Page 1

™

Monitor ISM/xL

Hardware

Guide

rev1.1

Page 2

Page 3

Contents

Part 1 Monitor ISM System Hardware....................................................................................................... 1

Main Control Board................................................................................................................................... 2

Keypad Modules.......................................................................................................................................3

LCD Keypad......................................................................................................................................3

Arming Station Reader......................................................................................................................4

Suite Security LED Keypads for Apartment and Office Protection......................................................7

8 and 16 Input/Output Expansion Modules.............................................................................................12

Output/Relay Card..................................................................................................................................13

RF Wireless Modules.............................................................................................................................. 14

Version 1......................................................................................................................................... 14

Version 2 Wireless........................................................................................................................... 17

North American Module ..............................................................................................................................17

European and Australian Module................................................................................................................ 19

Fire Module.............................................................................................................................................24

Graphic Map Annunciator Module........................................................................................................... 25

Smart / Vigil Module................................................................................................................................27

Door Controller Modules......................................................................................................................... 32

Version 1 Door Module.................................................................................................................... 32

Version 2 Door Module.................................................................................................................... 33

Multi-Door Controller........................................................................................................................34

Elevator / Lift Modules ............................................................................................................................ 35

Communication Modules........................................................................................................................42

Printer..............................................................................................................................................42

IP Module V3...................................................................................................................................43

MONITOR System Reference Topics..................................................................................................... 45

Adding Any Power Supply to the Module Bus .................................................................................................... 45

Communication Connections between the Main Controller and the Director PC Software................................ 45

Part 2 Monitor xL System Hardware.......................................................................................................47

Main Controller.......................................................................................................................................48

Modems.................................................................................................................................................. 49

Feature Expansion Board....................................................................................................................... 49

Wiring CA38A Alarm Jack for connection to xL Modems...................................................................................50

Keypad...................................................................................................................................................51

Input Point Expanders.............................................................................................................................52

VBUS......................................................................................................................................................52

Transistor Output Expander.................................................................................................................... 53

Relay Output Expander...........................................................................................................................53

Module Power Supply ............................................................................................................ ................. 54

Appendix “A” 12VDC Relay .................................................................................................................... 56

Appendix “B” Wiring Specifications ...................................................................................................... 56

Appendix “C” Basic Circuit Types ......................................................................................................... 57

Appendix “D” Mode m Notes................................................................................................................... 58

22-0375 rev1.1 (9.1.2006) © 2006 CSG Security Inc. / Sécurité CSG Inc. i

Page 4

Foreword

The Hardware Guide is designed as a quick reference for module circuit board layout, wiring and installation.

Some programming is included for e.g. Wireless, Smart and Printer modules. For Monitor ISM System programming

information, refer to the Commissioning Reference Guide. For Monitor xL System programming, refer to the Monitor

xL Simplified and Advanced programming guides. For software used with the Monitor ISM and Monitor xL systems,

refer to the Director Software User Guide. Specific installation and programming instructions produced for each

module by part number are referenced at the beginning of each module’s section in this manual.

VEREX Technology

5201 Explorer Drive, Mississauga, Ontario, L4W 4H1, Canada.

www.verextech.com | +1 877.249.9993

sales@verextech.com +1 905.206.8434

support@verextech.com +1 905.206.8436 | Fax: +1 905.629.4970

In This Issue:

V1.1 Additions/Deletions/Corrections

• Wire color for Arming Station Reader GProxI and II

Keypad Area Control Communications identified.

• Arming Station Reader LED and tone descriptions

added.

• Part 2, Monitor xL section updated to current status.

Includes correction to Relay Expansion Board’s

reversed contact labels.

• ULC, CE marks added to back cover.

ii Monitor ISM/xL™ Hardware Guide

22-0375 rev1.1

Page 5

Part 1

Monitor ISM

System

Hardware

22-0375 rev1.1 Monitor ISM/xL™ Hardware Guide 1

Page 6

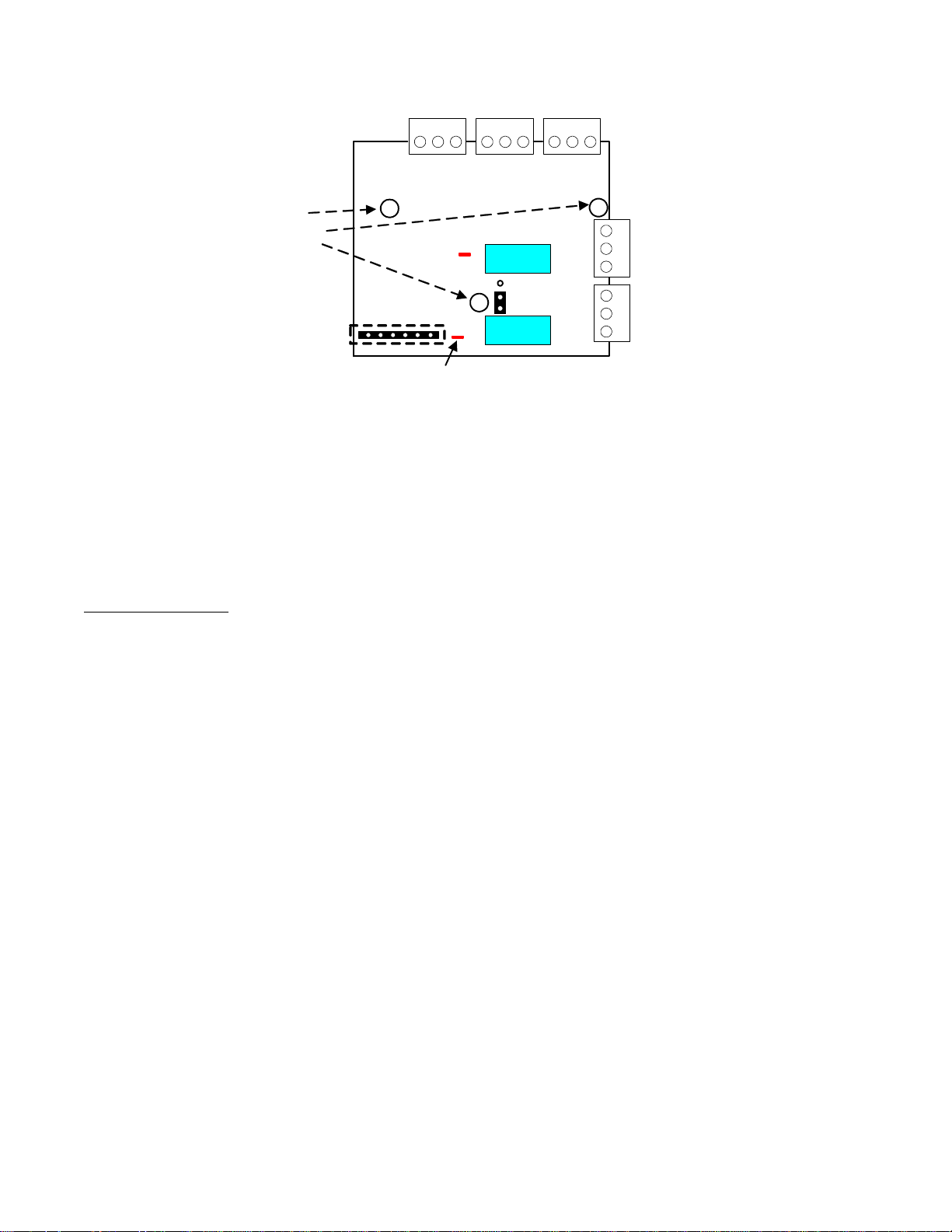

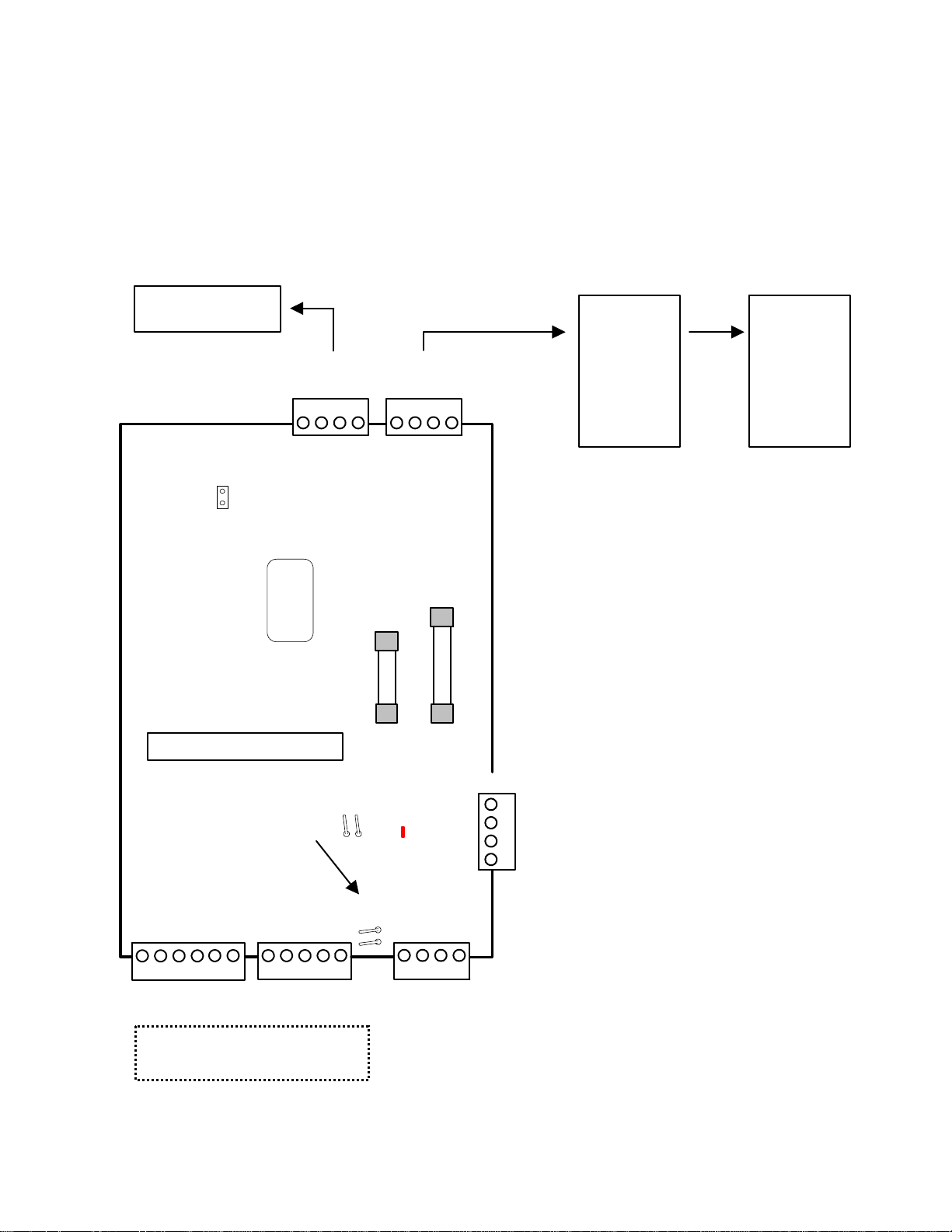

Main Control Board

Metal Enclosure

O/P3 Siren

(+)12V

Seized Tip

Seized Ring

TB1

12

TB2

1432

(+)

(-)

(+)

(-)

1432

O/P1

O/P2

O/P4

56

(-)0V

O/P Current Ratings

O/P1&4 = 10mA

O/P2 = 750mA

O/P3 = 1.8AMP

Telco Off Hook

TB4

1432

AC Input

16.5V, 40VA

(P/N 859-2246)

18 AWG CONNECTION

CABLE REQUIRED

Aux 12VDC

(750mA max.)

SIREN

TB3

LED

Fire

18V, 40VA

(P/N 859-0052)

Siren & Battery

are fused

F2

by a 1.8AMP

resetable fus e.

1 AMP

P/N 342-3350

AUX POWER

(-)

BATTERY

TELEPHONE

Tip

Ring

12

TB5

If using Station "Z" Quad cable for ground,

use all 4 conductors. Two wires can be

connected to terminal 1 and two to ter minal 2.

PHONE LINE

EARTH

GROUND

1.5 AMP

P/N 342-3821

F3

(-)

(+)

Resetable Fuse Notes

Will disconnect po wer if DC current

draw exceeds 1.8AMP.

WARNING: Very hot when

triggered: 120°C.

Disconnect battery for 1 min. to reset or,

silence siren. Hydro can stay connected.

Installation Notes for Further Reduction of RF Emissions

1. Terminating cables inside metal enclosure must never cross over the motherboard, behind

it or on top of it. Cables must run along th e sides of the board.

2. Cables being brought into the box should come in through the "knock out" ne arest the

terminal block it is being terminated at. E.g. A/C transformer cable should be brought in

through the knock out nearest the A/ C termianl block. Avoid leaving long cable lengths around

the board or inside box.

KNOCK OUTS

Main Control Board

To Clear Memory

with no power to panel

Short the upper lef t and

lower right silver pads.

See note

below.

Battery

micro-

processor

(+)

PLUG

Watchdog LED

TAMPER

SPRING

P/N 936-6800

I/P1

I/P2

COM

TB6

31 3 11312 2 2 2

Do not connect modules to this Module Bus connector

Reserved for Service use with LCD Keypad.

CABLE

INLET

Use plastic 3/4 in. bushings

P/N 364-5100 to insert in knockouts

before bringing i n cables.

R

A

M

32 pin

E-prom

socket

expansion RAM

36 pin battery backed

J5

IN (default) for Non

Res. UL Fire

OUT for Res. UL Fire

F5

1 AMP

TB9TB8TB7

MODULE BUS

I/P3

I/P4

I/P5

COM

I/P6

COM

I/P7

I/P8

COM

3

MODBUS 1

1432

TB16

TB15

TB14

TB13TB12

MODBUS 2 MODBUS 2

TB11

MODBUS 1

TB10

Host RS485

312

0V

B485

A485

GND/GND

CTS/RTS

RTS/CTS

DSR/DTR

5

DTR/DSR

TX/TX

RI/RI

CD/CD

1432

RX/RX

b

(-)0V

l

a

c

y

Data B

g

Data A

r

1432 1432 1432 1432

(+)12V

e

HOST PORTS

PC/Modem con nec tio n

k

e

l

l

o

w

r

e

e

n

d

2 Monitor ISM/xL™ Hardware Guide

22-0375 rev1.1

Page 7

Refer to Installation Instructions P/N 21

-

0369 for further information.

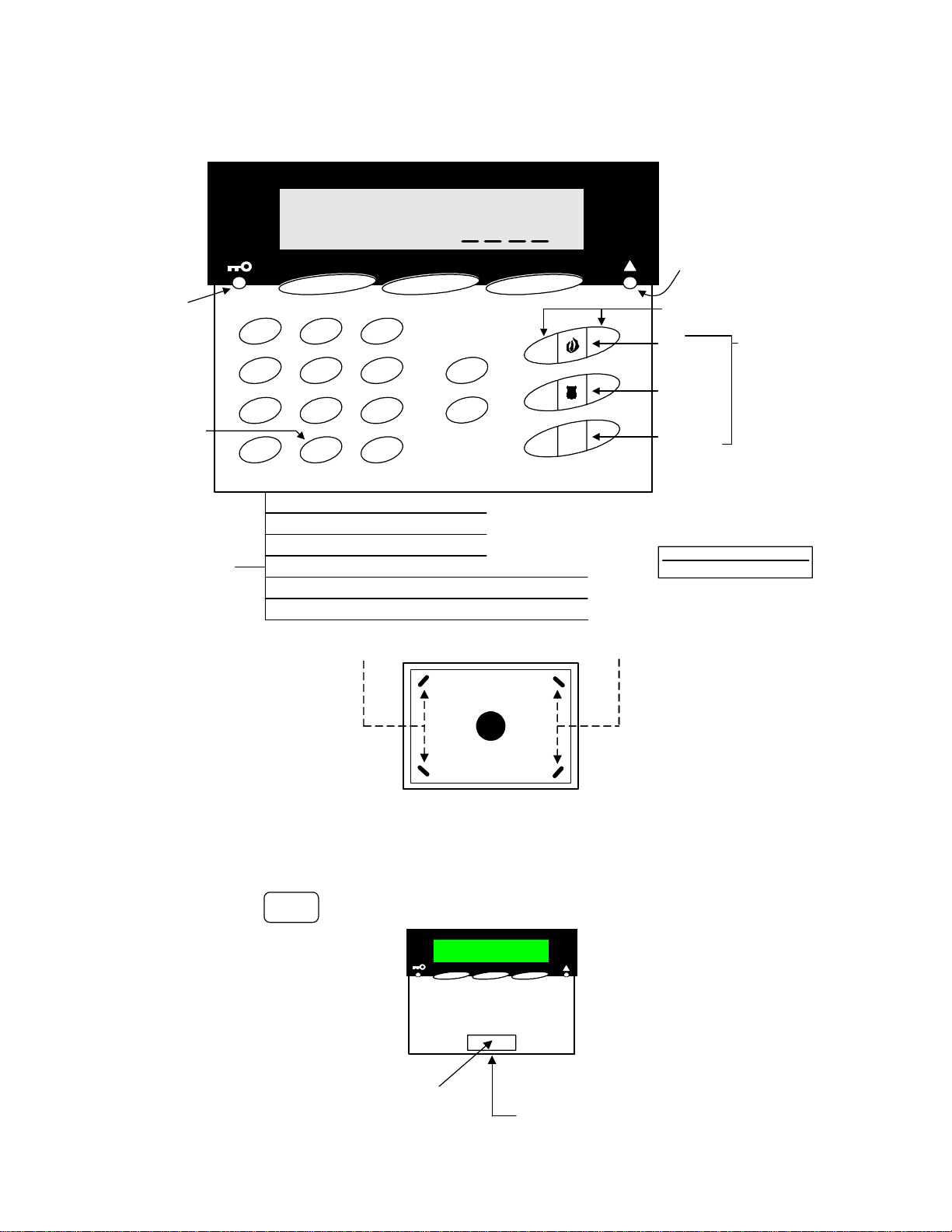

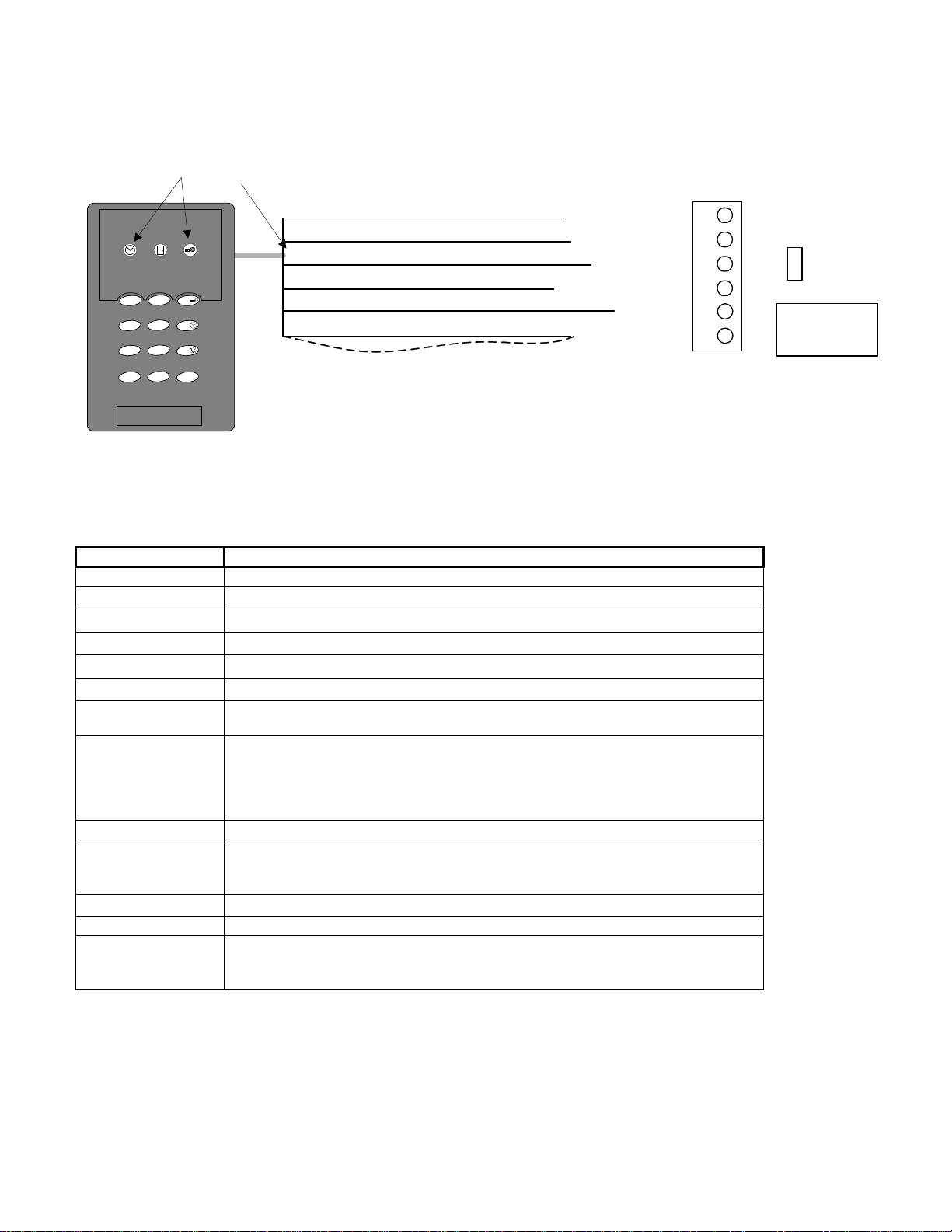

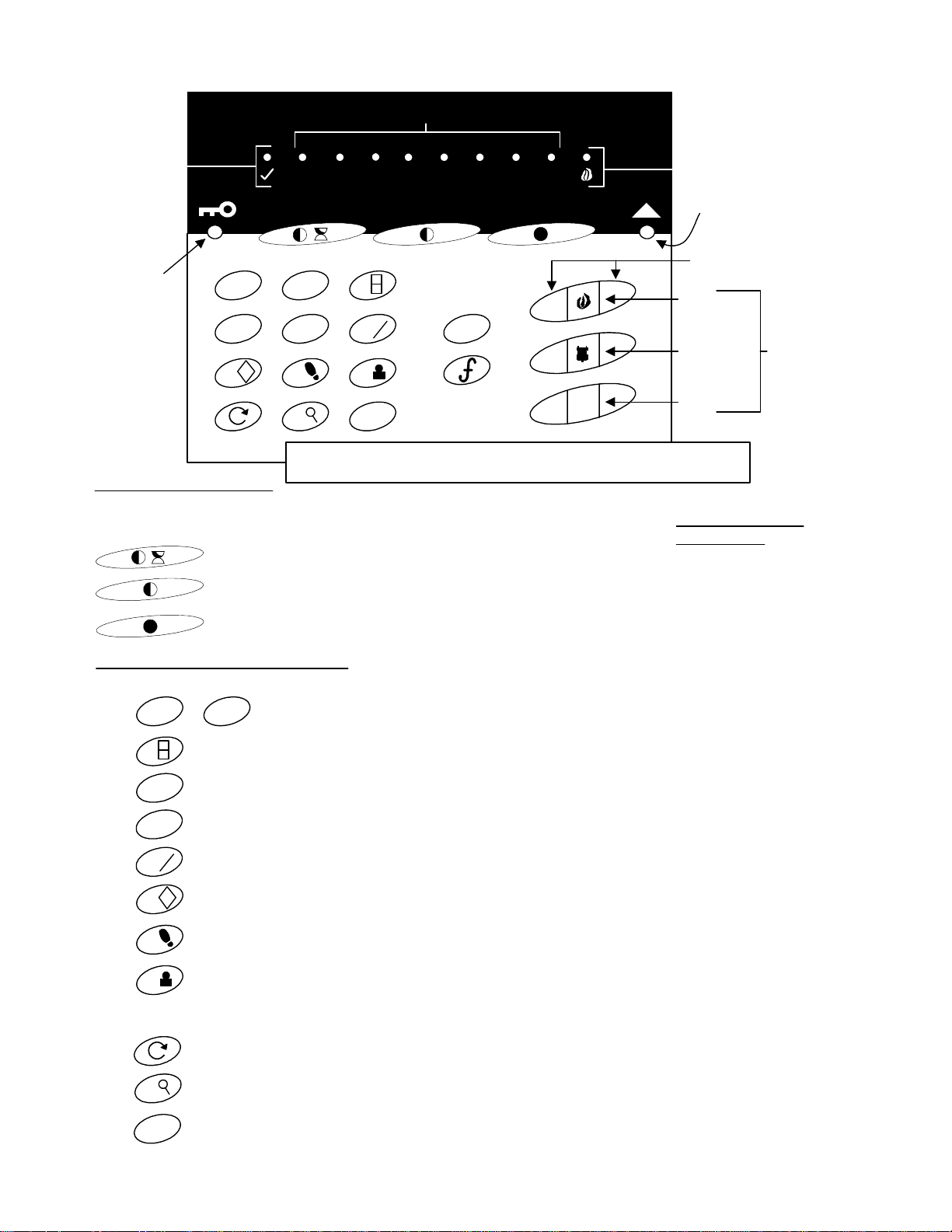

Keypad Modules

LCD Keypad

Area

Armed

Light

Steady =

STAY

Flashing =

Fully ON

When

programming,

use this key

"_" to insert a

blank space

or clear a

character

when cursor

flashing

under it.

Keypad

Wire

Connectors

WELCOME

Enter ID:

Down Arrow Keys

' - #

1 2 3

GHI JKL MNO

4 5 6

PRS TUV WXY

7 8 9

X

Left - Right arrow screen scrolling keys.

Orange = Hardwired Input. Connect common to Black

Blue = Hardwired Output. Obtain negative from Black

ABC DEF

_Q

Z

0

Red = Module Bus 12V Positive

Green = Module Bus Data "A"

Yellow = Module Bus Data "B"

Black = Module Bus Negative

Escape Key

Function Key

X

16 Character,

2 Line LCD

Screen

X

f

Power a device

(e.g. motion detector) from

Red (+) and Black

NOTE: This is Bus power and

must not be overloaded!

System Trouble

Indicator Light

Emergency Keys

Both buttons must be pressed

at same time to activate.

FIRE

POLICE

AUXILIARY

Apply emergency

label types

(supplied) in this

sequence to

match point type

default or blank

labels but, NEVER

LEAVE THESE

SPACES EMPTY!

Piezo sounder

is one volume only

(-- )

There is no Bus communications LED

indicator on the PCB board as whether the

LCD displays or not is used instead.

and not adjustable.

Module Current Rating

= 150mA max.

Always secure keypad base to wall using 4 screws.

Recommended mounting height: 1.5 meters (4 feet, 9 inches) from floor level to the

bottom of the keypad.

WARNING: If upgrading an existing previous version Fx LCD keypad with this one,

each keypad's base is a different size and their mounting holes do not align exactly

the same.

XXXXX

The sticker with the 5 digit serial number, for programming the module in Module

Programming, is located on the keypad PCB back when the keypad base is removed.

After placing the keypad

Apply dealer's logo label

(supplied) in the indented

space on keypad door.

on its base, make sure

the keypad's securing

screw (supplied) is

always I N !

22-0375 rev1.1 Monitor ISM/xL™ Hardware Guide 3

Page 8

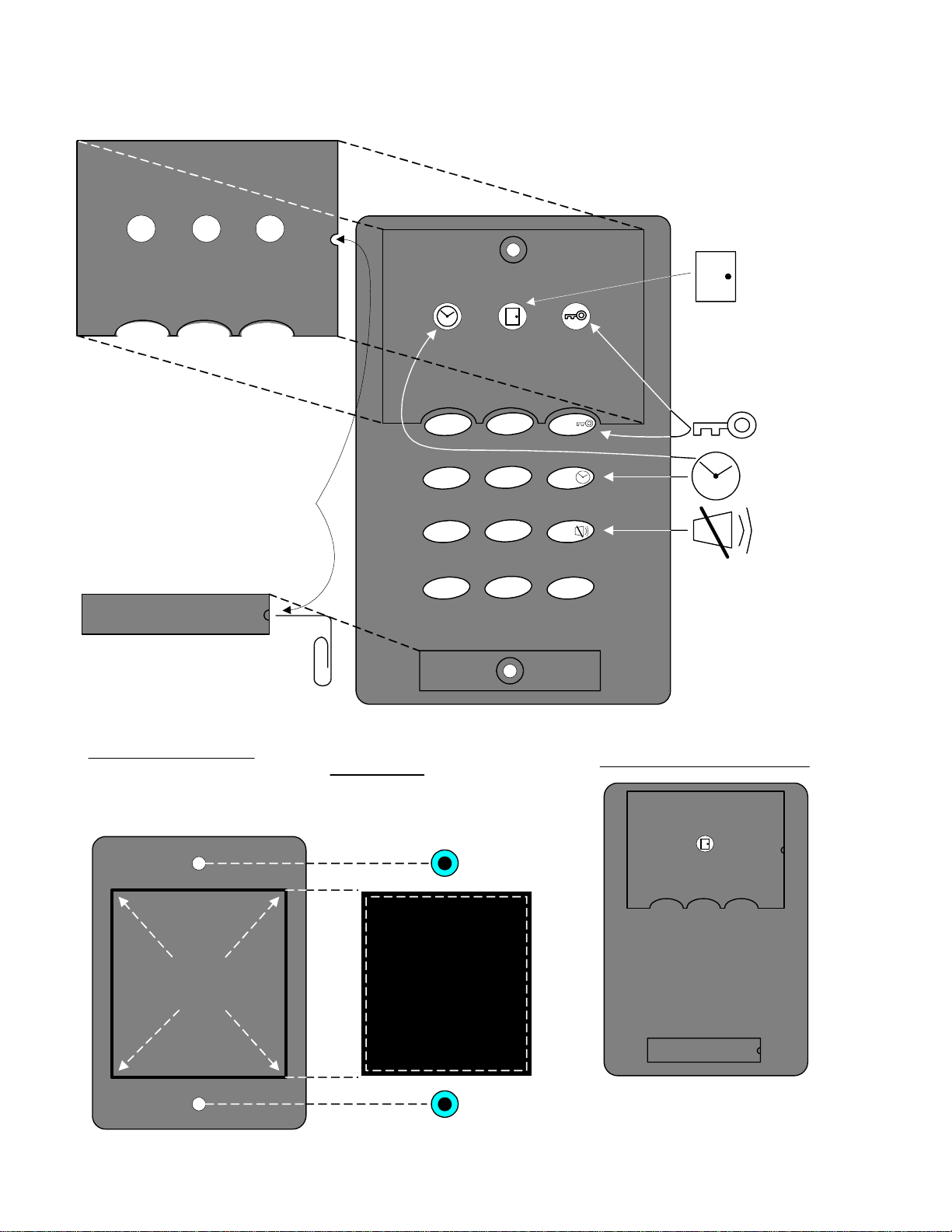

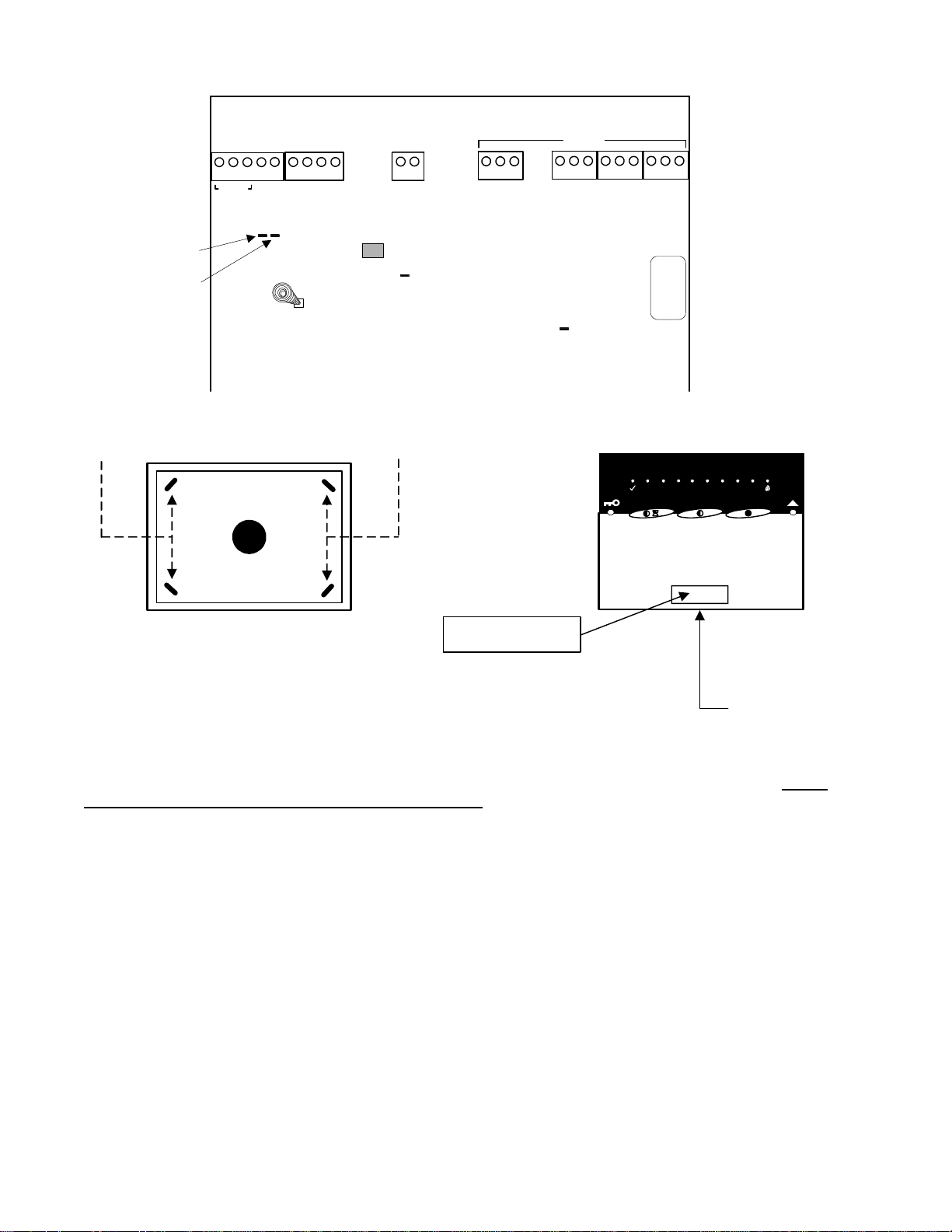

Arming Station Reader

Mounting

Remove detachable plates to

gain access to screw holes with a

pin like t ool (e.g. paper clip)

in the plate's notched right side.

Refer to Installation Instructions P/N 22-0346 for further information.

screw

hole

Door Unlock

bicolour light

Lights

1

4

7

2

5

8

3

6

9

Armed

Work Late

Silence

Mounting On Drywall

Reader back

Raised

Area

paper clip

example

0

screw

hole

WARNING!

Insert wall anchors FIRST

before cutting hole for inserting

reader back, raised area.

wall plug

screw anchor

Hole cut in

drywall for

reader back,

raised area.

#

Card Reader Only Version

single bicolour

door unlock light

wall plug

screw anchor

4 Monitor ISM/xL™ Hardware Guide

22-0375 rev1.1

Page 9

Wiring

NOTE: the Keypad area control communicatio ns

wire must be connected or the Work Late and

Armed LEDs will flash back and forth. 111-8240

GProxI wire is blue. 111-8270 (switch plate) or

111-8267 (mullion) GProxII wire is yellow.

Red Ensure power jumper set to 12V

Orange Controls Door Locked/Unlocked LED

Blue

White Data 1

2

1

4

7

3

5

6

8

9

0

#

Green

Black

or Yellow Keypad area control communications.

Data 0

GND + Shield Wire

Keypad Command Entries

NOTE:

Maximum cable distance from 2 Dr Access Module to

Arming Station is 500 feet.

Reader Connections at Door Access Module

1432

(+)5/1 2 VDC

Green LED

Red LED

Data 1 Clock

56

Data 0

Ground 0V

Arming Station Internal Buzzer follows LCD

Keypad Tones

e.g. Entry/Exit Delay, Work Late Tones etc. as

well as door access conditions e.g. Door Forced.

5V

Reader

12V

Arming Station

current rating =

80mA

Rea de r

Voltage

Jumper

...

<login> represents the form of user identification used e.g. badging card and or ID – PIN entry.

Key Sequence Command

< login > only Access (momentary unlock of door)

1 <login>

1 0 <login>

2 <login>

3 <login>

3 0 <login>

5 <login>

6 <login>

6 n <login>

7 <login>

9 <login>

# # Cancel any keys previously entered

# If performing a “” command with UID/PIN, insert a "#" key between

Turn area off

Turn all areas off

Turn area to stay mode

Turn area on

Turn all areas on

Toggle between Lock Door and Unlock Door & Disarm area

Door commands or if door is locked and area armed – unlocked and area disarmed.

Work Late in this area by 2 hours at a time from the current time. Scheduled

area only.

hours when the arming station will indicate closing time again with the work late LED

flashing and tones. At that time, this command can be used again to extend the

closing time another 2 hours.

Work Late in this area for n hours where n = 1…9. Scheduled area only.

Activate armed state LED display for approximately 20 seconds

To determine arming station’s area conditi on. Armed LED indicates for 20 sec:

green for OFF, red for STAY and flashing red for ON.

Silence alarm (in all areas)

command and UID/PIN entry (e.g. “ 1 # 341 1234 ” for user 341, pin=1234

trying to arm the area 1).

This command can only be used again at the end of the first entered 2

22-0375 rev1.1 Monitor ISM/xL™ Hardware Guide 5

Page 10

No Commands (Simple Access)

Door Mode <Login> Notes

Card Only <card> If a UID/PIN is entered, it will be ignored

Card & PIN <card> <pin> UID is not required since the card

automatically ident if ies the <u id >

Card or UID/PIN <card> or <uid> <pin>

UID/PIN Only <uid> <pin> If card is presented, it will be ignored.

<uid> – User ID

With Commands

Door Mode <cmd> <Login> Notes

Card Only <cmd> <card> If a UID/PIN is entered, it will be ignored

Card & PIN <cmd> <card> <pin> Card badging must always be done before

the PIN entry.

Card or UID/PIN <cmd> <card> or

<cmd> # <uid> <pin>

UID/PIN Only <cmd> # <uid> <pin> Pressing “#” is required between the

<cmd> – Command

Pressing “#” is required between the

command and uid/pin entry.

command and uid/pin entry. (Note

<cmd> # <pin> in PIN Only systems)

NOTES:

<login> requires your <card> OR alternatively, your uid/pin.

E.g. <3 digit UID> <4 digit PIN>. Leading zeros cannot be omitted in UID or PIN.

Example 1: Arm area using card – enter < 3 card >

Example 2: Work late for 3 hours using uid/pin – enter < 6 3 # 001 1234 > for user 001 with pin 1234

Example 3: Access area without using card – enter < 001 1234 > for user 001 with pin 1234.

Using Duress Pin at Arming Station

• A Duress Pin (reversing last 2 digits of a user’s pin entered on the keypad to transmit a potential hold-up

LED Indicators

Work Late LED

• Turns on if the area the Arming Station is assigned to is scheduled.

• Turns on solid 15 minutes before scheduled closing time.

• Does not operate if the area is not scheduled.

Door State LED

• Solid red if the door is locked.

• Solid green if the door is unlocked.

• Flashing red during disarming if there had been an alarm in the area.

Armed LED

• When activated, armed LED only stays on for the duration of the area’s Entry/Exit Delay during the following area

condition) can be used at an Arming Station if the duress feature has been enabled in the System Group.

arming state changes.

– Momentarily solid green when the area is disarmed to OFF.

– Momentarily solid red when the area is armed to STAY.

– Momentarily flashing red when the area is armed to Fully ON.

Arming Station Internal Buzzer Indications

• Entry/Exit tones same as LCD keypad.

• Fire Siren – intermittent tone.

• Burglary Siren – steady tone.

• Bad Command Entry – double short beeps.

• Command accepted – single long beep.

• Unauthorized to perform command – double long beep.

6 Monitor ISM/xL™ Hardware Guide

22-0375 rev1.1

Page 11

IMPORTANT:

Must refer to Installation Instructions P/N 21

-

9050 for detailed information.

User Guide

P/N 22

-

9050

IMPORTANT:

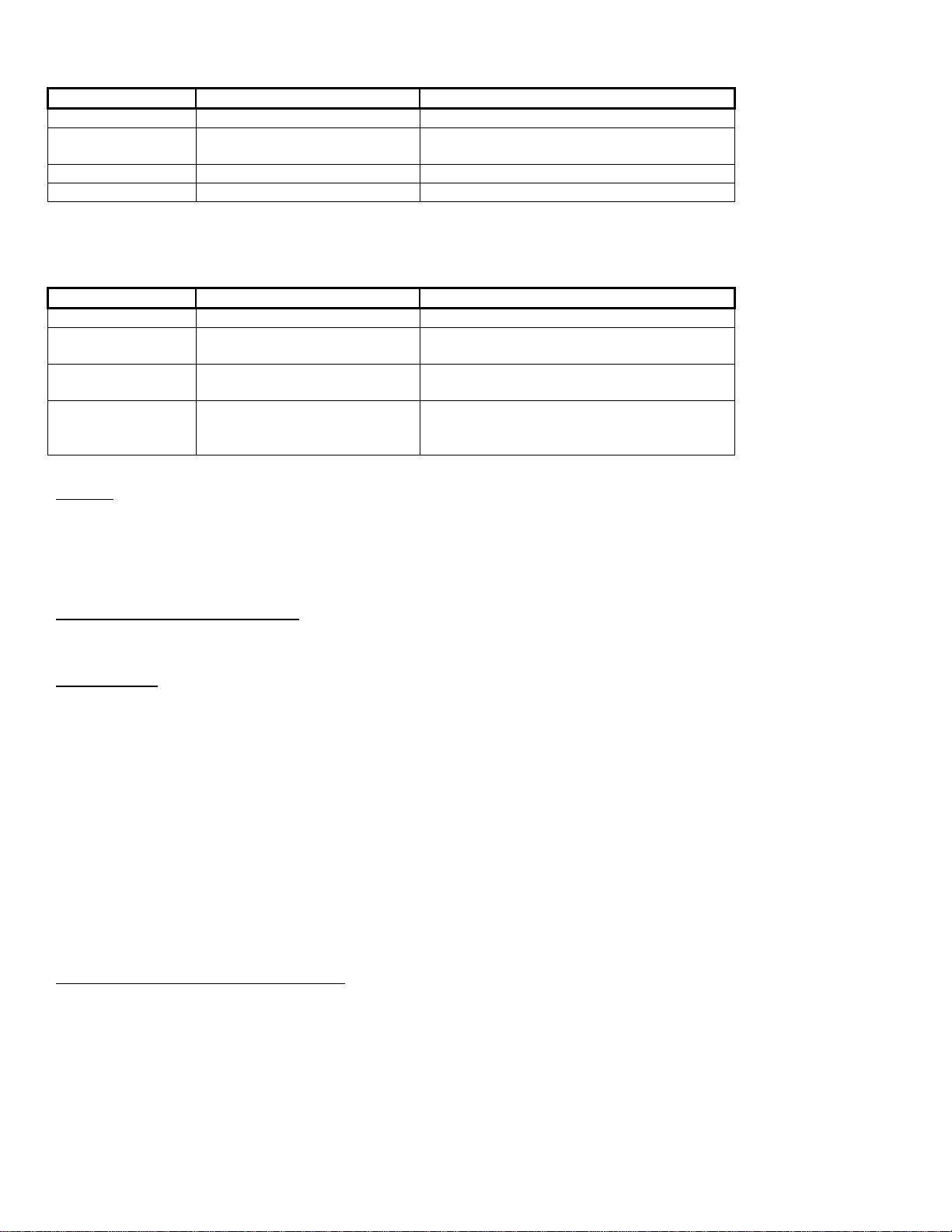

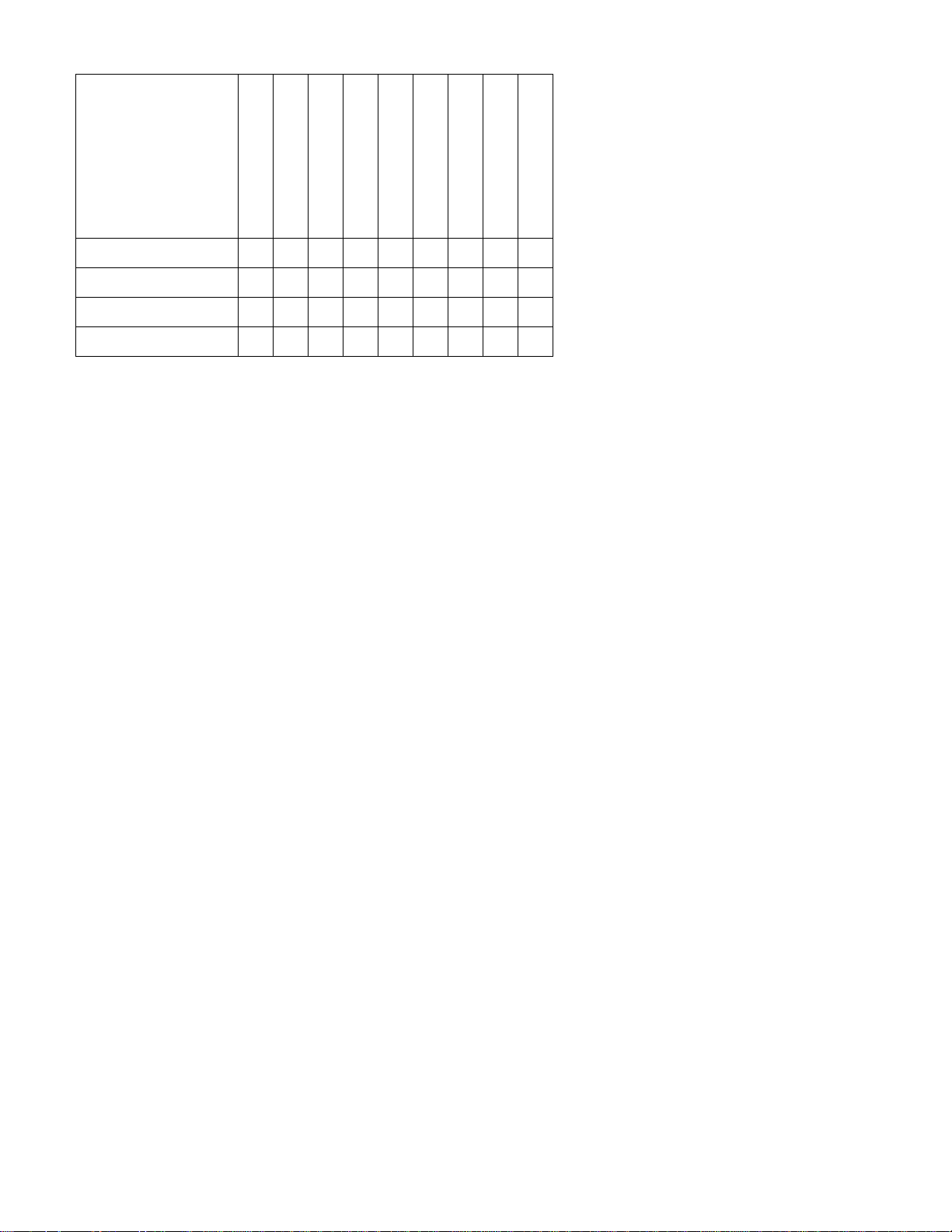

Suite Security LED Keypads for Apartment and Office Protection

2 Zone

System Armed Red Light

Flashing = System F ully ON

Solid = System in STAY

System Ready to Arm

Green Light

System Trouble

Yellow Light

1

12

4

3

56

789

Keypad Flip Cover

#

0

Protection Point # 1

Red Light

E.g. Main Entrance Door

Protection Point # 2

Red Light

E.g. Entry/Exit Route

Motion Detector

2

Wiring

s

e

r

d

i

a

Keypad

Base

(back

view)

XXXXX

5 digit serial number to

program in "Suite Security"

Programming . Lo cated on

keypad circuit board back,

when this plas tic base is

removed from keypad

housing.

e

W

l

y

l

F

"B" Connect Wire Flyleads to system cables.

RED Module Bus (+)12VDC Power

GREEN Module Bus Data A

YELLOW Module Bus Data B

BLACK Module Bus VDC Power

ORANGE Protection Point Input # 1

PURPLE Protection Point Input # 2

BLUE Output switching to ground.

BLACK #2 Either black can be used for

a Module negative BUS connection or

input point common connection. E.g. this

black could be used to connect input 1

and 2's common connection. A local

power supply's negative connection can

be connected to either of them as a

common for the output to operate.

Mounting Holes

(--)

(P/N 496-1700)

Installation Instructions P/N

21-9050 for Power & Cable

Ratings / Requirements.

Refer to

Release Tab. Ins ert flat head screw driver to push tab forward and release base

from keypad enlcosure to mount base.

22-0375 rev1.1 Monitor ISM/xL™ Hardware Guide 7

Page 12

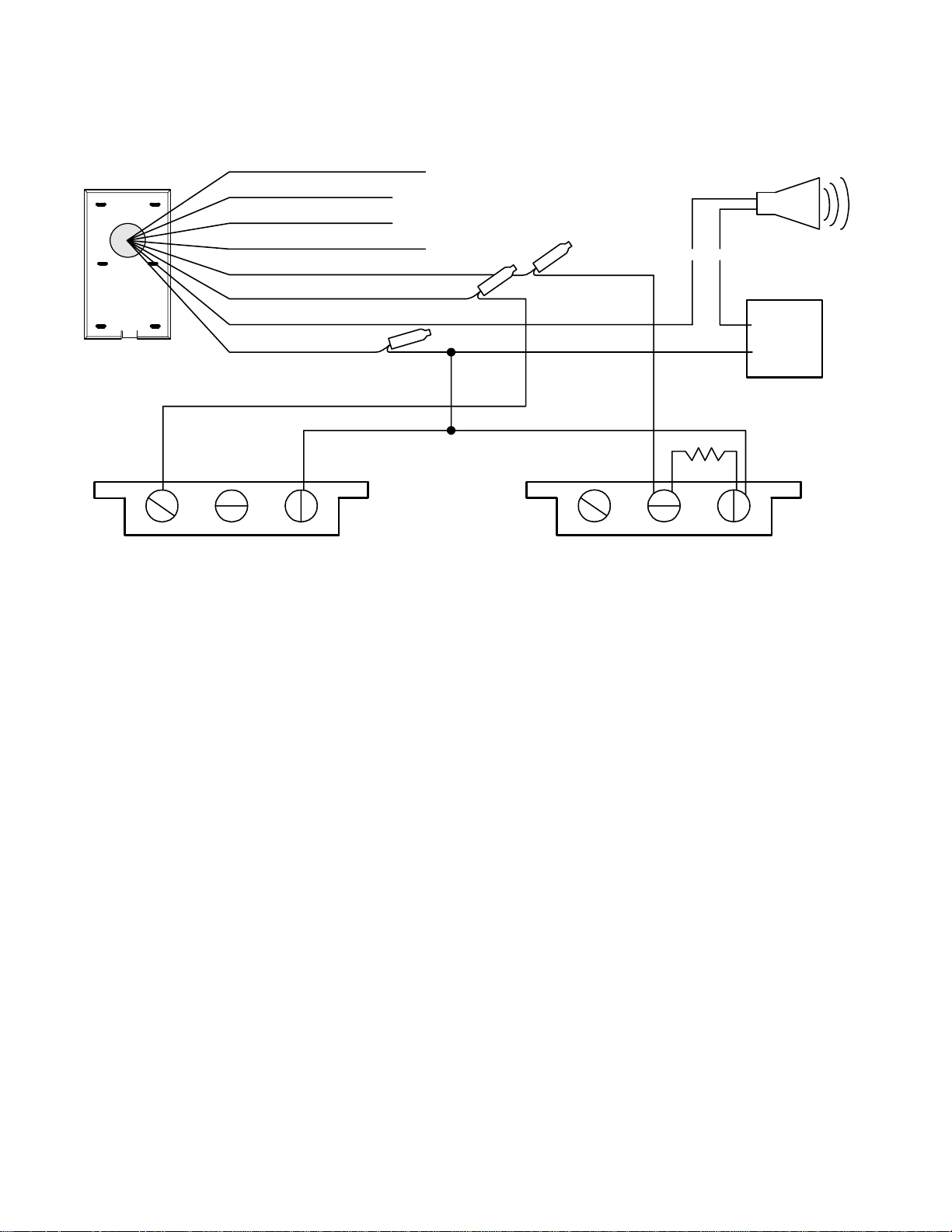

2 Zone Wiring cont.

Protection Input points 1 & 2 and Ou tput Wiring Example

RED

M

O

Keypad

Base

(back view)

GREEN

B

D

U

YELLOW

U

S

L

BLACK

E

ORANGE Protection Point Input # 1

PURPLE Protection Point Input # 2

BLUE Switching to GND Output.

BLACK Input point

common connection.

Output power source

negative.

Separate Data

A,B Cable

Separate

Power Cable

o

C

"

B

"

To output driven device.

E.g. electronic siren with

built in driver.

Siren

t

c

e

n

n

(+)(--)

Common

Negative

Reference

2.2 K

(+)

(--)

Power

Supply

NC NO

CM

Input # 2 e.g. Motion detector alar m contact.

Programmed and wired as normally closed.

NC NO

CM

Input # 1 e.g. Main entrance door contact.

Programmed and wired as norma lly open

with 2.2K end of line resist or.

8 Monitor ISM/xL™ Hardware Guide

22-0375 rev1.1

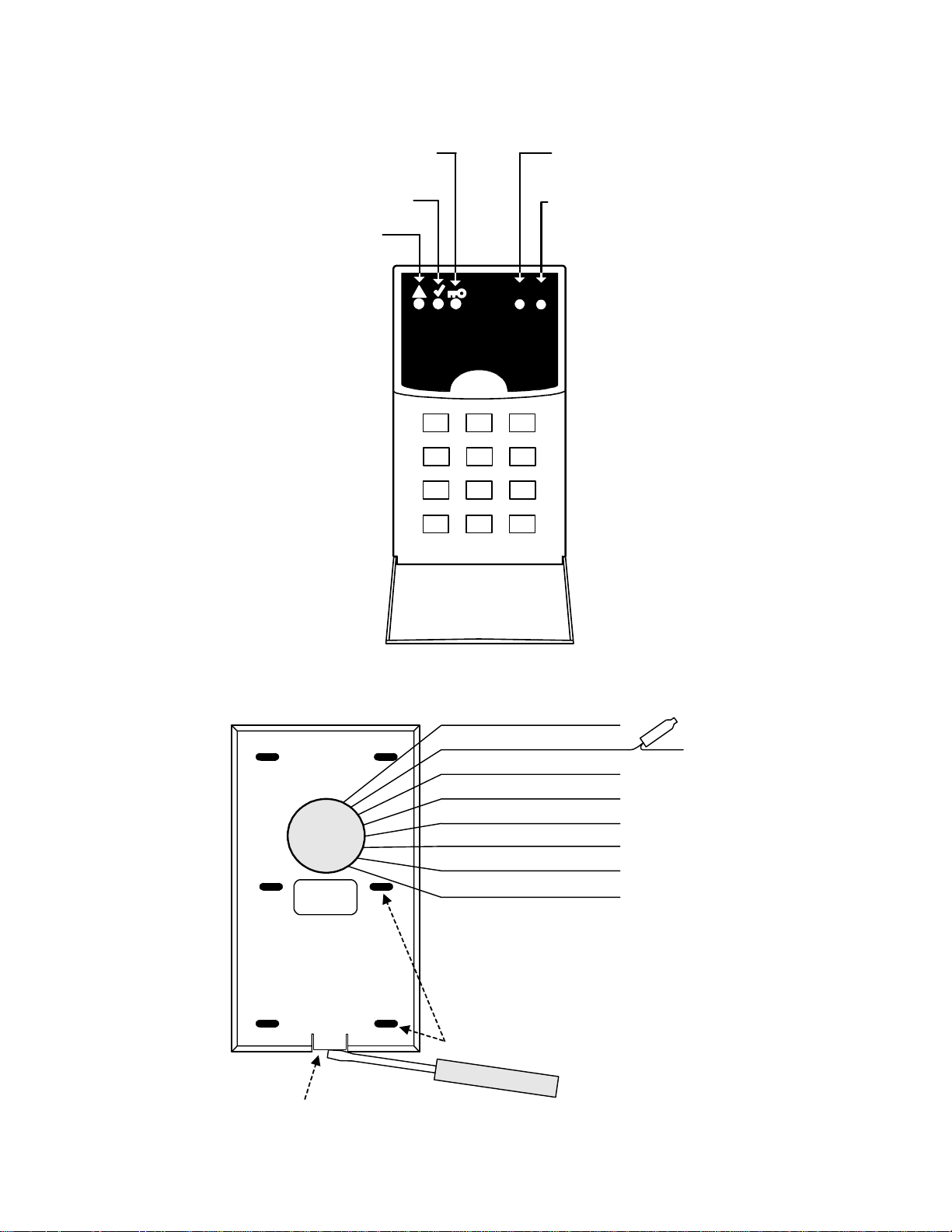

Page 13

f

f

f

f+f

f

f+f+f

f

f

IMPORTANT:

Must refer to Installation Instructions P/N 22

-

0362 for detailed information.

User Guide

P/N 22

-

9050

8 Zone

Input Points

Ready

Light

Area

Armed

Light

Steady =

STAY

Flashing =

Fully ON

Softkey Symbol Defi nitions

These keys can be used for Quick Arming from OFF wit h out having to include a PIN.

Pressing the Functi on key and then one of these key s will silence the arming tone.

Key Symbol Definitions and Functions

1 2 3

4 5 6

!

7 8 9

Arm to Stay with an Entry delay.

Arm to Stay with out an Ent ry delay. Instant alar m if entry made.

Arm to Fully On

1

2345

S

T

Function Key

0

Refer to Installation Instructions P/N 22-0362 and 2 Z one

Instructions P/N 21-9050 for Power & Cable Ratings / Requirements

67

Escape Key

X

8

Enter a user PIN only, to disarm the

system or silence an alarm c ondition.

f = function key

Pressing:

Fire Alarm

Light

System Trouble

Indicator Light

Emergency Keys

Both buttons pressed at

same time to activate.

FIRE

POLICE

AUXILIARY

The system trouble

indicator light will flash fast

if there is communication

trouble with the Module

Bus. Flash slowly if the

main control has AC Hydro

failure. On solid if the

keypad or input with tamper

supervision, is in tamper.

Apply

emergency label

types (supplied)

in this sequence

to match point

type default or

blank labels but,

NEVER LEAVE

THESE

SPACES

EMPTY!

+

+

+

+

+

+

+

+

or

1 2

S

T

3

4

5

6

7

8

9

+

+

+

+

!

+

+

+

+

0

+

+

+

= Grant lobby access.

PIN

= Verify User. Sends the main controller user identification in the event of a false alarm.

PIN

= Enable Chime.

PIN

= Disable Chime

PIN

= System test.

PIN

PIN

= Walk Test. As protection points are tripped, their keypad lights lock in for 5 min. or

press "X" to stop.

= Master User assigns new User's Authority Level and PIN.

PIN

F9 + master PIN + new user # (1 - 8) + Authority Level # + user's PIN # + confirm the same PIN #.

A user can be deleted by making the same entires but entering "0000" as their PIN #, twice.

The user's Authority Level must be "Suite Security Unassigned" to begin with in the Director 2 Software to assign

the user to this Suite Security Keypad.

Protection Point #

Master PIN

old PIN

depending on configurations. Repeat to turn them off.

Keypad tones when entry door opened.

LEDs, sounders turn on for 5 secs.

= Bypass/Unbypass input point.

PIN

+

User's PIN

+

new PIN confirm new PIN

++

= Displays user's ID number 1 - 8.

= Change PIN #.

= Output control. Pressing 1 can turn on output 1 and 2 can turn on output 2,

PIN

22-0375 rev1.1 Monitor ISM/xL™ Hardware Guide 9

Page 14

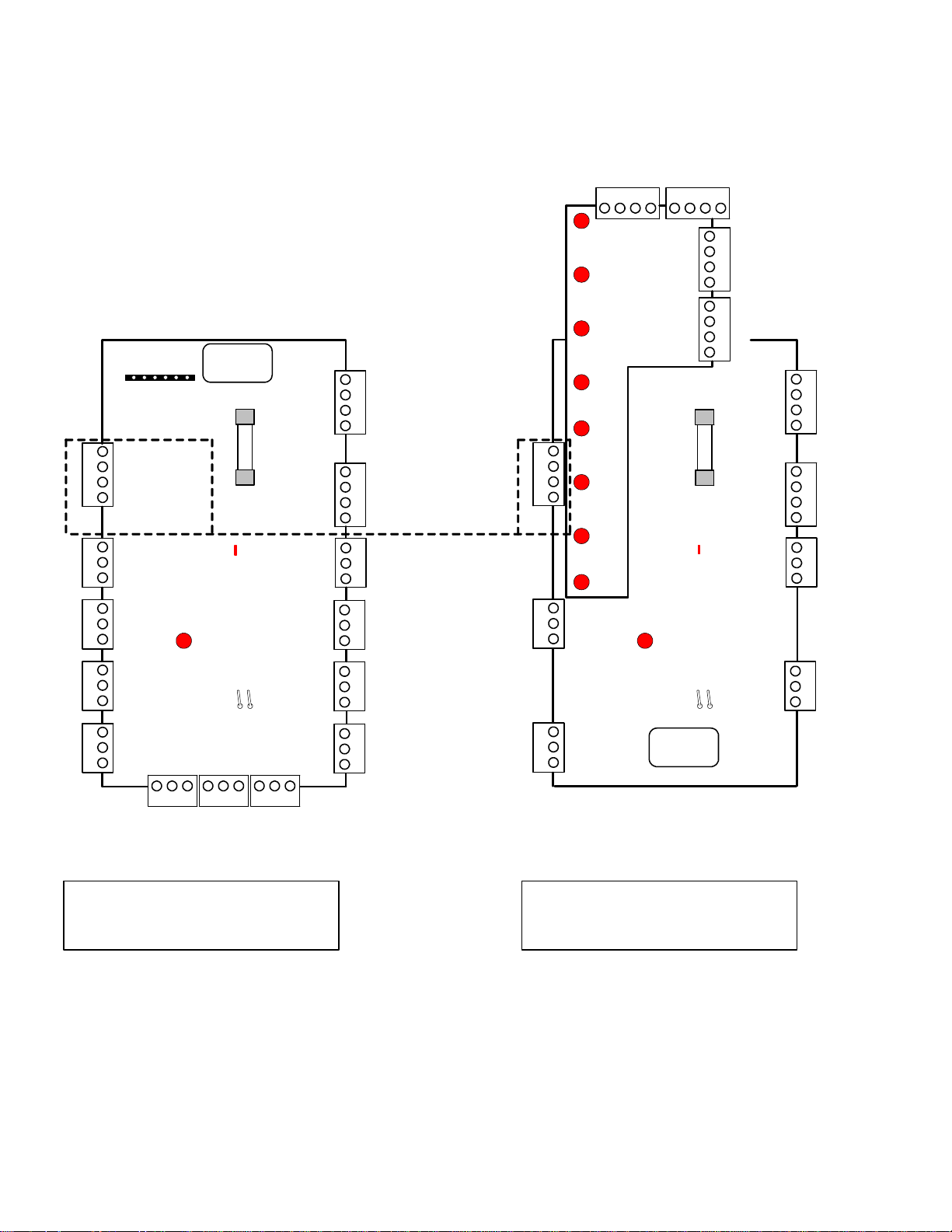

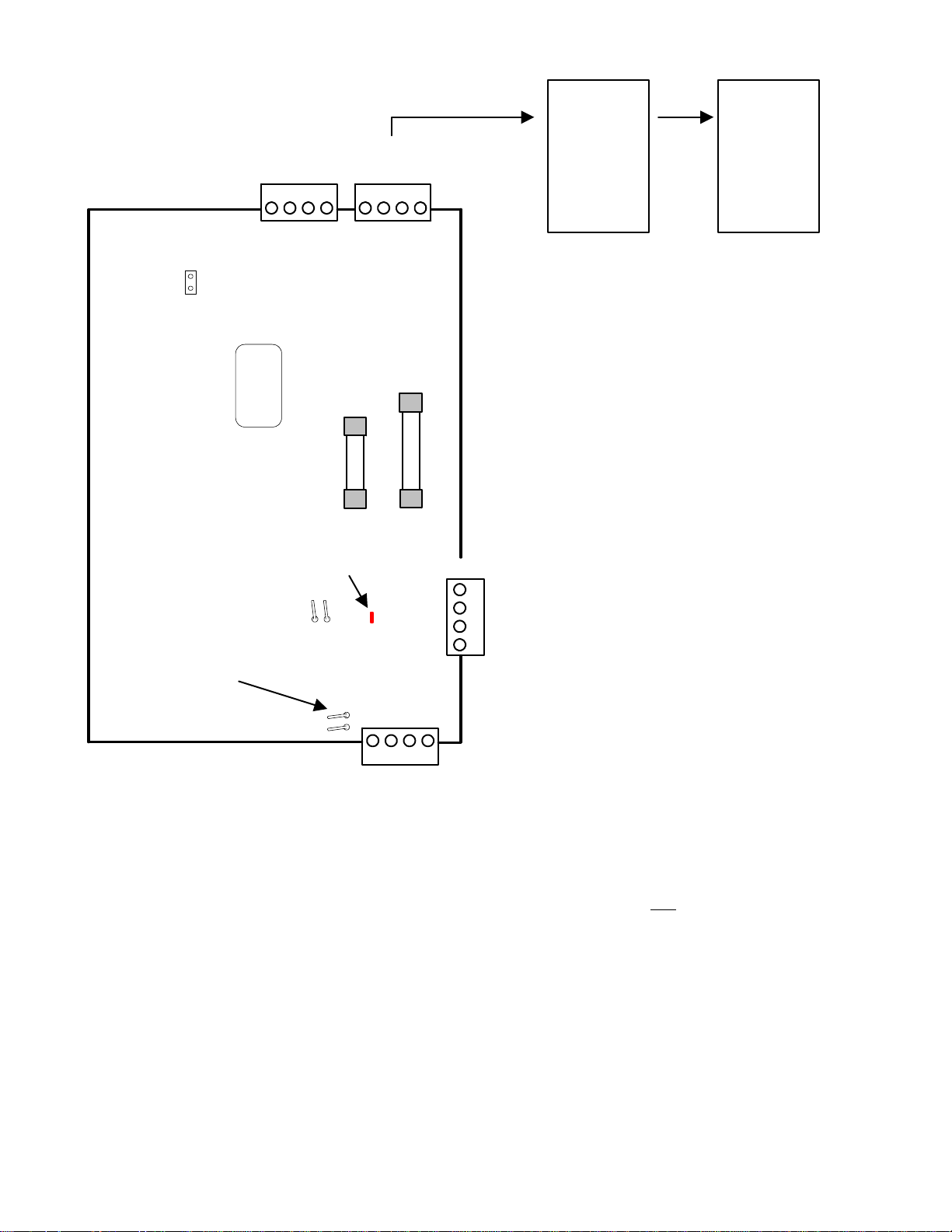

8 Zone Wiring and Mounting

Module Bus

1432

O/P2

(+)12V

Data A

n

d

w

e

o

l

e

l

r

e

g

y

Tamper

Spring

(-)0V

Data B

k

c

a

l

b

GND

COM

(+)12V

e

r

Current Consum ption

= 160mA max.

Reader

12

Data 0

Self resetting 0.5A fuse.

Unit voltage O K

indicator LED

Output 1

enabled LED

Output 2

enabled LED

NOTE: Output 2

current rating is

25mA.

Outputs

1432 5

O/P1

NC

NO

Always secure keypad base to wall using 4 scr ews.

Apply dealer's logo label

(supplied) in the indented

space on keypad door.

Recommended mounting height: 1.5

meters (4 feet, 9 inches) from floor

level to the bottom of the keypad.

Inputs

I/P6

I/P7

1

2345

313 1132 2 2

I/P8

COM

XXXXX

5 digit serial

number to

program in

Module

Programming

67

8

312

I/P3

I/P4

I/P5

COM

COM

I/P1

I/P2

Data 1

COM

Module Bus

communications

indicator LED

After placing the

keypad on its

base, make sure

the keypad's

securing screw

(supplied) is

always I N !

• Each 8 Zone Module 5 digit serial address sticker on the printed circuit board is entered in the “Suite

Security” programming. Not the Module programming.

Output 1 is a form “C” contact that changes state when this output turns on.

•

• Output 2 is a standard output that turns on 12VDC when it is enabled. It has a low current rating of 25mA to

trigger e.g. a low current relay.

• Input points can be configured as normally closed or open end of line (with 2.2K resistor) only.

• The Master Suite Security User can edit only Suite Security Authority Levels at the Suite Security Keypad and

LCD keypad. All other configurations must be done through the Director Software.

• Director Suite Security Authority Level “0”, System Authority Only means the user has no Suite Security abilities.

• Suite Security user groups can be allocated in blocks of 8 users. These are Director Suite Security Authority Level

“1”, Suite Security Unassigned. The F + 9 + PIN at a Suite Security keypad requires the user to be predefined in

the Director software database although you do not actually have to assign them to the suite (i.e. Suite Security

Authority of unassigned). A user assigned with suite Security Master Authority or through the Director software by

an Operator can do this via the Suite Security keypad MODULE at a later time. It simply allocates the space in the

database for the possible 8 users per Suite Security keypad similar to how you allocate points for possible future

use. The Director software restricts User's 1-8 to Suite Security keypad MODULE #1, User's 9-16 for Suite

Security keypad MODULE #2, etc .

10 Monitor ISM/xL™ Hardware Guide

22-0375 rev1.1

Page 15

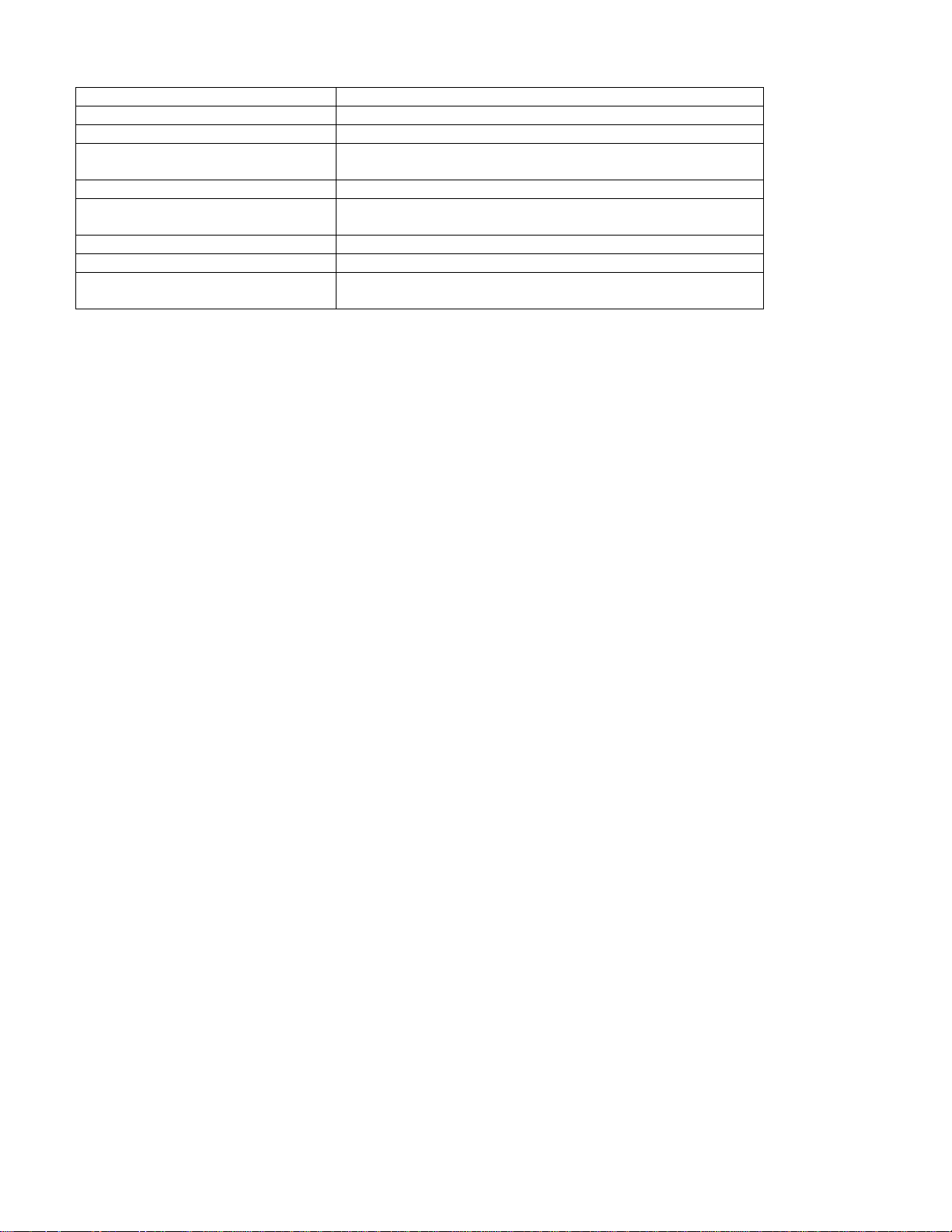

Authority Levels

MASTER enter “2”

Turn System ON

Turn System OFF

Turn System to STAY

Bypass Zones

Remove Bypass

Test System

Edit Users

Reset Alarms

Output Key Use

RESIDENT enter “3”

GUEST enter “4”

CLEANER enter “5”

Adding an Electronic Siren

• If it is necessary to add an electronic siren with a built in driver, the recommended connection is to use the on

board form “C” relay.

• An additional power supply must be added, as the Suite Security module does not have sufficient power to run a

siren.

• Connect the siren’s negative power connection to the power supply’s negative supply.

• Connect the power supply’s positive connection to the Suite Security module’s output # 1 relay common

connection.

• Connect the siren’s positive connection to output # 1 relay normally open connection. Program output # 1 to follow

when the area is in alarm (fire/burglary).

• When the area is in alarm, output # 1 will trigger and supply power to run the siren.

• The maximum number of Suite Security Modules that can be connected to one Main Panel is 60 and is separated

into 30 daisy chained on data connection: Module Bus 1 and 30 daisy chained on data connection: Module Bus 2

of the main control board.

• The ratio between the number of Suite Security Modules that can be used and regular modules that can be used

on one Main Panel is 5 Suite Security Modules for every 1 regular module.

• It is important to consider power requirements in big Suite Security Module systems. Adequate power supplies

must be added to the Suite Security Module cable runs and paralleled onto the Module Bus connections of the

Suite Security Module on the run that is designated where more power will be needed. Remember to add an

isolating diode to the Module Bus 12VDC connection at the Main Panel’s control board end as described in

Appendix “A”, “Adding a power supply to the Module Bus”, of this document. Otherwise, “Battery Trouble” will

occur.

22-0375 rev1.1 Monitor ISM/xL™ Hardware Guide 11

Page 16

8 and 16 Input/Output Exp ansion Modules

Refer to Installation Instructions P/N 22-0363 for

further information.

O/P15

O/P16

0V

0V

14321432

0V

O/P14

0V

O/P13

1432

TB9TB5TB1TB6TB2

312 312 312 312

5 digit serial number to

program in Module

Programming

XXXXX

Annunciator

output board

male plug.

Switched (+)

O/P1

0V

Switched (-)

O/P2

(+) 12V

I/P1

COM

I/P2

I/P3

COM

I/P4

I/P5

COM

I/P6

I/P7

COM

I/P8

O/P3

TB10 TB11 TB12

LED 1 Bus

communications

indicator

LED 2

follows O/P1

Tamper Pins

O/P4

O/P5

0V

312 312 312

0V

F1

P/N 342-3356

1/2 AMP

O/P6

Module Bus Aux Power

O/P7

0V

(-)

(+) 12V

(-)

(+) 12V

0V

Data B

Data A

(+) 12V

I/P16

COM

I/P15

I/P14

COM

I/P13

I/P12

COM

I/P11

I/P10

COM

I/P9

O/P8

1432

TB13

1432

312

312

312312

TB14

black

yellow

green

red

TB4

TB7 TB3 TB8

identical

operation

LED 9

LED 10

LED 11

LED 12

LED 13

1432

LED 14

TB9TB1TB2

LED 15

LED 16

I/P1

COM

312 312

I/P2

5 digit serial

number to

program in Module

Programming

I/P3

COM

I/P4

Outputs 3 - 8 do not exist.

Annunciator

Output Board

follows O/P1

XXXXX

TB3TB4

TB1 TB2

F1

1/2 AMP

P/N 342-3356

LED 1 Bus

communications

indicator

LED 2

Tamper Pins

0V

O/P12

0V

O/P11

0V

O/P10

0V

1432 1432

O/P9

(+) 12V

(+) 12V

Data B

Data A

(+) 12V

Module Bus Aux Power

COM

COM

(-)

(-)

0V

I/P8

I/P7

I/P6

I/P5

1432

TB13

1432

312

312

TB14

black

yellow

green

red

TB4

TB3

16 Input (8 Ou tput) Expander Module

16 Outputs with Annunciator Output Board

Current rating = 25mA without

annunciator card. 60mA with

annunciator card and all LEDs on.

8 Input (2 Output) Expander Module

10 outputs with Annunciator Output Board

Current rating = 25mA without

annunciator card. 52mA with

annunciator card and all LEDs on.

• The Annunciator Output Board (P/N 650-2660) can be used on either Input / Output module.

• When used on the 8 Input module, outputs 1 and 2 can be programmed but, in order to program outputs and

LEDs 9 – 16 on the annunciator card, outputs 3 – 8 must be skipped.

• The 8 Input module must still be assigned 16 outputs in order to program outputs/LEDs 9 – 16 on the annunciator

card.

• Outputs 1 and 2 are identical operation on both modules.

• 16 Inputs and 16 outputs are available on the 16 Input module using the annunciator card.

12 Monitor ISM/xL™ Hardware Guide

22-0375 rev1.1

Page 17

Output/Relay Card

TB4

312312 312

TB5

TB3

Mounting Holes

Screw into plastic

base posts at top of

Expander board.

Annunciator output

board female plug

back of this board.

Plug into Expand er board male plug

used for 8 outpu t/LED annunc. card

0V

O/P15

O/P16

LED2

Follows relay2

LED1

Follows relay1

0V

O/P14

Relay 2

J1

normal

dual

Relay 1

O/P13

O/P10

O/P12

NO

COM

NC

NO

COM

NC

O/P9

0V

O/P11

312

Form 'C' relays rated at 2 AMPS.

Current consumption = 70mA

312

with both relays/LEDs energized.

TB1 TB2

• Can be used in place of the 8-output/LED-annunciator card on 8 and 16 point Expander pods to reduce

installation of additional separate relays.

• Output 9 and 10 are relay outputs that can be configured the same as regular outputs but whose

contacts will change state upon activation.

• Outputs 11 to 16 act as standard voltage outputs that will turn 12VDC high upon activation.

• When using the card with the 8-pt. Expander, the pod is configured with 16 outputs and outputs 1 and 2

on the board can be programmed. Outputs 3 to 8 must be skipped, as they do not exist. Programming

for the card would then begin at 9 to 16.

• With the 16-pt. Expander, a full 16 outputs can be programmed.

Dual Action Relays

• When jumper J1 is in the lower position (dual), programming output 9 will cause both relays 1 and 2 to

trigger at the same time. Output 10 can not be programmed or used.

• When jumper J1 is in the upper position (normal), relay 1 will respond to output 9’s programming and

relay 2 will respond to output 10’s programming.

• In either jumper position, outputs 11 to 16 will react normally.

• If jumper J1 is not connected at all, relay 1 will follow output 9 but relay 2 and output 10 will not function

at all.

• LED 1 follows relay 1 when triggered and LED 2 follows relay 2 when triggered for Service use only.

NOTE: Also compatible with Chubb Smart Commercial Concentrator. Connected to a Chubb Smart alarm

system, card outputs would be 1 – 8. On a Smart commercial concentrator connected to a Fx/ISM Smart

Pod, card outputs would be the same as stated here, 9 – 16.

22-0375 rev1.1 Monitor ISM/xL™ Hardware Guide 13

Page 18

Refer to Installation Instructions P/N 22

-

0365 for further information.

RF Wireless Modules

Version 1

Insert in block inn er terminals

12 12

to align with module cover.

Antennas

NOTE: If the system’s Feature Set is greater than 5,

Module, Input number Type and Name are

programmed in the Director software program and

sent to the panel. All other wireless sensor

programming described here is done at the system’s

LCD keypad ‘Configs’ screens. Regardless that after

entering Configs, “No Local Edits” displays.

Monitor RF Module PCB

Current rating = 52 m A

Power ON LED

and RF reception

indicator.

5 digit serial num be r to

program in Module

Programming

Module Bus

Interface

Board

XXXXX

Bus

communications

indicator LED

ON

15678432

Dip Switch

Settings

must be left

in these

positions.

Tamper

Spring

Module Bus

ON

Jumper

J1 must

be out.

(+) 12V

1432

red

12

Data A

green

Data B

yellow

J1

0V

black

• Referred to as an Application Module.

• Uses ITI learn mode wireless sensors at 319.5 frequency.

• Maximum 32 sensors can be programmed per one Version 1 RF module.

• 16 wireless hand held keypads can be programmed per one V1 RF module.

• Programming is done locally through the LCD keypad. The RF module must be connected to the Module bus to

program.

• Mount centrally to the wireless sensors.

• Range approximately 31 meters (100 feet).

• If more than one V1 RF module is used, separate them 2.5 meters (8.5 feet) apart to prevent interference.

Programming

• Enter the module’s 5-digit address in Module programming and assign required number of input points for the

number of sensors being used. Do not assign outputs, as there are none. Turn on tamper and all other settings

may remain defaulted. Exit the Module programming and then go back to Module programming and the same

address. This initializes the module.

Hand Held Keypads

• When back at the same Module programming 5 digit address, press Save.

• Display reads No Keypad Learn. The first keypad-programming screen is e.g. M002A (A = 1

Keypad programming screens following this one are e.g. M001

can be programmed.

• Press the right arrow key. Display reads Enroll Keypad .

• Press the “ f “ (function) key on the hand held keypad.

• LCD keypad display changes to 00000.

• The first 2 zeros represent the area the keypad is assigned to.

• The next 3 zeros represent the input # the hand held keypad’s panic button (police badge icon) is assigned to.

Reserve a point # in the group of inputs assigned to the RF module for this.

14 Monitor ISM/xL™ Hardware Guide

st

keypad).

B – P for a total of 16 hand held keypads that

22-0375 rev1.1

Page 19

RF Handheld Keypad Operation

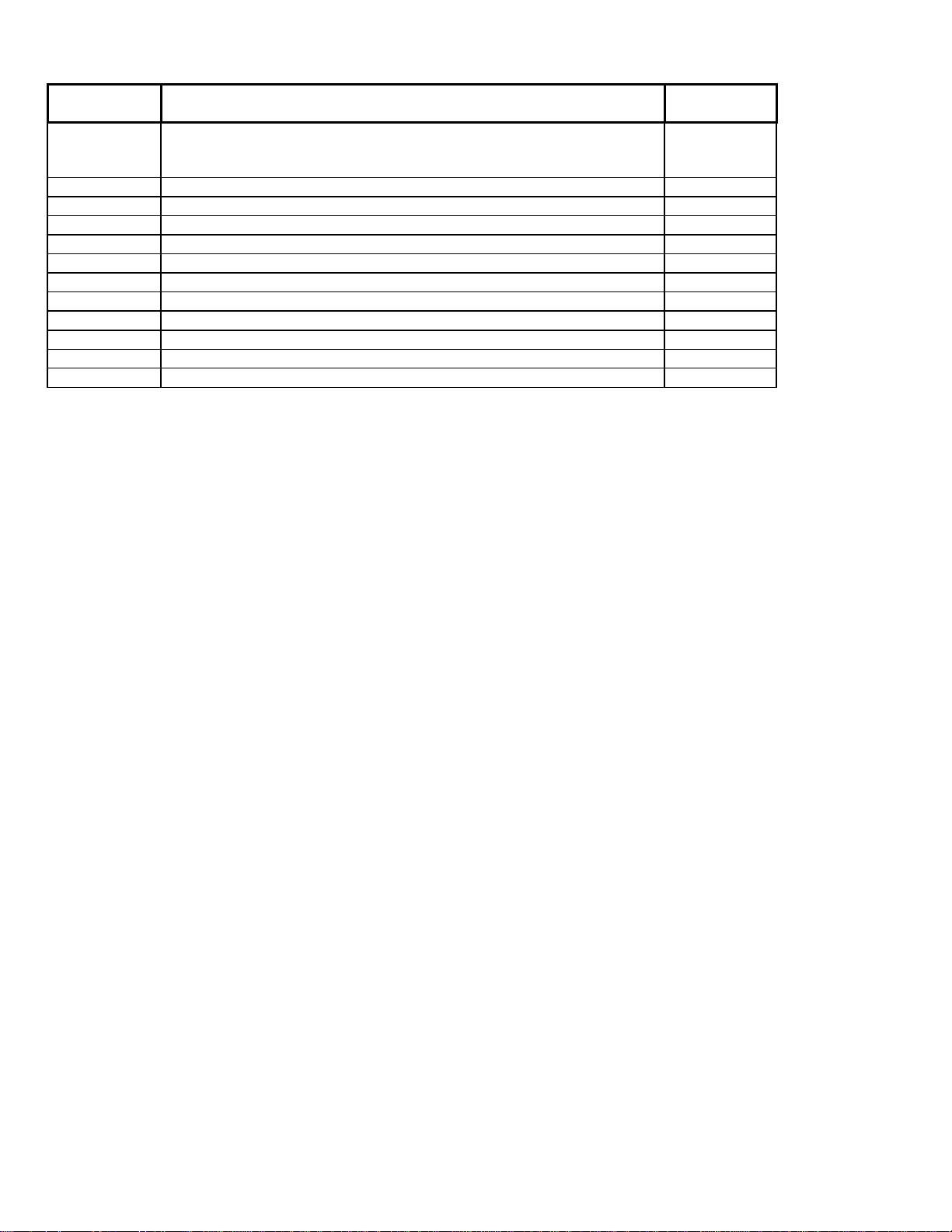

User Code + Command Key + 1 Turns Area OFF

User Code + Command Key + 2 Turns Area to STAY

User Code + Command Key + 3 Turns Area to Fully ON

User Code + Command Key + 4 System Test (turns on LCD keypad lights/sounder, system

siren for 5 seconds.

User Code + Command Key + 9 Clears or silences alarms.

User Code + Function Key + 1, 2

… 9

Function Key Press once to learn RF Hand Held Keypad into system.

(Escape Key) Used to clear incorrect entries.

Police Badge Icon Button Panic Button. Press and hold until rapid beeps heard to

NOTE: If “Allow User Entry Delay” in System programming is enabled, and a user arms to STAY, they are prompted

with a next screen message if they want an Entr y Delay or not while in ST A Y. If the area the Handhe ld Keypad is

assigned to is turned to STAY using the Handheld KP, this feature will default to “User Entry Delay Allowed”.

Engage Programmable Outputs Functions

enable.

Sensors

• Enter Point programming and the first input point # assigned to the RF module.

TIP: An easy way to find points assigned to this module and any modules with inputs and outputs is to

press the middle button when in the point’s main screen where its point type is configured. E.g. P001

button displays:

• Pressing the button below this will indicate on a help screen what module the point you are at is connected to.

E.g. screen displays:

digit module address). Outputs do not show, as the RF module has none. A module with outputs would also

include

applicable, in this special screen.

• Wireless sensor’s circuit types are always “0” – normally closed.

• Press Save and enter the Sensor’s name (12 characters max.) e.g. PIR JOHNS RM

• Press Save and a different screen displays saying No Sensor Learn.

• Press the right arrow key. Screen changes to Enroll…, Stop, Force.

• Trigger the tamper on the sensor or if there is no tamper, cause it to alarm.

• If it is not convenient to tamper the sensor, then it can be force learned by pressing the button beneath Force.

Cause the sensor to alarm to learn it into the system. Pressing the button beneath Stop can stop the Force

method.

• When the sensor has been learned, the screen will change to default: 3 .

• 3 represents the sensor’s supervisory signal time limit (0=disabled, 1=2hrs, 2=6hrs, 3=12hrs, 4=24hrs). The first

check mark is sensor tamper on or off. The second check is the hardwire input. Normally closed =

open =

keypad will toggle it.

• Press Save. Screen displays “Programming” and changes to the sensor’s wireless address e.g. Cnt:56DB5. Cnt

= wireless door window contact.

• The sensor has now been learned.

b000 – 000 in place of the mod address number. bCAPL output group and the output number range

. With the LCD screen cursor flashing under a check mark or a box, pressing any key number on the

(or ? for other modules).

002 (module # 2) Wireless (RF module) p013 – 016 (input point range 13 to 16) S#10097 (5

0, middle

normally

22-0375 rev1.1 Monitor ISM/xL™ Hardware Guide 15

Page 20

SENSOR

CATEGORY

Cnt Door Window Contact (surface mount)

FrP Fire Pull 3. .

Frz Freeze Temperature Detector 3..

Gls Glass Break Detector 3..

HKP Hand Held Keypad 0. .

PIR Passive Infra-red Detector 3..

Pnc Panic Pendant OR Hand Held Double Button Panic 0. .

Rcn Recessed Contact 3..

RoR Rate of Rise Detector 3. .

Smk Smoke Detector 3. .

SoS Shock and Sound Detector 3..

??? Unknown sensor type – delete this sensor and re-learn

- also used as an RF transmitter for hard wire inputs

- e.g. Overhead Door Contacts

DESCRIPTION DEFAULT

SETTINGS

.

3.

Testing (Signal Strength)

• Use the Service PIN to go to the TEST menu.

• Select App for application module and then W/L for wireless.

• Select Scan. Activate a sensor.

• The screen will display information about each sensor it receives. E.g. Cnt56DB5 (door/window contact and its

address),

• Press XESC escape to return to the TEST screen. Press Signal.

• Activate a sensor. Screen indicates signal strength of sensor it receives. E.g. “Strength is 8 !”. Signal strength of

7 to 8 is acceptable. Signal strength of 6 or less is poor to unacceptable. The input point # transmitting will also

indicate:

• Another method to check if a sensor is transmitting is to stand near the RF module holding a sensor and activate

the sensor. The large green LED, visible through the module’s cover will flash upon activating the sensor to

indicate signal transmission.

• RF Module sensor inputs OK or Not OK and Tamper can be checked in System Status/Area/Points.

• RF Module, hand held keypad(s) and sensor status can be checked in System Status under App – Wireless

using the left or right arrow LCD keypad keys for conditions such as low battery, sensor loss. Disregard any codes

in lower right corner of these screens.

014 (input #14), 80 02 4 (sensor transmit codes).

(Tx: 014).

16 Monitor ISM/xL™ Hardware Guide

22-0375 rev1.1

Page 21

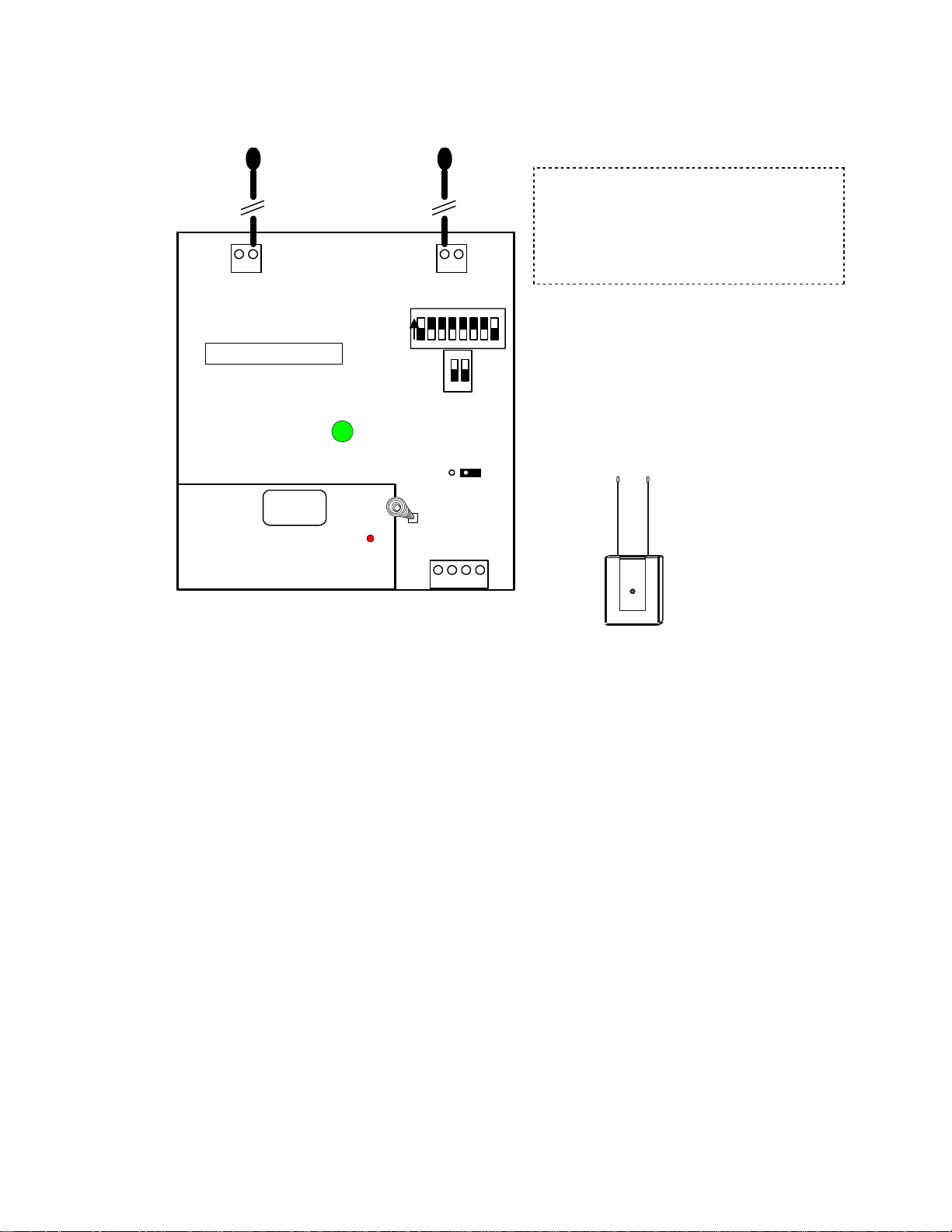

Version 2 Wireless

North American and

European Versions

are in the same

enclosures.

Antennas enclosed

North American Module

Version 2 Wireless Module

P/N 683-9240

(Refer to Installation Instructions P/N 22-9240 for further information.)

Side knockout

Plastic base cable

inlet knockouts

Interface Board

XXXXX

Box Tamper

Enable

Jumper

See NA Module Notes.

NOTE: DO NOT attempt to

jumper this pin block.

Damage may occur. It is for

the manufacturer’s use only.

1432

Interconnection

Data Send to Interf ace board LED

5 digit serial number

to program in Module

Programming

Back knockout

w

k

o

l

c

l

e

a

l

y

g

b

Green

(-)0V

Data B

Module Bus

Yellow

Diagnostic LEDs

See NA Module No tes.

Module Bus

communications

indicator LED

Box Tamper Spring

Box Tamper Enable Jum per must be

removed. See module notes below.

#1 or #2 Receiver Jumper

See NA Module Notes.

e

e

r

Data A

n

d

e

r

1432

(+)12V

Total Current

Consumption

= 75mA

1

2

Radio Receiver Board

Decode LED

Valid Decode LED

See NA Module Notes.

Radio Antennas

22-0375 rev1.1 Monitor ISM/xL™ Hardware Guide 17

Page 22

Versio n 2 No rth American Wireless General Information

• The V2 Wireless Module communicates with Inovonics learn mode wireless sensors. They transmit with Frequency

Agile 900MHz spread spectrum radio transmissions.

• For each sensor’s instructions, consult the Inovonic’s instructions packed with each sensor.

• Each wireless (RF) module supports a maximum of 32 wireless sensors. The V2 wireless module must be

connected to the module bus to enable programming.

• For programming information, see the MONITOR Commissioning Reference Guide, mentioned at the beginning of

these installation instr uc tio ns .

• Mount the module centrally to the wireless sensors.

• Install module away from large metal objects.

• Mounting the module on metal surfaces will impair performance.

• This module is intended for indoor use only. Use in outdoor applications may impair performance.

• If a sensor reports a ‘low battery’ and the sensor’s battery is replaced, the sensor’s reset button must be pressed to

restore the sensor.

NOTE:

Reed Switch

Hardwire

Input

Tamper

Example:

North American

Battery

Wireless Door/

Window Sensor

Internal View

Reset

Button

a hardwire input and some can only have a

hardwire input. Check your sensor’s model/part

number in your sales order to ensure you have the

correct version.

A North American version door/window sensor has

2 reed switches and one hardwire input. Eit her

position reed switch and the hardwire input can be

used for e.g. 2 doors. However, if only a reed

switch is used, the hardwire input must be closed

with a wire short. If only the Hardwire input is

used, the magnet must be installed next to one of

the reed switches to close the circuit.

Some sensors can have reed switches and

NA Module Notes

Tamper Enable Jumper

• Enable Box Tamper Detection: While the module is de-powered, remove this jumper. When power is applied to

the module, the spring box tamper on the Interface board will be active.

• Disable Box Tamper (factory default): While the module is de-powered, replace this jumper if it had been removed.

Re-power the module and the box tamper is disabled.

Diagnostic LEDs

Yellow LED Green LED Condition Description

0 to 9 pulses to

indicate module

serial number,

5 digit value.

Off Flashing slowly. All ok System operating normally.

On Flashing slowly. Sensor Trouble One or more of the RF sensors enrolled is having

On for 1 second

per serial number

digit.

Module Serial Five

Number display

When the board is first powered up, the serial

number is displayed in an encoded format. The

number of times the yellow LED flashes while the

green LED is ON steady gives the digit value.

E.g. green on, count 3 flashes on yellow, green

off, first digit is “3”. Green turns back on, yellow

flashes 9 times, green off, second digit is “9”.

Etc. etc. until the entire serial number is

displayed, one digit at a time. It takes several

seconds to complete the entire process. NOTE:

“0” is indicated by the green LED turning on and

the yellow LED does not flash.

trouble (supervision fail, sensor tamper or low

battery). Wireless test and status menus can be

checked at the system LCD keypad to identify

the sensor trouble. Consult the Commissioning

Reference Guide for these procedures.

18 Monitor ISM/xL™ Hardware Guide

22-0375 rev1.1

Page 23

Flashing slowly. Flashing slowly. Receiver Failure The receiver board is not communicating

properly with the interface board. Check the

condition of the three wire interconnec tio n

between the two boards and check power.

Flashing fast,

alternating with

the green LED.

Flashing fast,

alternating with

the yellow LED.

The Module serial

number is not

programmed.

The non-volatile module memory is not

programmed or has failed. If (re)programming

fails, return the module to the factory for a

replacement, .

Data Send to Interface Board LED

• Flashes as data is transmitted to the Interface, which then transmits the information over the module bus to the

main panel.

Decode LED

• Flashes as any RF data is being received.

Valid Decode LED

• Flashes as the receiver decodes a message.

# 1 or # 2 Receiver Jumper

• WARNING: Disconnect the module bus connector, to remove power, before re-positioning this jumper.

• If it is necessary to mount two receivers close to each other, they must be at least 91.4 cm apart (3 feet).

• This jumper on one of the receivers must be set in the # 1 position. This jumper on the other receiver must be in the

# 2 position.

• When there is only one receiver in a general area, this jumper is left in the # 1 position (default).

• Never leave this jumper out.

Interface Board

1432

Interconnection

Data Send to Interface board LE D

Radio

Box Tamper Spring

#1 or #2 Receiver Jumper

Position 1

Receiver 1

Position 2

Receiver 2

1

2

NOTE: If the system’s Feature Set is greater than 5,

Module, Input number Type and Name are

programmed in the Director software program and

sent to the panel. All other wireless sensor

programming described here is done at the system’s

LCD keypad ‘Configs’ screens. Regardless that after

entering Configs, “No Local Edits” displays.

Receiver

Board

European and Australian Module

Refer to Euro Installation Instructions P/N 22-9241 and Australian P/N 22-9242 for further information.

• The EURO and Australian V2 Wireless Modules communicate with Inovonics learn mode EURO wireless sensors.

For each sensor’s instructions, consult the Inovonic’s instructions packed with each sensor.

• Each EURO and Australian wireless (RF) module supports a maximum of 32 wireless sensors. The V2 wireless

module must be connected to the module bus to enable programming.

• Mount the module centrally to the wireless sensors.

• Install module away from large metal objects.

• Mounting the module on metal surfaces will impair performance.

• This module is intended for indoor use only. Use in outdoor applications may impair performance.

• If a sensor reports a ‘low battery’ and the sensor’s battery is replaced, the sensor’s reset button must be pressed to

restore the sensor. Re-check the sensor’s programming to ensure it is correct.

22-0375 rev1.1 Monitor ISM/xL™ Hardware Guide 19

Page 24

European and Australian Version 2 Wireless Module cont.

Hardwire Input

Reed Switch

Tamper

Example:

European

Battery

Door/Window

Wireless

Contact

Internal View

Factory Wired

Parallel

Interconnection

Reset

Button

NOTE:

Some sensors can have a reed switch and

hardwire input and some can only have a hardwire

input. Check your sensor’s model/part number in

your sales order to ensure you have the correct

version.

A European version door/window sensor has 1

reed switch on its side and one hardwire input.

Both can be used for e.g. 2 doors. However, if only

the reed switch is used, the hardwire input must

be closed with a wire short. If only the hardwire

input is used, the magnet must be installed next to

the reed switch to close the circuit.

Side knockout

Plastic base cable

inlet knockouts

Interface Board

XXXXX

Tamper

Enable

Jumper

See Module notes.

NOTE: DO NOT attempt to

jumper these pin blocks.

Damage may occur. They are

for the manufactur er ’ s use only .

Factory Wired

Parallel

1432

Interconnection

5 digit serial number

to program in Module

Programming

Factory Wired Parallel Interconnection

Back knockout

Yellow

Green

Diagnostic LEDs

Module Bus

communications

indicator LED

Interface Board Tamper Spr ing

Tamper Enable Jumper must be

removed. See Module notes.

w

k

o

e

l

c

l

e

r

e

a

l

y

g

b

(-)0V

Data A

Data B

Module Bus

n

d

e

r

1432

(+)12V

Total Current

Consumption

= 75mA

TX

RX

Transmit &

Receive to

Interface

Brd LEDs

Radio Antennas

Radio Brd Tamper Spring

New Zealand Australia

European

Radio Receiver

Board Version

Decode LED

See Module notes.

20 Monitor ISM/xL™ Hardware Guide

Radio Brd Tamper Spring

NOTE:

Ensure the location jumper

selection is in the correct position

Radio Antennas

Australian

Radio Receiver

Board Version

Decode LED

See Module notes

TX

RX

Transmit &

Receive to

Interface

Brd LEDs

22-0375 rev1.1

Page 25

Euro and Australian Wireless Module Notes

Tamper Enable Jumper

• Dual Tamper Detection: While the module is de-powered, remove this jumper. When power is applied to the

module, both the Interface and Radio board tampers are active. With the jumper in, only the Radio board’s tamper

is active.

Diagnostic LEDs

Operation is the same as the previously mentioned North American version.

Transmit and Receive data between Interface and Radio Boards, LEDs

• Flash as data is transmitted between the Interface and Radio boards, which supplies information over the module

bus to the main panel.

Decode LED

• Flashes as any RF data is being received.

Euro / Australian RF Repeater Module

LEDs

Decode.

(Processing RF

DATA)

Transmit DATA

Low S/B Battery

Main power on

Re-chargeable Stand-by Battery (12 hr life span)

Plug

Side knockout

Back knockout

Power Input

Insert a wire link

(short) in this block

to disable tamper.

Plastic base cable

inlet knockouts

Tamper

Spring

(+)12V

(-)0V

Total Current

Consumption

= 40mA

Press to reinitialize Repeater if all power lost.

Reset

Button

This 7 pin plug not used.

NOTE: Re-check the Repeater’s

programming to ensure it is correct.

• The repeater module is used to increase the range of transmitting and receiving signals.

• Mounting for the Repeater is the same as the Receiver as it is in the same plastic enclosure. Follow the same

General Information Notes as the Receiver.

Version 2 Wireless Programming

NA and Euro Modules

The version 2 wireless module is very similar to the

version 1 in the way it learns wireless sensors.

• The V2 does not support wireless keypads and it is

not necessary to re serve input point numbers for

keypad ‘panic’ buttons like V1.

V2 Module Programming

• The V2 has a 5-digit module serial number, which is

programmed into the system module programming,

like the V1. For systems with a Feature Set of 5 or

above, local configuration programming at an LCD

keypad cannot be done. Module enrollment, input

point assigning, must be done through the Director

software and sent to the panel. V2 wireless sensors

can be learned into the system the same as V1

through the LCD keypad. V1 wireless sensors can

not be used with the V2 module and V2 sensors can

not be used with the V1 module.

• If for some reason the serial number sticker is

missing, the V2 will display its serial number when it

is first powered. Using the yellow and green LEDs

beside the module bus terminal block, the number

of pulses on the yellow LED while the green LED is

ON, gives the digit value. E.g. green on, count 3

22-0375 rev1.1 Monitor ISM/xL™ Hardware Guide 21

Page 26

programmed through the

system’s LCD key pad. If the module config was sent

button, press it several

button) press the button on the keypad under Force.

When the sensor has been

pulses on yellow, green off, first digit is “3”. Green

turns on, yellow pulses 9 times, green off, second

digit is “9”. Etc. etc. until the entire serial number is

displayed, one digit at a time. It takes several

seconds to complete the entire process. NOTE: “0”

is indicated by the green on and NO pulses of the

yellow LED.

Module Programming

• Program the V2 module serial # into the module

configurations. Ass ign the number of input points

required (4 to 32). Like the V1, the V2 does not have

outputs. The outputs selection may be left as ‘0’.

After making these selections, press the button

below ‘Next’ in the LCD keypad’s module enrollment

screen, or send the module info to the panel from

Director.

• The next screen will look

like this. It can only be

AllSVN:1 Force:2

↓Save ↓

to the panel by the Director, go to an LCD keypad

on the system and log on as a service user. Select

‘Config’ and the first Module Configurations screen

for this module: e.g. M005

button from that screen to get to this one

AllSVN: V2 Module Supervision Timeouts. The

↓0. Press the ‘Next’

.

time allowed before a supervision signal is

transmitted from the V2 because it has not received

a trigger or supervisory signal from any of the

sensors assigned to it.

Selections: 1 = 2 Hrs, 15 Min (default)

2 = 6 Hrs, 35 Min

3 = 12 Hrs

4 = 25 Hrs, 15 Min

0 (None) cannot be entered.

Force: The number of times any sensors should be

triggered before the V2 will Force learn it into the

system. This can be helpful if in a big system with

e.g. wireless PIRs that are being periodically tripped,

the force count is increased to avoid false ‘force’

enrolment of a sensor.

The default is 2 triggers but can be changed from 1

to 9 triggers.

When these selections are acceptable, press the

Save button. Pressing the button will display the

module type and its input and output range.

Input Configuration

• Wireless sensor’s circu it types are always “0” –

normally closed.

• If the system’s Feature Set is greater than 5, the

input point type and name screens cannot be

programmed through the system’s LCD keypad

Configs. That information must be programmed in

the Director software and sent to the panel.

If the circuit type, sensor type and name have been

programmed into the system with the LCD keypad

and Save is pressed, the next screen below will

display:

If they were programmed in using the Director

because the Feature set is greater then 5, re-enter

input point programming at the keypad and ignore

any warnings about no programming using the

keypad. Wireless points are learned into the system

using keypad input programming regardless of the

Feature Set. Return to this following screen and

follow the next steps:

• Press the right arrow key

on the LCD keypad.

(xxx represents an input #)

• In this next screen, if the

V2 sensor has a tamper

times until the screen changes. Or, if the sensor does

No Sensor

↓Save ↓

→Learn

Pxxx↓2

Enroll....

↓Stop ↓Force

not have a tamper button (e.g. pendent panic

The down arrow next to Force will clear. Trigger the

sensor as many times as Force is set in the

previously mentioned

AllSVN:/ Force: screen

(default: 2 times). NOTE: The sensor cannot be

triggered in rapid successions. Trigger it once, wait

a few moments and then the next trigger and wait a

few moments again. As many times as the Force

times are set. To disengage Force, press the button

under ‘Stop’. The keypad display will return to the

‘No Sensor – Learn’ screen. If a sensor is not

enrolled within 1 minute, the

to be pressed again.

•

detected, this screen will

display:

• SVN: Sensor Supervision Timeouts. The time

Force button will need

SVN:0 TMP: IN:

↓Save ↓Del

allowed before the V2 will send a supervision signal

identifying a specific sensor that has not transmitted

after these timeout selections.

Selections: 0 = None (default)

1 = 2 Hrs, 15 Min

2 = 6 Hrs, 35 Min

3 = 12 Hrs

4 = 25 Hrs, 15 Min

TMP: Whether the sensor’s ‘Tamper’ will be

monitored (

IN: Whether the sensor alarm output is ‘Inverted’

) or not ( default). This selection should always

(

default) or not ().

be left defaulted unless it is necessary for a sensor

to act opposite to its regular normal or alarm

condition.

Del: Delete Sensor. After a sensor has been

programmed or, an error was made, the keypad

button below this selection can be pressed and the

sensor will be deleted. The screen will return to ‘No

Sensor – Learn’.

If the SVN:0 TMP: IN: screen selections are

acceptable, press

• The screen will momentarily display:

Programming...‘

‘

Save.

22 Monitor ISM/xL™ Hardware Guide

22-0375 rev1.1

Page 27

firmware version number.

• This screen will then

display:

SN#:1B3414: This is

SN#:1B3414 →Edit

↓Save ↓ Pxxx↓2

the Serial Number of the sensor that was enrolled

into this input number.

Pressing the keypad right arrow button will display

“SVN:0 TMP: IN:” screen for editing. The

the

‘Del‘ button can also be pressed to remove the

sensor and another sensor could be pr ogr am med

for this input number if desired.

Equipment/Pseudo Point Selections for Wireless V 2

Module Trouble (E011), ensure this is set to detect:

• Module Bus connection to V2 module failure.

• V2 module failure.

• V2 module has not received any sensor signal for X

amount of time (

AllSVN).

Module Battery Low (E012), ensure this is set so

‘Senor Low Battery’ will be detecte d.

Module Program Edit (E013) can be optionally set to

detect when the sensor settings have been changed.

This alert will not re-set until there have not been any

further program changes for one hour.

LCD Keypad Status

• Enter ‘Status’ at the system’s LCD keypad.

• Press the keypad’s right arrow key until ↓App

(Application Module) displays. Press the keypad

button under it.

• When Wireless2 or WL2 displays, press the butt on

under

↓Yes.

• Keypad left and right arrow keys can be pressed to

scroll through the input numbers and V2 module

conditions.

Input Number Status

• The input number range associated with the V2 will

display and the input’s condition e.g.

• It can also display the following for an input:

NoSvn‘ No Supervision. A sensor supervision signal

‘

009→Ok.

failure. The input will appear in point status as a

tamper.

Lobat‘ Low senor battery. This will generate a

‘

module or pod low battery alert. If the sensor’s

battery was replaced, the sensor’s reset button on

its printed circuit board must be pressed.

Not Enrolled‘ A sensor is not programmed to

‘

this input. The input will appear in point status as a

tamper. Delete the input if it will not be used.

NoRcv‘ No Receiver detected. V2 module

‘

malfunction.

PtTmp‘ Input sensor tamper. The input will appear

‘

in point status as a tamper.

V2 Module Status

• After scrolling through all the V2 input conditions, the

condition of the V2 module will display: e.g.

Pod→Ok.

• It can also display the following for a module:

NoSvn‘ The V2 module is not communicating on the

‘

module bus.

‘

NoSen‘ The V2 module has not received

communication from its sensors, based on the

supervision delay period set for the V2 module

AllSVN).

(

• Module Status will displ a y the V2 m odule in tamper

for either of these conditions.

V2 Test Menus

• Log on to the system LCD keypad as a Service

User.

• Select ‘Test‘ from the Menu and App → WL2 or

Wireless2.

• This screen will display:

(X.Xx) indicates the V2

• ‘Signal‘ selects a sensor signal strength menu.

• Pr es s ing ‘Signal‘ will

display this screen:

xxx represents an

input sensor number on the V2 module.

< > keypad left and right arrow keys can be pressed

to scroll through the input numbers.

Si(gnal) > 3 OK is an example of the V2 receiver

getting an adequate signal strength from the sensor.

• This screen is an example

of the V2 receiver getting

an inadequate signal from

the sensor.

• The second line in both screens displays the actual

signal strength measured on a scale of 000 to 021

(maximum).

• If a sensor has not been enrolled in an input

number,

• ‘Scan‘ selects an RF scanning menu.

• When ‘Scan’ is pressed the screen will display

‘

Waiting...’ to receive an RF transmission from

‘Not Enrolled‘ will display on the top line.

any sensor. NOTE: if this screen never changes, it is

possible the V2 module is not working properly.

• If this screen displays

when a signal is received,

it is from a sensor that has

not been enrolled in the system, indicated by

LEARN. SN#:1B3414 is the sensor’s unique serial

number.

• If this screen displays

when a signal is received,

it is from a sensor that is

enrolled in the system, indicated by P#xxx where

xxx is the input number.

• Either an asterisk or a blank will display after a

sensor’s serial number as it toggles every time a

transmission from a different sensor is received.

• In either screen, ‘AA BB‘ is changing data that can

be ignored. It is for internal Engineering use only.

Check (X.Xx)

↓Signal ↓Scan

xxx < > Si > 3 OK

Signal 014 of 21

xxx < > Si > 4 Weak

Signal 001 of 21

SN#:1B3414 LEARN

AA BB

SN#:1B3414*P#xxx

AA BB

22-0375 rev1.1 Monitor ISM/xL™ Hardware Guide 23

Page 28

Refer to Installation Instructions P/N 22

-

0367 for further information.

Fire Module

5 digit serial number to

program in Module

Programming

Annunciator

Jumper for each input.

IN = Input wired Class "A"

(double loop)

OUT = Input wired Class "B"

(normally open, 2.2K resistor

end of line).

TB9

1432

output board

male plug.

Switched (+)

O/P1

0V

Switched (-)

O/P2

(+) 12V

NOTE: Do not twist pairs

together under connections.

Keep connections separate.

red

green

yellow

black

loop 1

loop 1

loop 2

loop 2

loop 1

loop 1

loop 2

loop 2

loop 1

black

loop 1

loop 2

loop 2

2.2K

loop 1

loop 1

loop 2

loop 2

yellow

1432 1432 1432 1432

Jumper IN

INPUT1

Jumper OUT

INPUT2

INPUT3INPUT4

m

r

a

l

A

Tamper

(if existing)

r

a

l

A

Tamper

(if existi ng)

Class "A" Wiring

(fire switches)

t

c

a

common

t

n

o

C

normally open

normally closed

closed tamper

closed tamper

Class "B" Wiring

(door contacts, PIRs)

t

c

a

common

t

n

o

C

normally open

m

normally closed

closed tamper

closed tamper

Current Rating = 25mA without annunciator card.

60mA with annunciator card and all LEDs on.

• Capacity of 8 inputs and 10 outputs (with standard plug on output annunciator card).

• With jumper settings illustrated, inputs can be wired class “A”. A short between the 2 loops wired between normally

open connections = alarm. Either loop opening = tamper. Most commonly used to monitor water flow sprinkler

alarm switches.

Or the inputs can be wired class “B”

connections = alarm. Resistor loss = tamper. This connection can be used to monitor sprinkler switches such as

water pressure and gate valve but can also be used as burglary inputs.

• Whether the point is class “A” or “B”, fire or burglary, the point circuit type is always “0” normally closed. Any point

type may be used. However, for a class “A” fire point, it must be defined as “010” = Fire Class A.

• For an approved fire monitoring system, an 18V, 40VA, AC transformer (P/N 859-0052) must be installed on the

control unit box. This txmr. has two 18V secondary white leads connected to motherboard AC input. The txmr.

primary is then fastened to an AC supply (e.g. 2X4 electrical box, P/N 573-3735 and cover, P/N 573-3742).

• For ULC applications all cabling connected to the fire module MUST be run inside armored BX flex cable. From fire

module to sprinkler switches and Module Bus line from fire module directly back to main control unit.

• When programming outputs, this board is similar to the 8/16 input/output expander module. Outputs 3 to 8 do not

exist. Therefore, if the outputs on the annunciator card are required, the module is programmed with 16 outputs.

st

The 1

annunciator card.

and 2nd output can be programmed. Outputs 3 to 8 are skipped. Outputs 9 to 16 can be programmed on the

. A short across the 2.2K end of line resistor between normally open

XXXXX

F1

1/2 AMP

P/N 342-3356

LED 1 Bus

communications

indicator

LED 2

follows O/P1

Tamper Pins

Fire Module

(-)

(+) 12V

(-)

(+) 12V

Aux Power

0V

Data B

Data A

(+) 12V

Module Bus

INPUT5 INPUT6 INPUT7 INPUT8

TB14

1432

TB13

1432

1432

143214321432

black

yellow

green

red

loop 2

loop 2

loop 1

loop 1

loop 2

loop 2

loop 1

loop 1

loop 2

loop 2

loop 1

loop 1

loop 2

loop 2

loop 1

loop 1

24 Monitor ISM/xL™ Hardware Guide

22-0375 rev1.1

Page 29

Graphic Map Annunciator Module

Refer to Installation Instructions

P/N 22-0364 for further

Features:

• Recommended mounting height: 1.5 meters (4 feet, 9 inches).

• Can be assigned with maximum 16 outputs to turn on any 16 LEDs over the display of 70 possible LED locations.

• This module can be assigned with 4 hardwire inputs.

• Outputs 1 and 2 can be the first 2 LEDs on the screen or used as hardwire outputs or both as these 2 outputs will

turn on both sources (LEDs or hardwire connections) at the same time.

• When outputs 1 and 2 are used as hardwire connections they behave the same as on the input/output modules.

Output 1 turns positive 12V and output 2 turns negativ e.

• The 0V negative for hardwire positive output #1 and 12V positive for hardwire negative output #2 can also be used

as auxiliary 12V power connections (fused at .5 AMP).

• Applying a magnet to a reed switch on the PCB will turn on all LEDs in the display for testing.

• The Map Module drawing software is a Windows based draw program. It is installed as a template to use over and

over. It allows a user to do a diagram of a system’s layout for the LEDs to turn on and highlight certain point

programmable output conditions in the diagram. E.g. point not normal, point in alarm. It could also be used to make

alpha/numeric labels that can have the LEDs turn on next to them for various area, point indications. E.g. “Area 1

ON”, “Area 2 STAY”. When the diagram is complete, it can be printed out and cut out to fit inside the Map Module’s

display.

• The Map Module drawing software is available on the Director Software CD and listed as “MAP MODULE

TEMPLATE.dot.”

LED PIN CONNECTION STRIP

LED Test Reed Switch

hold magnet over it and