the IP fixed lens dome camera

To mount the IP fixed lens dome camera on a surface:

1. Use the supplied template to mark out the mounti ng area.

Drill mounting holes in the surface using the holes

labeled number “1” on the drill template.

To route the cable harness through the mounti ng surface,

cut a cable access hole in the mounting surface,

referencing the letter “A” on the drill template. Skip this

step if you want to route the cables on the surface.

Installation Guide 43

Page 48

Drill Template

Hole A: for cables routed through the ceiling

screw hole 1: for Mounting Base

1

1

1

A

2. Using the supplied Torx wrench, loosen the screws to

remove the dome housi ng.

3. Attach the dome on the mounting surface using the

supplied hardware.

44 Installation Guide

Page 49

Note: If required, route cables through the si de opening

of the mounting base.

4. Loosen the tilt adjust screws (see image below) and

adjust the tilt position of the lens assembly within a range

of 75 degrees. Retighten the tilt adj ust screws.

Rotate the dome liner to adjust the pan posi tion within a

range of 355 degrees. Rotate the lens assembly (0 to

355°) to obtain the desired surveillance angle.

Installation Guide 45

Page 50

Tilt adjust screw

5. (Optional) If using a micro SD card (not included):

To remove the SD card, push the micro SD card forward.

The micro SD card will spring out.

6. Re-attach the dome housi ng and tighten the Torx screws.

46 Installation Guide

Page 51

Mounting the IP wedge dome camera

To mount the IP wedge dome camera on a surface:

1. Use the supplied template (supplied) to mark out the

mounting area. Drill mounting holes in the surface using

the holes labeled number “1” on the drill template.

To route the cable harness through the mounti ng surface,

cut a cable access hole in the mounting surface,

referencing the letter “A” on the drill template. Skip this

step if you want to route the cables on the surface.

2. Secure the adapter plate to the mounting surface using

the drill template (optional).

Installation Guide 47

Page 52

Note: If required, remove the knockout (A) on the side of

the adapter plate to allow for cable access.

3. Loosen the Torx screws with a Torx wrench (supplied) to

remove the dome housing.

4. Attach the camera base to the adapter plate or directly to

the mounting surface.

48 Installation Guide

Page 53

5. Loosen the locking screw, located near the lens

assembly using the Torx wrench. Align the Lens

Adjustment Tool with the two small holes located on the

camera assembly. Rotate (pan) the camera assembly

using the Lens Adjustment Tool until the lens is

positioned in the correct location. The tool is also used to

adjust the tilt angle.

Locking screw

Installation Guide 49

Page 54

Pan

Lens adjustment tool

Tilt Rotation

6. Re-attach the dome housing cover to the camera base.

Mounting the IP turret camera

To mount the IP turret cam era on a surface:

1. Use the supplied template (supplied) to mark out the

mounting area. Drill mounting holes in the surface using

the holes labeled number “1” on the drill template.

To route the cable harness through the mounti ng surface,

cut a cable access hole in the mounting surface,

50 Installation Guide

Page 55

referencing the letter “A” on the drill template. Skip this

step if you want to route the cables on the surface.

Use the supplied adapter plate if installing the turret

camera to a wall mount or other accessory. Fix the

adapter plate to the accessory with three PM4X8 screws,

referencing number “2”.

2. Rotate the trim ring counterclockwise to remove it from

the camera.

Installation Guide 51

Page 56

Trim ring

Lens

assembly

3. There two options for routing the cables.

Route the cables directly out of the bottom of the camera

or through the side access point shown below. Remove

one of the knockouts (using pliers) on the edge of the trim

ring to provide cable access.

Side access point

4. Connect the corresponding power and network cables.

5. Attach the camera to the mounting surface using the

supplied hardware.

52 Installation Guide

Page 57

6. Adjust the lens.

a) Loosen the locking screw using a Philips screw

driver.

b) Rotate the lens assembly to adjust the pan angle.

Rotate the lens assembly to adjust the tilt angle.

c) Tighten the locking screw to secure the lens at the

desired surveillance angle.

Locking screw

Installation Guide 53

Page 58

7. Attach the trim ring to the camera and rotate it clockwise

to secure it.

54 Installation Guide

Page 59

Using the camera with a recorder

Please refer to the recorder user manuals for instructions on

connecting and operating the camera with these systems.

Using the camera with TruVision Navigator

A camera must be connected to an Interlogix NVR or hybrid

DVR in order to be operated by TruVision Navi gator. Please

refer to the TruVision Navigator user manual for instructions

on operating the camera with the TruVision Navigator.

Installation Guide 55

Page 60

Specifications

Electrical

Voltage input

Power consumption

Miscellaneous

Connectors

Operating temperature

Dimensions

Weight

Environmental rating

Electrical

Voltage input

Power consumption

Miscellaneous

Connectors

Operating temperature

Dimensions

105 × 94.7 × 301.4 mm / 4.13 × 3.74

TruVision IP fixed lens bullet cameras

12 VDC, PoE (IEEE 802.3af)

Max. 5 W

DC jack flying lead, RJ45 flying lead

-30 to +60°C (-22 to +140°F)

60 × 153 mm (2.3 × 6.0 in.)

373 g (0.82 lb.)

IP67

TruVision IP VF lens bullet cameras

12 VDC, PoE (IEEE 802.3af)

Max. 7.5 W

DC jack flying lead, RJ45 flying lead

-30 to +60°C (-22 to +140°F)

105 × 94.7 × 265.4 mm / 4.13 ×

3.74 × 10.4 in. (without back box)

× 11.86 in. (with back box)

56 Installation Guide

Page 61

Weight

Environmental rating

Electrical

Voltage input

Power consumption

Miscellaneous

Connectors

Operating temperature

Dimensions

× 94.7 × 301.4 mm / 4.13 × 3.74

Weight

Environmental rating

Electrical

Voltage input

Power consumption

Miscellaneous

Connectors

800 g (1.76 lb.)

IP67

TruVision IP motorized lens bullet cameras

12 VDC, PoE (IEEE 802.3af)

Max. 7.5 W

DC jack flying lead, RJ45 flying lead

-30 to +60°C (-22 to +140°F)

105 × 94.7 × 265.4 mm / 4.13 ×

800 g (1.76 lb.)

3.74 × 10.4 in. (without back box)

105

× 11.86 in. (with back box)

IP67

TruVision IP VF lens dome cameras

12 VDC, PoE (IEEE 802.3af)

Max. 5.5 W

DC jack flying lead, RJ45 flying

Installation Guide 57

lead

Page 62

Operating temperature

-30 to +60°C (-22 to +140°F)

Dimensions (L × W × H)

Weight

Environmental rating

Electrical

Voltage input

Power consumption

Miscellaneous

Connectors

Operating temperature

Dimensions (L × W × H)

Weight

Environmental rating

140 × 100 mm

(5.51 × 3.94 in.)

807 g (1.78 lb.)

IP67

TruVision IP motorized lens dome cameras

12 VDC, PoE (IEEE 802.3af)

Max. 5.5 W

DC jack flying lead, RJ45 flying

807 g (1.78 lb.)

lead

-30 to +60°C (-22 to +140°F)

140 × 100 mm

(5.51 × 3.94 in.)

IP67

58 Installation Guide

Page 63

TruVision IP fixed lens dome

Electrical

Voltage input

Power consumption

Miscellaneous

Connectors

Operating temperature

Dimensions (L × W × H)

Weight

Environmental rating

Electrical

Voltage input

Power consumption

Miscellaneous

Connectors

Operating temperature

Dimensions (L × W × H)

Weight

Environmental rating

12 VDC, PoE (IEEE 802.3af)

Max. 5 W

DC jack flying lead, RJ45 flying lead

-30 to +60°C (-22 to +140°F)

111 × 82 mm (4.4 × 3.2 in.)

370 g (0.81 lb.)

IP67

TruVision IP wedge cameras

12 VDC, PoE (IEEE 802.3af)

Max. 5 W (Max. 7 W with IR on)

DC jack flying lead, RJ45 flying lead

-30 to +60°C (-22 to +140°F)

98 × 89 × 329 mm

(3.86 × 3.49 × 12.94 in.)

409 g (0.9 lb.)

IP67

Installation Guide 59

Page 64

TruVision IP turret cameras

Electrical

Voltage input

Power consumption

Miscellaneous

Connectors

Operating temperature

Dimensions (L ×

Weight

Environmental rating

12 VDC, PoE (IEEE 802.3af)

Max. 5.5 W (Max. 7.5 W with IR on)

DC jack flying lead, RJ45 flying lead

-30 to +60°C (-22 to +140°F)

W × H) 127 × 97.5 mm

(5 × 3.84 in.)

548 g (1.21 lb.)

IP67

60 Installation Guide

Page 65

Pin definitions

There are eight wires on a standard UTP/STP cable and each

wire is color-coded. The following shows the pin allocation and

color of straight and crossover cable connection:

Figure 9: Straight-through cable

1 White/Orange

2 Orange Orange 2

3 White-G reen White-Gr een 3

4 Blue Blue 4

5 White/Blue White/Blue 5

6 Green Green 6

7 White/Brown White/Brown 7

8 Brown Brown 8

Figure 10: Cross-over cable

1 White/Orange

2 Orange Orange 2

3 White-G reen White -Green 3

4 Blue Blue 4

5 White/Blue White/Blue 5

6 Green Green 6

7 White/Brown White/Brown 7

8 Brown Brown 8

White/Orange 1

White/Orange 1

Installation Guide 61

Page 66

Please make sure your connected cables have the same pin

assignment and color as above before depl oying the cables in

your network.

62 Installation Guide

Page 67

Page 68

Loading...

Loading...