Page 1

GE

y

Securit

DI601 / DDI602 Outdoor PIR

Detector / Outdoor Dual PIR

Detector Installation Sheet

EN

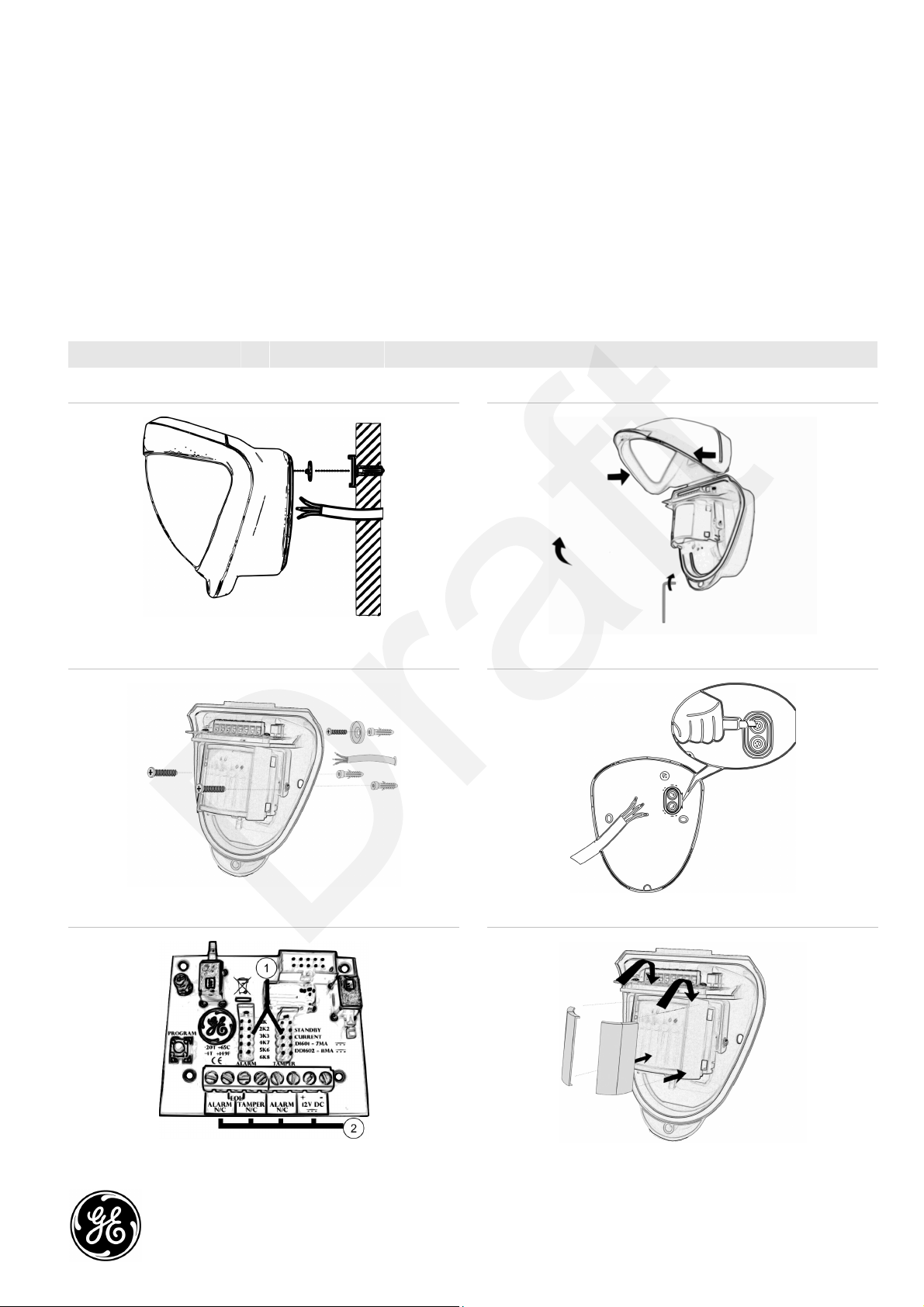

1

2

3

5

4

6

© 2009 GE Security, Inc.

P/N 1069153 / 1069154 • REV 00.09 • ISS 18DEC09

1 of 8

Page 2

7

8

9

11

9

10

12

10

11

12

2 of 8 P/N 1069153 / 1069154 • REV 00.09 • ISS 18DEC09

Page 3

13

14

13

15

14

P/N 1069153 / 1069154 • REV 00.09 • ISS 18DEC09 3 of 8

Page 4

16

18

17

• 1 x hex wrench

• 2 x 31.75 mm / 1.25 in. wall plugs

• 2 x 31.75 mm / 1.25 in. screws

• 1 x lens mask

• 2 x additional curtain shutters

• 1 x tamper cup

• 2 x tamper caps (different lengths)

• 1 x plastic locking tool

• 1 x installation sheet

• 1 x front cover screw cap

EN: Installation Sheet

Introduction

DI601 / DDI602 Outdoor PIR Detector / Outdoor Dual PIR Detector

is an outdoor motion detector and alarm trigger that uses two

independent passive infrared detectors plus a microwave sensor

module. Both All three sensors must trigger to cause the detector

to signal an alarm. There is also a programmable option to select

either PIR or Microwave alarm activation. DI601 / DDI602 uses

triple detection technology to deliver precise, reliable presence

detection. DI601 / DDI602 uses dual pyro technology to deliver

precise, reliable presence detection. It is designed for use in CCTV

and intruder alarm systems.

Programmable options include a variable pulse count and a

choice of three detection ranges: 10 m / 33 ft., 20 m / 66 ft., and

30 m / 98 ft.

The integral dual-axis tilt sensor allows 180º of pan and 90º of tilt.

This increases the speed of the outdoor installation and provides

incredibly accurate aiming of the detection pattern.

The electronics module is acrylic coated for additional component

stability. It is encased in a vandal-resistant, high-impact, UV

stabilized plastic housing with an opaque polyethylene front cover

ensuring that the sensor is impervious to and unaffected by

weather conditions.

The combination of precision electronics, digital white light

filtering, and double shielding eliminates false alarms from the sun

and other visible light sources.

DI601 / DDI602 design has a neat and professional appearance

that gives no visible indication of the orientation of the detector

head and totally hides the wiring.

Package

The package contains:

• 1 x DI601 / DDI602

• 1 x drilling template for fixing holes

4 of 8 P/N 1069153 / 1069154 • REV 00.09 • ISS 18DEC09

Quick installation

1. Mount and connect the detector following the instructions

given later in this sheet.

2. Apply supply voltage to the unit.

Page 5

The detection LED (blue) flashes three times.

3. Wait approximately 2 to 3 minutes to allow the detector to

settle.

4. Press the programming button once to activate walk test

mode.

The detection LED is now enabled for five minutes.

Note: The front cover must be fitted when walk testing.

The default settings are:

• Range: 30 meters / 98 feet

• Pulse count: 1

• Detection LED: off

• AND logic: on

Alternatively, you can remove the jumpers and connect a discrete

resistor directly to the alarm or tamper outputs, as specified by

third-party equipment.

Table 1: Connections

Terminal Label Description

1, 2 ALARM N/C Alarm relay, normally closed

2, 3 EOL End-of-line resistors

3, 4 TAMPER N/C Tamper relay, normally closed

5, 6 ALARM N/O Alarm relay, normally open

PIR output in OR mode

Microwave output in OR mode

7, 8 +, − 12V DC 12 V power supply

Mounting the unit

During installation, protect the electronics against water, as

trapped moisture can affect or damage the unit.

Note: Please leave minimum 10 cm (4 in.) clearance above the top

of the detector housing to allow the cover to be positioned

correctly.

To mount the detector:

1. Drill the wall to accept the two fixing screws, the cable entry,

and the tamper cup (if used). See Figures 1 and 3.

A hole-drilling template is provided.

Note: We recommend using the tamper cup on uneven wall

surfaces.

2. Remove the cover assembly by loosening the locking screw

using the hex wrench provided. Squeeze the sides of the front

cover to release the internal catches. The cover hinges from

the top and lifts out of the location slot. See Figure 2.

3. Use a razor knife to open a rubber seal to allow the cabling

into the unit (see Figure 4). Feed standard eight-core alarm

cable into the cable entry. Bare the wires and connect to the

top PCB terminal block (Figure 5, item 2).

4. Screw the unit to the wall ensuring that the tamper pin is

correctly located and that the tamper microswitch is closed.

To aid installation, two spare tamper feet are provided. One is

1 mm shorter and the other is 2 mm shorter than the tamper

foot originally fitted. The tamper foot is a push fit and can be

removed by carefully pulling it from the pin. See Figure 1.

5. When the detector is aligned, connected, and programmed to

suit the installation:

a. Fit the cover to the detector base.

b. Lightly screw the locking screw using the hex wrench.

c. Put the top of the locking tool into the small notch on

each side of the cover, and then apply slight pressure

until the cover locks into the base, as shown in Figure 17.

d. Tighten the locking screw.

Connecting the unit

DI601 / DDI602 includes jumpers that let you configure internal

end-of-line (EOL) resistor values, when EOL resistors are required.

Values are: 1, 2.2, 3.3, 4.7, 5.6, and 6.8 kΩ. Figure 5 shows:

1. EOL resistor jumpers

2. Wiring points

Multibeam alignment and masking

The multifunction lens fitted to DI601 / DDI602 detector produces

seven long-range beams and seven medium- to short-range

curtain PIR beams. The PIR circuitry detects changes in heat and

movement in the beam pattern; therefore items such as trees,

shrubs, ponds, boiler flues, and animals should be considered

when positioning the detector. The microwave module detects

actual movement towards or away from the detector and is

programmed to ignore any objects that move outside of the

preselected detection range.

Note: PIR sensor is more sensitive to a movement across the

beams, and less sensitive to a movement directly towards or away

from the beams. Microwave sensor is more sensitive to movement

towards and away from the sensor.

The detector module is fitted with two sliding shutters to reduce

the detection angle of the PIR sensor only.

The curtains are fitted to the pan and tilt module as shown in

Figure 6. Each section of the detector lens gives a coverage

pattern of approximately 10 degrees.

An additional set of curtain sliders is provided should the beam

pattern be narrowed even further, e.g. if the minimum detection

angle of 10 degrees is required.

When coverage exceeds the desired detection area, adjust the

module as required and mask off any beams, either vertically or

horizontally, to avoid unwanted detection.

Use portions of the self-adhesive silver mask applied to the rear,

smooth side of the lens as shown in Figures 9 to 12. Gently lift the

top and bottom edges of the pan and tilt module to release the

lens. To replace the module, please begin by sliding one side of the

lens into the clips on the pan and tilt module. After one side is

secure, do the same for the opposite side. Once both sides are

secure, gently lift the top and bottom edges of the pan and tilt

module and press on the lens to click it into place.

Always replace the lens the correct way up to ensure exact beam

pattern coverage. The top of the lens is marked TOP as shown in

Figure 7.

Table 2 below summarizes typical masking configurations for use

when the range option is set to 30 meters.

Table 2: Masking configurations for maximum range

Configuration Height

(m / ft.)

Multibeam, optimum 3 / 10 0 30 / 98 Figure 9

Multibeam 6 / 20 9 25 / 82 Figure 10

Tilt (°) Max. range

(m / ft.)

Reference

P/N 1069153 / 1069154 • REV 00.09 • ISS 18DEC09 5 of 8

Page 6

Configuration Height

(m / ft.)

Pet immunity [1] 1.5 / 5 −2 30 / 98 Figure 11

Curtain coverage [2] 6 / 20 45 5 / 16 Figure 12

[1] Black area should be masked for pet alley applications up to

30 meters / 98 feet.

[2] Black area should be masked for curtain coverage applications.

Tilt (°) Max. range

(m / ft.)

Reference

Figure 13 shows the pattern for the maximum range in the

optimum position (see Figure 9). Masking the top section of the

lens reduces the range to 20 m / 66 ft. Item 1 is the microwave

coverage, item 2 is the PIR pattern.

Figure 14 shows the pattern for the minimum range (10 m / 33 ft.)

In this case masking the top section of the lens reduces the range

to 6 meters.

Figure 15 shows possible alignments when the detector is

mounted close to a wall.

DI601 / DDI602 includes magnetically immune, volt-free relay

contacts that can be used to trigger alarm inputs on connected

equipment.

The contacts are rated at a maximum of 24 V AC/DC at 50 mA.

The contacts can be set to operate only when both the microwave

AND the PIR circuits have detected movement (the default setting).

Alternatively the contacts can be programmed to operate when

either the microwave OR the PIR circuit has detected an alarm. In

this case the PIR alarm is signalled on the N/C contact, and the

microwave alarm is signalled on the N/O contact.

Note: Rain can cause false alarms from the microwave sensor.

When the pulse count is set to 1, the detector is most sensitive.

Detection LED enabled

• Off: Detection LED is disabled

• On: Detection LED signals detection

Figure 15 legend

Item Description

1. 90° mounting, not recommended

2. 55° mounting, recommended

3. Detector housing

4. Long range beam direction

5. Wall

The alignment shown as item 1 in Figure 15 is not recommended.

If the detector head is mounted at an angle of 90° to the

perimeter, the mounting wall may cut off short and medium range

beams. The long-range beam still will detect an intruder, however

the wall can cause false alarms when heated by sunlight.

Item 2 in Figure 15 shows the recommended alignment. The

detector head is mounted at a 55° angle to the perimeter. As a

result, short and medium range beams are parallel to the

perimeter, but the detection range along the perimeter is reduced

to 25 m.

LEDs

LEDs are shown on Figure 18.

Figure 18 legend

Item Colour Description

1. Blue Detection alarm

2. Infrared Walk tester communication

1. Red PIR active

2. Green Microwave active

3. Blue Detection alarm

4. Infrared Walk tester communication

Programming

Figure 16 legend

Item Description

1. Programming LED (red)

2. Programming button

All available settings are listed in Table 3 below.

Table 3: Programming settings

Value

Option 1 2 3

1. Range (m / ft.) 10 / 33 20 / 66 30* / 98*

2. Pulse count 1* 2

3. Detection LED OFF* ON

4. PIR/MW logic AND* OR

* Default settings

To change any of DI601 / DDI602 settings:

1. Press the programming button to select the option number

you want to change. Press once for range, twice for pulse

count, and three times for detection LED. Press once for

range, twice for pulse count, three times for detection LED,

and four times for PIR/MW logic.

2. Wait until the programming (red) LED turns off (typically

4 seconds).

3. Count the number of times the programming LED flashes to

determine the current value for that option.

4. Press the programming button to select the value number for

the new setting. Example: To set the range to 30 m / 98 ft.,

press three times.

Programmable options

Pulse count

Pulse count is the number of times the detector must detect a

presence before signalling an alarm.

If the PIR/MW logic option is set to AND, detection must occur on

both PIR and microwave sensors to be counted. If the option is set

to OR, a detection on either type of sensor is counted.

value was set.

Any alterations made to DI601 / DDI602 settings are stored in the

detector’s nonvolatile memory.

Example

To change the detection LED setting from OFF to ON:

1. Press the programming button three times.

2. Wait until the programming LED turns off.

6 of 8 P/N 1069153 / 1069154 • REV 00.09 • ISS 18DEC09

The programming LED blinks twice to indicate that the new

Page 7

3. The programming LED flashes once to show that the current

value is off.

4. Press the programming button twice.

5. The programming LED flashes twice showing that the new

value has been stored. The detector returns to normal

operation.

Resetting options

To reset the detector to the default settings:

1. Remove the power from the detector.

2. Press and hold the programming button (see Figure 16,

item 2).

3. Apply the power to the detector.

4. After the programming LED flashes, release the programming

button.

You can reset the detector either before installation, with a PP3

battery, or by applying 12 V to the unit on site.

Walk test

In walk test mode, the blue detection LED option is set to ON, and

the pulse count option is set to 1. The detection LED lights each

time DI601 / DDI602 detects your presence.

To enter the walk test mode, press the programming button once.

The detection LED lights and pulse count 1 is automatically

selected. The unit can then be aligned. The detection LED lights on

DI601 / DDI602 every time detection takes place.

The test mode ends automatically five minutes after last detection.

Alternatively, remove and then reapply the power to cancel the

walk test mode.

Note: When you conduct a walk test, make sure that the front

cover is in place. Do not conduct walk tests with the cover

removed.

The range of the detector increases without the protective front

cover. Therefore the front cover must be fitted to establish the

correct beam pattern. Use Table 3 on page 6 to adjust the range

as necessary. Pan and tilt the lens module over the field of view to

obtain the correct coverage area.

Accessories

GE Security can provide a handheld walk tester DI601-WT to aid

installations.

LEDs Top red: Programming LED

Red: Programming LED

Red: PIR active

Green: Microwave active

Blue: Detector alarm

Infrared: Walk tester communication

Microwave module

DDI602-F1

DDI602-F2

DDI602-F3

Outputs

N/O

N/C

Power input 9 to 15 V

Current 7 mA (12 V nominal)

Operating frequency (country specific)

10.525 GHz

10.587 GHz

9.9 GHz

Silent, solid state, magnetically immune.

Triggering selectable by microwave OR

PIR, or by microwave AND PIR.

Volt free relay, signal contact 24 VAC/DC at

50 mA with an integral 25 Ω series resistor.

Alarm time 5 seconds.

Volt free relay, signal contact 24 VAC/DC at

50 mA with an integral 25 Ω series resistor.

Alarm time 5 seconds.

11 mA (12 V nominal)

Pulse count 1 or 2

Temperature

compensation

Control Digital microprocessor with nonvolatile

Walk test Output test mode with LED indication. Option

Operating temperature −20 to +65°C / −4 to 149°F

Housing High impact ABS plastic with HDPE cover,

Dimensions, W x H x D 147 x 187 x 140 mm / 5.79 x 7.36 x 5.51 in.

Weight 306 g net, 532 g gross / 10.79 oz net,

Analogue (thermistor) and digital sensitivity

adjustment

memory

to disable LEDs.

UV stabilized

18.77 oz gross

323 g net, 549 g gross / 11.39 oz net,

19.37 oz gross

Mounting height Variable up to 6 m / 20 ft.

Optimum height 3 m / 10 ft. for full range

Cable < 200 m / 656 ft. Utilising all three outputs (including tamper) —

eight-core 7/0.2 mm² / 24 AWG

Cable < 500 m / 1640 ft. Utilising all three outputs (including tamper) —

eight-core 16/0.2 mm² / 20 AWG

Specifications

Detection range Programmable: 10 m / 30 ft., 20 m / 66 ft., or

30 m / 98 ft.

Coverage 10 to 70° detection angle, 30 x 24 m /

98 x 79 ft. coverage max.

Adjustment 180° pan, 90° tilt

Fresnel lens 28 zones for each detection element, which

can be masked with the curtain sliders

Customized optics Double silicon shielded quad element

eliminates 50,000 lux of white light

P/N 1069153 / 1069154 • REV 00.09 • ISS 18DEC09 7 of 8

Certification

INCERT (pending)

EN (pending) Grade 2 Class IV

Environmental class Minimum IP55 (IP65 pending)

European Union

directives

1999/5/EC (R&TTE directive): Hereby, GE Security

declares that this device is in compliance with the

essential requirements and other relevant

provisions of Directive 1999/5/EC.

Regulatory information

Page 8

2002/96/EC (WEEE directive): Products marked

with this symbol cannot be disposed of as

unsorted municipal waste in the European Union.

For proper recycling, return this product to your

2004/108/EC (EMC directive): Non-European

Usage restrictions

DDI602-F1

(10.525 GHz):

DDI602-F2

(10.587 GHz):

DDI602-F3

(9.9 GHz) :

local supplier upon the purchase of equivalent

new equipment, or dispose of it at designated

collection points. For more information see:

www.recyclethis.info.

manufacturers must designate an authorized

representative in the Community. Our authorized

manufacturing representative is:

GE Security B.V., Kelvinstraat 7,

6003 DH Weert, The Netherlands.

Only use the listed models in the following

countries:

Albania, Argentina, Australia, Belgium,

Brazil, Denmark, Holland, Hungary, Iceland,

Indonesia, Lativa, Lithuania, Malta, Norway,

Portugal, Russia, South Africa, Spain,

Taiwan, Ukraine, USA

Greece, Italy, Thailand, UAE, UK

Czech Republic, France, Poland

Contact information

For contact information see our Web site: www.gesecurity.eu.

8 of 8 P/N 1069153 / 1069154 • REV 00.09 • ISS 18DEC09

Loading...

Loading...