Page 1

TruVision Covert IP

Camera Installation

Manual

P/N 1072912-EN • REV C • ISS 13OCT15

Page 2

Copyright

rade names used in this document may be trademarks or registered trademarks

Any changes or modifications not expressly approved by the party responsible for

disposed of as unsorted municipal waste in the European Union. See the product

Trademarks and

patents

Manufacturer

Certifica tion

FCC compliance

ACMA compliance

Canada

European Union

directives

© 2015 United Technologies Corporation

Interlogix is part of UTC Building & Industrial Systems, a unit of United

Technologies Corporation. All rights reserved.

T

of the manufacturers or vendors of the respective products.

Interlogix

2955 Red Hill Avenue, Costa Mesa, CA 92626-5923, USA

Authorized EU manufacturing representative:

UTC Fire & Security B.V.

Kelvinstraat 7, 6003 DH Weert, The Netherlands

N4131

Class A: This device complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions:

(1) This device may not cause harmful interference

(2) This Device must accept any interference received, including interference

that may cause undesired operation.

compliance could void the user’s authority to operate the equipment.

Notice! This is a Class A product. In a domestic environment this product may

cause radio interference in which case the user may be required to take

adequate measures.

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-0330 du

Canada.

12004/108/EC (EMC directive): Hereby, UTC Fire & Security declares that this

device is in compliance with the essential requirements and other relevant

provisions of Directive 2004/108/EC.

2012/19/EU (WEEE directive): Products marked with this symbol cannot be

disposed of as unsorted municipal waste in the European Union. For proper

recycling, return this product to your local supplier upon the purchase of

equivalent new equipment, or dispose of it at designated collection points. For

more information see: www.recyclethis.info.

2006/66/EC (Battery directive): This product contains a battery that cannot be

documentation for specific battery information. The battery is marked with this

symbol, which may include lettering to indicate cadmium (Cd), lead (Pb), or

mercury (Hg). For proper recycling, return the battery to your supplier or to a

designated collection point. For more information see: www.recyclethis.info.

Contact information

For contact information, see www.interlogix.com or

www.utcfssecurityproducts.eu.

Page 3

Content

Product overview 4

Installation 4

Installation environment 4

Package contents 5

Cable requirements 5

Camera description 6

Set up camera unit 9

Prepare covert holes with adhesive tape 11

Install lens 12

Complete the installation 18

Configuration 19

Access the SD card 19

Use the camera with an Interlogix NVR and TruVision Navigator 19

Specifications 19

TruVision covert IP cameras 19

Pin definitions 20

Installation Manual 3

Page 4

Product overview

This is the installation manual for the following TruVision Covert IP camera models:

TVA-1101 (1.3MPX IP ATM/covert camera, WDR, PAL)

TVA-3101 (1.3MPX IP ATM/covert camera, W DR, NTSC)

TVL-0101 (TruVision Covert Lens, 1.3MPx, Pinhole, 3.7mm@ F2.3, 2m cable)

TVL-0102 (TruVision Covert Lens, 1.3MPx, L-shape, 3.7mm@ F2.3, 2m cable)

TVL-0103 (TruVision Covert Lens, 1.3MPx, Cylinder, 4mm@ F2.0, 2m cable)

TVL-0104 (TruVision Covert Lens, 1.3MPx, Pinhole, 3.7mm@ F2.3, 8m cable)

TVL-0105 (TruVision Covert Lens, 1.3MPx, L-shape, 3.7mm@ F2.3, 8m cable)

TVL-0106 (TruVision Covert Lens, 1.3MPx, Cylinder, 4mm@ F2.0, 8m cable)

TVL-0107 (TruVision Covert Lens, 1.3MPx, L-shape, 2mm@ F2.0, 2m cable)

TVL-0108 (TruVision Covert Lens, 1.3MPx, Cylinder, 2mm@ F2.0, 2m cable)

TVL-0109 (TruVision Covert Lens, 1.3MPx, L-shape, 2mm@ F2.0, 8m cable)

TVL-0110 (TruVision Covert Lens, 1.3MPx, Cylinder, 2mm@ F2.0, 8m cable)

Installation

This chapter provides information on how to install the cameras.

Installation environment

When installing your product, consider these factors:

• Electrical: Install electrical wiring carefully. It should be done by qualified service

personnel. Always use a proper PoE switch or a 12 VDC UL listed Class 2 or CE

certified power supply to power the camera. Do not overload the power cord or

adapter.

• Ventilation: Ensure that the location planned for the installation of the camera is

well ventilated.

• Temperature: Do not operate the camera beyond the specified temperature,

humidity or power source ratings. The operating temperature of the camera is

between -30 to +60°C (-22 to 140°F). Humidity is below 90%.

• Moisture: Do not expose the camera to rain or moisture, or try to operate it in wet

areas. Turn the power off immediately if the camera is wet and ask a qualified

service person for servicing. Moisture can damage the camera and also create the

danger of electric shock.

4 Installation Manual

Page 5

• Servicing: Do not attempt to service this camera yourself. Any attempt to

dismantle or remove the covers from this product will invalidate the warranty and

may also result in serious injury. Refer all servicing to qualified service personnel.

• Cleaning: Do not touch the sensor modules with fingers. If cleaning is necessary,

use a clean cloth with some ethanol and wipe the camera gentl y. If the camera will

not be used for an extended period of time, put on the lens cap to protect the

sensors from dirt.

Package contents

Check the package and contents for visible damage. If any components are damaged

or missing, do not attempt to use the unit; contact the supplier immediately. If the unit

is returned, it must be shipped back in its original packaging.

Package contents:

• Camera or lens

• Mounting accessories

• Installation manual

• CD with Configuration Manual and TruVision Device Manager

Note:

The ATM/covert camera has no lens in the product package. The lens needs to be

purchased separately according to the application needs. Please notice that there are

different cable length and form factor options.

CAUTION: Use direct plug-in UL listed power supplies marked Class 2/CE certified or

LPS (limited power source) of the required output rating as listed on the unit.

CAUTION: Risk of explosion if battery is replaced by an incorrect type. Dispose of

used batteries according to the instructions.

Cable requirements

For proper operation, adhere to the following cable and power requirements for the

cameras. Category 5 cabling or better is recommended. All network cabling must be

installed according to applicable codes and regulations.

Recommended power cable requirements to connect the camera:

12 VDC power jack or PoE (802.3-af)

Installation Manual 5

Page 6

Covert camera unit:

7. Audio In/Out

3

1

2

ALARM

RS232

RXD TXD GND IN1 1B 1A

LAN(PoE)

DC 12V

RESET

SD

VIN1

AUDIO

OUT

AUDIO

IN

4

5

6

7

8

9

10

11

12

13

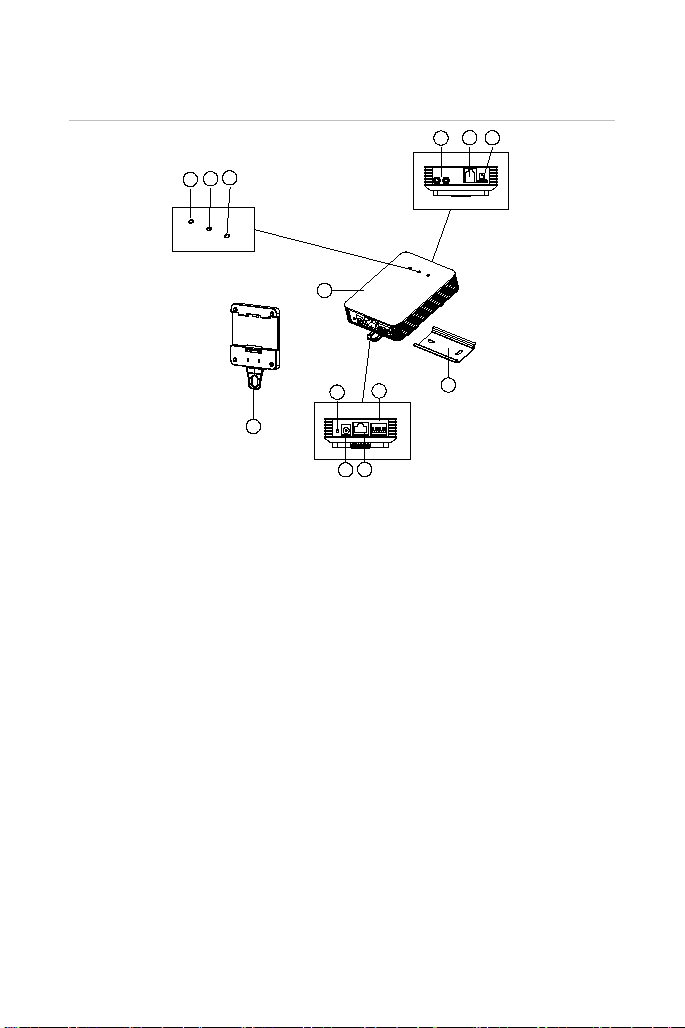

Camera description

Figure 1: Covert IP camera description

1. Main unit

2. Mounting rack

3. Mounting plate

4. Power indicator

5. Status indicator

6. Link indicator

6 Installation Manual

8. RJ-12 port

9. Micro SD card slot

10. Reset button

11. 12V DC Power port

12. PoE and network port

13. RS-232 and alarm port

Page 7

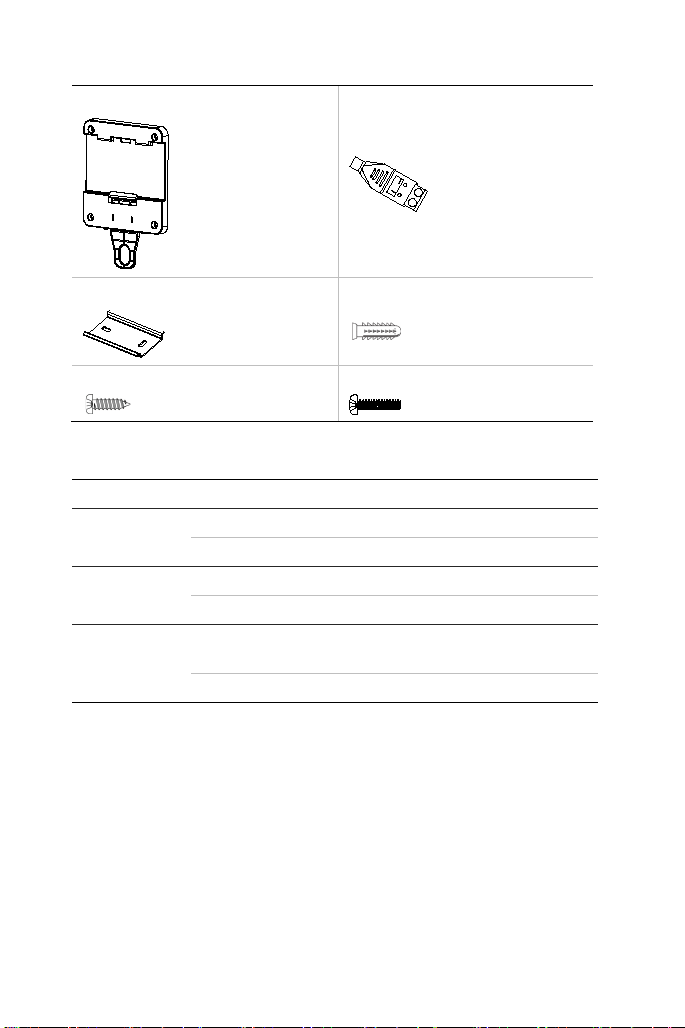

Accessories

Mounting plate

Mounting rack

Screw A, Ø4 x 25 mm (3 pcs)

Table 1: LED Indicators

LED Color and Status Indication

POWER Solid red Normal operation

Unlit Power Off

STATUS Solid green Camera works properly

Unlit Camera does not work properly.

LINK Flashing amber

Unlit No network connection

12 VDC connector: DC jack

socket to terminal connectors

with positive and negative indicators.

Drywall anchor, Ø7.5 x 24.5 mm (3

pcs)

Screw B, Ø2 x 6 mm (4 pcs)

Network connection is functioning

properly

Installation Manual 7

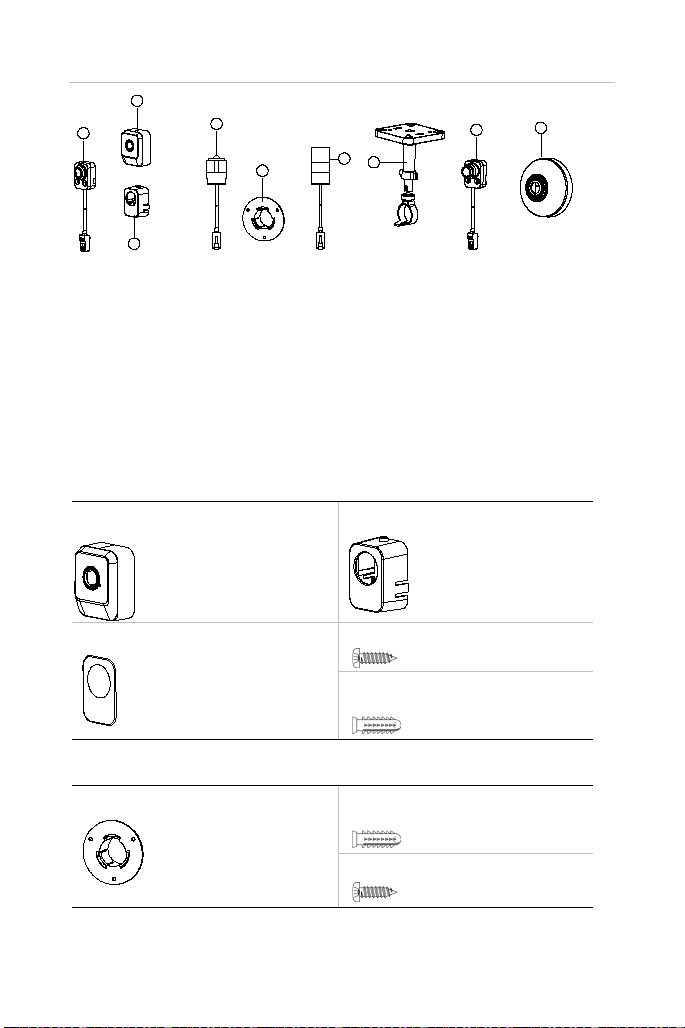

Page 8

mount cover

8

9

1

2

3

4

5

6

7

Figure 2: Covert IP camera Lens and bracket description

Lens and brackets: (purchased separately)

1. L-shape lens

2. L-shape lens cover

3. L-shape lens mounting bracket

4. Pinhole lens

5. Pinhole lens mounting bracket

Accessories

L-shape lens:

Cover

Adhesive tape (2 pcs, 1 mm and 4 mm)

6. Cylinder lens

7. Cylinder lens mounting

bracket

8. L-shape 2mm lens

9. L-shape 2mm lens surface

Mounting bracket

Screw A Ø4 x 25 mm (3 pcs)

Drywall anchor Ø7.5 x 24.5 mm (3

pcs)

Pinhole lens:

Mounting bracket

Drywall anchor Ø7.5 x 24.5 mm (3

pcs)

Screw A Ø4 x 25 mm (3 pcs)

8 Installation Manual

Page 9

Cylinder lens:

Mounting bracket

Drywall anchor Ø7.5 x 24.5 mm (3

pcs)

Screw A Ø4 x 25 mm (3 pcs)

L-shape lens (2 mm):

Cover

Adhesive tape

Drywall anchor Ø7.5 x 24.5 mm (3 pcs)

Screw A Ø4 x 25mm (3 pcs)

Set up camera unit

Note: If the light source where the camera is installed experiences rapid, wide-

variations in lighting, the camera may not operate as intended.

Install a camera block:

1. Prepare the mounting surface. The surface should be smooth and clean.

2. Fix the mounting rack on the mounting surface using the enclosed screws A.

Installation Manual 9

Page 10

3. Fix the mounting bracket on the rear panel of the camera block wi th the four

enclosed screws B.

4. Hook the top catch of the camera mounting bracket on the prepared rack. Then

gently press the lower part of the camera block against the rack so that it snaps

into position on the rack.

Note: If there is a standard rail installed, you can directly snap the camera block with

mounting bracket on the prepared rail.

10 Installation Manual

Page 11

Prepare covert holes with adhesive tape

Note: Before installing a covert lens, please ensure that the mounting surface is

suitable for adhesive mounting.

L-shape lens

There are two types of adhesive tape (1 mm and 4 mm) included in the package. Drill

the covert hole to an appropriate diameter depending on the thickness of the mounting

surface. Refer to Figure 3 below for details.

Figure 3: Covert hole for L-shape lens

4 mm thick wall 1 mm thin wall

When the mounting surface is around

4 mm thick, drill a covert lens hole that is

10.5 mm in diameter.

Use the enclosed 1 mm adhesive tape to

adhere the bracket in place.

When the mounting surface is around

1 mm thick, drill a covert lens hole that

is 4.5 mm in diameter.

Use the enclosed 4 mm adhesive tape

to adhere the bracket in place.

Pinhole lens

Adhesive tape is provided with the mounting bracket for pinhole lens. Drill the covert

hole to an appropriate diameter depending on the mounting surface thickness. Refer to

Figure 4 on page 12 for details.

Installation Manual 11

Page 12

Figure 4: Covert hole for pinhole lens

6 mm thick wall 1 mm thin wall

When the mounting surface is around

6 mm thick, drill a covert lens hole that

that is 12 mm in diameter.

When the mounting surface is around

1 mm thick, drill a covert lens hole

that is 4.5 mm in diameter.

Install lens

L-shape lens for covert mounting:

1. See section “Prepare covert holes with adhesive tape” on page 11 on preparing

the covert hole. Keep the mounting surface clean and dry for the adhesive

mounting.

2. Remove the protective film from the adhesive tape and firmly adhere the tape on

the L-shaped mounting bracket. Align the bracket with the prepared covert hole

and firmly adhere the bracket on the m ounting surface.

12 Installation Manual

Page 13

3. Insert the L-shape lens into the mounting bracket and fasten the locking screw to

finish the installation.

L-shape lens for surface mounting:

1. Fix the L-shape lens on the mounting surface with screws A.

2. Drill a cable hole in the mounting surface and pull the lens cable through the hole

(optional).

Installation Manual 13

Page 14

3. Cover the installed L-shape lens unit with the enclosed cover to finish the

installation.

Pinhole lens for covert mounting:

1. See section “Prepare covert holes with adhesive tape” on page 11 on preparing

the covert hole. Keep the mounting surface clean and dry for the adhesive

mounting.

2. Remove the protective film from the adhesive tape and firmly adhere the tape on

the pinhole lens mounting bracket. Align the bracket with the prepared covert hole

and firmly adhere it on mounting surface.

3. Insert the pinhole lens into the mounted bracket and adjust the lens position fitting

with the mounting surface.

14 Installation Manual

Page 15

4. Twist the locking sleeve to lock lens in place.

L-shape 2mm lens for surface mounting with a cover:

1. Remove the protective film from the served adhesive tape and firmly adhere the

tape on the back of the lens.

2. Drill a cable hole close to the lens mounting position and pull the lens cable

through the hole. Then adhere the lens to the mounting surface.

3. Fix the lens on the mounting surface with screws A.

Installation Manual 15

Page 16

4. Cover the installed lens and cable wit h served round shape cover to finish

installation.

Cylind er lens for bracket mounting:

1. Fix the cylinder bracket mounting base to the ceiling with the two supplied screws.

2. Hook the bracket cover to the mounting base.

3. Screw the bracket to the installed mounting base.

16 Installation Manual

Page 17

4. Insert the cylinder lens into the bracket holding circle and fasten the locking screw.

5. Attach the assembled cylinder lens with the holding circle to the installed bracket.

Continue twisting until it is securely fastened.

6. Loosen the knob to adjust the surveillance angle and then tighten the lock nut to

complete the installation.

Installation Manual 17

Page 18

Knob

Lock nut

Complete the installation

1. Connect the RJ-12 connector of lens cable to the camera block.

2. Connect an audio device.

Connect a 3.5 mm microphone and an audio output device to the AUDIO IN and

AUDIO OUT interfaces.

3. Connect an ATM transition capture device or other device via the RS-232 port.

4. Connect alarm input/output devices.

18 Installation Manual

Page 19

Electrical

Voltage input

Power consumption

Miscellaneous

Connectors

Operating temperature

Dimensions

Weight

Configuration

Set up the camera’s network and streaming parameters so that the camera can be

controlled over the network. For further information, please refer to the “TruVision

Covert IP Camera Configuration Manual”.

Access the SD card

Insert a SD card up to 128GB for local storage as a backup in case the network fails.

The card is not supplied with the camera.

Video and log files stored on the Micro SD card can only be accessed via the Web

browser. You cannot access the card using TruVision Navigator or a recording device.

Use the camera with an Interlogix NVR and TruVision

Navigator

The camera can be connected to an Interlogix NVR or hybrid DVR or directly to

TruVision Navigator. Please refer to the user manual of TruVision Navigator and/or

NVR or hybrid DVR for instructions.

Specifications

TruVision covert IP cameras

210 g (0.46 lb.)

Installation Manual 19

12 VDC ± 10%, PoE (IEEE 802.3af)

Max. 6.5 W

DC jack flying lead, RJ45 flying lead

-30 to 60°C (-22°F to 140°F)

78 × 105 × 32 mm (3.07 × 4.13 × 1.25 in.)

Page 20

Pin definitions

There are eight wires on a standard UTP/STP cable and each wire is color-coded. The

following shows the pin allocation and color of straight and crossover cable connection:

Figure 5: Straight-through cable

1 White/Orange

2 Orange Orange 2

3 W hite-Green White-Green 3

4 Blue Blue 4

5 White/Blue W hite/Blue 5

6 Green Green 6

7 W hite/Brown W hite/Brown 7

8 Brown Bro wn 8

Figure 6: Cross-over cable

1 White/Orange

2 Orange Orange 2

3 White-Green White-Green 3

4 Blue Blue 4

5 White/Blue White/Blue 5

6 Green Green 6

7 White/Brown White/Brown 7

8 Brown Brown 8

Please make sure your connected cables have the same pin assignment and color as

above before deploying the cables in your network.

White/Orange 1

White/Orange 1

20 Installation Manual

Page 21

Page 22

Page 23

Page 24

Loading...

Loading...