Page 1

D19110SHR

D19110SHR-R3

D19130SHR

D19130SHR-R3

IFS Fiber Module

Installation & Operation

Instructions

P/N 1062844 • REV B • ISS 01AUG11

Page 2

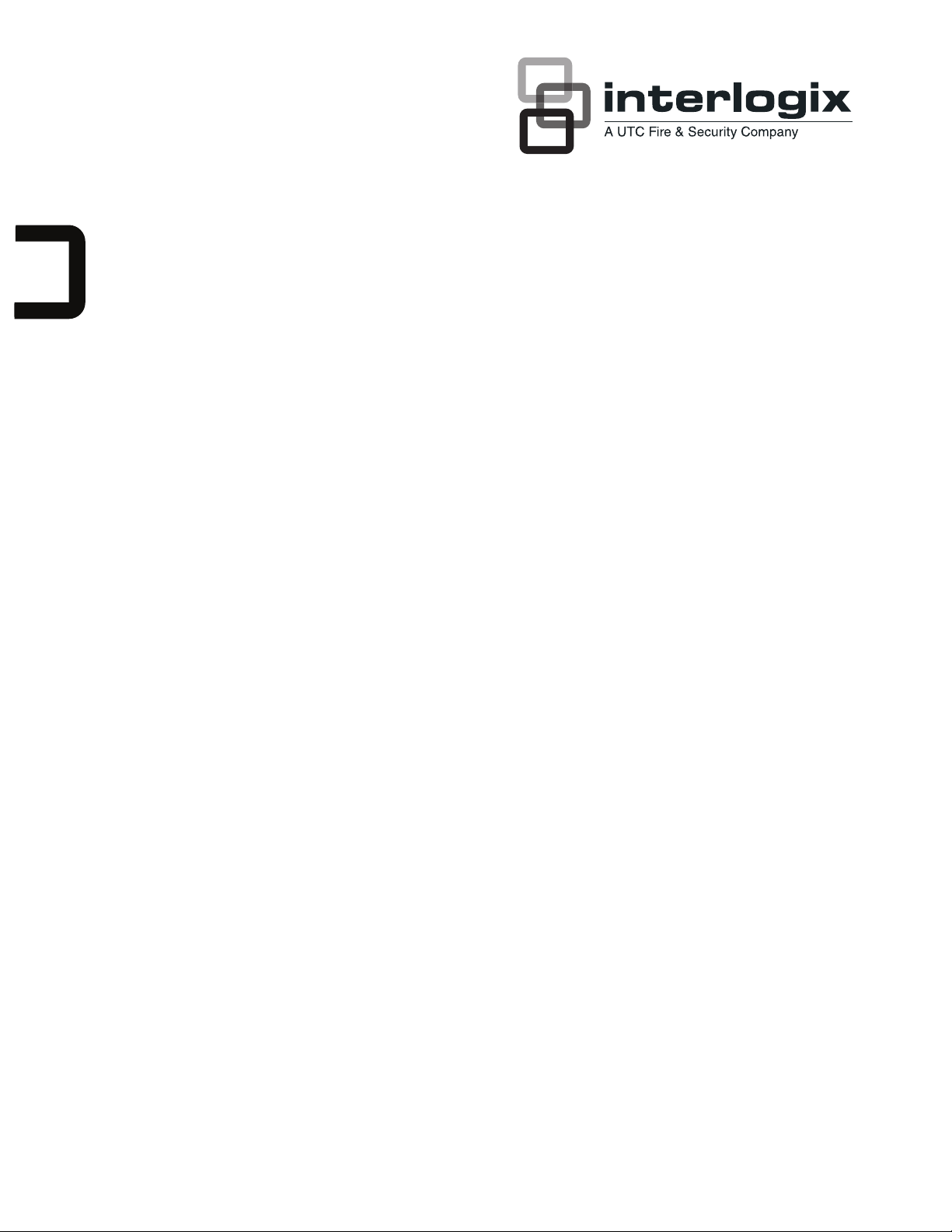

RS - 232 DATA

(DCE MODE)

GROUND

DATA INPUT

7

6

5

4

3

2

1

8

20

RS - 232 DATA

(DTE MODE)

GROUND7

6

5

4

3

2

1

8

20

DATA OUTPUT

CONTROL LINES

DATA OUTPUT

DATA INPUT

8

6

5

4

3

2

1

9

20

RTS

CHASSIS GRD

CTS

DSR

DTR

DCD

D19100SHR Series

(DCE MODE)

CONTROL LINES

(DTE MODE)

1

2

3

4

5

6

8

9

CHASSIS GRD

RTS

CTS

DSR

DCD

20

DTR

Page 3

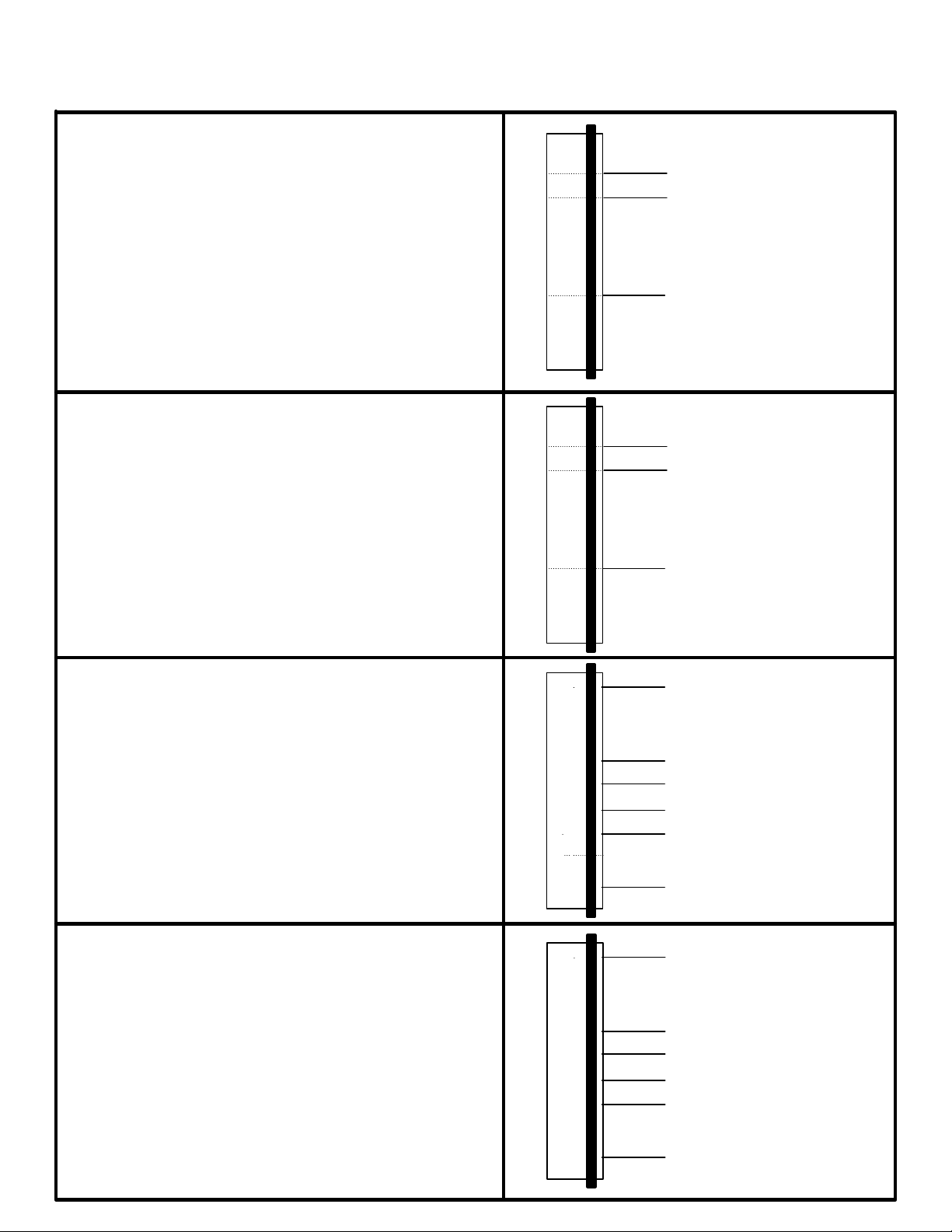

OTHER CONNECTIONS*

* For further information see Appendix

RS-422 DATA

2w RS-485 DATA

4w RS-485 DATA

D19100SHR Series

9

10

11

12

13

21

22

23

24

14

15

16

17

+ 5 VOLTS JABBER RESET

MAY BE TEMPORARILY

CONNECTED TO PIN 24 TO

RESET ANTI-STREAMING

"FAIL" CONTACT CLOSURE,

NORMALLY CLOSED

MASTER RELAY ACTIVE MODE

CONTACT CLOSURE

CONNECT TO PIN 24 FOR

MASTER CONTROL MODE

SIGNAL GROUND

DATA IN +

DATA IN DATA OUT +

DATA OUT -

14

15

14

15

16

17

DATA IN / OUT +

DATA IN / OUT-

DATA IN +

DATA IN DATA OUT +

DATA OUT -

Page 4

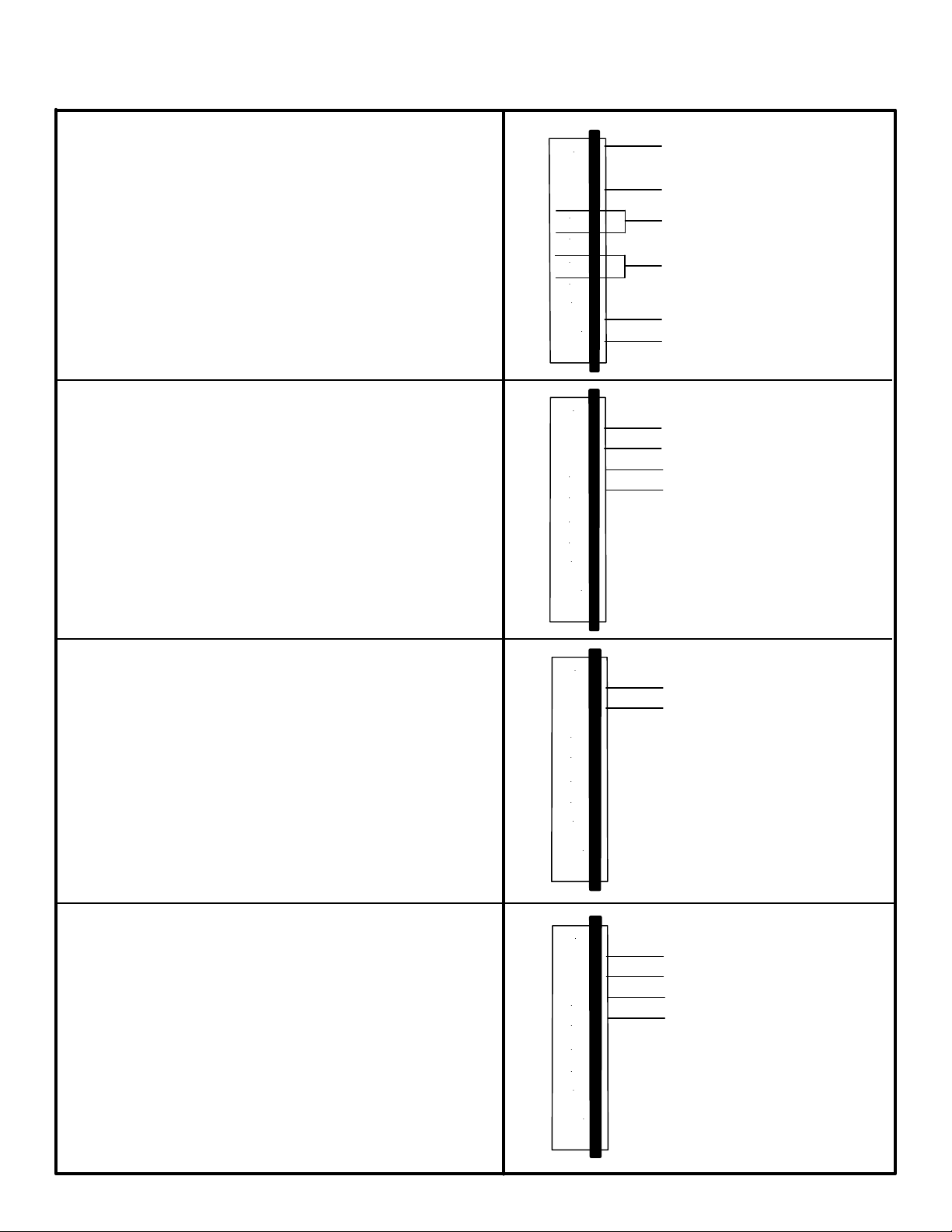

D19100SHR

NOTE: WITHOUT PROPER FIBER

CONNECTION, LED's DO NOT INDICATE

CORRECT OPERATIONAL STATUS.

B

A

J

K

L

ACReceive A

B

RTS

C

D

M

N

E

F

G

H

I

T

S

R

Q

P

O

A: Optical Input

LED illuminates when RTS is in active state.

Transmit B

D Fail

E A Direction*

F Receive B

G CTS

H Transmit A

I Not Used (OFF)

J RX A

K TX A

L Loss - of - Data

M Power

N B Direction*

O Set as Master

P TX B

Q RX B

R Set as Slave

B: Optical Output

LED illuminates when one of the receive ports stops receiving

optical energy or in a jabber error state.

LED illuminates Green when complete optical path

is established in A direction.

B: Optical Input

LED illuminates when CTS is in active state.

A: Optical Output

N/A

LED illuminates when optical data is present on A input.

LED illuminates when data is present on A output.

LED illuminates upon loss of electrical input data.

LED illuminates when power is applied.

LED illuminates Green when complete optical path

is established in B direction.

LED illuminates

LED illuminates when data is present on B output

LED illuminates when optical data is present on B input.

LED illuminates

S Jabber Error

T Reset Switch

* LED illuminates yellow when upstream data is interrupted in that fiber loop.

LED off when break in fiber of that loop.

LED illuminates

Press to reset jabber alarm state.

Page 5

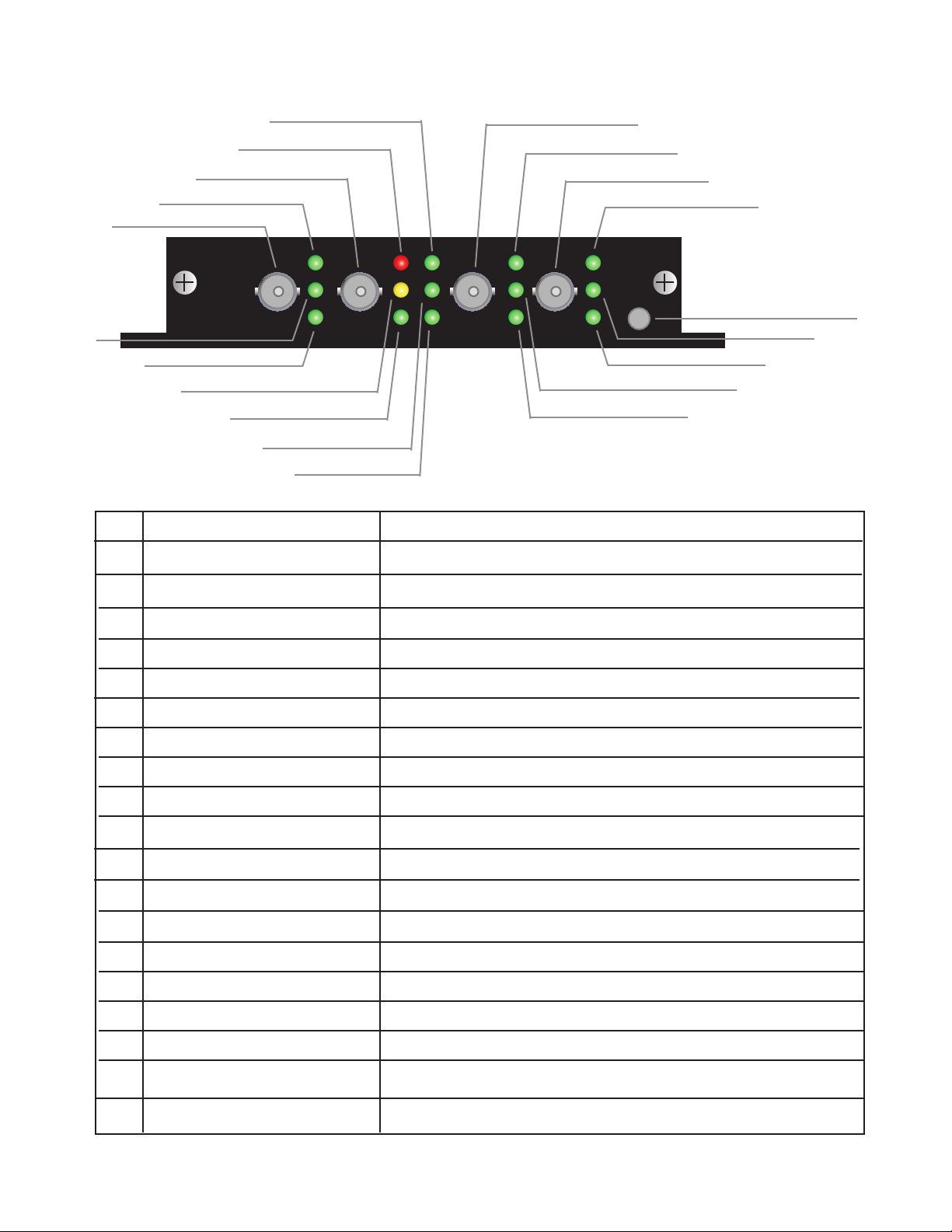

Internal Jumper Settings

#1

#2

D19100WDM Series

#2

#1

JMP 3

B

A

JMP 2

JMP 4

NOT

USED

USED

JABBER

RTS

LOD

B A

64 SEC

32 SEC

16 SEC

8 SEC

4 SEC

JABBER TIME

RS232

RS422

RS485 (2w)

RS485 (4w)

JMP 5

LOD TIME

64 SEC

32 SEC

16 SEC

8 SEC

B

B

BBA

A

A

A

Page 6

A

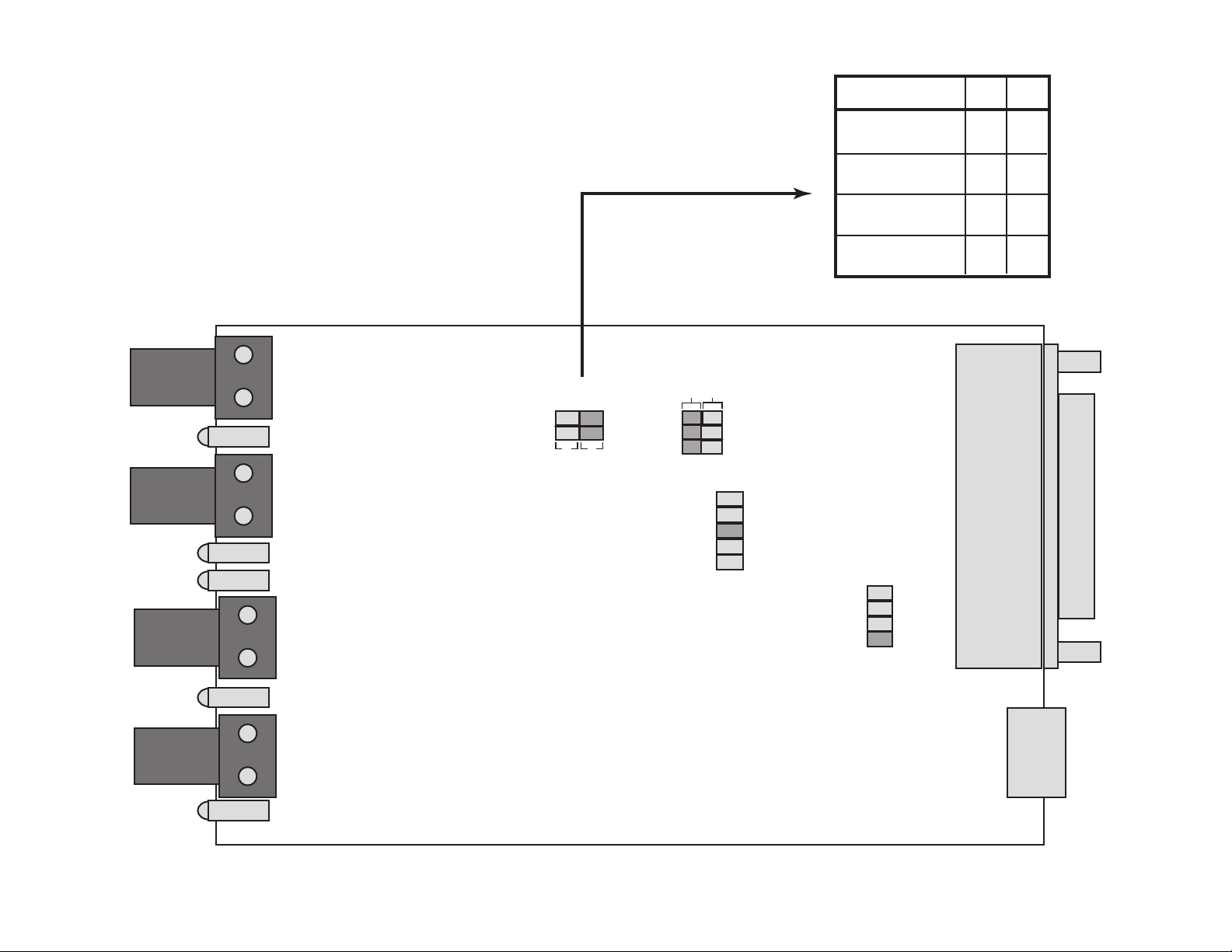

D19100SHR Series

B

1 2

Auto

Manual DTE Slave

C ED

ACPower Connector

B

Data / Control Lines Connector

Auto / Manual Selector Switch

D DCT / DTE Selector Switch

E Master / Slave Selector Switch

DCE Master

Page 7

D19100SHR Series

1 2

Auto

Manual DTE Slave

MANUAL: Use this setting on all units in a single master

configuration or on a slave unit.

AUTO: Use this setting on a master unit in a redundant

master configuration.

All slave units should always be set to manual.

DCE Master

Page 8

D19100SHR Series

1 2

Auto

DCE Master

Manual DTE Slave

DCE: RS232 connections are configured as

Data Communications Equipment

DTE: RS232 connections are configured as

Data Terminal Equipment

Page 9

D19100SHR Series

1 2

Auto

DCE Master

Manual DTE Slave

When Auto/Manual switch is set to Manual,

sets master and slave units.

In a single master configuration.

When Auto/Manual switch is set to Auto,

Master sets primary master,

Slave sets redundant master.

Page 10

D19100SHR Series

FAILURE LOGIC TABLE

If break in: Loop LED Master Slave 1 Slave 2 Slave 3

Y

G

Y

G

OFF

A1

A2

A Y

B G

A

B

A

OFF

G

Y

G

Y

G

G

G

Y

G

OFF

G

G

A3

B

G

G

G

G

NOTE:

Grayed out areas

indicate good

operational loop

in noted direction.

Multiple fiber breaks

follow the failure logic

for that loop.

A4

B1

B2

B3

B4

B3

A

B

A

Y

G

G

G

G

G

G

G

G

G

G

G

KEY:

B

A

B

A

B

A

B

Y

G

Y

G

Y

G

Y

Y

G

Y

G

OFF

G

G

Y

G

OFF

G

G

G

G

OFF

G

G

G

G

G

G

G - Green

Y - Yellow

SLAVE 2

D19100 Series

TxB

ifs

203.426.1180

www.ifs.com

International

Fiber

Systems

Incorporated

RxB

B2

SLAVE 1

D19100 Series

ifs

203.426.1180

www.ifs.com

TxB

International

Fiber

Systems

Incorporated

RxB

TxA

RxA

B4

A2

A1

RxA

TxA

RxB

MASTER

D19100 Series

ifs

203.426.1180

www.ifs.com

International

Fiber

Systems

Incorporated

TxA

RxA

TxB

A3

A4

RxA

TxA

B1

TxB

D19100 Series

ifs

203.426.1180

www.ifs.com

D19100 Series

RxB

SLAVE 3

International

Fiber

Systems

Incorporated

Page 11

INSTALLATION INSTRUCTIONS FOR ADDITIONAL COMPONENTS NEEDED

TO MEET EMISSION REQUIREMENTS ON THE D19100SHR SERIES PRODUCTS.

INSTALL AS SHOWN.

D19100SHR

DB 25 DATA CABLE

(CUSTOMER SUPPLIED)

RADIO SHACK PART NO. 26-240

OR EQUIVALENT

12 VDC POWER CABLE SUPPLIED

1) INSTALL A SEPARATE SUPPLIED

EMI FILTER CLAMP AS SHOWN

2) DIGI-KEY PART NUMBER

240-2065-ND OR STEWARD PART

NUMBER 28A0640-0A0

OR EQUIVALENT

DB 25 DATA CABLE

(CUSTOMER SUPPLIED)

RADIO SHACK PART NO. 26-240

OR EQUIVALENT

1) INSTALL A SEPARATE SUPPLIED

EMI FILTER CLAMP AS SHOWN

2) DIGI-KEY PART NUMBER

240-2065-ND OR STEWARD PART

NUMBER 28A0640-0A0

OR EQUIVALENT

1) INSTALL A SEPARATE SUPPLIED

EMI FILTER CLAMP AS SHOWN

2) DIGI-KEY PART NUMBER

240-2076-ND OR STEWARD PART

NUMBER 28A2029-0A0

OR EQUIVALENT

D19100SHR-R3

Page 12

Appendix

Automatic Switching Master

The automatic switching master feature gives the Self Healing Ring the capability of having two

redundant masters for the purpose of increasing fault tolerance Each master node may be connected

to individual host computers, or to a single host computer using a simple Y connection. Master nodes

may be located anywhere in the ring. In a redundant master configuration, one master will always be

in active mode while the other in standby mode. The active master will transmit and receive

RS232/485/422 data as usual while the master in standby mode will ignore data at at it’s data input

and it’s data output will be inactive and stay in tristate. If a master in active mode fails for any reason,

through automatic switching, the other master will enter active mode.

Loss-of-Data Detection

The loss-of-data detection feature increases fault tolerance in the RS232 data path from master to

host computer. This feature is only applicable when automatic switching master is enabled. A loss-ofdata jumper setting on the SHR sets a timeout on host data input inactivity. If the data input from the

host computer remains inactive for a set amount of time, a break in the data path is assumed. In this

case, a master in active mode will enter standby mode allowing the other master to become active.

Jabber Error Detection (Anti Streaming)

Used to detect an out-of-control RS232 data source. In some systems, an RS232 data source should

not continuously transmit for more than a specified amount of time. This feature is used to disable an

out-of-control data source by monitoring how long the CTS/RTS input line remains active. If it remains

active for more than the set amount of time, the RS232 input is gate off. Once an error occurs, the

error is latched. The only way it may be reset is by manually pressing the Anti-Streaming Reset button

or cycling power. In order for Jabber Error Detection to gate off the RS232 input, CTS/RTS must be

enabled.

Fail Relay

This solid-state relay is normally closed and only opens during a failure. On a slave, the fail state indicates that lock cannot be achieved one or both of the fiber inputs. On a master, the fail state indicates

that lock cannot be achieved one or both of the fiber inputs, or that a fiber loop is reversed indicating a

failure somewhere in the ring. On both a master and slave, a Jabber Error is considered as a fail state

and opens the relay.

RTS/CTS

The RTS/CTS input is always looped around and drives the RTS/CTS output for use with computers

that require hardware flow control. The only exception to this is when Auto Switching Master is

enabled and the unit is in standby mode. In this case, the RTS/CTS RS232 output driver is tristate so

that a Y cable may be used to connect the output from both masters together. If a Y cable is not used,

the RTS/CTS input is used to gate RS232 input data. In this case, RS232 input data would be gated

off unless CTS/RTS is in the active state.

Master Relay

When Auto Switching Master is disabled, the solid-state relay is closed when the unit is configured as

a master and open when configured as a slave. By enabling Auto Switching Master, the unit becomes

a master. But in this case, the relay is closed when the unit is in active mode and open in standby

mode.

Page 13

FCC Compliance

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesirable operation.

Changes or modifications not expressly approved by International Fiber Systems, Inc. could void

the user’s authority to operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to

rect the interference at his own expense.

cor-

CLASS 1 LASER PRODUCT

(For purposes of IEC 60825-1)

Complies with FDA Performance Standard for Laser Products

Title 21

Code of Federal Regulations

Subchapter J

Comprehensive

Lifetime Warranty

(a) Seller warrants to the original End User that products and any

services furnished hereunder will be free from defects in material

and workmanship as of the date of delivery, and will conform to

Seller’s published technical specications. The foregoing shall

apply only to failures to meet said warranties which appear within

that period of time during which the Products are installed in their

original installation for the original End User and operator of such

Products; provided, however, that in the event of product discontinuance, warranty support is limited to ve (5) years from the

announcement of discontinuance. Notwithstanding the preceding

sentence, the duration of the warranty period for

manufactured by Seller (e.g., ber optic cabling, test equipment,

power supplies or batteries) shall be the warranty period oered by

the original manufacturer, if any.

(b) The conditions of any tests shall be mutually agreed upon and

Seller shall be notied of, and may be represented at, all tests that

may be made. The warranties and remedies set forth herein are

conditioned upon (a) proper storage, installation, use and maintenance, and

Seller and (b) Buyer promptly notifying Seller of any defects and,

if required, promptly making the product available for correction.

(c) If any product or service fails to meet the foregoing warranties,

Seller shall thereupon correct any such failure either at its option,

conformance with any applicable recommendations of

products not

(i) by repairing any defective or damaged product or parts of the

products, or (ii) by making available any necessary repaired or

replacement products or parts thereof. Any repaired or replacement

part or product shall be warranted for the remaining period of the

original Warranty Period. Seller shall pay, or credit Buyer for, the

cost of freight for all return shipments of products or parts to

Buyer. Where a failure cannot be corrected by Seller's reasonable

eorts, the parties will negotiate an equitable adjustment in price.

(d) The preceding paragraph sets forth the exclusive remedies for

claims based on defect in or failure of products or services,

whether the claim is in contract, indemnity, warranty, tort

(including Seller's negligence), strict liability or otherwise and

however instituted. Upon the expiration of the warranty period,

all such liability shall terminate and BUYER shall have a reasonable time, within thirty days after the warranty period, to give

written notice of any defects which appeared during the warranty

period. The foregoing warranties are exclusive and in lieu of all

other warranties, whether written, oral, implied or statutory.

NO IMPLIED OR STATUTORY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR PARTICULAR

PURPOSE SHALL APPLY. Seller does not warrant any

products or services of others which BUYER has designated.

Page 14

Contacting us

For help installing, operating, maintaining, and troubleshooting this product, refer to this document and any

other documentation provided. If you still have questions, contact us during business hours (Monday through

Friday, excluding holidays, between 5 a.m. and 5 p.m. Pacific Time).

Sales and support contact information

North

America

Toll-free: 855.286.8889 in the US, including Alaska and Hawaii;

Puerto Rico; Canada.

Outside the toll-free area: 503.885.5700.

E-mail: techsupport@interlogix.com

Europe

Australia

Select Contact Us at www.utcfssecurityproducts.eu

security.tech.support@interlogix.com.au

Note: Be ready at the equipment before calling.

Online

Another great resource for assistance with your Interlogix product is our online publication library. To access

the library, go to our website at the following location:

http://www.interlogix.com/transmission

1

1. Many Interlogix documents are provided as PDFs (portable document format). To read these documents, you will

need Adobe Reader, which can be downloaded free from Adobe’s website at www.adobe.com.

Page 15

Product Disassembly Instructions for WEEE

Per European Directive 2002/95/EC Waste Electrical and

Electronic Equipment

Required Tools:

One number 2 Phillips (crosstip) screwdriver.

One number 2 flat screwdriver.

For the enclosed box version:

1. Locate and remove box cover securement screws. Usually, but not limited to, at least

4 screws.

2. Lift off box top cover.

3. Locate and remove securement screws for printed circuit board.

4. If there are multiple boards to the assembly, continue removing securement screws

until none are left.

5. Lift off printed circuit board.

6. Disassembly of box version of product is complete.

For rack version:

1. Locate and remove securement screws for printed circuit board. Usually, but not

limited to, at least 4 screws.

2. If there are multiple boards to the assembly, continue removing securement screws

until none are left.

3. Lift off printed circuit board(s).

4. Disassembly of rack card version of product is complete.

Page 16

Copyright © 2011 UTC Fire & Security. All rights reserved.

r

Trademarks and

patents

Manufacture

Certification

ACMA compliance Notice! Thi

Canada This Class A digital apparatus complies with Canadian ICES-003.

European Union

directives

Interlogix and IFS names and logos are trademarks of

UTC Fire & Security.

Other trade names used in this document may be trademarks or

registered trademarks of the manufacturers or vendors of the

respective products.

UTC Fire & Security Americas Corporation, Inc.

2955 Red Hill Avenue, Costa Mesa, CA 92626-5923, USA

Authorized EU manufacturing representative:

UTC Fire & Security B.V.

Kelvinstraat 7, 6003 DH Weert, The Netherlands

N4131

product may cause radio interference in which case the user may be

required to take adequate measures.

Cet appareil numérique de la classe A est conforme à la norme

NMB-0

2004/108/EC (EMC directive): Hereby, UTC Fire & Security

decl

requirements and other relevant provisions of Directive

2004/108/EC.

03 du Canada.

ares that this device is in compliance with the essential

s is a Class A product. In a domestic environment this

2002/96/EC (WEEE directive): Products marked with this symbol

cannot be disposed of as unsorted municipal waste in the European

Union. For proper recycling, return this product to your local supplier

upon the purchase of equivalent new equipment, or dispose of it at

designated collection points. For more information see:

www.recyclethis.info.

Contact information For contact information, see www.interlogix.com.

Loading...

Loading...