Page 1

EV1116 Series PIR Detector Installation Sheet

)

EN DA DE ES FI FR IT NL NO PL PT SV

1

3

4

2

(1)

(3)

16 m range (52 ft. 6 in.)

10 m (32 ft. 9 in.)

8 m (26 ft. 2 in.)

6 m (19 ft. 8 in.)

4 m (13 ft. 1 in.)

2 m (6 ft. 6 in.)

0 m

2 m (6 ft. 6 in.)

4 m (13 ft. 1 in.)

6 m (19 ft. 8 in.)

8 m (26 ft. 2 in.)

10 m (32 ft. 9 in.)

(optimum) 2.4 m

(7 ft. 10 in.)

1.2 m (3 ft. 11 in.)

4 m (13 ft. 1 in.)

2

m

(2)

16 (52 ft. 6 in.

.0 m

Note: For UL compliant installations please note an undercrawl

zone of 3 feet at minimum mounting height and 5 feet at

maximum mounting height.

© 2013 UTC Fire & Security Americas Corporation, Inc. 1 / 32 P/N 146251999-4 (ML) • REV D • ISS 12MAR13

All rights reserved.

Page 2

5

J6

J4

J3

EV1116

J1

EV1116AM

J4

J3

J6

J1

6

2 / 32 P/N 146251999-4 (ML) • REV D • ISS 12MAR13

Page 3

7

(1)

()2

EV1116

GND

+12V

Alarm

Alarm

Tamper

Ta m p e r

4

567

WT

D/N

8

J3

J4

J3

123

CP

Normal

< 33 Ω

larmA

8

Zone X

EV1116 EV1116AM

J3

J4

CP

Normal

larmA

Tam p er

Short

4.7 k

9.4

8

0

Ω

GND

+12V

123

Ω

kΩ

Alarm

Alarm

Ta m p e r

Tamper

567

4

Zone X

WT

J4

D/N

J3

8

J4

J3

GND

+12V

123

GND

+12V

123

Alarm

Alarm

Alarm

4

Alarm

4

Ta m p e r

Ta m p e r

567

Tamper

Tamper

567

WT

WT

D/N

J4

8

J3

CP

D/ND/N

8

Normal

larmA

Tamper

Short

AM/TF

EV1116AM

J4

CP

Normal

larmA

GND

+12V

Alarm

2

3

1

4.7 k

Ω

9.4

kΩ

88

0

Ω

< 33 Ω

8

Alarm

Tamper

5

4

Zone X

AM

Alarm

4

Zone X

Rtest

11

WT

D/N

AM

Ta m p e r

Ta m p e r

5

6

AM

Rtest

7

9

8

11

10

Zone Y

Alarm

3

Alarm

3

Alarm

Tamper

5

4

Alarm

Tamper

5

4

WT

D/N

AM

Ta m p e r

AM

Rtest

7

9

8

6

Ta m p e r

6

WT

7

11

10

D/N

AM

AM

Rtest

9

8

11

10

J3

J4

J4

J3

GND

1

GND

1

+12V

2

+12V

2

GND

+12V

Alarm

3

2

1

WT

D/N

AM

Ta m p e r

7

9

8

6

10

Zone Y

J4

J3

Normal

Ta mp er

Short

GND

+12V

Alarm

Alarm

Ta m p e r

Tamper

WT

567

123

4.7 k

9.4

0

Ω

kΩ

8

Ω

larmA

4

8

Zone X

EN: Installation Sheet

Introduction

The EV1116 series includes the EV1116 and EV1116AM PIR

motion sensors. They have a patented mirror, pyro and signal

processing technology.

Note: EV1116AM has not been evaluated by UL.

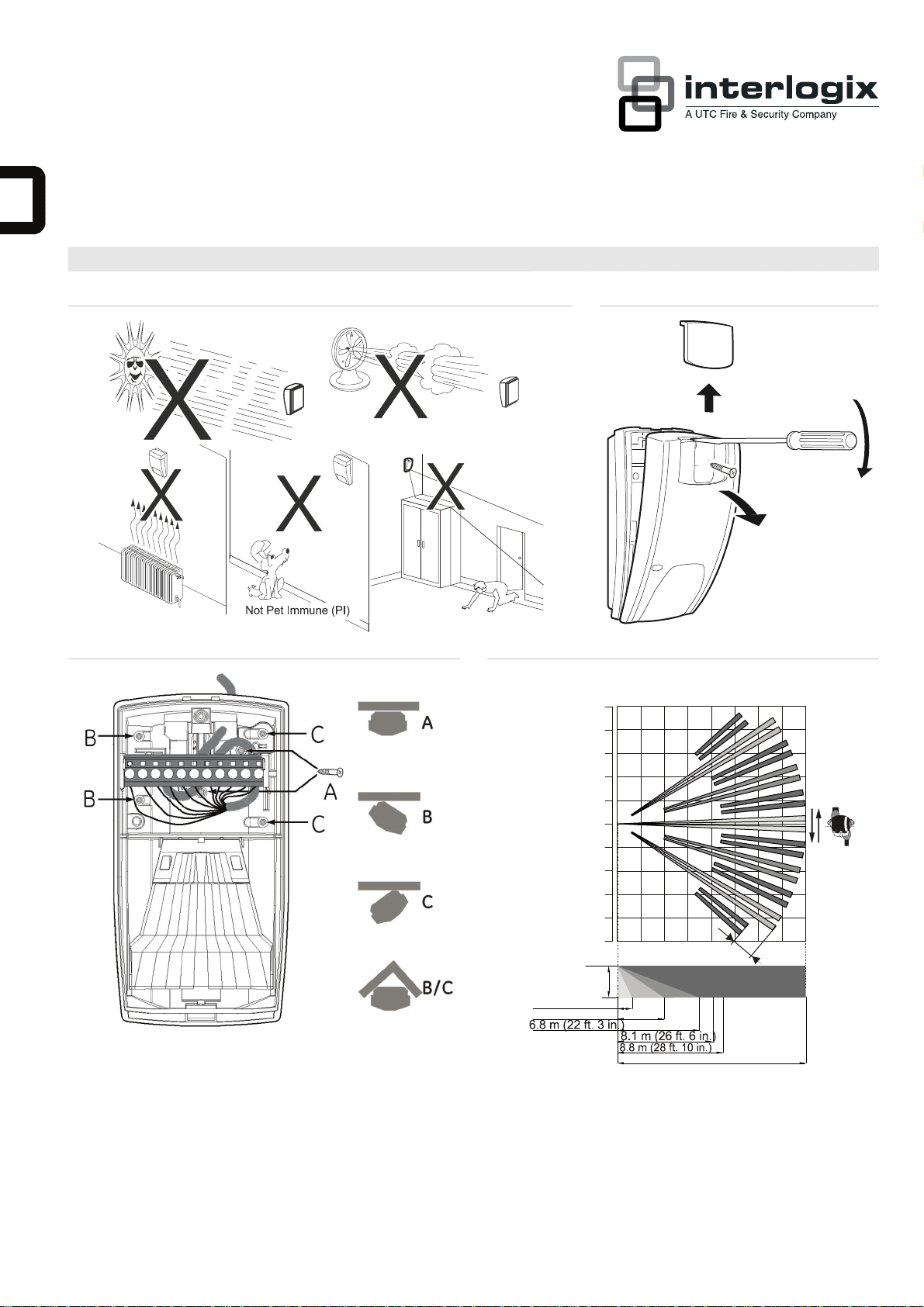

Installation guidelines

The technology used in these detectors resists false alarm

hazards. However, avoid potential causes of instability (see

Figure 1) such as:

• Direct sunlight on the detector

• Strong draughts onto the detector

• Heat sources within the detector field of view

• Animals within the detector field of view

• Obscuring the detector field of view with large objects,

such as furniture

• Objects within 50 cm (20 in.) of the anti-masking (AM)

detector

• Installing two detectors facing each other and less than

50 cm (20 in.) apart (only AM detectors)

J4

J3

GND

+12V

2

1

WT

D/N

Alarm

Alarm

3

4

AM

Ta m p e r

Ta m p e r

5

AM

Rtest

7

9

8

6

11

10

CP

4.7 k

9.4

0

Ω

kΩ

88

Zone X

Ω

Zone Y

Normal

larmA

Tamper

Short

AM/TF

Installing the detector

Figure 7 legend

Item Description

(1) Standard connection (factory default)

(2) Dual loop connection

CP Control panel

WT Walk test

AM Antimasking

D/N Day/night

Rtest Remote test

To install the detector:

1. Lift off the custom insert and remove the screw

(see Figure 2, step 1).

2. Using a screwdriver, carefully prise open the detector (see

Figure 2, steps 2 and 3).

3. Fix the base to the wall between 1.8 and 3.0 m (5.9 and

9.8 ft.) from the floor. For flat mounting use a minimum of

two screws (DIN 7998) in positions A. For corner-mounting

use screws in positions B or C (Figure 3). To install a pryoff tamper, use position A or C.

P/N 146251999-4 (ML) • REV D • ISS 12MAR13 3 / 32

Page 4

Note: Using the pry-off tamper has not been evaluated by

UL.

4. Wire the detector (see Figures 3 and 7).

UL installations: All wiring must be made according to

National Electrical Code, NFPA70, and CSA C22.1,

Canadian Electrical Code Part I, Safety Standards for

electrical Installations.

5. Select the desired jumper and DIP switch settings (see

Figure 5). See “Jumper settings” below for more

information.

Remove the blinders and add the stickers, if required (see

6.

Figure 6 for an example).

7. For ceiling-mount applications that require a 90° coverage

use the SB01 swivel-mount bracket.

Note: Using the swivel-mount bracket has not been

evaluated by UL. Ceiling mount application has not been

evaluated by UL.

8. Close the cover.

9. Insert the screw and place the custom insert.

For EN 50131 Grade 3 installations, do not use mounting

position B.

Jumper settings

See Figure 5 for the jumper locations in the detector.

J1: Mode jumper

Note: Bi-curtain jumper functionality is available in EV1116

with firmware version 1.13 or later, and in EV1116AM with

firmware version 1.21 or later.

On: BI-curtain mode. In this mode an extra level of processing

is applied to provide enhanced stability in the presence of false

alarm hazards. Bi-curtain is used to reduce the possibility of

false alarms. It looks for signal verification and requires the

intruder to be seen in two curtains.

This mode is not suitable for single curtain applications.

Off: Standard mode (default). This mode is suitable for most of

the wide angle and single curtain applications. The mode must

be used in EN 50131 compliant installations.

J3 and J4: Dual loop setting

This sets the alarm and tamper relays. It allows you to connect

the detector to any control panel. Use jumpers 3 and 4. See

Figure 7.

Use Remote Test (RT) to test the detector from the control

panel. The detector will activate the Alarm relay if the test

result is positive, and the AM relay if the test result is negative.

J6: Polarity setting of the control voltage (CV)

On (factory default):

• The detector is in Day mode (system disarmed) when the

D/N input is connected to GND (terminal 1)

• The detector is in Night mode (system armed) when the

D/N input is connected to +12 V (terminal 2)

• The detector is in Walk Test Off mode (LEDs are disabled)

when the WT input is connected to GND (terminal 1)

• The detector is on Walk Test On mode (LEDs are

enabled) when the WT input is connected to +12 V

(terminal 2)

Off:

• The detector is in Day mode (system disarmed) when the

D/N input is connected to +12 V (screw terminal 2).

• The detector is in Night mode (system armed) when the

D/N input is connected to GND (terminal 1).

• The detector is in Walk Test Off mode (LEDs are disabled)

when the WT input is connected to +12 V (terminal 2).

• The detector is on Walk Test On mode (LEDs are

enabled) when the WT input is connected to GND

(terminal 1).

D/N and WT functionality

The D/N input:

• Controls the LED functionality together with the WT input.

• Resets the alarm memory

• Controls the AM relay functionality during the NIGHT

mode together with SW1.

The WT input controls the LED functionality together with the

D/N input.

When the detector is in the Day mode and Walk Test On

mode, the LEDs of the detector can be activated. See “

ation” on page 5 for more information.

indic

During the Night mode the LE

Ds are always switched off.

LED

If a PIR intruder alarm if detected in the Night mode and the

detector switches back to Day mode, the red LED starts

flashing to indicate an alarm in memory.

The alarm memory is reset by switching the detector to Night

mode.

DIP switch settings

Factory default:

54321

ON

SW 1: When to signal AM (anti-masking) or TF (technical

fault) output

On: Signals AM or TF only when the system is in Day mode

(factory default).

Off: Always signals AM or TF during Day and Night mode.

SW 2: AM sensitivity

On: Selects a higher level of AM sensitivity. AM relay reacts

within 6 seconds.

Off: Selects the standard AM sensitivity. AM relay reacts within

12 seconds (factory default).

SW 3: Resetting the AM/TF output

The system will only reset an AM alarm if it has ensured that

the cause of the AM alarm has been removed. If the AM

circuitry cannot return to its original reference levels, then

either the detector is still masked or possibly has been

damaged. The owner should then visually check that the

detector is still fully functional.

On: Resets the AM or TF status 40 seconds after a PIR alarm.

Off: Resets the AM or TF status after a PIR alarm when the

system is in Day and Walk Test mode. The yellow LED will

blink quickly. When the system is in Night status, the yellow

LED will turn off and the system is reset (factory default).

SW 4: Signaling AM or TF output

On: Signals AM on both the AM and Alarm relays. Signals TF

on the AM relay only (EN 50131).

Off: Signals AM and TF on the AM relay (factory default).

4 / 32 P/N 146251999-4 (ML) • REV D • ISS 12MAR13

Page 5

SW 5: Setting LEDs

On: Enables both LEDs on the detector at all times (factory

default).

Off: Puts both LEDs under the control of the Walk Test and

EV1116 EV1116AM

Pry-off tamper (not

evaluated by UL/cUL)

AM relay characteristic — 80 mA at 30 VDC

Day/Night input. This activates the memory feature of the

detector.

LED indication

PIR Red LED Alarm relay To reset

Start up

Low voltage

PIR intruder

alarm

PIR/AM Red

LED

Start up

Low voltage

PIR intruder

alarm

Latched PIR

(Memory)

AM alarm

After AM reset

Technical fault

Continuously on Normal blinking (1 Hz)

Fast blinking (4 Hz)

* Depends on the setting of the DIP switch SW4.

Closed Automatically after 25 s

Open (Alarm) Apply correct voltage

Open (Alarm) Automatically after 3 s

Yellow

LED

Alarm

relay

Closed Closed Automatically

Open

(Alarm)

Open

(Alarm)

Switch to Night

Open*

(Alarm)

Switch to

Open

AM

relay

Open

(Alarm)

Automatically

Open

(Alarm)

(Alarm)

To reset

after 60 s

Apply correct

voltage

after 3 s

mode

See DIP

switch 3

Night mode

Do a successful

walk test

Specifications

EV1116 EV1116AM

Detector PIR PIR + AM

Signal processing DSP

Range 16 m

Optical 11 high-density mirror curtains

Memory Yes

Input power

For UL installations

Peak-to-peak ripple 2 V (at 12 VDC)

Detector start-up time 25 s 60 s

Normal current

For UL installations

Current in Alarm 2.5 mA 3.8 mA

Maximum current

(LED on)

Mounting height 1.8 m to 3.0 m (5.9 ft. to 9.8 ft.)

Target speed range 30 cm/s to 3 m/s

Alarm (NC) / Tamper relay

characteristic

9 to 15 VDC (12 V nominal)

10 to 15 VDC (12 V nominal)

5.5 mA

0.0528 mW

11.5 mA 24 mA

(1 ft./s to 10 ft./s)

20 cm/s to 3 m/s

80 mA 30 VDC, resistive

10 mA

—

(0.65 ft./s to

10 ft./s)

PIR alarm time 3 s

Operating temperature

For UL installations

Dimensions (H x W x D) 125 × 55 × 60 mm

Relative humidity 95% max. noncondencing

Weight 150 g

IP/IK rating IP30 IK02

Regulatory information

Manufacturer UTC Fire & Security Americas Corporation, Inc.

1275 Red Fox Rd., Arden Hills, MN 55112-6943, USA

Authorized EU manufacturing representative:

UTC Fire & Security B.V.

Kelvinstraat 7, 6003 DH Weert, The Netherlands

Certification

UL The product must be connected to a listed burglar

FCC Note: This equipment has been tested and found to

This device complies with part 15 of the FCC Rules.

system compatible control unit or power supply unit,

which provides a minimum 4 hours of standby power

and has a voltage output between 10 and 15 VDC.

All wiring must be made according to National

Electrical Code, NFPA70, and CSA C22.1, Canadian

Electrical Code Part I, Safety Standards for Electrical

Installations.

Perform walk test at least one per year.

Use only a listed power-limited supply.

EV1116AM has not been evaluated by UL.

comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against

harmful interference in a residential installation. This

equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful

interference to radio communications. However, there

is no guarantee that interference will not occur in a

particular installation. If this equipment does cause

harmful interference to radio or television reception,

which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment

and receiver

• Connect the equipment into an outlet on a circuit

different from that to which the receiver is

connected

• Consult the dealer or an experienced radio/TV

technician for help

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference,

and (2) this device must accept any interference

received, including interference that may cause

undesired operation.

Optional On-board (Yes)

max., resistive

−10 to +55°C (14 to 130°F)

0 to 49°C (32 to 120°F)

(4.92 x 2.16 x

2.36 in.)

(UL Installations)

125 × 65 × 60 mm

(4.92 x 2.6 x

2.36 in.)

P/N 146251999-4 (ML) • REV D • ISS 12MAR13 5 / 32

Page 6

2002/96/EC (WEEE directive): Products marked with

this symbol cannot be disposed of as unsorted

municipal waste in the European Union. For proper

recycling, return this product to your local supplier

upon the purchase of equivalent new equipment, or

dispose of it at designated collection points. For more

information see: www.recyclethis.info.

Contact information

www.utcfireandsecurity.com or www.interlogix.com

For customer support, see www.utcfssecurityproducts.eu

5. Vælg de ønskede jumper- og DIP-switch-indstillinger (se

figur 5). Se “Jumper-indstillinger” nedenfor, hvis du ønsker

erligere oplysninger.

yd

6. Fjern afskærmningen og påsæt klæbemærker efter behov

(se eksempel i Figur 6).

7. Til loftsmontering med 90 graders anvendelse benyttes

SB01-svingmonteringskonsol.

8. Luk frontlågen.

9. Isæt skruen og anbring dækpladen.

Til EN 50131 Grade 3-installationer må monteringsposition B

ikke anvendes.

DA: Installationsvejledning

Introduktion

EV1100-serien omfatter EV1116 og EV1116AM PIRrumdetektorer. De har patenteret spejl, pyro og

signalbehandlingsteknologi.

Installationsvejledning

Den anvendte teknologi i disse detektorer er modstandsdygtig

over for falske alarmer. Undgå imidlertid mulige årsager til

ustabilitet (se Figur 1), f.eks.:

• Direkte sollys på detektoren

• Kraftig træk på detektoren.

• Varmekilder inden for detektorens synsfelt

• Dyr inden for detektorens synsfelt

• Blokering af detektorens synsfelt med store genstande

som f.eks. møbler

• Genstand under 50 cm (20 in.) fra anti-maskeringsdetektor

(AM)

• Installation af to detektorer mod hinanden og mindre end

50 cm (20 in.) fra hinanden (kun AM-detektorer)

Installation af detektoren

Figur 7 symbolforklaring

Punkt Beskrivelse

(1) Standardtilslutning (fabriksstandard)

(2) Dobbelt sløjfe-tilslutning

CP Central

WT Gangtest

AM Antimaskning

D/N Dag/nat

Rtest Fjernbetj test

Sådan installeres detektoren:

1. Tag dækpladen af og fjern skruen (se Figur 2, trin 1).

2. Åbn forsigtigt detektoren med en skruetrækker (Figur 2,

trin 2 og 3).

3. Gør soklen fast til væggen mellem 1,8 og 3,0 m (5,9 og

9,8 ft.) fra gulvet. Til fladmontering anvendes mindst to

skruer (DIN 7998) i position A. Til hjørnemontering

anvendes skruer i position B eller C (Figur 3). Til at

installere vægsabotagekontakt anvendes position A

eller C.

4. Tilslut detektoren (se figur 3 og 7).

Jumper-indstillinger

Se jumpernes placeringer i detektoren i figur 5.

J1: Signalbehandling

Note: Jumper for Bi-curtain indstilling er muligt i EV1116 med

firmware version 1.13 eller nyere, og i EV1116AM med

firmware version 1.21 eller nyere.

Til: (Bi-Curtain): I denne indstilling vil en yderligere

signalbehandling give en forøget stabilitet i tilfælde af falske

alarmer ved vanskelige installationsmiljøer. Denne indstilling

bruges til reduktion af falske alarmer. Signalverifikation for

alarm kræver at en person passerer to gardiner.

Denne indstillng bør ikke benyttes ved korridordækning (kun

1 gardin).

Fra: Standard indstilling (Fabriksindstilling). Dette valg er for

alle normale installations-miliøer og ved korridordækning med

et enkelt gardin. Indstillingen skal bruges I EN 50131 krævede

installationer..

J3 og J4: Dobbelt løkkeindstilling

Bruges til indstilling af alarm- og sabotagerelæ. Den giver dig

mulighed for at tilslutte detektoren til et kontrolpanel. Brug

jumpers 3 og 4. Se Figur 7.

Brug fjerntest (RT) til at afprøve detektoren fra kontrolpanelet.

Detektoren aktiverer alarmrelæet, hvis testresultatet er positivt

og AM-relæet, hvis testresultatet er negativt.

J6: Polaritetsindstilling af kontrolspænding (CV)

Til (fabriksstandard):

• Detektoren er i dagtilstand (system frakoblet), når D/Ninput tilsluttes GND (terminal 1)

• Detektoren er i nattilstand (system tilkoblet), når D/N-input

tilsluttes +12 V (terminal 2)

• Detektoren er i tilstanden gangtest fra (LED er

deaktiveret), når WT-input tilsluttes GND (terminal 1)

• Detektoren er i tilstanden gangtest til (LED er aktiveret),

når WT-input tilsluttes +12 V (terminal 2)

Fra:

• Detektoren er i dagtilstand (system frakoblet), når D/Ninput tilsluttes +12 V (skrueterminal 2)

• Detektoren er i nattilstand (system tilkoblet), når D/N-input

tilsluttes GND (terminal 1).

• Detektoren er i tilstanden gangtest fra (LED er

deaktiveret), når WT-input tilsluttes +12 V (terminal 2)

• Detektoren er i tilstanden gangtest til (LED er aktiveret),

når WT-input tilsluttes GND (terminal 1)

D/N- og WT-funktionalitet

D/N-input:

• Styrer LED-funktionen sammen med WT-input.

6 / 32 P/N 146251999-4 (ML) • REV D • ISS 12MAR13

Loading...

Loading...