Page 1

Capabilities

Concord Express v4

Concord 4/Concord

Commercial v4

Zones

32

96

Partitions

2

6

Bus devices

16

16

User codes

16

230

Power

Input for an AC step-down, plug-in style

transformer.

Auxiliary power

output

Output that supplies 9 to 14 VDC w ith up to 1

amp for bus devices and hardwired detectors,

such as smoke and motion detectors.

Bus A and B

Input and output that provides communication

between bus devices and the panel.

Siren driver

Output that can drive an 8-ohm load and provides

intrusion and fire alarm sounds for partition 1 (6

watts maximum).

Two onboard

outputs

Can be used to activate other signaling devices

based on system events. Out 1 is a 9 to 14 VDC

source output, limited to 1.0 amp maximum. Out

2 is an open-collector output, rated up to 14 VDC,

300 mA maximum.

Microphone input

Input used for two-way audio w hen used in

conjunction w ith the Interrogator 200 audio

verification module.

Eight supervised

hardwired zones

Inputs for various hardwired detectors. Zone 8

can be set up in programming to accept tw o-wire

smoke detectors. It sources 9 to 14 VDC, 90 mA

maximum.

Built-in RF

receiver

Allows use of up to 96 or 32 319.5 MHz crystal

and/or SAW learn mode w ireless sensors and

touchpads.

Concord 4 Installation Guide

Content

Contact information 1

Description 1

Panel location 2

Power and wire length 2

Mounting the panel 3

Programming 4

Sensor group characteristics 7

Specifications 9

Regulatory information 9

Contact information

For contact information, see www.utcfireandsecurity.com

or www.interlogix.com.

Table 1: Panel capabilities

Table 2 below describes the basic panel (out-of-box)

hardware capabilities for all panels:

Table 2: Panel hardware capabilities

For technical support, toll-free: 888.437.3287 in the US

including Alaska, Hawaii, Puerto Rico, and Canada.

Outside the tool-free area, contact your dealer.

© 2012 UTC Fire & Security Americas Corporation, Inc.

Interlogix is part of UTC Climate Controls & Security, a

unit of United Technologies Corporation. All rights

reserved.

Description

This is the Installation Guide for the following Concord 4

control panel models:

• 600-1021-95R Concord 4 RF

• 600-1022-95R Concord Express V4

• 600-1040 Concord Commercial V4

• 600-1042 Concord Hybrid

This manual provides information for installing a basic

UL Listed Fire and Security System. To modify or use for

other purposes, visit the UTC Fire & Security website for

additional instructions and training.

Table 1 below shows the standard panel capabilities.

P/N 466-2371 • REV C • NOV12 1

Page 2

Phone line

connection

Allows panel to communicate with central

monitoring station and/or pagers.

Device

Max. wire

length to

panel

Standby

mA draw

Alarm mA

draw

SuperBus 2000 2x16 LCD

alphanumeric touchpad

22 ga.: 300 ft.

18 ga.: 750 ft.

15 mA

90 mA

SuperBus 2000 ATP 1000

alphanumeric touchpad

22 ga.: 300 ft.

18 ga.: 750 ft.

12 mA

110 mA

SuperBus 2000 ATP 2100

alphanumeric touchpad

22 ga.: 300 ft.

18 ga.: 750 ft.

30 mA

165 mA

SuperBus 2000 ATP 2600

alphanumeric touchpad

22 ga.: 300 ft.

18 ga.: 750 ft.

30 mA

165 mA

SuperBus 2000 GTS 50

22 ga.: 100 ft.

18 ga.: 250 ft.

270 mA

300 mA

SuperBus 2000 fixed display

touchpad

22 ga.: 300 ft.

18 ga.: 700 ft.

11 mA

65 mA

SuperBus 2000 FTP 1000

fixed display touchpad

22 ga.: 300 ft.

18 ga.: 700 ft.

12 mA

75 mA

SuperBus 2000 RF

transceiver

22 ga.: 1,000 ft.

18 ga.: 2,500 ft.

45 mA

55 mA

SuperBus 2000 RF receiver

1

22 ga.: 1,100 ft.

18 ga.: 2,800 ft.

35 mA

35 mA

SuperBus 2000 phone

interface/voice module

22 ga.: 40 ft.

18 ga.: 120 ft.

25 mA

600 mA

SuperBus 2000 voice-only

module

22 ga.: 40 ft.

18 ga.: 120 ft.

20 mA

300 mA

(jumper)

600 mA (no

jumper)

SuperBus 2000 2 amp

power supply

N/A

No load

No load

4 input/2 output SnapCard

N/A

20 mA

185 mA 1

8Z hardw ired zone

expander SnapCard

N/A

38 mA

230 mA 1

4 output SnapCard

N/A

1 mA

130 mA 1

SuperBus 2000 8Z input

module

22 ga.: 1,800 ft.

18 ga.: 4,000 ft.

18 mA

35 mA

SuperBus 2000 4-relay

output module

22 ga.: 350 ft.

18 ga.: 900 ft.

12 mA

180 mA

SuperBus 2000 energy

saver module

22 ga.: 1,600 ft.

18 ga.: 4,000 ft.

20 mA

20 mA

SuperBus 2000 cellular

backup module

Standard

power 22 ga.:

15 ft. 18 ga.:

40 ft. High

power 22

ga.: 10 ft. 18

ga.: 30 ft.

90 mA

90 mA

1600 mA

1900 mA

SuperBus 2000 automation

module

22 ga.: 1,500 ft.

18 ga.: 4,000 ft.

30 mA

35 mA

SuperBus 2000 w ireless

gateway-ready kit

22 ga.: 40 ft.

18 ga.: 90 ft.

65 mA

1600 mA

Interrogator 200

22 ga.: 3,200 ft.

18 ga.: 4,500 ft.

10 mA

10 mA

Note: The total current sourced from all terminals cannot

exceed 1 amp.

Panel location

Before permanently mounting the panel, use the

following guidelines to choose a mounting location.

• To help reduce wire run lengths and labor, centrally locate

the panel with relation to detection devices whenever

possible.

• Locate the panel where the temperature will not exceed

120ºF (49ºC) or fall below 32ºF (0ºC).

• To prevent wire runs from picking up electrical noise,

avoid running wires parallel with electrical wiring or fixtures

such as fluorescent lighting.

• Mount the panel at a comfortable working height.

• Leave at least 24 inches in front of the panel to open the

cabinet door and access the panel.

• Leave space to the left and right of the panel for wiring,

phone jack, and mounting optional modules.

• Leave at least 9 inches above the panel cabinet for

antennas.

Table 3: Wire length requirements

Power and wire length

The panel can supply up to 1 amp (1,000 mA) in full load

alarm condition for system devices connected to panel

terminals 4 (+12V), 7 and 8 (speaker terminals), 9

(OUT1), 11 (+12V), 24 (2W SMK ZONE 8), and

SnapCard terminals.

For 24-hour backup, the total standby current draw for all

devices connected to panel terminals 4 (+12V), 9

(OUT1), 11 (+12V), 24 (if configured for two-wire smoke

loop), and SnapCard terminals is limited to 90 mA

(during normal standby condition) using a 4.5 or 5.0 Ah

battery, or 190 mA (during normal standby condition)

using a 7.0 Ah battery.

The total system wire length allowed can vary depending

on devices powered by the panel, the wire length

between devices and the pane, and the combined wire

length of all devices.

Table 3 below describes the maximum wire length

allowed between compatible devices and the panel, and

the minimum and maximum current draw of each device.

2 Concord 4 Installation Guide

Page 3

Device

Max. wire

length to

panel

Standby

mA draw

Alarm mA

draw

Interrogator AVM

22 ga.: 110 ft.

18 ga.: 260 ft.

45 mA

300 mA

Two-wire smoke detectors

(429AT, 429C, 429CT,

521B, 521BXT, 521NCSXT

22 ga.: 330 ft.

18 ga.: 330 ft.

70 uA

60 mA

Two-wire smoke detectors

(system sensor 2400,

2400TH)

22 ga.: 330 ft.

18ga.: 330 ft.

120 uA

80 mA

Hardw ired interior siren (13-

949)

22 ga.: 750 ft.

18 ga.: 1,500 ft.

0 mA

85 mA

Piezo dynamic exterior siren

(13-060)

22 ga.: 750 ft.

18 ga.: 1,500 ft.

0 mA

150 mA

Speaker siren (60-528 or

13-060)

18 ga.: 100 ft.

0 mA

500 mA

Wire type

Total system wire

18-gauge, unshielded

4,000 ft.

18-gauge, shielded

3,000 ft.

22-gauge, unshielded

4,000 ft.

22-gauge, shielded

3,000 ft.

Device

Wire requirements

AC power transformer

2-conductor, 18-gauge, 25 ft. max.

Earth ground

Single conductor, 16-gauge solid, 25 ft. max.

Telephone (RJ-31X)

4-conductor

Detection devices

2- or 4-conductor, 22-gauge, 1,000 ft. max.

2- or 4-conductor, 18-gauge, 2,500 ft. max.

(based on 30 ohms max. loop resistance

including device)

Speakers

2-conductor, 18-gauge, 100 ft. max.

Device

Wire requirements

SuperBus 2000

devices

4-conductor, 22- or 18-gauge

Interrogator 200 AVM

power and microphone

4-conductor, 22-gauge, shielded

Two-wire smoke

detectors

2-conductor, 22-gauge, 330 ft. max.

2-conductor, 18-gauge, 830 ft. max.

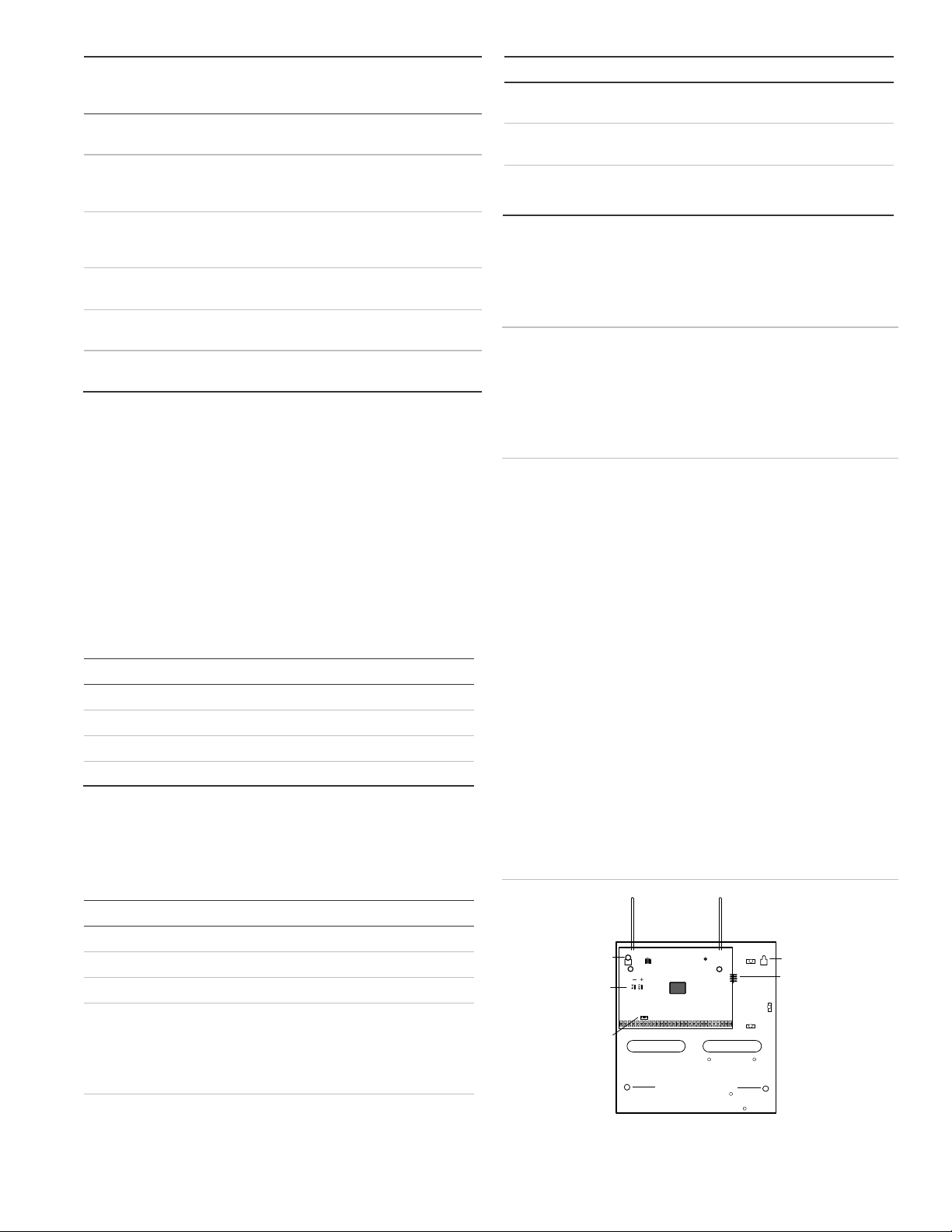

EPROM

Antennas

Mounting hole

Mounting hole

Mounting holes

Snapcard

connector

Terminal strip

Programming

touchpad

header

Battery

terminals

1

Maximum current draw for the SnapCards does not include the load

which may be applied to their auxiliary DC supply.

Note: When installing SuperBus 2000 RF receiver

modules, the antenna tamper feature must be set to off.

Mounting the panel

Mount the panel to the wall or wall studs.

Caution: Make sure you are free of static electricity

whenever you work on the panel with the cover open. To

discharge any static, first touch the metal panel chassis,

and then stay in contact with the chassis when touching

the circuit board. We recommend using a grounding

strap.

To mount the panel:

Table 4 below describes the total system wire lengths

allowed for all SuperBus 2000 devices when installing

systems using unshielded or shielded cable. The

maximum wire length for individual devices is shown

instable below.

Table 4: Total system wire lengths

After determining panel location, run all necessary wires

to that location using the guidelines in Table.

Table 5: Device wire requirements

1. Remove the panel door and remove the necessary

wiring knockouts. Be careful not to damage the

circuit board.

2. Feed all wires through wiring knockouts and place

the panel in position against the wall.

3. Level the panel and mark the top and bottom

mounting holes.

4. Install anchors where studs are not present.

5. Partially insert screws into the two top mounting hole

locations, then hang the panel on the two screws.

6. Recheck for level, insert the two lower screws, and

tighten all four mounting screws.

Figure 1 below shows the main component locations.

Figure 1: Panel components

Concord 4 Installation Guide 3

Page 4

Grounding the panel

Button

Programming function

#

Select menu item or data entry.

*

Deselect menu item or data entry (if pressed

before #).

A ()

B ()

Scroll through available option at the current

menu tier. Scroll through sensor text options

during sensor text programming.

C

Enter pauses when programming phone

numbers.

D

Delete certain programming settings.

0 to 9

Enter numeric values wherever needed.

1 and 2

Select off (1) or on (2) w herever needed.

1 to 6

Press and hold to enter alphabetical characters A

through F for account numbers.

7 and 9

Press and hold to enter * (7) or # (9) for phone

numbers.

The display shows SYSTEM PROGRAMMING.

For maximum protection from lightning strikes and

transients, connect the enclosure to earth ground. Use

16-gauge, solid copper wire from an earth grounded cold

water pipe clamp to the enclosure. For best results, we

recommend that you crimp a spade lug on the wire end

at the panel and secure the lug to the enclosure.

Antenna shrouds

Install a plastic antenna shroud (included with the panel)

over each antenna and snap them into the holes on top

of the enclosure (skip this step for hybrid and

commercial systems).

Programming

For onsite system programming, you must have an

alphanumeric touchpad.

You must use an installer/dealer code (default 4321) to

enter program mode. You may place the system into

programming mode only when you disarm all partitions.

Note: If the system is powered up after the programming

touchpad is connected or if a bus command scan is

executed, the programming touchpad will be learned

(programmed) into the system and must later be

manually deleted.

7. After programming is complete, disconnect the

touchpad from the panel header.

Touchpad programming options

In program mode, touchpad buttons let you navigate to

all installer programming menus for configuring the

system.

Table 6 below describes the touchpad button functions

in program mode.

Table 6: Touchpad programming functions

To enter program mode:

1. Make sure you disarm the system in all partitions.

2. Press 8, 4321, 0, 0.

The display shows SYSTEM PROGRAMMING.

To enter program mode using a programming

touchpad:

1. Connect the red, black, green, and white wires from

the programming touchpad cable (60-791) to the

power and bus wires/terminals on an alphanumeric

touchpad, matching the +12V (red), Bus A (green),

Bus B (white), and GDN (black) on each.

2. Make sure the system is powered up and disarmed.

3. Connect the plug on the cable onto the panel

programming touchpad header.

4. Press 8, 4321, 0, 2.

The touchpad sounds one short beep.

5. Press * and verify that the display shows SERVICE

TOUCHPAD ACTIVE.

Menu navigation

There are two basic tiers of programming menus, tier 1

and tier 2.

From the tier 1 System Programming menu, you can

access the following tier 2 programming menus:

• Security

• Phones

• Phone options

• Timers

• Light controls

• Touchpad options

• Reporting

• Siren options

• Sensors

• Audio verification

• Accessory modules

• Onboard options

• Macro keys

6. Press 8, 4321, 0, 0.

4 Concord 4 Installation Guide

Page 5

Only when the display shows SYSTEM PROGRAMMING

Sensor

How to trip the sensor

Hardw ired zones

Start with the zone in its normal state, and

then trip the zone into its alarm state. A

normally closed door, for example, should

be closed when you begin the learn

sensors process. To trip the zone, open

the door.

Wireless sensors

Follow the instructions included w ith each

sensor.

Wireless door/w indow

sensors with external

contacts

Place the external contact in the alarm

condition, and then activate the sensor

tamper sw itch.

Self-actuated bells

Activate the tamper sw itch.

Sensor

How to trip the sensor

Handheld wireless

touchpads

Press the BYPASS button.

Key fobs *

Press and hold the lock and unlock

buttons together until the key fob LED

flashes.

ELM key fobs *

Press and release the unlock button twice

quickly, then press and hold until the LED

flashes three times.

Press and release the unlock button once

quickly, then press and hold until the LED

flashes two times.

Press and hold the unlock button until the

LED flashes once.

can you advance to tier 2 programming menus.

Press B or # to advance forward through menus. Press

A or * to move backward through the menus.

Only when a specific menu is displayed can you

advance to those menu settings. For example, from the

SENSORS display, pressing # gives you access to

learning sensors, programming sensor text, deleting

sensors, and viewing/editing sensor programming.

To exit program mode:

1. Press * until the display shows SYSTEM

PROGRAMMING.

2. Press A or B until the display shows EXIT

PROGRAMMING READY.

3. Press # and the touchpad displays the time and

date.

* Key fobs have not been investigated by UL for use in a UL Listed

installation.

Learn sensors

The default setting is “None”.

Sensors menu

The Sensors menu gives you access to the following

settings:

• Learn sensors. Add (learn) hardwired zones, wireless

sensors, and wireless touchpads into panel memory.

• Sensor text. Name the sensors and zones you have

added to the system.

• Delete sensors. Delete zones and sensors from panel

memory.

• Edit sensors. View or change a sensor group or partition

assignment. You can also identify whether a zone is

wireless or hardwired, whether it is configured as normally

closed (NC) or normally open (NO), and whether the zone

is a touchpad.

Table 7 below describes how to trip different types of

sensors to program (learn) them in the panel.

Table 7: Tripping sensors

The panel comes with factory programmed onboard

hardwired zones. Install 2 kohm, end of line (EOL)

resistors on all unused factory sensors shown above and

hardwired zones. If you don’t want to install EOL

resistors, delete any unused zones from memory. See

Table on page 6 for onboard hardwired zone factory

programming. Sensors must be placed in a partition or

sensor group. To change the sensor group or partition

assignment after adding a sensor or zone, use the Edit

Sensors menu.

To add (learn) sensors into panel memory:

1. With the display showing SENSORS, press #.

The display shows LEARN SENSORS.

2. Press #.

The display shows SENSOR PTN 1.

3. Press # to select partition 1 or press 2, 3, 4, 5, or 6

and then press # to select the desired partition.

The display shows SENSOR GROUP 0.

4. Enter the sensor group and press #. (See Table for

a description of all sensor group characteristics.)

Concord 4 Installation Guide 5

The display shows TRIP SENSOR nn, where nn is

the displayed (next available) sensor number.

5. To change the displayed sensor number, enter the

desired sensor number and press #.

The desired sensor number is displayed.

6. With the desired sensor number displayed, use the

guidelines in Table 6 to force the sensor or zone you

Page 6

are adding (learning) into the panel memory to send

Zone input

Group number and description

1

10 - entry/exit

2

17 – instant interior follower

3

13 – instant perimeter

4

13 – instant perimeter

5

13 – instant perimeter

6

13 – instant perimeter

7

13 – instant perimeter

8

13 – instant perimeter

Account number

Partition number 1 to 6

Account number 00000

CS phone

CS phone 1

CS phone none

CS phone 2

CS phone none

CS phone 3

CS phone none

Learn sensors

Sensor partition number 1 to 6

Sensor group 0

Trip sensor number 1 to 96

End programming

a signal to the panel.

3. Cycle through the menus as shown in Table 9

below.

7. To add another sensor to the same sensor group

and partition, repeat the process.

8. To add sensors to another sensor group or partition,

press * twice and repeat the process.

Table 8 below describes the factory default zone inputs.

Table 8: Zone factory programming

If the panel memory is cleared, all onboard hardwired zone factory

programming w ill be cleared.

Table 9: Quick programming menu structure

Quick programming mode

Use the quick programming mode to program basic

system programming with a SuperBus 2000 fixed display

touchpad, SuperBus 2000 FTP 1000 touchpad, or any

SuperBus 2000 alphanumeric touchpad. The following

menus are accessible:

• Account number (all partitions)

• SC phone 1

• CS phone 2

• CS phone 3

• Learn sensors (limited to selecting sensor number, sensor

group, and partition assignment). An alphanumeric

touchpad is required for programming sensor text in

standard programming mode.

Use the A and B buttons to toggle across main menus

and use the # and * buttons to toggle up and down

through the submenus.

To enter quick programming mode:

1. Make sure the system is disarmed in all partitions.

2. Press 8, enter the installer/dealer code, and then

press 03.

The display shows ACCOUNT NUMBER.

6 Concord 4 Installation Guide

Page 7

Number

Name

Application

Alarm

Delay

Restoral

Supervisor

y

CS

report

Chime

(level)

Active

(level)

00

Fixed panic

24-hour audible fixed emergency

buttons

Police

Instant X X

1, 2, 3

01

Portable

panic

24-hour audible portable emergency

buttons

Police

Instant X

1, 2, 3

02

Fixed panic

24-hour silent fixed emergency

buttons

Silent

Instant X X

1, 2, 3

03

Portable

panic

24-hour silent portable emergency

buttons

Silent

Instant X

1, 2, 3

04

Fixed

auxiliary

24- hour auxiliary sensor, such as

pendant panic or holdup button

Auxiliar

y

Instant X X

1, 2, 3

05

Fixed

auxiliary

24-hour auxiliary emergency button,

siren shutoff confirms CS report

Auxiliar

y

Instant X X

1, 2, 3

06

Portable

auxiliary

24-hour portable auxiliary alert

button

Auxiliar

y

Instant X

1, 2, 3

07

Portable

auxiliary

24-hour portable auxiliary button,

siren shutoff confirms CS report

Auxiliar

y

Instant X

1, 2, 3

08

Special

intrusion

Special belongings, such as gun

cabinets and wall safes

Police

Instant X X X

1, 2, 3

09

Special

intrusion

Special belongings, such as gun

cabinets and wall safes

Police

Standard X X X

1, 2, 3

10

Entry/exit

delay

Entry and exit doors that require a

standard delay time

Police

Standard X X X X

2, 3

11

Entry/exit

delay

Garage doors and entrances that

require extended delay time 1

Police

Extended X X X X

2, 3

12

Entry/exit

delay

Drivew ay gates and entrances that

require a twice extended delay time

1

Police

Twice

extended

X X X

X

2, 3

13

Instant

perimeter

Exterior doors and w indows

Police

Instant X X X X

2, 3

14

Instant

interior

Interior doors (hardwired)

Police

Follower X X X

2, 3

15

Instant

interior

Interior PIR motion sensors 1 (RF

wireless)

Police

Follower X X

2, 3

16

Instant

interior

Interior doors (hardwired)

Police

Follower X X X

3

17

Instant

interior

PIR motion sensors 1 (RF wireless)

Police

Follower X X

3

18

Instant

interior

Instant interior cross-zone # PIR

motion sensors

1 2

Police

Follower X X

3

Sensor group characteristics

Table 10 below shows what the sensors on your Concord 4 system do. Every sensor is assigned to a group, and this

table specifies those groups and functions. Every device must be assigned to one of these groups.

Note: The “X” marks in the table represent characteristics present in a group.

Table 10: Sensor group characteristics

Concord 4 Installation Guide 7

Page 8

Number

Name

Application

Alarm

Delay

Restoral

Supervisor

y

CS

report

Chime

(level)

Active

(level)

19

Delayed

interior

Interior doors that initiate a delay

before going into alarm 1

Police

Interior X X X

3

20

Delayed

interior

PIR motion sensors that initiate a

delay before going into alarm 1

Police

Standard X X

3

21

Local instant

interior

24-hour local alarm zone protecting

anything that opens and closes

Police

Instant X X

1, 2, 3

22

Local

delayed

interior

Same as group 21, plus activation

initiates a delay before going into

alarm

Police

Standard X X

1, 2, 3

23

Local instant

auxiliary

24-hour local alarm zone protecting

anything that opens and closes 3

Auxiliar

y

Instant X X

1, 2, 3

24

Local instant

auxiliary

24-hour local alarm zone protecting

anything that opens and closes,

sirens shut off at restoral 1

Auxiliar

y

Instant X X

1, 2, 3

25

Local

special

chime

Notify the user when a door is

opened, sounds emit from a local

annunciator 1

Special

chime

Instant X

1, 2, 3

26

Fire

24-hour fire, rate-of-rise heat, and

smoke sensors

Fire

Instant X X X

1, 2, 3

27

Output

module

Hardw ired output module (HOM)

lamp control or other customer

features 3

Silent

Instant X X

1, 2, 3

28

Output

module

HOM, PIR motion sensor, sound

sensor, or pressure mat 3

Silent

Instant X

1, 2, 3

29

Auxiliary

Freeze sensor

Auxiliar

y

Instant X X X

1, 2, 3

32

Output

module

HOM, PIR motion sensor, sound

sensor, or pressure mat 3

Silent

Instant

1, 2, 3

33

Siren

Wireless siren supervision

Silent

Instant X X

1, 2, 3

34

Gas

Carbon monoxide (CO) gas

detectors 3

Auxiliar

y

Instant X X X

1, 2, 3

35

Local instant

police (day

zone)

Local alarm levels 1 and 2, report to

CS in level 3

Police

Instant X X

X (level 3

only)

1, 2, 3

38

Auxiliary

Water sensor 3

Auxiliar

y

Instant X X X

1, 2, 3

1. This group is not certified as a primary protection circuit for UL-listed systems and is for supplementary use only.

2. Sound instant police siren if two or more sensors are tripped within 4 minutes. Otherw ise sensors are followers to delayed sensors. If

Alarm Verification is on, group 18 functions like group 17.

3. This group has not been investigated by UL.

4. This group is required for UL-listed residential fire alarm applications.

8 Concord 4 Installation Guide

Page 9

Specifications

Power requirements

Class 2, 16.5 VAC, 40 VA, 60 Hz (600-1023 or

600-1024)

Rechargeable battery: 12 VDC, 4.5 or 5.0 Ah

lead-acid (60-681) or 12 VDC, 7 Ah (60-680).

The battery will last 24 hours with no AC and

specified stand-by load.

Auxiliary power

output

1.0 A at 9 to 14 VDC (12 VDC typical)

Radio frequency

319.5 MHz

Nominal RF range

1,000 feet (305 m) typical open air

Storage temperature

-30 to 140ºF (-34 to 60ºC)

Operating

temperature

32 to 120ºF (0 to 49ºC)

Maximum humidity

85% relative humidity, noncondensing

Dimensions (H x W x

D)

14 x 12 x 3 in. (35.6 x 30.5 x 7.6 cm)

• Hardwired magnetic contact (13-068 or 13-071) or

wireless learn mode door/window sensor (60-362)

• Immediate beeps set to on.

• UL 98 options set to on.

• Receiver failure set to on (if wireless devices are used).

• Siren verify set to on.

• Exit delay set to 60 seconds.

• Quick exit set to off.

• Siren timeout set to 4 minutes or more.

• Entry delay set to 45 seconds or less.

• RF TX timeout set to 24 hours (if system includes built in

receiver or SuperBus 2000 RF receiver or SuperBus 2000

RF transceiver and wireless burglary sensors).

• Extended delay set to off.

• Sleep time set to off.

• Two trip error set to off.

• Alarm verify set to off.

• Disable trouble beeps set to off.

Household fire warning system (UL 985)

Regulatory information

UL listed installations

This section describes the requirements for UL listed

installations.

Basic system:

• Control panel (600-1021-95R Concord 4 RF, 600-1022-

95R Concord Express V4, 600-1040 Concord Commercial

V4, or 600-1042 Concord 4 Hybrid).

• Standard class 2 16.5 VAC, 40 VA power transformer 22-

145 or 22-156 (600-1023), 22-156-CN, or 22-145-CN

(600-1023-CN), or power line carrier class 2 16.5 VAC, 40

VA power transformer 22-149 (600-1024) or 22-149-CN

(600-1024-CN). You must order these transformers

separately from UTC Fire & Security.

• Backup battery 12 V 4.5 or 5.0 Ah (60-681) or 12 V 7 AH

(60-680).

• SuperBus 2000 fixed display touchpad (60-820), FTP

1000 (600-1020), 2x16 LCD touchpad (60-746-01), ATP

1000 (60-983), ATP 2100 (60-985), ATP 2600 (60-984),

2x20 LCD touchpad (60-803), or 2x20 VFD touchpad (60-

804).

• Interior speaker siren (60-528), hardwired interior siren

(13-949), or speaker siren (13-060).

• Basic system but also include a SuperBus 2000 RF

receiver (60-764-95R-01) or a SuperBus transceiver (6001025-01-95R).

Household burglary alarm system unit (UL 1023)

Basic system plus the following:

Concord 4 Installation Guide 9

Basic system plus the following:

• Wireless smoke sensor 60-506-319.5, 60-848-02-95, or

TX-6010-01-1 learned into sensor group 26.

• Immediate beeps set to on.

• UL 98 options set to on.

• Receiver failure set to on (if wireless devices are used).

• Siren verify set to on.

• Sleep time set to off.

• Siren timeout set to 4 minutes or more.

• Two-trip error set to off.

• Disable trouble beeps set to off.

• RF TX timeout set to 4 hours (if system includes built in

receiver or SuperBus 2000 RF transceiver and wireless

smoke sensors).

UL 1023 and 985 24-hour backup

For 24-hour backup, the total current draw for all

connected devices is limited to 90 mA (during normal

standby conditions) using a 4.5 or 5.0 Ah battery, or 190

mA (during normal standby conditions) using a 7.0 Ah

battery.

SIA system requirements

SIA system requirements are the same as those

described for a UL-listed basic system. If multiple

annunciation is required, use additional touchpads. This

applies to model numbers 60-746-01, 60-803, 60-804,

60-820, 60-983, 60-984, 60-985, and 600-1020. UL

requirements take priority over SIA requirements.

Table 11 on page 10 describes programming

requirements to meet ANSI-SIA CP-01.

Page 10

Table 11: SIA setting requirements

Function

Default setting

Required setting

Exit extension

On

On

Duress code

Disabled

Disabled

Dialer abort delay

30 seconds

15 to 45 seconds

Cancel message

On

On

Call w ait cancel

Disabled

On if reporting to

central station and

customer has call

waiting service.

Entry delay

30 seconds

30 to 240 seconds

Exit delay

60 seconds

45 to 184 seconds

Swinger limit

1

1

Smoke verify

Off

On if smoke alarms

are programmed into

system.

Cross zone

Disabled

Enabled for zones

with high probability of

false alarms

Function

Operation

SIA false alarm

Enabled

Auto stay arming

Enabled

Disarm during entry delay

Enter code only (or 1 + CODE)

Cancel alarm

Enter code only (or 1 + CODE).

Abort annunciation

Enabled

Exit error

Enabled

Entry/exit progress annunciation

Enabled

Table 12 below describes nonprogrammable (hardcoded) system operation, as required to meet ANSI-SIA

CP-01 and is provided only for your reference.

• UL approved bell/housing, such as Ademco #AB12M or

equivalent.

• Immediate beeps set to on.

• UL 98 options set to on.

• Receiver failure set to on (if wireless devices are used).

• RF TX timeout set to 4 hours.

• 24-hour tamper set to on.

• System tamper set to on.

• Automatic phone test set to on.

• Phone text frequency set to 1.

• Next phone test set to 1.

• Siren verify set to on.

• AC failure set to on.

• Exit delay set to 120 seconds or less.

• Quick exit set to off.

• Two-trip error set to off.

• Alarm verify set to off.

• Disable trouble beeps set to off.

• Phone number must be programmed.

• High level reports set to on.

• Low level reports set to on.

• Communication failure set to on.

• Extended delay set to off.

• Sleep time set to off.

• Siren timeout set to 4 minutes or more.

Table 12: ANSI-SIA CP-01 requirements

Note: You may use the silent arming feature to suppress

arming level and exit beeps for the current arming

period. Refer to the Concord 4 user manual for more

information on silent arming.

Commercial burglary alarm system unit (UL 1610)

Basic system using control panel 600-1040, SuperBus

2000 RF transceiver module (600-1025-01-95R), plus

the following:

• Hardwired magnetic contact (13-068 or 13-071) or

wireless learn mode door/window sensor (60-499).

• SAW PIR sensor (60-639-95R), crystal PIR sensor (60-

703-95R), or DS924i PIR sensor (60-511-01-95).

UL 1610 24-hour backup

Same as UL 1023 and 985.

UL 1635 digital alarm communicator system

For UL 1635 installations, entry delay plus dialer abort

delay must not exceed 60 seconds. Same as UL 1023,

985, and 1610 plus:

• AC failure set to on.

• Phone number must be programmed.

• Low CPU battery set to on.

• Next phone test set to 1.

• Phone test frequency set to 1.

• High level reports set to on.

• Low level reports set to on.

• Communication failure set to on.

• RF TX timeout set to 4 hours.

Central station reporting

The panel has been tested with the following central

station receivers using SIA and Contact ID reporting

formats:

• CS-5000 central station receiver

• Sur-Gard central station receiver with models SG-DRL2A

and SG-CPM2

• Osborne Hoffman central station receiver

10 Concord 4 Installation Guide

Page 11

Note: The installer must verify the compatibility between

this panel and the central station receivers being used.

UL Canada listed installations

This section describes the requirements for CUL (UL

Canada) listed installations.

Residential burglary alarm system unit (ULC subject

C1023-1974)

Basic system as described for UL 1023 listed

installations plus:

• Hardwired magnetic contact (13-068 or 13-071) or

wireless learn mode door/window sensor (60-362)

• Siren timeout set to 5 minutes or more

Residential fire warning system control unit (ULCS545-M89)

Basic system as described for UL 985 listed installations

plus:

• Hardwired smoke detector: System sensor models 2400

or 2400TH learned into sensor group 26, or ESL models

429AT, 429CT, 521B, 521BXT, 521NCSXT, 711U, 711UT,

721U, 721UT, TS7-2, or TS7-2T learned into sensor group

26.

• Wireless smoke sensor 60-319.5 60-848-02-95, TX-6010-

01-1learned into sensor group 26.

• Siren timeout set to 5 minutes or more.

• RF TX timeout set to 4 hours (if system includes SuperBus

2000 RF transceiver and wireless smoke sensors).

• Immediate trouble beeps set to on.

uses, and can radiate radio frequency energy and, of not

installed and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. However, there is no guarantee that

interference will not occur in a particular installation.

If this equipment does cause harmful interference to

radio or television reception, which can be determined

by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or

more of the following:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and

receiver.

• Connect the affected equipment and the panel receiver to

separate outlets, on different branch circuits.

• Consult the dealer or an experienced radio/TV technician

for help.

Part 68. This equipment complies with Part 68 of the

FCC rules. Located on this equipment is a label that

contains, among other information, the FCC registration

number and the ringer equivalence number (REN) for

this equipment. If requested, this information must be

provided to the telephone company.

FCC Part 68 registration number: US: B4ZAL02B55910.

Note: For 24-hour backup, external power drain is

limited to 90 mA (during normal standby condition) using

a 4.5 or 5.0 Ah battery, or 190 mA continuous using a

7.0 Ah battery.

California State Fire Marshall listed installations

Same as Household Fire Warning System (UL 985) plus:

• Smoke verify must be set to off.

FCC compliance

Changes or modifications not expressly approved by

UTC Fire & Security can void the user’s authority to

operate the equipment.

This equipment has been tested and found to comply

with the limits for a Class B digital device, pursuant to

part 15 of the FCC rules. These limits are designed to

provide reasonable protection against harmful

interference when the equipment is operated in a

residential environment. This equipment generates,

Concord 4 Installation Guide 11

Loading...

Loading...